Cu-Doped Sb2Se3 Thin-Film Solar Cells Based on Hybrid Pulsed Electron Deposition/Radio Frequency Magnetron Sputtering Growth Techniques

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. NaF Layer Effect on Sputtered and PED Sb2Se3 Based Solar Cells

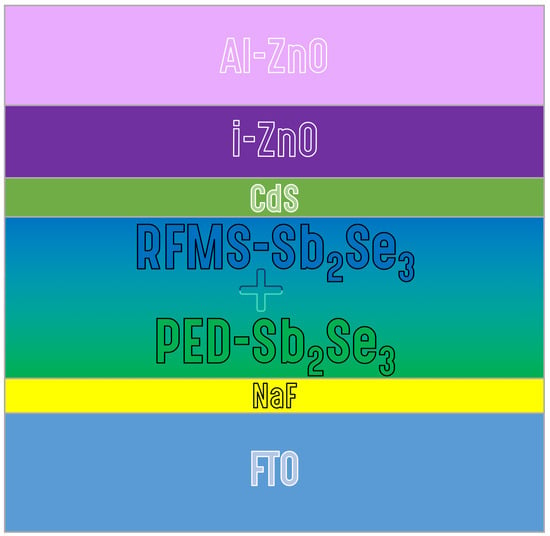

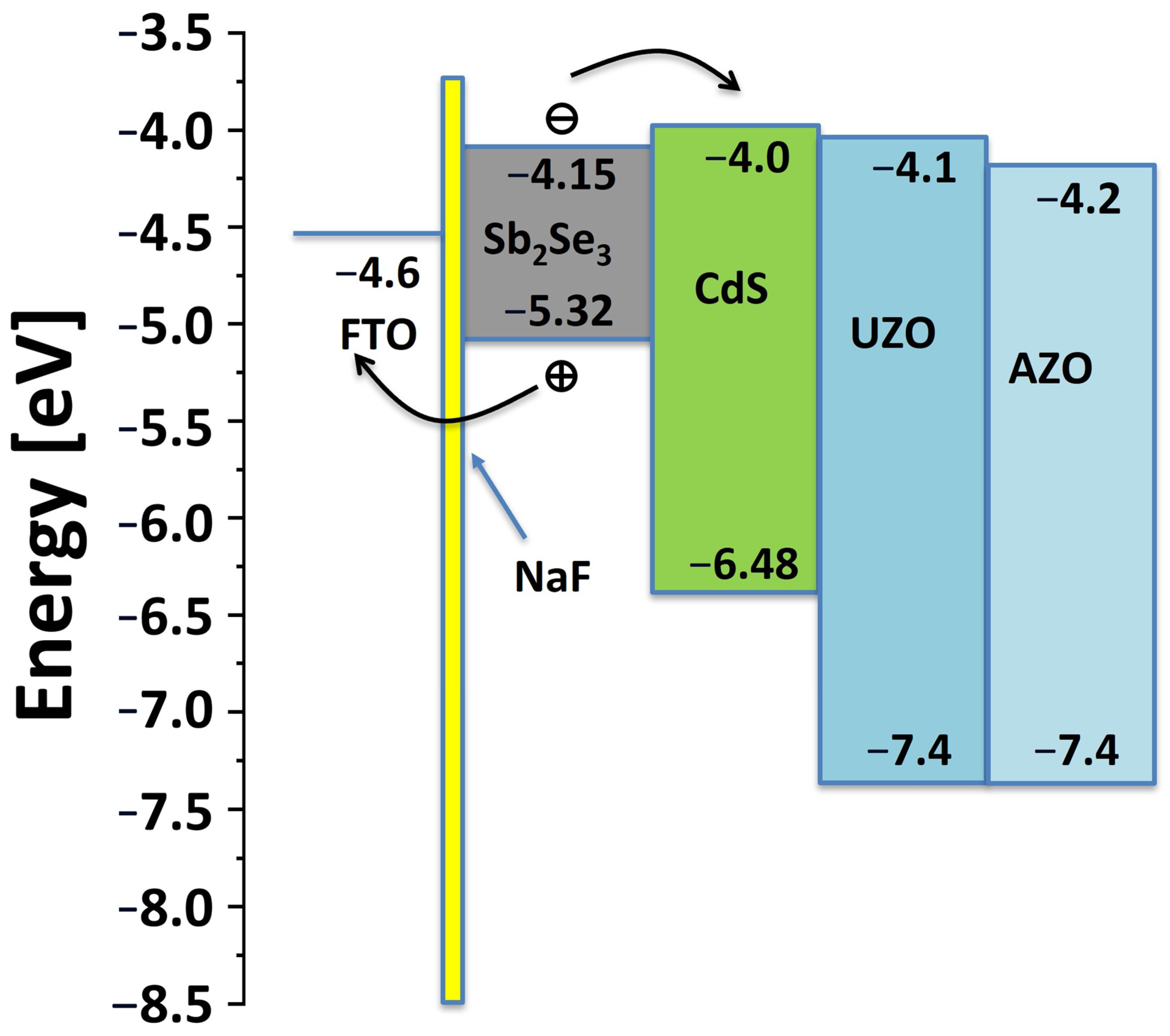

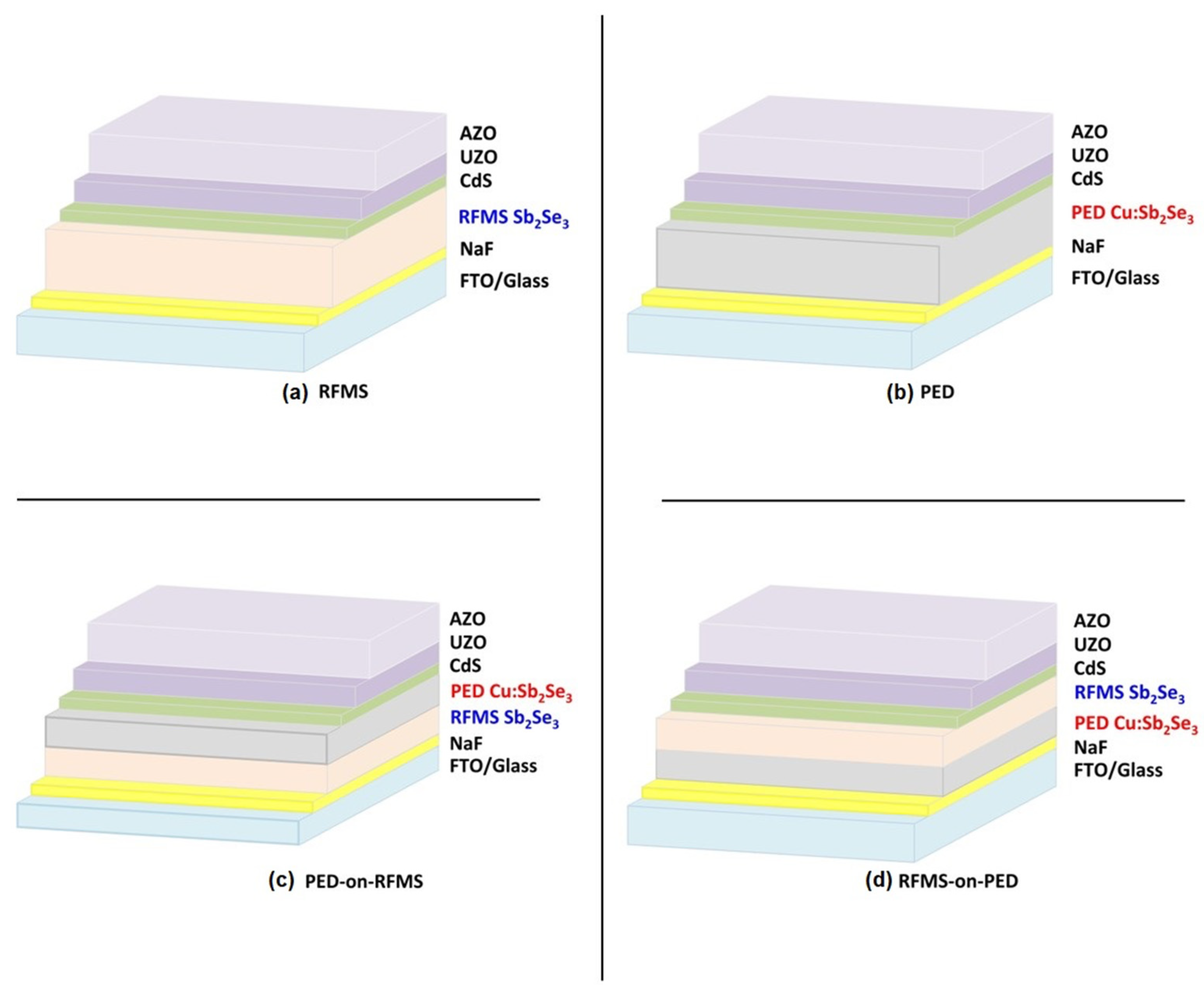

3.2. Fabrication of Bi-Layered PED/Sputtering Sb2Se3 Solar Cells

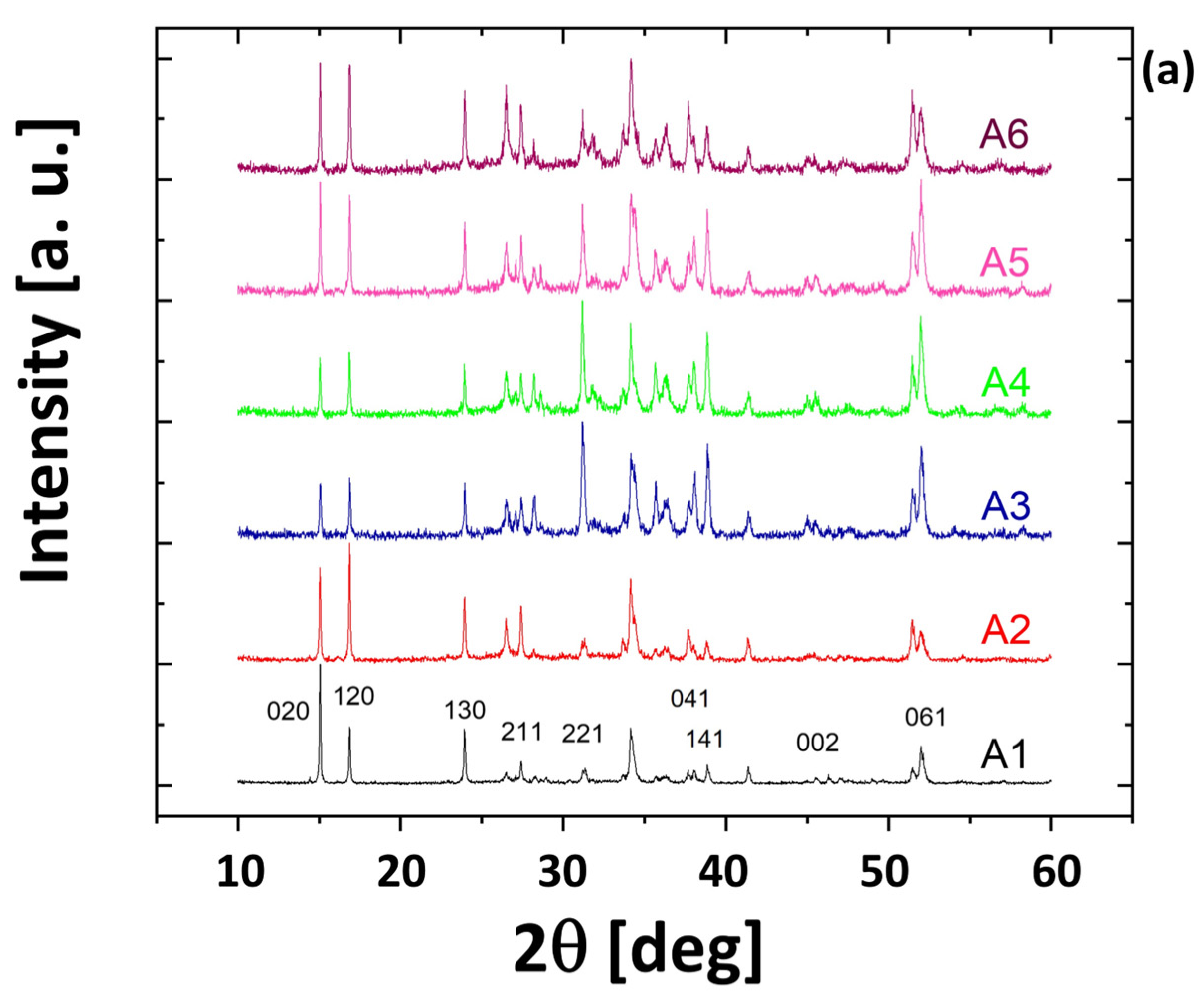

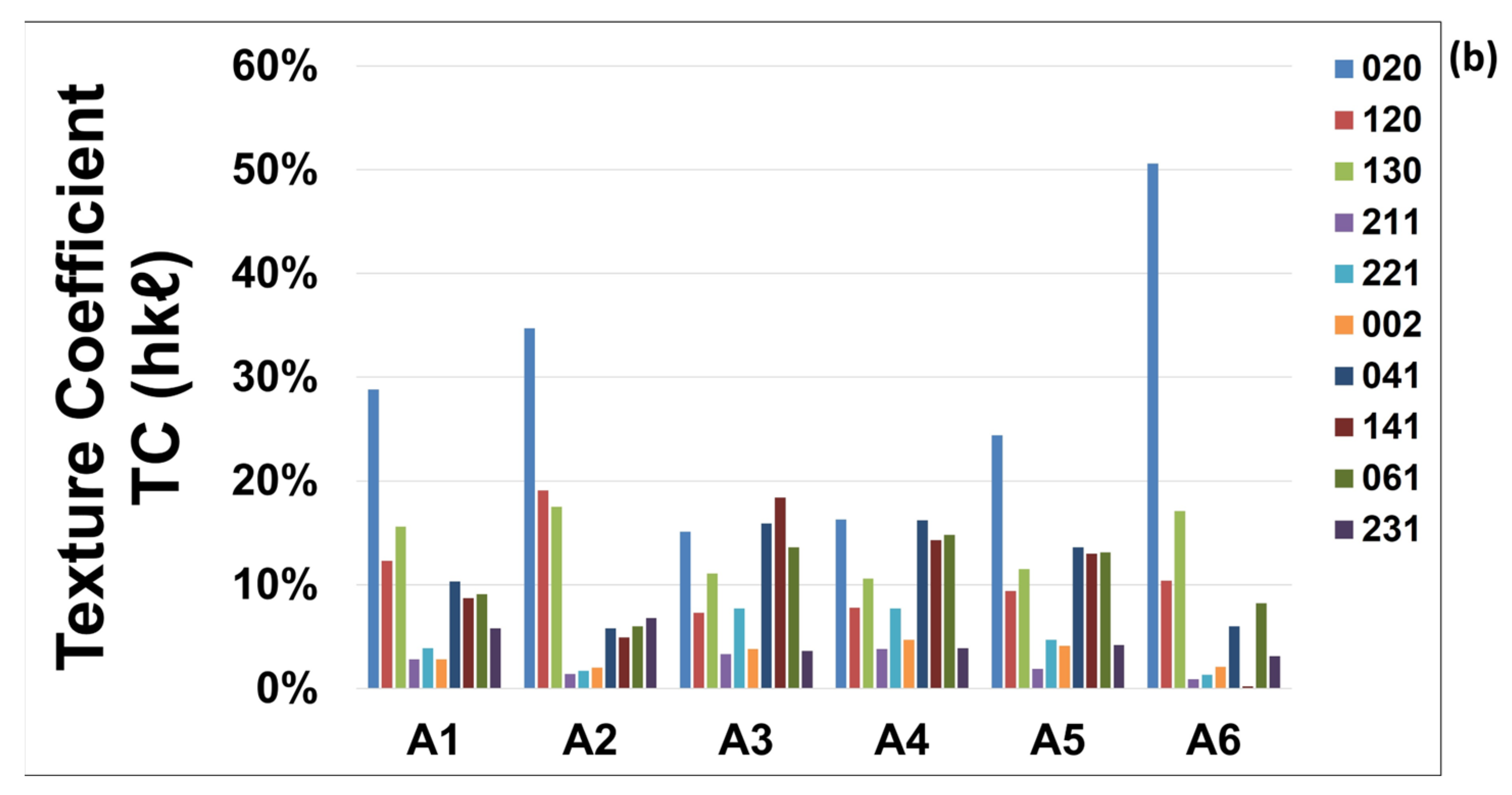

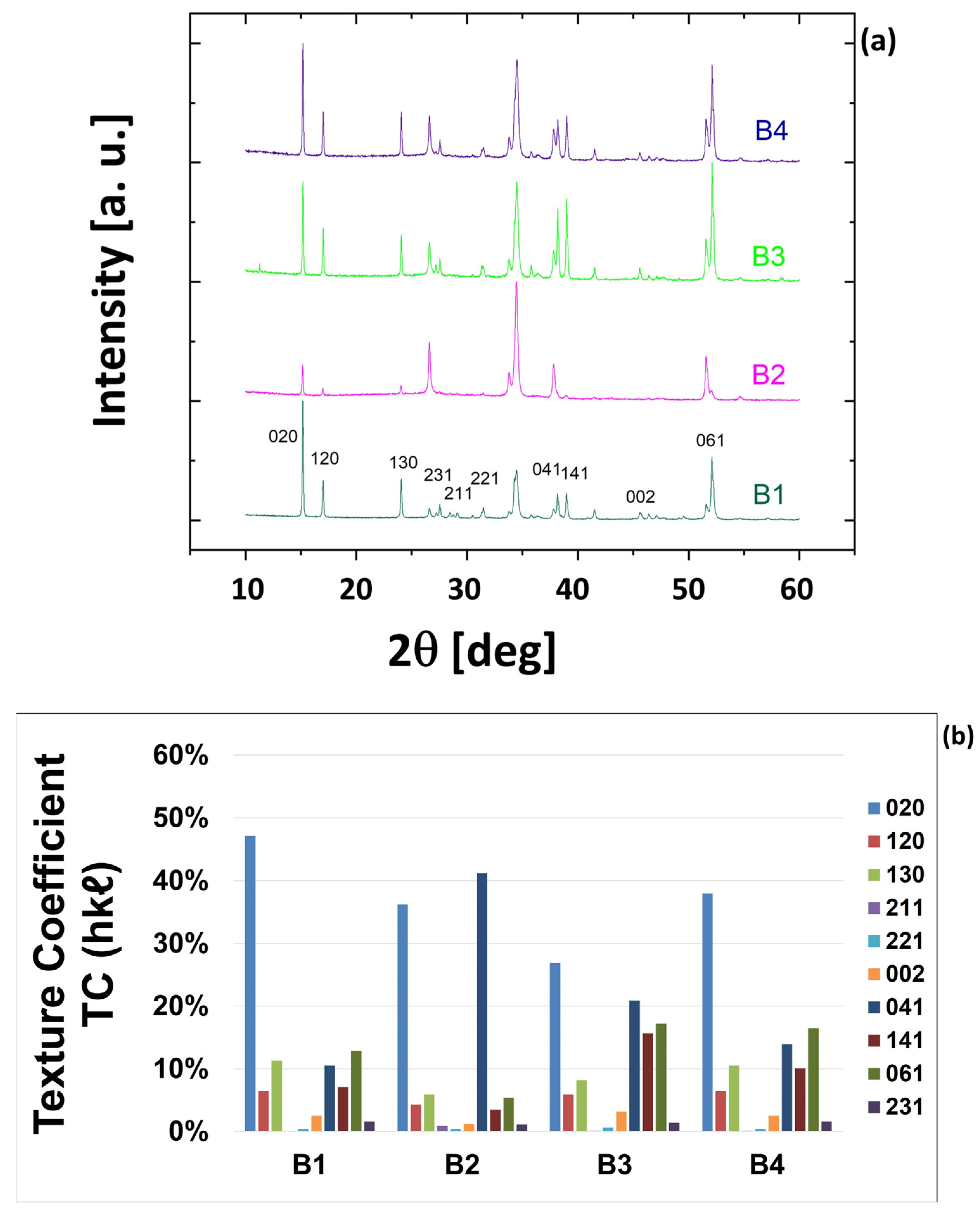

3.3. Structural Analysis

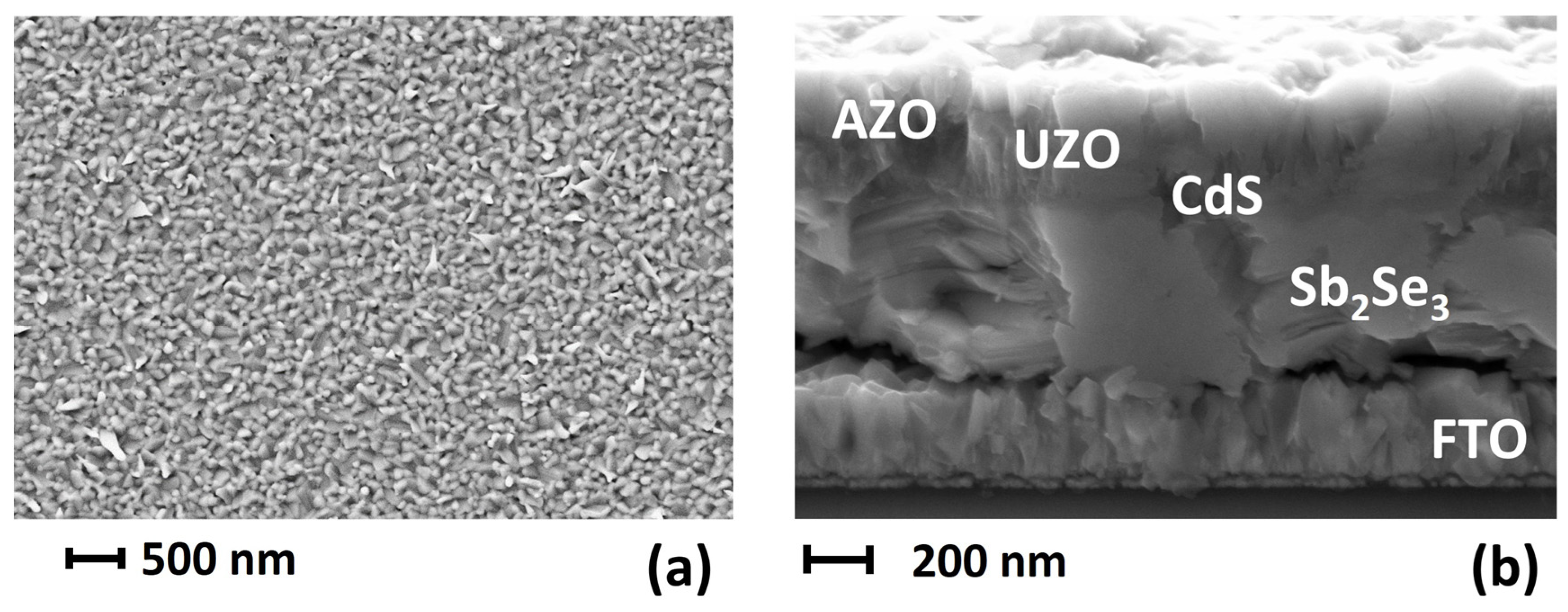

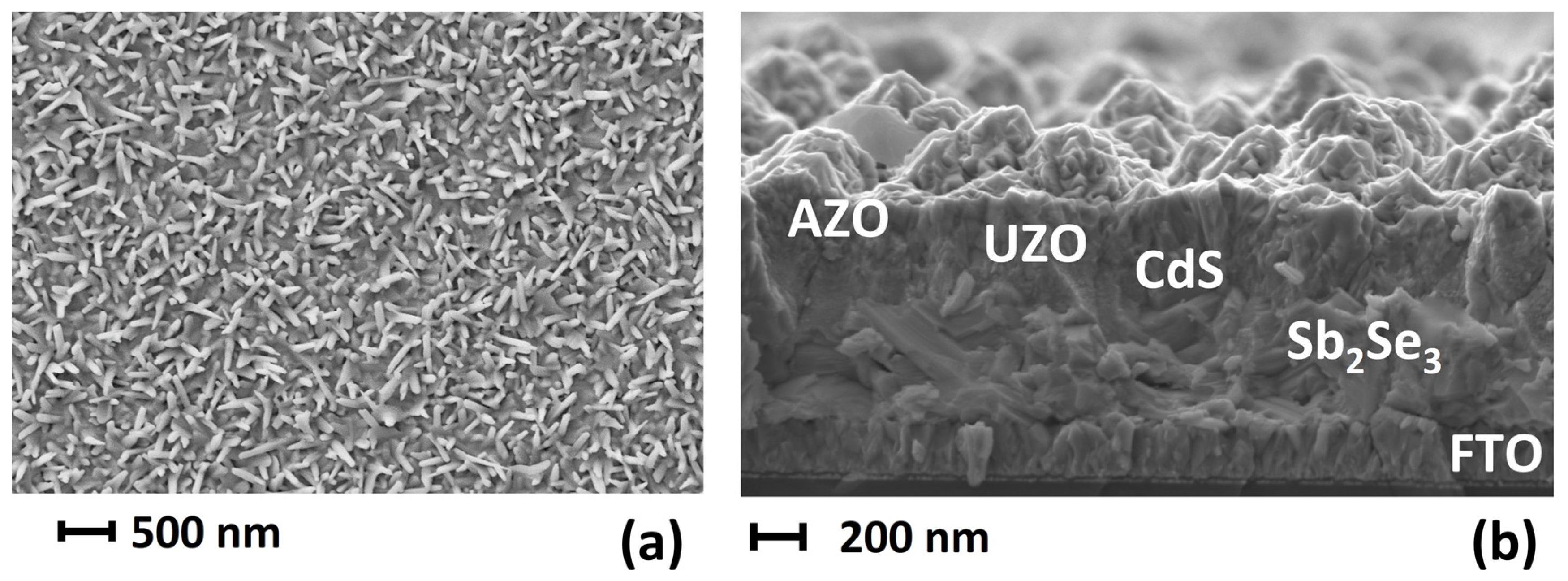

3.4. Morphological Analysis

