Abstract

In the present study, a new Design for Additive Manufacturing (DfAM) method for hot stamping dies is evaluated, namely lattice structured. In order to evaluate the benefits of the lattice structured method with regards to the thermal performance, a hot stamping die integrated with a lattice structure and a traditional solid die were additively manufactured. The dies were subsequently tested in the hot stamping of AA7075 aluminium alloy blanks under cyclic loading conditions, with the temperature evolutions, of both the blank and die, being presented. The analysis of the results shows that the lattice structured method has considerably improved the cooling performance of hot stamping dies.

1. Introduction

Sustainability is a multi-disciplinary challenge in manufacturing and there is increasing pressure for OEMs to meet stringent environmental regulations. Apart from electrification, weight reduction is an enabler towards sustainability as weight is proportionally related to vehicle emissions and inversely proportional to the range of electrified vehicles. To meet weight requirements, UHSS and aluminium alloys have increased their proportion in vehicle structures over the past decades. The main challenge of processing these materials is their low formability at room temperature, leading to poor quality of the final component. Hot stamping is a hybrid forming process which enables the forming of advanced lightweight alloys with low ductility at room temperature.

Recently, Imperial College London developed the innovative Fast light Alloy Stamping Technology (FAST), which enables increased formability of aluminium alloys, superior post-form strength, decreased springback, and significantly reduced cycle time [1,2]. The aluminium alloy blank is heated to an elevated temperature at an ultra-fast heating rate, so its microstructure will not be affected while its ductility is enhanced, and then the hot blank is transferred to the die.

The importance of the hot stamping dies being maintained at room temperature is significant because they act as a heat sink that extracts heat from the hot blank, which is key in achieving the desired cooling rate. This blank quenching stage is one of the main bottlenecks for the reduction of process cycle time [3]. Currently, hot stamping dies are manufactured by conventional manufacturing methods, such as milling and drilling. In order to increase their quenching efficiency, cooling channels, with an appropriate liquid cooling medium, are integrated into their body. The most established and cost-effective method of manufacturing internal cooling channels for hot stamping dies is drilling. This approach is limited to producing straight-line cooling channels that are unable to maintain equidistance from a complex 3D geometry of the tool working surface. Consequently, “hot spots” occur on a final component, resulting from cooling at different rates compared to the rest of the component, and these hot spots inherently exhibit varied mechanical properties [4].

Additive Manufacturing (AM) technologies allow for the manufacture of conformal cooling channels with greater design freedom and complexity. Cortina et al. [5] compared the heat transfer capability between conventionally drilled cooling channels and AMed conformal cooling channels. The temperatures obtained in both designs were almost identical. Moreover, a die with conformal cooling channels and another with straight conventionally drilled channels were compared. The former demonstrated simultaneously more homogeneous temperature distribution and 50 ℃ lower temperature than the latter. In another study by Muller et al. [6], an additively manufactured die designed with conformal cooling channels cooled down six times faster than a conventional die with drilled cooling channels. Moreover, the study concluded that quenching time can be reduced by 50%, which corresponds to a reduction of 20% in the cycle time. The benefit of AM is not limited only to the manufacturing of conformal cooling channels. There are numerous geometries that can be manufactured without increasing manufacturing cost. For instance, lattice structures can be manufactured within the cooling channels increasing heat transfer due to increased interfacial surface areas and fluid vorticity, as shown in the study by Brooks et al. [7]

This study proposes a new Design for Additive Manufacturing (DfAM) method to produce hot stamping dies, i.e., lattice structured hot stamping dies. A die designed with the lattice structured methodology was compared with a traditionally designed solid die in the hot stamping of AA7075-T6 aluminium alloy blanks, in terms of their thermal behaviour. Temperature data of both blank and dies were analysed and it was concluded that the lattice structured method improves the cooling performance by 100% in the temperature interval 425–180 ℃ and by 30–50% between 450 ℃ and 100 ℃.

