Properties of Oil Extracted from Oat Grains before and after the Roasting Process Conducted under Different Conditions †

Abstract

:1. Introduction

2. Methods

2.1. Fat Extraction from Oat

2.2. GC Analysis

2.3. Oxidative Stability by Pressure Differential Scanning Calorimetry (PDSC) Method

2.4. Calorimetric Bomb Method

2.5. Acid Value Determination

2.6. Peroxide Value Determination

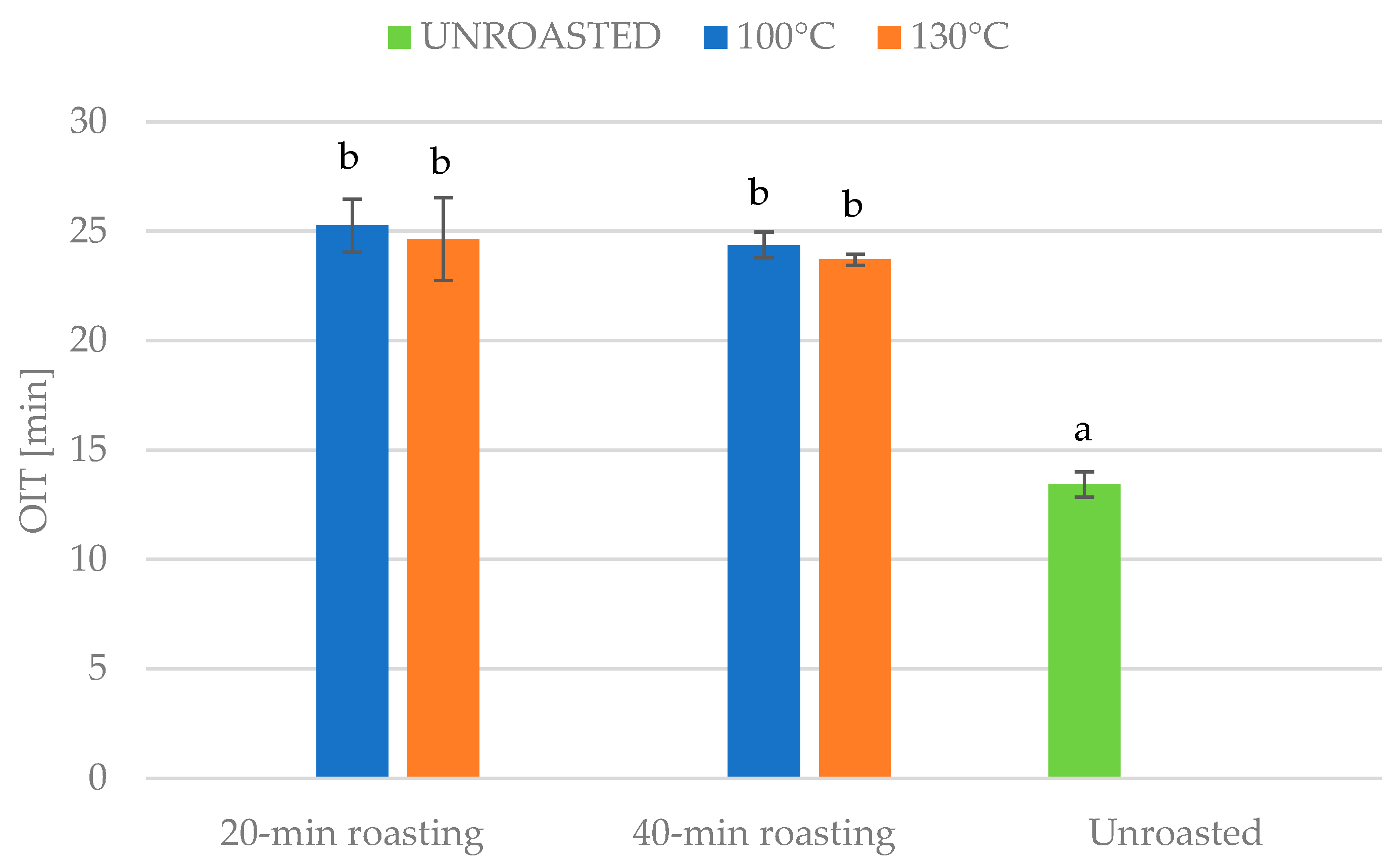

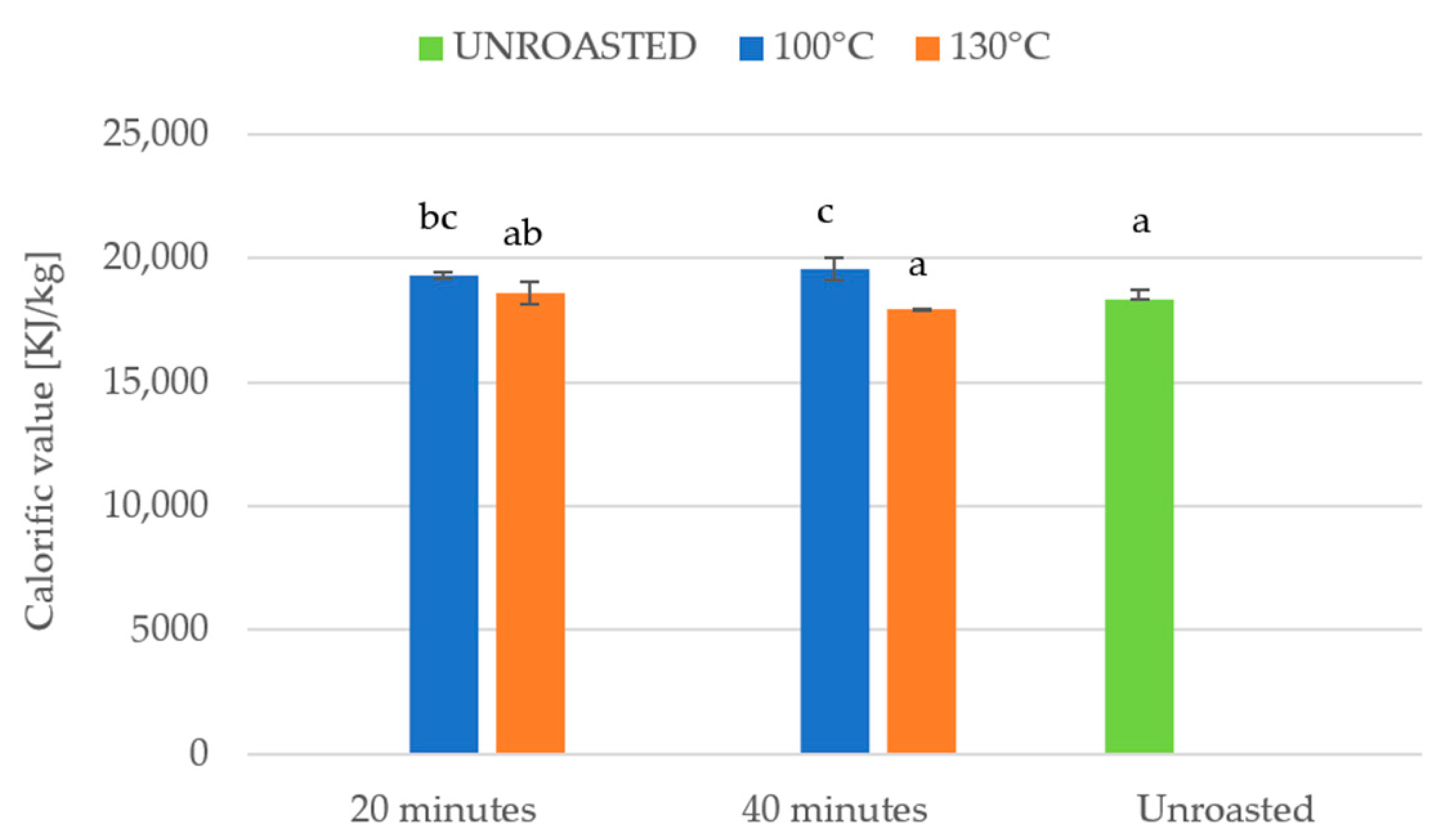

