Investigation of Friction Coefficient Evolution and Lubricant Breakdown Behaviour at Elevated Temperatures in a Pin-on-Disc Sliding System †

Abstract

:1. Introduction

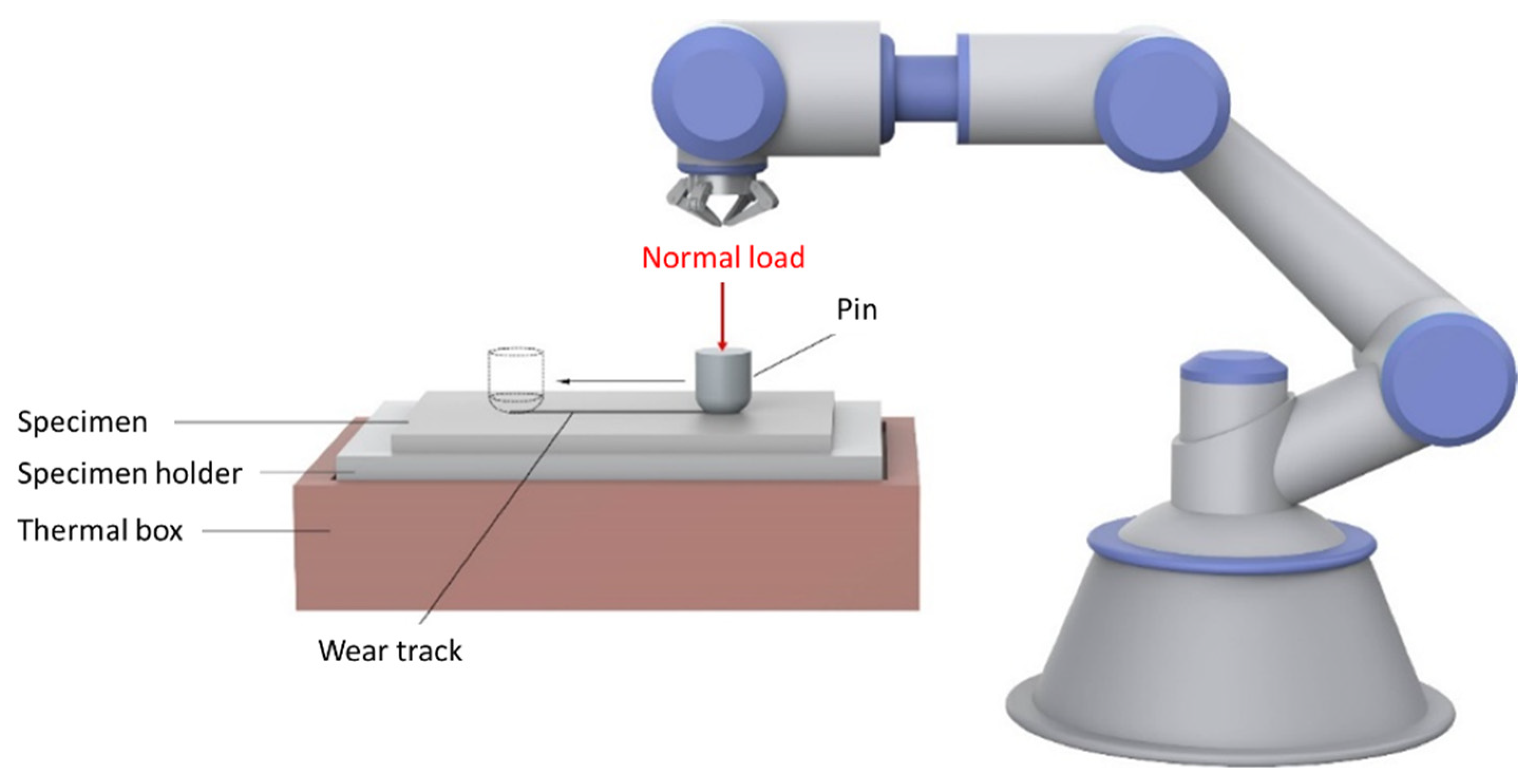

2. Methodology

3. Results and Discussion

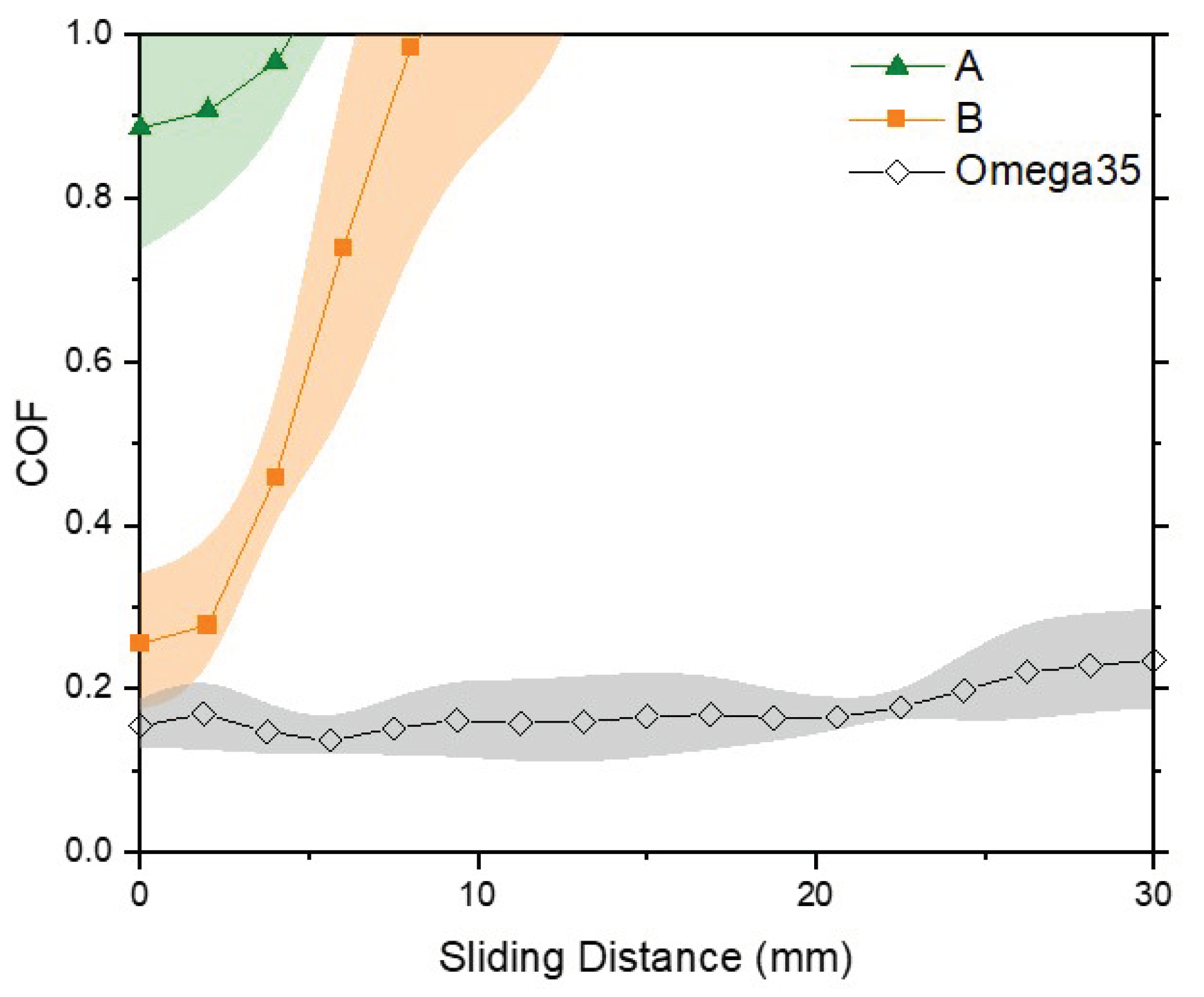

3.1. Lubricant Breakdown of Water-Graphite Two-Phase Lubricants

3.2. Comparison with Oil-Graphite Two-Phase Lubricant

