Solar Heat for Industrial Processes (SHIP): An Overview of Its Categories and a Review of Its Recent Progress

Abstract

1. Introduction

1.1. Classifications of SHIP Systems

- (1)

- Stationary: no sun tracking, no moving parts.

- (2)

- (3)

1.2. Objectives

2. Method

2.1. SHIP Capacity Relative to Other Power Sources

2.2. Estimated Solar Radiation Power

2.3. Outline of the Study

2.4. Use of Third-Party Illustrations

2.5. Contribution of the Current Study

- What was the SHIP installation in 2024?

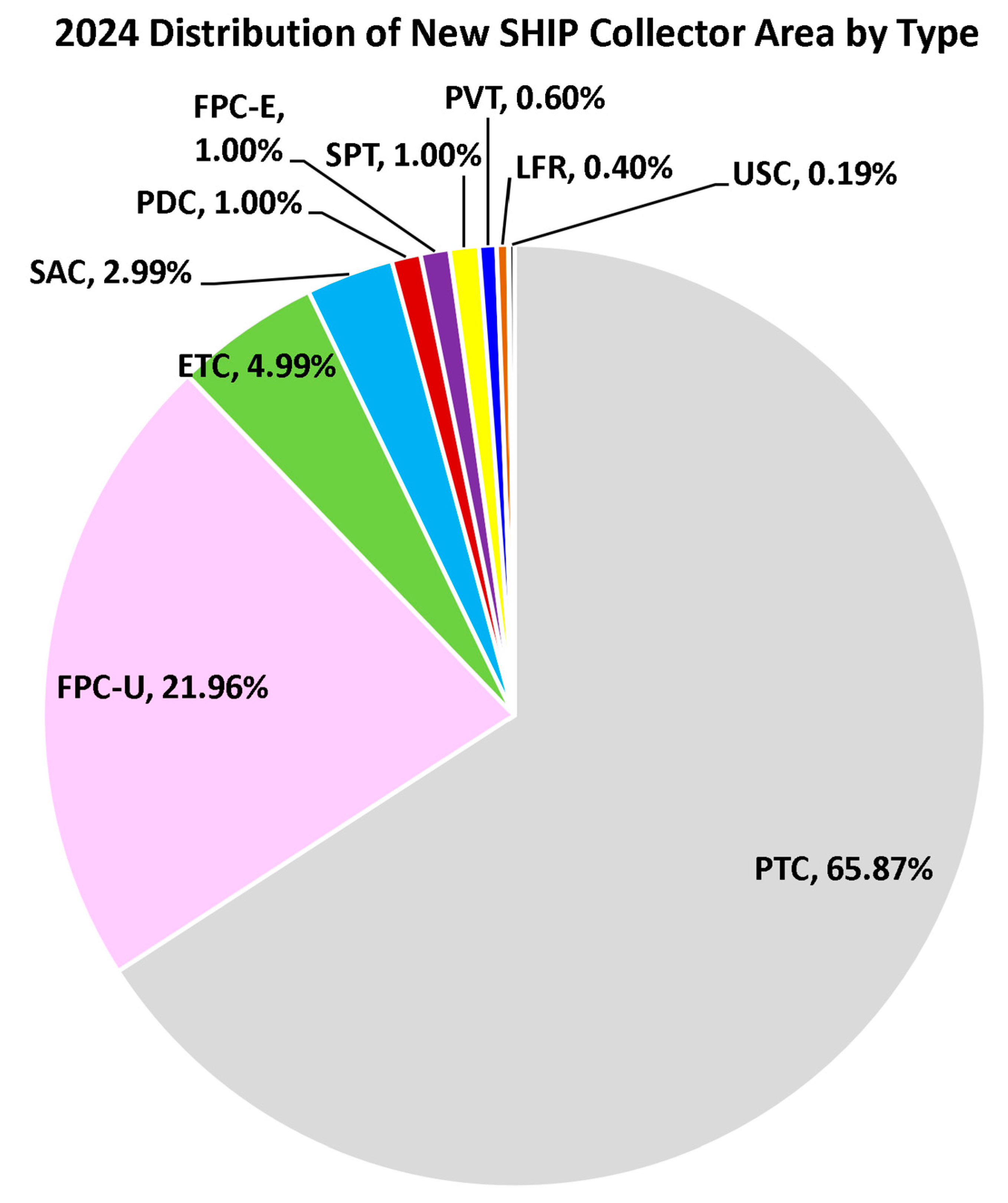

- What was the SHIP type with the largest installation capacity in 2024?

- Was the SHIP installation affected by the COVID-19 pandemic?

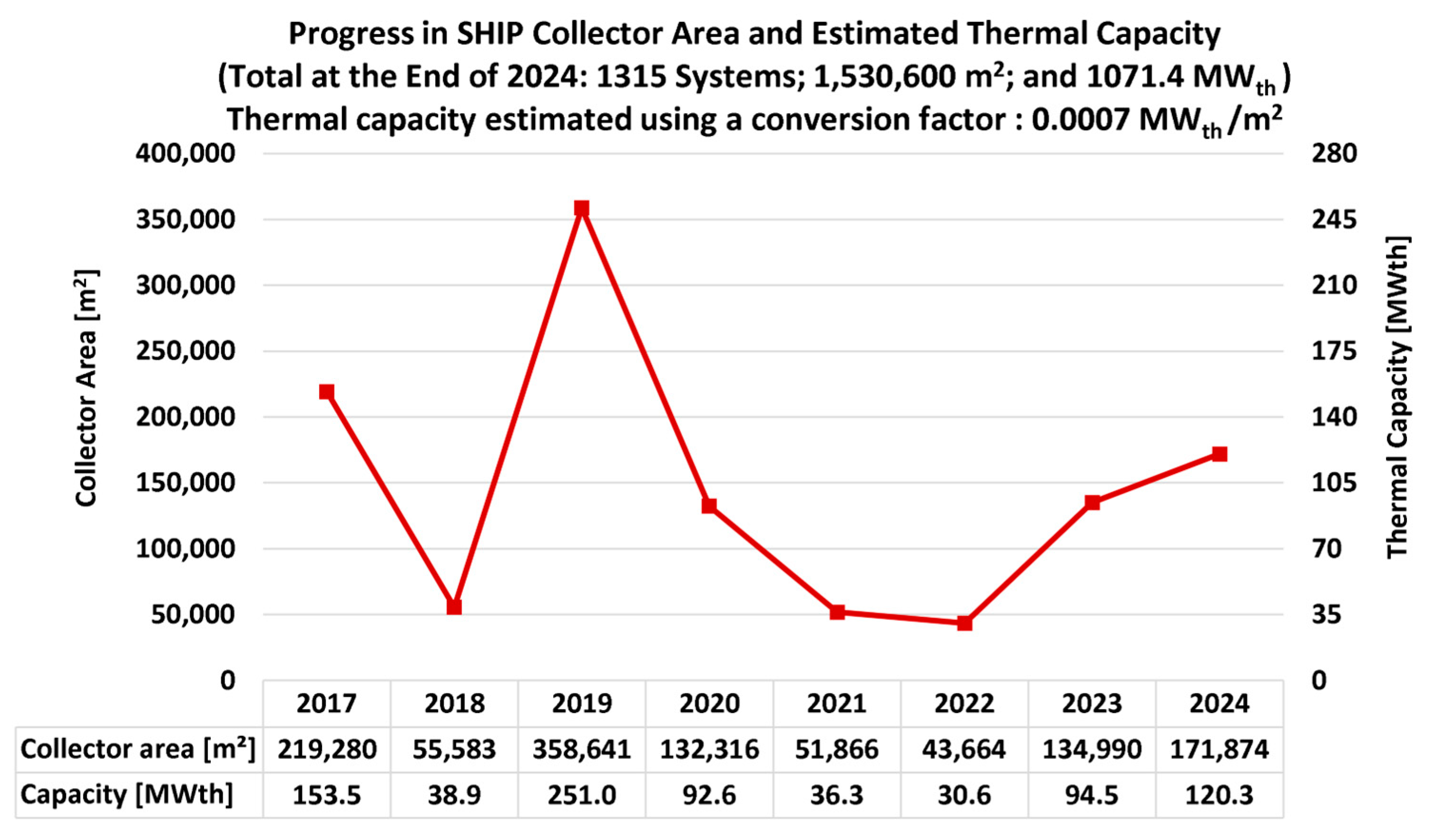

- What is the historical progress in SHIPs between 2017 and 2024?

- What are the top 10 countries in terms of installed SHIP capacity in 2024?

- What are the different types of SHIP systems?

- How are SHIP systems classified?

- Can SHIP systems replace natural gas combustion for enhanced oil recovery (EOR)?

- What is the anticipated size of the SHIP installation for steam installation in mining?

- What are the challenges of small-scale non-SHIP solar thermal systems?

- What are the recommendations for SHIP systems for improved deployment?

- What are the nine main categories of SHIP designs?

- Can the photovoltaic–thermal (PVT) technology be used with bifacial photovoltaic systems?

- What was the average capacity for a parabolic trough collector (PTC) system in 2024?

- What SHIP designs are also used for CSP (concentrated solar power) applications, and why?

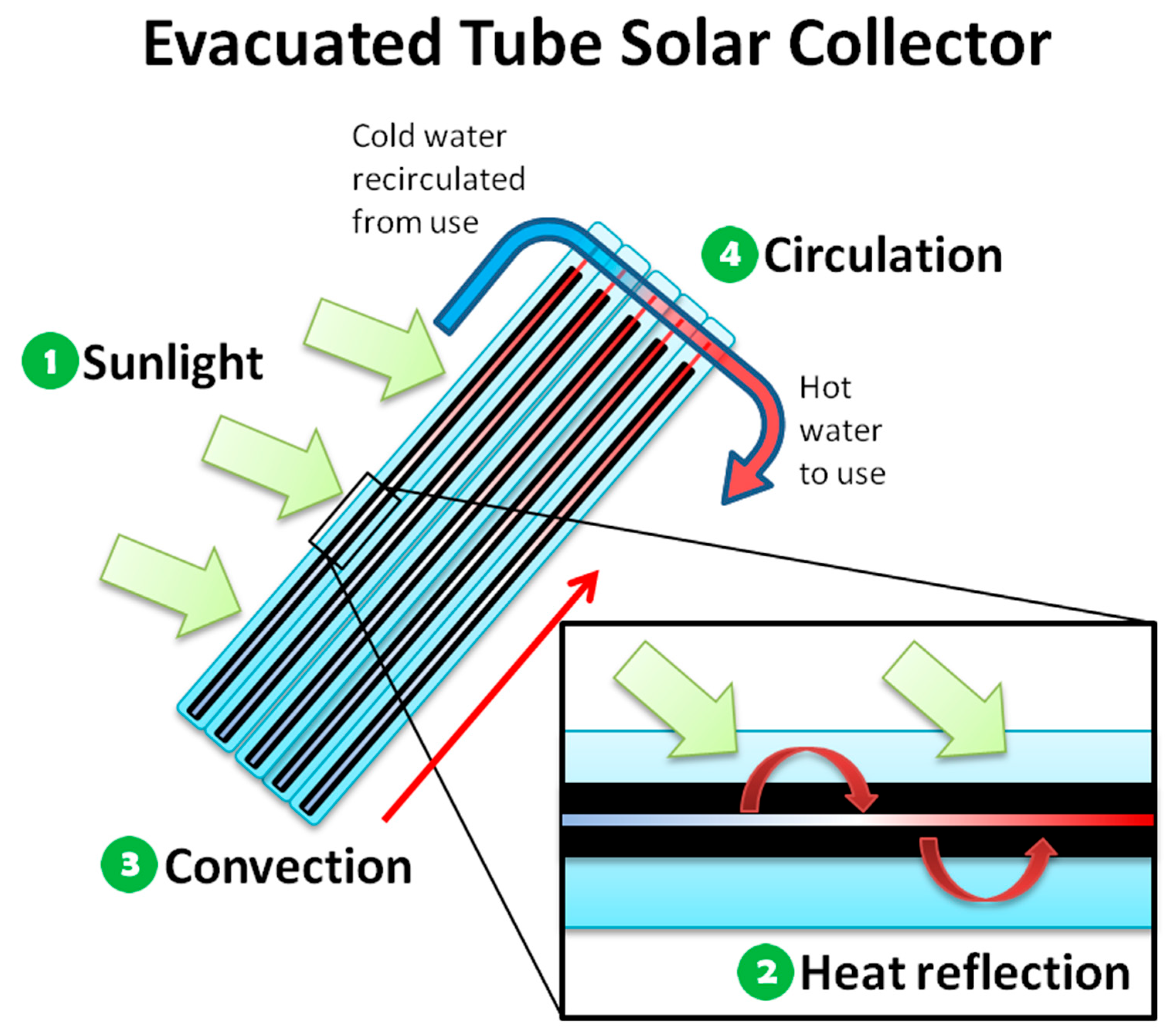

- What is the significance of tube evacuation in SHIP systems?

- What are the approaches and tools suitable for modeling SHIP systems?

- Can SHIP systems be used for retrofitting an existing steam generation system, and is there a successful case like this?

- What is the meaning of PV-to-heat configuration (PVH)?

- What is the expected contribution of the Maaden Solar I to the SHIP sector, and when?