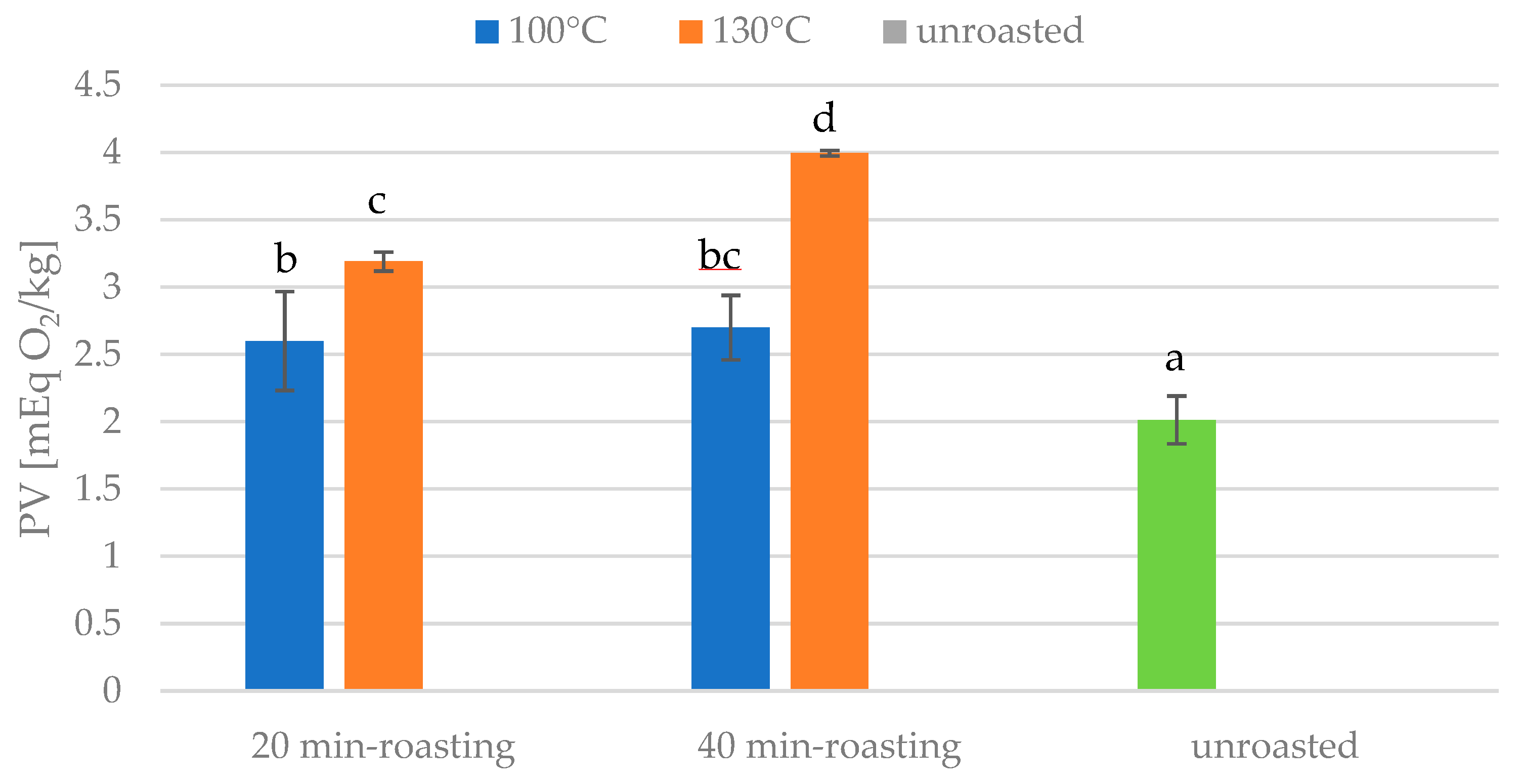

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martens, J.W. Oat Stem Rust. In Cereal Rusts; Roelfs, A.P., Bushnell, W.R., Eds.; Academic Press Inc.: London, UK, 1985; Volume 2, pp. 103–129. [Google Scholar]

