Comparing Outdoor to Indoor Performance for Bifacial Modules Affected by Polarization-Type Potential-Induced Degradation

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Addressing Challenges

2. Materials and Methods

2.1. Outdoor Testbed and Performance Measurements

2.2. Data Quality Assurance

2.3. Analysis

2.3.1. Outdoor Data Preparation

2.3.2. Indoor Data Transformations

- Rear-side efficiency is equal to that of the front (i.e., bifaciality = 1) and for all irradiances;

- Albedo non-uniformity = 0;

- Cell mismatch effects are negligible;

- Rear spectral mismatch losses are negligible;

- Rear-side gain contributes negligibly to voltage and primarily to current;

- is a non-zero constant at 0 W/m2 200 W/m2.

- Method 1

- Outdoor data are directly compared to indoor front side at . This provides a baseline for comparing how other analyses change the indoor curve.

- Method 2

- The indoor curve is taken at and is used primarily to compare to Method 3.

- Method 3

- The front-side curve is taken at . This method is using the equivalent irradiance in the IEC TS 60904-1-2 standard [19] using a based on . is calculated using of the rear side at 200 W/m2 and dividing by the front-side at 200 W/m2. Using times attempts to account for cell mismatch effects since is calculated from rear-side measurements.

- Method 4

- The front-side curve is split into voltage and current, with current values added by the rear at to account for rear cell mismatch. Since the is taken directly from rear-side measurements, is naturally included and cell mismatch losses are more closely approximated.

- Method 5

- The front-side current from Method 4 is combined with the voltage from Method 2. This accounts for and cell mismatch effects on current but assumes those have no effect on rear voltage contributions. Despite being similar to Method 3, the current values for this method are expected to be more accurate since it is using direct rear-side current measurements.

