The Utilisation of Small Wind Turbines in Built-Up Areas: Prospects and Challenges

Abstract

1. Introduction

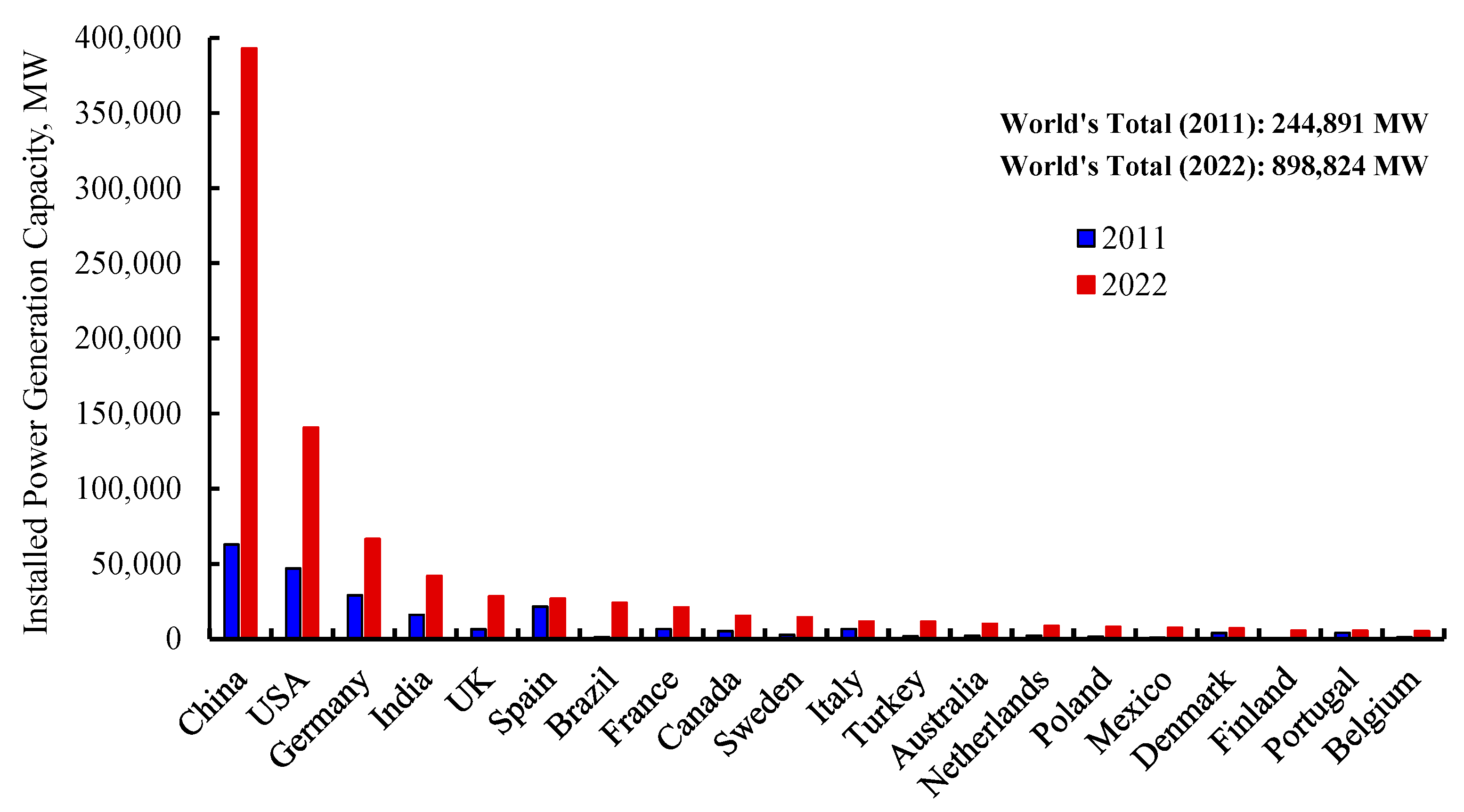