- Kaur, P.; Kaur, K.; Basha, S.J.; Kennedy, J.F. Current trends in the preparation, characterization and applications of oat starch—A review. Int. J. Biol. Macromol. 2022, 212, 172–181. [Google Scholar] [CrossRef]

- Banaś, K.; Harasym, J. Current Knowledge of Content and Composition of Oat Oil—Future Perspectives of Oat as Oil Source. Food Bioprocess Technol. 2021, 14, 232–247. [Google Scholar] [CrossRef]

- Babiker, E.E.; Uslu, N.; Al Juhaimi, F.; Ahmed, I.A.M.; Ghafoor, K.; Özcan, M.M.; Almusallam, I.A. Effect of roasting on antioxidative properties, polyphenol profile and fatty acids composition of hemp (Cannabis sativa L.) seeds. LWT 2021, 139, 110537. [Google Scholar] [CrossRef]

- Boselli, E.; Velazco, V.; Caboni, M.F.; Lercker, G. Pressurized liquid extraction of lipids for the determination of oxysterols in egg-containing food. J. Chromatogr. A 2021, 917, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Dolatowska-Żebrowska, K.; Ostrowska-Ligęza, E.; Wirkowska-Wojdyła, M.; Bryś, J.; Górska, A. Characterization of thermal properties of goat milk fat and goat milk chocolate by using DSC, PDSC and TGA methods. J. Therm. Anal. Calorim 2019, 138, 2769–2779. [Google Scholar] [CrossRef]

- Bryś, J.; Vaz Flores, I.F.; Górska, A.; Wirkowska-Wojdyła, M.; Ostrowska-Ligęza, E.; Bryś, A. Use of GC and PDSC methods to characterize human milk fat substitutes obtained from lard and milk thistle oil mixtures. J. Therm. Anal. Calorim. 2017, 130, 319–327. [Google Scholar] [CrossRef]

- Symoniuk, E.; Ratusz, K.; Krygier, K. Comparison of the oxidative stability of linseed (Linum usitatissimum L.) oil by pressure differential scanning calorimetry and Rancimat measurements. J. Food Sci. Technol. 2016, 53, 3986–3995. [Google Scholar] [CrossRef] [PubMed]

- ISO Standards 1928:2009; Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of Net Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 660:2009; Animal and Vegetable Fats and Oils—Determination of Acid Value and Acidity. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 3960:2007; Animal and Vegetable Fats and Oils—Determination of Peroxide Value—Iodometric (Visual) Endpoint Determination. International Organization for Standardization: Geneva, Switzerland, 2007.

- Kamal-Eldin, A.; Pokorny, J. Lipid oxidation products and methods used for their analysis. In Analysis of Lipid Oxidation, 1st ed.; Kamal-Eldin, A., Pokorny, J., Eds.; AOCS Champaign: Urbana, IL, USA, 2005. [Google Scholar]

- Valdez, E.; Tabil, L.G.; Mupondwa, E.; Cree, D.; Moazed, H. Microwave torrefaction of oat hull: Effect of temperature and residence time. Energies 2021, 14, 4298. [Google Scholar] [CrossRef]

- Kan, A. Characterization of the fatty acid and mineral compositions of selected cereal cultivars from Turkey. Rec. Nat. Prod. 2015, 9, 124. [Google Scholar]

- Biel, W.; Bobko, K.; Maciorowski, R. Chemical composition and nutritive value of husked and naked oats grain. J. Cereal. Sci. 2009, 49, 413–418. [Google Scholar] [CrossRef]

- Van den Broeck, H.C.; Londono, D.M.; Timmer, R.; Smulders, M.J.; Gilissen, L.J.; Van der Meer, I.M. Profiling of nutritional and health-related compounds in oat varieties. Foods 2016, 5, 2. [Google Scholar] [CrossRef] [PubMed]

