Effect of Alkaline Extrusion Temperature on Rheological Properties of Andean Corn Dough †

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Alkaline Extrusion of Corn Flours

2.3. Composition of Macronutrients in Processed Flours

2.4. Physicochemical Properties of Processed Flours

2.4.1. Degree of Gelatinization (DG)

2.4.2. Viscous Properties of Processed Flours

2.4.3. Subjective Water Absorption Water (SWAC)

2.5. Rheological Properties of Doughs

Textural Properties

2.6. Statistical Analysis

3. Results and Discussion

3.1. Macronutrient Composition of Processed Flours

3.2. Physicochemical Properties of Alkaline-Extruded Flours

3.2.1. Degree of Gelatinization

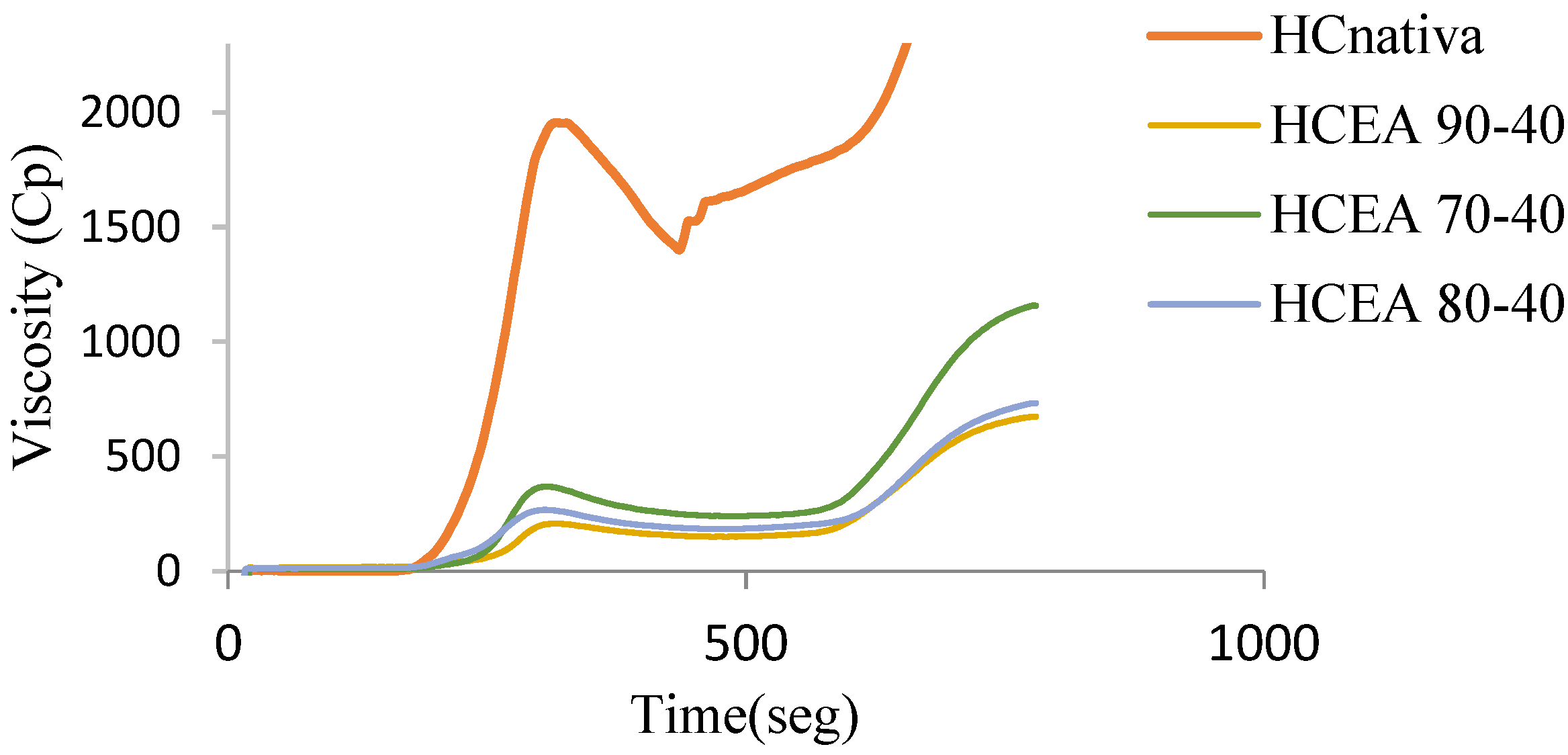

3.2.2. Viscous Properties

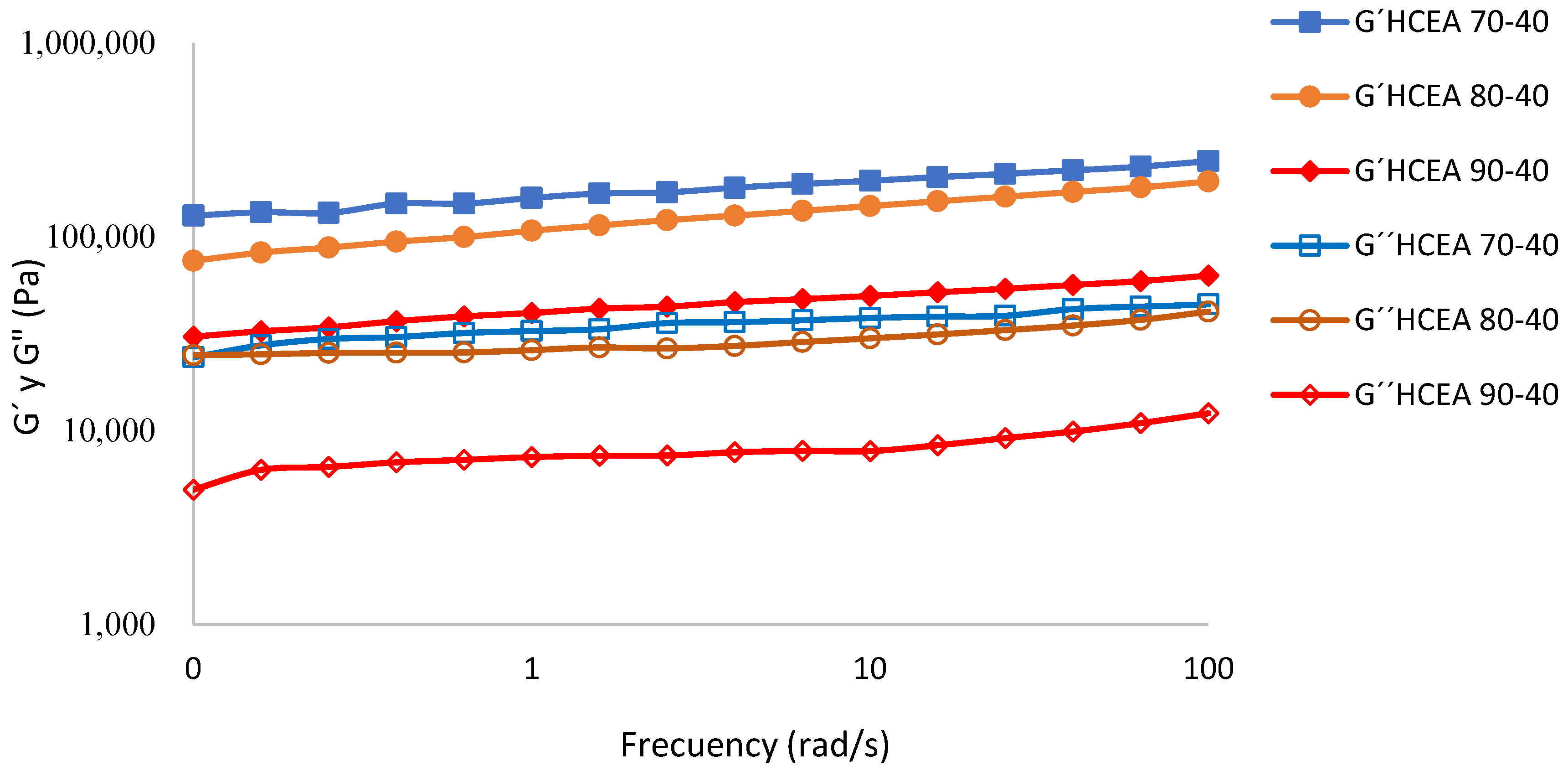

3.3. Rheological Properties

Textural Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Escalante-Aburto, A.; Mariscal-Moreno, R.M.; Santiago-Ramos, D.; Ponce-García, N. An update of different nixtamalization technologies, and its effects on chemical composition and nutritional value of corn tortillas. Food Rev. Int. 2020, 36, 456–498. [Google Scholar] [CrossRef]