2.4. Comparison Methods

3. Results and Discussion

3.1. Impact of Low-Irradiance Data

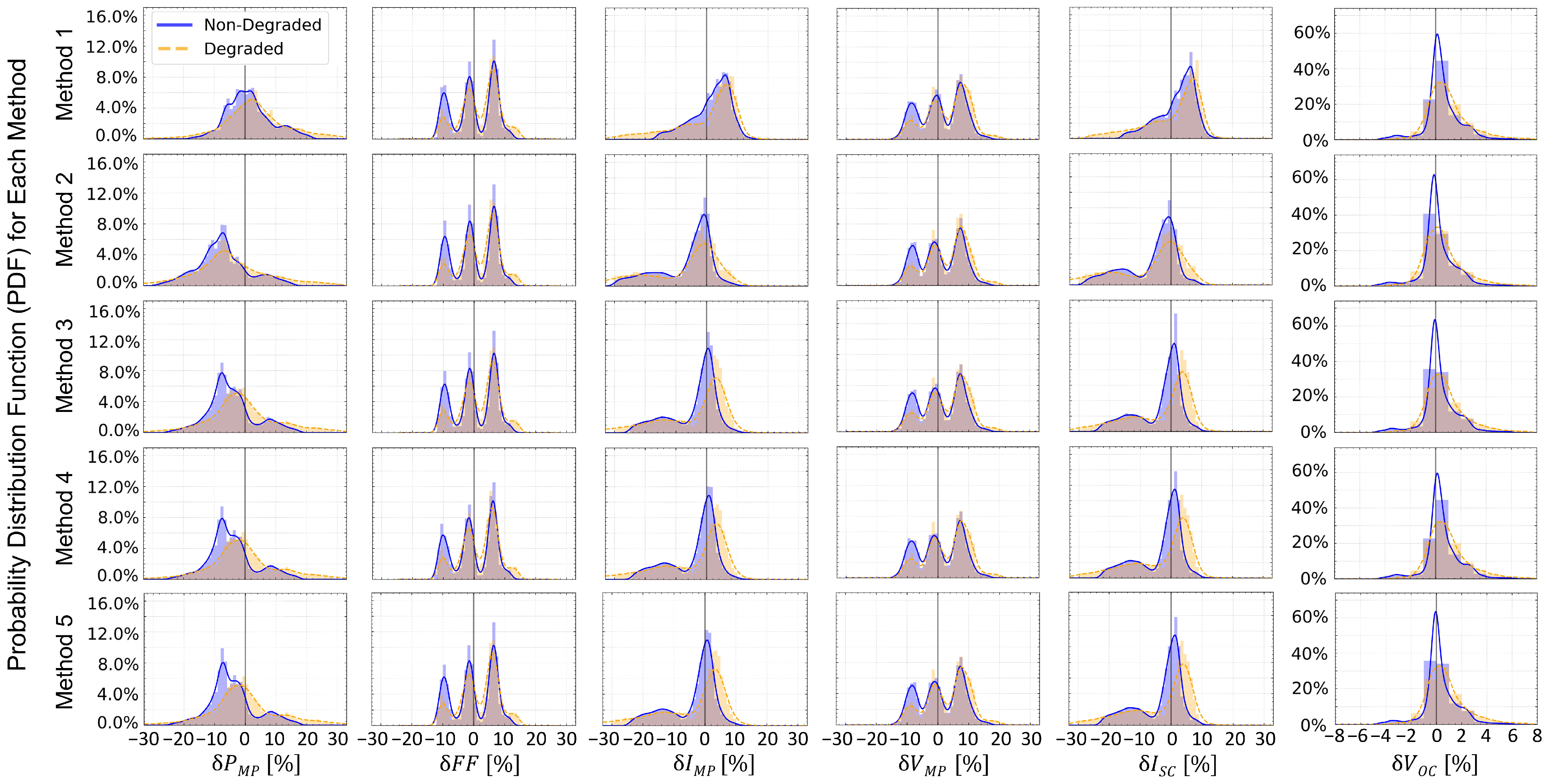

3.2. Impact of Indoor Transformation Methods

4. Conclusions

- Use EL image analysis to estimate degree of cell mismatch and calculate a metric to correct curves.

- Measure non-uniformity on the rear side for different installation conditions and different incident sunlight angles and calculate a metric to correct curves.

- Measure modules indoors with a nearly perfectly non-reflective cover and compare to outdoor curves on the same modules.

- Apply the model in [27] to account for changes in and non-uniformity throughout the day.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM1.5G | Air Mass 1.5 Global |

| FF | Fill Factor |

| G | Irradiance |

| HV | High-Voltage |

| Current at Maximum Power | |

| Short-Circuit Current | |

| I–V | Current–Voltage |

| MAPE | Mean Absolute Percent Error |

| PERC | Passivated Emitter and Rear Cell |

| PID | Potential-Induced Degradation |

| PID-p | Polarization-type Potential-Induced Degradation |

| Maximum Power, Power at the Maximum Power Point |

| POA | Plane of Array |

| PV | Photovoltaic |

| TOPCon | Tunnel Oxide Passivated Contact |

| Voltage at Maximum Power | |

| Open-Circuit Voltage |

References

- International Technology Roadmap for Photovoltaic (ITRPV), 14th ed.; Technical Report; Verband Deutscher Maschinen und Anlagenbau (German Engineering Federation): Frankfurt, Germany, 2023.

- García, M.A.; Quispe, G.R.; Zamudio, M.A.; Conde, L.A.; Angulo, J.R.; Berastain, A.E.; Töfflinger, J.A. Outdoor I-V characterization of tilted and vertical bifacial PV modules. J. Phys. Conf. Ser. 2023, 2538, 012002. [Google Scholar] [CrossRef]

- Dolara, A.; Leva, S.; Mazzeo, D.; Ogliari, E. Characterization of Bifacial Photovoltaic Modules Based on I-V Curves Outdoor Measurement. In Proceedings of the 2023 IEEE International Conference on Environment and Electrical Engineering and 2023 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 6–9 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Kawagoe, K.; Hishikawa, Y.; Yamada, N. Outdoor Direct STC Performance Measurement of PV Modules Based on a Sun-Shading Technique. IEEE J. Photovoltaics 2017, 7, 1725–1730. [Google Scholar] [CrossRef]