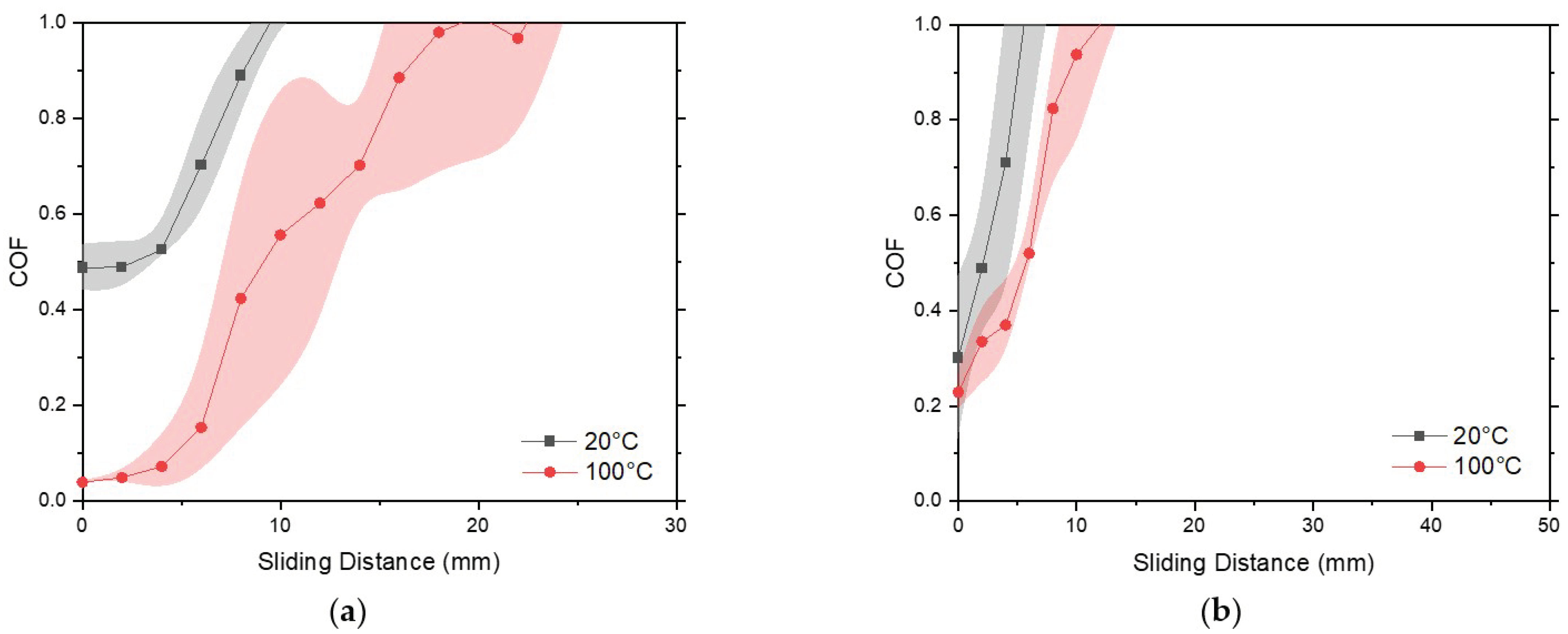

3.3. Effect of Tooling Temperatures on the Lubricant Behaviours

4. Conclusions

- The transient behaviours and breakdown phenomenon of the water-graphite based lubricants are due to the transformation of lubrication mechanisms, which is caused by both the physical diminution and chemical decomposition. The water–graphite lubricants performed better at lower workpiece temperatures.

- By comparing the 2 water-graphite lubricants to oil-graphite lubricants, both the initial COF value and lubricant breakdown distance indicated that the oil-graphite based lubricant has superior performance compared to the water–graphite lubricants. It may be because of the high viscosity and slow liquid agent evaporation for the oil-graphite lubricant.

