Author Contributions

Conceptualization and methodology, R.M.S.; software, R.M.S. and C.D.; validation, formal analysis, R.M.S., C.D. and H.T.; investigation, R.M.S.; resources, R.M.S. and M.W.; data curation, R.M.S., C.D. and H.T.; writing—original draft preparation, all authors; writing—review and editing, all authors; visualization, R.M.S., C.D. and H.T.; supervision, M.W.; project administration, R.M.S. and M.W.; funding acquisition, M.W. All authors have read and agreed to the published version of the manuscript.

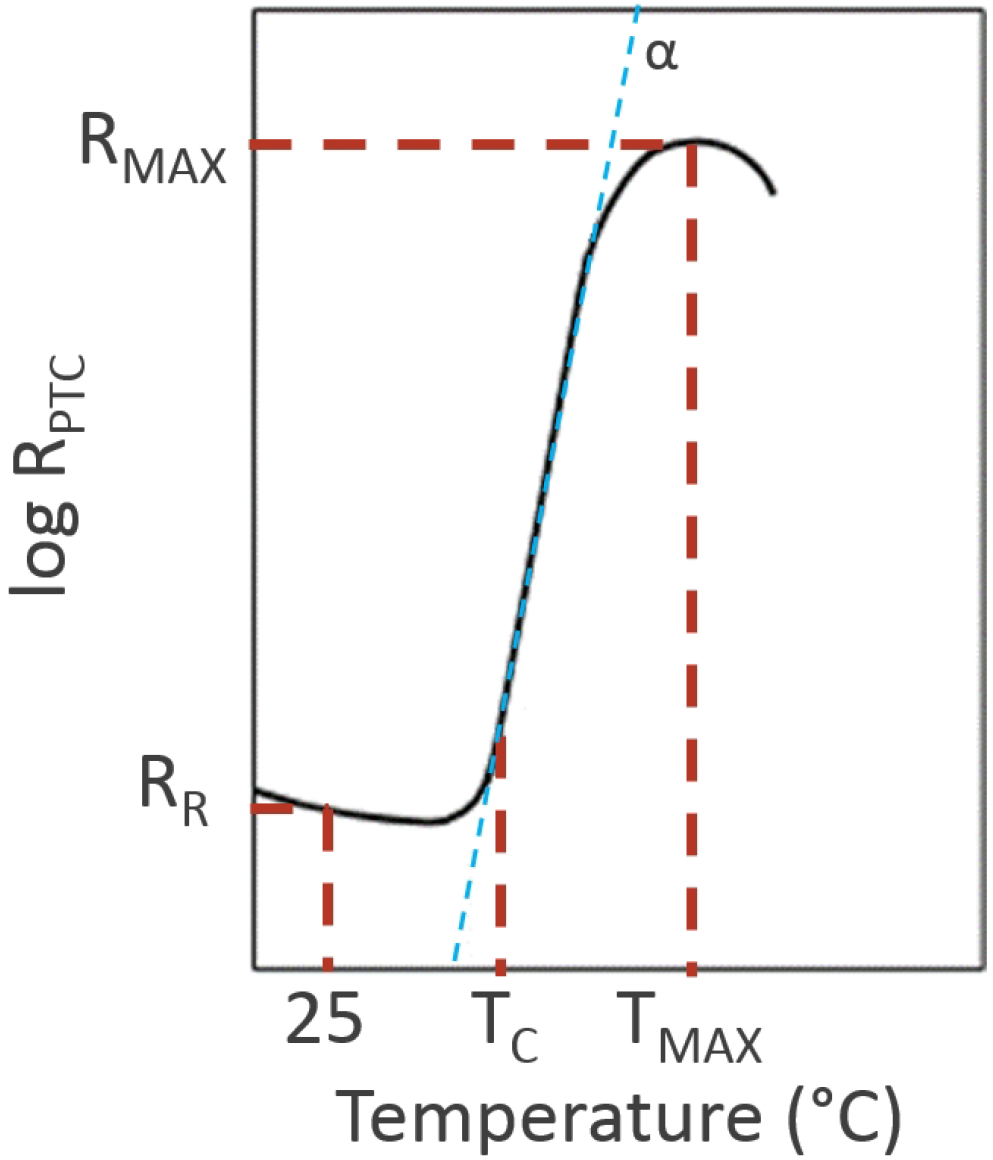

Figure 1.

PTC devices such as N-type doped barium titanate exhibit a typical behavior charted as the logarithm of resistance versus linear temperature. RR represents the device’s rated resistance at 25 °C. With rising temperature, the resistance initially drops slightly, then increases near the Curie temperature (TC). Beyond TC, resistance follows a predictable rate () until reaching maximum resistance (RMAX) at TMAX. Above TMAX, resistance decreases. The proposed system operates near or below the Curie temperature.

Figure 1.

PTC devices such as N-type doped barium titanate exhibit a typical behavior charted as the logarithm of resistance versus linear temperature. RR represents the device’s rated resistance at 25 °C. With rising temperature, the resistance initially drops slightly, then increases near the Curie temperature (TC). Beyond TC, resistance follows a predictable rate () until reaching maximum resistance (RMAX) at TMAX. Above TMAX, resistance decreases. The proposed system operates near or below the Curie temperature.

