Ohmic Heating as an Emerging Technology for the Improvement of the Techno-Functional Properties of Common Bean Flour †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biological Material

2.2. Ohmic Heating Cooking (OH)

2.3. Traditional Cooking (TC)

2.4. Crude (C)

2.5. Water Absorption Index (WAI)

2.6. Oil Absorption Capacity (OAC)

2.7. Emulsifying Capacity (EmC)

2.8. Foaming Capacity (FC)

2.9. Least Gelation Concentration (GC)

2.10. Quantification of Soluble Proteins

2.11. Lectin Quantification

2.12. Quantification of Trypsin Inhibitors

2.13. Statistical Analysis

3. Results and Discussion

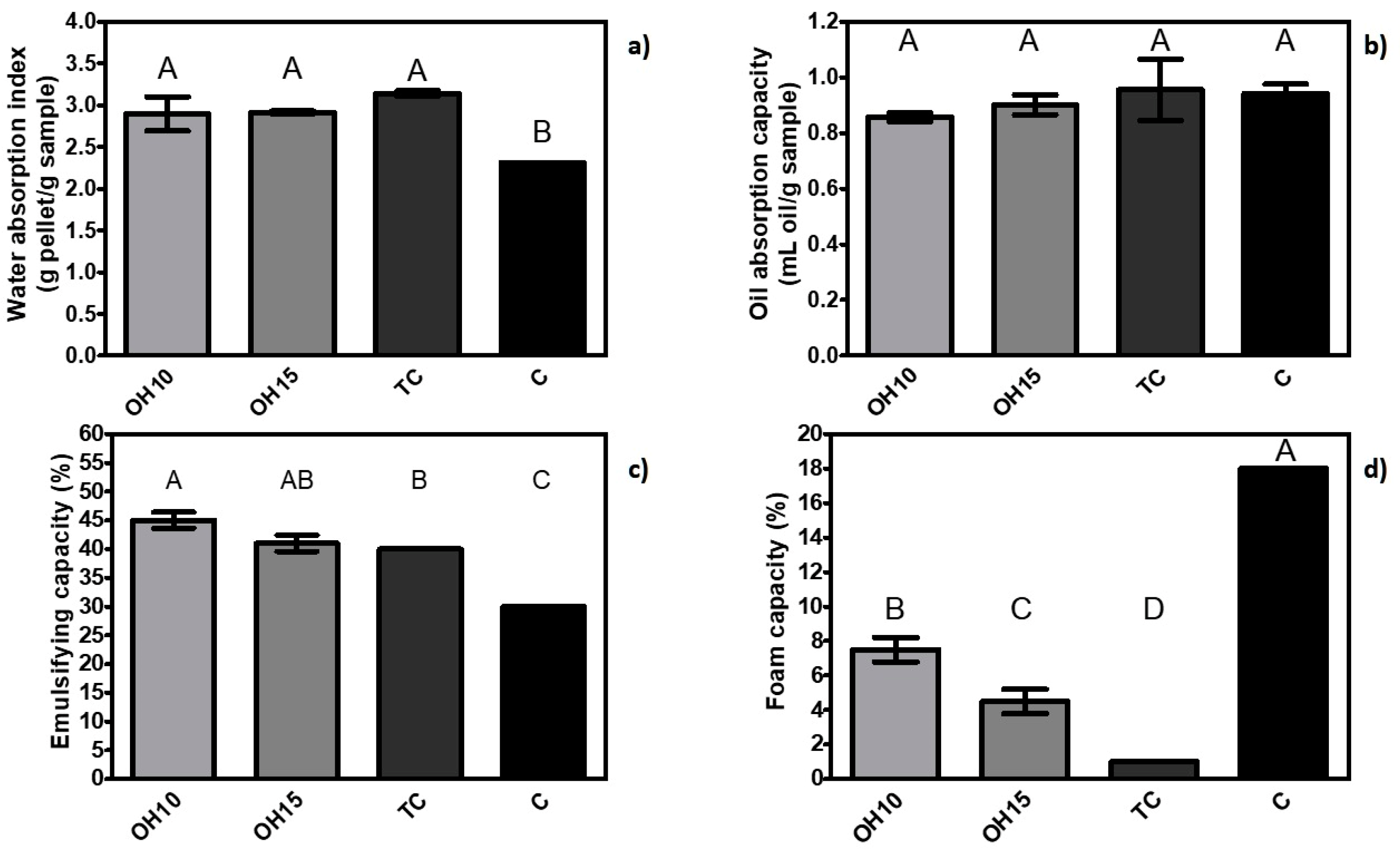

3.1. Water Absorption Index (WAI)

3.2. Oil Absorption Capacity (OAC)

3.3. Emulsifying Capacity (EmC)

3.4. Foam Capacity (FC)

3.5. Least Gelation Concentration (GC)

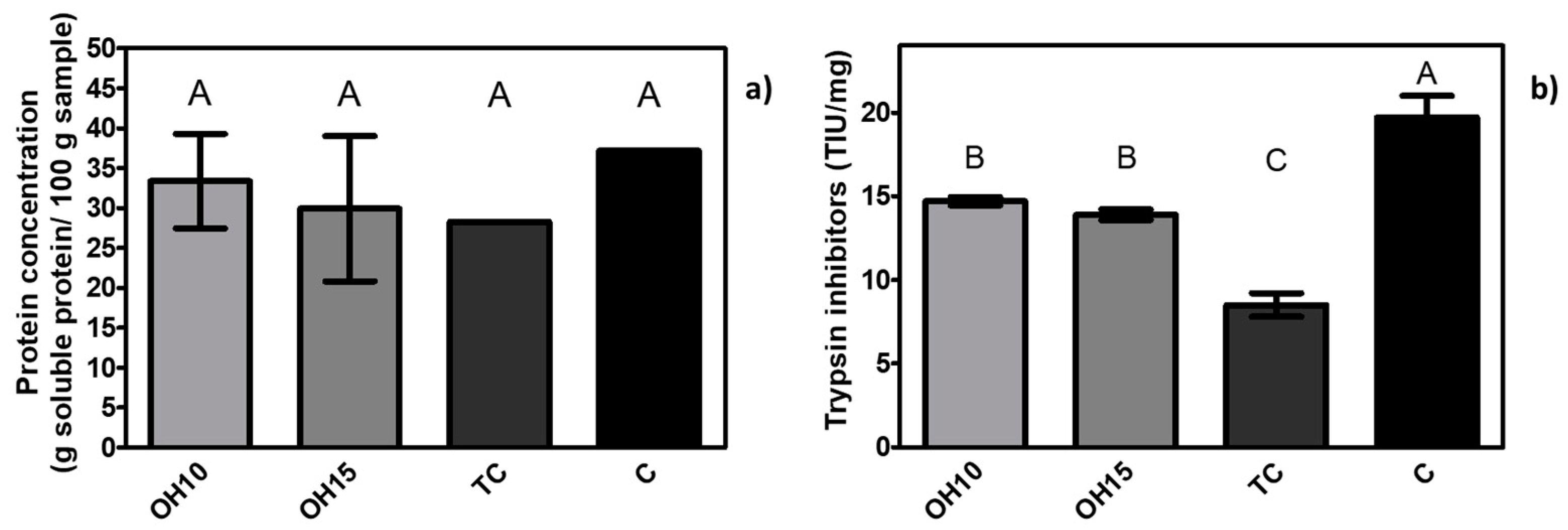

3.6. Quantification of Soluble Proteins

3.7. Quantification of Trypsin Inhibitors

3.8. Quantification of lectins

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mwaipopo, B.; Nchimbi-Msolla, S.; Njau, P.; Tairo, F.; William, M.; Binagwa, P.; Kweka, E.; Kilango, M.; Mbanzibwa, D. Viruses infecting common bean (Phaseolus vulgaris L.) in Tanzania: A review on molecular characterization, detection and disease management options. Afr. J. Agric. Res. 2017, 12, 18. [Google Scholar]

- Sparvoli, F.; Laureati, M.; Pilu, R.; Pagliarini, E.; Toschi, I.; Giuberti, G.; Bollini, R. Exploitation of common bean flours with low antinutrient content for making nutritionally enhanced biscuits. Front. Plant Sci. 2016, 7, 928. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bressani, R. Factors Influencing Nutritive Value in Food Grain Legumes: Mucuna Compared to Other Grain Legumes. Capítulo 8. En: Food and Feed from Mucuna: Current Uses and the Way Forward. In Proceedings of the International Workshop, Tegucigalpa, Honduras, 26–29 April 2002. [Google Scholar]