- It was found that the increase of tooling temperature and dwelling time after the lubricant was applied on the warm tool would increase the breakdown distance and decrease the initial COF, which was likely due to the deposition of solid additives and formation of tribo-layer at the contact interface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Liu, X.; Liu, H.; Politis, D.J.; Leyvraz, D.; Wang, L. Experimental and modelling study of friction evolution and lubricant breakdown behaviour under varying contact conditions in warm aluminium forming processes. Tribol. Int. 2021, 158, 106934. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar]

- Yang, X.; Zhang, L.; Politis, D.J.; Zhang, J.; Gharbi, M.M.; Leyvraz, D.; Wang, L. Experimental and modelling studies of the transient tribological behaviour of a two-phase lubricant under complex loading conditions. Friction 2021, 10, 911–926. [Google Scholar] [CrossRef]

- Noder, J.; George, R.; Butcher, C.; Worswick, M.J. Friction characterization and application to warm forming of a high strength 7000-series aluminum sheet. J. Mater. Process. Technol. 2021, 293, 117066. [Google Scholar] [CrossRef]

- Yousif, A.E.; Nacy, S.M. Hydrodynamic behaviour of two-phase (liquid-solid) lubricants. Wear 1981, 66, 223–240. [Google Scholar] [CrossRef]

- Ding, H.; Wang, M.; Li, M.; Huang, K.; Li, S.; Xu, L.; Yang, X.; Xia, J. Synthesis of a water-soluble, rubber seed oil–based sulfonate and its tribological properties as a water-based lubricant additive. J. Appl. Polym. Sci. 2018, 135, 46119. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, L.; Politis, D.J.; Masen, M.A. Development of an interactive friction model for the prediction of lubricant breakdown behaviour during sliding wear. Tribol. Int. 2017, 110, 370–377. [Google Scholar] [CrossRef] [Green Version]

| No. | Workpiece Temperature (°C) | Contact Load (N) | Sliding Speed (mm/s) | Tool Temperature (°C) |

|---|---|---|---|---|

| 1 | 300 | 6 | 30 | 20 |

| 2 | 250 | 6 | 30 | 20 |

| 3 | 350 | 6 | 30 | 20 |

| 4 | 350 | 6 | 30 | 100 |

| 5 | 300 | 6 | 30 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Yang, X.; Zhang, Q.; Zheng, Y.; Liu, X.; Politis, D.J.; Fakir, O.E.; Wang, L. Investigation of Friction Coefficient Evolution and Lubricant Breakdown Behaviour at Elevated Temperatures in a Pin-on-Disc Sliding System. Phys. Sci. Forum 2022, 4, 11. https://doi.org/10.3390/psf2022004011

Zhang L, Yang X, Zhang Q, Zheng Y, Liu X, Politis DJ, Fakir OE, Wang L. Investigation of Friction Coefficient Evolution and Lubricant Breakdown Behaviour at Elevated Temperatures in a Pin-on-Disc Sliding System. Physical Sciences Forum. 2022; 4(1):11. https://doi.org/10.3390/psf2022004011

Chicago/Turabian StyleZhang, Lemeng, Xiao Yang, Qunli Zhang, Yang Zheng, Xiaochuan Liu, Denis J. Politis, Omer El Fakir, and Liliang Wang. 2022. "Investigation of Friction Coefficient Evolution and Lubricant Breakdown Behaviour at Elevated Temperatures in a Pin-on-Disc Sliding System" Physical Sciences Forum 4, no. 1: 11. https://doi.org/10.3390/psf2022004011

APA StyleZhang, L., Yang, X., Zhang, Q., Zheng, Y., Liu, X., Politis, D. J., Fakir, O. E., & Wang, L. (2022). Investigation of Friction Coefficient Evolution and Lubricant Breakdown Behaviour at Elevated Temperatures in a Pin-on-Disc Sliding System. Physical Sciences Forum, 4(1), 11. https://doi.org/10.3390/psf2022004011