- Contreras-Jiménez, B.; Gaytán-Martínez, M.; Morales-Sánchez, E.; Figueroa-Cardenas, J. Effects of tempering time, Ca (OH)2 concentration, and particle size on the rheological properties of extruded corn flour. Cereal Chem. 2017, 94, 230–236. [Google Scholar] [CrossRef]

- Enríquez-Castro, C.M.; Contreras-Jiménez, B.; Morales-Sánchez, E. Innovation in Nixtamalization by Extrusion Using the Wet Process. 2024. In Expploring the World of Cereal Crops; IntechOpen: Rijeka, Croatia, 2024. [Google Scholar] [CrossRef]

- Platt-Lucero, L.C.; Ramírez-Wong, B.; Torres-Chávez, P.I.; López-Cervantes, J. Improving textural characteristics of tortillas by adding gums during extrusion to obtain nixtamalized corn flour. J. Texture Stud. 2010, 41, 736–755. [Google Scholar] [CrossRef]

- Mohamed, I.O. Interaction of starch with some food macromolecules during the extrusion process and its effect on modulating physicochemical and digestible properties. A review. Carbohydr. Polym. Technol. Appl. 2023, 5, 100294. [Google Scholar] [CrossRef]

- AOAC. Association of Official Analytical Chemists. International. Official Methods of Analysis. Available online: www.aoac.org (accessed on 20 January 2020).

