Physicochemical Properties of French Fries After Several Cycles of Frying with Moringa or Olive Oil †

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Frying of the Potatoes

2.3. Analytical Determinations

2.4. Sensory Analysis

2.5. Statistical Analysis

3. Results and Discussion

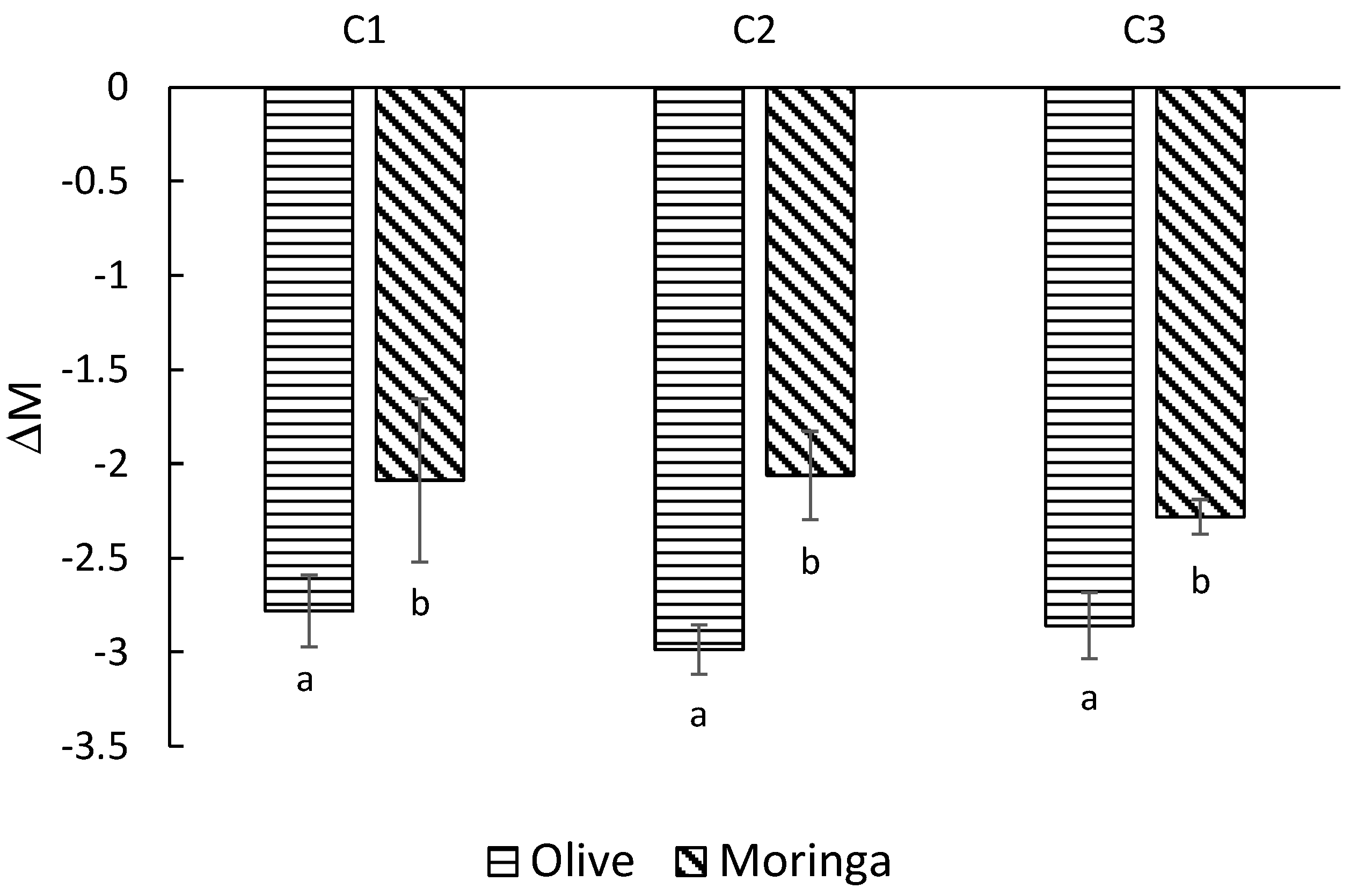

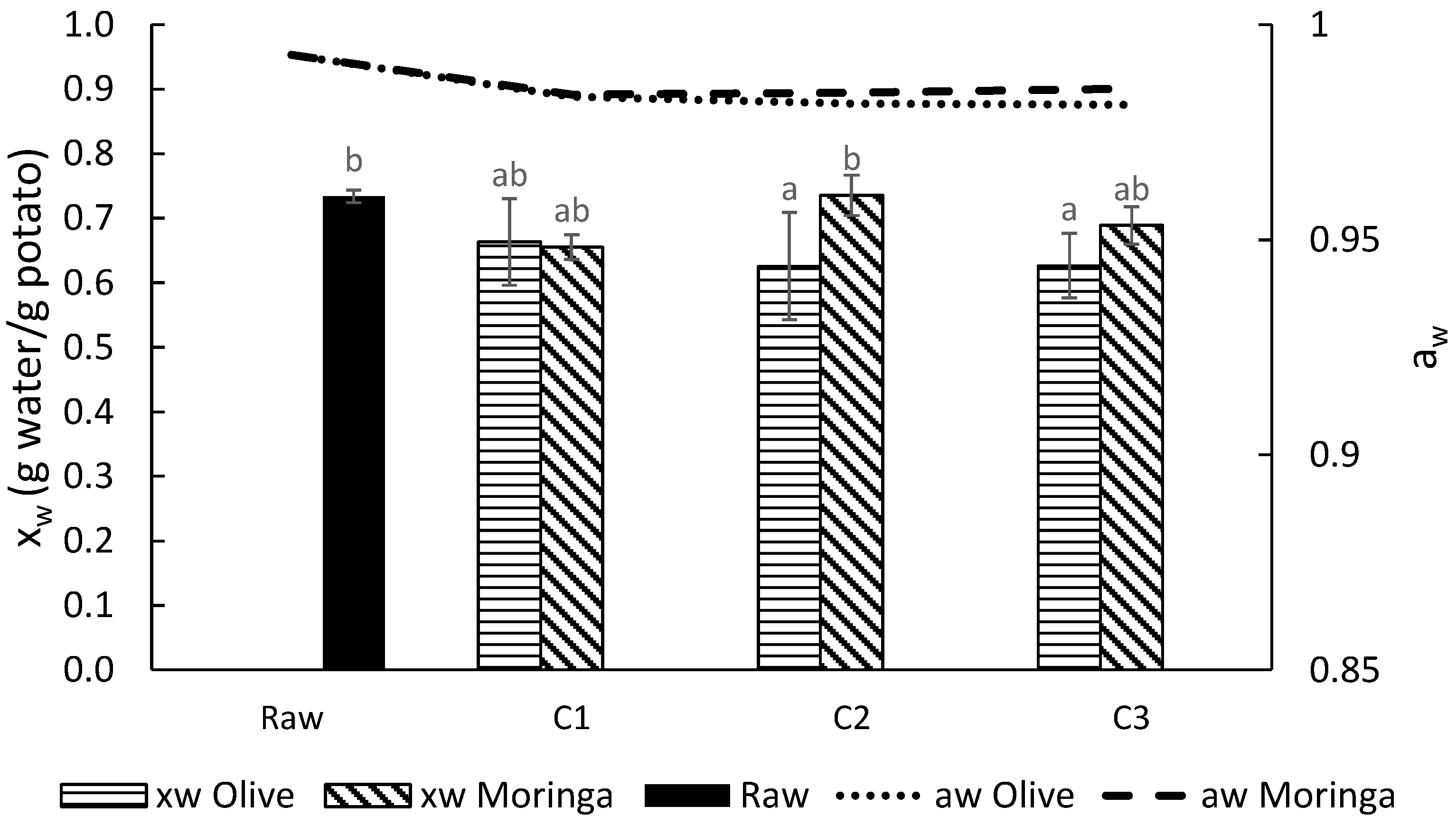

3.1. Physicochemical Properties