- Polo, J.; Martín-Chivelet, N.; Alonso-García, M.C.; Zitouni, H.; Alonso-Abella, M.; Sanz-Saiz, C.; Vela-Barrionuevo, N. Modeling I-V curves of photovoltaic modules at indoor and outdoor conditions by using the Lambert function. Energy Convers. Manag. 2019, 195, 1004–1011. [Google Scholar] [CrossRef]

- Gu, W.; Li, S.; Liu, X.; Chen, Z.; Zhang, X.; Ma, T. Experimental investigation of the bifacial photovoltaic module under real conditions. Renew. Energy 2021, 173, 1111–1122. [Google Scholar] [CrossRef]

- Singh, J.P.; Aberle, A.G.; Walsh, T.M. Electrical characterization method for bifacial photovoltaic modules. Sol. Energy Mater. Sol. Cells 2014, 127, 136–142. [Google Scholar] [CrossRef]

- Baloch, A.A.; Hammat, S.; Figgis, B.; Alharbi, F.H.; Tabet, N. In-field characterization of key performance parameters for bifacial photovoltaic installation in a desert climate. Renew. Energy 2020, 159, 50–63. [Google Scholar] [CrossRef]

- Matam, M.; Smith, R.M.; Seigneur, H. PV Module Degradation Due to Frequent and Prolonged Inverter Clipping: A Preliminary Study. In Proceedings of the 2022 IEEE 49th Photovoltaics Specialists Conference (PVSC), Philadelphia, PA, USA, 5–10 June 2022; pp. 0596–0603. [Google Scholar] [CrossRef]

- González-Moreno, A.; Mazzeo, D.; Dolara, A.; Ogliari, E.; Leva, S. Outdoor Performance Comparison of Bifacial and Monofacial Photovoltaic Modules in Temperate Climate and Industrial-like Rooftops. Appl. Sci. 2024, 14, 5714. [Google Scholar] [CrossRef]

- Lee, S.; Nam, J.; Choi, D.; Jang, H.; Lee, Y.; Sohn, J.W.; Hong, K.K.; Kim, D.; Kang, Y.; Bae, S.; et al. Characterization of rear-side potential-induced degradation in bifacial p-PERC solar modules. Sol. Energy Mater. Sol. Cells 2024, 278, 113131. [Google Scholar] [CrossRef]

- Park, H.; Jeong, J.; Shin, E.; Kim, S.; Yi, J. A reliability study of silicon heterojunction photovoltaic modules exposed to damp heat testing. Microelectron. Eng. 2019, 216, 111081. [Google Scholar] [CrossRef]

- Patel, M.T.; Vijayan, R.A.; Asadpour, R.; Varadharajaperumal, M.; Khan, M.R.; Alam, M.A. Temperature-dependent energy gain of bifacial PV farms: A global perspective. Appl. Energy 2020, 276, 115405. [Google Scholar] [CrossRef]

- Molto, C.; Oh, J.; Mahmood, F.I.; Li, M.; Hacke, P.; Li, F.; Smith, R.; Colvin, D.; Matam, M.; DiRubio, C.; et al. Review of Potential-Induced Degradation in Bifacial Photovoltaic Modules. Energy Technol. 2023, 11, 2200943. [Google Scholar] [CrossRef]

- Mahmood, F.i.; Li, F.; Hacke, P.; Molto, C.; Colvin, D.; Seigneur, H.; TamizhMani, G. Susceptibility to polarization type potential induced degradation in commercial bifacial p-PERC PV modules. Prog. Photovoltaics Res. Appl. 2023, 31, 1078–1090. [Google Scholar] [CrossRef]

- Sinton, R.; Cuevas, A. A Quasi-Steady-State Open-Circuit Voltage Method for Solar Cell Characterization. In Proceedings of the 16th European Photovoltaic Solar Energy Conference, Glasgow, Scotland, 1–5 May 2000; pp. 1152–1155. [Google Scholar]

- Colvin, D.J.; Iqbal, N.; Yerger, J.H.; Li, F.; Sinha, A.; Vicnansky, G.; Brummer, G.; Zheng, N.; Schneller, E.J.; Barkaszi, J.; et al. Degradation of Monocrystalline Silicon Photovoltaic Modules from a 10-Year-Old Rooftop System in Florida. IEEE J. Photovoltaics 2023, 13, 275–282. [Google Scholar] [CrossRef]

- Colvin, D.J.; Schneller, E.J.; Davis, K.O. Impact of interconnection failure on photovoltaic module performance. Prog. Photovoltaics Res. Appl. 2021, 29, 524–532. [Google Scholar] [CrossRef]

- IEC TS 60904-1-2; Photovoltaic Devices—Part 1-2: Measurement of Current-Voltage Characteristics of Bifacial Photovoltaic (PV) Devices. IEC: Geneva, Switzerland, 2019.

