Fabrication of Cu-CNT Composite and Cu Using Laser Powder Bed Fusion Additive Manufacturing

Abstract

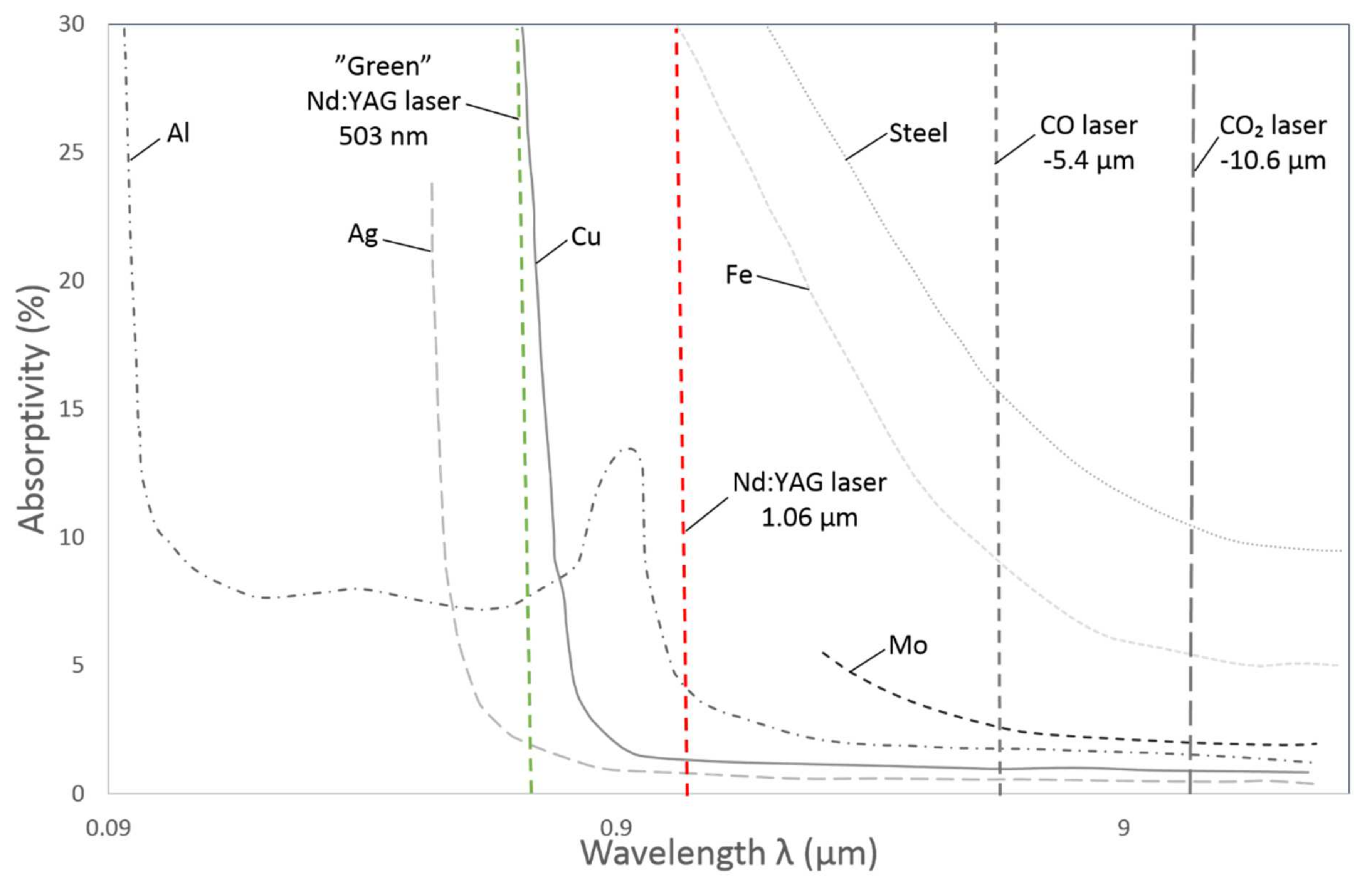

1. Introduction

2. Materials and Methods

3. Results