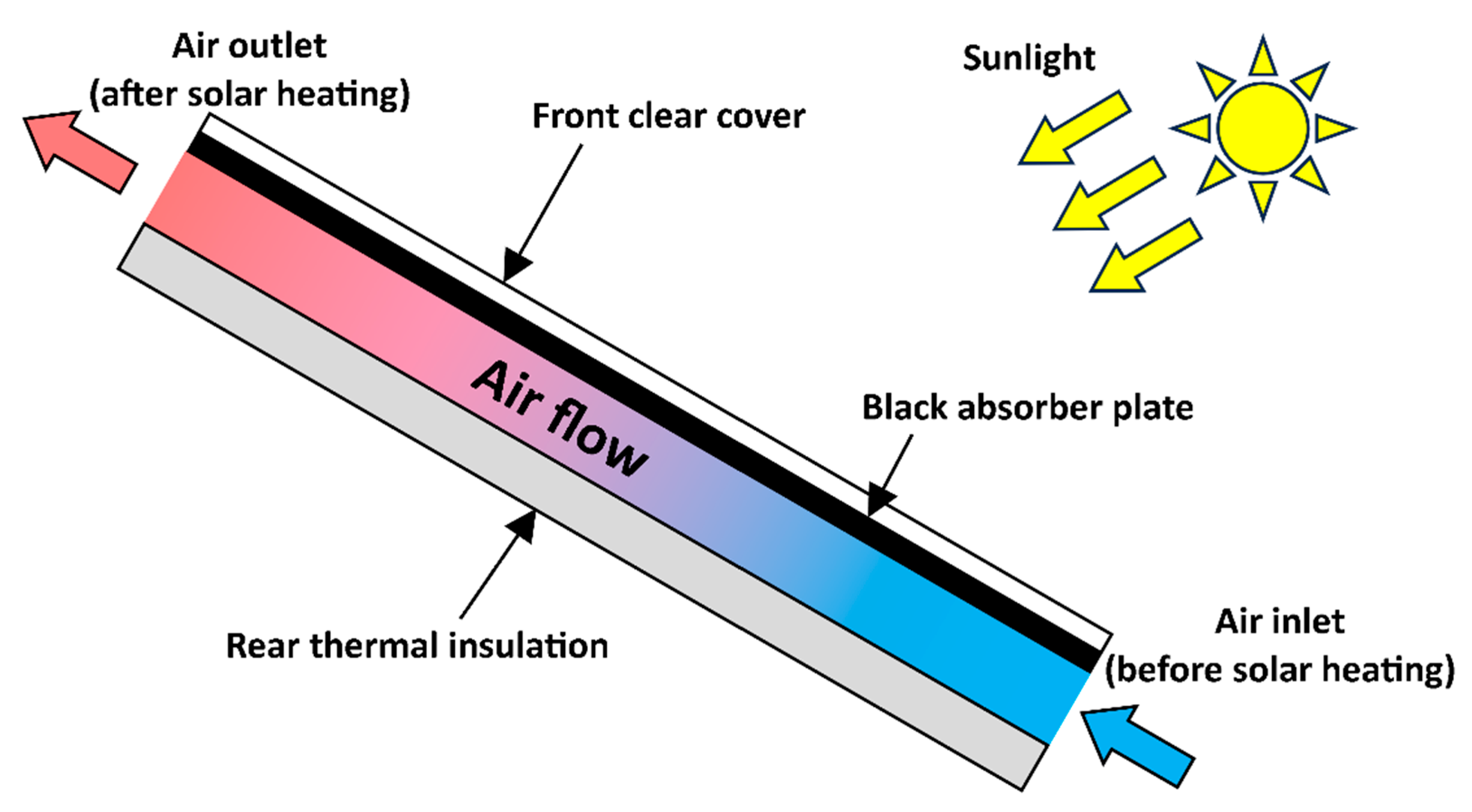

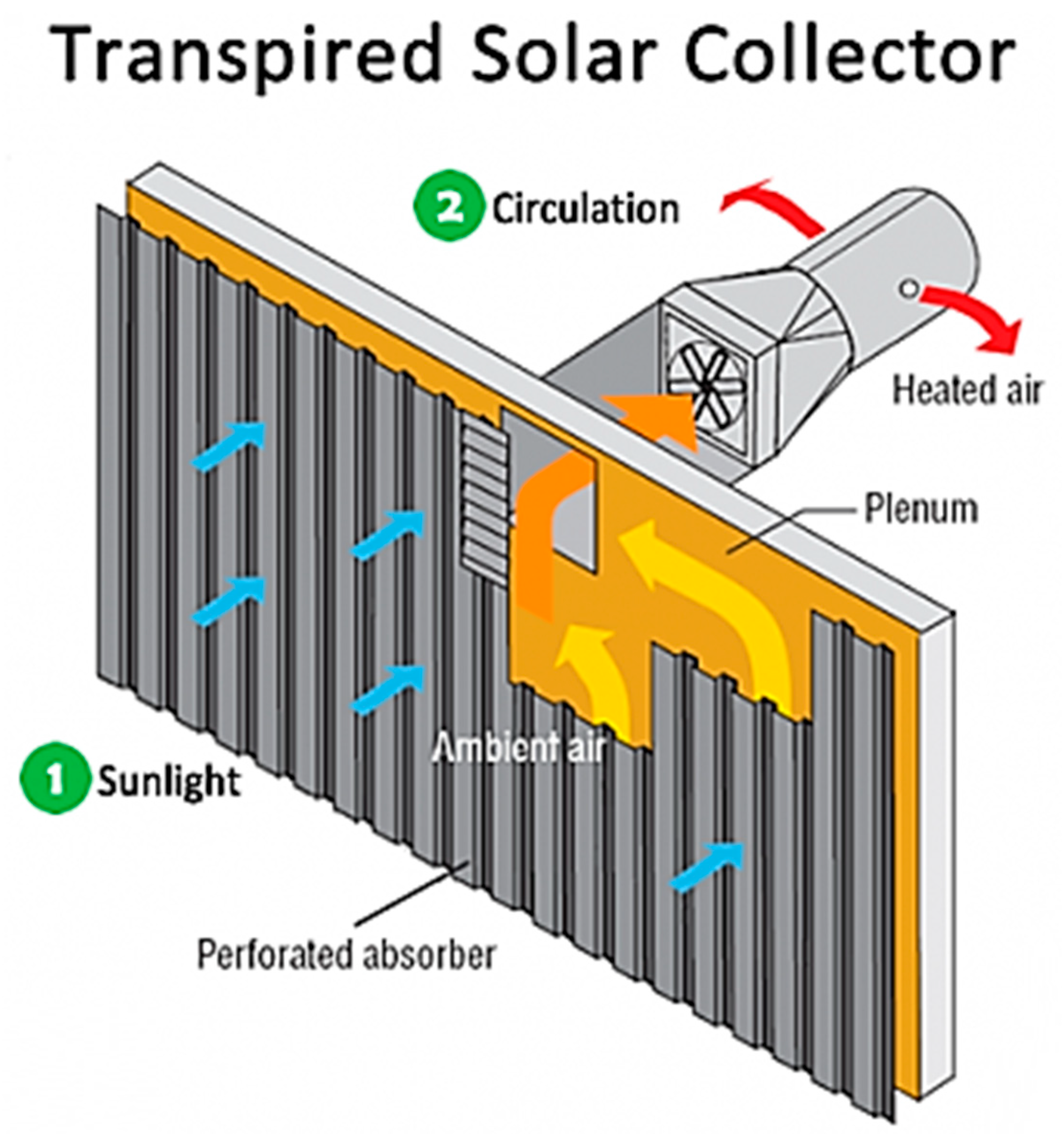

- What is the technological difference between a transpired solar air collector SHIP system and a plate solar air collector SHIP system?

- What does (low temperature) SHIP system mean?

- What are the applications for SHIP systems at high temperatures?

- How does the global SHIP capacity compare to the global capacity of renewable energy technologies as power sources?

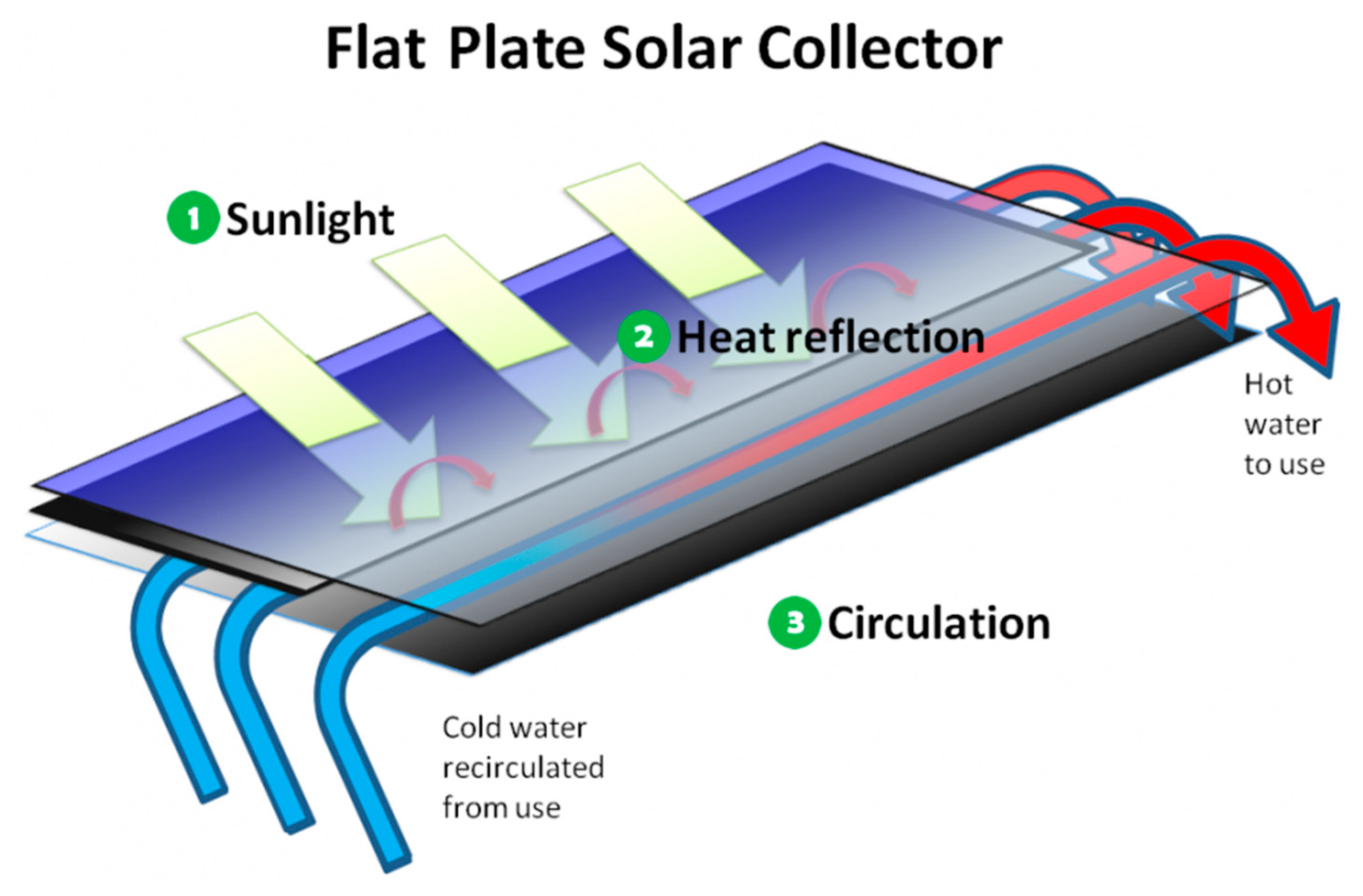

- Was evacuation a commonly adopted feature in flat plate collectors in 2024?

- What was the average collector area of an unglazed solar collector in 2024?

- What was the total number of SHIP projects in 2024?

- How big is the disparity in terms of project size among SHIP designs?

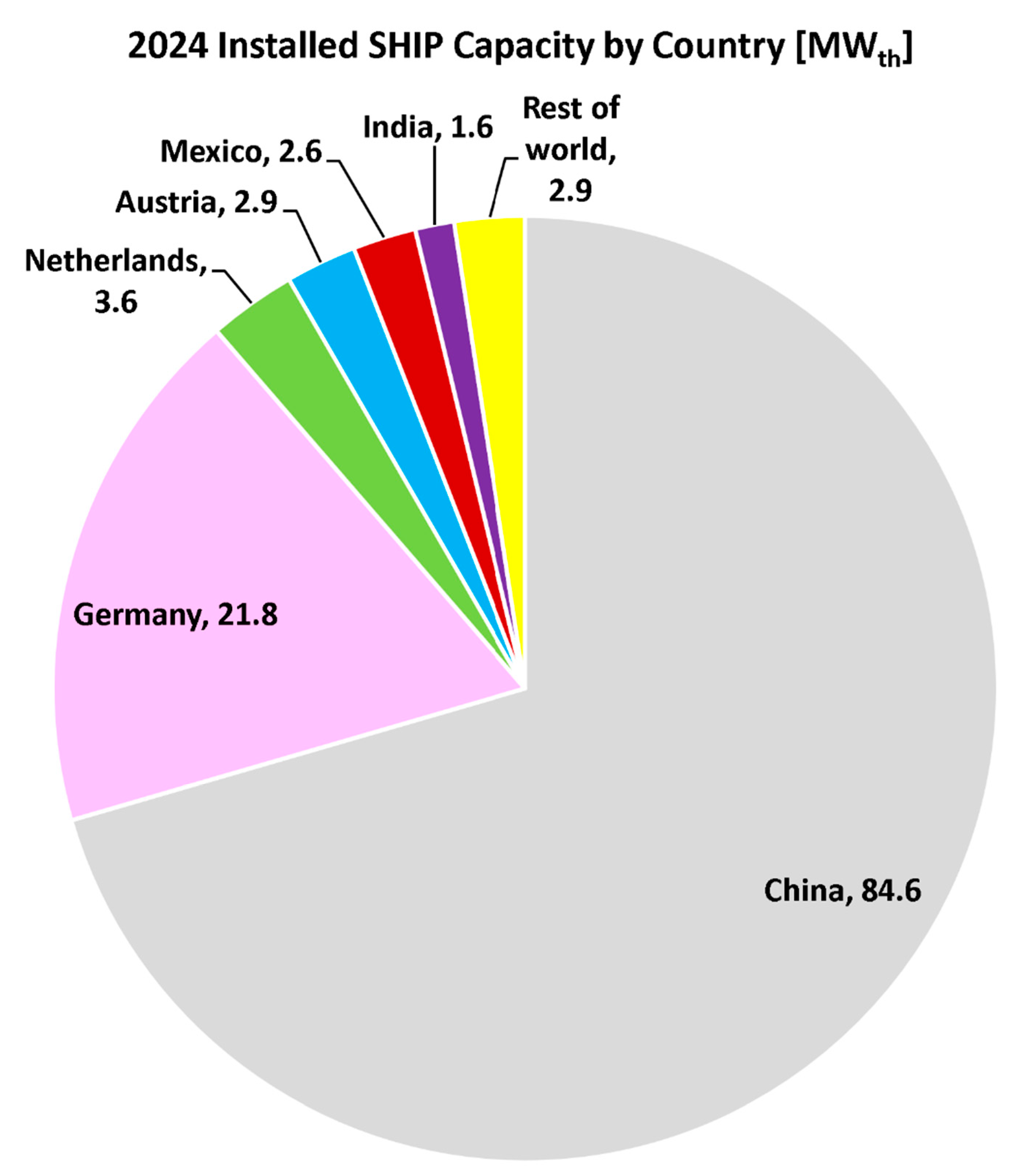

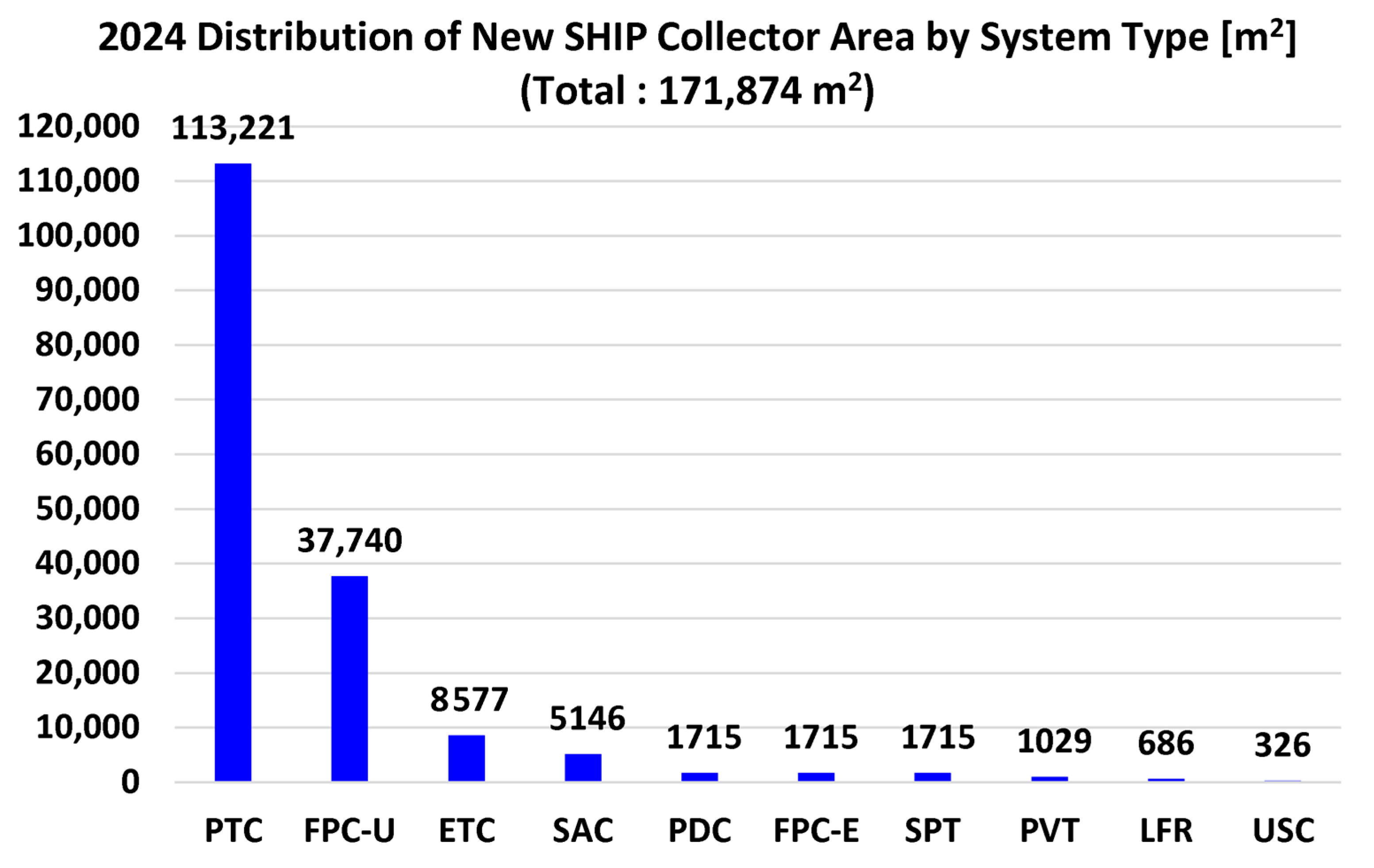

- What was the 2024 distribution of new SHIP collector areas by type?

- What was the total collector area of SHIP systems in 2024?