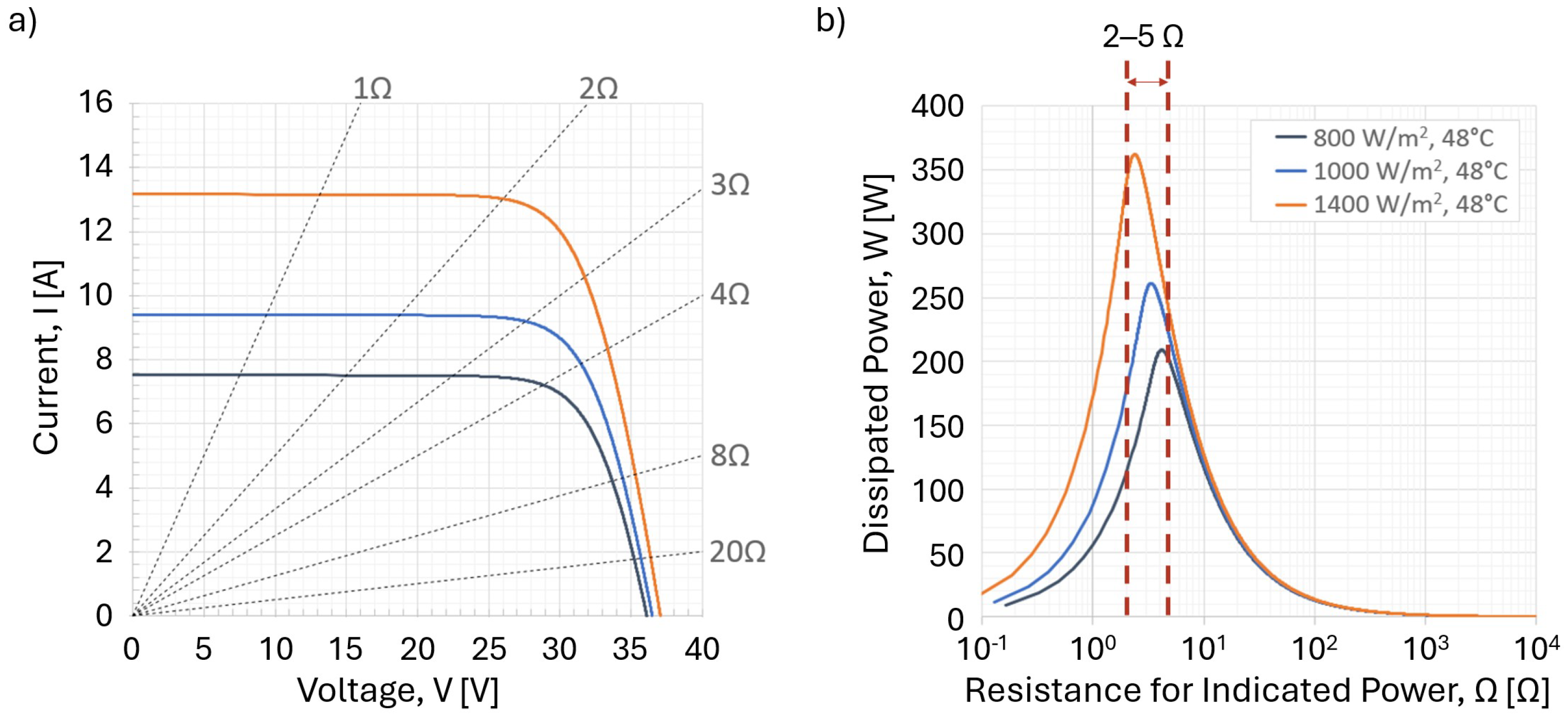

Figure 2.

The nominal STC resistance for commercially available silicon modules of various cell architectures has remained stable, by architecture, over time. Al-BSF, PERC, and TOPCon modules generally fall between 2

and 5

(dashed lines to guide the eye) while HJT and IBC architectures show larger spread at increased nominal resistance. Data from [

13].

Figure 2.

The nominal STC resistance for commercially available silicon modules of various cell architectures has remained stable, by architecture, over time. Al-BSF, PERC, and TOPCon modules generally fall between 2

and 5

(dashed lines to guide the eye) while HJT and IBC architectures show larger spread at increased nominal resistance. Data from [

13].

Figure 3.

Current–voltage (I-V) curves for a typical silicon module are shown (left) with constant resistance lines between 1 and 20 at three irradiances. Analysis of power dissipation along lines of constant resistance yields power–resistance (P-R) curves such as shown (right) which suggest that an ideal PTC heater resistance lies in a narrow range.

Figure 3.

Current–voltage (I-V) curves for a typical silicon module are shown (left) with constant resistance lines between 1 and 20 at three irradiances. Analysis of power dissipation along lines of constant resistance yields power–resistance (P-R) curves such as shown (right) which suggest that an ideal PTC heater resistance lies in a narrow range.

Figure 4.

Diagram of the experimental setup. The bench-test experimental setup used a constant voltage power supply; the second experiment utilized three series-connected PV modules.

Figure 4.

Diagram of the experimental setup. The bench-test experimental setup used a constant voltage power supply; the second experiment utilized three series-connected PV modules.