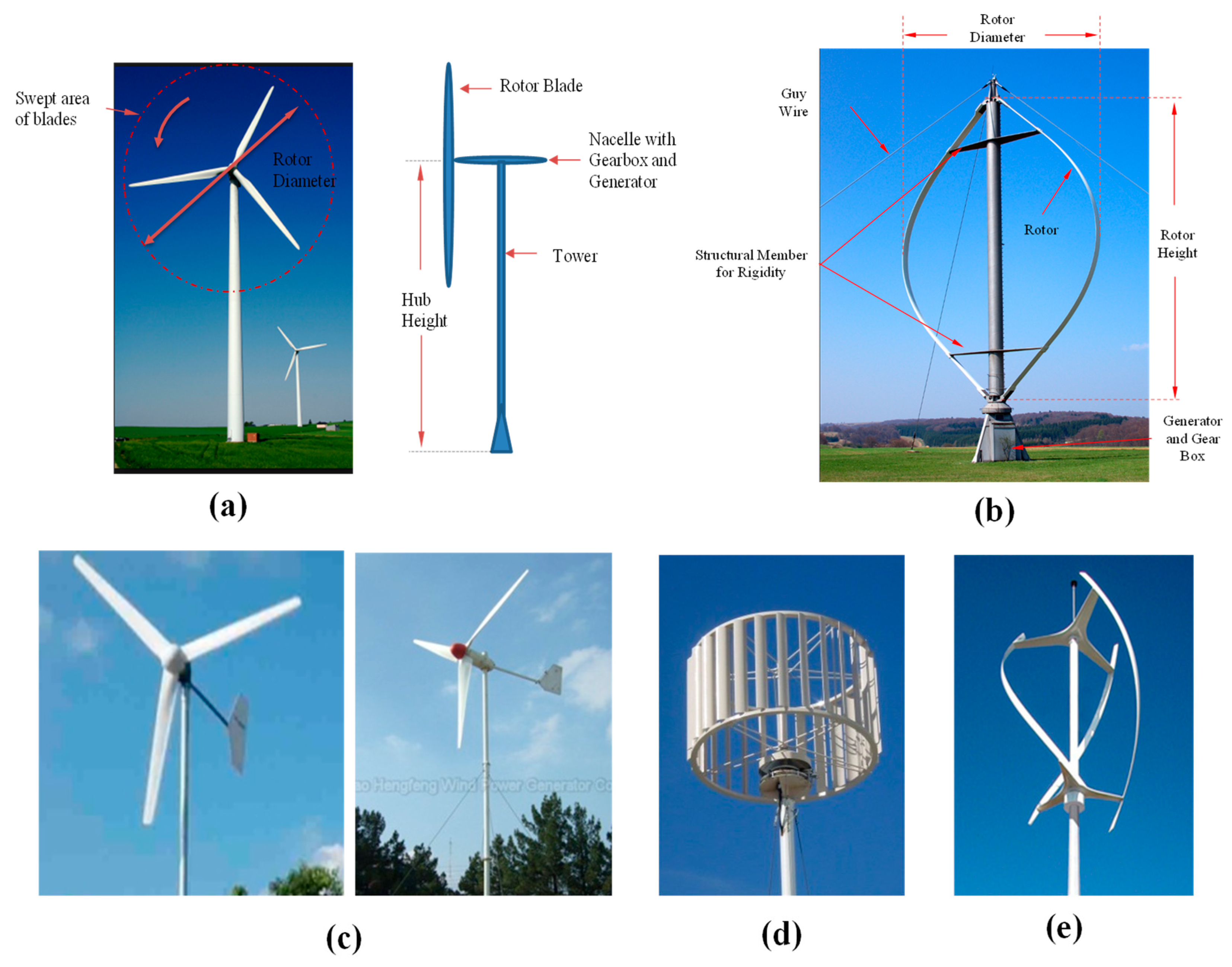

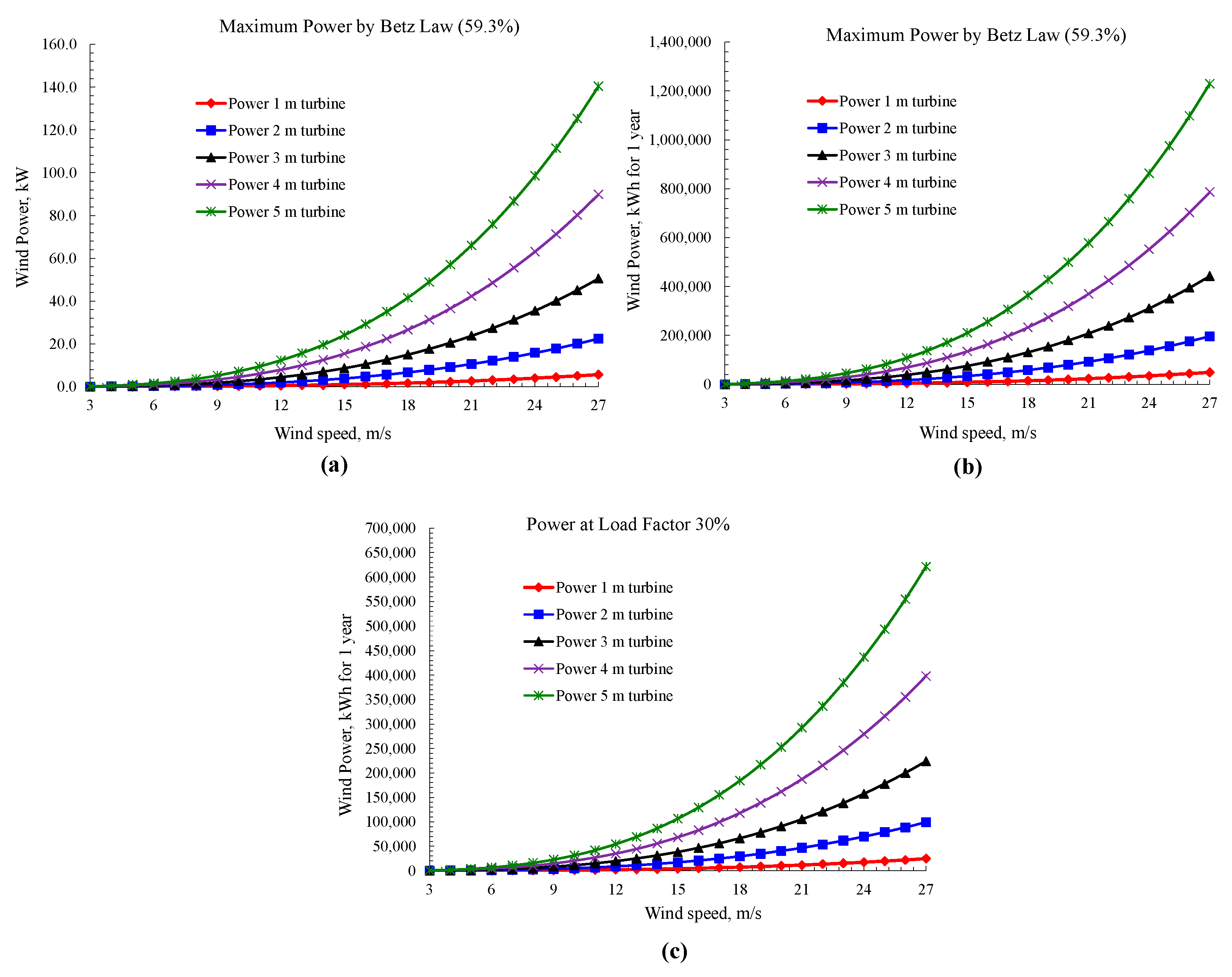

2. Prospects for Small-Scale Wind Turbines

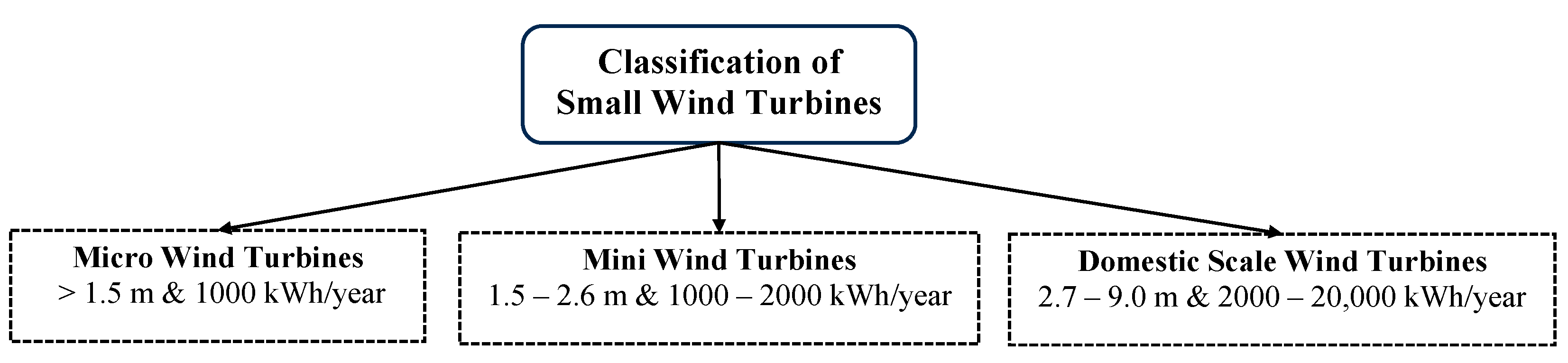

- (a)