2. Methods

2.1. Lattice Structured Design for Additively Manufactured Hot Stamping Dies

The lattice structured concept heavily utilises lattice structures in the geometric design of the hot stamping die, as shown in Figure 1. The benefit of the lattice structure is three-fold. Firstly, the lattice structure exhibits lower thermal conductance than the equivalent solid material whilst offering superior die strength and stiffness. This enables enhanced heat control where the area far from the cooling channel can be selectively insulated, while the region in proximity to the cooling channel remains solid and comparatively conductive. As a result, there is a significant reduction of the overall thermal mass, which needs to be cycled during the hot stamping process. Secondly, AM of a lattice structure requires less powder than its solid counterpart, thus the lattice structured design is resource-efficient. Lastly, due to the reduced printed volume in the lattice structured concept, AM production time benefits can be realised.

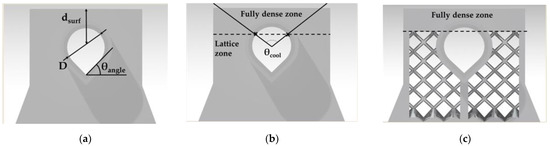

Figure 1.

(a) Schematic of key design variables; (b) graphic representation of segmentation; (c) hot stamping die designed with lattice structures.

However, a hot stamping die cannot be designed solely with lattice structures as it would not be able to bear the forming load during the process. Thus, the question of which areas in the die should be solid and which should have lattice structures is key in order to utilize the aforementioned benefits.

With regards to cooling, a system must be designed which will be able to sufficiently cool the die and consequently rapidly quench the hot blank. There are three main design variables that must be selected at this stage: (i) the diameter of the cooling channel (), (ii) the distance of the cooling channel from the working surface of the die (dsurf), and (iii) the distance between two consecutive channels (dcons) [8]. In this study, only the cooling channel diameter and its distance from the working surface are investigated since only one die segment is studied. D and dsurf are defined as 10 mm in accordance with standard industrial practices and the guidelines given by Lim et al. [9]. The cross-section of the cooling channel is a “teardrop” shape instead of circular because circular cooling channels are not self-supported geometries. An overhang is a common issue of any AM component and occurs with slanting or curved surfaces beyond 45° from the vertical build direction. Thus, θangle is required to be more than 45°.

The second step is to divide the die’s body into two zones. The first one is the “fully dense zone”, which is the solid structure, and the second zone is the “lattice zone”, where the designer can selectively change the solid area with any geometry. In this method, the segmentation element is a straight line defined by two points, which are the results of the intersection between the effective cooling angle (θcool) and the cross-section of the cooling channel respectively. The effective cooling angle is the vertical angle of an isosceles triangle formed by the working surface of the tool and the center of the cooling channel [9]. In this study, θcool is set as 360° and 100° degrees for the solid and lattice structured dies, respectively.

The third step is to replace the solid area of the “design zone” with other suitable geometries that will reduce the thermal mass of the die. In this study, body-centered cubic lattice structures are used. The radius and length of the struts are 0.8 mm and 8 mm, respectively. Throughout the design, struts in the BCC cells should be maintained at 45° from the vertical build direction to be self-supporting. Conal structures are introduced to prevent overhanging faces where the lattice region transitions into the solid region during printing.

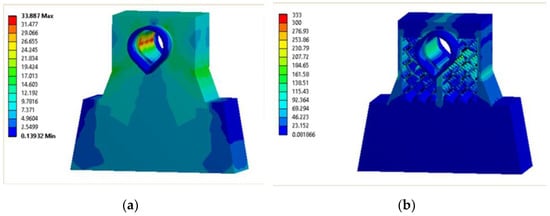

Finally, the lattice structured die was modelled to undergo a preliminary stress finite element analysis, as shown in Figure 2. A static pressure of 15 MPa was applied on the working surface and the solid die experienced a maximum von Mises stress of 34 MPa. Introduction of lattice structures increased the maximum stress to 420 MPa, experienced at one of the lattice struts, which is a stress concentration feature. In order to reduce the stresses below the yield strength of stainless steel 316 L, a thin central pillar, 2 mm thick, was designed right below the teardrop cooling channel and extends to the solid region. This additional feature makes no significant change to the response of the die to heat transfer although considerably decreases the maximum stress to 333 MPa.

Figure 2.

Stress analysis of demonstrators: (a) solid die; (b) lattice structured die.

