Microwave Expansion Kinetics of Third-Generation Extruded Corn Pellets under Different Moisture Contents †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Corn 3G Extruded Pellets

2.2. Microwave Expansion

2.2.1. Microwave Dehydration-Kinetics

2.2.2. Microwave Expansion-Kinetics

2.3. Statistical Analysis

3. Results and Discussion

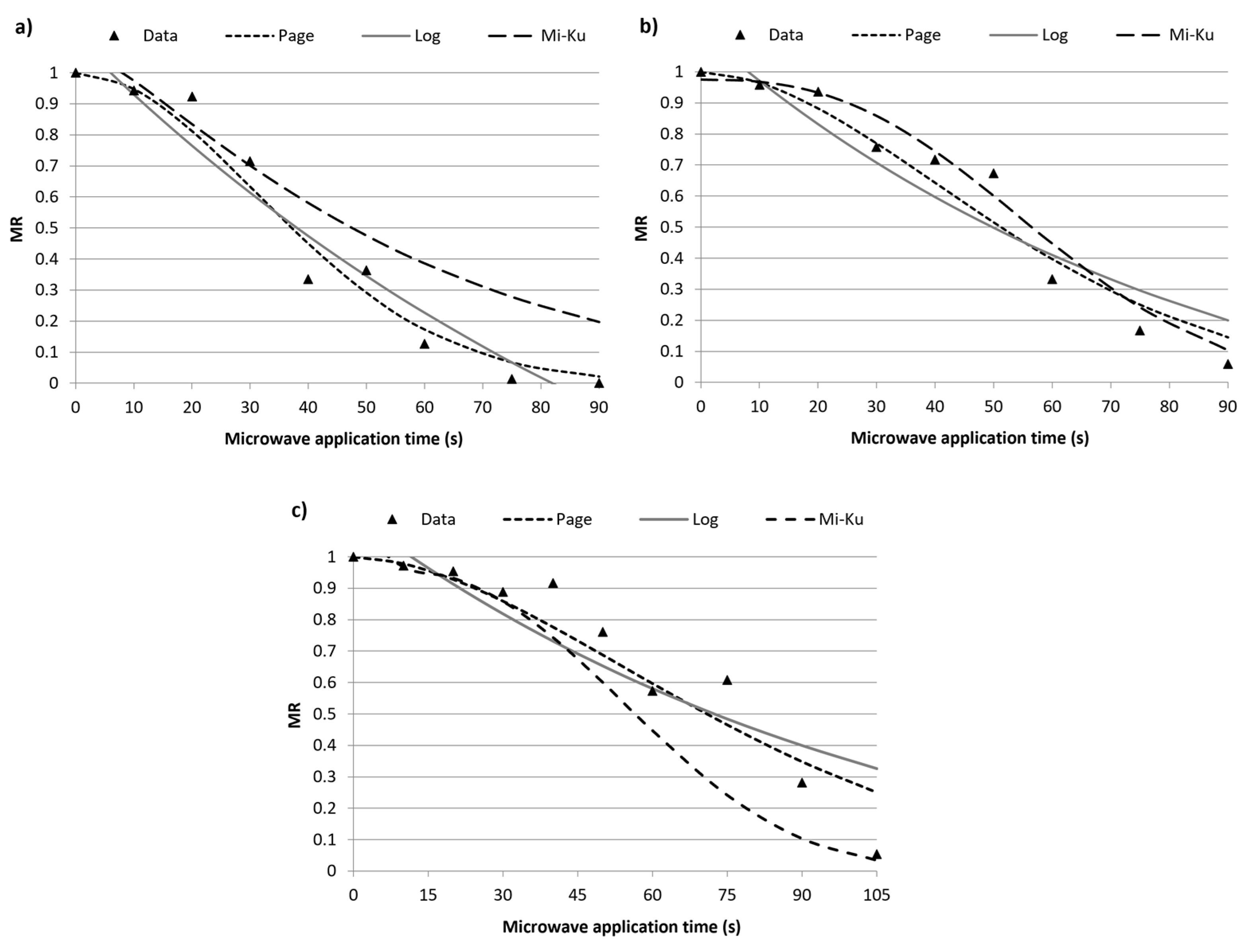

3.1. Microwaving Dehydration Kinetic. Mathematical Modeling

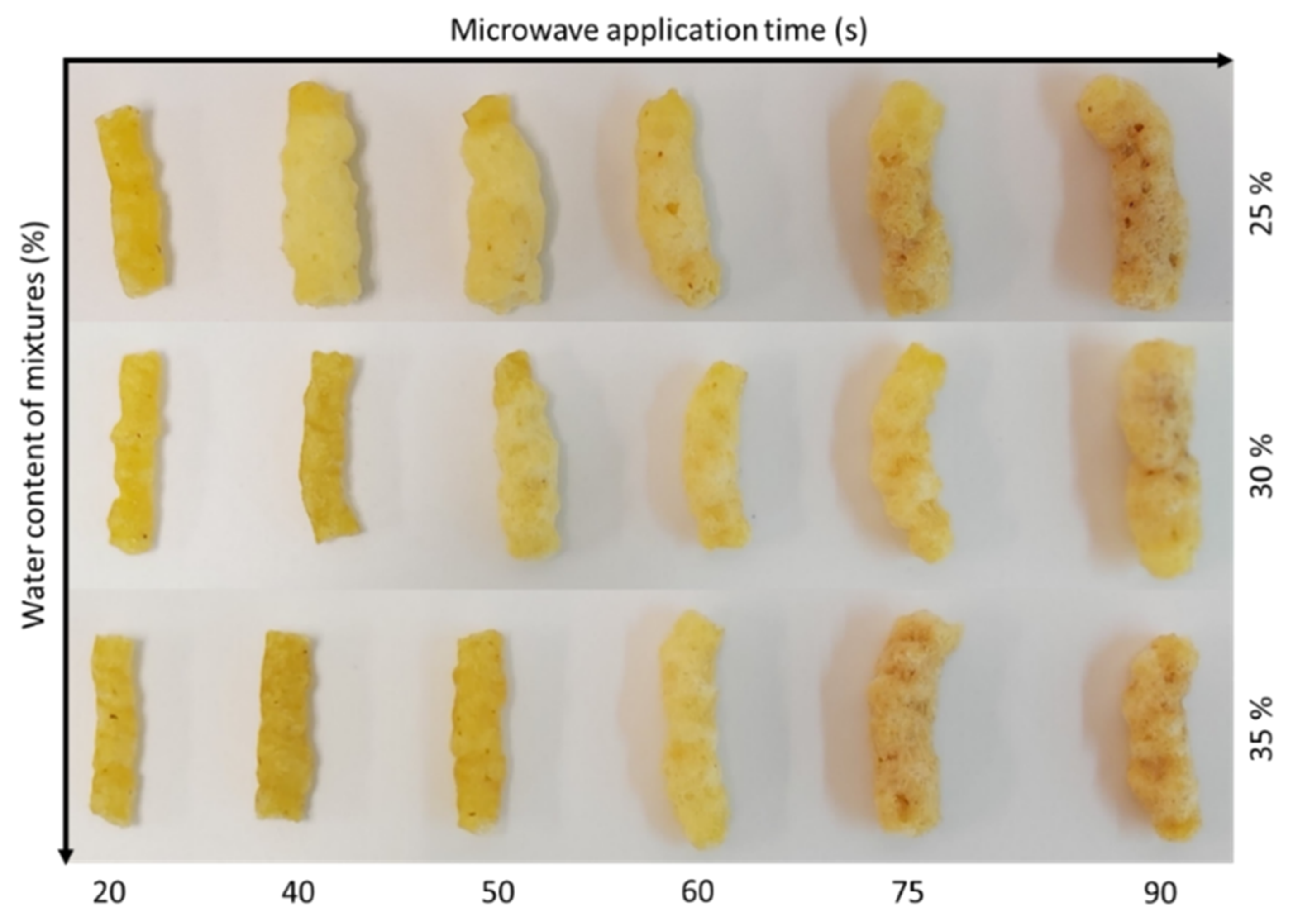

3.2. Sectional Expansion Index (SEI) and Volumetric Expansion Index (VEI) and Appearance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kraus, S.; Sólyom, K.; Schuchmann, H.P.; Gaukel, V. Drying kinetics and expansion of non-predried extruded starch-based pellets during microwave vacuum processing. J. Food Process Eng. 2013, 36, 763–773. [Google Scholar] [CrossRef]

- Tang, J. Unlocking potentials of microwaves for food safety and quality. J. Food Sci. 2015, 80, E1776–E1793. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, J.D.; Catalá-Civera, J.M.; Bows, J.; Peñaranda-Foix, F.L. Dynamic measurement of dielectric properties of food snack pellets during microwave expansion. J. Food Eng. 2017, 202, 1–8. [Google Scholar] [CrossRef]

- Neder-Suárez, D.; Quintero-Ramos, A.; Meléndez-Pizarro, C.O.; de Jesús Zazueta-Morales, J.; Paraguay-Delgado, F.; Ruiz-Gutiérrez, M.G. Evaluation of the physicochemical properties of third-generation snacks made from blue corn, black beans, and sweet chard produced by extrusion. LWT 2021, 146, 111414. [Google Scholar] [CrossRef]

- Arimi, J.M.; Duggan, E.; O’Sullivan, M.; Lyng, J.G.; O’Riordan, E.D. Effect of moisture content and water mobility on microwave expansion of imitation cheese. Food Chem. 2010, 121, 509–516. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, M.; Gao, R.; Xue, L.; Gao, F.; Shen, L.; Zheng, X. Effects of process parameters on texture quality of blue honeysuckle berry snack under continuous microwave puffing conditions. J. Food Process Preserv. 2021, 45, e16047. [Google Scholar] [CrossRef]