3.5. Solar Cell Performance and Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X. Solar cell efficiency tables (version 62). Prog. Photovolt. 2023, 31, 651–663. [Google Scholar] [CrossRef]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Hameed, T.A.; Cao, W.; Mansour, B.A.; Elzawaway, I.K.; Abdelrazek, E.-M.M.; Elsayed-Ali, H.E. Properties of Cu(In,Ga,Al)Se2 thin films fabricated by magnetron sputtering. J. Vac. Sci. Technol. A 2015, 33, 031201. [Google Scholar] [CrossRef]

- Chen, C.; Li, K.; Tang, J. Ten Years of Sb2Se3 Thin Film Solar Cells. Solar RRL 2022, 6, 2200094. [Google Scholar] [CrossRef]

- Wang, J.; Li, K.; Tang, J.; Chen, C. A Perspective of Antimony Chalcogenide Photovoltaics toward Commercialization. Solar RRL 2023, 7, 2300436. [Google Scholar] [CrossRef]

- Liu, X.; Chen, J.; Luo, M.; Leng, M.; Xia, Z.; Zhou, Y.; Qin, S.; Xue, D.-J.; Lv, L.; Huang, H.; et al. Thermal Evaporation and Characterization of Sb2Se3 Thin Film for Substrate Sb2Se3/CdS Solar Cells. ACS Appl. Mater. Interfaces 2014, 6, 10687–10695. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Fu, Y.; Ishaq, M.; Li, C.; Ren, D.; Su, Z.; Qiao, X.; Fan, P.; Liang, G.; Tang, J. Carrier recombination suppression and transport enhancement enable high-performance self-powered broadband Sb2Se3 photodetectors. InfoMat 2023, 5, e12400. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed Balance Limit of Efficiency of p-n Junction Solar Cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Li, C.; Che, B.; Chen, X.; Chen, H.; Tang, R.; Wang, X.; Chen, G.; Wang, T.; et al. Regulating deposition kinetics via a novel additive-assisted chemical bath deposition technology enables fabrication of 10.57%-efficiency Sb2Se3 solar cells. Energy Environ. Sci. 2022, 15, 5118–5128. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Chen, S.; Qin, S.; Liu, X.; Chen, J.; Xue, D.-J.; Luo, M.; Cao, Y.; Cheng, Y.; et al. Thin-film Sb2Se3 photovoltaics with oriented one-dimensional ribbons and benign grain boundaries. Nat. Photon. 2015, 9, 409–415. [Google Scholar] [CrossRef]

- Ganose, A.M.; Savory, C.N.; Scanlon, D.O. Beyond methylammonium lead iodide: Prospects for the emergent field of ns2 containing solar absorbers. Chem. Commun. 2017, 53, 20–44. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.C.; Mandal, T.N.; Yang, W.S.; Lee, Y.H.; Im, S.H.; Noh, J.H.; Seok, S.I. Sb2Se3-Sensitized Inorganic-Organic Heterojunction Solar Cells Fabricated Using a Single-Source Precursor. Angew. Chem. 2014, 126, 1353–1357. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, C.; Xing, Y.; Tian, H.; Yan, D.; Zhang, S.; Jia, X.; Qiu, J.; Yuan, N.; Ding, J. High-Efficiency Sb2Se3 Solar Cells Modified by Potassium Hydroxide. J. Phys. Chem. Lett. 2021, 12, 12352–12359. [Google Scholar] [CrossRef]