3. Results (Part 1: SHIP Designs)

3.1. Overview of Solar Collectors

3.2. SHIP Applications

3.3. Some Published Works

3.4. SAC (Solar Air Collector)

3.5. PVT (Photovoltaic–Thermal)

3.6. USC (Unglazed Solar Collector)

3.7. FPC (Flat Plate Collector)

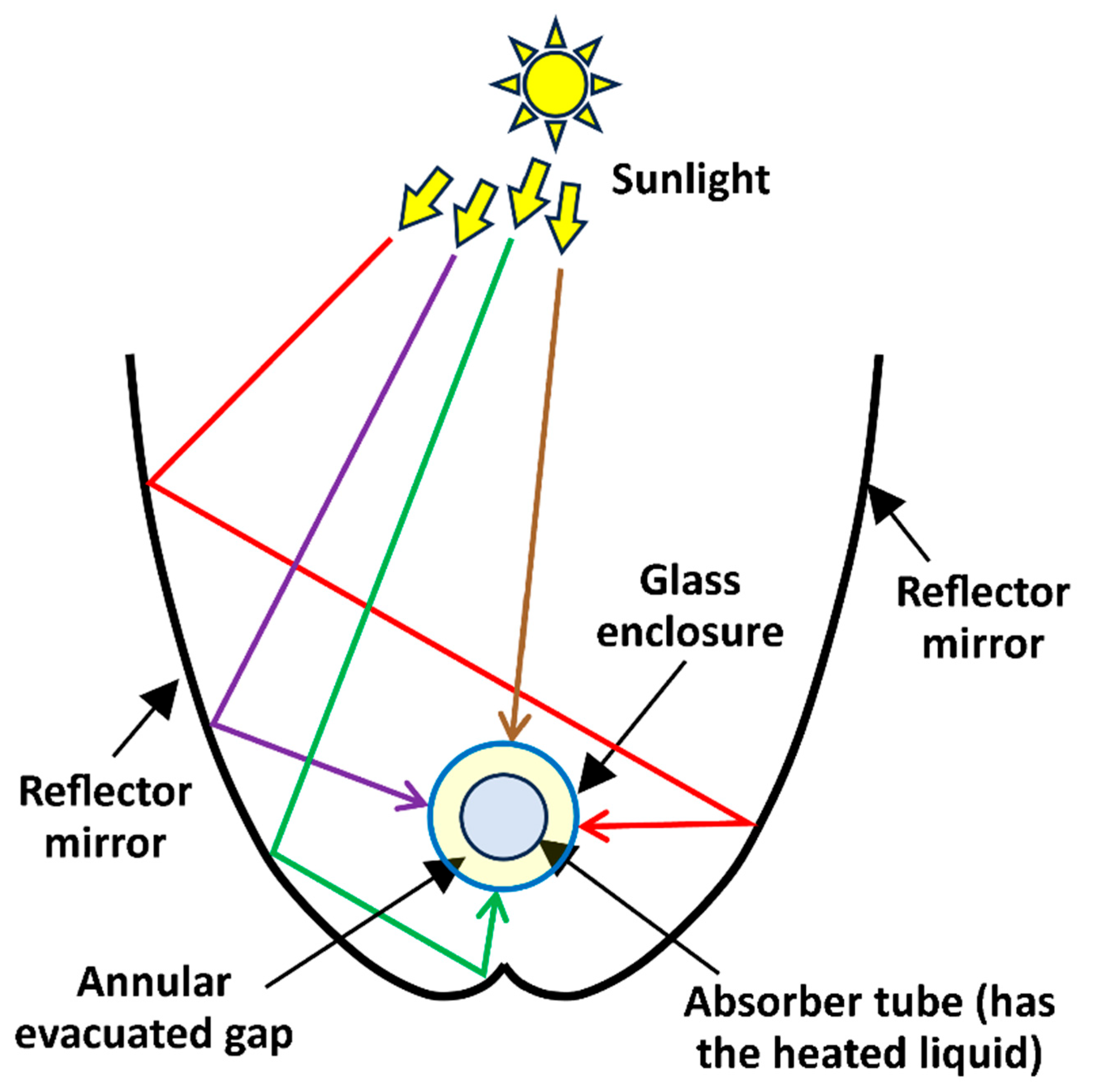

3.8. ETC (Evacuated Tube Collector)

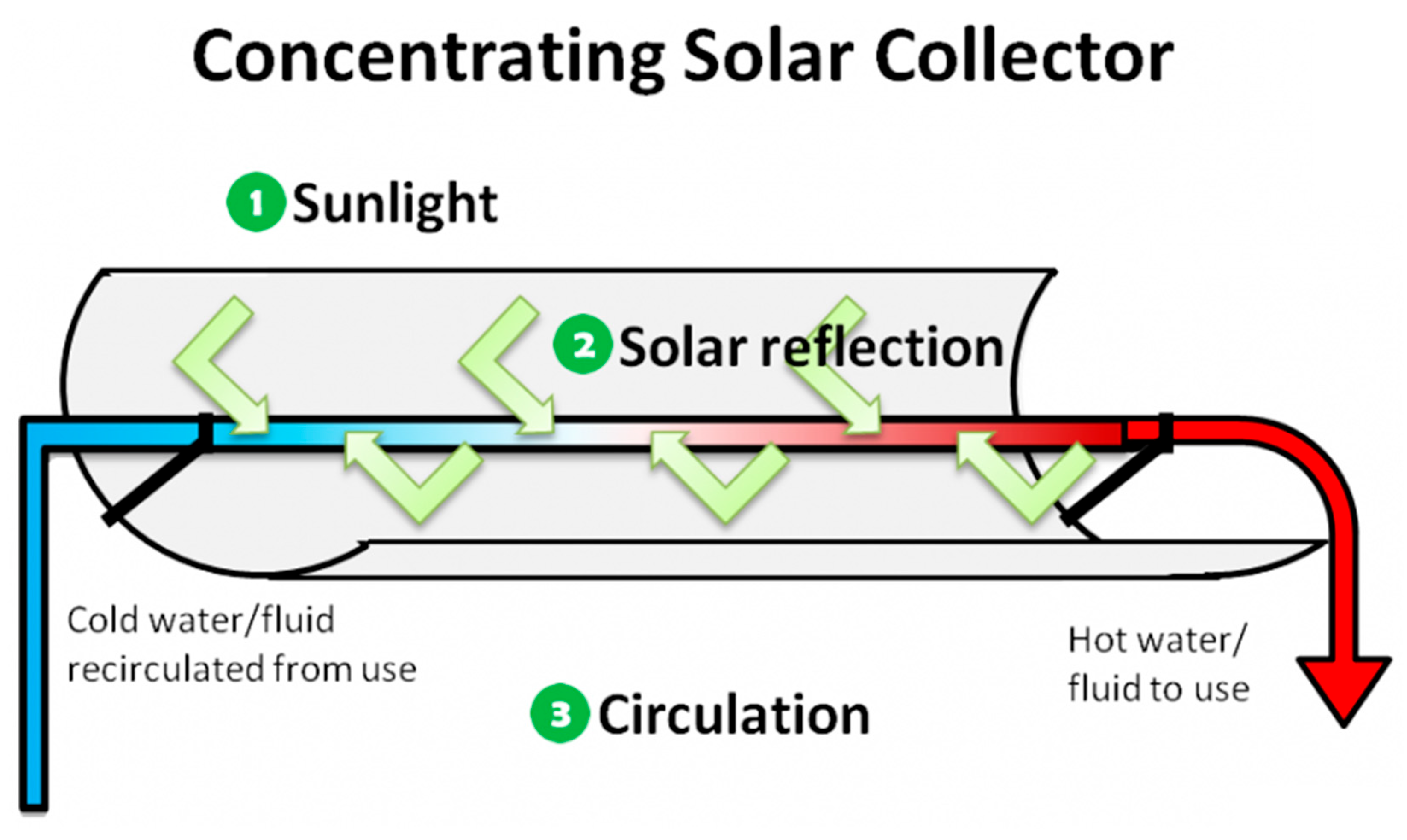

3.9. PTC (Parabolic Trough Collector)

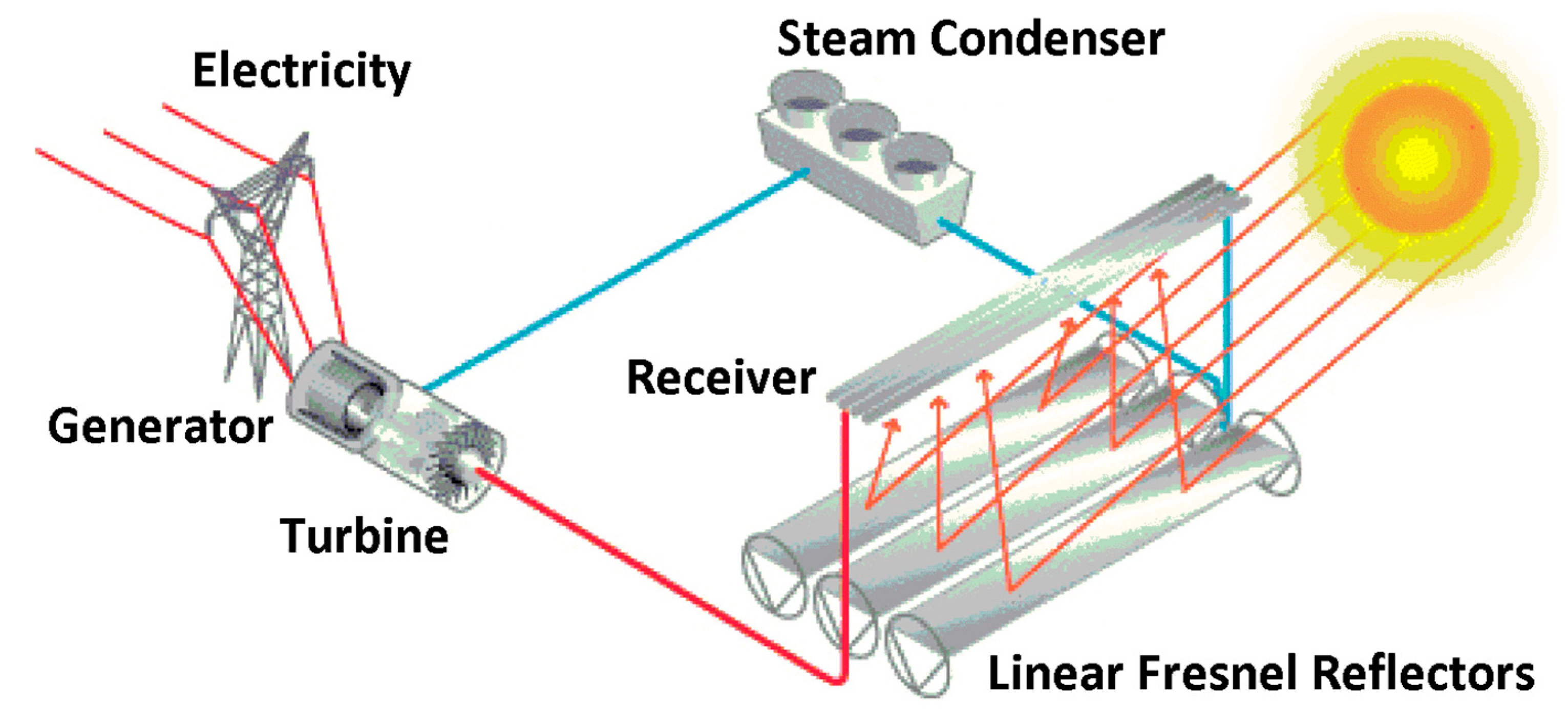

3.10. LFR (Linear Fresnel Reflector)

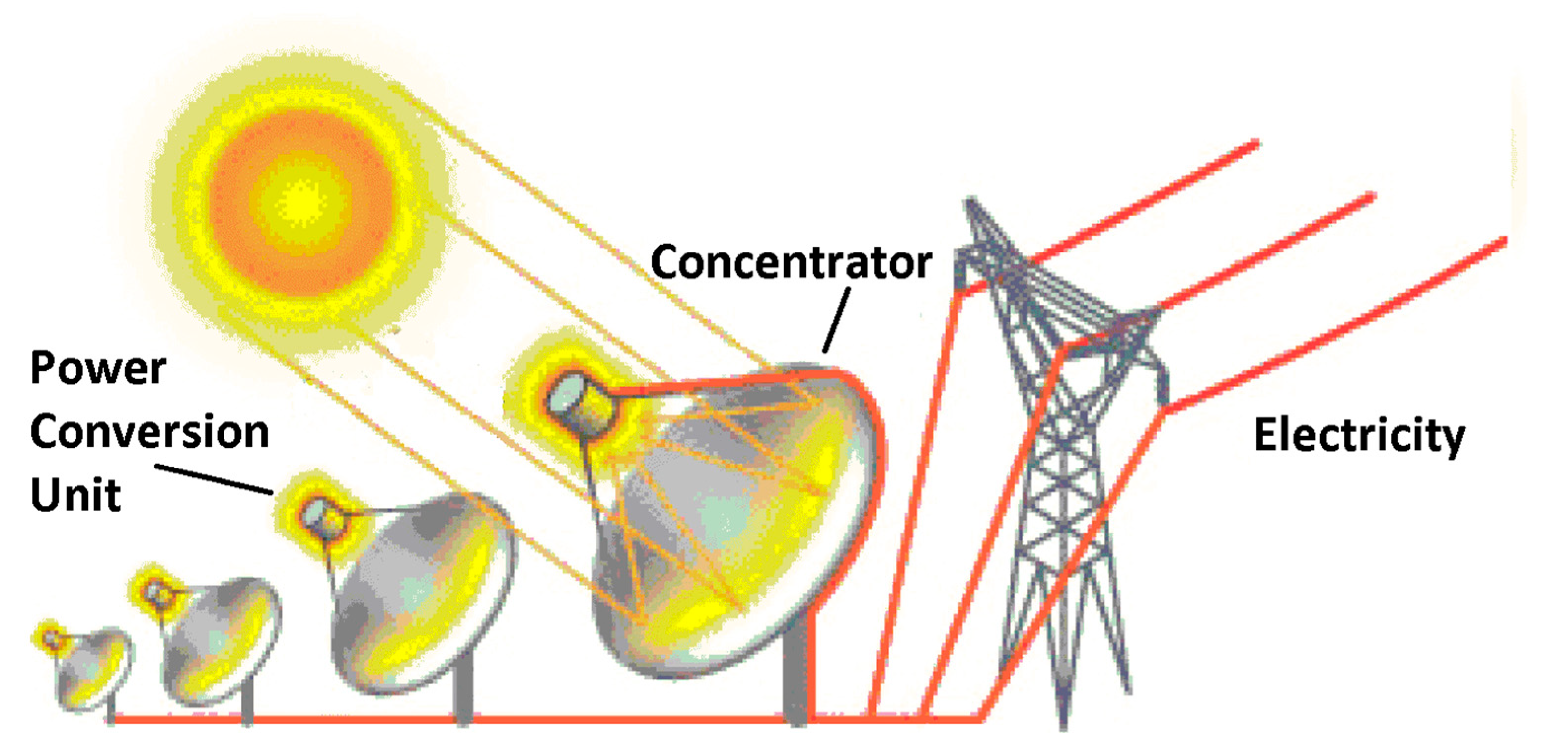

3.11. PDC (Parabolic Dish Collector)

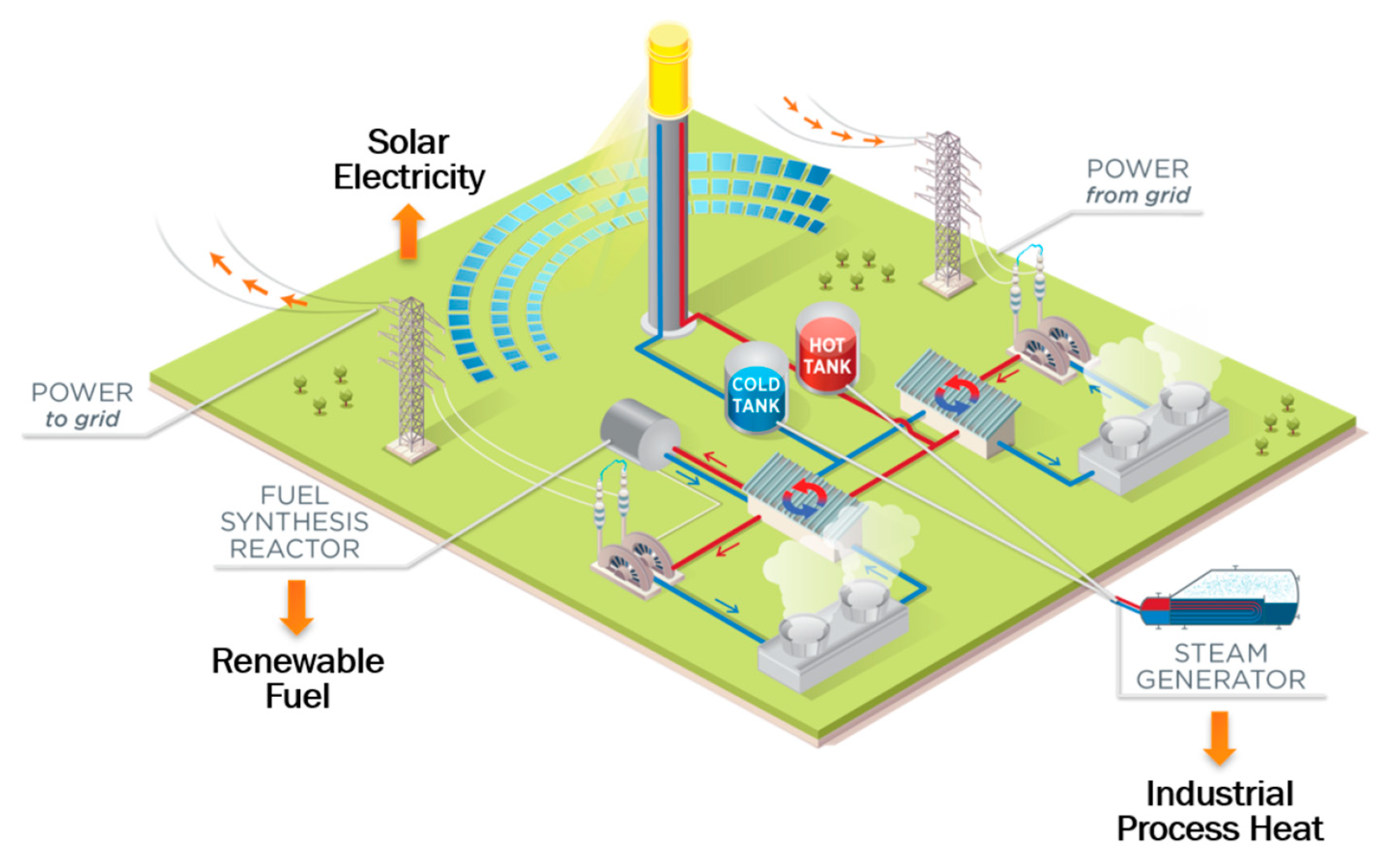

3.12. SPT (Solar Power Tower)

4. Results (Part 2: SHIP Progress)

4.1. SHIP Historical Growth

4.2. SHIP Additions in 2024

- China.