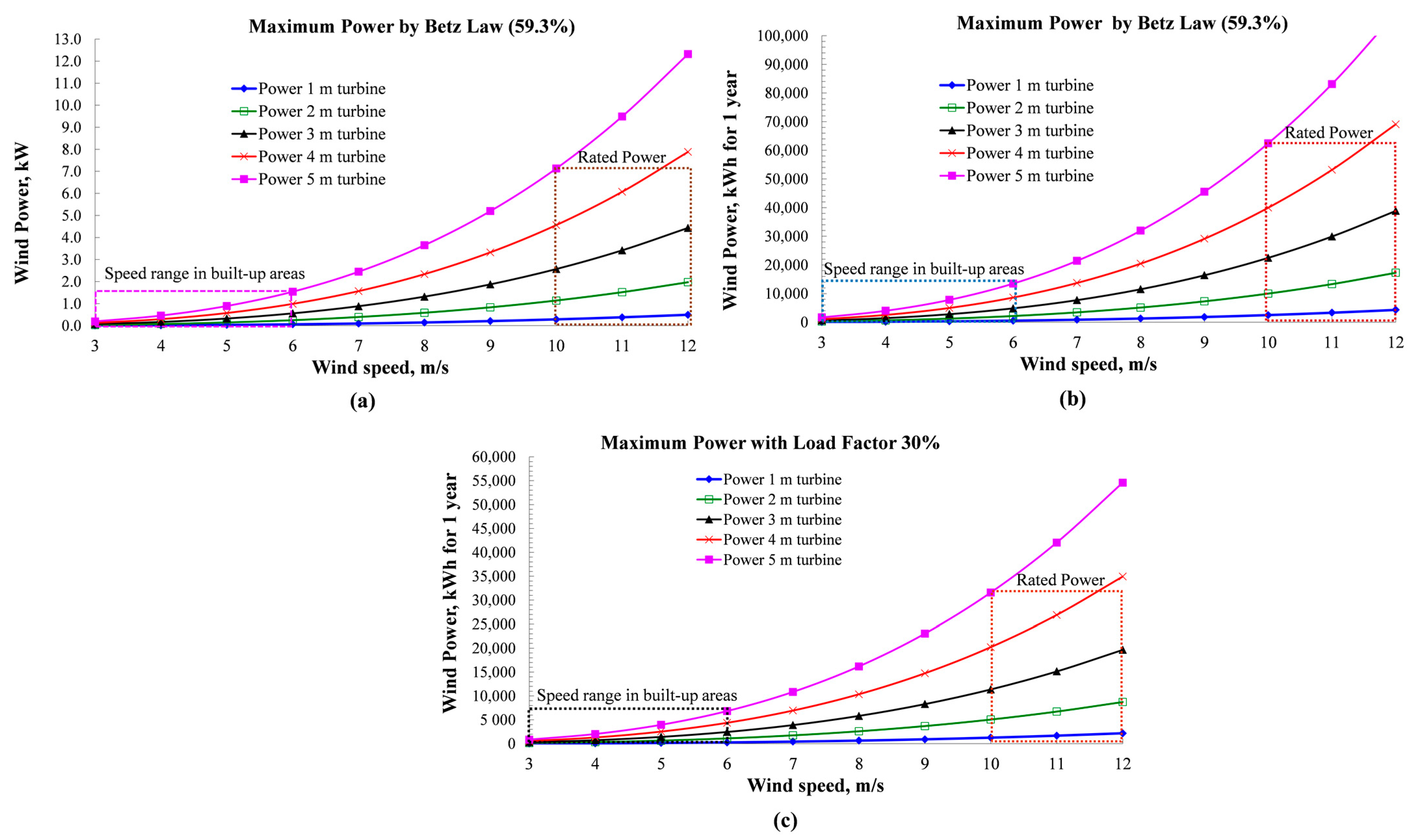

- Micro wind turbines produce roughly 1000 kWh annually at locations with an average wind speed of 5.5 m/s and have very small swept-area rotor diameters of around 1.5 m or less. In distant locations, they are frequently utilised for low-power purposes such as fence charging, simple illumination, powering sailboats, battery charging, and remote devices such as traffic warning signs.

- (b)

- Mini wind turbines typically produce 1000–2000 kWh per year at sites with wind speeds of around 5.5 m/s and have swept-area rotor diameters of 1.5–2.6 m.

- (c)

- Domestic-scale wind turbines are used for a variety of applications, including residential households, telecommunications, farms, ranches, and small businesses. Domestic-scale wind turbines include swept-area rotors with diameters between 2.7 and 9.0 m and speeds of 5.5 m/s and can produce power between 2000 and 20,000 kWh annually.