- Babu, A.K.; Kumaresan, G.; Raj, V.A.A.; Velraj, R. Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew. Sustain. Energy Rev. 2018, 90, 536–556. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Nawi, N.M.; Abdan, K. Modeling the thin-layer drying of fruits and vegetables: A review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef] [PubMed]

- Igual, M.; Cebadera, L.; Cámara, R.M.; Agudelo, C.; Martínez-Navarrete, N.; Cámara, M. Novel ingredients based on grapefruit freeze-dried formulations: Nutritional and bioactive value. Foods 2019, 8, 506. [Google Scholar] [CrossRef] [PubMed]

- Patil, R.T.; Berrios, J.d.J.; Tang, J.; Swanson, B.G. Evaluation of methods for expansion properties of legume extrudates. Appl. Eng. Agric. 2007, 23, 777–783. [Google Scholar] [CrossRef]

- Umbach, S.L.; Davis, E.A.; Gordon, J.; Callaghan, P.T. Water self-diffusion coefficients and dielectric properties determined for starch-gluten-water mixtures heated by microwave and by conventional methods. Cereal Chem. 1992, 69, 637–642. [Google Scholar]

- Simpson, R.; Ramírez, C.; Nuñez, H.; Jaques, A.; Almonacid, S. Understanding the success of Page’s model and related empirical equations in fitting experimental data of diffusion phenomena in food matrices. Trends Food Sci. Technol. 2017, 62, 194–201. [Google Scholar] [CrossRef]

- Ling, B.; Wang, S. Dielectric properties of pistachio kernels as influenced by frequency, temperature, moisture and salt content. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, WA, USA, 16–19 July 2017; p. 1. [Google Scholar]

- Tao, Y.; Yan, B.; Fan, D.; Zhang, N.; Ma, S.; Wang, L.; Wu, Y.; Wang, M.; Zhao, J.; Zhang, H. Structural changes of starch subjected to microwave heating: A review from the perspective of dielectric properties. Trends Food Sci. Technol. 2020, 99, 593–607. [Google Scholar] [CrossRef]

- Samray, M.N.; Masatcioglu, T.M.; Koksel, H. Bread crumbs extrudates: A new approach for reducing bread waste. J. Cereal Sci. 2019, 85, 130–136. [Google Scholar] [CrossRef]

- Lusas, E.W.; Rooney, L.W. Snack Foods Processing; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

| Water Content of Mixtures (%) | Model | |||

|---|---|---|---|---|

| Page | Logarithmic | Midilli–Kucuk | ||

| 25 | Model constants | k: 0.00062 n: 1.93984 | a: 2.2581 k: 0.0082 c: −1.150 | a: 1.0939 k: 0.0069 n: 1.2271 b: −0.0029 |

| Adj. R2 | 96.36 | 91.52 | 91.41 | |

| RMSE | 0.078 | 0.119 | 0.120 | |

| 30 | Model constants | k: 0.00054 n: 1.81839 | a: 1.4349 k: 0.0115 c: −0.3080 | a: 0.9752 k: 0.00002 n: 2.6097 b: −0.0006 |

| Adj. R2 | 93.99 | 84.15 | 95.93 | |

| RMSE | 0.086 | 0.140 | 0.071 | |

| 35 | Model constants | k: 0.00038 n: 1.76371 | a: 1.3090 k: 0.4091 c: −0.1780 | a: 1.1008 k: 0.0005 n: 1.4632 b: −0.0051 |

| Adj. R2 | 89.07 | 75.83 | 87.98 | |

| RMSE | 0.1064 | 0.1582 | 0.0718 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acurio, L.; Moreau, F.; García-Segovia, P.; Martínez-Monzó, J.; Igual, M. Microwave Expansion Kinetics of Third-Generation Extruded Corn Pellets under Different Moisture Contents. Biol. Life Sci. Forum 2022, 18, 51. https://doi.org/10.3390/Foods2022-12952

Acurio L, Moreau F, García-Segovia P, Martínez-Monzó J, Igual M. Microwave Expansion Kinetics of Third-Generation Extruded Corn Pellets under Different Moisture Contents. Biology and Life Sciences Forum. 2022; 18(1):51. https://doi.org/10.3390/Foods2022-12952

Chicago/Turabian StyleAcurio, Liliana, Faustine Moreau, Purificación García-Segovia, Javier Martínez-Monzó, and Marta Igual. 2022. "Microwave Expansion Kinetics of Third-Generation Extruded Corn Pellets under Different Moisture Contents" Biology and Life Sciences Forum 18, no. 1: 51. https://doi.org/10.3390/Foods2022-12952

APA StyleAcurio, L., Moreau, F., García-Segovia, P., Martínez-Monzó, J., & Igual, M. (2022). Microwave Expansion Kinetics of Third-Generation Extruded Corn Pellets under Different Moisture Contents. Biology and Life Sciences Forum, 18(1), 51. https://doi.org/10.3390/Foods2022-12952