- Chen, C.; Li, K.; Chen, S.; Wang, L.; Lu, S.; Liu, Y.; Li, D.; Song, H.; Tang, J. Efficiency Improvement of Sb2Se3 Solar Cells via Grain Boundary Inversion. ACS Energy Lett. 2018, 3, 2335–2341. [Google Scholar] [CrossRef]

- Liang, G.-X.; Zhang, X.-H.; Ma, H.-L.; Hu, J.-G.; Fan, B.; Luo, Z.-K.; Zheng, Z.-H.; Luo, J.-T.; Fan, P. Facile preparation and enhanced photoelectrical performance of Sb2Se3 nano-rods by magnetron sputtering deposition. Sol. Energy Mater. Sol. Cells 2017, 160, 257–262. [Google Scholar] [CrossRef]

- Tang, R.; Chen, X.-Y.; Liang, G.-X.; Su, Z.-H.; Luo, J.; Fan, P. Magnetron sputtering deposition and selenization of Sb2Se3 thin film for substrate Sb2Se3/CdS solar cells. Surf. Coat. Technol. 2019, 360, 68–72. [Google Scholar] [CrossRef]

- Spaggiari, G.; Pattini, F.; Bersani, D.; Calestani, D.; De Iacovo, A.; Gilioli, E.; Mezzadri, F.; Sala, A.; Trevisi, G.; Rampino, S. Growth and structural characterization of Sb2Se3 solar cells with vertical Sb4Se6 ribbon alignment by RF magnetron sputtering. J. Phys. D Appl. Phys. 2021, 54, 385502. [Google Scholar] [CrossRef]

- Park, S.-N.; Kim, S.-Y.; Lee, S.-J.; Sung, S.-J.; Yang, K.-J.; Kang, J.-K.; Kim, D.-H. Controlled synthesis of (hk1) preferentially oriented Sb2Se3 rod arrays by co-evaporation for photovoltaic applications. J. Mater. Chem. A 2019, 7, 25900–25907. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, B.; Qin, Y.; Li, D.; Li, L.; Qian, X.; Yan, F. Tunable Quasi-One-Dimensional Ribbon Enhanced Light Absorption in Sb2Se3 Thin-Film Solar Cells Grown by Close-Space Sublimation. Solar RRL 2018, 2, 1800128. [Google Scholar] [CrossRef]

- Tao, R.; Tan, T.; Zhang, H.; Meng, Q.; Zha, G. Sb2Se3 solar cells fabricated via close-space sublimation. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2021, 39, 052203. [Google Scholar] [CrossRef]

- Li, Z.; Liang, X.; Li, G.; Liu, H.; Zhang, H.; Guo, J.; Chen, J.; Shen, K.; San, X.; Yu, W.; et al. 9.2%-efficient core-shell structured antimony selenide nanorod array solar cells. Nat. Commun. 2019, 10, 125. [Google Scholar] [CrossRef]

- Duan, Z.; Liang, X.; Feng, Y.; Ma, H.; Liang, B.; Wang, Y.; Luo, S.; Wang, S.; Schropp, R.E.I.; Mai, Y.; et al. Sb2Se3 Thin-Film Solar Cells Exceeding 10% Power Conversion Efficiency Enabled by Injection Vapor Deposition Technology. Adv. Mater. 2022, 34, 2202969. [Google Scholar] [CrossRef]

- Bosio, A.; Foti, G.; Pasini, S.; Spoltore, D. A Review on the Fundamental Properties of Sb2Se3-Based Thin Film Solar Cells. Energies 2023, 16, 6862. [Google Scholar] [CrossRef]

- Li, W.-H.; Li, M.; Hu, Y.-J.; Cheng, C.-H.; Kan, Z.-M.; Yu, D.; Leng, J.; Jin, S.; Cong, S. Enhanced performance of antimony selenide thin film solar cell using PbI2 as a dopant. Appl. Phys. Lett. 2021, 118, 093903. [Google Scholar] [CrossRef]

- Spaggiari, G.; Bersani, D.; Calestani, D.; Gilioli, E.; Gombia, E.; Mezzadri, F.; Casappa, M.; Pattini, F.; Trevisi, G.; Rampino, S. Exploring Cu-Doping for Performance Improvement in Sb2Se3 Photovoltaic Solar Cells. Int. J. Mol. Sci. 2022, 23, 15529. [Google Scholar] [CrossRef]

- Hobson, T.D.C.; Shiel, H.; Savory, C.N.; Swallow, J.E.N.; Jones, L.A.H.; Featherstone, T.J.; Smiles, M.J.; Thakur, P.K.; Lee, T.-L.; Das, B.; et al. P-type conductivity in Sn-doped Sb2Se3. J. Phys. Energy 2022, 4, 045006. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Y.; Luo, J.; Chen, W.; Yang, B.; Wen, X.; Lu, S.; Chen, C.; Zeng, K.; Song, H.; et al. The effect of sodium on antimony selenide thin film solar cells. RSC Adv. 2016, 6, 87288–87293. [Google Scholar] [CrossRef]

- Ren, D.; Chen, S.; Cathelinaud, M.; Liang, G.; Ma, H.; Zhang, X. Fundamental Physical Characterization of Sb2Se3-Based Quasi-Homojunction Thin Film Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 30572–30583. [Google Scholar] [CrossRef]

- Mungan, E.S.; Wang, X.; Alam, M.A. Modeling the Effects of Na Incorporation on CIGS Solar Cells. IEEE J. Photovolt. 2013, 3, 451–456. [Google Scholar] [CrossRef]

- Urbaniak, A.; Igalson, M.; Pianezzi, F.; Bücheler, S.; Chirilă, A.; Reinhard, P.; Tiwari, A.N. Effects of Na incorporation on electrical properties of Cu(In,Ga)Se2-based photovoltaic devices on polyimide substrates. Sol. Energy Mater. Sol. Cells 2014, 128, 52–56. [Google Scholar] [CrossRef]

- Cavallari, N.; Pattini, F.; Rampino, S.; Annoni, F.; Barozzi, M.; Bronzoni, M.; Gilioli, E.; Gombia, E.; Maragliano, C.; Mazzer, M.; et al. Low temperature deposition of bifacial CIGS solar cells on Al-doped Zinc Oxide back contacts. Appl. Surf. Sci. 2017, 412, 52–57. [Google Scholar] [CrossRef]