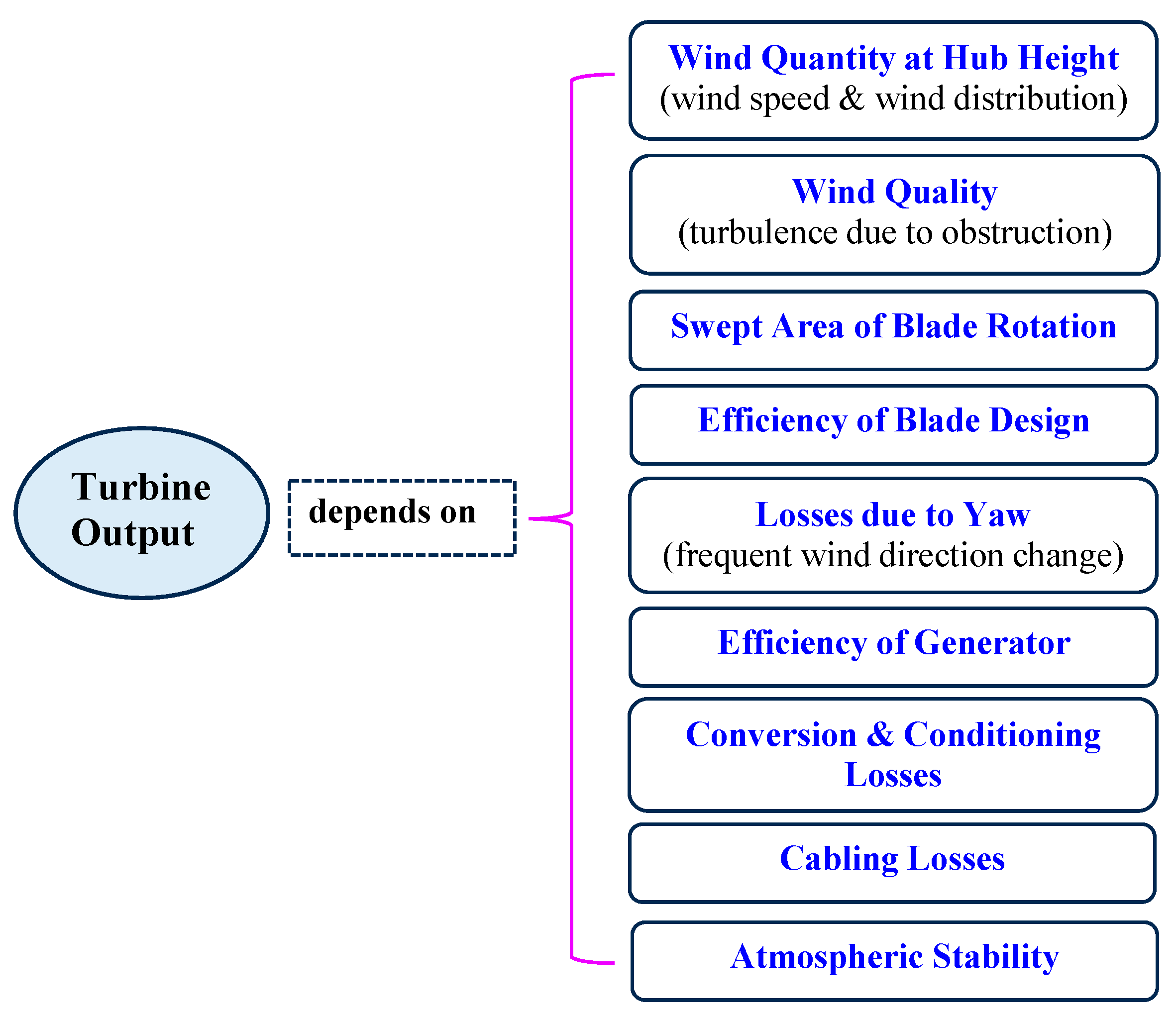

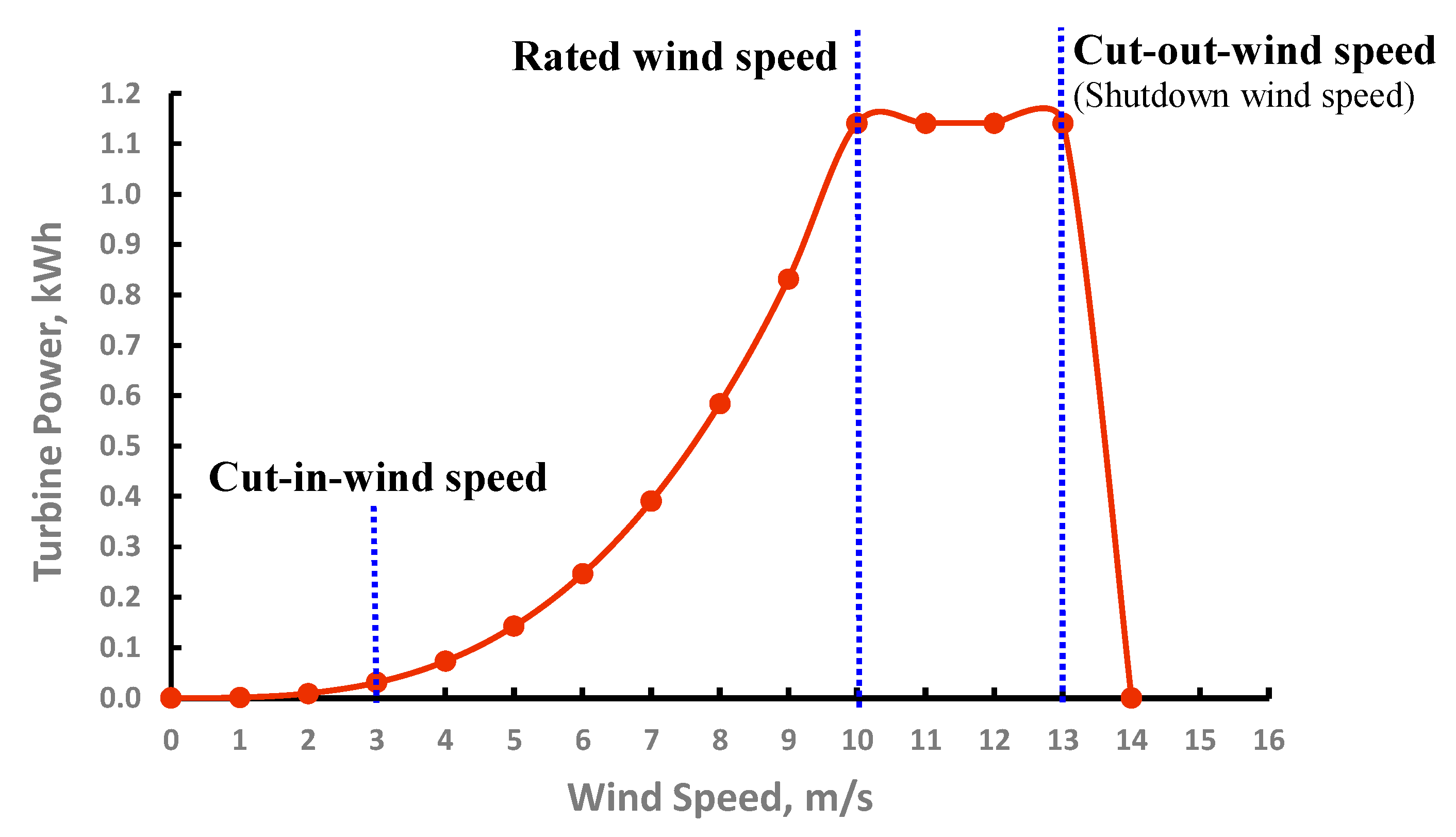

3. Small-Scale Wind Turbines: Contributing Factors

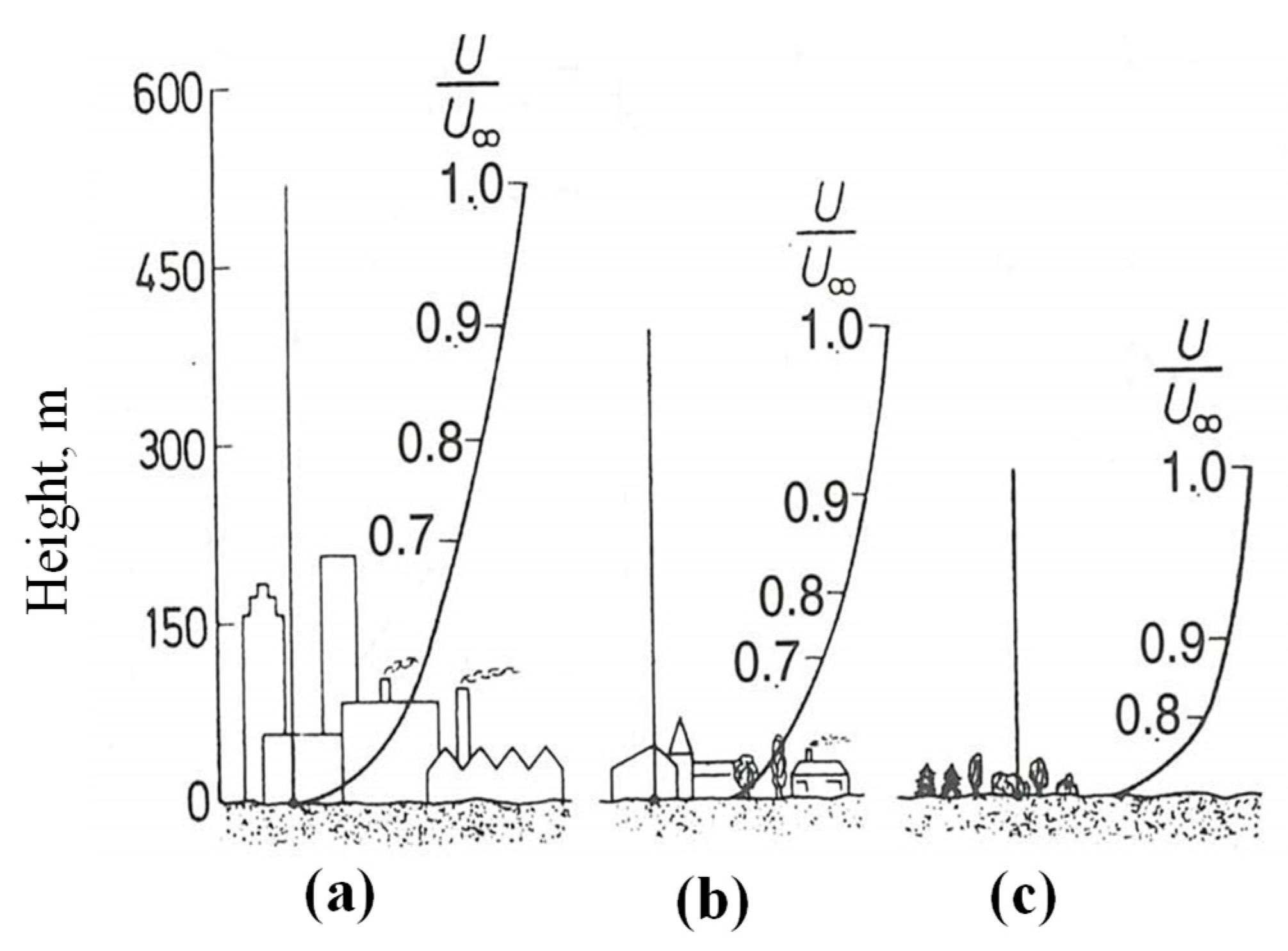

3.1. Urban Wind Characteristics

3.2. Permits for Planning, Insurance, and Grid Connectivity

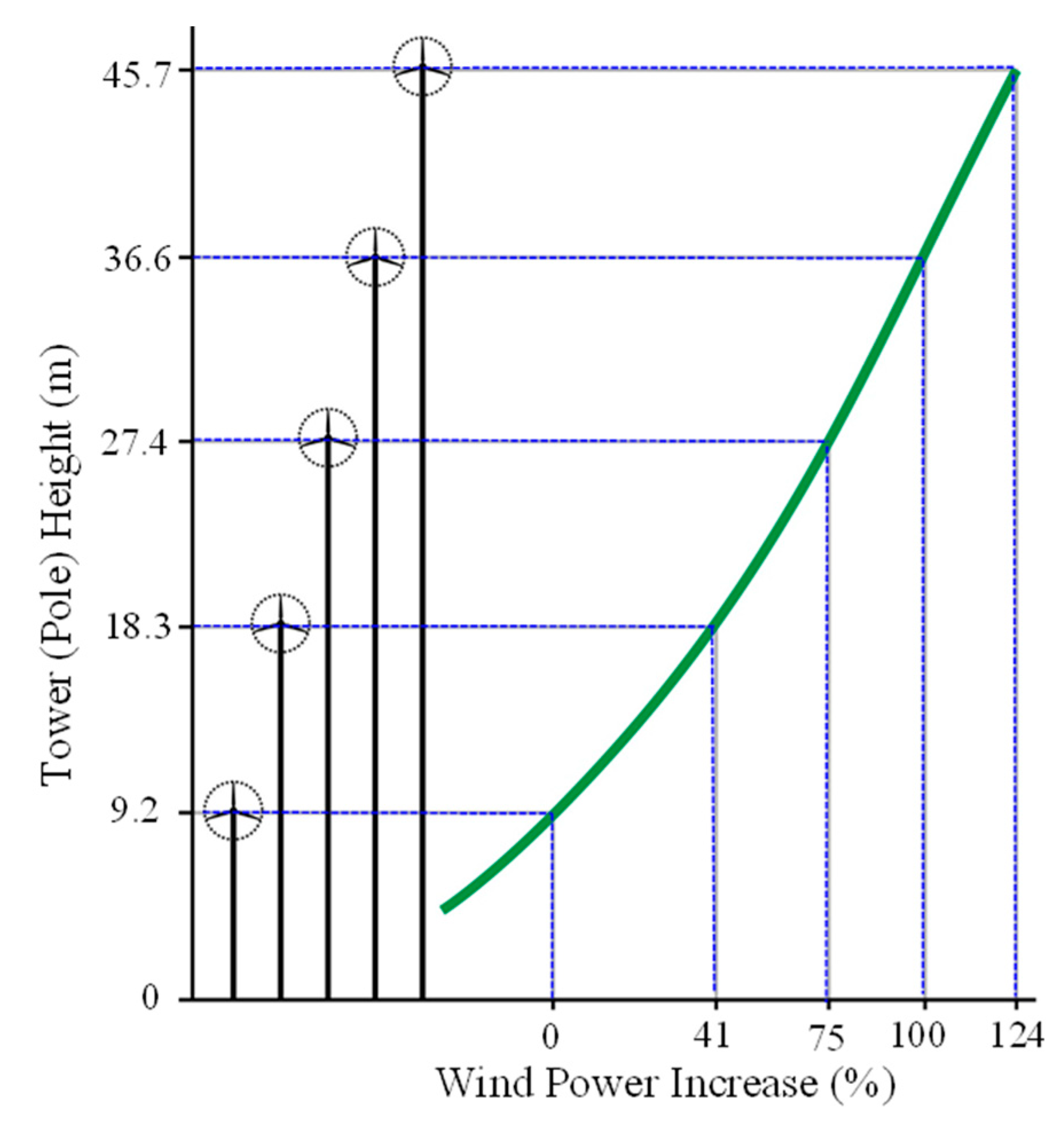

3.3. Turbine Tower

- Hmin is the minimum tower height (m);

- Ht is the height of tallest obstacle within 150 m;

- Hbuffer is the 10 m gap between the tallest obstacle and tip of the blade;

- Lblade is length of the turbine blade (m).

3.4. Turbine Control and Maintenance

3.5. Small Wind Turbine Global Market

3.6. Cost Analysis

3.7. Wind Turbine Noise

4. In Situ Performance Measurement Case Studies

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alam, F.; Ali, A.; Khan, I.; Mobin, S. Status of Power Generation by Domestic Scale Wind Turbines in Australia. Procedia Eng. 2012, 49, 205–212. [Google Scholar] [CrossRef][Green Version]

- Aldawi, F.; Alam, F.; Date, A.; Alghamdi, M.; Aldhawi, F. A New House Wall System for Residential Buildings. Energy Build. 2013, 67, 403–418. [Google Scholar] [CrossRef]

- Ahsan, S.; Ahmmed, T.; Alam, F. The COVID-19, power generation and economy—Case study of a developing country. Electr. J. 2022, 35, 107145. [Google Scholar] [CrossRef]

- Clean Energy Council, 2010 Clean Energy Australia Annual Report. Available online: http://www.cleanenergycouncil.org.au (accessed on 20 April 2023).

- Global Electricity Mix by Energy Source. 2022. Available online: https://www.statista.com/statistics/269811/world-electricity-production-by-energy-source/ (accessed on 21 July 2023).

- Webb, A. The Viability of Domestic Wind Turbines for Urban Melbourne; Alternative Technology Association (ATA): Melbourne, Australia, 2007; pp. 1–53. [Google Scholar]