- Germany.

- Netherlands.

- Austria.

- Mexico.

- India.

- Italy.

- Brazil.

- USA.

- France.

- Panama.

- Jordan.

- Serbia.

- Spain.

- Kenya.

- Ecuador.

- Finland.

- Morocco.

- Colombia.

- Cuba.

4.3. Small-Scale Non-Industrial Solar Thermal Applications

4.4. PV-to-Heat Configuration (PVH)

4.5. Thermal Modeling Tools

4.6. Perspectives and Recommendations

5. Discussion and Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Modest, M.F. Radiative Heat Transfer, 2nd ed.; Academic Press: Amsterdam, The Netherlands; Boston, MA, USA, 2003; ISBN 978-0-12-503163-9. [Google Scholar]

- Howell, J.R.; Mengüc, M.P.; Daun, K.; Siegel, R. Thermal Radiation Heat Transfer, 7th ed.; CRC Press: Boca Raton, FL, USA, 2020; ISBN 978-0-429-32730-8. [Google Scholar]

- Peuser, D.F.A.; Remmers, K.-H.; Schnauss, M. Solar Thermal Systems: Successful Planning and Construction; Routledge: London, UK, 2013; ISBN 978-1-315-06724-7. [Google Scholar]

- Romero, M.; González-Aguilar, J. Solar Thermal CSP Technology. WIREs Energy Environ. 2014, 3, 42–59. [Google Scholar] [CrossRef]

- Smith, G.A.; Barnes, S.A. Electrical Power Generation from Heat Engines. In Proceedings of the IEE Colloquium on Power Electronics for Renewable Energy (Digest No: 1997/170), London, UK, 16 June 1997; pp. 5/1–5/6. [Google Scholar]

- Marzouk, O.A. Radiant Heat Transfer in Nitrogen-Free Combustion Environments. Int. J. Nonlinear Sci. Numer. Simul. 2018, 19, 175–188. [Google Scholar] [CrossRef]

- Fernández-Arias, P.; Vergara, D.; Orosa, J.A. A Global Review of PWR Nuclear Power Plants. Appl. Sci. 2020, 10, 4434. [Google Scholar] [CrossRef]

- Hashemian, H.M. On-Line Monitoring Applications in Nuclear Power Plants. Prog. Nucl. Energy 2011, 53, 167–181. [Google Scholar] [CrossRef]

- Marzouk, O.A. Subcritical and Supercritical Rankine Steam Cycles, under Elevated Temperatures up to 900 °C and Absolute Pressures up to 400 Bara. Adv. Mech. Eng. 2024, 16, 16878132231221065. [Google Scholar] [CrossRef]

- Marzouk, O.A. Technical Review of Radiative-Property Modeling Approaches for Gray and Nongray Radiation, and a Recommended Optimized WSGGM for CO2/H2O-Enriched Gases. Results Eng. 2025, 25, 103923. [Google Scholar] [CrossRef]

- Gallo, A.; Marzo, A.; Fuentealba, E.; Alonso, E. High Flux Solar Simulators for Concentrated Solar Thermal Research: A Review. Renew. Sustain. Energy Rev. 2017, 77, 1385–1402. [Google Scholar] [CrossRef]

- Mir-Artigues, P. The Economics and Policy of Concentrating Solar Power Generation; Green Energy and Technology Series; Springer International Publishing AG: Cham, Switzerland, 2019; ISBN 978-3-030-11937-9. [Google Scholar]

- Chien, J.C.-L. Concentrating Solar Thermal Power: A Viable Alternative in China’s Energy Supply. Master’s Thesis, Lauder Institute of International Studies, University of Pennsylvania, Philadelphia, PA, USA, 2009. [Google Scholar]

- EASAC (European Academies Science Advisory Council). Concentrating Solar Power: Its Potential Contribution to a Sustainable Energy Future; EASAC (European Academies Science Advisory Council): Halle (Saale), Germany, 2011; pp. 1–67. [Google Scholar]

- Zhu, J.; Chen, Z. Optical Design of Compact Linear Fresnel Reflector Systems. Sol. Energy Mater. Sol. Cells 2018, 176, 239–250. [Google Scholar] [CrossRef]

- Rungasamy, A.E.; Craig, K.J.; Meyer, J.P. Comparative Study of the Optical and Economic Performance of Etendue-Conserving Compact Linear Fresnel Reflector Concepts. Sol. Energy 2019, 181, 95–107. [Google Scholar] [CrossRef]

- Khan, M.I.; Gutiérrez-Alvarez, R.; Asfand, F.; Bicer, Y.; Sgouridis, S.; Al-Ghamdi, S.G.; Jouhara, H.; Asif, M.; Kurniawan, T.A.; Abid, M.; et al. The Economics of Concentrating Solar Power (CSP): Assessing Cost Competitiveness and Deployment Potential. Renew. Sustain. Energy Rev. 2024, 200, 114551. [Google Scholar] [CrossRef]

- Palacios, A.; Calderón, A.; Barreneche, C.; Bertomeu, J.; Segarra, M.; Fernández, A.I. Study on Solar Absorptance and Thermal Stability of Solid Particles Materials Used as TES at High Temperature on Different Aging Stages for CSP Applications. Sol. Energy Mater. Sol. Cells 2019, 201, 110088. [Google Scholar] [CrossRef]

- Giostri, A.; Macchi, E. An Advanced Solution to Boost Sun-to-Electricity Efficiency of Parabolic Dish. Sol. Energy 2016, 139, 337–354. [Google Scholar] [CrossRef]

- Zhai, H.; Wang, S.; An, B.; Dai, X. Performance and Parameter Sensitivity Comparison of CSP Power Cycles under Wide Solar Energy Temperature Ranges and Multiple Working Conditions. Energy Convers. Manag. 2020, 218, 112996. [Google Scholar] [CrossRef]

- Giostri, A. Preliminary Analysis of Solarized Micro Gas Turbine Application to CSP Parabolic Dish Plants. Energy Procedia 2017, 142, 768–773. [Google Scholar] [CrossRef]

- García-Ferrero, J.; Merchán, R.P.; Santos, M.J.; Medina, A.; Calvo Hernández, A. Brayton Technology for Concentrated Solar Power Plants: Comparative Analysis of Central Tower Plants and Parabolic Dish Farms. Energy Convers. Manag. 2022, 271, 116312. [Google Scholar] [CrossRef]

- Giaconia, A.; Iaquaniello, G.; Metwally, A.A.; Caputo, G.; Balog, I. Experimental Demonstration and Analysis of a CSP Plant with Molten Salt Heat Transfer Fluid in Parabolic Troughs. Sol. Energy 2020, 211, 622–632. [Google Scholar] [CrossRef]

- Cipollone, R.; Cinocca, A.; Gualtieri, A. Gases as Working Fluid in Parabolic Trough CSP Plants. Procedia Comput. Sci. 2013, 19, 702–711. [Google Scholar] [CrossRef]

- Abbas, R.; Muñoz, J.; Martínez-Val, J.M. Steady-State Thermal Analysis of an Innovative Receiver for Linear Fresnel Reflectors. Appl. Energy 2012, 92, 503–515. [Google Scholar] [CrossRef]

- Hofer, A.; Cuevas, F.; Heimsath, A.; Nitz, P.; Platzer, W.J.; Scholl, S. Extended Heat Loss and Temperature Analysis of Three Linear Fresnel Receiver Designs. Energy Procedia 2015, 69, 424–433. [Google Scholar] [CrossRef]

- He, Y.-L.; Qiu, Y.; Wang, K.; Yuan, F.; Wang, W.-Q.; Li, M.-J.; Guo, J.-Q. Perspective of Concentrating Solar Power. Energy 2020, 198, 117373. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A. Exergy Analysis of Parabolic Trough Solar Collectors Integrated with Combined Steam and Organic Rankine Cycles. Energy Convers. Manag. 2014, 77, 441–449. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A. Energy and Sizing Analyses of Parabolic Trough Solar Collector Integrated with Steam and Binary Vapor Cycles. Energy 2013, 58, 561–570. [Google Scholar] [CrossRef]

- Struchtrup, H. Thermodynamics and Energy Conversion, 1st ed.; Springer: Berlin, Germany, 2014; ISBN 978-3-662-43715-5. [Google Scholar]

- Marzouk, O.A. Direct Numerical Simulations of the Flow Past a Cylinder Moving With Sinusoidal and Nonsinusoidal Profiles. J. Fluids Eng. 2009, 131, 121201. [Google Scholar] [CrossRef]

- Marzouk, O.A. A Two-Step Computational Aeroacoustics Method Applied to High-Speed Flows. Noise Control Eng. J. 2008, 56, 396. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Ghadimi, N.; Marefati, M.; Ghorbanian, S.A. Numerical Investigation of a New Combined Energy System Includes Parabolic Dish Solar Collector, Stirling Engine and Thermoelectric Device. Int. J. Energy Res. 2021, 45, 16436–16455. [Google Scholar] [CrossRef]

- Marzouk, O.A. The Sod Gasdynamics Problem as a Tool for Benchmarking Face Flux Construction in the Finite Volume Method. Sci. Afr. 2020, 10, e00573. [Google Scholar] [CrossRef]

- Barreto, G.; Canhoto, P. Modelling of a Stirling Engine with Parabolic Dish for Thermal to Electric Conversion of Solar Energy. Energy Convers. Manag. 2017, 132, 119–135. [Google Scholar] [CrossRef]

- Marzouk, O.A. Reduced-Order Modeling (ROM) of a Segmented Plug-Flow Reactor (PFR) for Hydrogen Separation in Integrated Gasification Combined Cycles (IGCC). Processes 2025, 13, 1455. [Google Scholar] [CrossRef]

- Backes, J.G.; D’Amico, A.; Pauliks, N.; Guarino, S.; Traverso, M.; Lo Brano, V. Life Cycle Sustainability Assessment of a Dish-Stirling Concentrating Solar Power Plant in the Mediterranean Area. Sustain. Energy Technol. Assess. 2021, 47, 101444. [Google Scholar] [CrossRef]

- Adeoti, O.; Oyewole, B.A.; Adegboyega, T.D. Solar Photovoltaic-Based Home Electrification System for Rural Development in Nigeria: Domestic Load Assessment. Renew. Energy 2001, 24, 155–161. [Google Scholar] [CrossRef]

- Marzouk, O.A. Adiabatic Flame Temperatures for Oxy-Methane, Oxy-Hydrogen, Air-Methane, and Air-Hydrogen Stoichiometric Combustion Using the NASA CEARUN Tool, GRI-Mech 3.0 Reaction Mechanism, and Cantera Python Package. Eng. Technol. Appl. Sci. Res. 2023, 13, 11437–11444. [Google Scholar] [CrossRef]

- Chatzimouratidis, A.I.; Pilavachi, P.A. Objective and Subjective Evaluation of Power Plants and Their Non-Radioactive Emissions Using the Analytic Hierarchy Process. Energy Policy 2007, 35, 4027–4038. [Google Scholar] [CrossRef]

- Patel, A.; Soni, A.; Baredar, P. Green Buildings Integrated with Solar Thermal Energy Systems in India—Concepts, Utilization and Potential. In Proceedings of the 2024 IEEE 3rd International Conference on Electrical Power and Energy Systems (ICEPES), Bhopal, India, 21–22 June 2024; pp. 1–5. [Google Scholar]

- Marzouk, O.A. Compilation of Smart Cities Attributes and Quantitative Identification of Mismatch in Rankings. J. Eng. 2022, 2022, 5981551. [Google Scholar] [CrossRef]

- Yousef, B.A.A.; Obaideen, K.; AlMallahi, M.N.; Alajmi, N.; Radwan, A.; Al-Shihabi, S.; Elgendi, M. On the Contribution of Concentrated Solar Power (CSP) to the Sustainable Development Goals (SDGs): A Bibliometric Analysis. Energy Strategy Rev. 2024, 52, 101356. [Google Scholar] [CrossRef]

- Jia, L.; Ma, J.; Cheng, P.; Liu, Y. A Perspective on Solar Energy-Powered Road and Rail Transportation in China. CSEE J. Power Energy Syst. 2020, 6, 760–771. [Google Scholar] [CrossRef]

- Marzouk, O.A. Urban Air Mobility and Flying Cars: Overview, Examples, Prospects, Drawbacks, and Solutions. Open Eng. 2022, 12, 662–679. [Google Scholar] [CrossRef]

- Al-Ghussain, L.; Darwish Ahmad, A.; Abubaker, A.M.; Mohamed, M.A.; Hassan, M.A.; Akafuah, N.K. Optimal Sizing of Country-Scale Renewable Energy Systems towards Green Transportation Sector in Developing Countries. Case Stud. Therm. Eng. 2022, 39, 102442. [Google Scholar] [CrossRef]

- Bartłomiejczyk, M. Potential Application of Solar Energy Systems for Electrified Urban Transportation Systems. Energies 2018, 11, 954. [Google Scholar] [CrossRef]

- Aprà, F.M.; Smit, S.; Sterling, R.; Loureiro, T. Overview of the Enablers and Barriers for a Wider Deployment of CSP Tower Technology in Europe. Clean Technol. 2021, 3, 377–394. [Google Scholar] [CrossRef]

- Marzouk, O.A. Performance Analysis of Shell-and-Tube Dehydrogenation Module. Int. J. Energy Res. 2017, 41, 604–610. [Google Scholar] [CrossRef]

- Ziuku, S.; Seyitini, L.; Mapurisa, B.; Chikodzi, D.; van Kuijk, K. Potential of Concentrated Solar Power (CSP) in Zimbabwe. Energy Sustain. Dev. 2014, 23, 220–227. [Google Scholar] [CrossRef]

- Bijarniya, J.P.; Sudhakar, K.; Baredar, P. Concentrated Solar Power Technology in India: A Review. Renew. Sustain. Energy Rev. 2016, 63, 593–603. [Google Scholar] [CrossRef]

- Marzouk, O.A. Detailed Derivation of the Scalar Explicit Expressions Governing the Electric Field, Current Density, and Volumetric Power Density in the Four Types of Linear Divergent MHD Channels Under a Unidirectional Applied Magnetic Field. Contemp. Math. 2025, 6, 4060–4100. [Google Scholar] [CrossRef]

- Rodat, S.; Thonig, R. Status of Concentrated Solar Power Plants Installed Worldwide: Past and Present Data. Clean Technol. 2024, 6, 365–378. [Google Scholar] [CrossRef]

- Marzouk, O.A. Detailed and Simplified Plasma Models in Combined-Cycle Magnetohydrodynamic Power Systems. Int. J. Adv. Appl. Sci. 2023, 10, 96–108. [Google Scholar] [CrossRef]

- Furlan, G.; You, F. Robust Design of Hybrid Solar Power Systems: Sustainable Integration of Concentrated Solar Power and Photovoltaic Technologies. Adv. Appl. Energy 2024, 13, 100164. [Google Scholar] [CrossRef]

- Marzouk, O.A. Estimated Electric Conductivities of Thermal Plasma for Air-Fuel Combustion and Oxy-Fuel Combustion with Potassium or Cesium Seeding. Heliyon 2024, 10, e31697. [Google Scholar] [CrossRef]

- Marzouk, O.A. Power Density and Thermochemical Properties of Hydrogen Magnetohydrodynamic (H2MHD) Generators at Different Pressures, Seed Types, Seed Levels, and Oxidizers. Hydrogen 2025, 6, 31. [Google Scholar] [CrossRef]

- Soni, N.; Reddy, K.S. Techno-Economic Assessment of Concentrated Solar Power Technologies Integrated with Thermal Energy Storage System for Green Hydrogen Production. Int. J. Hydrogen Energy 2024, 72, 1184–1203. [Google Scholar] [CrossRef]

- Muhammad, H.A.; Naseem, M.; Kim, J.; Kim, S.; Choi, Y.; Lee, Y.D. Solar Hydrogen Production: Technoeconomic Analysis of a Concentrated Solar-Powered High-Temperature Electrolysis System. Energy 2024, 298, 131284. [Google Scholar] [CrossRef]

- Reddy, V.J.; Hariram, N.P.; Maity, R.; Ghazali, M.F.; Kumarasamy, S. Sustainable E-Fuels: Green Hydrogen, Methanol and Ammonia for Carbon-Neutral Transportation. World Electr. Veh. J. 2023, 14, 349. [Google Scholar] [CrossRef]

- Marzouk, O.A. Hydrogen Utilization as a Plasma Source for Magnetohydrodynamic Direct Power Extraction (MHD-DPE). IEEE Access 2024, 12, 167088–167107. [Google Scholar] [CrossRef]

- Bellotti, D.; Rivarolo, M.; Magistri, L. Clean Fuels Synthesis from Green Hydrogen: A Techno-Economic Comparative Analysis. E3S Web Conf. 2021, 238, 03001. [Google Scholar] [CrossRef]

- Meda, U.S.; Rajyaguru, Y.V.; Pandey, A. Generation of Green Hydrogen Using Self-Sustained Regenerative Fuel Cells: Opportunities and Challenges. Int. J. Hydrogen Energy 2023, 48, 28289–28314. [Google Scholar] [CrossRef]

- Marzouk, O.A. Facilitating Digital Analysis and Exploration in Solar Energy Science and Technology through Free Computer Applications. Eng. Proc. 2022, 31, 75. [Google Scholar] [CrossRef]

- Gil, J.D.; Topa, A.; Álvarez, J.D.; Torres, J.L.; Pérez, M. A Review from Design to Control of Solar Systems for Supplying Heat in Industrial Process Applications. Renew. Sustain. Energy Rev. 2022, 163, 112461. [Google Scholar] [CrossRef]

- Jia, T.; Huang, J.; Li, R.; He, P.; Dai, Y. Status and Prospect of Solar Heat for Industrial Processes in China. Renew. Sustain. Energy Rev. 2018, 90, 475–489. [Google Scholar] [CrossRef]

- Solar Payback Market Segments. Available online: https://www.solar-payback.com/markets (accessed on 18 April 2025).