- AACC International Methods; American Association of Cereal Chemists (AACC) International: St. Paul, MN, USA, 2000.

- Tabibloghmany, F.S.; Mazaheri Tehrani, M.; Koocheki, A. Optimization of the extrusion process through response surface methodology for improvement in functional and nutritional properties of soybean hull. J. Food Sci. Technol. 2020, 57, 4054–4064. [Google Scholar] [CrossRef] [PubMed]

- Topete-Betancourt, A.; Santiago-Ramos, D.; Figueroa-Cárdenas, J. Relaxation tests and textural properties of nixtamalized corn masa and their relationships with tortilla texture. Food Biosci. 2020, 33, 100500. [Google Scholar] [CrossRef]

- Rolandelli, G.; Shan, S.; Campanella, O.H. Effects of alkalinization and addition of pea protein as a co-protein to zein for the development of gluten-free doughs. Food Hydrocoll. 2024, 146, 10931. [Google Scholar] [CrossRef]

| Muestras | Free Lipids (%) | Protein (%) | TDF (%) | IDF (%) | SDF (%) | DG (%) |

|---|---|---|---|---|---|---|

| HCEA 70-40 | 2.39 ± 0.14 b | 11.11 ± 0.14 ab | 11.23 ± 0.01 ab | 6.12 ± 0.03 a | 5.11 ± 0.01 d | 31.74 ± 0.64 a |

| HCEA 80-40 | 2.14 ± 0.16 a | 11.27 ± 0.14 bc | 11.01 ± 0.50 a | 7.70 ± 0.14 b | 3.31 ± 0.36 c | 36.47 ± 0.03 b |

| HCEA 90-40 | 2.14 ± 0.35 ab | 11.10 ± 0.04 ab | 11.85 ± 0.07 c | 9.82 ± 0.02 c | 2.03 ± 0.05 b | 71.64 ± 0.03 c |

| HC nativa | 4.08 ± 0.11 c | 11.09 ± 0.19 ab | 11.55 ± 0.25 b | 10.5 ± 0.10 d | 1.05 ± 0.14 a | ND |

| Muestras | SWAC (%) | Elasticity (mm) | Cohesive |

|---|---|---|---|

| HCEA 70-40 | 0.79 ± 0.00 b | 0.29 ± 0.00 b | 0.33 ± 0.02 b |

| HCEA 80-40 | 0.80 ± 0.00 c | 0.29 ± 0.02 b | 0.38 ± 0.04 c |

| HCEA 90-40 | 0.67 ± 0.01a | 0.26 ± 0.01 a | 0.28 ± 0.02 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominguez, N.E.; Gimenez, M.A.; Segundo, C.N.; Gremasqui, I.d.l.A.; Lobo, M.O.; Samman, N.C. Effect of Alkaline Extrusion Temperature on Rheological Properties of Andean Corn Dough. Biol. Life Sci. Forum 2024, 37, 19. https://doi.org/10.3390/blsf2024037019

Dominguez NE, Gimenez MA, Segundo CN, Gremasqui IdlA, Lobo MO, Samman NC. Effect of Alkaline Extrusion Temperature on Rheological Properties of Andean Corn Dough. Biology and Life Sciences Forum. 2024; 37(1):19. https://doi.org/10.3390/blsf2024037019

Chicago/Turabian StyleDominguez, Natalia Ester, María Alejandra Gimenez, Cristina Noemi Segundo, Ileana de los Angeles Gremasqui, Manuel Oscar Lobo, and Norma Cristina Samman. 2024. "Effect of Alkaline Extrusion Temperature on Rheological Properties of Andean Corn Dough" Biology and Life Sciences Forum 37, no. 1: 19. https://doi.org/10.3390/blsf2024037019

APA StyleDominguez, N. E., Gimenez, M. A., Segundo, C. N., Gremasqui, I. d. l. A., Lobo, M. O., & Samman, N. C. (2024). Effect of Alkaline Extrusion Temperature on Rheological Properties of Andean Corn Dough. Biology and Life Sciences Forum, 37(1), 19. https://doi.org/10.3390/blsf2024037019