- Noman, A.A.; Tasneem, Z.; Abhi, S.H.; Badal, F.R.; Rafsanzane, M.; Islam, M.R.; Alam, F. Savonius wind turbine blade design and performance evaluation using ANN-based virtual clone: A new approach. Heliyon 2023, 9, e156729. [Google Scholar] [CrossRef] [PubMed]

- Noman, A.A.; Tasneem, Z.; Sahed, M.F.; Muyeen, S.M.; Das, S.K.; Alam, F. Towards next generation Savonius wind turbine: Artificial intelligence in blade design trends and framework. Renew. Sustain. Energy Rev. 2022, 168, 112531. [Google Scholar] [CrossRef]

- Global Wind Energy Outlook. Available online: http://www.gwec.net/index.php?id=181&L=0%B4 (accessed on 30 June 2023).

- Renewable Capacity Statistics 2023, International Renewable Energy Agency (IRENA). Available online: https://www.irena.org/Publications/2023/Mar/Renewable-capacity-statistics-2023 (accessed on 15 May 2023).

- Ridden, P. Vestas Reveals Offshore Turbine with World’s Largest Sweep. New Atlas. 2021. Available online: https://newatlas.com/energy/vestas-v236-15-mw-offshore-wind-turbine/ (accessed on 2 June 2023).

- Mavrokefalidis, D. World’s Most Powerful Wind Turbine Emerges in China. Energy Live News. 2023. Available online: https://www.energylivenews.com/2023/01/11/worlds-most-powerful-wind-turbine-emerges-in-china/ (accessed on 2 June 2023).

- Kwok, K.C.S.; Hu, G. Wind energy system for buildings in an urban environment. J. Wind Eng. Ind. Aerodyn. 2023, 234, 105349. [Google Scholar] [CrossRef]

- World Population Prospects 2022: Summary of Results, UN Department of Economic and Social Affairs, Population Division. Available online: https://www.un.org/development/desa/pd/sites/www.un.org.development.desa.pd/files/wpp2022_summary_of_results.pdf (accessed on 21 June 2023).

