Solar Cells with Laser Doped Boron Layers from Atmospheric Pressure Chemical Vapor Deposition

Abstract

:1. Introduction

2. Materials and Methods

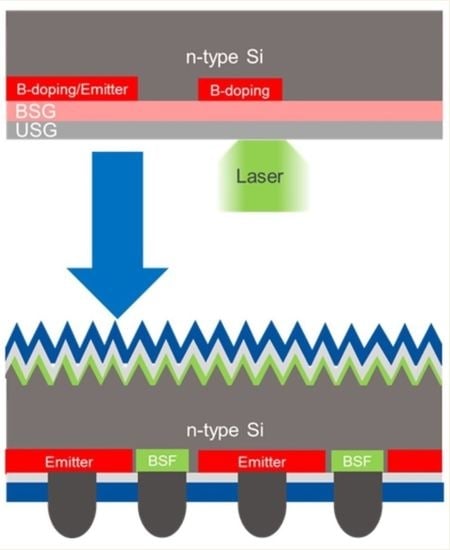

2.1. Solar Cells

2.2. Structure of Test Samples

- Sheet resistance Rsh;

- Lifetime τ;

- Saturation current density J0;

- Contact resistivity ρc.

2.3. Laser Doping Set-Up

2.4. Deposition of APCVD-Layers

3. Results

3.1. Laser Doping and Sheet Resistance

- Boron concentration CB within the BSG;

- Thickness dBSG of the BSG;

- Thickness dUSG of the capping layer USG, or daSi of aSi.

3.1.1. Laser Pulse Overlap

3.1.2. Boron Concentration

3.1.3. Variation of Capping Layer

3.1.4. Thickness of BSG

- Hp,thres,1 = 2.4 J/cm2 for dBSG,1 = 20 nm;

- Hp,thres,2 = 2.45 J/cm2 for dBSG,2 = 40 nm;

- Hp,thres,3 = 2.9 J/cm2 for dBSG,3 = 80 nm;

- Hp,thres,4 = 3.2 J/cm2 for dBSG,4 = 120 nm.

3.1.5. Homogeneity of APCVD-Layers

3.1.6. Stability of APCVD-Layers

3.2. Saturation Current Densities

- Unperforated wafers with 200 nm thick SiN deposited on both sides;

- Perforated wafers to avoid floating of the wafers during APCVD depositions (“perforation” means small holes in the wafer);

- Unperforated wafers.

3.3. Contact Resistivity

3.4. Solar Cell Results

4. Absorption in the Precursor Layer

- Boron concentration CB of in the BSG;

- Thickness dBSG of the BSG as the source for laser doping;

- Thickness dUSG of the protecting USG-cap.

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Cell | Area Acell [cm2] | Efficiency η [%] | Short Circuit Current Density Jsc [mA/cm2] | Open Circuit Voltage Voc [mV] | Fill Factor FF [%] |

|---|---|---|---|---|---|

| Cell 1, in-house | 244.3 | 22.4 | 41.1 | 682.7 | 79.8 |

| Cell 1, ISE | 244.3 | 22.32 ± 0.34 | 40.83 | 682.9 | 80 |

| Cell 2, in-house | 244.3 | 22.4 | 41.4 | 685.8 | 79 |

| Cell 2, ISE | 244.3 | 22.24 ± 0.34 | 41.19 | 684.5 | 78.9 |

Appendix B

| Module | MPP Power PMPP,mod [W] | Efficiency ηmod [%] | Short Circuit Current Isc,mod [A] | Open Circuit Voltage Voc,mod [V] | Fill Factor FFmod [%] |

|---|---|---|---|---|---|

| Front: Module 1—mean | 323.4 | 19.45 | 10 | 42.03 | 76.93 |

| Front Module 1—st. dev. | 0.1163 | 0.0069 | 0.0018 | 0.0084 | 0.035 |

| Rear: Module 1—mean | 223.7 | 13.45 | 7.016 | 41.09 | 77.61 |

| Rear: Module 1—st. dev. | 0.07 | 0.0042 | 0.0022 | 0.0018 | 0.022 |

| Bifaciality B: Module 1 | 0.692 | 0.692 | |||

| Front: Module 2—mean | 305.8 | 18.38 | 9.68 | 40.79 | 77.47 |

| Front Module 2—st. dev. | 0.156 | 0.0094 | 0.0032 | 0.0159 | 0.04 |

| Rear: Module 2—mean | 216.4 | 13.01 | 7.006 | 40.03 | 77.17 |

| Rear: Module 2—st. dev. | 0.064 | 0.0038 | 0.003 | 0.0108 | 0.0367 |

| Bifaciality B: Module 2 | 0.724 | 0.724 |

References

- Monthly TaiyangNews Update on Commercially Available High Efficiency Solar Modules. Available online: https://taiyangnews.info/top-modules/top-solar-modules-listing-april-2022/ (accessed on 16 May 2022).