- Marzouk, O.A. Zero Carbon Ready Metrics for a Single-Family Home in the Sultanate of Oman Based on EDGE Certification System for Green Buildings. Sustainability 2023, 15, 13856. [Google Scholar] [CrossRef]

- SHE (Solar Heat Europe). Solar Energy for Heating and Cooling. Available online: https://solarheateurope.eu/wp-content/uploads/2024/11/2-graphs_2023_sector_heat.png (accessed on 18 April 2025).

- Sarbu, I.; Sebarchievici, C. Review of Solar Refrigeration and Cooling Systems. Energy Build. 2013, 67, 286–297. [Google Scholar] [CrossRef]

- SHC (Solar Heating and Cooling Programme). Solar Heat for Industrial Processes (SHIP); IEA (International Energy Agency): Paris, France, 2024; pp. 1–9. [Google Scholar]

- Kalogirou, S.A. Solar Thermal Collectors and Applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Palombo, A. Chapter 6—Solar Thermal Collectors. In Solar Hydrogen Production; Calise, F., D’Accadia, M.D., Santarelli, M., Lanzini, A., Ferrero, D., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 151–178. ISBN 978-0-12-814853-2. [Google Scholar]

- Goswami, D.Y. Principles of Solar Engineering, 4th ed.; CRC Press: Boca Raton, FL, USA, 2022; ISBN 978-1-00-324438-7. [Google Scholar]

- Sheikholeslami, M. Solar Thermal Systems and Applications: New Design Techniques for Improved Thermal Performance; Elsevier: London, UK, 2024; ISBN 978-0-443-15839-1. [Google Scholar]

- Lei, Z.; Li, C.; Chen, B. Extractive Distillation: A Review. Sep. Purif. Rev. 2003, 32, 121–213. [Google Scholar] [CrossRef]

- Chan, Y.H.; Loh, S.K.; Chin, B.L.F.; Yiin, C.L.; How, B.S.; Cheah, K.W.; Wong, M.K.; Loy, A.C.M.; Gwee, Y.L.; Lo, S.L.Y.; et al. Fractionation and Extraction of Bio-Oil for Production of Greener Fuel and Value-Added Chemicals: Recent Advances and Future Prospects. Chem. Eng. J. 2020, 397, 125406. [Google Scholar] [CrossRef]

- KROHNE KROHNE|Distillation in the Chemical Industry—Atmospheric and Vacuum Distillation Measuring. Available online: https://www.krohne.com/en-us/industries/chemical-industry/distillation (accessed on 10 August 2025).

- Gu, W.; Huang, Y.; Wang, K.; Zhang, B.; Chen, Q.; Hui, C.-W. Comparative Analysis and Evaluation of Three Crude Oil Vacuum Distillation Processes for Process Selection. Energy 2014, 76, 559–571. [Google Scholar] [CrossRef]

- Atta, M.S.; Khan, H.; Ali, M.; Tariq, R.; Yasir, A.U.; Iqbal, M.M.; Din, S.U.; Krzywanski, J. Simulation of Vacuum Distillation Unit in Oil Refinery: Operational Strategies for Optimal Yield Efficiency. Energies 2024, 17, 3806. [Google Scholar] [CrossRef]

- Hafez, A.Z.; Yousef, A.M.; Harag, N.M. Solar Tracking Systems: Technologies and Trackers Drive Types—A Review. Renew. Sustain. Energy Rev. 2018, 91, 754–782. [Google Scholar] [CrossRef]

- Marzouk, O.A. Coupled Differential-Algebraic Equations Framework for Modeling Six-Degree-of-Freedom Flight Dynamics of Asymmetric Fixed-Wing Aircraft. Int. J. Appl. Adv. Sci. 2025, 12, 30–51. [Google Scholar] [CrossRef]

- Marzouk, O.A. Tilt Sensitivity for a Scalable One-Hectare Photovoltaic Power Plant Composed of Parallel Racks in Muscat. Cogent Eng. 2022, 9, 2029243. [Google Scholar] [CrossRef]

- Beily, M.D.E.; Sinaga, R.; Syarif, Z.; Pae, M.G.; Rochani, R. Design and Construction of a Low Cost of Solar Tracker Two Degree of Freedom (DOF) Based On Arduino. In Proceedings of the 2020 International Conference on Applied Science and Technology (iCAST), Padang, Indonesia, 24 October 2020; pp. 384–388. [Google Scholar]

- Marzouk, O.A. Characteristics of the Flow-Induced Vibration and Forces With 1- and 2-DOF Vibrations and Limiting Solid-to-Fluid Density Ratios. J. Vib. Acoust. 2010, 132, 041013. [Google Scholar] [CrossRef]

- Safari, A.; Saidur, R.; Sulaiman, F.A.; Xu, Y.; Dong, J. A Review on Supercooling of Phase Change Materials in Thermal Energy Storage Systems. Renew. Sustain. Energy Rev. 2017, 70, 905–919. [Google Scholar] [CrossRef]

- Zheng, H. Chapter 2—Solar Energy Utilization and Its Collection Devices. In Solar Energy Desalination Technology; Zheng, H., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 47–171. ISBN 978-0-12-805411-6. [Google Scholar]

- SINTEF Solar Heat in Industrial Processes (SHIP). Available online: https://www.sintef.no/en/expert-list/sintef-energy-research/solar-heat-in-industrial-processes-ship (accessed on 20 April 2025).

- Bees Group Solar Heat for Industrial Process—SHIP. Available online: https://www.beesgroup.energy/en/services/solar-heat-for-industrial-process-ship (accessed on 20 April 2025).

- Marzouk, O.A. Globalization and Diversity Requirement in Higher Education. In Proceedings of the 11th World Multi-Conference on Systemics, Cybernetics and Informatics (WMSCI 2007)—The 13th International Conference on Information Systems Analysis and Synthesis (ISAS 2007), Orlando, FL, USA, 8–11 July 2007; IIIS (International Institute of Informatics and Systemics): Orlando, FL, USA, 2007; Volume III (3), pp. 101–106. [Google Scholar]

- Korkut, T.B.; Rachid, A. EduSolar: A Remote-Controlled Photovoltaic/Thermal Educational Lab with Integrated Daylight Simulation. Solar 2024, 4, 440–454. [Google Scholar] [CrossRef]

- Marzouk, O.A. Benchmarks for the Omani Higher Education Students-Faculty Ratio (SFR) Based on World Bank Data, QS Rankings, and THE Rankings. Cogent Educ. 2024, 11, 2317117. [Google Scholar] [CrossRef]

- Ciriminna, R.; Meneguzzo, F.; Pecoraino, M.; Pagliaro, M. Rethinking Solar Energy Education on the Dawn of the Solar Economy. Renew. Sustain. Energy Rev. 2016, 63, 13–18. [Google Scholar] [CrossRef]

- Marzouk, O.A. Benchmarking Retention, Progression, and Graduation Rates in Undergraduate Higher Education Across Different Time Windows. Cogent Educ. 2025, 12, 2498170. [Google Scholar] [CrossRef]

- Ghomshei, M.; Villecco, F. Energy Metrics and Sustainability. In Computational Science and Its Applications—ICCSA 2009; Gervasi, O., Taniar, D., Murgante, B., Laganà, A., Mun, Y., Gavrilova, M.L., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 693–698. [Google Scholar]

- Marzouk, O.A. Temperature-Dependent Functions of the Electron–Neutral Momentum Transfer Collision Cross Sections of Selected Combustion Plasma Species. Appl. Sci. 2023, 13, 11282. [Google Scholar] [CrossRef]

- Lima, M.A.; Mendes, L.F.R.; Mothé, G.A.; Linhares, F.G.; de Castro, M.P.P.; da Silva, M.G.; Sthel, M.S. Renewable Energy in Reducing Greenhouse Gas Emissions: Reaching the Goals of the Paris Agreement in Brazil. Environ. Dev. 2020, 33, 100504. [Google Scholar] [CrossRef]

- Marzouk, O.A. Assessment of Global Warming in Al Buraimi, Sultanate of Oman Based on Statistical Analysis of NASA POWER Data over 39 Years, and Testing the Reliability of NASA POWER against Meteorological Measurements. Heliyon 2021, 7, e06625. [Google Scholar] [CrossRef] [PubMed]

- Philander, S.G. Encyclopedia of Global Warming and Climate Change: A–E; SAGE: London, UK, 2008; ISBN 978-1-4129-5878-3. [Google Scholar]

- Marzouk, O.A. Portrait of the Decarbonization and Renewables Penetration in Oman’s Energy Mix, Motivated by Oman’s National Green Hydrogen Plan. Energies 2024, 17, 4769. [Google Scholar] [CrossRef]

- RMG (Royal Museums Greenwich). Calculating the Energy Output of the Sun; RMG (Royal Museums Greenwich): London, UK, 2017; pp. 1–2. [Google Scholar]

- SWS (Australian Space Weather Forecasting System). The Solar Constant. Available online: https://www.sws.bom.gov.au/Educational/2/1/12 (accessed on 18 April 2025).

- Adel, M.M. Religion-Scientific Study of Solar Resting Phase and Solar-Lunar Finality: Solar Resting Phase and Solar-Lunar Finality. AL-IKHSAN Interdiscip. J. Islam. Stud. 2023, 1, 82–100. [Google Scholar] [CrossRef]

- Thirugnanasambandam, M.; Iniyan, S.; Goic, R. A Review of Solar Thermal Technologies. Renew. Sustain. Energy Rev. 2010, 14, 312–322. [Google Scholar] [CrossRef]

- Marzouk, O.A. Land-Use Competitiveness of Photovoltaic and Concentrated Solar Power Technologies near the Tropic of Cancer. Sol. Energy 2022, 243, 103–119. [Google Scholar] [CrossRef]

- WEC (World Energy Council). World Energy Resources: 2013 Survey; WEC (World Energy Council): London, UK, 2013; pp. 1–468. [Google Scholar]

- Mathew, S. Analysis of Wind Regimes. In Wind Energy: Fundamentals, Resource Analysis and Economics; Mathew, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 45–88. ISBN 978-3-540-30906-2. [Google Scholar]

- Eni. World Energy Review (WER), 23rd ed.; Eni S.p.A.: Rome, Italy, 2024; pp. 1–328. [Google Scholar]

- Marzouk, O.A. Expectations for the Role of Hydrogen and Its Derivatives in Different Sectors through Analysis of the Four Energy Scenarios: IEA-STEPS, IEA-NZE, IRENA-PES, and IRENA-1.5 °C. Energies 2024, 17, 646. [Google Scholar] [CrossRef]

- IEA (International Energy Agency). World Energy Outlook (WEO) 2023, 26th ed.; IEA (International Energy Agency): Paris, France, 2023; pp. 1–355. [Google Scholar]

- IRENA (International Renewable Energy Agency). World Energy Transitions Outlook (WETO) 2023: 1.5 °C Pathway, 3rd ed.; IRENA (International Renewable Energy Agency): Abu Dhabi, United Arab Emirates, 2023; Volume 1, pp. 1–258. [Google Scholar]

- WEF (World Economic Forum). Fostering Effective Energy Transition—INSIGHT REPORT; WEF (World Economic Forum): Geneva, Switzerland, 2024; pp. 1–58. [Google Scholar]

- IRENA (International Renewable Energy Agency). Renewable Capacity Statistics 2025; IRENA (International Renewable Energy Agency): Abu Dhabi, United Arab Emirates, 2025; pp. 1–75. [Google Scholar]

- Ember. Global Electricity Review 2025; Eni S.p.A.: London, UK, 2025; pp. 1–118. [Google Scholar]

- Kennedy, R. Solar Supplied over 10% of Global Electricity Consumption in 2024. Available online: https://pv-magazine-usa.com/2025/04/15/solar-supplied-over-10-of-global-electricity-consumption-in-2024 (accessed on 16 April 2025).

- IEA (International Energy Agency). Global Energy Review 2025; IEA (International Energy Agency): Paris, France, 2025; pp. 1–43. [Google Scholar]

- Casey, J.P. IEA: World Reaches 2.2TW of Cumulative Installed Solar Capacity. Available online: https://www.pv-tech.org/iea-world-reaches-2-2tw-cumulative-installed-solar-capacity (accessed on 16 April 2025).

- Siemens Gamesa Siemens Gamesa|Onshore Business. Available online: https://www.siemensgamesa.com/global/en/home/products-and-services/onshore.html (accessed on 28 July 2025).

- Marzouk, O.A. Wind Speed Weibull Model Identification in Oman, and Computed Normalized Annual Energy Production (NAEP) From Wind Turbines Based on Data from Weather Stations. Eng. Rep. 2025, 7, e70089. [Google Scholar] [CrossRef]

- IRENA (International Renewable Energy Agency). Renewable Capacity Highlights 2025; IRENA (International Renewable Energy Agency): Abu Dhabi, United Arab Emirates, 2025; pp. 1–4. [Google Scholar]

- REN21 Market and Industry Trends|CSP. Available online: https://www.ren21.net/gsr-2024/modules/energy_supply/02_market_and_industry_trends/02_csp (accessed on 18 April 2025).

- IRENA (International Renewable Energy Agency). Renewable Energy Benefits: Leveraging Local Capacity for Concentrated Solar Power; IRENA (International Renewable Energy Agency): Abu Dhabi, United Arab Emirates, 2025; pp. 1–56. [Google Scholar]

- Pag, F.; Jesper, M.; Vajen, K.; Jordan, U. Oversizing Solar Heating Plants in Industry: A Cost-Effective Solution to Increase Solar Fractions. Sol. Energy Adv. 2024, 4, 100071. [Google Scholar] [CrossRef]

- REN21 Market and Industry Trends|Solar Thermal Heating. Available online: https://www.ren21.net/gsr-2024/modules/energy_supply/02_market_and_industry_trends/08_solarthermal (accessed on 18 April 2025).

- REN21 Market and Industry Trends|Ocean Power. Available online: https://www.ren21.net/gsr-2024/modules/energy_supply/02_market_and_industry_trends/06_oceanpower (accessed on 18 April 2025).

- Melikoglu, M. Current Status and Future of Ocean Energy Sources: A Global Review. Ocean Eng. 2018, 148, 563–573. [Google Scholar] [CrossRef]

- Marzouk, O.A.; Nayfeh, A.H. Characterization of the Flow over a Cylinder Moving Harmonically in the Cross-Flow Direction. Int. J. Non-Linear Mech. 2010, 45, 821–833. [Google Scholar] [CrossRef]

- Martínez, M.L.; Vázquez, G.; Pérez-Maqueo, O.; Silva, R.; Moreno-Casasola, P.; Mendoza-González, G.; López-Portillo, J.; MacGregor-Fors, I.; Heckel, G.; Hernández-Santana, J.R.; et al. A Systemic View of Potential Environmental Impacts of Ocean Energy Production. Renew. Sustain. Energy Rev. 2021, 149, 111332. [Google Scholar] [CrossRef]

- Fernández-García, A.; Zarza, E.; Valenzuela, L.; Pérez, M. Parabolic-Trough Solar Collectors and Their Applications. Renew. Sustain. Energy Rev. 2010, 14, 1695–1721. [Google Scholar] [CrossRef]

- OTT HydroMet Kipp & Zonen|Introduction (Solar Radiation). Available online: https://www.kippzonen.com/Knowledge-Center/Theoretical-info/Solar-Radiation/Introduction (accessed on 18 April 2025).

