Abstract

Climate change requires a transition to crops that need less water and are more tolerant of high temperatures. In this regard, the adaptation of Moringa oleifera to the Spanish Mediterranean Basin offers the sustainable alternative production of a plant with a high nutritional value. It might also serve as a substitute crop with significant economic potential in less developed tropical regions in the world. Moreover, to provide the market with a homogeneous product, the stabilization of the leaves is necessary. The lack of control in the traditional form of moringa leaf drying (which only makes use of shade and air) does not guarantee a final homogeneous water content that can extend the crop’s shelf life. Consequently, the purpose of this study was to develop a modular, affordable, and expandable dryer that enables the dehydration of leaves in the same field, lowering production costs in the process. The drying kinetics of leaves from crops of different ages (1 and 4 years) have been fitted to several mathematical models, using the “field dryer” and a semi-industrial tray dryer. In addition, their physicochemical properties were also compared. The outcomes demonstrate the viability of the field dryer’s design. The drying kinetics of both dryers were more effectively adapted to the logarithmic model. Due to the variable air conditions in the field, the equilibrium moisture level attained was somewhat greater using the field dryer than using the tray dryer, but the product color and antioxidant and protein contents were similar. Finally, younger plants produced leaves with greater antioxidant capacities and a lower final water content.

1. Introduction

Moringa leaves contain many essential nutrients, e.g., vitamins, minerals, amino acids, beta-carotene, antioxidants, anti-inflammatory, anti-nutrients, and omega 3 and 6 fatty acids [1]. Drying these leaves is a common technique designed to extend their shelf life and also to guarantee homogeneous conditions for the introduction of dried moringa leaf powder in other food matrices, mainly in the bakery sector [2]. Furthermore, this powder can be used as a fortifier, in fish feed, or in livestock fodder [3].

The aim of this study was to model the drying kinetics of moringa leaves from 1- or 4-year-old crops using a field dryer or a tray dryer. In addition, the color, protein content, and antioxidant capacity were recorded.

2. Materials and Methods

2.1. Raw Materials

Moringa oleifera leaves collected during the months of October and November 2021 from specimens planted in 2016 and 2021, in the experimental plot of the Universitat Politècnica de València, Spain, were used for this research.

2.2. Drying Conditions and Equipment

In order to stabilize and prolong the shelf life of the moringa leaves, they were subjected to two types of dehydration for 30 h: in a tray dryer with a controlled relative humidity (35%) and temperature (40 °C) (Pol-Eko Aparatura, Clk 750 Top+), using 0.67 kg of moringa leaves/m2 tray; and in a field dryer designed in a modular format. Specifically, it comprised two overlapping plastic pallet boxes perforated at the base, a lid, a retractable tube for air removal, an air extraction fan, an air heater (Voltomat Heating Industrial Heater), a temperature controller thermostat (HiLetgo XH-W3001 220V Digital LED Temperature Controller Thermostat), a temperature probe, a plug-in timer, a plastic tarpaulin, microperforated baskets, and dataloggers for recording the temperature and relative humidity values.

2.3. Drying Modeling

The drying kinetics were adjusted to the different models selected because they had been used in other vegetable products [4], in which the driving force * was related to the time (t) by means of different coefficients. For this purpose, the variations in the weight and moisture of the leaves were obtained at different drying times (0, 1, 2, 3, 5, 7, 24, 26, 28, and 30 h).

* Xw is the amount of water in dry basis, e is equilibrium, 0 denotes the initial conditions, and t is the time.

2.4. Analytical Determinations

The moisture content of moringa leaves was determined via a gravimetric method, and their protein content was obtained via Kjeldahl methodology. Furthermore, the antioxidant capacity was registered via DPPH, and the CIEL*a*b* coordinates were recorded using a spectrophotometer (“Konica Minolta” Inc. Model CM—3600d, Tokyo, Japan) with a reference illuminant D65 and a 10° observer.

2.5. Statistical Analysis

Statgraphics Centurion software was used for the statistical analysis of the results. ANOVA (analysis of variance) was performed using the LSD (least significant difference) test at a significance level of 95% (p-value ≤ 0.05).

3. Results and Discussion

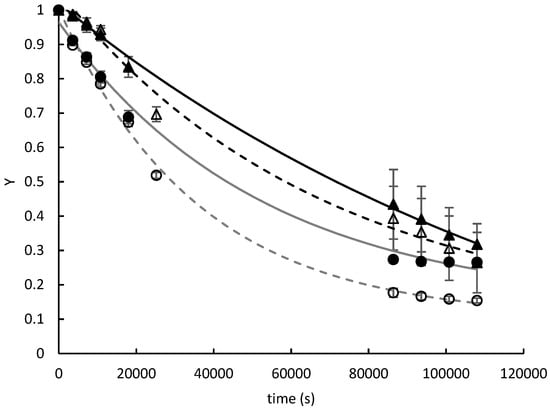

Figure 1 shows the experimental values of the driving forces with respect to the time in the moringa leaf drying process using both dryers and with moringa crops of differing ages, along with the fitting of the logarithmic model (Y = a·e−kt + c), which exhibited the highest R2 (≥99% for the tray dryer and ≥96% for the field dryer). Focusing on its parameters (Table 1), we can see that the value of k (the drying constant) was higher for leaves dried in the field dryer than in the tray dryer, without any effect from the plantation age. As this parameter is associated with the effect of external conditions on drying, the greater variability in these conditions is evident in the field dryer. As was expected, the drying kinetic in the field dryer was slightly slower than in the tray dryer, as the temperature conditions were not as homogeneous at night. Thus, the moisture content in the moringa leaves after 30 h in the field dryer was ≈48%, whereas in the tray dryer, it was ≈40%. Furthermore, the younger the crop, the lower the water content in the leaves at the end of the drying process.