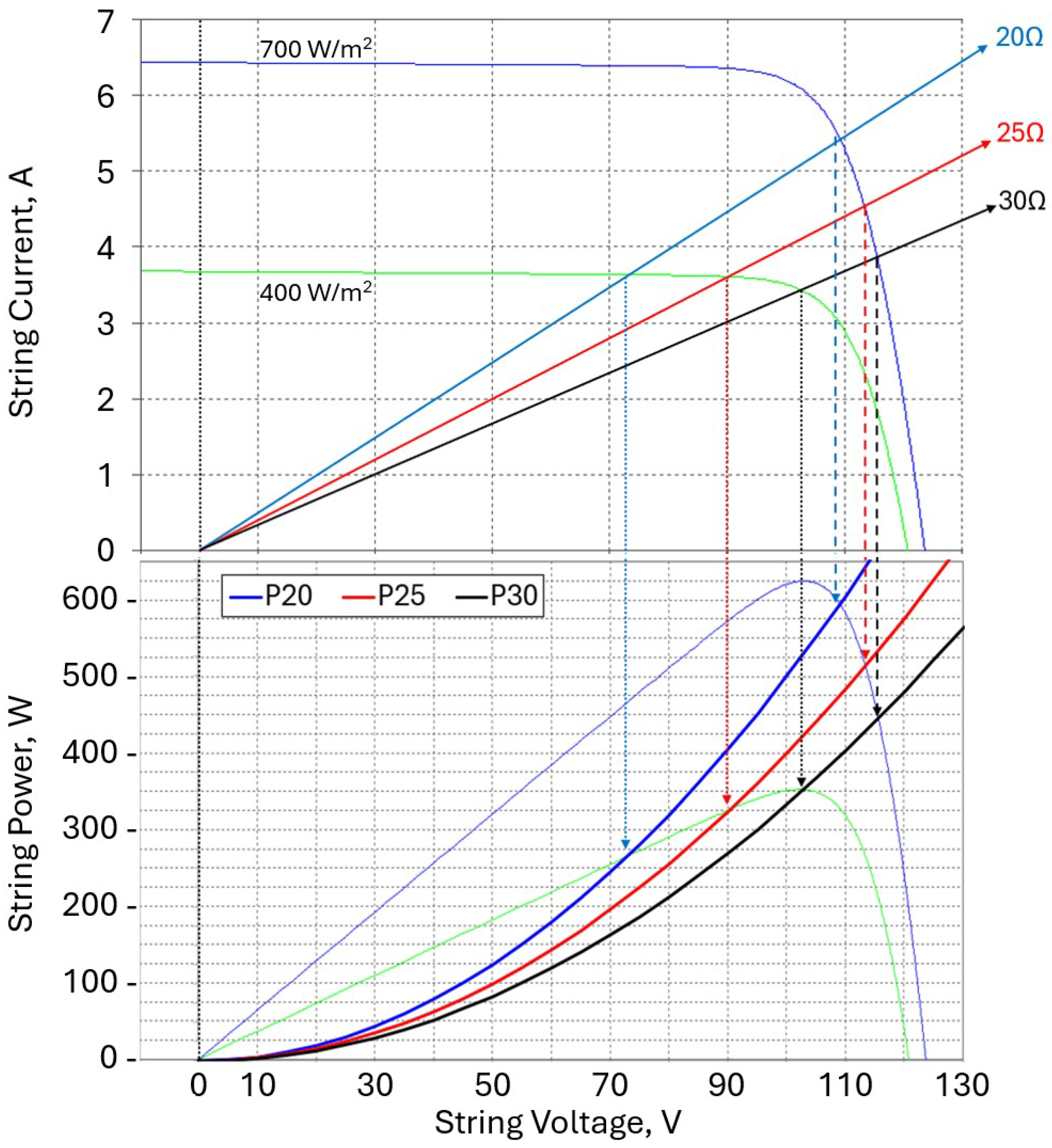

Figure 5.

Current-voltage (top) and power-voltage (bottom) curves at 700 and 400 W/m2 and 0 °C for a series-connected string of three 270 W modules. Constant resistance lines of 20 , 25 , and 30 are superimposed over the I-V and P-V curves showing where potential PTC heating elements would operate.

Figure 5.

Current-voltage (top) and power-voltage (bottom) curves at 700 and 400 W/m2 and 0 °C for a series-connected string of three 270 W modules. Constant resistance lines of 20 , 25 , and 30 are superimposed over the I-V and P-V curves showing where potential PTC heating elements would operate.

Figure 6.

The ideal loading resistance for a series-connected string of three 270 W modules is shown for temperatures in Anchorage, Alaska, −40 °C to +45 °C and irradiances of 200 to 1200 W/m2. A nominal irradiance of 700 W/m2 was chosen for PTC element selection, yielding an ideal resistance range between 15.1 and 21.2 .

Figure 6.

The ideal loading resistance for a series-connected string of three 270 W modules is shown for temperatures in Anchorage, Alaska, −40 °C to +45 °C and irradiances of 200 to 1200 W/m2. A nominal irradiance of 700 W/m2 was chosen for PTC element selection, yielding an ideal resistance range between 15.1 and 21.2 .

Figure 7.

Design schematic of the heater assembly showing eight ceramic PTC elements per side in a dual sandwich configuration. All measurements are in millimeters unless otherwise noted.

Figure 7.

Design schematic of the heater assembly showing eight ceramic PTC elements per side in a dual sandwich configuration. All measurements are in millimeters unless otherwise noted.

Figure 8.

Component breakout of the designed heater assembly. Not shown are the PTC stones, polyimide electrical insulating film, electrical conductors, and diagnostic thermocouples.

Figure 8.

Component breakout of the designed heater assembly. Not shown are the PTC stones, polyimide electrical insulating film, electrical conductors, and diagnostic thermocouples.