- Pattini, F.; Rampino, S.; Mezzadri, F.; Calestani, D.; Spaggiari, G.; Sidoli, M.; Delmonte, D.; Sala, A.; Gilioli, E.; Mazzer, M. Role of the substrates in the ribbon orientation of Sb2Se3 films grown by Low-Temperature Pulsed Electron Deposition. Sol. Energy Mater. Sol. Cells 2020, 218, 110724. [Google Scholar] [CrossRef]

- Chen, M.; Ishaq, M.; Ren, D.; Ma, H.; Su, Z.; Fan, P.; Le Coq, D.; Zhang, X.; Liang, G.; Chen, S. Interface optimization and defects suppression via NaF introduction enable efficient flexible Sb2Se3 thin-film solar cells. J. Energy Chem. 2024, 90, 165–175. [Google Scholar] [CrossRef]

- Wada, T.; Maeda, T. Optical properties and electronic structures of CuSbS2, CuSbSe2, and CuSb(S1−xSex)2 solid solution. Phys. Status Solidi C 2017, 14, 1600196. [Google Scholar] [CrossRef]

- Wang, Y.; Ji, S.; Moon, C.; Chu, J.; Jung, H.J.; Shin, B. Efficiency boosting in Sb2(S,Se)3 solar cells enabled by tailoring bandgap gradient via a hybrid growth method. J. Mater. Chem. A 2023, 11, 23071–23079. [Google Scholar] [CrossRef]

- Bérubé, L.P.; L’Espérance, G. A Quantitative Method of Determining the Degree of Texture of Zinc Electrodeposits. J. Electrochem. Soc. 1989, 136, 2314–2315. [Google Scholar] [CrossRef]

- Hameed, T.A.; Sharmoukh, W.; Anis, B.; Youssef, A.M. Enhanced photocatalytic activity and diode performance of ZnO-GO nanocomposites via doping with aluminum. Int. J. Energy Res. 2022, 46, 22601–22624. [Google Scholar] [CrossRef]

- Tang, R.; Zheng, Z.-H.; Su, Z.-H.; Li, X.-J.; Wei, Y.-D.; Fu, Y.-Q.; Luo, J.-T. Highly Efficient and Stable Planar Heterojunction Solar Cell Based on Sputtered and Post-Selenized Sb2Se3 Thin Film. Nano Energy 2019, 64, 103929. [Google Scholar] [CrossRef]

