Optical Characterization of a New Facility for Materials Testing under Concentrated Wavelength-Filtered Solar Radiation Fluxes †

Abstract

:1. Introduction

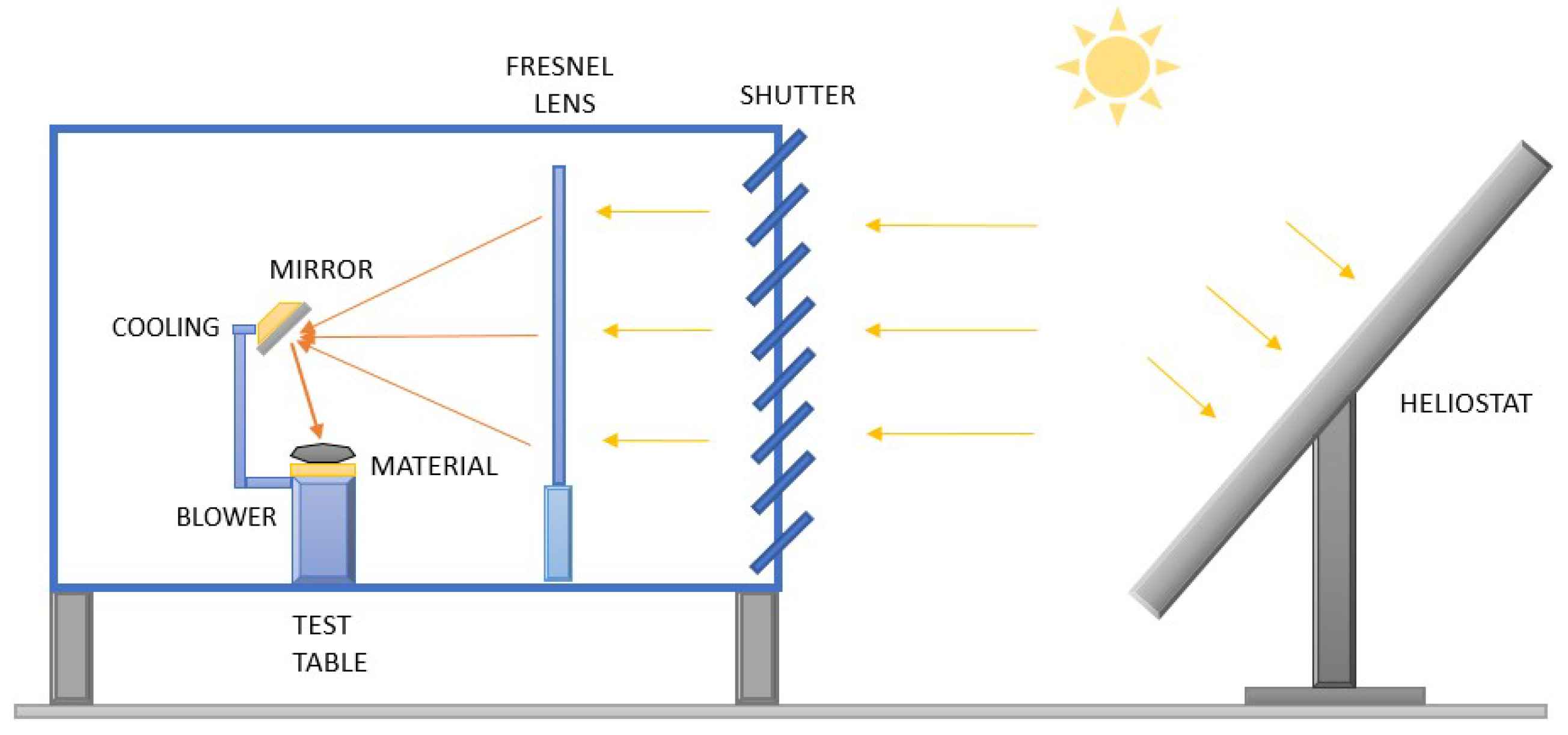

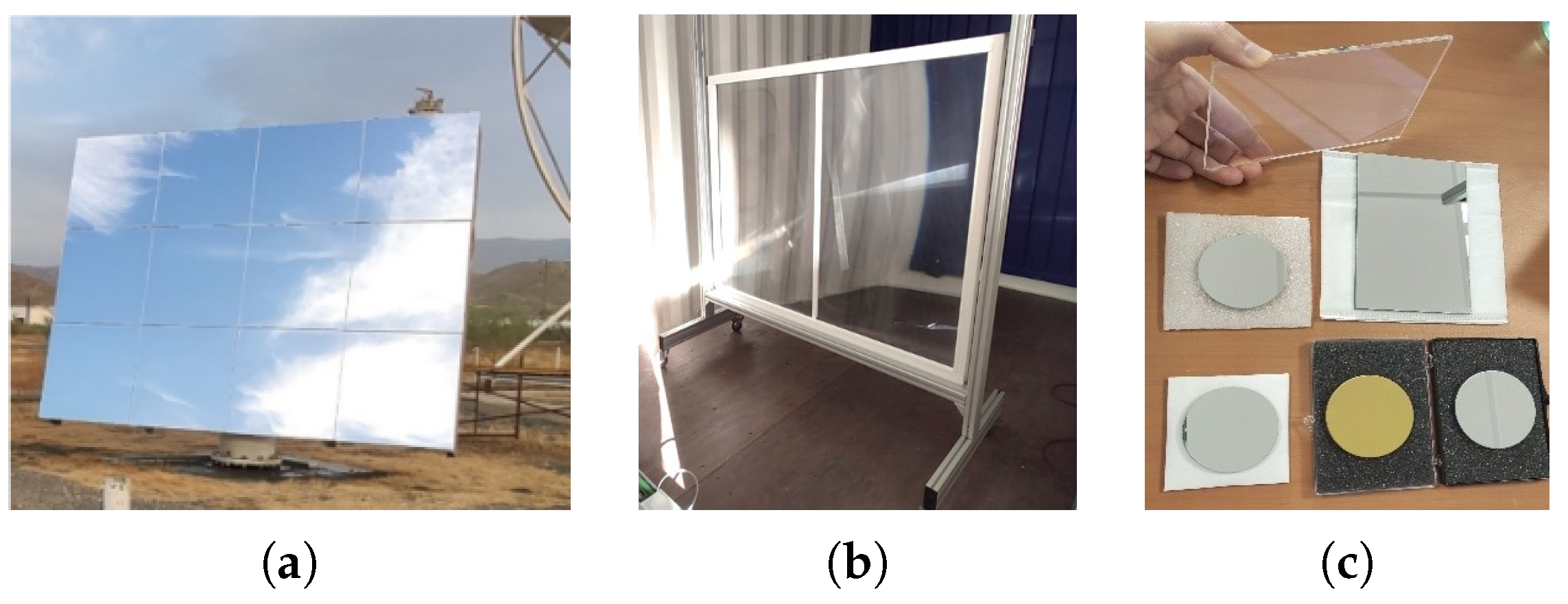

2. Materials and Methods

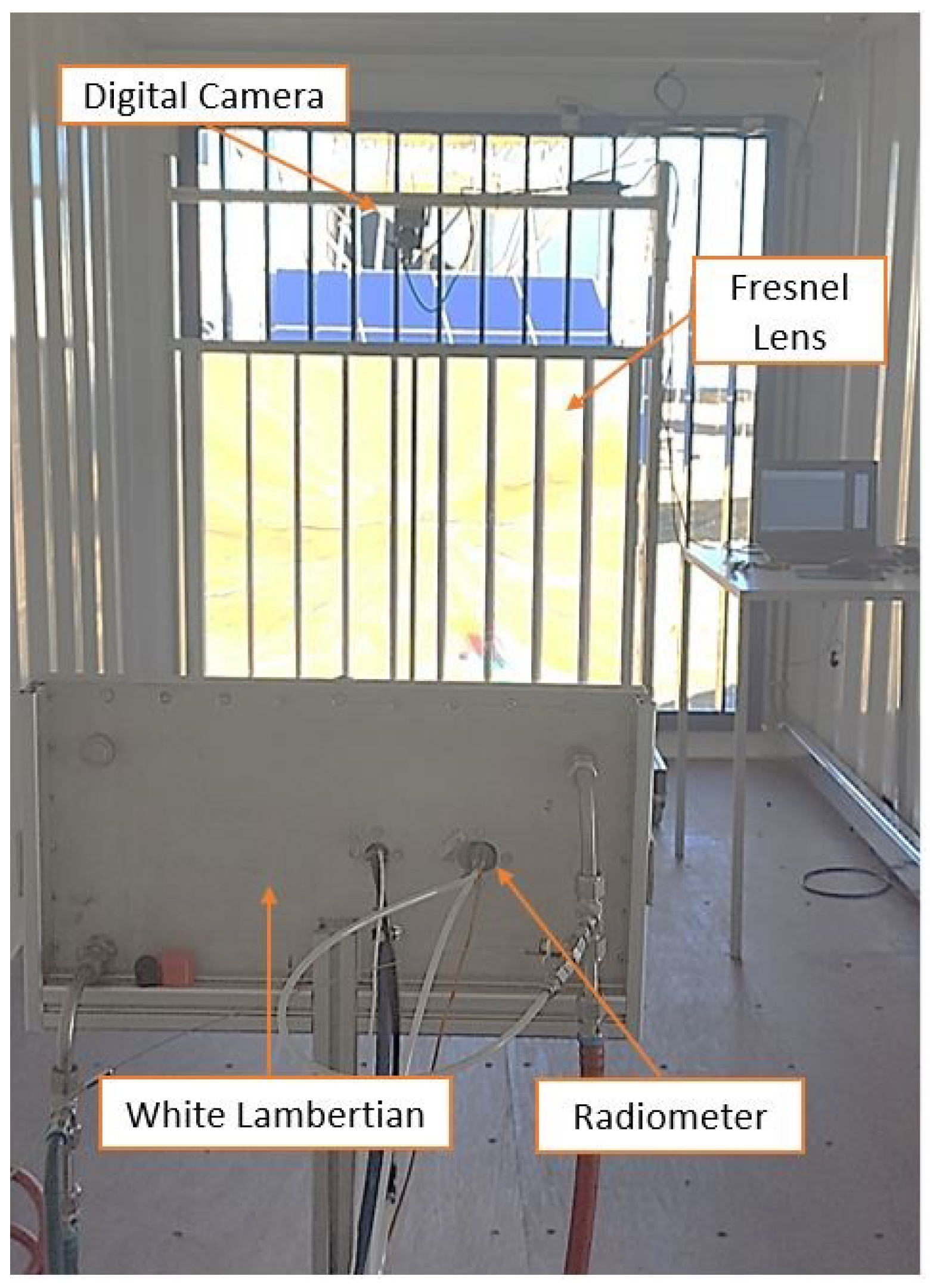

- The Lambertian target consists of a flat aluminum plate coated by means of thermal sputtering with alumina (), which gives it the required Lambertian properties (very high diffuse reflectance). In order to avoid excessive heating of the device, the Lambertian target is cooled by a closed water circuit and, thus, it can withstand solar fluxes above 2000 .

- The digital camera used is a Hamamatsu Orca Flash 4.0. V2 16–bits Digital CMOS camera C11440–22CU. In order to prevent the images from being overexposed to excess light, an ND7 neutral optical density filter was used.