- Korevaar, M.A.N. Measuring Solar Irradiance for Photovoltaics. In Solar Radiation—Measurement, Modeling and Forecasting Techniques for Photovoltaic Solar Energy Applications; IntechOpen: London, UK, 2022; ISBN 978-1-83968-859-1. [Google Scholar]

- Marzouk, O.A. Lookup Tables for Power Generation Performance of Photovoltaic Systems Covering 40 Geographic Locations (Wilayats) in the Sultanate of Oman, with and without Solar Tracking, and General Perspectives about Solar Irradiation. Sustainability 2021, 13, 13209. [Google Scholar] [CrossRef]

- Golive, Y.R.; Singh, H.K.; Kottantharayil, A.; Vasi, J.; Shiradkar, N. Investigation of Accuracy of Various STC Correction Procedures for I-V Characteristics of PV Modules Measured at Different Temperature and Irradiances. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 2743–2748. [Google Scholar]

- Zhu, Y.; Zhu, H.; Zhu, R.; Zhou, Y.; Qiu, M.; Li, Q. Photon-Engineered All-Day Radiative Warming Utilizing Solar and Atmospheric Energy. Adv. Opt. Mater. 2025, 13, 2402432. [Google Scholar] [CrossRef]

- Marzouk, O.A.; Nayfeh, A.H. New Wake Models With Capability of Capturing Nonlinear Physics. In Proceedings of the ASME 2008 27th International Conference on Offshore Mechanics and Arctic Engineering (OMAE 2008), Estoril, Portugal, 15–20 June 2008; ASME (American Society of Mechanical Engineers): Estoril, Portugal, 2009; pp. 901–912. [Google Scholar] [CrossRef]

- Lawson, D. A Closer Look at Planck’s Blackbody Equation. Phys. Educ. 1997, 32, 321. [Google Scholar] [CrossRef]

- Lévesque, L. Law of Cooling, Heat Conduction and Stefan-Boltzmann Radiation Laws Fitted to Experimental Data for Bones Irradiated by CO2 Laser. Biomed. Opt. Express BOE 2014, 5, 701–712. [Google Scholar] [CrossRef]

- Crepeau, J. Josef Stefan and His Contributions to Heat Transfer; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2009; pp. 669–676. [Google Scholar]

- Hoyt, D.V.; Schatten, K.H. The Role of the Sun in Climate Change; Oxford University Press: New York, NY, USA, 1997; ISBN 978-0-19-535748-6. [Google Scholar]

- Boyd, C.E. Solar Radiation and Water Temperature. In Water Quality: An Introduction; Boyd, C.E., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 21–39. ISBN 978-3-030-23335-8. [Google Scholar]

- Miroshnichenko, L. Main Characteristics of the Sun. In Solar-Terrestrial Relations: From Solar Activity to Heliobiology; Miroshnichenko, L., Ed.; Springer International Publishing: Cham, Switzerland, 2023; pp. 7–20. ISBN 978-3-031-22548-2. [Google Scholar]

- Lapenta, G. Chapter 8—Space Weather: Variability in the Sun-Earth Connection. In The Dynamical Ionosphere; Materassi, M., Forte, B., Coster, A.J., Skone, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 61–85. ISBN 978-0-12-814782-5. [Google Scholar]

- Menezes, F.; Selhorst, C.L.; Valio, A. The Subterahertz Sun. Bol. Soc. Astronômica Bras. 2020, 31, 57–61. [Google Scholar]

- del Burgo, C.; Allende Prieto, C. Accurate Parameters for HD 209458 and Its Planet from HST Spectrophotometry. Mon. Not. R. Astron. Soc. 2016, 463, 1400–1408. [Google Scholar] [CrossRef]

- CENDI (United States Commerce, Energy, NASA, and Defense Information). Frequently Asked Questions about Copyright; CENDI (United States Commerce, Energy, NASA, and Defense Information): Washington, DC, USA, 2017. [Google Scholar]

- Tasmin, N.; Farjana, S.H.; Hossain, M.R.; Golder, S.; Mahmud, M.A.P. Integration of Solar Process Heat in Industries: A Review. Clean Technol. 2022, 4, 97–131. [Google Scholar] [CrossRef]

- Masera, K.; Tannous, H.; Stojceska, V.; Tassou, S. An Investigation of the Recent Advances of the Integration of Solar Thermal Energy Systems to the Dairy Processes. Renew. Sustain. Energy Rev. 2023, 172, 113028. [Google Scholar] [CrossRef]

- Mohammadi, K.; Khanmohammadi, S.; Immonen, J.; Powell, K. Techno-Economic Analysis and Environmental Benefits of Solar Industrial Process Heating Based on Parabolic Trough Collectors. Sustain. Energy Technol. Assess. 2021, 47, 101412. [Google Scholar] [CrossRef]

- Ismail, M.I.; Yunus, N.A.; Hashim, H. Integration of Solar Heating Systems for Low-Temperature Heat Demand in Food Processing Industry—A Review. Renew. Sustain. Energy Rev. 2021, 147, 111192. [Google Scholar] [CrossRef]

- Said, Z.; Ghodbane, M.; Tiwari, A.K.; Ali, H.M.; Boumeddane, B.; Ali, Z.M. 4E (Energy, Exergy, Economic, and Environment) Examination of a Small LFR Solar Water Heater: An Experimental and Numerical Study. Case Stud. Therm. Eng. 2021, 27, 101277. [Google Scholar] [CrossRef]

- EPA (United States Environmental Protection Agency). Solar Heating and Cooling Technologies. Available online: https://19january2017snapshot.epa.gov/rhc/solar-heating-and-cooling-technologies (accessed on 19 April 2025).

- OpenLearn (The Open University). Can Renewable Energy Sources Power the World? Available online: https://www.open.edu/openlearn/mod/oucontent/view.php?id=73759§ion=7 (accessed on 19 April 2025).

- Vengadesan, E.; Senthil, R. A Review on Recent Developments in Thermal Performance Enhancement Methods of Flat Plate Solar Air Collector. Renew. Sustain. Energy Rev. 2020, 134, 110315. [Google Scholar] [CrossRef]

- Ramani, B.M.; Gupta, A.; Kumar, R. Performance of a Double Pass Solar Air Collector. Sol. Energy 2010, 84, 1929–1937. [Google Scholar] [CrossRef]

- Tripanagnostopoulos, Y.; Souliotis, M.; Nousia, T. Solar Collectors with Colored Absorbers. Sol. Energy 2000, 68, 343–356. [Google Scholar] [CrossRef]

- Marzouk, O.A. Dataset of Total Emissivity for CO2, H2O, and H2O-CO2 Mixtures; over a Temperature Range of 300-2900 K and a Pressure-Pathlength Range of 0.01-50 Atm.m. Data Brief 2025, 59, 111428. [Google Scholar] [CrossRef] [PubMed]

- Badache, M.; Rousse, D.R.; Hallé, S.; Quesada, G. Experimental and Numerical Simulation of a Two-Dimensional Unglazed Transpired Solar Air Collector. Sol. Energy 2013, 93, 209–219. [Google Scholar] [CrossRef]

- Karim, M.A.; Hawlader, M.N.A. Development of Solar Air Collectors for Drying Applications. Energy Convers. Manag. 2004, 45, 329–344. [Google Scholar] [CrossRef]

- Myroniuk, K.; Furdas, Y.; Zhelykh, V.; Adamski, M.; Gumen, O.; Savin, V.; Mitoulis, S.-A. Passive Ventilation of Residential Buildings Using the Trombe Wall. Buildings 2024, 14, 3154. [Google Scholar] [CrossRef]

- EPA (United States Environmental Protection Agency). EPA Sketch|Transpired Solar Air Collectors. Available online: https://19january2017snapshot.epa.gov/sites/production/files/styles/medium/public/2014-11/transpired.png (accessed on 12 April 2025).

- García, J.; Socolovsky, H.; Plá, J. On the Spectral Response Measurement of Multijunction Solar Cells. Meas. Sci. Technol. 2017, 28, 055203. [Google Scholar] [CrossRef]

- Simon, M.; Meyer, E.L. The Effects of Spectral Evaluation of C-Si Modules. Prog. Photovolt. Res. Appl. 2011, 19, 1–10. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, C.; Wang, J.; Kuang, X.; Su, Q. A Dual-Mode Solar Spectral Converter CaLaGa3S6O:Ce3+,Pr3+: UV-Vis-NIR Luminescence Properties and Solar Spectral Converting Mechanism. J. Mater. Chem. 2012, 22, 2226–2232. [Google Scholar] [CrossRef]

- Farina, A.; Carlotto, A.; Varas, S.; Chiasera, A.; Pietralunga, S.M. An Asymmetric Low Concentrator and Spectral Splitting Approach to Bifacial Four-Terminal Photovoltaic Modules. Prog. Photovolt. Res. Appl. 2023, 31, 1299–1314. [Google Scholar] [CrossRef]

- Ferrada, P.; Marzo, A.; Cabrera, E.; Chu, H.; del Campo, V.; Rabanal, J.; Diaz-Almeida, D.; Schneider, A.; Kopecek, R. Potential for Photogenerated Current for Silicon Based Photovoltaic Modules in the Atacama Desert. Sol. Energy 2017, 144, 580–593. [Google Scholar] [CrossRef]

- Zhao, J.; Song, Y.; Lam, W.-H.; Liu, W.; Liu, Y.; Zhang, Y.; Wang, D. Solar Radiation Transfer and Performance Analysis of an Optimum Photovoltaic/Thermal System. Energy Convers. Manag. 2011, 52, 1343–1353. [Google Scholar] [CrossRef]

- Law, A.M.; Jones, L.O.; Walls, J.M. The Performance and Durability of Anti-Reflection Coatings for Solar Module Cover Glass—A Review. Sol. Energy 2023, 261, 85–95. [Google Scholar] [CrossRef]

- Sjerps-Koomen, E.A.; Alsema, E.A.; Turkenburg, W.C. A Simple Model for PV Module Reflection Losses under Field Conditions. Sol. Energy 1996, 57, 421–432. [Google Scholar] [CrossRef]

- Herrando, M.; Pantaleo, A.M.; Wang, K.; Markides, C.N. Solar Combined Cooling, Heating and Power Systems Based on Hybrid PVT, PV or Solar-Thermal Collectors for Building Applications. Renew. Energy 2019, 143, 637–647. [Google Scholar] [CrossRef]

- Lorestani, A.; Ardehali, M.M. Optimization of Autonomous Combined Heat and Power System Including PVT, WT, Storages, and Electric Heat Utilizing Novel Evolutionary Particle Swarm Optimization Algorithm. Renew. Energy 2018, 119, 490–503. [Google Scholar] [CrossRef]

- Ishak, M.A.A.B.; Ibrahim, A.; Fazlizan, A.; Fauzan, M.F.; Sopian, K.; Rahmat, A.A. Exergy Performance of a Reversed Circular Flow Jet Impingement Bifacial Photovoltaic Thermal (PVT) Solar Collector. Case Stud. Therm. Eng. 2023, 49, 103322. [Google Scholar] [CrossRef]

- Rajani, A.; Said, D.M.; Noorden, Z.A.; Ahmad, N.; Atmaja, T.D.; Fudholi, A. Performance Evaluation of Bifacial Photovoltaic Thermal Systems in Environmental Condition. In Proceedings of the 2024 IEEE International Conference on Advanced Power Engineering and Energy (APEE), Johor Bahru, Malaysia, 10–11 September 2024; pp. 53–58. [Google Scholar]

- Mahmood, A.J. Experimental Study for Improving Unglazed Solar System. Cogent Eng. 2021, 8, 1961564. [Google Scholar] [CrossRef]

- Medved, S.; Arkar, C.; Černe, B. A Large-Panel Unglazed Roof-Integrated Liquid Solar Collector––Energy and Economic Evaluation. Sol. Energy 2003, 75, 455–467. [Google Scholar] [CrossRef]

- Shemelin, V.; Matuska, T. Unglazed Solar Thermal Collector for Building Facades. Energy Rep. 2022, 8, 605–617. [Google Scholar] [CrossRef]

- EPA (United States Environmental Protection Agency). EPA Sketch|Unglazed Solar Collector. Available online: https://19january2017snapshot.epa.gov/sites/production/files/styles/large/public/2014-11/unglazed.png (accessed on 12 April 2025).

- Dagdougui, H.; Ouammi, A.; Robba, M.; Sacile, R. Thermal Analysis and Performance Optimization of a Solar Water Heater Flat Plate Collector: Application to Tétouan (Morocco). Renew. Sustain. Energy Rev. 2011, 15, 630–638. [Google Scholar] [CrossRef]

- Klein, S.A. Calculation of Flat-Plate Collector Utilizability. Sol. Energy 1978, 21, 393–402. [Google Scholar] [CrossRef]

- Pandey, K.M.; Chaurasiya, R. A Review on Analysis and Development of Solar Flat Plate Collector. Renew. Sustain. Energy Rev. 2017, 67, 641–650. [Google Scholar] [CrossRef]

- EPA (United States Environmental Protection Agency). EPA Sketch|Flat-Plate Solar Collectors. Available online: https://19january2017snapshot.epa.gov/sites/production/files/styles/large/public/2014-11/flat-plate.png (accessed on 12 April 2025).

- Griffiths, P.W.; di Leo, M.; Cartwright, P.; Eames, P.C.; Yianoulis, P.; Leftheriotis, G.; Norton, B. Fabrication of Evacuated Glazing at Low Temperature. Sol. Energy 1998, 63, 243–249. [Google Scholar] [CrossRef]

- Marzouk, O.A. InvSim Algorithm for Pre-Computing Airplane Flight Controls in Limited-Range Autonomous Missions, and Demonstration via Double-Roll Maneuver of Mirage III Fighters. Sci. Rep. 2025, 15, 23382. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Measured Thermal Performance of a Combined Suspended Particle Switchable Device Evacuated Glazing. Appl. Energy 2016, 169, 469–480. [Google Scholar] [CrossRef]

- Collins, R.E.; Robinson, S.J. Evacuated Glazing. Sol. Energy 1991, 47, 27–38. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Effect of Sky Clearness Index on Transmission of Evacuated (Vacuum) Glazing. Renew. Energy 2017, 105, 160–166. [Google Scholar] [CrossRef]

- Sampathkumar, K.; Arjunan, T.V.; Senthilkumar, P. The Experimental Investigation of a Solar Still Coupled with an Evacuated Tube Collector. Energy Sources Part A Recovery Util. Environ. Eff. 2013, 35, 261–270. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.V.; Pandey, A.K.; Sari, A. Global Advancement on Experimental and Thermal Analysis of Evacuated Tube Collector with and without Heat Pipe Systems and Possible Applications. Appl. Energy 2018, 228, 351–389. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Mekhilef, S.; Mahian, O. Progress and Latest Developments of Evacuated Tube Solar Collectors. Renew. Sustain. Energy Rev. 2015, 51, 1038–1054. [Google Scholar] [CrossRef]

- Chai, S.; Yao, J.; Liang, J.-D.; Chiang, Y.-C.; Zhao, Y.; Chen, S.-L.; Dai, Y. Heat Transfer Analysis and Thermal Performance Investigation on an Evacuated Tube Solar Collector with Inner Concentrating by Reflective Coating. Sol. Energy 2021, 220, 175–186. [Google Scholar] [CrossRef]

- Sobhansarbandi, S.; Martinez, P.M.; Papadimitratos, A.; Zakhidov, A.; Hassanipour, F. Evacuated Tube Solar Collector with Multifunctional Absorber Layers. Sol. Energy 2017, 146, 342–350. [Google Scholar] [CrossRef]

- Chen, X.; Yang, X. Heat Transfer Enhancement for U-Pipe Evacuated Tube Solar Absorber by High-Emissivity Coating on Metal Fin. J. Build. Eng. 2022, 50, 104213. [Google Scholar] [CrossRef]

- EPA (United States Environmental Protection Agency). EPA Sketch|Evacuated Tube Solar Collectors. Available online: https://19january2017snapshot.epa.gov/sites/production/files/styles/large/public/2014-11/evacuated-tube.png (accessed on 12 April 2025).

- AET (Alternative Energy Tutorials). Evacuated Tube Collector for Solar Hot Water System. Available online: https://www.alternative-energy-tutorials.com/solar-hot-water/evacuated-tube-collector.html (accessed on 19 April 2025).