- Rezaeiha, A.; Montazeri, H.; Blocken, B. A framework for preliminary large-scale urban wind energy potential assessment: Roof-mounted wind turbines. Energy Convers. Manag. 2020, 214, 112770. [Google Scholar] [CrossRef]

- Small-Scale Wind. Available online: https://energypedia.info/wiki/Small-Scale_Wind (accessed on 18 June 2023).

- Loganathan, B.; Chowdhury, H.; Mustary, I.; Rana, M.M.; Alam, F. Design of a micro wind turbine and its economic feasibility study for residential power generation in built-up areas. Energy Procedia 2019, 160, 812–819. [Google Scholar] [CrossRef]

- Karmakar, S.D.; Chattopadhyay, H. A review of augmentation methods to enhance the performance of vertical axis wind turbine. Sustain. Energy Technol. Assess. 2022, 53, 102469. [Google Scholar] [CrossRef]

- Takao, M.; Kuma, H.; Maeda, T.; Kamada, Y.; Oki, M.; Minoda, A. A straight-bladed vertical axis wind turbine with a directed guide vane row—Effect of guide vane geometry on the performance. J. Therm. Sci. 2009, 18, 54–57. [Google Scholar] [CrossRef]

- Kim, D.; Gharib, M. Efficiency improvement of straight-bladed vertical-axis wind turbines with an upstream deflector. J. Wind Eng. Ind. Aerodyn. 2013, 115, 48–52. [Google Scholar] [CrossRef]

- Kim, D.; Gharib, M. Unsteady loading of a vertical-axis turbine in the interaction with an upstream deflector. Exp. Fluids 2014, 55, 1658. [Google Scholar] [CrossRef]

- Jin, X.; Wang, Y.; Ju, W.; He, J.; Xie, S. Investigation into parameter influence of upstream deflector on vertical axis wind turbines output power via three dimensional CFD simulation. Renew. Energy 2018, 115, 41–53. [Google Scholar] [CrossRef]

- Stout, C.; Islam, S.; White, A.; Arnott, S.; Kollovozi, E.; Shaw, M.; Droubi, G.; Sinha, Y.; Bird, B. Efficiency improvement of vertical axis wind turbines with an upstream deflector. Energy Procedia 2017, 118, 141–148. [Google Scholar] [CrossRef]

- Nimvari, M.E.; Fatahian, H.; Fatahian, E. Performance improvement of a Savonius vertical axis wind turbine using a porous deflector. Energy Convers. Manag. 2020, 220, 113062. [Google Scholar] [CrossRef]

- Zhao, P.; Jiang, Y.; Liu, S.; Stoesser, T.; Zou, L.; Wang, K. Investigation of fundamental mechanism leading to the performance improvement of vertical axis wind turbines by deflector. Energy Convers. Manag. 2021, 247, 114680. [Google Scholar] [CrossRef]

- Hashem, I.; Mohamed, M.H. Aerodynamic performance enhancements of H-rotor Darrieus wind turbine. Energy 2018, 142, 531–545. [Google Scholar] [CrossRef]

- Kuang, L.; Su, J.; Chen, Y.; Han, Z.; Zhou, D.; Zhang, K.; Zhao, Y.; Bao, Y. Wind-capture-accelerate device for performance improvement of vertical-axis wind turbines: External diffuser system. Energy 2022, 39, 122196. [Google Scholar] [CrossRef]

- Ohya, Y.; Karasudani, T. A Shrouded Wind Turbine Generating High Output Power with Wind-lens Technology. Energies 2010, 3, 634–649. [Google Scholar] [CrossRef]

- Watanabe, K.; Takahashi, S.; Ohya, Y. Application of a Diffuser Structure to Vertical-Axis Wind Turbines. Energies 2016, 9, 406. [Google Scholar] [CrossRef]

- Mohamed, M.H.; Janiga, G.; Pap, E.; Thevenin, D. Optimization of Savonius turbines using an obstacle shielding the returning blade. Renew. Energy 2010, 35, 2618–2626. [Google Scholar] [CrossRef]

- Mohamed, M.H.; Janiga, G.; Pap, E.; Thevenin, D. Optimal blade shape of a modified Savonius turbine using an obstacle shielding the returning blade. Energy Convers. Manag. 2011, 52, 236–242. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mohammadi, R.; Ramadan, A.; Mohamed, M.H. Numerical investigation of performance refinement of a drag wind rotor using flow augmentation and momentum exchange optimization. Energy 2018, 158, 592–606. [Google Scholar] [CrossRef]

- Altan, B.D.; Atılgan, M. An experimental and numerical study on the improvement of the performance of Savonius wind rotor. Energy Convers. Manag. 2008, 49, 3425–3432. [Google Scholar] [CrossRef]

- Altan, B.D.; Atılgan, M. The use of a curtain design to increase the performance level of a Savonius wind rotors. Renew. Energy 2010, 35, 821–829. [Google Scholar] [CrossRef]

- El-Askary, W.A.; Nasef, M.H.; Abdel-Hamid, A.A.; Gad, H.E. Harvesting wind energy for improving performance of Savonius rotor. J. Wind Eng. Ind. Aerodyn. 2015, 139, 8–15. [Google Scholar] [CrossRef]

- Irabu, K.; Roy, J.N. Characteristics of wind power on Savonius rotor using a guidebox tunnel. Exp. Therm. Fluid Sci. 2007, 32, 580–586. [Google Scholar] [CrossRef]

- Chong, W.T.; Fazlizan, A.; Poh, S.C.; Pan, K.C.; Hew, W.P.; Hsiao, F.B. The design, simulation and testing of an urban vertical axis wind turbine with the omnidirection-guide-vane. Appl. Energy 2013, 112, 601–609. [Google Scholar] [CrossRef]

- Wong, K.H.; Chong, W.T.; Yap, H.T.; Fazlizan, A.; Omar, W.Z.W.; Poh, S.C.; Hsiao, F.B. The design and flow simulation of a power-augmented shroud for urban wind turbine system. Energy Procedia 2014, 61, 1275–1278. [Google Scholar] [CrossRef]

- Nobile, R.; Vahdati, M.; Barlow, J.F.; Mewburn-Crook, A. Unsteady flow simulation of a vertical axis augmented wind turbine: A two-dimensional study. J. Wind Eng. Ind. Aerodyn. 2014, 125, 168–179. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, S.; Tagawa, K.; Feng, F. Starting performance effect of a truncated-coneshaped wind gathering device on small-scale straight-bladed vertical axis wind turbine. Energy Convers. Manag. 2018, 167, 70–80. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, S.; Qu, C.; Tong, G.; Feng, F.; Zhao, B.; Kotaro, T. Aerodynamic characteristics of Straight-bladed Vertical Axis Wind Turbine with a curved-outline wind gathering device. Energy Convers. Manag. 2020, 203, 112249. [Google Scholar] [CrossRef]

- Pope, K.; Rodrigues, V.; Doyle, R.; Tsopelas, A.; Gravelsins, R.; Naterer, G.F.; Tsang, E. Effects of stator vanes on power coefficients of a zephyr vertical axis wind turbine. Renew. Energy 2010, 35, 1043–1051. [Google Scholar] [CrossRef]

- Pope, K.; Dincer, I.; Naterer, G.F. Energy and exergy efficiency comparison of horizontal and vertical axis wind turbines. Renew. Energy 2010, 35, 2102–2113. [Google Scholar] [CrossRef]

- Kalluvila, J.B.S.; Sreejith, B. Numerical and experimental study on a modified Savonius rotor with guide blades. Int. J. Green Energy 2018, 15, 744–757. [Google Scholar] [CrossRef]