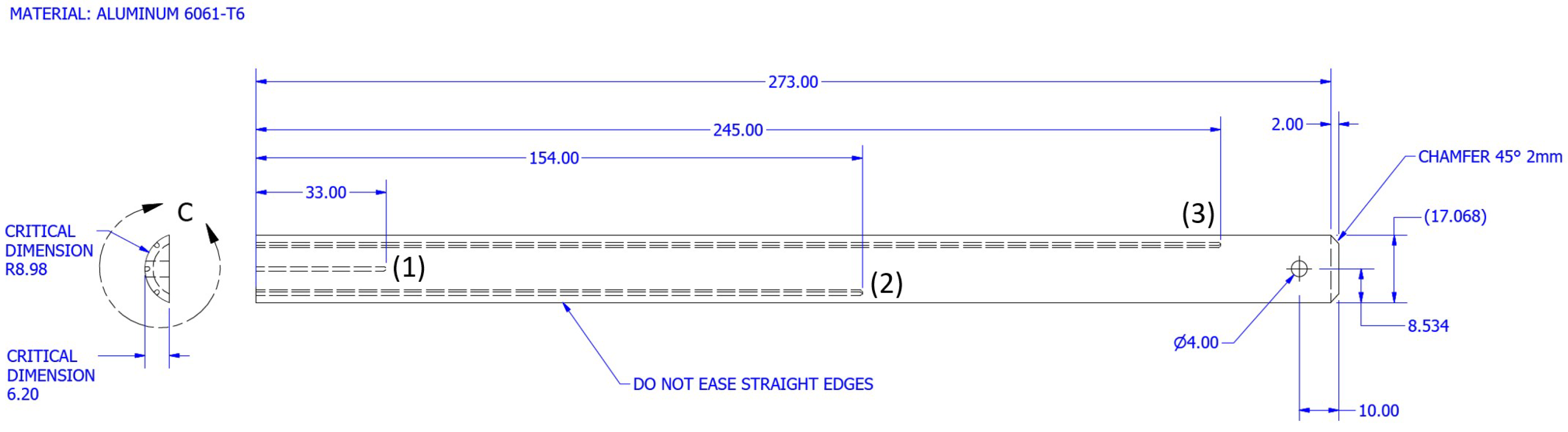

Figure 9.

Design schematic of the heat spreader showing the thermocouple locations on each side for monitoring the heater assembly thermal performance. Positions 1, 2, and 3 indicate the extent of thermocouple depth as measured from the outer end of the component. Detail C is the cross-section of the heat spreader. All measurements are in millimeters unless otherwise noted.

Figure 9.

Design schematic of the heat spreader showing the thermocouple locations on each side for monitoring the heater assembly thermal performance. Positions 1, 2, and 3 indicate the extent of thermocouple depth as measured from the outer end of the component. Detail C is the cross-section of the heat spreader. All measurements are in millimeters unless otherwise noted.

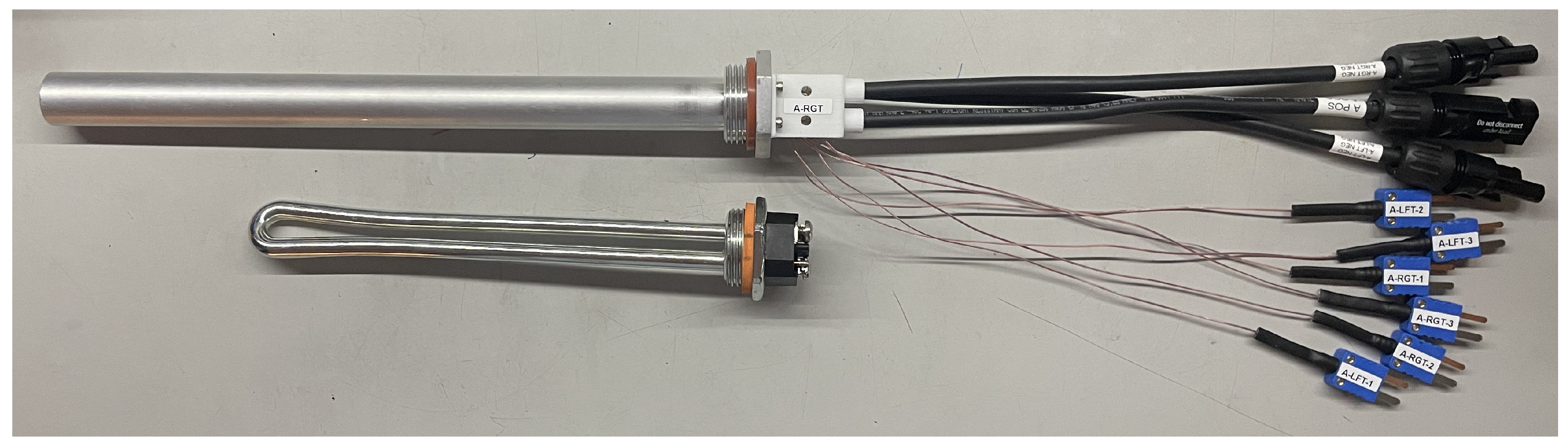

Figure 10.

Images of the original heating element removed from the as-received water heater (bottom) and the experimental PTC heating assembly (top) showing power leads to each electrode of the heater core and the six heater core thermocouples. Each experimental heating assembly is visually identical.

Figure 10.

Images of the original heating element removed from the as-received water heater (bottom) and the experimental PTC heating assembly (top) showing power leads to each electrode of the heater core and the six heater core thermocouples. Each experimental heating assembly is visually identical.