2.2. Additive Manufacturing of Dies

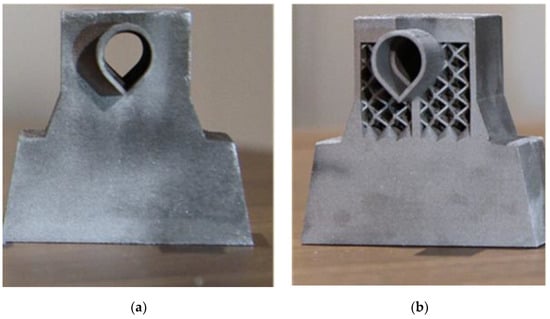

A Concept Laser Mlab Cusing machine (Lichtenfels, Germany) was used to manufacture the test specimens with LPW-316-AAAU powder, as shown in Figure 3. The selected process parameters and the chemical composition of the powder are presented in Table 1 and Table 2, respectively. The selected process parameters deliver a volumetric energy density of 70.6 J/mm3 and ensure that the final material will have at least 99% density [10]. Finally, to avoid extensive use of the support structure, the dies were oriented with their working surface towards the base plate of the SLM machine. After the processing, the dies underwent a three-stage heat treatment. The dies were heated to 550 ℃ for 3 h and subsequently were tempered for 6 h at 550 ℃ before cooling to room temperature. Finally, the working surface is polished down to 0.8 µm.

Figure 3.

Printed demonstrators: (a) solid die; (b) proposed die.

Table 1.

SLM build parameters.

Table 2.

Composition of LPW-316-AAAU.

2.3. Apparatus for Simulating Hot Stamping Processes: IHTC-Mate

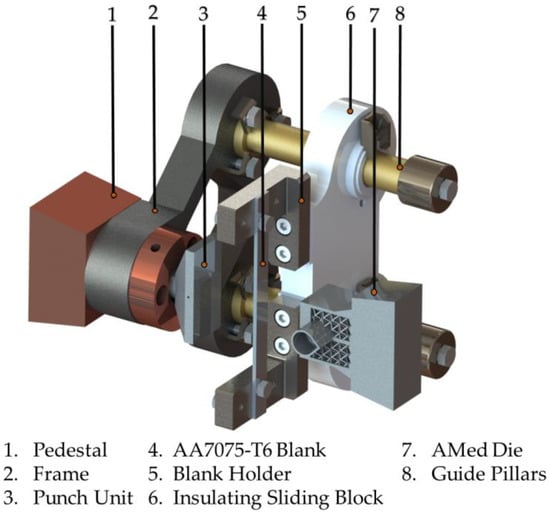

In order to evaluate the performance of the proposed AM dies, an in-house developed testing apparatus was used in combination with the thermomechanical simulator Gleeble 3800 (Poestenkill, New York, NY, USA) [11]. The testing apparatus consists of one pedestal (No. 1 in Figure 4), fixed on one side of the Gleeble 3800 chamber, while the proposed die (No. 8 in Figure 4) is clamped on the opposite side. On the fixed pedestal, a frame (No. 2 in Figure 4) is attached and holds two guide pillars (No. 8 in Figure 4) on which the blank can move horizontally. During a cycle, the specimen die pushes horizontally through the blank towards the fixed punch (No. 3 in Figure 4). The temperature is monitored through K-type thermocouples attached on both the blank and the die, and the data are stored in the Gleeble controller in order to be post-processed at a later stage. Moreover, the heating of the blank is realized by induction heating at a heating rate of 30 ℃/s. Finally the die is cooled by circulating water through the cooling channel. A Reynolds number of 4000 to 10,000 could maintain turbulent flow in the cooling fluid, which has far superior heat transfer properties than that of laminar flow [9]. Thus, the target Reynolds number was 8000 in this research, and the corresponding water flowrate of 0.105 L/s was controlled using a flowmeter. The temperature of the water was set at 25 ℃.

Figure 4.

Testing facility used for the thermal response of AM hot stamping dies.

3. Results and Discussion

In this study, a 2 mm AA7075-T6 blank experienced five hot stamping cycles. The temperature was monitored at the center of the blank and die. In order to assess the thermal performance of each die, two criteria were defined:

- The cooling rate from 425 ℃ to 180 ℃ in the cycle should have a minimum value. This value is determined from analysis of the continuous cooling precipitation (CCP) diagram of A7075-T6 [12].