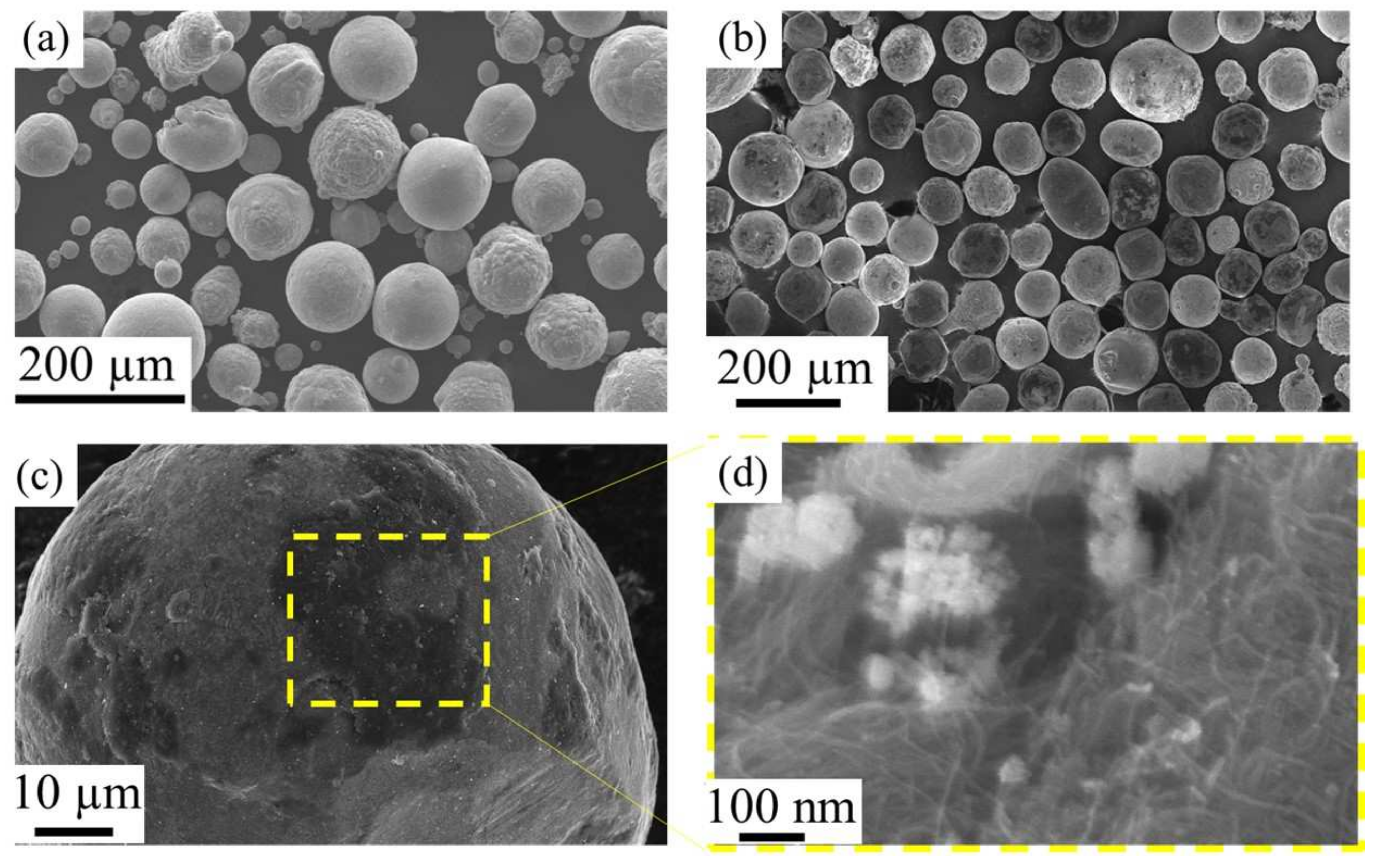

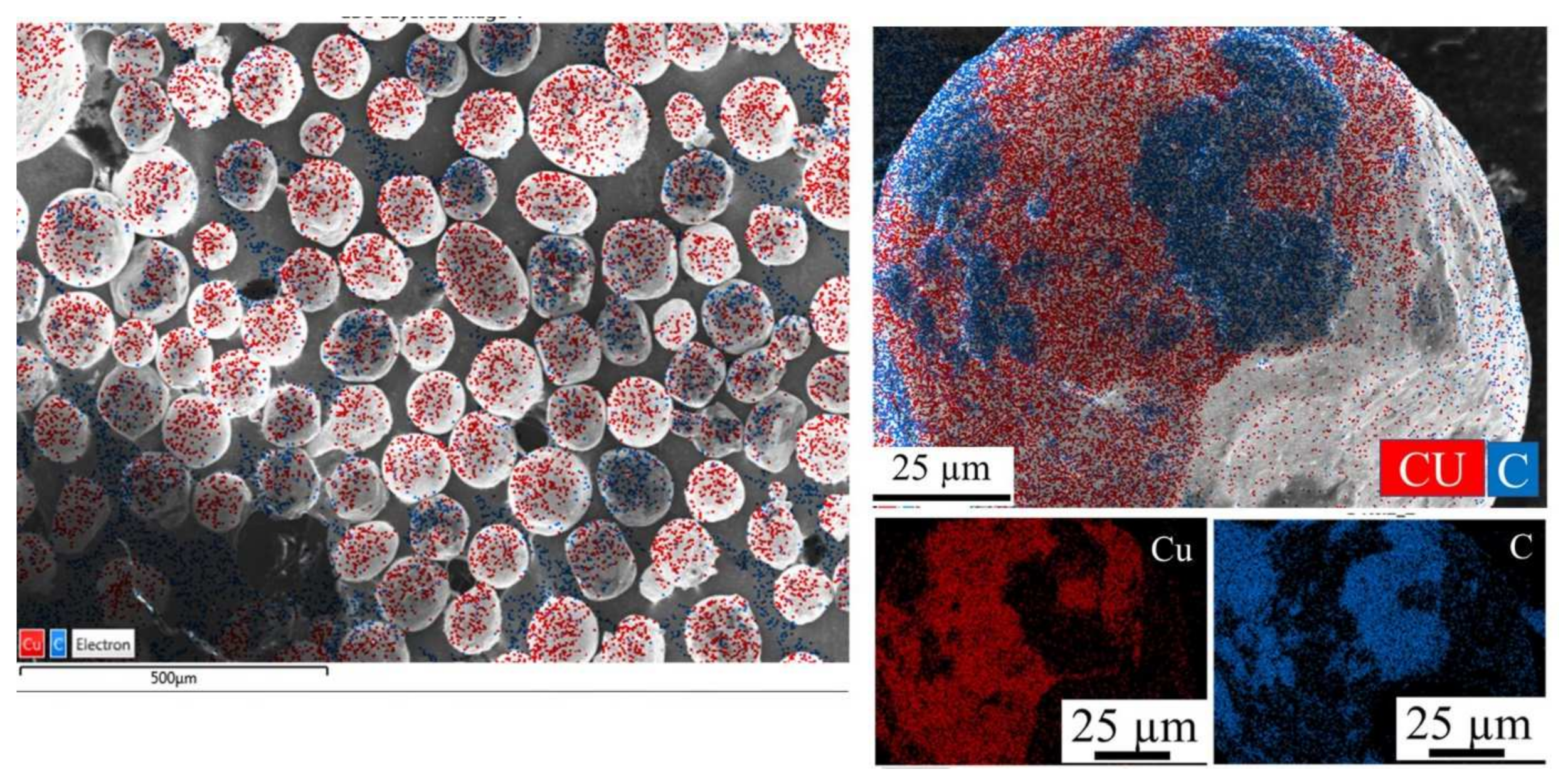

3.1. Evaluation of Powders

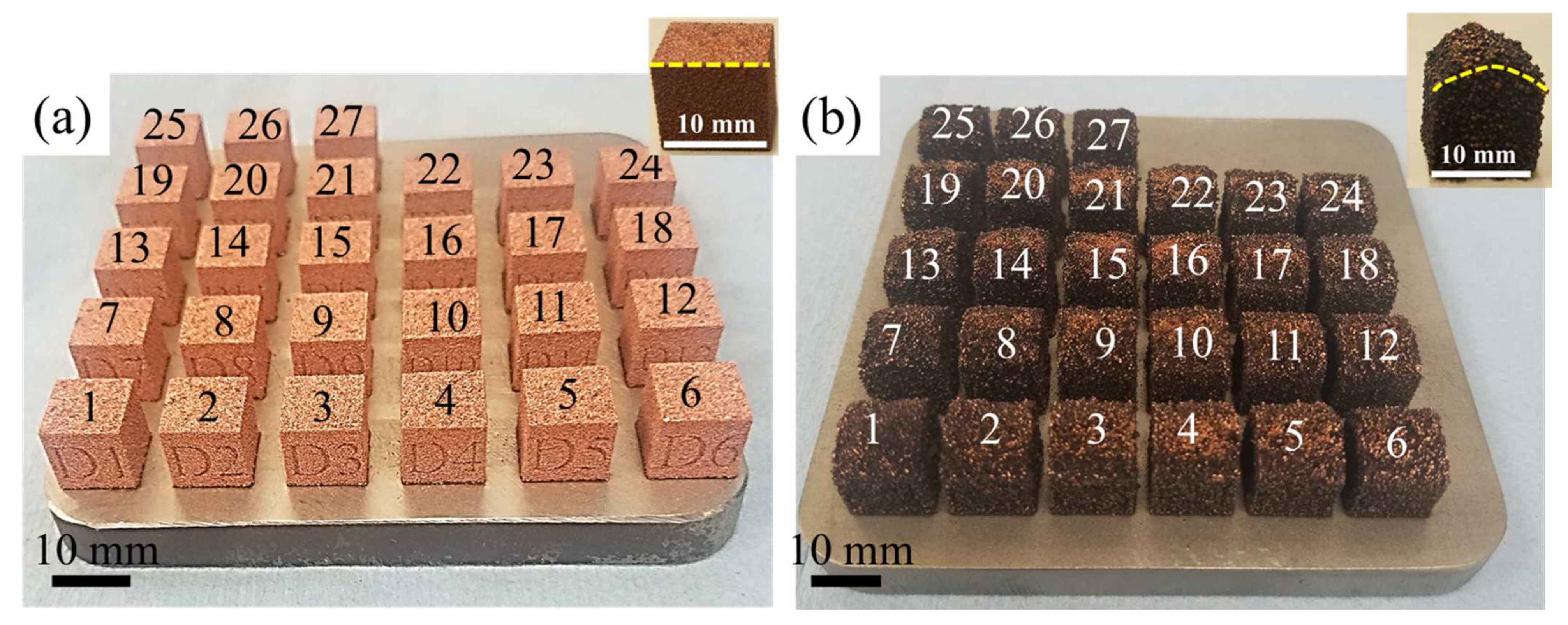

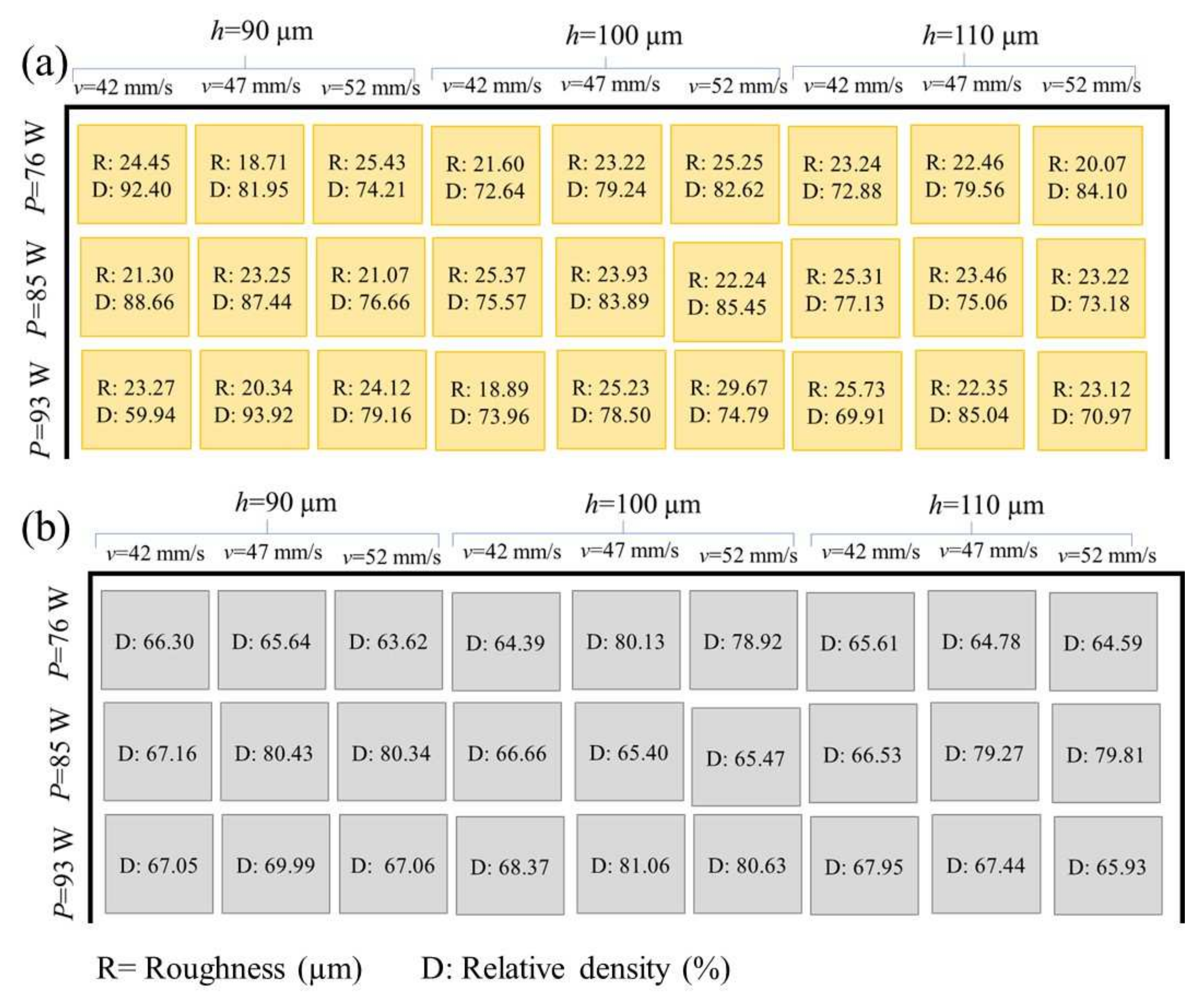

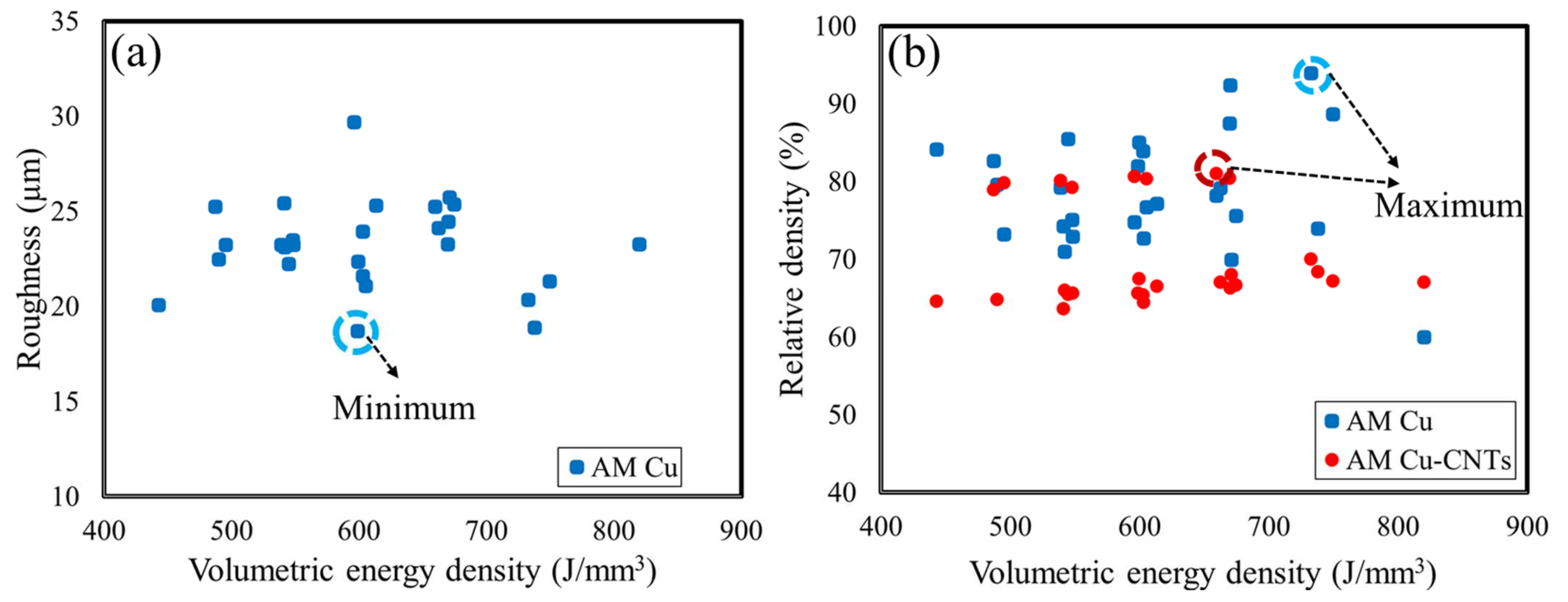