- Tian, W.; Mao, Z.; Ding, H. Numerical study of a passive-pitch shield for the efficiency improvement of vertical axis wind turbines. Energy Convers. Manag. 2019, 183, 732–745. [Google Scholar] [CrossRef]

- Yao, Y.X.; Tang, Z.P.; Wang, X.W. Design based on a parametric analysis of a drag driven VAWT with a tower cowling. J. Wind Eng. Ind. Aerodyn. 2013, 116, 32–39. [Google Scholar] [CrossRef]

- Ying, P.; Chen, Y.K.; Xu, Y.G.; Tian, Y. Computational and experimental investigations of an omni-flow wind turbine. Appl. Energy 2015, 146, 74–83. [Google Scholar] [CrossRef]

- Bhuyan, S.; Biswas, A. Investigations on self-starting and performance characteristics of simple H and hybrid H-Savonius vertical axis wind rotors. Energy Convers. Manag. 2014, 87, 859–867. [Google Scholar] [CrossRef]

- Hosseini, A.; Goudarzi, N. Design and CFD study of a hybrid vertical-axis wind turbine by employing a combined Bach-type and H-Darrieus rotor systems. Energy Convers. Manag. 2019, 189, 49–59. [Google Scholar] [CrossRef]

- Chong, W.-T.; Wong, K.-H.; Wang, C.-T.; Gwani, M.; Chu, Y.-J.; Chia, W.-C.; Poh, S.-C. Cross-axiswind-turbine: A complementary design to push the limit of wind turbine technology. Energy Procedia 2017, 105, 973–979. [Google Scholar] [CrossRef]

- Chong, W.-T.; Muzammil, W.K.; Wong, K.-H.; Wang, C.-T.; Gwani, M.; Chu, Y.-J.; Poh, S.-C. Cross axis wind turbine: Pushing the limit of wind turbine technology with complementary design. Appl. Energy 2017, 207, 78–95. [Google Scholar] [CrossRef]

- Reupke, P.; Probert, S.D. Slatted-blade Savonius wind-rotors. Appl. Energy 1991, 40, 65–75. [Google Scholar] [CrossRef]

- Mohamed, O.S.; Ibrahim, A.A.; Etman, A.K.; Abdelfatah, A.A.; Elbaz, A.M.R. Numerical investigation of Darrieus wind turbine with slotted airfoil blades. Energy Convers. Manag. 2020, 5, 100026. [Google Scholar] [CrossRef]

- Chen, J.; Yang, H.; Yang, M.; Xu, H. The effect of the opening ratio and location on the performance of a novel vertical axis Darrieus turbine. Energy 2015, 89, 819–834. [Google Scholar] [CrossRef]

- Yousefi, R.M.; Khaleghinia, J.; Eshagh, N.M.; Salarian, H. Performance improvement of Darrieus wind turbine using different cavity layouts. Energy Convers. Manag. 2021, 246, 114693. [Google Scholar] [CrossRef]

- Al-Ghriybah, M.; Zulkafli, M.F.; Didane, D.H.; Mohd, S. The effect of inner blade position on the performance of the Savonius rotor. Sustain. Energy Technol. Assess. 2019, 36, 100534. [Google Scholar] [CrossRef]

- Al-Ghriybah, M.; Fadhli, Z.M.; Hissein, D.D.; Mohd, S. The effect of spacing between inner blades on the performance of the Savonius wind turbine. Sustain. Energy Technol. Assess. 2021, 43, 100988. [Google Scholar] [CrossRef]

- Saad, A.S.; Elwardany, A.; El-Sharkawy, I.I.; Ookawara, S.; Ahmed, M. Performance evaluation of a novel vertical axis wind turbine using twisted blades in multistage Savonius rotors. Energy Convers. Manag. 2021, 235, 114013. [Google Scholar] [CrossRef]

- Krishnan, A.; Paraschivoiu, M. 3D analysis of building mounted VAWT with diffuser shaped shroud. Sustain. Cities Soc. 2016, 27, 160–166. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Zhang, W.; Zhu, H. Effect of building diffusers on aerodynamic performance for building augmented vertical axis wind turbine. J. Renew. Sustain. Energy 2021, 13, 023306. [Google Scholar] [CrossRef]

- Kanya, B.; Visser, K.D. Experimental validation of a ducted wind turbine design strategy. Wind Energy Sci. 2018, 3, 919–928. [Google Scholar] [CrossRef]

- Fthenakis, V.; Kim, H.C. Land use and electricity generation: A life-cycle analysis. Renew. Sustain. Energy Rev. 2009, 13, 1465. [Google Scholar] [CrossRef]

- Impact of Wind Power Generation in Ireland on the Operation of Conventional Plant and the Economic Implications. Available online: https://docs.wind-watch.org/EirGrid-WindImpact-Main.pdf (accessed on 28 June 2023).

- Small Wind Turbines, 1–6 kW. Available online: https://www.greenspec.co.uk/building-design/small-wind-turbines/ (accessed on 1 July 2023).

- Tong, W. Wind Power Generation and Wind Turbine Design; WIT Press: Southampton, UK, 2010; ISBN 978-1-84564-205-1. [Google Scholar]

- Tasneem, Z.; Noman, A.A.; Das, S.K.; Saha, D.K.; Islam, M.R.; Ali, M.F.; Badal, M.F.R.; Ahamed, M.H.; Moyeen, S.I.; Alam, F. An analytical review on the evaluation of wind resource and wind turbine for urban application: Prospect and challenges. Dev. Built Environ. 2020, 4, 100033. [Google Scholar] [CrossRef]

- Hucho, W.H. Aerodynamics of Road Vehicles; Society of Automotive Engineers (SAE): Warrendale, PA, USA, 1998; ISBN 0-7680-0029-7. [Google Scholar]

- Davenport, A.G. Some Aspect of Wind Loading; Paper EIC ′63-CIV 3; Transaction of the Institute of Canada: Toronto, ON, Canada, 1963. [Google Scholar]

- Tominaga, Y. CFD Prediction for Wind Power Generation by a Small Vertical Axis Wind Turbine: A Case Study for a University Campus. Energies 2023, 16, 4912. [Google Scholar] [CrossRef]

- Elkinton, M.R.; Rogers, A.L.; McGowan, J.G. An Investigation of Wind-Shear Models and Experimental Data Trends for Different Terrains. Wind Eng. 2006, 30, 341–350. [Google Scholar] [CrossRef]

- Karsten, L. Middle-class households with children on vertical family living in Hong Kong. Habitat Int. 2015, 47, 241–247. [Google Scholar] [CrossRef]

- Al-Kodmany, K.; Xue, Z.; Sun, C. Reconfiguring Vertical Urbanism: The Example of Tall Buildings and Transit-Oriented Development (TB-TOD) in Hong Kong. Buildings 2022, 12, 197. [Google Scholar] [CrossRef]

- Yusaf, T.; Goh, S.; Borserio, J.A. Potential of renewable energy alternatives in Australia. Renew. Sustain. Energy Rev. 2011, 15, 2214–2221. [Google Scholar] [CrossRef]

- Stapleton, G.; Milne, G.; Riedy, C.; Ross, K. Wind System. Available online: https://www.homebaseperth.com.au/wp-content/uploads/Your-home/05-Energy/Energy-WindSystems.pdf (accessed on 29 May 2023).