- The blank must reach a temperature below 100 ℃, which is lower than the artificial ageing temperature of AA7075 (120 ℃), in less than 5 s.

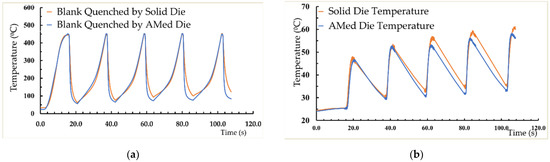

Figure 5 shows the temperature evolutions of the blank and die during five hot stamping cycles. In general, it is observed that the lattice structured die quenches the blank faster and reaches a lower temperature at the end of each cycle (Figure 1a). Moreover, both dies start from the same temperature and their peak temperatures are almost identical for the first two cycles followed by a divergence where the lattice structured die operates at a lower temperature.

Figure 5.

(a) Temperature evolution of the blank; (b) temperature evolution of each die.

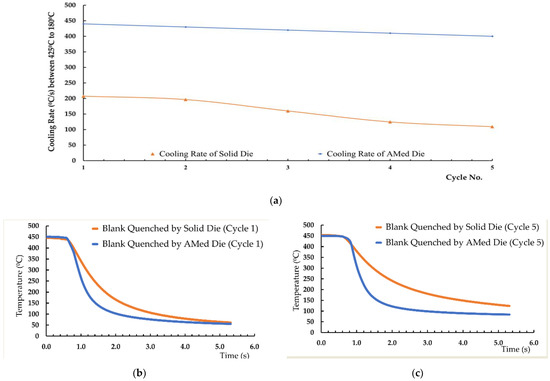

The critical cooling rate (CCR) of the blank material is achieved in every hot stamping cycle. However, the lattice structured die achieves a significantly higher cooling rate than the solid die, as can be seen in Figure 6a. Another observation is that the cooling rate of the solid die at cycle 5 is just above the CCR, which means that in a scenario of more loading cycles, it would likely fail to meet this CCR requirement. Moreover, magnified graphs of blank temperature evolution for the first and last cycle of each die are presented in Figure 6b,c. It is clear that the two cooling curves are diverging as the stamping cycles increase, which is expected due to the thermal history of the dies.

Figure 6.

(a) Cooling rates of the blank for each cycle; (b) blank temperature evolution—1st cycle; (c) blank temperature evolution—5th cycle.

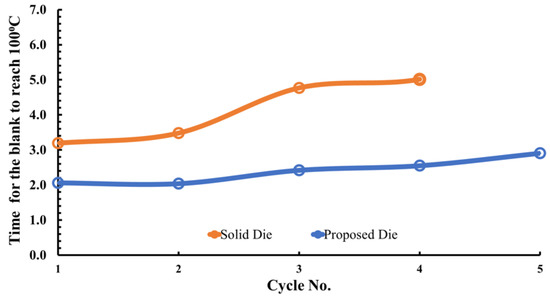

Figure 7 shows the time required for each die to cool down the blank to 100 ℃. Overall, both curves follow the same trend with the increasing loading cycle. The lattice structured die quenches the blank to 100 ℃ faster, by approximately 30–50%. It is worth mentioning that the blank quenched by the solid die in the 5th cycle failed to reach the desired temperature in 5 s.

Figure 7.

Time for the blank to cool down to 100 ℃.

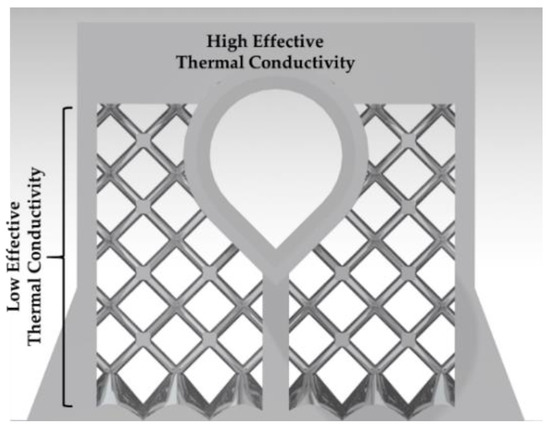

It can be concluded that lattice structures eliminate the majority of the metal mass from the die while providing mechanical support to the working surface. It is found that while heat transfer between the die working surface and cooling channel is unaffected, heat transfer from the cooling channel to the body of the die is greatly reduced, because of the decrease in thermal mass and increase in thermal resistance that the lattice structure provides. Consequently, the thermal mass, which must be cooled down by the cooling channel, is now reduced to 50% of the “fully dense” zone, as shown in Figure 8, thus making rapid thermal cycling of the die surface possible.