3.2. Relative Density and Surface Roughness of As-Built Parts

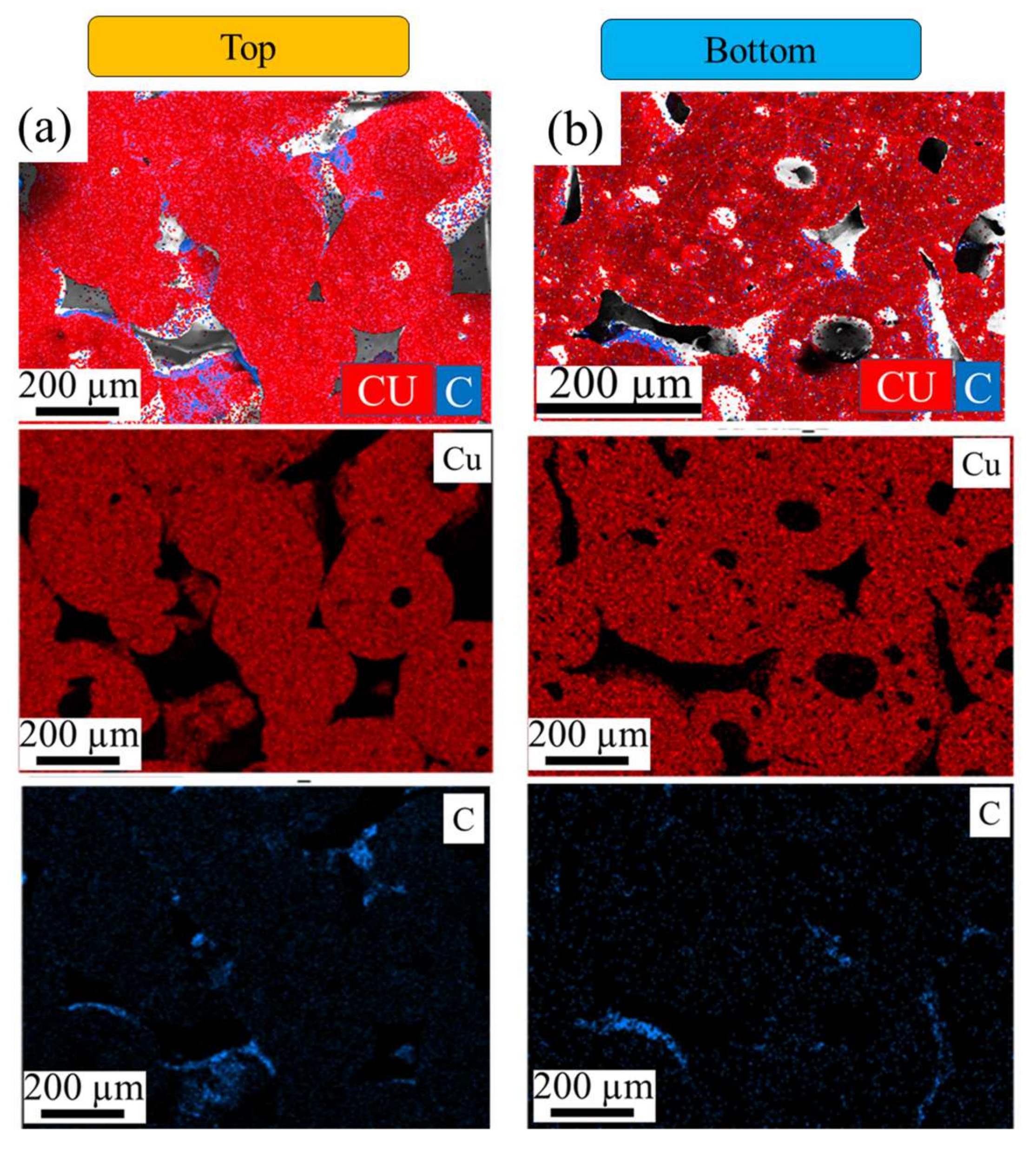

3.3. Microstructure and Elemental Characterization of As-Built Parts

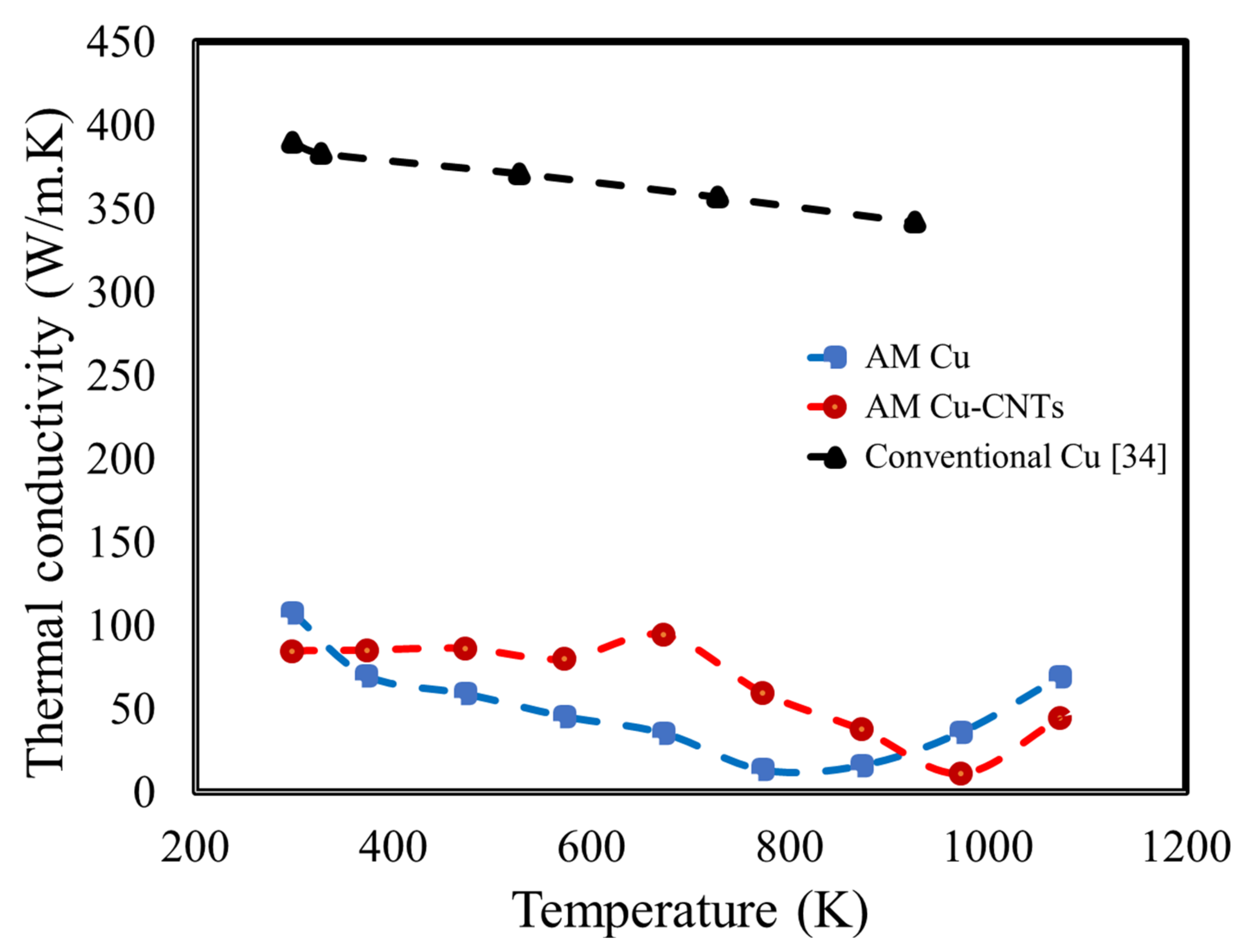

3.4. Thermal Conductivity and Electrical Conductivity

4. Discussion

Effect of Manufacturing and CNT Addition on Thermal Conductivity and Electrical Conductivity of As-Built Samples

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Caiazzo, F.; Campanelli, S.L.; Cardaropoli, F.; Contuzzi, N.; Sergi, V.; Ludovico, A.D. Manufacturing and characterization of similar to foam steel components processed through selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 92, 2126–2130. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A Review on Additive Manufacturing of Pure Copper. Coatings 2021, 11, 740. [Google Scholar] [CrossRef]