- Elouafy, Y.; El Idrissi, Z.L.; El Yadini, A.; Harhar, H.; Alshahrani, M.M.; AL Awadh, A.A.; Goh, K.W.; Ming, L.C.; Bouyahya, A.; Tabyaoui, M. Variations in Antioxidant Capacity, Oxidative Stability, and Physicochemical Quality Parameters of Walnut (Juglans regia) Oil with Roasting and Accelerated Storage Conditions. Molecules 2022, 27, 7693. [Google Scholar] [CrossRef] [PubMed]

- Nabloussi, A.; Hanine, H.; Harfi, M.E.; Rizki, H. Moroccan sesame: An overview of seed and oil quality. In Science within Food: Up-to-Date Advances on Research and Educational Ideas; Méndez-Vilas, A., Ed.; Food Science Series: Formatex Research Center S.L.: Badajoz, Spain, 2017; pp. 168–175. [Google Scholar]

| Fatty Acid | Unroasted | 100 °C/20 min | 100 °C/40 min | 130 °C/20 min | 130 °C/40 min |

|---|---|---|---|---|---|

| C14:0 | 0.23 ± 0.14 | 0.35 ± 0.01 | 0.55 ± 0.30 | 0.35 ± 0.01 | 0.40 ± 0.08 |

| C16:0 | 17.73 ± 0.35 | 16.26 ± 0.08 | 19.04 ± 4.99 | 16.12 ± 0.35 | 16.29 ± 0.25 |

| C16:1 | 0.240 ± 0.001 | 0.32 ± 0.01 | 0.38 ± 0.09 | 0.32 ± 0.02 | 0.34 ± 0.01 |

| C18:0 | 1.89 ± 0.14 | 1.380 ± 0.001 | 1.28 ± 0.17 | 1.35 ± 0.03 | 1.39 ± 0.10 |

| C18:1 n-9 | 42.10 ± 0.18 | 37.00 ± 0.02 | 35.95 ± 2.40 | 37.02 ± 0.14 | 37.41 ± 0.46 |

| C18:2 n-6 | 34.62 ± 0.13 | 40.090 ± 0.007 | 38.29 ± 2.28 | 39.99 ± 0.10 | 38.68 ± 1.56 |

| C18:3 n-3 | 1.20 ± 0.01 | 2.03 ± 0.01 | 1.84 ± 0.22 | 2.06 ± 0.01 | 1.94 ± 0.08 |

| C20:0 | 0.31 ± 0.01 | 0.19 ± 0.01 | 0.23 ± 0.04 | 0.19 ± 0.04 | 0.32 ± 0.14 |

| C20:1 | 1.68 ± 0.04 | 1.16 ± 0.02 | 1.16 ± 0.23 | 1.18 ± 0.64 | 1.51 ± 0.52 |

| Others | 1.080 ± 0.001 | 1.19 ± 0.07 | 1.26 ± 0.16 | 1.410 ± 0.001 | 1.70 ± 0.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palani, B.K.; Bryś, J.; Gruczyńska-Sękowska, E.; Bryś, A.; Koczoń, P. Properties of Oil Extracted from Oat Grains before and after the Roasting Process Conducted under Different Conditions. Biol. Life Sci. Forum 2023, 26, 66. https://doi.org/10.3390/Foods2023-15044

Palani BK, Bryś J, Gruczyńska-Sękowska E, Bryś A, Koczoń P. Properties of Oil Extracted from Oat Grains before and after the Roasting Process Conducted under Different Conditions. Biology and Life Sciences Forum. 2023; 26(1):66. https://doi.org/10.3390/Foods2023-15044

Chicago/Turabian StylePalani, Bharani Kumar, Joanna Bryś, Eliza Gruczyńska-Sękowska, Andrzej Bryś, and Piotr Koczoń. 2023. "Properties of Oil Extracted from Oat Grains before and after the Roasting Process Conducted under Different Conditions" Biology and Life Sciences Forum 26, no. 1: 66. https://doi.org/10.3390/Foods2023-15044

APA StylePalani, B. K., Bryś, J., Gruczyńska-Sękowska, E., Bryś, A., & Koczoń, P. (2023). Properties of Oil Extracted from Oat Grains before and after the Roasting Process Conducted under Different Conditions. Biology and Life Sciences Forum, 26(1), 66. https://doi.org/10.3390/Foods2023-15044