- Pedrosa, M.M.; Varela, A.; Domínguez-Timón, F.; Tovar, C.A.; Moreno, H.M.; Borderías, A.J.; Díaz, M.T. Comparison of Bioactive Compounds Content and Techno-Functional Properties of Pea and Bean Flours and their Protein Isolates. Plant Foods Hum. Nutr. 2020, 75, 642–650. [Google Scholar] [CrossRef] [PubMed]

- Barrón-García, O.Y.; Morales-Sánchez, E.; Gaytán-Martínez, M. Inactivation kinetics of Agaricus bisporus tyrosinase treated by ohmic heating: Influence of moderate electric field. Innov. Food Sci. Emerg. Technol. 2019, 56, 102179. [Google Scholar] [CrossRef]

- Gavahian, M.; Chu, Y.H.; Farahnaky, A. Effects of ohmic and microwave cooking on textural softening and physical properties of rice. J. Food Eng. 2019, 243, 114–124. [Google Scholar] [CrossRef]

- Knirsch, M.C.; Dos Santos, C.A.; de Oliveira Soares, A.A.M.; Penna, T.C.V. Ohmic heating—A review. Trends Food Sci. Technol. 2010, 21, 436–441. [Google Scholar] [CrossRef]

- Silva, R.; Rocha, R.S.; Ramos, G.L.P.; Xavier-Santos, D.; Pimentel, T.C.; Lorenzo, J.M.; Henrique, P.; Marcia, C.; Silvaa, C.; Esmerinob, E.A.; et al. What are the challenges for ohmic heating in the food industry? Insights of a bibliometric analysis. Food Res. Int. 2022, 157, 111272. [Google Scholar] [CrossRef] [PubMed]

- Aparicio-Fernández, X.; Manzo-Bonilla, L.; Loarca-Piña, G.F. Comparison of antimutagenic activity of phenolic compounds in newly harvested and stored common beans Phaseolus vulgaris against aflatoxin B1. J. Food Sci. 2005, 70, S73–S78. [Google Scholar] [CrossRef]

- Alfaro-Diaz, A.; Urías-Silvas, J.E.; Loarca-Piña, G.; Gaytan-Martínez, M.; Prado-Ramirez, R.; Mojica, L. Techno-functional properties of thermally treated black bean protein concentrate generated through ultrafiltration process. LWT 2021, 136, 110296. [Google Scholar] [CrossRef]

- Chandra, S.; Singh, S.; Kumari, D. Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. J. Food Sci. Technol. 2015, 52, 3681–3688. [Google Scholar] [CrossRef]

- Mojica, L.; de Mejía, E.G. Characterization and Comparison of Protein and Peptide Profiles and their Biological Activities of Improved Common Bean Cultivars (Phaseolus vulgaris L.) from Mexico and Brazil. Plant Foods Hum. Nutr. 2015, 70, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Reynoso-Camacho, R.; de Mejía, E.G.; Loarca-Piña, G. Purification and acute toxicity of a lectin extracted from tepary bean (Phaseolus acutifolius). Food Chem. Toxicol. Int. J. Publ. Br. Ind. Biol. Res. Assoc. 2003, 41, 21–27. [Google Scholar] [CrossRef]

- Granito, M.; Guerra, M.; Torres, A.; Guinand, J. Efecto del procesamiento sobre las propiedades funcionales de Vigna Sinensis. Interciencia 2004, 29, 521–526. [Google Scholar]

- Ramírez-Jiménez, A.K.; Reynoso-Camacho, R.; Mendoza-Díaz, S.; Loarca-Piña, G. Functional and technological potential of dehydrated Phaseolus vulgaris L. flours. Food Chem. 2014, 161, 254–260. [Google Scholar] [CrossRef]

- Kristinsson, H.G.; Rasco, B.A. Fish protein hydrolysates: Production, biochemical, and functional properties. Crit. Rev. Food Sci. Nutr. 2000, 40, 43–81. [Google Scholar] [CrossRef]

- Alves, J.S.; Rodrigues, A.S.; Moro, K.I.; Boeira, C.P.; Londero, P.M.; Rosa, C.S. Chemical characterization, bioactive compounds, and functional technological properties of flour from two cultivars of landrace common beans (Phaseolus vulgaris L.). Int. Food Res. J. 2019, 26, 565–572. [Google Scholar]