- Jadhav, S.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Ladani, L. Local and Global Mechanical Behavior and Microstructure of Ti6Al4V Parts Built Using Electron Beam Melting Technology. Met. Mater. Trans. A 2015, 46, 3835–3841. [Google Scholar] [CrossRef]

- Ladani, L. Additive Manufacturing of Metals: Materials, Processes, Tests, and Standards; DEStech Publications: Lancaster, PA, USA, 2020. [Google Scholar]

- Ladani, L.; Sadeghilaridjani, M. Review of Powder Bed Fusion Additive Manufacturing for Metals. Metals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Ahsan, F.; Ladani, L. Temperature Profile, Bead Geometry, and Elemental Evaporation in Laser Powder Bed Fusion Additive Manufacturing Process. JOM 2019, 72, 429–439. [Google Scholar] [CrossRef]

- Andreotta, R.; Ladani, L.; Brindley, W. Finite element simulation of laser additive melting and solidification of Inconel 718 with experimentally tested thermal properties. Finite Elements Anal. Des. 2017, 135, 36–43. [Google Scholar] [CrossRef]

- Ahsan, F.; Razmi, J.; Ladani, L. Multi-Physics Modeling of Laser Interaction with Surface in Powder Bed Melting Process. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, 9–15 November 2018; Volume 2. [Google Scholar] [CrossRef]

- Romano, J.; Ladani, L.; Sadowski, M. Laser Additive Melting and Solidification of Inconel 718: Finite Element Simulation and Experiment. JOM 2016, 68, 967–977. [Google Scholar] [CrossRef]

- Romano, J.; Ladani, L.; Sadowski, M. Thermal Modeling of Laser Based Additive Manufacturing Processes within Common Materials. Procedia Manuf. 2015, 1, 238–250. [Google Scholar] [CrossRef]

- Keshavarzkermani, A.; Sadowski, M.; Ladani, L. Direct metal laser melting of Inconel 718: Process impact on grain formation and orientation. J. Alloy. Compd. 2018, 736, 297–305. [Google Scholar] [CrossRef]

- Mian, J.; Razmi, J.; Ladani, L. Defect analysis and fatigue strength prediction of as-built Ti6Al4V parts, produced using electron beam melting (EBM) AM technology. Materialia 2021, 16, 101041. [Google Scholar] [CrossRef]

- Ladani, L.; Razmi, J.; Choudhury, S.F. Mechanical Anisotropy and Strain Rate Dependency Behavior of Ti6Al4V Produced Using E-Beam Additive Fabrication. J. Eng. Mater. Technol. 2014, 136, 031006. [Google Scholar] [CrossRef]

- Mian, J.; Razmi, J.; Ladani, L. Mechanical Behavior of Electron Beam Powder Bed Fusion Additively Manufactured Ti6Al4V Parts at Elevated Temperatures. J. Manuf. Sci. Eng. 2020, 143, 1–24. [Google Scholar] [CrossRef]

- Ladani, L.; Romano, J.; Brindley, W.; Burlatsky, S. Effective liquid conductivity for improved simulation of thermal transport in laser beam melting powder bed technology. Addit. Manuf. 2017, 14, 13–23. [Google Scholar] [CrossRef]

- Sadowski, M.; Ladani, L.; Brindley, W.; Romano, J. Optimizing quality of additively manufactured Inconel 718 using powder bed laser melting process. Addit. Manuf. 2016, 11, 60–70. [Google Scholar] [CrossRef]

- Romano, J.; Ladani, L.; Razmi, J.; Sadowski, M. Temperature distribution and melt geometry in laser and electron-beam melting processes—A comparison among common materials. Addit. Manuf. 2015, 8, 1–11. [Google Scholar] [CrossRef]

- Shanmugasundaram, S.A.; Razmi, J.; Mian, J.; Ladani, L. Mechanical Anisotropy and Surface Roughness in Additively Manufactured Parts Fabricated by Stereolithography (SLA) Using Statistical Analysis. Materials 2020, 13, 2496. [Google Scholar] [CrossRef]

- Sundaram, R.M.; Sekiguchi, A.; Sekiya, M.; Yamada, T.; Hata, K. Copper/carbon nanotube composites: Research trends and outlook. R. Soc. Open Sci. 2018, 5, 180814. [Google Scholar] [CrossRef]

- Ladani, L. Multi-Scale Manufacturing of Carbon Nanotube Composites. U.S. Patent No. 15/684,455, 23 August 2016. [Google Scholar]

- Awad, I.; Ladani, L. Mechanical integrity of a carbon nanotube/copper-based through-silicon via for 3D integrated circuits: A multi-scale modeling approach. Nanotechnology 2015, 26, 485705. [Google Scholar] [CrossRef]

- Ladani, L.; Awad, I.; She, Y.; Dardona, S.; Schmidt, W. Fabrication of carbon nanotube/copper and carbon nanofiber/copper composites for microelectronics. Mater. Today Commun. 2017, 11, 123–131. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, B.; Tan, C.C.; Raghavan, S.; Lim, Y.-F.; Sun, C.-N.; Wei, J.; Chi, D. Microstructural characteristics and mechanical properties of carbon nanotube reinforced Inconel 625 parts fabricated by selective laser melting. Mater. Des. 2016, 112, 290–299. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, R.; Song, H.; Jia, X. Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives. Appl. Surf. Sci. 2018, 428, 630–639. [Google Scholar] [CrossRef]