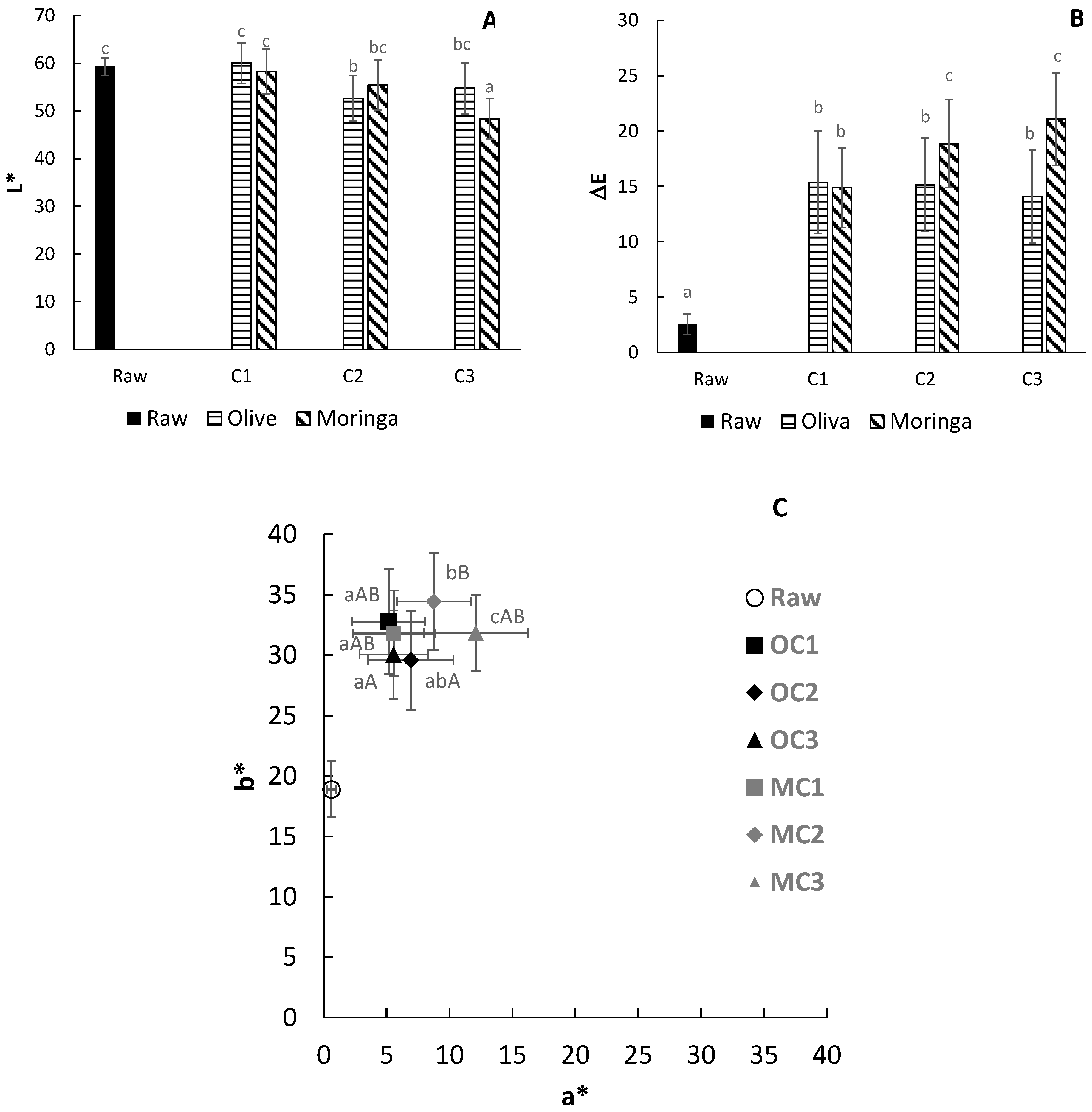

3.2. Optical Properties

3.3. Mechanical Properties

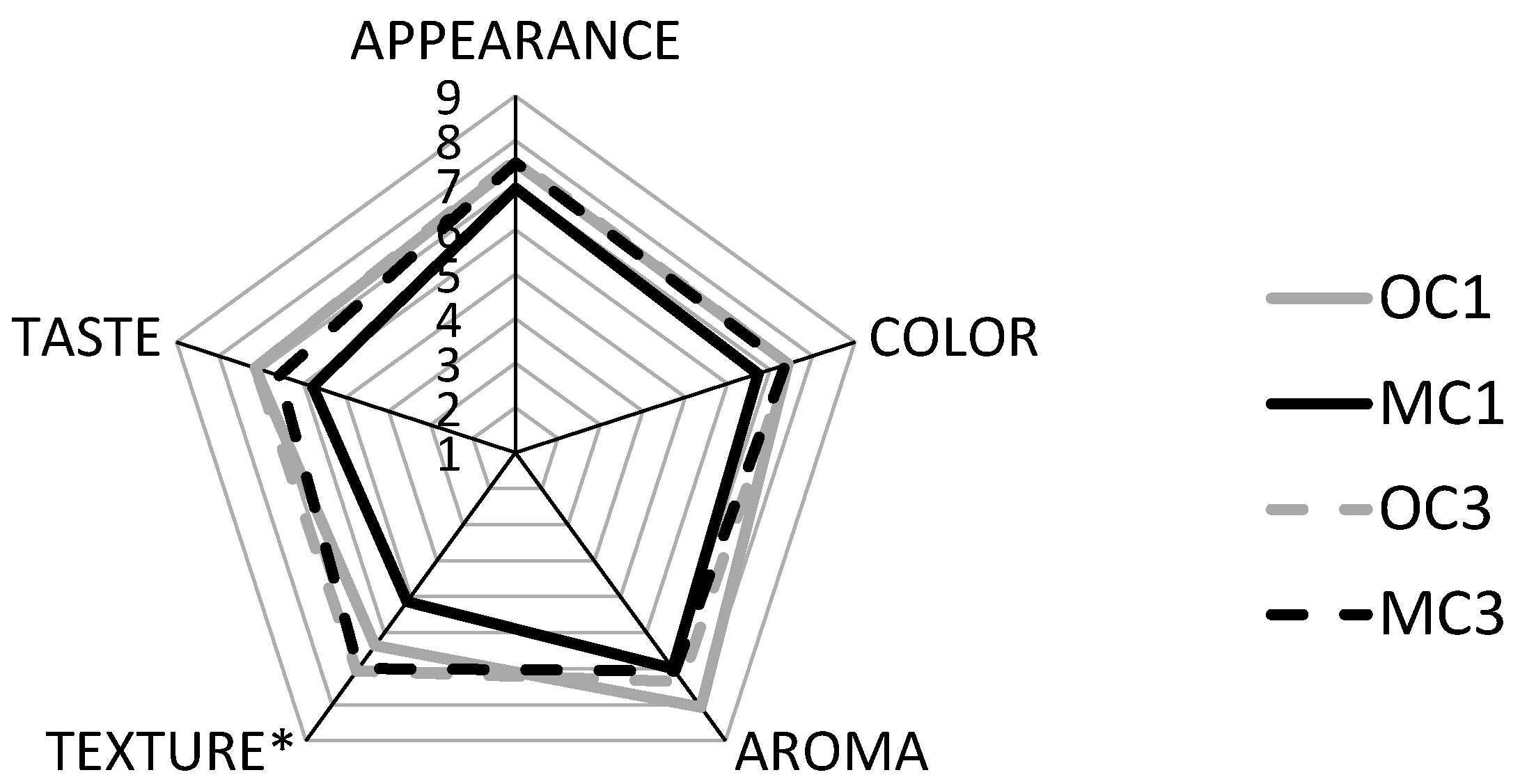

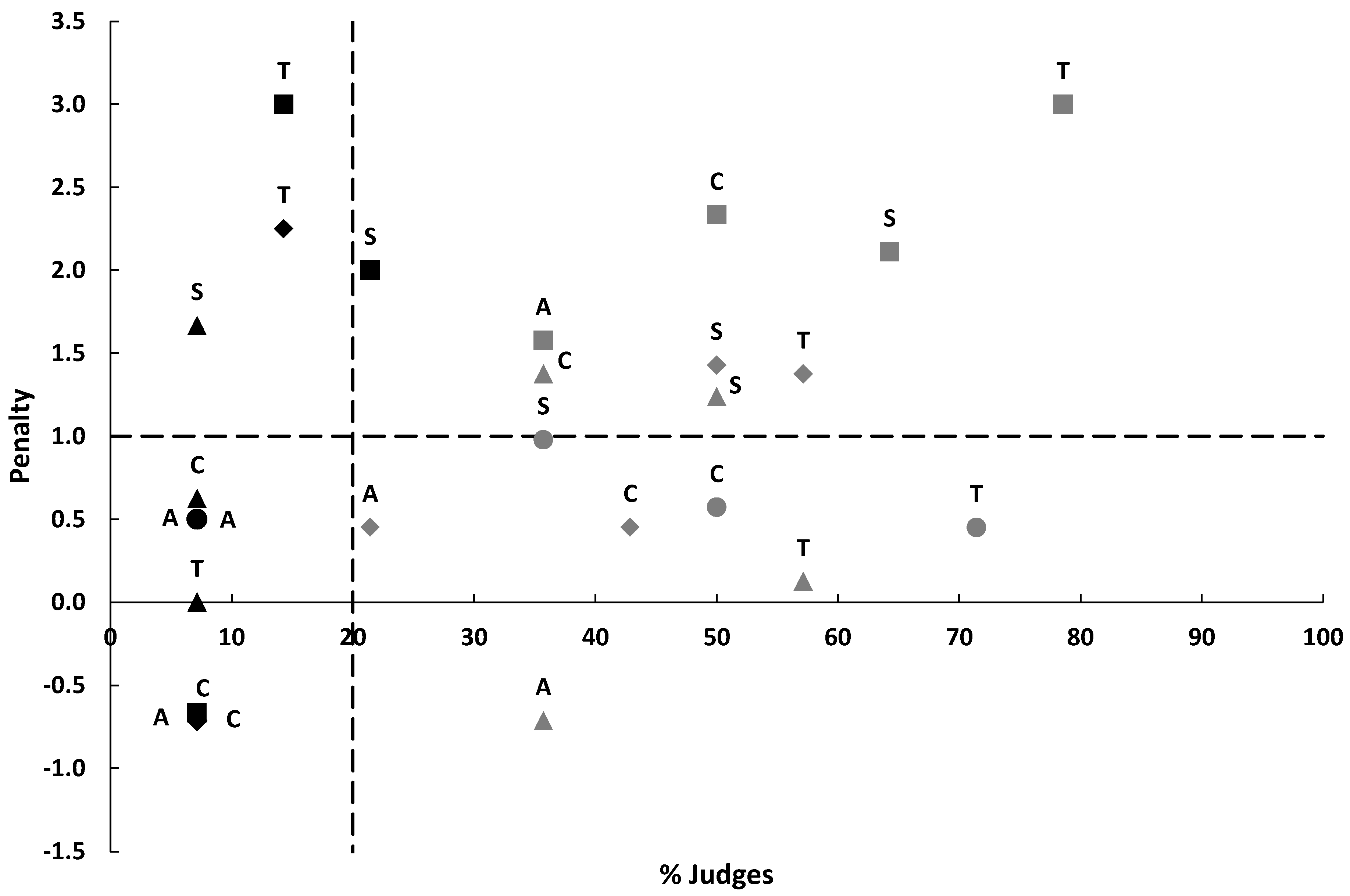

3.4. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anwar, F.; Latif, S.; Ashraf, M.; Gilani, A.H. Moringa oleifera: A Food Plant with Multiple Medicinal Uses. Phytother. Res. 2007, 21, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Su, J.; Hou, L.; Zhu, P.; Hou, Y.; Zhang, K.; Li, H.; Liu, X.; Jia, C.; Xu, J. Physicochemical and Thermal Characteristics of Moringa oleifera Seed Oil. Adv. Compos. Hybrid Mater. 2021, 4, 685–695. [Google Scholar] [CrossRef]