- Piliougine, M.; Oukaja, A.; Sidrach-de Cardona, M.; Spagnuolo, G. Temperature coefficients of degraded crystalline silicon photovoltaic modules at outdoor conditions. Prog. Photovoltaics Res. Appl. 2021, 29, 558–570. [Google Scholar] [CrossRef]

- Paudyal, B.R.; Imenes, A.G. Investigation of temperature coefficients of PV modules through field measured data. Sol. Energy 2021, 224, 425–439. [Google Scholar] [CrossRef]

- Gasparin, F.P.; Kipper, F.D.; Oliveira, F.S.d.; Krenzinger, A. Assessment on the variation of temperature coefficients of photovoltaic modules with solar irradiance. Sol. Energy 2022, 244, 126–133. [Google Scholar] [CrossRef]

- Hishikawa, Y.; Doi, T.; Higa, M.; Yamagoe, K.; Ohshima, H. Precise Outdoor PV Module Performance Characterization Under Unstable Irradiance. IEEE J. Photovoltaics 2016, 6, 1221–1227. [Google Scholar] [CrossRef]

- Monokroussos, C.; Gao, Q.; Zhang, X.; Lee, E.; Wang, Y.; Zou, C.; Rimmelspacher, L.; Castro, J.B.; Schweiger, M.; Herrmann, W. Rear-side spectral irradiance at 1 sun and application to bifacial module power rating. Prog. Photovoltaics Res. Appl. 2020, 28, 755–766. [Google Scholar] [CrossRef]

- Ganesan, K.; Winston, D.P.; Sugumar, S.; Prasath, T.H. Performance investigation of n-type PERT bifacial solar photovoltaic module installed at different elevations. Renew. Energy 2024, 227, 120526. [Google Scholar] [CrossRef]

- Ozkalay, E.; Lopez-Garcia, J.; Pinero-Prieto, L.; Gracia-Amillo, A.; Kenny, R.P. Evaluation of the non-uniformity of rear-side irradiance in outdoor mounted bifacial silicon PV modules. AIP Conf. Proc. 2019, 2147, 020011. [Google Scholar] [CrossRef]

- Zhang, Q.; Peng, J.; Luo, Y.; Wang, M.; Wang, S.; Tan, Y.; Ma, T. Development of a novel power generation model for bifacial photovoltaic modules based on dynamic bifaciality. Energy Convers. Manag. 2025, 324, 119305. [Google Scholar] [CrossRef]

- Riedel-Lyngskær, N.; Ribaconka, M.; Pó, M.; Thorseth, A.; Thorsteinsson, S.; Dam-Hansen, C.; Jakobsen, M.L. The effect of spectral albedo in bifacial photovoltaic performance. Sol. Energy 2022, 231, 921–935. [Google Scholar] [CrossRef]

| Assumptions | ||||||

|---|---|---|---|---|---|---|

| Method | 1 | 2 | 3 | 4 | 5 | 6 |

| 1 | N/A | N/A | N/A | N/A | N/A | N/A |

| 2 | ✓ | ✓ | ✓ | ✓ | ✓ | |

| 3 | ✓ | ✓ | ✓ | |||

| 4 | ✓ | ✓ | ✓ | ✓ | ||

| 5 | ✓ | ✓ * | ✓ | ✓ | ||

| Method | MAPEPMP [%] | MAPEFF [%] | MAPEIMP [%] | MAPEVMP [%] | MAPEISC [%] | MAPEVOC [%] | ∑MAPEXi [%] |

|---|---|---|---|---|---|---|---|

| Method 1 | 5.7% (4.5%) | 5.8% (6.2%) | 5.4% (4.5%) | 6.2% (6.1%) | 5.4% (4.8%) | 0.97% (1.0%) | 30% (27%) |