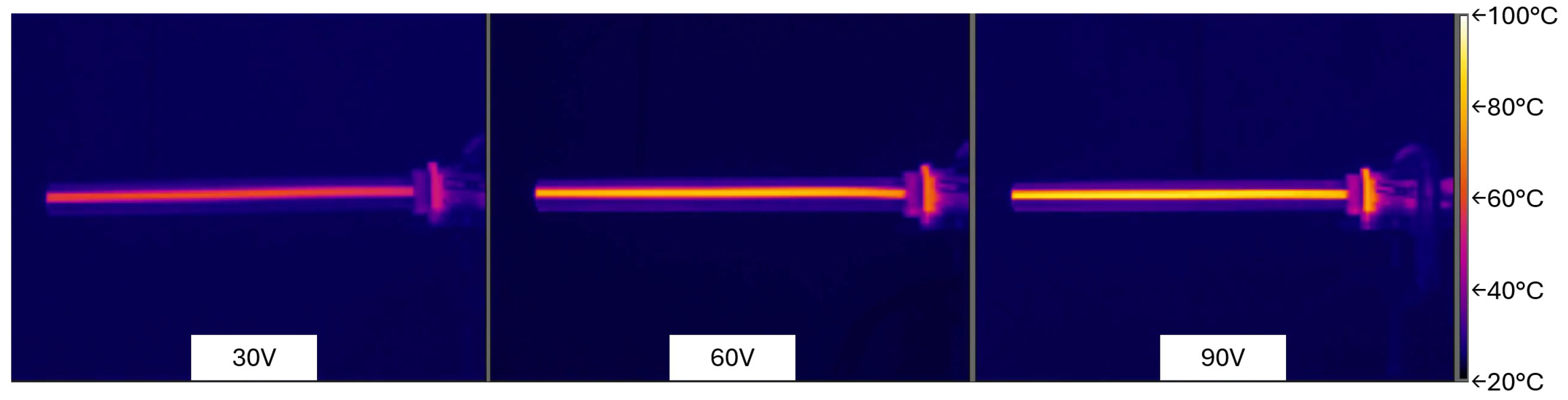

Figure 11.

Infrared images of heater “A” at various voltages in free air. Polyimide tape was attached to the thermowell assembly to improve emissivity. Stabilized temperature is consistent along the length of the assembly and is a function of applied voltage.

Figure 11.

Infrared images of heater “A” at various voltages in free air. Polyimide tape was attached to the thermowell assembly to improve emissivity. Stabilized temperature is consistent along the length of the assembly and is a function of applied voltage.

Figure 12.

Heater power and resistance comparison through the first 300 s (5 m) of operation under constant potential from a bench power supply. The left side shows the only test of the 50 °C TC heater at 90 V. The right side shows tests of the 70 °C TC heaters at 60 V, 90 V, and 110 V. Loaded resistances significantly differ from the initial measured unloaded resistances.

Figure 12.

Heater power and resistance comparison through the first 300 s (5 m) of operation under constant potential from a bench power supply. The left side shows the only test of the 50 °C TC heater at 90 V. The right side shows tests of the 70 °C TC heaters at 60 V, 90 V, and 110 V. Loaded resistances significantly differ from the initial measured unloaded resistances.