Figure 8.

Effect of lattice structures on thermal conductivity of a hot stamping die.

4. Conclusions

In this paper A DfAM method for lattice structured hot stamping dies was presented and experimentally evaluated. The benefits of using the lattice structured design are significant, with the achieved cooling rates being two times greater than the conventional solid design. As far as production efficiency is concerned, it is worth mentioning that the lattice structured die required 13.8 h of printing, 2.8 h less than the manufacture of the solid die, which translates to a manufacturing time reduction of 20.2%. The lattice structured method takes advantage of the complexity that AM can deliver and demonstrates that lattice structures can be integrated into a dies’ body, leading to a reduction of its thermal mass. Therefore, the cooling efficiency of a cooling channel can be greatly increased.

Author Contributions

D.C. and L.W. conceived and designed the study. X.L. performed the experiments. D.C., X.L., D.J.P. and L.W. drafted this paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, L.; Elfakir, O.; Sun, Y.; Ji, K.; Luan, X.; Cai, Z.; Liu, X. A method of forming parts from sheet metal. International Patent WO/2019/038556, 28 February 2019. [Google Scholar]

- Zhang, Q.; Luan, X.; Dhawan, S.; Politis, D.J.; Du, Q.; Fu, M.W.; Wang, K.; Gharbi, M.M.; Wang, L. Development of the post-form strength prediction model for a high-strength 6xxx aluminium alloy with pre-existing precipitates and residual dislocations. Int. J. Plast. 2019, 119, 230–248. [Google Scholar] [CrossRef]

- Fernández, B.; González, B.; Artola, G.; de Lacalle, N.L.; Angulo, C. A quick cycle time sensitivity analysis of boron steel hot stamping. Metals 2019, 9, 235. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.I.; Calleja, A.; Ukar, E.; Alberdi, A. Case study to illustrate the potential of conformal cooling channels for hot stamping dies manufactured using hybrid process of laser metal deposition (LMD) and milling. Metals 2018, 8, 102. [Google Scholar] [CrossRef]

- Muller, B.; Gebauer, M.; Hund, R.; Malek, R.; Gerth, N. Metal Additive Manufacturing for tooling applications—Aser Beam Melting technology increases efficiency of dies and molds. In Proceedings of the Metal Additive Manufacturing Conference MAMC, Vienna, Austria, 20–21 November 2014; pp. 1–14. [Google Scholar]

- Brooks, H.; Brigden, K. Design of conformal cooling layers with self-supporting lattices for additively manufactured tooling. Addit. Manuf. 2016, 11, 16–22. [Google Scholar] [CrossRef]

- Lin, Z.-C.; Chou, M.-H. Design of the cooling channels in nonrectangular plastic flat injection mold. J. Manuf. Syst. 2002, 21, 167–186. [Google Scholar] [CrossRef]

- Lim, W.-S.; Choi, H.-S.; Ahn, S.-Y.; Kim, B.-M. Cooling channel design of hot stamping tools for uniform high-strength components in hot stamping process. Int. J. Adv. Manuf. Technol. 2014, 70, 1189–1203. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Liu, X.; El Fakir, O.; Zheng, Y.; Gharbi, M.M.; Wang, L. Effect of tool coatings on the interfacial heat transfer coefficient in hot stamping of aluminium alloys under variable contact pressure conditions. Int. J. Heat Mass Transf. 2019, 137, 74–83. [Google Scholar] [CrossRef]

- Zheng, K.; Dong, Y.; Zheng, J.-H.; Foster, A.; Lin, J.; Dong, H.; Dean, T.A. The effect of hot form quench (HFQ®) conditions on precipitation and mechanical properties of aluminium alloys. Mater. Sci. Eng. A 2019, 761, 138017. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).