- Horn, L.; Shakela, N.; Mutorwa, M.K.; Naomab, E.; Kwaambwa, H.M. Moringa oleifera as a Sustainable Climate-Smart Solution to Nutrition, Disease Prevention, and Water Treatment Challenges: A Review. J. Agric. Food Res. 2022, 10, 100397. [Google Scholar] [CrossRef]

- Singh, J.; Kaur, L. (Eds.) Advances in Potato Chemistry and Technology, 4th ed.; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Wang, Y.; Wu, X.; McClements, D.J.; Chen, L.; Miao, M.; Jin, Z. Effect of New Frying Technology on Starchy Food Quality. Foods 2021, 10, 1852. [Google Scholar] [CrossRef] [PubMed]

- Santos, C.S.P.; Cruz, R.; Cunha, S.C.; Casal, S. Effect of Cooking on Olive Oil Quality Attributes. Food Res. Int. 2013, 54, 2016–2024. [Google Scholar] [CrossRef]

- UNE 87025:1996; Análisis Sensorial. Metodología. Perfil de Textura. Asociacion Española de Normalización: Madrid, Spain, 1996.

- ISO 4121:2003; Sensory Analysis—Guidelines for the Use of Quantitative Response Scales. International Organization for Standardization: Geneva, Switzerland, 2003.

- Pedreschi, F.; Segnini, S.; Dejmek, P. Evaluation of the Texture of Fried Potatoes. J. Texture Stud. 2004, 35, 277–291. [Google Scholar] [CrossRef]

- Pedreschi, F.; Moyano, P.; Kaack, K.; Granby, K. Color Changes and Acrylamide Formation in Fried Potato Slices. Food Res. Int. 2005, 38, 1–9. [Google Scholar] [CrossRef]

- Lalas, S.; Gortzi, O.; Tsaknis, J. Frying Stability of Moringa Stenopetala Seed Oil. Plant Foods Hum. Nutr. 2006, 61, 99–108. [Google Scholar] [CrossRef] [PubMed]

- Segnini, S.; Dejmek, P.; Öste, R. Reproducible Texture Analysis of Potato Chips. J. Food Sci. 1999, 64, 309–312. [Google Scholar] [CrossRef]

| Sample | Maximum Force (Newtons) | Area Under the Curve (N·s) |

|---|---|---|

| Olive C1 | 5.7 ± 1.9 b | 27 ± 10 b |

| Olive C2 | 3.3 ± 0.5 a | 12.2 ± 2.3 a |

| Olive C3 | 4.8 ± 1.9 ab | 27 ± 9 b |

| Moringa C1 | 3.8 ± 1.2 ab | 14.6 ± 6.6 a |

| Moringa C2 | 6.12 ± 1.5 b | 30 ± 8 b |

| Moringa C3 | 5.9 ± 1.7 b | 29 ± 11 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sesé, T.; Cervera-Chiner, L.; García-Mares, F.J.; Castelló, M.L.; Ortolá, M.D. Physicochemical Properties of French Fries After Several Cycles of Frying with Moringa or Olive Oil. Biol. Life Sci. Forum 2024, 37, 17. https://doi.org/10.3390/blsf2024037017

Sesé T, Cervera-Chiner L, García-Mares FJ, Castelló ML, Ortolá MD. Physicochemical Properties of French Fries After Several Cycles of Frying with Moringa or Olive Oil. Biology and Life Sciences Forum. 2024; 37(1):17. https://doi.org/10.3390/blsf2024037017

Chicago/Turabian StyleSesé, Tomás, Lourdes Cervera-Chiner, Francisco José García-Mares, María Luisa Castelló, and María Dolores Ortolá. 2024. "Physicochemical Properties of French Fries After Several Cycles of Frying with Moringa or Olive Oil" Biology and Life Sciences Forum 37, no. 1: 17. https://doi.org/10.3390/blsf2024037017

APA StyleSesé, T., Cervera-Chiner, L., García-Mares, F. J., Castelló, M. L., & Ortolá, M. D. (2024). Physicochemical Properties of French Fries After Several Cycles of Frying with Moringa or Olive Oil. Biology and Life Sciences Forum, 37(1), 17. https://doi.org/10.3390/blsf2024037017