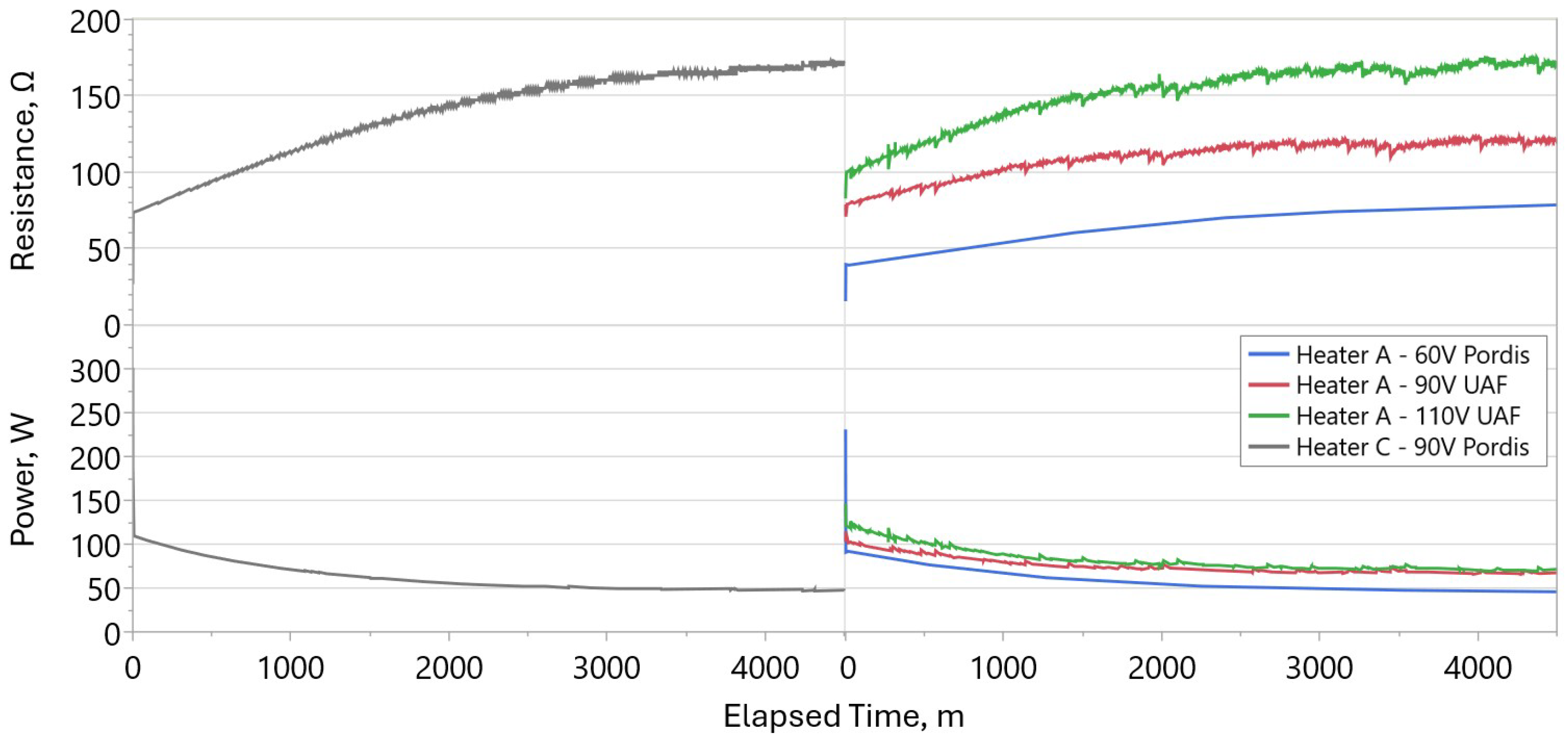

Figure 13.

Heater power and resistance comparison through the first 4500 m (75 h) of operation under constant potential from a bench power supply. The left side shows the only test of the 50 °C TC heater at 90 V. The right side shows tests of the 70 °C TC heaters at 60 V, 90 V, and 110 V. Loaded resistances significantly differ from the initial measured unloaded resistances.

Figure 13.

Heater power and resistance comparison through the first 4500 m (75 h) of operation under constant potential from a bench power supply. The left side shows the only test of the 50 °C TC heater at 90 V. The right side shows tests of the 70 °C TC heaters at 60 V, 90 V, and 110 V. Loaded resistances significantly differ from the initial measured unloaded resistances.

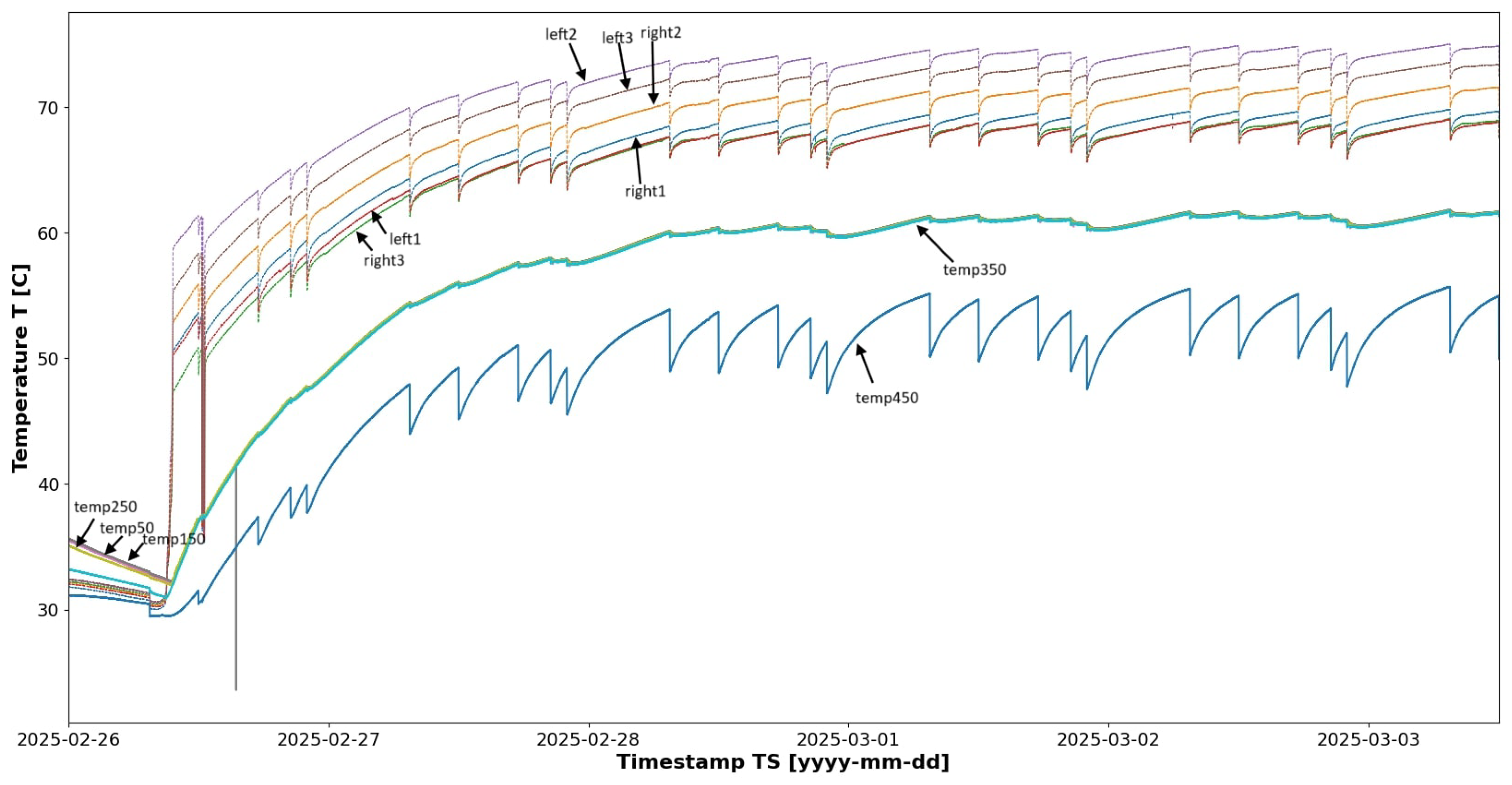

Figure 14.