| Sample | Sputtering Layer (nm) | PED Layer (nm) |

|---|---|---|

| A1 | 1200 | 0 |

| A2 | 1100 | 100 |

| A3 | 950 | 250 |

| A4 | 800 | 400 |

| A5 | 400 | 800 |

| A6 | 200 | 1000 |

| Sample | PED Layer (nm) | Sputtering Layer (nm) |

|---|---|---|

| B1 | 1200 | 0 |

| B2 | 1000 | 200 |

| B3 | 200 | 1000 |

| B4 | 100 | 1100 |

| Sample | ΣTC (ℓ ≠ 0) (%) |

|---|---|

| A1 | 43.36 |

| A2 | 28.63 |

| A3 | 66.43 |

| A4 | 65.33 |

| A5 | 54.65 |

| A6 | 21.82 |

| B1 | 35.04 |

| B2 | 53.65 |

| B3 | 59.04 |

| B4 | 45.05 |

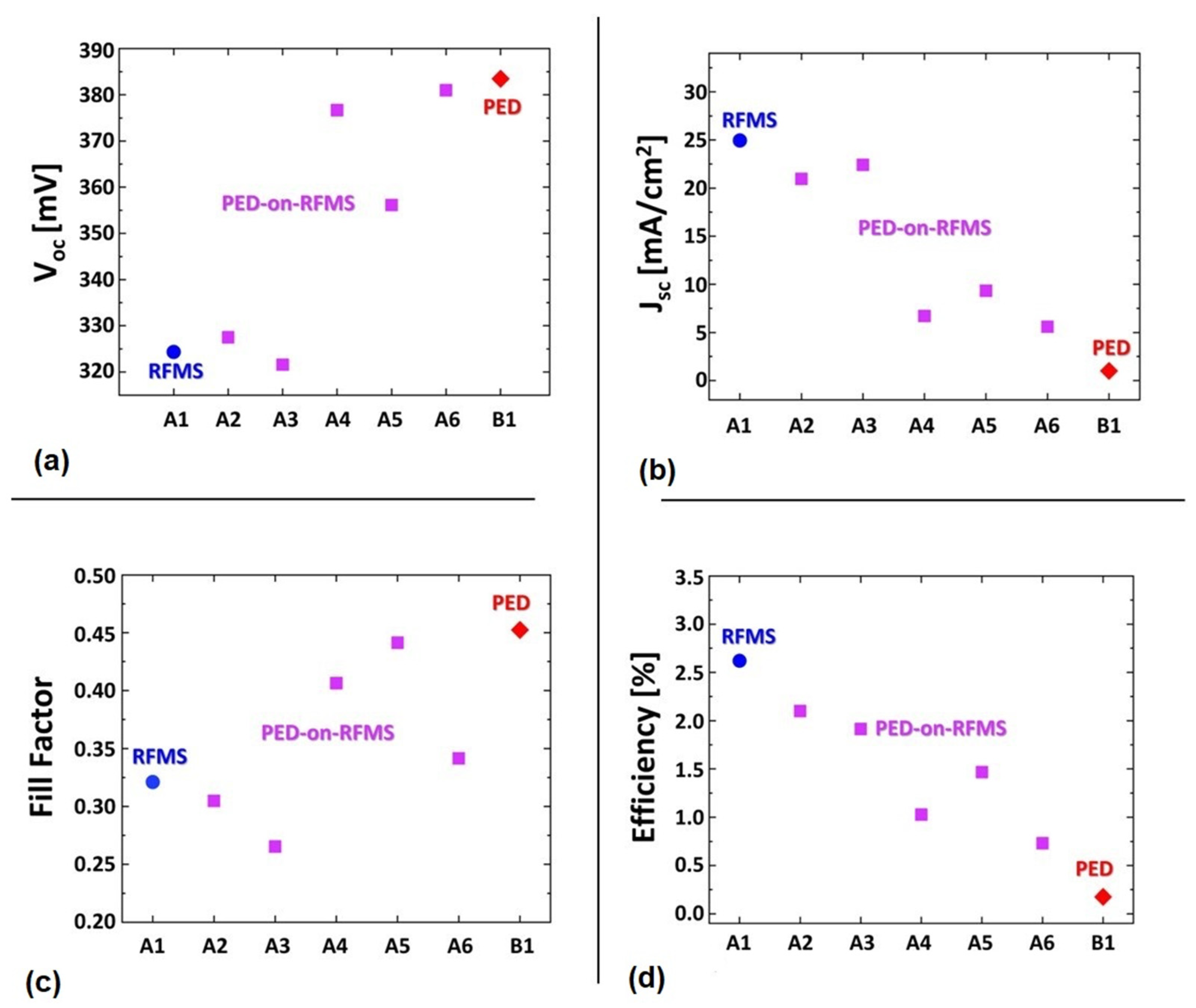

| Sample | VOC (mV) | JSC (mA/cm2) | FF (%) | PCE (%) | Rs (Ωcm2) | Rsh (Ωcm2) | J0 (mA/cm2) | n |

|---|---|---|---|---|---|---|---|---|

| A1 | 305 ± 32 (324) | 22.5 ± 6.6 (31.2) | 29.3 ± 2.2 (32.0) | 2.03 ± 0.66 (3.24) | 6.86 | 342.7 | 6.7 × 10−3 | 2.7 |

| A2 | 296 ± 62 (327) | 9.15 ± 7.66 (20.95) | 37.2 ± 8 (30.4) | 0.9 ± 0.6 (2.04) | 4.17 | 149.2 | 9.5 × 10−4 | 3.5 |

| A3 | 343 ± 43 (321) | 9.35 ± 7.5 (22.4) | 33.9 ± 4.5 (26.5) | 0.93 ± 0.52 (1.91) | 18.34 | 4566.6 | 6.7 × 10−5 | 2.4 |

| A4 | 373 ± 9 (377) | 5.46 ± 0.95 (6.7) | 37.1 ± 1.9 (40.6) | 0.76 ± 0.16 (1.02) | 9.05 | 5754.4 | 7.4 × 10−5 | 1.3 |

| A5 | 342 ± 22 (356) | 8.08 ± 1.7 (9.32) | 41.3 ± 5.4 (44.0) | 1.15 ± 0.28 (1.47) | 3.6 | 405.9 | 1.7 × 10−3 | 2.5 |

| A6 | 395 ± 13 (381) | 3.67 ± 1.18 (5.58) | 35.3 ± 1.1 (34.0) | 0.51 ± 0.14 (0.73) | 4.45 | 26,833.2 | 7.6 × 10−6 | 1.3 |

| B1 | 385 ± 19 (355) | 0.74 ± 0.2 (1.25) | 42.6 ± 3.7 (40.6) | 0.12 ± 0.02 (0.18) | 3.75 | 21,298.0 | 4.6 × 10−6 | 1.4 |

| B2 | 359 ± 3 (361) | 9.07 ± 0.47 (9.05) | 41.1 ± 1.9 (43.2) | 1.35 ± 0.06 (1.41) | 2.35 | 3314.1 | 7.2 × 10−5 | 1.3 |

| B3 | 358 ± 7 (349) | 9.89 ± 2.6 (14.58) | 45.0 ± 2.5 (44.5) | 1.58 ± 0.38 (2.27) | 4.59 | 1633.4 | 8.5 × 10−5 | 1.4 |

| B4 | 347 ± 7 (344) | 14.65 ± 3.3 (26.6) | 48.8 ± 3.5 (42.2) | 2.45 ± 0.39 (3.85) | 1.81 | 460.2 | 5.4 × 10−5 | 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakomin, R.; Rampino, S.; Spaggiari, G.; Casappa, M.; Trevisi, G.; Del Canale, E.; Gombia, E.; Bronzoni, M.; Sossoe, K.K.; Mezzadri, F.; et al. Cu-Doped Sb2Se3 Thin-Film Solar Cells Based on Hybrid Pulsed Electron Deposition/Radio Frequency Magnetron Sputtering Growth Techniques. Solar 2024, 4, 83-98. https://doi.org/10.3390/solar4010004

Jakomin R, Rampino S, Spaggiari G, Casappa M, Trevisi G, Del Canale E, Gombia E, Bronzoni M, Sossoe KK, Mezzadri F, et al. Cu-Doped Sb2Se3 Thin-Film Solar Cells Based on Hybrid Pulsed Electron Deposition/Radio Frequency Magnetron Sputtering Growth Techniques. Solar. 2024; 4(1):83-98. https://doi.org/10.3390/solar4010004

Chicago/Turabian StyleJakomin, Roberto, Stefano Rampino, Giulia Spaggiari, Michele Casappa, Giovanna Trevisi, Elena Del Canale, Enos Gombia, Matteo Bronzoni, Kodjo Kekeli Sossoe, Francesco Mezzadri, and et al. 2024. "Cu-Doped Sb2Se3 Thin-Film Solar Cells Based on Hybrid Pulsed Electron Deposition/Radio Frequency Magnetron Sputtering Growth Techniques" Solar 4, no. 1: 83-98. https://doi.org/10.3390/solar4010004

APA StyleJakomin, R., Rampino, S., Spaggiari, G., Casappa, M., Trevisi, G., Del Canale, E., Gombia, E., Bronzoni, M., Sossoe, K. K., Mezzadri, F., & Pattini, F. (2024). Cu-Doped Sb2Se3 Thin-Film Solar Cells Based on Hybrid Pulsed Electron Deposition/Radio Frequency Magnetron Sputtering Growth Techniques. Solar, 4(1), 83-98. https://doi.org/10.3390/solar4010004