- Gipe, P. Wind Energy Basics: A Guide to Home and Community Scale Wind Energy Systems, 2nd ed.; Chelsea Green Publishing: Hartford, VT, USA, 2009; pp. 1–192. [Google Scholar]

- Musial, W.D.; Sheppard, R.E.; Dolan, D.; Naughton, B. Development of Offshore Wind Recommended Practice for U.S. Waters; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2013; pp. 1–13. Available online: https://permanent.access.gpo.gov/gpo41492/57880.pdf (accessed on 13 May 2023).

- Woofenden, I. Wind Generator Tower Basics. Available online: https://www.renewablereality.net/wp-content/uploads/2018/09/Wind-Generator-Tower-article-from-Home-Power-magazine-1.pdf (accessed on 3 June 2023).

- Clarke, S. Electricity Generation Using Small Wind Turbines for Home or Farm Use, Ontario Ministry of Agriculture, Food and Rural Affairs, Toronto, Canada. Available online: https://files.ontario.ca/omafra-electricity-generation-small-wind-turbines-home-farm-use-18-005-en-24-03-2021.pdf (accessed on 6 June 2023).

- Hadad, M.S.; Al-Jiboori, M.H. Choosing Minimum Height for Continuing Operation wind Energy Generation Over Urban Cities. J. Educ. Pure Sci.—Univ. Thi-Qar 2019, 9, 193–203. [Google Scholar] [CrossRef]

- Al-Jiboori, M.H.; Qassim, M.S. Choosing of relevant low height for operation wind turbine over urban Baghdad city. J. Phys. Conf. Ser. 2018, 1032, 012011. [Google Scholar] [CrossRef]

- Small Wind Electric Systems—A U.S. Consumer’s Guide, U.S. Department of Energy, USA. Available online: https://www.nrel.gov/docs/fy07osti/42005.pdf (accessed on 30 May 2023).

- Rhodes, M.; Brown, H.; Hailes, D. Encraft Warwick Wind Trials Project. 2009. Available online: https://s1.solacity.com/docs/Warwick%20Wind%20Trials%20Report.pdf (accessed on 10 May 2023).

- Small Wind Market, Research and Markets. Available online: https://www.researchandmarkets.com/reports/4375404/ (accessed on 22 May 2023).

- Davy, J.L.; Burgemeister, K.; Hillman, D.; Carlile, S. A Review of the Potential Impacts of Wind Turbine Noise in the Australian Context. Acoust. Aust. 2020, 48, 181–197. [Google Scholar] [CrossRef]

- Access Canberra. Overview Noise Standards. ACT Government, Canberra, Australia. Available online: https://www.accesscanberra.act.gov.au/s/article/noise-thresholds-tab-overview (accessed on 28 April 2023).

- Song, J.; Yorke, I. Wind Farms Environmental Noise Guidelines; Environment Protection Authority (EPA) South Australia: Adelaide, Australia, 2021; ISBN 978-1-876562-43-9.

- Domestic Small-Scale Wind Field Trial Report, Energy Saving Trust UK. Available online: https://eprints.soton.ac.uk/353113/1/Location_Location_Location_field_trial_small-scale_wind_report%25281%2529.pdf (accessed on 14 April 2023).

- Shaw, S.; Rosen, A.; Beavers, D.; Korn, D. Status Report on Small Wind Energy Projects, Massachusetts Renewable Energy Trust & The Cadmus Group, USA. Available online: https://archives.lib.state.ma.us/handle/2452/335409 (accessed on 11 May 2023).

- Mertens, S. Project Group Test Field Small Wind Turbines (kW) Zeeland, Netherlands. Available online: https://s1.solacity.com/docs/ZEE0900786.pdf (accessed on 18 May 2023).

- Lombardo, T. Rooftop Wind Turbines: Are They Worthwhile? Available online: https://www.engineering.com/story/rooftop-wind-turbines-are-they-worthwhile-qxrvl (accessed on 13 May 2023).

- Sun, W.; Tian, C.; Jin, Y. Cost and Reliability Analysis of a Hybrid Renewable Energy Systems—A Case Study on an Administration Building. MIST Int. J. Sci. Technol. 2022, 10, 29–35. [Google Scholar]

- How Much Electricity Does an Australian Home Use? Available online: http://www.arelectrical.com.au/average-electricity-usage-in-australia/ (accessed on 22 May 2022).

- Wind Turbine Sound, Office of Energy Efficiency & Renewable Energy, Wind Exchange, US Department of Energy, USA. Available online: https://windexchange.energy.gov/projects/sound#:~:text=Do%20Wind%20Turbines%20Make%20Sound,blades%20moving%20through%20the%20air (accessed on 21 July 2023).

| Augmentation Type | Augmentation Methods | Maximum Power Coefficient |

|---|---|---|

| Unidirectional Inlet Flow | 0.21 0.45 0.21 0.27 0.28 1.37 0.90 0.25 0.39 0.38 0.52 0.26 | |

| Omni Directional Inlet Flow | 0.42 0.80 0.23 0.12 0.28 0.28 | |

| Contemporary Style | 0.48 0.18 0.34 0.41 0.08 | |

| Blade Customisation | 0.02 0.30 0.41 0.27 0.19 0.26 | |

| Building Integrated Wind Turbines | 0.34 1.56 |

| States | Time | Not to Exceed Noise Level |

|---|---|---|

| Australian Capital Territory (ACT) | 07:00–22:00 | 45 dB (A) |

| 22:00–07:00 | 35 dB (A) | |

| South Australia (SA) | 07:00–22:00 | 52 dB (A) |

| 22:00–07:00 | 45 dB (A) | |

| Queensland (QLD) | - | 40 dB (A) |

| Number of Turbines and Locations | Turbine Diameter (m) | Cut-in Speed and Rated Speed (m/s) | Major Findings | |

|---|---|---|---|---|

| Case study 1 (British Energy Saving Trust) [88] | Studied 57 turbines (building mounted and free-standing pole mounted) for 1 year, urban and suburban areas in the UK | 1.1–5.6 | 2.5–4.5 & 11.0–15.5 |

|

| Case study 2 (Cadmus Group) [89] | Studied 21 free-standing pole mounted (40 m–140 m) small wind turbines for 1.5 years, in suburban areas in Massachusetts, USA | Up to 8 | - |

|

| Case study 3 (Warwick Wind Trials) [81] | Studied 26 building mounted (including 45 m tall, exposed flats in isolated settings on hilltops and 5 m above the roofline) small wind turbines for 1.5 years in suburban and rural areas in the UK | - | - |

|

| Case study 4 (Zeeland small wind turbine) [90] | Studied 11 small wind turbines for over 4 years in one area with the same heights of 12 and 17 m in the Netherlands | 1–5 | - |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, F.; Jin, Y. The Utilisation of Small Wind Turbines in Built-Up Areas: Prospects and Challenges. Wind 2023, 3, 418-438. https://doi.org/10.3390/wind3040024

Alam F, Jin Y. The Utilisation of Small Wind Turbines in Built-Up Areas: Prospects and Challenges. Wind. 2023; 3(4):418-438. https://doi.org/10.3390/wind3040024

Chicago/Turabian StyleAlam, Firoz, and Yingai Jin. 2023. "The Utilisation of Small Wind Turbines in Built-Up Areas: Prospects and Challenges" Wind 3, no. 4: 418-438. https://doi.org/10.3390/wind3040024

APA StyleAlam, F., & Jin, Y. (2023). The Utilisation of Small Wind Turbines in Built-Up Areas: Prospects and Challenges. Wind, 3(4), 418-438. https://doi.org/10.3390/wind3040024