- Radiometer. A large 1″ diameter Radiometer with zynolyte coating was installed on the Lambertian target. The radiometer is used to transform the illumination levels of the Lambertian target captured by the CMOS camera into physical power units, and, therefore, it is necessary to calibrate the camera/filter/Lambertian target assembly. The radiometer used is of the water-cooled Gardon type and its measurement is based on a copper–constantan differential thermocouple transducer (Seebeck effect). The incident power on the sensor is proportional to the voltage generated. The accuracy of the radiometer used on the measurement system equals 3.0%

- Data acquisition system. The radiometer signals, as well as those of the cooling water temperature control thermocouples, were acquired with a SIEMENS 1231 14 bits data acquisition card.

Fresnel Lens Characterization Method

3. Results and Discussion

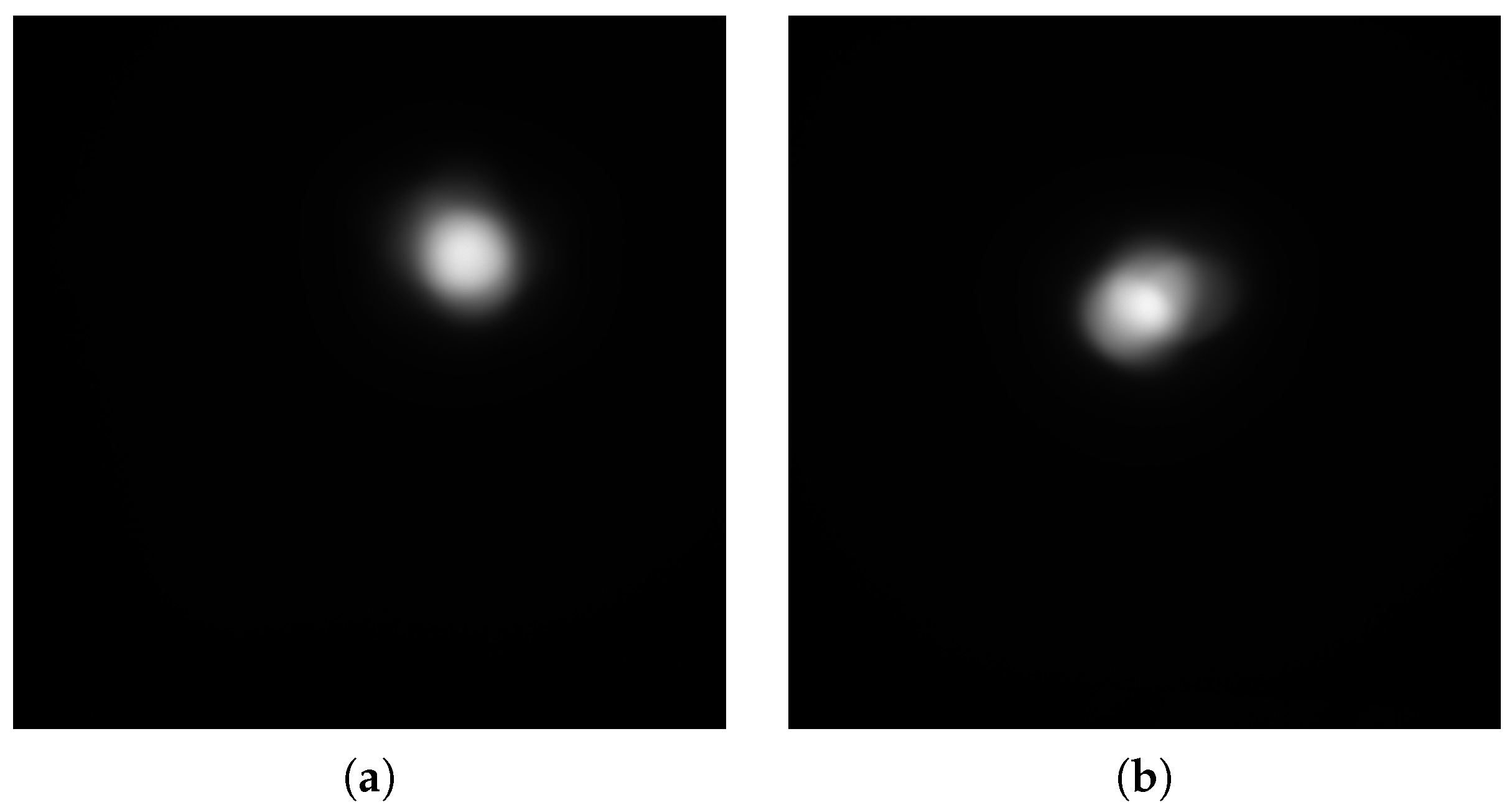

3.1. Fresnel Lens Characterization Results

- Position #1: With the rough side facing the heliostat and the smooth side in focus towards the test table (characterization A).

- Position #2: With the rough side facing the test table and the smooth side facing the heliostat (characterization B).

3.2. Characterization Results of Selective Spectral Reflectance Mirrors

4. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Air Mass |

| AOI | Angle Of Incidence |

| ASTM | American Society for Testing and Materials |

| CMOS | Complementary metal-oxide semiconductor |

| DNI | Direct Normal Irradiance |

| IR | Infrared |

| NREL | National Renewable Energy Laboratory |

| OPAC | Optical Characterization and Durability Analysis of Solar Reflectors |

| PSA | Plataforma Solar de Almería |

References

- Perez, M.; Perez, R. Update 2022— A fundamental look at supply side energy reserves for the planet. Sol. Energy Adv. 2022, 2, 100014. [Google Scholar] [CrossRef]