- Siddiq, M.; Kelkar, S.; Harte, J.B.; Dolan, K.D.; Nyombaire, G. Functional properties of flour from low-temperature extruded navy and pinto beans (Phaseolus vulgaris L.). LWT-Food Sci. Technol. 2013, 50, 215–219. [Google Scholar] [CrossRef]

- Lafarga, T.; Álvarez, C.; Bobo, G.; Aguiló-Aguayo, I. Characterization of functional properties of proteins from Ganxet beans (Phaseolus vulgaris L. var. Ganxet) isolated using an ultrasound-assisted methodology. LWT-Food Sci. Technol. 2018, 98, 106–112. [Google Scholar] [CrossRef] [Green Version]

- Habiba, R. Changes in anti-nutrients, protein solubility, digestibility, and HClextractability of ash and phosphorus in vegetable peas as affected by cooking methods. Food Chem. 2002, 77, 187–192. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Mo, H. Effects of pulsed electric fields on physicochemical properties of soybean protein isolates. LWT-Food Sci. Technol. 2007, 40, 1167–1175. [Google Scholar] [CrossRef]

- Moses, E.; Hinz, H.-J. Basic pancreatic trypsin inhibitor has unusual thermodynamic stability parameters. J. Mol. Biol. 1983, 170, 765–776. [Google Scholar] [CrossRef]

- Linsberger-Martin, G.; Weiglhofer, K.; Phuong, T.P.T.; Berghofer, E. High hydrostatic pressure influences anti-nutritional factors and in vitro protein digestibility of split peas and whole white beans. LWT-Food Sci. Technol. 2013, 51, 331–336. [Google Scholar] [CrossRef]

- Batista, K.A.; Prudêncio, S.H.; Fernandes, K.F. Changes in the Functional Properties and Anti-nutritional Factors of Extruded Hard-to-Cook Common Beans (Phaseolus vulgaris, L.). J. Food Sci. 2010, 75, C286–C290. [Google Scholar] [CrossRef] [PubMed]

| Suspension Concentration | ||||

|---|---|---|---|---|

| Sample | 4% | 8% | 12% | 14% |

| OH10 | — | X | X | X |

| OH15 | — | X | X | X |

| TC | X | X | X | X |

| C | — | — | X | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima-Becerra, I.; María, B.-A.; Dorantes-Campuzano, F.; Mojica, L.; Loarca-Piña, G.; Morales-Sánchez, E.; Ramírez-Jiménez, A.K.; Gaytán-Martínez, M. Ohmic Heating as an Emerging Technology for the Improvement of the Techno-Functional Properties of Common Bean Flour. Biol. Life Sci. Forum 2021, 6, 95. https://doi.org/10.3390/Foods2021-11000

Lima-Becerra I, María B-A, Dorantes-Campuzano F, Mojica L, Loarca-Piña G, Morales-Sánchez E, Ramírez-Jiménez AK, Gaytán-Martínez M. Ohmic Heating as an Emerging Technology for the Improvement of the Techno-Functional Properties of Common Bean Flour. Biology and Life Sciences Forum. 2021; 6(1):95. https://doi.org/10.3390/Foods2021-11000

Chicago/Turabian StyleLima-Becerra, Italia, Balbuena-Alonso María, Fernanda Dorantes-Campuzano, Luis Mojica, Guadalupe Loarca-Piña, Eduardo Morales-Sánchez, Aurea Karina Ramírez-Jiménez, and Marcela Gaytán-Martínez. 2021. "Ohmic Heating as an Emerging Technology for the Improvement of the Techno-Functional Properties of Common Bean Flour" Biology and Life Sciences Forum 6, no. 1: 95. https://doi.org/10.3390/Foods2021-11000

APA StyleLima-Becerra, I., María, B.-A., Dorantes-Campuzano, F., Mojica, L., Loarca-Piña, G., Morales-Sánchez, E., Ramírez-Jiménez, A. K., & Gaytán-Martínez, M. (2021). Ohmic Heating as an Emerging Technology for the Improvement of the Techno-Functional Properties of Common Bean Flour. Biology and Life Sciences Forum, 6(1), 95. https://doi.org/10.3390/Foods2021-11000