- Marzouk, O.A.; Huckaby, E.D. Simulation of a Swirling Gas-Particle Flow Using Different k-Epsilon Models and Particle-Parcel Relationships. Eng. Lett. 2010, 18, 1–12. [Google Scholar]

- Jafari Mosleh, H.; Jahangiri Mamouri, S.; Shafii, M.B.; Hakim Sima, A. A New Desalination System Using a Combination of Heat Pipe, Evacuated Tube and Parabolic Trough Collector. Energy Convers. Manag. 2015, 99, 141–150. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Kotb, A.; Elsamni, O. Thermal Performance of a Heat-Pipe Evacuated-Tube Solar Collector at High Inlet Temperatures. Appl. Therm. Eng. 2019, 154, 315–325. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A. Thermal Performance Analysis of a Solar Water Heating System with Heat Pipe Evacuated Tube Collector Using Data from a Field Trial. Sol. Energy 2013, 90, 17–28. [Google Scholar] [CrossRef]

- Tauquir, A.; Singh, S.K. Analysis of Evacuated Tube Heatpipe Collectors Using Oil and Foamed Metals:—A Review. Int. J. Eng. Technol. Appl. Sci. 2022, 8, 1–6. [Google Scholar]

- Marzouk, O.A. Evolutionary Computing Applied to Design Optimization. In Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC-CIE 2007), Las Vegas, NV, USA, 4–7 September 2007; ASME (American Society of Mechanical Engineers): Las Vegas, NV, USA, 2009; Volume 2, pp. 995–1003. [Google Scholar] [CrossRef]

- Rybár, R.; Beer, M. The Comparative Field Performance Study of Heat Pipe Evacuated Tube Collectors with Standard Design Manifold Header and Parallel Flow Manifold Header Based on the Metal Foam Structural Element. Sol. Energy 2015, 122, 359–367. [Google Scholar] [CrossRef]

- Ratismith, W.; Favre, Y. Novel Non-Tracking Solar Collector with Metal-to-Water Contact. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 347–351. [Google Scholar]

- Marzouk, O.A.; Nayfeh, A.H. A Study of the Forces on an Oscillating Cylinder. In Proceedings of the ASME 2007 26th International Conference on Offshore Mechanics and Arctic Engineering (OMAE 2007), San Diego, CA, USA, 10–15 June 2007; ASME (American Society of Mechanical Engineers): San Diego, CA, USA, 2009; pp. 741–752. [Google Scholar] [CrossRef]

- Lim, C.S.L.; Sobhansarbandi, S. CFD Modeling of an Evacuated U-Tube Solar Collector Integrated with a Novel Heat Transfer Fluid. Sustain. Energy Technol. Assess. 2022, 52, 102051. [Google Scholar] [CrossRef]

- Marzouk, O.A. One-Way and Two-Way Couplings of CFD and Structural Models and Application to the Wake-Body Interaction. Appl. Math. Model. 2011, 35, 1036–1053. [Google Scholar] [CrossRef]

- Marzouk, O.A. Contrasting the Cartesian and Polar Forms of the Shedding-Induced Force Vector in Response to 12 Subharmonic and Superharmonic Mechanical Excitations. Fluid Dyn. Res. 2010, 42, 035507. [Google Scholar] [CrossRef]

- Fok, S.C.; Tan, F.L.; Leow, K.K. CAD Modelling of Solidification Phase Front around a Vertical Finned Tube. Int. J. Comput. Aided Eng. Technol. 2012, 4, 420–431. [Google Scholar] [CrossRef]

- Marzouk, O.A. Flow Control Using Bifrequency Motion. Theor. Comput. Fluid Dyn. 2011, 25, 381–405. [Google Scholar] [CrossRef]

- Rosa, C.; Panagiotis, T.; Vassiliki, D. Optical Analysis of an Evacuated Tube Collector with Built-in Compound Parabolic Concentrator for Process Heat Applications. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012040. [Google Scholar] [CrossRef]

- Jebasingh, V.K.; Herbert, G.M.J. A Review of Solar Parabolic Trough Collector. Renew. Sustain. Energy Rev. 2016, 54, 1085–1091. [Google Scholar] [CrossRef]

- Manikandan, G.K.; Iniyan, S.; Goic, R. Enhancing the Optical and Thermal Efficiency of a Parabolic Trough Collector—A Review. Appl. Energy 2019, 235, 1524–1540. [Google Scholar] [CrossRef]

- Naveenkumar, R.; Ravichandran, M.; Stalin, B.; Ghosh, A.; Karthick, A.; Aswin, L.S.R.L.; Priyanka, S.S.H.; Kumar, S.P.; Kumar, S.K. Comprehensive Review on Various Parameters That Influence the Performance of Parabolic Trough Collector. Environ. Sci Pollut. Res 2021, 28, 22310–22333. [Google Scholar] [CrossRef]

- Kalogirou, S.A. A Detailed Thermal Model of a Parabolic Trough Collector Receiver. Energy 2012, 48, 298–306. [Google Scholar] [CrossRef]

- EPA (United States Environmental Protection Agency). EPA Sketch|Concentrating Solar Systems (Parabolic Trough Collector). Available online: https://19january2017snapshot.epa.gov/sites/production/files/styles/large/public/2014-11/concentrating-solar.png (accessed on 12 April 2025).

- Gharat, P.V.; Bhalekar, S.S.; Dalvi, V.H.; Panse, S.V.; Deshmukh, S.P.; Joshi, J.B. Chronological Development of Innovations in Reflector Systems of Parabolic Trough Solar Collector (PTC)—A Review. Renew. Sustain. Energy Rev. 2021, 145, 111002. [Google Scholar] [CrossRef]

- Upadhyay, B.H.; Patel, A.J.; Ramana, P.V. A Detailed Review on Solar Parabolic Trough Collector. Int. J. Ambient Energy 2022, 43, 176–196. [Google Scholar] [CrossRef]

- Goel, A.; Manik, G.; Mahadeva, R. A Review of Parabolic Trough Collector and Its Modeling. In Soft Computing: Theories and Applications; Pant, M., Sharma, T.K., Verma, O.P., Singla, R., Sikander, A., Eds.; Springer: Singapore, 2020; pp. 803–813. [Google Scholar]

- Mokhtar, G.; Boussad, B.; Noureddine, S. A Linear Fresnel Reflector as a Solar System for Heating Water: Theoretical and Experimental Study. Case Stud. Therm. Eng. 2016, 8, 176–186. [Google Scholar] [CrossRef]

- Abbas, R.; Montes, M.J.; Piera, M.; Martínez-Val, J.M. Solar Radiation Concentration Features in Linear Fresnel Reflector Arrays. Energy Convers. Manag. 2012, 54, 133–144. [Google Scholar] [CrossRef]

- Wang, G.; Wang, F.; Shen, F.; Jiang, T.; Chen, Z.; Hu, P. Experimental and Optical Performances of a Solar CPV Device Using a Linear Fresnel Reflector Concentrator. Renew. Energy 2020, 146, 2351–2361. [Google Scholar] [CrossRef]

- DOE (United States Department of Energy). DOE Sketch|Linear Fresnel Reflector Systems. Available online: https://www.energy.gov/sites/default/files/styles/full_article_width/public/linear_frisnel.gif (accessed on 12 April 2025).

- Wang, G.; Ge, Z.; Lin, J. Design and Performance Analysis of a Novel Solar Photovoltaic/Thermal System Using Compact Linear Fresnel Reflector and Nanofluids Beam Splitting Device. Case Stud. Therm. Eng. 2022, 35, 102167. [Google Scholar] [CrossRef]

- Wang, G.; Wang, F.; Shen, F.; Chen, Z.; Hu, P. Novel Design and Thermodynamic Analysis of a Solar Concentration PV and Thermal Combined System Based on Compact Linear Fresnel Reflector. Energy 2019, 180, 133–148. [Google Scholar] [CrossRef]

- Babu, M.; Sekhar Babu, P.; Raj, S.S.; Saravanan, S. Theoretical Design, Material Study and Material Selection for Compact Linear Fresnel Reflector Concentrating System. Mater. Today Proc. 2021, 45, 1671–1678. [Google Scholar] [CrossRef]

- Kumar, K.H.; Daabo, A.M.; Karmakar, M.K.; Hirani, H. Solar Parabolic Dish Collector for Concentrated Solar Thermal Systems: A Review and Recommendations. Environ. Sci. Pollut. Res. 2022, 29, 32335–32367. [Google Scholar] [CrossRef] [PubMed]

- Maurya, A.; Kumar, A.; Sharma, D. A Comprehensive Review on Performance Assessment of Solar Cavity Receiver with Parabolic Dish Collector. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 4808–4845. [Google Scholar] [CrossRef]

- Vishnu, S.K.; Senthil, R. Experimental Performance Evaluation of a Solar Parabolic Dish Collector Using Spiral Flow Path Receiver. Appl. Therm. Eng. 2023, 231, 120979. [Google Scholar] [CrossRef]

- DOE (United States Department of Energy). DOE Sketch|Dish/Engine System. Available online: https://www.energy.gov/sites/default/files/styles/full_article_width/public/dish_receivers.gif (accessed on 12 April 2025).

- Srilakshmi, G.; Venkatesh, V.; Thirumalai, N.C.; Suresh, N.S. Challenges and Opportunities for Solar Tower Technology in India. Renew. Sustain. Energy Rev. 2015, 45, 698–709. [Google Scholar] [CrossRef]

- Segal, A.; Epstein, M. The Optics of the Solar Tower Reflector. Sol. Energy 2001, 69, 229–241. [Google Scholar] [CrossRef]

- Milidonis, K.; Blanco, M.J.; Grigoriev, V.; Panagiotou, C.F.; Bonanos, A.M.; Constantinou, M.; Pye, J.; Asselineau, C.-A. Review of Application of AI Techniques to Solar Tower Systems. Sol. Energy 2021, 224, 500–515. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, J.; Xiao, B.; Hou, G.; Xing, F. Analysis of Chimney Height for Solar Chimney Power Plant. Appl. Therm. Eng. 2009, 29, 178–185. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, F.; Ochieng, R.M. A Review of Solar Chimney Power Technology. Renew. Sustain. Energy Rev. 2010, 14, 2315–2338. [Google Scholar] [CrossRef]

- Marzouk, O.A. Energy Generation Intensity (EGI) of Solar Updraft Tower (SUT) Power Plants Relative to CSP Plants and PV Power Plants Using the New Energy Simulator “Aladdin”. Energies 2024, 17, 405. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, G.; Yang, W.; Huang, D.; Cheng, X.; Setunge, S. Determining the Influencing Factors on the Performance of Solar Chimney in Buildings. Renew. Sustain. Energy Rev. 2018, 88, 223–238. [Google Scholar] [CrossRef]

- Ong, K.S. A Mathematical Model of a Solar Chimney. Renew. Energy 2003, 28, 1047–1060. [Google Scholar] [CrossRef]

- Ong, K.S.; Chow, C.C. Performance of a Solar Chimney. Sol. Energy 2003, 74, 1–17. [Google Scholar] [CrossRef]

- Afonso, C.; Oliveira, A. Solar Chimneys: Simulation and Experiment. Energy Build. 2000, 32, 71–79. [Google Scholar] [CrossRef]

- DOE (United States Department of Energy). DOE Sketch|Power Tower System (Solar Electricity and Industrial Process Heat). Available online: https://www.energy.gov/sites/default/files/styles/full_article_width/public/2023-05/Concentrating-Solar-Thermal-Power-Applications.PNG (accessed on 12 April 2025).

- DOE (United States Department of Energy). DOE Sketch|Power Tower System. Available online: https://www.energy.gov/sites/default/files/styles/full_article_width/public/power_tower.gif (accessed on 12 April 2025).

- Mubarrat, M.; Mashfy, M.M.; Farhan, T.; Ehsan, M.M. Research Advancement and Potential Prospects of Thermal Energy Storage in Concentrated Solar Power Application. Int. J. Thermofluids 2023, 20, 100431. [Google Scholar] [CrossRef]

- Alexopoulos, S.; Hoffschmidt, B. Concentrating Receiver Systems (Solar Power Tower). In Solar Thermal Energy; Alexopoulos, S., Kalogirou, S.A., Eds.; Springer: New York, NY, USA, 2022; pp. 63–110. ISBN 978-1-07-161422-8. [Google Scholar]

- Okoroigwe, E.; Madhlopa, A. An Integrated Combined Cycle System Driven by a Solar Tower: A Review. Renew. Sustain. Energy Rev. 2016, 57, 337–350. [Google Scholar] [CrossRef]

- Collado, F.J.; Guallar, J. A Review of Optimized Design Layouts for Solar Power Tower Plants with Campo Code. Renew. Sustain. Energy Rev. 2013, 20, 142–154. [Google Scholar] [CrossRef]

- Boretti, A.; Castelletto, S.; Al-Zubaidy, S. Concentrating Solar Power Tower Technology: Present Status and Outlook. Nonlinear Eng. 2019, 8, 10–31. [Google Scholar] [CrossRef]

- Reddy, K.S.; Ravi Kumar, K.; Devaraj, V.A. Feasibility Analysis of Megawatt Scale Solar Thermal Power Plants. J. Renew. Sustain. Energy 2012, 4, 063111. [Google Scholar] [CrossRef]

- Pavlović, T.M.; Radonjić, I.S.; Milosavljević, D.D.; Pantić, L.S. A Review of Concentrating Solar Power Plants in the World and Their Potential Use in Serbia. Renew. Sustain. Energy Rev. 2012, 16, 3891–3902. [Google Scholar] [CrossRef]

- Poullikkas, A. Economic Analysis of Power Generation from Parabolic Trough Solar Thermal Plants for the Mediterranean Region—A Case Study for the Island of Cyprus. Renew. Sustain. Energy Rev. 2009, 13, 2474–2484. [Google Scholar] [CrossRef]

- Kaltschmitt, M.; Streicher, W.; Wiese, A. (Eds.) Solar Thermal Power Plants. In Renewable Energy: Technology, and Environment Economics; Springer: Berlin/Heidelberg, Germany, 2007; pp. 171–228. ISBN 978-3-540-70949-7. [Google Scholar]

- Ahmed, M.H.; Rady, M.; Amin, A.M.A.; Montagnino, F.M.; Paredes, F. Comparison of Thermal and Optical Performance of Linear Fresnel and Parabolic Trough Concentrator. In Proceedings of the 2015 International Conference on Renewable Energy Research and Applications (ICRERA), Palermo, Italy, 22–25 November 2015; pp. 626–629. [Google Scholar]

- Abu-Bakar, S.H.; Muhammad-Sukki, F.; Ramirez-Iniguez, R.; Burek, S.; Mallick, T.K.; McLennan, C.; Munir, A.B.; Yasin, S.H.M. Renewable Heat Incentive for Solar Thermal Systems in the United Kingdom: The next Big Thing? In Proceedings of the 2012 IEEE International Conference on Power and Energy (PECon), Kota Kinabalu, Malaysia, 2–5 December 2012; pp. 626–631. [Google Scholar]

- Grubler, A.; Wilson, C. Energy Technology Innovation: Learning from Historical Successes and Failures; Cambridge University Press: New York, NY, USA, 2013; ISBN 978-1-107-72918-6. [Google Scholar]

- Lizárraga-Morazán, J.-R.; Picón-Núñez, M. Optimal Determination of the Q/A Factor for Parabolic Concentrator Solar Collector Networks. Chem. Eng. Trans. 2024, 114, 319–324. [Google Scholar] [CrossRef]

- SSC WG (Small-Scale Working Group). Annex 3 Analysis and Explanation of the Conversion Factor for Solar Thermal Collectors; UNFCCC (United Nations Framework Convention on Climate Change): Bonn, Germany, 2007; pp. 1–3. [Google Scholar]

- Reddy, K.S.; Kumar, K.R. Solar Collector Field Design and Viability Analysis of Stand-Alone Parabolic Trough Power Plants for Indian Conditions. Energy Sustain. Dev. 2012, 16, 456–470. [Google Scholar] [CrossRef]

- Perers, B.; Karlsson, B. External Reflectors for Large Solar Collector Arrays, Simulation Model and Experimental Results. Sol. Energy 1993, 51, 327–337. [Google Scholar] [CrossRef]

- Obstawski, P.; Bakoń, T.; Czekalski, D. Comparison of Solar Collector Testing Methods—Theory and Practice. Processes 2020, 8, 1340. [Google Scholar] [CrossRef]

- Cau, G.; Cocco, D. Comparison of Medium-Size Concentrating Solar Power Plants Based on Parabolic Trough and Linear Fresnel Collectors. Energy Procedia 2014, 45, 101–110. [Google Scholar] [CrossRef]

- Solarthermalworld Solarthermalworld|About Us. Available online: https://solarthermalworld.org/about-us (accessed on 20 April 2025).

- EEF (European Energy Forum). ICA Europe. Available online: https://www.europeanenergyforum.eu/associate-member/european-copper-institute (accessed on 20 April 2025).

- Solar Payback Solar Payback|Suppliers. Available online: https://www.solar-payback.com/suppliers (accessed on 20 April 2025).

- Solrico Solrico|Contact Us. Available online: https://www.solrico.com/index.php?id=12 (accessed on 20 April 2025).

- Fairlie, R.; Fossen, F.M. The Early Impacts of the COVID-19 Pandemic on Business Sales. Small Bus Econ 2022, 58, 1853–1864. [Google Scholar] [CrossRef]

- Meyer, B.H.; Prescott, B.; Sheng, X.S. The Impact of the COVID-19 Pandemic on Business Expectations. Int. J. Forecast. 2022, 38, 529–544. [Google Scholar] [CrossRef] [PubMed]

- Szczygielski, J.J.; Brzeszczyński, J.; Charteris, A.; Bwanya, P.R. The COVID-19 Storm and the Energy Sector: The Impact and Role of Uncertainty. Energy Econ. 2022, 109, 105258. [Google Scholar] [CrossRef]

- Solarthermalworld Solarthermalworld|2024 Global SHIP Market According to New Capacity per Country. Available online: https://solarthermalworld.org/wp-content/uploads/2025/03/2024-Global-SHIP-market-according-to-new-capacity-per-country.png (accessed on 21 April 2025).

- Solarthermalworld Solarthermalworld|2024 Global SHIP Market According to Collector Type. Available online: https://solarthermalworld.org/wp-content/uploads/2025/03/2024-Global-SHIP-market-according-to-collector-type.png (accessed on 21 April 2025).