- Protermosolar. Available online: https://www.protermosolar.com/la-energia-termosolar/el-sector-en-cifras/ (accessed on 10 July 2022).

- IEA. Technology Roadmap. Concentrating Solar Power. 2010. Available online: https://www.iea.org/reports/technology-roadmap-concentrating-solar-power (accessed on 10 July 2022).

- Kolb, G.J.; Ho, C.K.; Mancini, T.R. Power Tower Technology Roadmap and Cost Reduction Plan. Sandia Rep. 2011, 7, 1–20. [Google Scholar]

- Setien, E.; Fernández-Reche, J.; Álvarez-de-Lara, M.; Ariza, M.J. Experimental system for long term aging of highly irradiated tube type receivers. Sol. Energy 2014, 105, 303–313. [Google Scholar] [CrossRef]

- Setien, E.; Fernández-Reche, J.; Ariza, M.J.; Álvarez-de-Lara, M. Solar aging of receivers made of nickel super alloys. AIP Conf. Proc. 2018, 2033, 230012. [Google Scholar]

- Nijaoui, A.; Rachidi, S.; Bouzekri, H.; Raccurt, O.; Vidal, F.; Albert, R.; Le Baron, E.; Boudi, M. Survey of potential outdoor accelerated aging systems for the characterization of CSP components’ durability. In Proceedings of the 9th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 20–22 March 2018; pp. 1–8. [Google Scholar]

- Selvaraj, P.; Baig, H.; Mallick, T.K.; Siviter, J.; Montecucco, A.; Li, W.; Paul, M.; Sweet, T.; Gao, M.; Knox, A.R.; et al. Enhancing the efficiency of transparent dye–sensitized solar cells using concentrated light. Sol. Energy Mater. Sol. Cells 2018, 1, 29–34. [Google Scholar] [CrossRef]

- Estremera-Pedriza, N.; Fernández-Reche, J.; Carballo, J.A. Nueva instalación de longitud de onda selectiva para la caracterización y envejecimiento de materiales sometidos a altos flujos de radiación solar. In Proceedings of the XVIII Congreso Ibérico y XIV Congreso Iberoamericano de Energía Solar, Palma, Spain, 20–22 June 2022; pp. 97–104. [Google Scholar]

- Guerra–Rosa, L. Solar heat for materials processing: A review on recent achievements and a prospect on future trends. ChemEngineering 2019, 3, 1–19. [Google Scholar]