Time series graph of the 70 °C TC heating elements contained within heater “A” powered via a power supply set to 90 V. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details. Note that temp50 through temp350 overlay with very little difference.

Figure 14.

Time series graph of the 70 °C TC heating elements contained within heater “A” powered via a power supply set to 90 V. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details. Note that temp50 through temp350 overlay with very little difference.

Figure 15.

Time series graph of the 70 °C heating element powered via PV panels during a period of sunny weather in March 2025. Graph (A) represents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) represents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

Figure 15.

Time series graph of the 70 °C heating element powered via PV panels during a period of sunny weather in March 2025. Graph (A) represents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) represents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

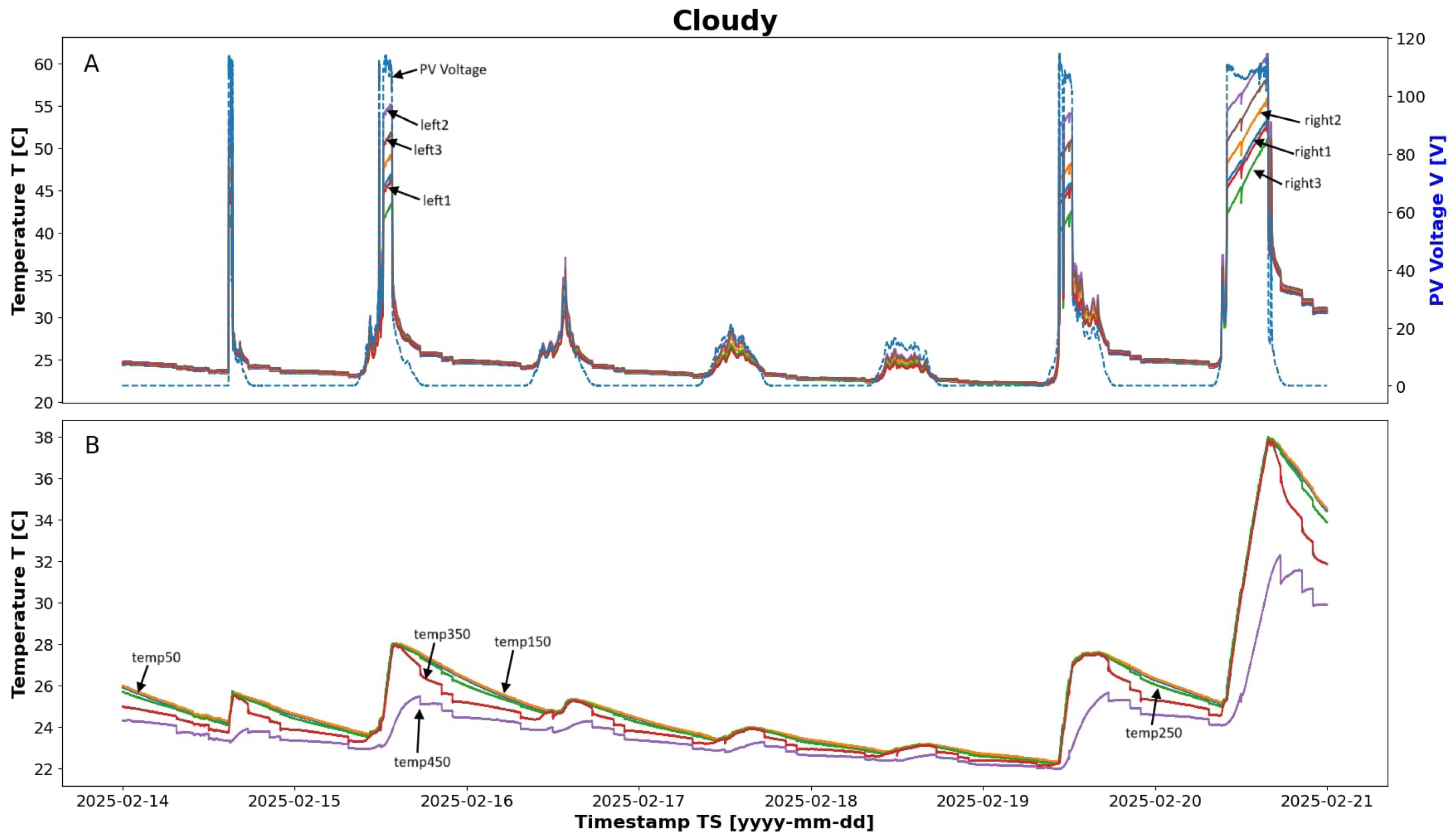

Figure 16.

Time series graph of the 70 °C TC heating element powered via PV panels during a period of cloudy weather in February 2025. Graph (A) represents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) represents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

Figure 16.