- Otte, P.P. Solar Cookers in Developing Countries—What Is Their Key to Success? Energy Policy 2013, 63, 375–381. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. A Comprehensive Review on Solar Cookers. Appl. Energy 2013, 102, 1399–1421. [Google Scholar] [CrossRef]

- Arunachala, U.C.; Kundapur, A. Cost-Effective Solar Cookers: A Global Review. Sol. Energy 2020, 207, 903–916. [Google Scholar] [CrossRef]

- Padonou, E.A.; Akabassi, G.C.; Akakpo, B.A.; Sinsin, B. Importance of Solar Cookers in Women’s Daily Lives: A Review. Energy Sustain. Dev. 2022, 70, 466–474. [Google Scholar] [CrossRef]

- Wentzel, M.; Pouris, A. The Development Impact of Solar Cookers: A Review of Solar Cooking Impact Research in South Africa. Energy Policy 2007, 35, 1909–1919. [Google Scholar] [CrossRef]

- Xiaowu, W.; Ben, H. Exergy Analysis of Domestic-Scale Solar Water Heaters. Renew. Sustain. Energy Rev. 2005, 9, 638–645. [Google Scholar] [CrossRef]

- Buckles, W.E.; Klein, S.A. Analysis of Solar Domestic Hot Water Heaters. Sol. Energy 1980, 25, 417–424. [Google Scholar] [CrossRef]

- Nanda, I.R.; Pambudi, N.A.; Aziz, M. Review on the Progress of Solar Water Heaters and Their Future Perspectives. Energy Technol. 2023, 11, 2300191. [Google Scholar] [CrossRef]

- Jaisankar, S.; Ananth, J.; Thulasi, S.; Jayasuthakar, S.T.; Sheeba, K.N. A Comprehensive Review on Solar Water Heaters. Renew. Sustain. Energy Rev. 2011, 15, 3045–3050. [Google Scholar] [CrossRef]

- Al-Badi, A.H.; Albadi, M.H. Domestic Solar Water Heating System in Oman: Current Status and Future Prospects. Renew. Sustain. Energy Rev. 2012, 16, 5727–5731. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Environmental Benefits of Domestic Solar Energy Systems. Energy Convers. Manag. 2004, 45, 3075–3092. [Google Scholar] [CrossRef]

- Ayadi, O.; Al-Dahidi, S. Comparison of Solar Thermal and Solar Electric Space Heating and Cooling Systems for Buildings in Different Climatic Regions. Sol. Energy 2019, 188, 545–560. [Google Scholar] [CrossRef]

- Artur, C.; Neves, D.; Cuamba, B.C.; Leão, A.J. Comparison of Two Dynamic Approaches to Modelling Solar Thermal Systems for Domestic Hot Water. Sustain. Energy Technol. Assess. 2018, 30, 292–303. [Google Scholar] [CrossRef]

- Nafey, A.S. Simulation of Solar Heating Systems—An Overview. Renew. Sustain. Energy Rev. 2005, 9, 576–591. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Iten, M. Modelling of A Solar Thermal Energy System For Energy Efficiency Improvement In A Ceramic Plant. Renew. Energy Environ. Sustain. 2021, 6, 31. [Google Scholar] [CrossRef]

- Modelica Association Modelica|Modelica Language. Available online: https://modelica.org/language (accessed on 11 August 2025).

- OSMC (Open Source Modelica Consortium). OpenModelica|Projects. Available online: https://openmodelica.org/research/projects (accessed on 11 August 2025).

- OSMC (Open Source Modelica Consortium). OpenModelica|Modelica.Thermal. Available online: https://build.openmodelica.org/Documentation/Modelica.Thermal.html (accessed on 11 August 2025).

- Ferhatbegović, T.; Zucker, G.; Palensky, P. Model Based Predictive Control for a Solar-Thermal System. In Proceedings of the IEEE Africon ’11, Victoria Falls, Zambia, 13–15 September 2011; pp. 1–6. [Google Scholar]

- Marzouk, O.A.; Nayfeh, A.H. Mitigation of Ship Motion Using Passive and Active Anti-Roll Tanks. In Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC-CIE 2007), Las Vegas, NV, USA, 4–7 September 2007; ASME (American Society of Mechanical Engineers): Las Vegas, NV, USA, 2009; pp. 215–229. [Google Scholar] [CrossRef]

- da Silva, R.M.; Fernandes, J.L.M. Hybrid Photovoltaic/Thermal (PV/T) Solar Systems Simulation with Simulink/Matlab. Sol. Energy 2010, 84, 1985–1996. [Google Scholar] [CrossRef]

- Marzouk, O.A.; Nayfeh, A.H. Control of Ship Roll Using Passive and Active Anti-Roll Tanks. Ocean Eng. 2009, 36, 661–671. [Google Scholar] [CrossRef]

- Marzouk, O.A.; Nayfeh, A.H. Fluid Forces and Structure-Induced Damping of Obliquely-Oscillating Offshore Structures. In Proceedings of the Eighteenth International Offshore and Polar Engineering Conference (ISOPE-2008), Vancouver, BC, Canada, 6–11 July 2008; ISOPE (International Society of Offshore and Polar Engineers): Vancouver, BC, Canada, 2008; Volume 3, pp. 460–468. [Google Scholar]

- Marzouk, O.A.; Nayfeh, A.H. Reduction of the Loads on a Cylinder Undergoing Harmonic In-Line Motion. Phys. Fluids 2009, 21, 083103. [Google Scholar] [CrossRef]

- Malvi, C.S.; Dixon-Hardy, D.W.; Crook, R. Energy Balance Model of Combined Photovoltaic Solar-Thermal System Incorporating Phase Change Material. Sol. Energy 2011, 85, 1440–1446. [Google Scholar] [CrossRef]

- Marzouk, O.A.; Nayfeh, A.H. Loads on a Harmonically Oscillating Cylinder. In Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC-CIE 2007), Las Vegas, NV, USA, 4–7 September 2007; ASME (American Society of Mechanical Engineers): Las Vegas, NV, USA, 2009; pp. 1755–1774. [Google Scholar] [CrossRef]

- Lamnatou, C.; Mondol, J.D.; Chemisana, D.; Maurer, C. Modelling and Simulation of Building-Integrated Solar Thermal Systems: Behaviour of the System. Renew. Sustain. Energy Rev. 2015, 45, 36–51. [Google Scholar] [CrossRef]

- Tijani, A.S.; Roslan, A.M.S.B. Simulation Analysis of Thermal Losses of Parabolic Trough Solar Collector in Malaysia Using Computational Fluid Dynamics. Procedia Technol. 2014, 15, 841–848. [Google Scholar] [CrossRef]

- Bierman, B.; Al-Lawatia, H.; DiFilippo, M.; O’Donnell, J. Deploying Enclosed Trough for Thermal EOR at Commercial Scale. AIP Conf. Proc. 2018, 2033, 030002. [Google Scholar] [CrossRef]

- Vajpayee, S.; Rawat, T.; Bhalala, V. Mathematical Modeling of Thermal Enhanced Oil Recovery Method. JME 2023, 13, 9. [Google Scholar] [CrossRef]

- EPCM EPCM|An Overview and History of Oil Recovery from On-Shore Oil Reserves. Available online: https://epcmholdings.com/an-overview-and-history-of-oil-recovery-from-on-shore-oil-reserves (accessed on 11 August 2025).

- GlassPoint GlassPoint|Maaden Solar I. Available online: https://www.glasspoint.com/projects/maaden-solar (accessed on 11 August 2025).

- Kar, M.K.; Önal, M.A.R.; Borra, C.R. Alumina Recovery from Bauxite Residue: A Concise Review. Resour. Conserv. Recycl. 2023, 198, 107158. [Google Scholar] [CrossRef]

- Donoghue, A.M.; Frisch, N.; Olney, D. Bauxite Mining and Alumina Refining: Process Description and Occupational Health Risks. J. Occup. Environ. Med. 2014, 56, S12. [Google Scholar] [CrossRef]

- Mahadevan, H.; Ramachandran, T.R. Recent Trends in Alumina and Aluminium Production Technology. Bull. Mater. Sci. 1996, 19, 905–920. [Google Scholar] [CrossRef]

- Metson, J. Alumina. In Fundamentals of Aluminium Metallurgy; Lumley, R., Ed.; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing: Cambridge, UK, 2011; pp. 23–48. ISBN 978-1-84569-654-2. [Google Scholar]

- Maaden (Saudi Arabian Mining Company). Maaden|About Maaden. Available online: https://maaden.com/discover-us/about-maaden (accessed on 11 August 2025).

- Huang, J.; Fan, J.; Furbo, S. Feasibility Study on Solar District Heating in China. Renew. Sustain. Energy Rev. 2019, 108, 53–64. [Google Scholar] [CrossRef]

- Perez-Mora, N.; Bava, F.; Andersen, M.; Bales, C.; Lennermo, G.; Nielsen, C.; Furbo, S.; Martínez-Moll, V. Solar District Heating and Cooling: A Review. Int. J. Energy Res. 2018, 42, 1419–1441. [Google Scholar] [CrossRef]

- de Vega, M.; Almendros-Ibañez, J.A.; Ruiz, G. Performance of a LiBr–Water Absorption Chiller Operating with Plate Heat Exchangers. Energy Convers. Manag. 2006, 47, 3393–3407. [Google Scholar] [CrossRef]

- Yu, F.W.; Chan, K.T.; Sit, R.K.Y.; Yang, J. Review of Standards for Energy Performance of Chiller Systems Serving Commercial Buildings. Energy Procedia 2014, 61, 2778–2782. [Google Scholar] [CrossRef]

| Line-Focused (Line-Concentrator) | Point-Focused (Point-Concentrator) | |

|---|---|---|

| Type 1 | LFR (linear Fresnel reflector) CLFR (compact linear Fresnel reflector) | PDC (parabolic dish collector) |

| Type 2 | PTC (parabolic trough collector) | SPT (solar power tower) or heliostats |

| Collector Type | Low Temperature Rise (Below 75 °C) | Medium Temperature Rise (75–150 °C) | High Temperature Rise (150–400 °C) |

|---|---|---|---|

| SAC (solar air collector) | ✓ | ||

| PVT (photovoltaic–thermal) | ✓ | ||

| USC (unglazed solar collector) | ✓ | ||

| FPC-U (flat plate collector, unevacuated) | ✓ | ✓ | ✓ |

| FPC-E (flat plate collector, evacuated) | ✓ | ✓ | ✓ |

| ETC (evacuated tube collector) | ✓ | ✓ | ✓ |

| ETC-CPC (evacuated tube collector with compound parabolic concentrator) | ✓ | ✓ | |

| PTC-U (parabolic trough collector, unevacuated absorber) | ✓ | ✓ | |

| PTC-E (parabolic trough collector, evacuated absorber) | ✓ | ✓ | |

| LFR-U (linear Fresnel reflector, unevacuated absorber); also, CLFR-U (compact linear Fresnel reflector, unevacuated) | ✓ | ✓ | |

| LFR-E (linear Fresnel reflector, evacuated absorber); also, CLFR-E (compact linear Fresnel reflector, evacuated) | ✓ | ✓ | |

| PDC (parabolic dish collector) | ✓ | ✓ | |

| SPT (solar power tower) or heliostats | ✓ |

| Collector Type | Stationary | Single-Axis Tracking | Two-Axis Tracking |

|---|---|---|---|

| SAC (solar air collector) | ✓ | ||

| PVT (photovoltaic–thermal) | ✓ | ||

| USC (unglazed solar collector) | ✓ | ||

| FPC (flat plate collector) | ✓ | ||

| ETC (evacuated tube collector) | ✓ | ||

| PTC (parabolic trough collector) | ✓ | ||

| LFR (linear Fresnel reflector) | ✓ | ||

| PDC (parabolic dish collector) | ✓ | ||

| SPT (solar power tower) or heliostats | ✓ |

| Power Capacity Type | Value | Reference(s) |

|---|---|---|

| Power radiated from the sun | 3.849 × 1017 GW | [101,102,103] |

| Solar power reaching the Earth | 1.8 × 108 GW | [104,105,106,107] |

| Global electricity, 2023 | 8900 GW | [108] |

| Global electricity, 2022 | 8643 GW | [109] |

| Global electricity, 2021 | 8230 GW | [110] |

| Global electricity, 2020 | 7694 GW | [111] |

| Global renewable power, 2024 | 4448 GW | [112] |

| Global renewable power, 2023 | 3863 GW | [113] |

| Global solar power, 2024 | 2200 GW (almost entirely photovoltaic “PV”) | [114,115,116,117] |

| Global hydropower, 2024 | 1283 GW | [118,119,120] |

| Global wind power, 2024 | 1133 GW | |

| Global bio power, 2024 | 151 GW | |

| Global geothermal power, 2024 | 15 GW | |

| Global CSP, 2023 | 6.7 GW | [121] |

| Global CSP, 2020 | 6.4 GW | [122] |

| SHIP, 2023 | 0.951 GW | [123] |

| SHIP, 2022 | 0.857 GW | [124] |

| Global marine (ocean) power, 2023 | 0.513 GW | [125,126,127,128] |

| Power radiated from 1 m2 of the sun | 0.0633 GW | [129,130,131] |

| Standard test condition (STC) of solar radiative power to 1 m2 of the Earth | 10−6 GW | [132,133] |

| Application Process | |||

|---|---|---|---|

| Application Sector | Low Temperature Rise (Below 75 °C) | Medium Temperature Rise (75–150 °C) | High Temperature Rise (150–400 °C) |

| Agriculture | Greenhouse heating Drying | ||

| Buildings | Space heating Showering Washing Cleaning | Cooking | |

| District heating | Feeding into heat networks | Feeding into heat networks | |

| Industry | Heat treatment Drying | Distilling Pulping Drying of paint | |

| Chemical | Distilling | Distilling | Distilling |

| Food and beverage | Drying | Boiling Pasteurizing Sterilizing | |

| Mining | Copper electrolytic refining Mineral drying processes | Copper electrolytic refining Mineral drying processes | Nitrate melting Alumina production |

| Textile | Washing | Bleaching Dyeing | Dyeing |

| Wood | Steaming (steam bending) | Steaming (steam bending) | Drying |

| Main Aim | System Type | Main Findings | Reference |

|---|---|---|---|

| Integrating solar process heat in industries | Flat plate, parabolic trough, air collector | In the (food, beverage, and agriculture) sector, 51% of the solar process heat integration takes place at the supply level, while 27.3% takes place at the process level. | [146] |

| Integration of solar thermal energy systems into the dairy processes | Parabolic trough, linear Fresnel | The dairy industry has a big potential to utilize solar energy for heating. Parabolic trough collectors and linear Fresnel reflectors are the most suitable solar collectors for this sector. Solar-powered cooling through the use of solar absorption chillers can be implemented. | [147] |

| Techno-economic-environmental analysis for using a 5 MWth system | Parabolic trough collector | A SHIP plant in Salt Lake City, Utah, USA, can deliver an annual thermal energy of 15,389.24 MWth/year. Compared to a natural gas plant, the SHIP plant was found to be able to avoid annual emissions of CO2 at the level of 3582.4 tonnes/year. | [148] |

| Integration of SHIP systems for meeting low-temperature heat demands in the food processing industry | Flat plate collector | Flat plate collector systems were the most adopted SHIP type in the food industry, with a share of 38%. The most frequent heating applications are preheating, cleaning, and pasteurization. | [149] |

| 4E (Energy, Exergy, Economic, and Environment) examination of a small LFR solar water heater | Linear Fresnel reflector | The study was performed in the Blida area in Algeria during the winter season. The optical efficiency was found to exceed 42%. The thermal efficiency was found to exceed 29%. | [150] |

| Quantity | 2024 Addition | Cumulative (End of 2024) | Percentage of the 2024 Addition (Relative to the Cumulative Value at the End of 2024) |

|---|---|---|---|

| Number of SHIP systems | 106 | 1315 | 8.06% |

| Collector area [m2] | 171,874 | 1,530,600 | 11.23% |

| Thermal power [MWth] | 120.3 | 1071.4 | 11.23% |

| Category Number | SHIP Category | 2024 Added Systems | 2024 Added Collector Area [m2] | Average Collector Area per System for New Systems in 2024 [m2/project] |

|---|---|---|---|---|

| 1 | Parabolic trough (PT) | 3 | 113,221 | 37,740.5 |

| 2 | Unevacuated flat plate (FP-U) | 48 | 37,740 | 786.3 |

| 3 | Evacuated tube (ET) | 24 | 8577 | 357.4 |

| 4 | Solar air collector (Air) | 19 | 5146 | 270.9 |

| 5 | Parabolic dish (PD) | 3 | 1715 | 571.8 |

| 6 | Evacuated flat plate (FP-E) | 1 | 1715 | 1715.5 |

| 7 | Solar power tower/heliostats (SPT) | 1 | 1715 | 1715.5 |

| 8 | Photovoltaic–thermal (PVT) | 3 | 1029 | 343.1 |

| 9 | Linear Fresnel (LF) | 2 | 686 | 343.1 |

| 10 | Unglazed (Ung) | 2 | 326 | 163.0 |

| Total (Overall) | 106 | 171,874 | 1621.4 | |

| 11 | flat plate (FP) | 49 | 39,456 | 805.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marzouk, O.A. Solar Heat for Industrial Processes (SHIP): An Overview of Its Categories and a Review of Its Recent Progress. Solar 2025, 5, 46. https://doi.org/10.3390/solar5040046

Marzouk OA. Solar Heat for Industrial Processes (SHIP): An Overview of Its Categories and a Review of Its Recent Progress. Solar. 2025; 5(4):46. https://doi.org/10.3390/solar5040046

Chicago/Turabian StyleMarzouk, Osama A. 2025. "Solar Heat for Industrial Processes (SHIP): An Overview of Its Categories and a Review of Its Recent Progress" Solar 5, no. 4: 46. https://doi.org/10.3390/solar5040046

APA StyleMarzouk, O. A. (2025). Solar Heat for Industrial Processes (SHIP): An Overview of Its Categories and a Review of Its Recent Progress. Solar, 5(4), 46. https://doi.org/10.3390/solar5040046