- Xie, W.T.; Dai, Y.J.; Wang, R.Z.; Sumathy, K. Concentrated solar energy applications using Fresnel lenses: A review. Renew. Sustain. Energy Rev. 2011, 15, 2588–2606. [Google Scholar] [CrossRef]

- Fernández-González, D.; Ruiz-Bustinza, I.; González-Gasca, C.; Piñuela-Noval, J.; Mochón-Castaños, J.; Sancho-Gorostiaga, J.; Verdeja, L.F. Concentrated solar energy applications in materials science and metallurgy. Sol. Energy 2018, 170, 520–540. [Google Scholar]

- Devices & Services. 2010. Available online: https://www.devicesandservices.com/15R-USB%20Spec%20Sheet.pdf (accessed on 23 November 2022).

- Ballestrín, J.; Carra, M.E.; Enrique, R.; Monterreal, R.; Fernández-Reche, J.; Polo, J.; Casanova, M.; Barbero, F.J.; Marzo, A. Diagnosis of a Lambertian target in solar context. Measurement 2018, 119, 265–269. [Google Scholar] [CrossRef]

- Lee, H.; Chai, K.; Kim, J.; Lee, S.; Yoon, H.; Yu, C.; Kang, Y. Optical performance evaluation of a solar furnace by measuring the highly concentrated solar flux. Energy 2014, 66, 63–69. [Google Scholar] [CrossRef]

- Edmund Optics Europe. 2020. Available online: https://www.edmundoptics.eu/c/optical-mirrors/609/# (accessed on 30 March 2022).

- ASTM. ASTM-E903-12; Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres. ASTM International: West Conshohocken, PA, USA, 2012.

| Characterization A (Position #1) | Characterization B (Position #2) | |

|---|---|---|

| Total Energy (kW) | ||

| Peak Power () | ||

| 90% Energy Radius (mm) | ||

| Flux density () | ||

| Characterization A (Position #1) | Characterization B (Position #2) | |

|---|---|---|

| Peak Power () | ||

| G () | ||

| C |

| Mirror # | Selective Band (nm) | Specifications | Solar Hemispherical Reflectance (-) |

|---|---|---|---|

| 1 | 450–10,000 | 50 mm diameter. Silver protection | |

| 2 | 250–700 | 50 mm diameter. UV Enhanced Aluminum | |

| 3 | 700–10,000 | 50 mm diameter. Gold protection | |

| 4 | 450–650 | 50 mm diameter. Enhanced Aluminum | |

| 5 | 400–700 | 73 × 116 mm, mirror 4–6 | |

| 6 | 400–1125 | 101 × 127mm, 45° AOI |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estremera-Pedriza, N.; Fernández-Reche, J.; Carballo, J.A. Optical Characterization of a New Facility for Materials Testing under Concentrated Wavelength-Filtered Solar Radiation Fluxes. Solar 2023, 3, 76-86. https://doi.org/10.3390/solar3010007

Estremera-Pedriza N, Fernández-Reche J, Carballo JA. Optical Characterization of a New Facility for Materials Testing under Concentrated Wavelength-Filtered Solar Radiation Fluxes. Solar. 2023; 3(1):76-86. https://doi.org/10.3390/solar3010007

Chicago/Turabian StyleEstremera-Pedriza, Noelia, Jesús Fernández-Reche, and Jose A. Carballo. 2023. "Optical Characterization of a New Facility for Materials Testing under Concentrated Wavelength-Filtered Solar Radiation Fluxes" Solar 3, no. 1: 76-86. https://doi.org/10.3390/solar3010007

APA StyleEstremera-Pedriza, N., Fernández-Reche, J., & Carballo, J. A. (2023). Optical Characterization of a New Facility for Materials Testing under Concentrated Wavelength-Filtered Solar Radiation Fluxes. Solar, 3(1), 76-86. https://doi.org/10.3390/solar3010007