Time series graph of the 70 °C TC heating element powered via PV panels during a period of cloudy weather in February 2025. Graph (A) represents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) represents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

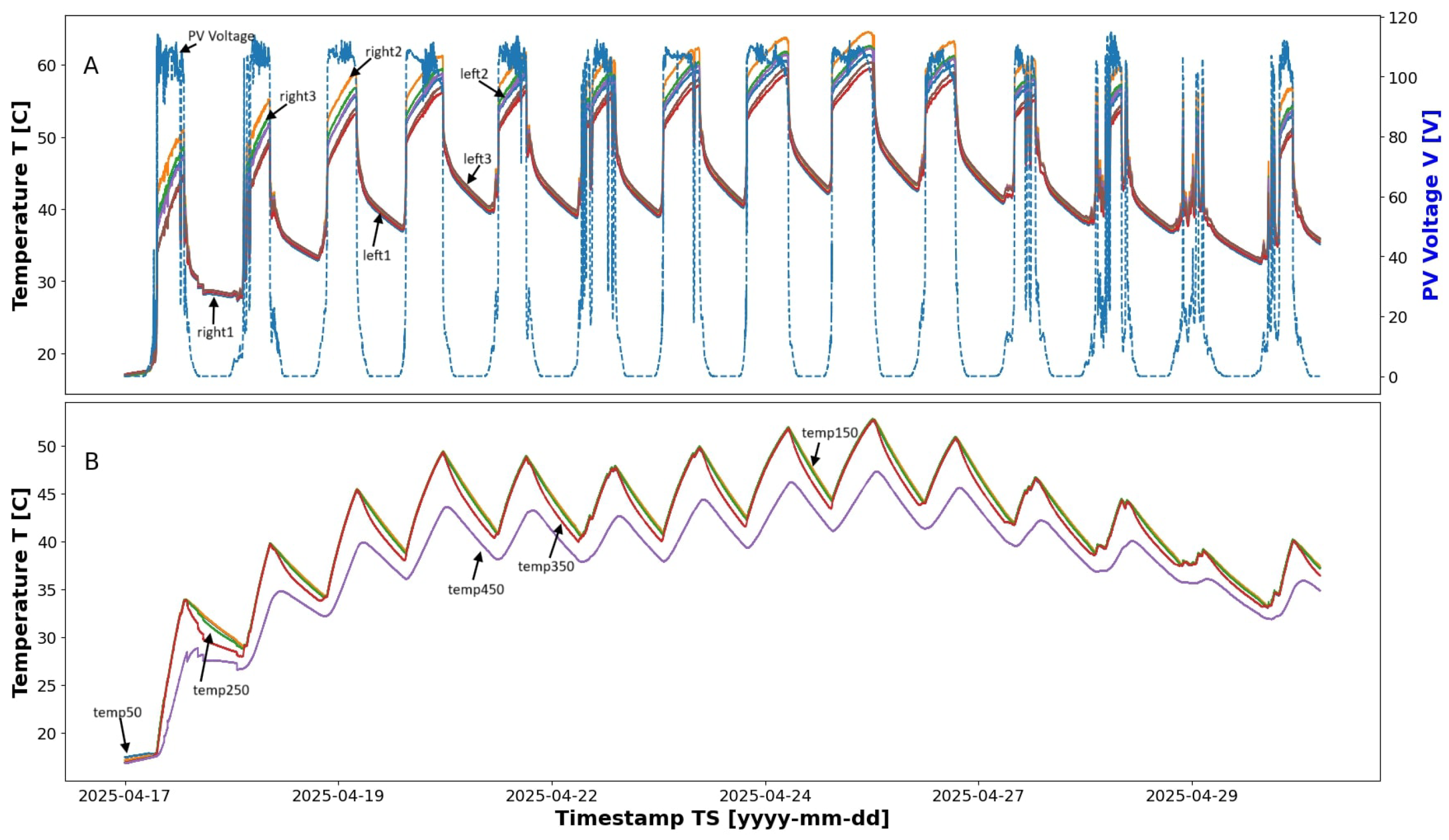

Figure 17.

Time series graph of the 50 °C TC heating element powered via PV panels during a period of sunny weather in April 2025. Graph (A) represents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) represents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

Figure 17.

Time series graph of the 50 °C TC heating element powered via PV panels during a period of sunny weather in April 2025. Graph (A) represents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) represents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

Figure 18.

Time series graph of the 50 °C TC heating element powered via PV panels during one day of sunny weather. Graph (A) presents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) presents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

Figure 18.

Time series graph of the 50 °C TC heating element powered via PV panels during one day of sunny weather. Graph (A) presents the temperature readings of the cores of the heating element. Lines labeled left1-3/right1-3 represent temperature readings of heating element cores, see text for details. Graph (B) presents the temperature readings of the water in the tank. Lines labeled temp50-450 represent temperature in water heater tank at depths of 50 mm to 450 mm, see text for details.

Figure 19.

Daily global horizontal insolation for the Anchorage, Alaska area sourced from the ERA5 data set.

Figure 19.

Daily global horizontal insolation for the Anchorage, Alaska area sourced from the ERA5 data set.

Table 1.

Summary table showing loaded power dissipation and resistance after 75 h of continuous operation heating 45.4 L of water. Unloaded resistances were described previously.

Table 1.

Summary table showing loaded power dissipation and resistance after 75 h of continuous operation heating 45.4 L of water. Unloaded resistances were described previously.

| Device | TC

°C | Potential

V | Loaded

Power

W | Loaded

Resistance

| Unloaded

Resistance

| Loading

Multiplier |

|---|

| Heater “A” | 70 | 60 | 45.9 | 78.5 | 30.3 | 2.59 |

| Heater “A” | 70 | 90 | 67.6 | 120.1 | 30.3 | 3.96 |

| Heater “A” | 70 | 110 | 71.6 | 169.4 | 30.3 | 5.59 |

| Heater “C” | 50 | 90 | 47.7 | 169.6 | 19.8 | 8.57 |