- Zhu, H.; Lu, L.; Fuh, J. Development and characterisation of direct laser sintering Cu-based metal powder. J. Mater. Process. Technol. 2003, 140, 314–317. [Google Scholar] [CrossRef]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.; Hague, R.; Galea, M.; Dickens, P. Electrical resistivity of pure copper processed by medium-powered laser powder bed fusion additive manufacturing for use in electromagnetic applications. Addit. Manuf. 2019, 29, 100831. [Google Scholar] [CrossRef]

- Raab, S.J.; Guschlbauer, R.; Lodes, M.A.; Körner, C. Thermal and Electrical Conductivity of 99.9% Pure Copper Processed via Selective Electron Beam Melting. Adv. Eng. Mater. 2016, 18, 1661–1666. [Google Scholar] [CrossRef]

- Kumar, A.Y.; Wang, J.; Bai, Y.; Huxtable, S.T.; Williams, C.B. Impacts of process-induced porosity on material properties of copper made by binder jetting additive manufacturing. Mater. Des. 2019, 182, 108001. [Google Scholar] [CrossRef]

- Ahsan, F.; Razmi, J.; Ladani, L. Experimental measurement of thermal diffusivity, conductivity and specific heat capacity of metallic powders at room and high temperatures. Powder Technol. 2020, 374, 648–657. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, S.; Xiao, B.; Xue, P.; Wang, W.; Ma, Z. Effect of ball-milling time on mechanical properties of carbon nanotubes reinforced aluminum matrix composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2161–2168. [Google Scholar] [CrossRef]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.-F.; Lu, Y.F. Laser 3D printing of complex copper structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Vleugels, J.; Hofkens, J.; Van Puyvelde, P.; Yang, S.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of Carbon Nanoparticle Addition (and Impurities) on Selective Laser Melting of Pure Copper. Materials 2019, 12, 2469. [Google Scholar] [CrossRef]

- Sobamowo, G.M.; Ibrahim, S.A.; Salami, M.O. A Study on Thermal Performance of Palladium as Material for Passive Heat Transfer Enhancement Devices in Thermal and Electronics Systems. Semicond. Sci. Inf. Devices 2020, 2, 15–24. [Google Scholar] [CrossRef]

- Rho, H.; Lee, S.; Bae, S.; Kim, T.-W.; Lee, D.S.; Lee, H.J.; Hwang, J.Y.; Jeong, T.; Kim, S.; Ha, J.-S.; et al. Three-Dimensional Porous Copper-Graphene Heterostructures with Durability and High Heat Dissipation Performance. Sci. Rep. 2015, 5, 12710. [Google Scholar] [CrossRef]

- Van Duong, L.; Anh, N.N.; Trung, T.B.; Chung, L.D.; Huan, N.Q.; Nhung, D.T.; Phuong, M.T.; Minh, P.N.; Phuong, D.D.; Van Trinh, P. Effect of annealing temperature on electrical and thermal property of cold-rolled multi-walled carbon nanotubes reinforced copper composites. Diam. Relat. Mater. 2020, 108, 107980. [Google Scholar] [CrossRef]

- Uddin, S.M.; Mahmud, T.; Wolf, C.; Glanz, C.; Kolaric, I.; Volkmer, C.; Höller, H.; Wienecke, U.; Roth, S.; Fecht, H.-J. Effect of size and shape of metal particles to improve hardness and electrical properties of carbon nanotube reinforced copper and copper alloy composites. Compos. Sci. Technol. 2010, 70, 2253–2257. [Google Scholar] [CrossRef]

| Factors | Levels | ||

|---|---|---|---|

| Laser power (W) | 76 | 85 | 93 |

| Scan speed (mm/s) | 42 | 47 | 52 |

| Hatch spacing (mm) | 0.09 | 0.1 | 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ladani, L.; Razmi, J.; Sadeghilaridjani, M. Fabrication of Cu-CNT Composite and Cu Using Laser Powder Bed Fusion Additive Manufacturing. Powders 2022, 1, 207-220. https://doi.org/10.3390/powders1040014

Ladani L, Razmi J, Sadeghilaridjani M. Fabrication of Cu-CNT Composite and Cu Using Laser Powder Bed Fusion Additive Manufacturing. Powders. 2022; 1(4):207-220. https://doi.org/10.3390/powders1040014

Chicago/Turabian StyleLadani, Leila, Jafar Razmi, and Maryam Sadeghilaridjani. 2022. "Fabrication of Cu-CNT Composite and Cu Using Laser Powder Bed Fusion Additive Manufacturing" Powders 1, no. 4: 207-220. https://doi.org/10.3390/powders1040014

APA StyleLadani, L., Razmi, J., & Sadeghilaridjani, M. (2022). Fabrication of Cu-CNT Composite and Cu Using Laser Powder Bed Fusion Additive Manufacturing. Powders, 1(4), 207-220. https://doi.org/10.3390/powders1040014