Figure 1.

Evolution of the driving force (Y) versus drying time (s) of moringa leaves: the logarithmic model (continuous lines, 4-year-old moringa; dashed lines, 1-year-old moringa; black, field dryer; grey, tray dryer) and experimental points (triangles, field dryer; circles, tray dryer; filled symbols, 4-year-old moringa; empty symbols, 1-year-old moringa). Y, the driving force.

Table 1.

The parameters of the logarithmic model for the drying kinetics of moringa leaves.

The protein content of the fresh moringa leaves was 10.8 ± 0.5%, with no significant differences as a result of the plantation age. After dehydration, a protein content of about 40% was reached, and neither the type of the dryer nor the age of the plantation was found to have a significant effect.

The % of DPPH inhibition was significantly higher in the dried moringa leaves from 1-year-old crops (≈50%) than from 4-year-old crops, and the type of dryer used had no significant effect.

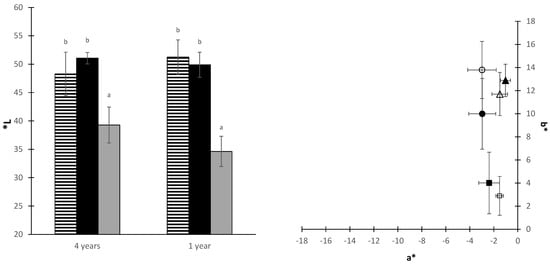

Figure 2 shows the values of the CIELa*b* coordinates of the dried moringa leaves used in this study. Drying, regardless of the method and the crop age, increased the luminosity of the samples. The leaf color was placed in the second quadrant of the chromatic diagram, which corresponds to the area of yellows and greens. The fresh leaves exhibited a lower color purity, as they were located more in the center of the diagram. The difference between the field-dried and tray-dried leaves was less marked, with the latter being more greenish in tone.

Figure 2.

The luminosity (L*) (bars with horizontal lines, tray dryer; black bars, field dryer; grey bars, fresh leaves) and the location in the chromatic diagram (b* vs. a*) of the moringa dried leaves in this study (square, fresh leaves; triangles, field dryer; circles, tray dryer; filled symbols, 4-year-old moringa; empty symbols, 1-year-old moringa). Identical letters indicate homogeneous groups obtained in the ANOVA with n.s: 95%.

4. Conclusions

A modular and economical dryer placed in the same field in which moringa is produced could be a feasible way to enhance a circular economy, although the equilibrium humidity reached in the moringa leaves was slightly higher than that obtained using the tray dryer because the air conditions were less homogeneous throughout the process. A logarithmic model is useful for the purposes of estimating the proper drying time. The dehydrated moringa leaves registered a high antioxidant capacity, especially the leaves from the 1-year-old plantation, with the type of dryer having no effect. Due to the high protein content of dried moringa leaves (≈40%), they could be incorporated into different food matrices to improve the nutritional level. Finally, dehydration increased the luminosity and color purity of moringa leaves.

Author Contributions

Conceptualization, M.D.O., J.F.G.-M., M.D.S. and M.L.C.; methodology, J.F.G.-M. and B.M.; validation, M.D.O. and M.L.C.; formal analysis, B.M., M.D.O. and M.L.C.; investigation, B.M. and J.F.G.-M.; resources B.M., M.D.O., M.L.C.; data curation, M.D.O. and M.L.C.; writing—original draft preparation, B.M..; writing—review and editing, M.D.O. and M.L.C.; supervision, M.D.O., M.L.C., J.F.G.-M. and M.D.S. funding acquisition, M.D.O., M.D.S. and M.L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the project “Mejora de la producción y calidad de hojas de moringa en Paraguay para contribuir al aporte nutricional de grupos desfavorecidos (MORNUPAY)” (Ref. AD2115—Centre for Development Cooperation (CCD)—Universitat Politècnica de València, Spain). The APC was funded by la ValSe-Food grant (119RT0567).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request from the authors.

Acknowledgments

The authors thank the support provided by the Universitat Politècnica de València and la ValSe-Food.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Essa, M.M.; Subash, S.; Parvathy, S.; Meera, A.; Guillemin, G.J.; Memon, M.A.; Manivasagam, T. Brain health benefits of Moringa oleifera. Food Brain Health 2014, 2, 113–118. [Google Scholar]

- El-Gammal, R.; Ghoneim, G.; ElShehawy, S. Effect of Moringa Leaves Powder (Moringa oleifera) on Some Chemical and Physical Properties of Pan Bread. J. Food Dairy Sci. 2016, 7, 307–314. [Google Scholar] [CrossRef]

- Abd El-Hack, M.E.; Alagawany, M.; Elrys, A.S.; Desoky, E.S.M.; Tolba, H.M.N.; Elnahal, A.S.M.; Elnesr, S.S.; Swelum, A.A. Effect of forage Moringa oleifera L. (Moringa) on animal health and nutrition and its beneficial applications in soil, plants and water purification. Agriculture 2018, 8, 145. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Nawi, N.M.; Abdan, K. Modeling the Thin-Layer Drying of Fruits and Vegetables: A Review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).