| Method 2 | 9.5% (8.4%) | 5.7% (6.0%) | 7.4% (2.6%) | 6.1% (6.2%) | 7.1% (2.5%) | 0.90% (1.0%) | 37% (27%) |

| Method 3 | 7.5% (6.5%) | 5.8% (6.0%) | 5.8% (1.8%) | 6.1% (6.2%) | 5.6% (1.8%) | 0.90% (1.0%) | 32% (23%) |

| Method 4 | 7.4% (6.4%) | 5.8% (6.4%) | 5.7% (1.8%) | 6.2% (6.3%) | 5.4% (1.8%) | 0.97% (1.0%) | 32% (24%) |

| Method 5 | 7.3% (6.3%) | 5.8% (6.1%) | 5.7% (1.8%) | 6.2% (6.2%) | 5.4% (1.8%) | 0.90% (1.0%) | 31% (23%) |

| Method | MAPEPMP [%] | MAPEFF [%] | MAPEIMP [%] | MAPEVMP [%] | MAPEISC [%] | MAPEVOC [%] | ∑MAPEXi [%] |

|---|---|---|---|---|---|---|---|

| Method 1 | 8.4% (6.5%) | 5.6% (6.0%) | 8.2% (6.2%) | 6.7% (6.1%) | 7.7% (6.6%) | 1.3% (1.6%) | 38% (33%) |

| Method 2 | 11% (7.6%) | 5.5% (5.9%) | 11% (2.9%) | 6.5% (6.1%) | 9.6% (2.9%) | 1.2% (1.5%) | 44% (27%) |

| Method 3 | 8.6% (5.9%) | 5.5% (5.9%) | 8.6% (3.1%) | 6.6% (6.2%) | 8.0% (3.6%) | 1.2% (1.6%) | 39% (26%) |

| Method 4 | 8.5% (5.8%) | 5.5% (6.1%) | 8.6% (3.2%) | 6.6% (6.2%) | 7.9% (3.7%) | 1.3% (1.6%) | 38% (27%) |

| Method 5 | 8.5% (5.8%) | 5.5% (5.9%) | 8.6% (3.2%) | 6.6% (6.1%) | 7.9% (3.7%) | 1.2% (1.6%) | 38% (26%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colvin, D.J.; Molto, C.; Smith, R.M.; Matam, M.; Hacke, P.; Li, F.; Thompson, B.A.; Barkaszi, J.; Tamizhmani, G.; Seigneur, H.P. Comparing Outdoor to Indoor Performance for Bifacial Modules Affected by Polarization-Type Potential-Induced Degradation. Solar 2025, 5, 43. https://doi.org/10.3390/solar5030043

Colvin DJ, Molto C, Smith RM, Matam M, Hacke P, Li F, Thompson BA, Barkaszi J, Tamizhmani G, Seigneur HP. Comparing Outdoor to Indoor Performance for Bifacial Modules Affected by Polarization-Type Potential-Induced Degradation. Solar. 2025; 5(3):43. https://doi.org/10.3390/solar5030043

Chicago/Turabian StyleColvin, Dylan J., Cécile Molto, Ryan M. Smith, Manjunath Matam, Peter Hacke, Fang Li, Brent A. Thompson, James Barkaszi, Govindasamy Tamizhmani, and Hubert P. Seigneur. 2025. "Comparing Outdoor to Indoor Performance for Bifacial Modules Affected by Polarization-Type Potential-Induced Degradation" Solar 5, no. 3: 43. https://doi.org/10.3390/solar5030043

APA StyleColvin, D. J., Molto, C., Smith, R. M., Matam, M., Hacke, P., Li, F., Thompson, B. A., Barkaszi, J., Tamizhmani, G., & Seigneur, H. P. (2025). Comparing Outdoor to Indoor Performance for Bifacial Modules Affected by Polarization-Type Potential-Induced Degradation. Solar, 5(3), 43. https://doi.org/10.3390/solar5030043