- Smith, D.; Cousins, P.; Westerberg, S.; De Jesus-Tabajonda, R.; Aniero, G.; Shen, Y.-C. Toward the Practical Limits of Silicon Solar Cells. IEEE J. Photovolt. 2014, 4, 1465–1469. [Google Scholar] [CrossRef]

- Cousins, P.; Smith, D.; Luan, H.; Manning, J.; Dennis, T.; Waldhauer, A.; Wislon, K.; Harley, G.; Mulligan, W. Generation 3: Improved performance at lower cost. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 000275–000278. [Google Scholar]

- Smith, D.D.; Cousins, P.J.; Masad, A.; Westerberg, S.; Zhu, X.; Meyers, B.; Bourne, B.; Shields, M.; Rose, D.; Bergstrom, N. SunPower’s Maxeon Gen III solar cell: High efficiency and energy yield. In Proceedings of the 2013 IEEE 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; pp. 0908–0913. [Google Scholar]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (Version 58). Prog. Photovolt. Res. Appl. 2021, 29, 657–667. [Google Scholar] [CrossRef]

- Dahlinger, M.; Bazer-Bachi, B.; Röder, T.C.; Köhler, J.R.; Zapf-Gottwick, R.; Werner, J.H. Laser-Doped Back-Contact Solar Cells. IEEE J. Photovolt. 2015, 5, 812–818. [Google Scholar] [CrossRef]

- Dahlinger, M.; Bazer-Bachi, B.; Röder, T.C.; Köhler, J.R.; Zapf-Gottwick, R.; Werner, J.H. 22.0% Efficient laser doped back contact solar cells. Energy Procedia 2013, 382, 50–253. [Google Scholar] [CrossRef] [Green Version]

- Köhler, J.R.; Grabitz, P.; Eisele, S.J.; Röder, T.C.; Werner, J.H. Laser doped selective emitters yield 0.5% efficiency gain. In Proceedings of the 24th EUPVSEC, Hamburg, Germany, 17–22 September 2009; pp. 1847–1850. [Google Scholar]

- Weber, J.; Gutscher, S.; Lohmüller, S.; Brand, A.A. Laser-doped selective emitter—Process development and speed-up. In Proceedings of the 35th EUPVSEC, Brussels, Belgium, 24–28 September 2018; pp. 379–384. [Google Scholar]

- Pengcheng, Q.; Pengxiang, Q. Characteristics and development of interdigital back contact solar cells. IOP Conf. Ser. Earth Environ. Sci. 2021, 621, 012067. [Google Scholar] [CrossRef]

- Dahlinger, M.; Carstens, K.; Hoffmann, E.; Zapf-Gottwick, R.; Werner, J.H. 23.2% laser processed back contact solar cell: Fabrication, characterization and modeling. Prog. Photovolt. Res. Appl. 2017, 25, 192–200. [Google Scholar] [CrossRef]

- Rothhardt, P.; Demberger, C.; Wolf, A.; Biro, D. Co-diffusion from APCVD BSG and POCl3 for industrial n-type solar cells. Energy Procedia 2013, 38, 305–311. [Google Scholar] [CrossRef]

- Meier, S.; Wiesnet, S.; Mack, S.; Werner, S.; Maier, S.; Unmüßig, S.; Demberger, C.; Knauss, H.; Biro, D.; Wolf, A. Co-Diffusion for p-type PERT solar cells using APCVD BSG layers as Boron doping source. In Proceedings of the 32nd EUPVSEC, Munich, Germany, 20–24 June 2016; pp. 20–24. [Google Scholar]

- Heilig, M.; Engelhardt, J.; Hahn, G.; Terheiden, B. Comparison of Laser-Doped Emitters from As-Deposited and Thermally Diffused APCVD Doping Glasses on Silicon Substrates. AIP Conf. Proc. 2019, 2147, 070004. [Google Scholar] [CrossRef]

- Kern, W.; Puotinen, D. Cleaning Solutions Based on Hydrogen Peroxide for Use in Silicon Semiconductor Technology. RCA Rev. 1970, 31, 187. [Google Scholar]

- Dahlinger, M.; Carstens, K. Optimized laser doped back surface field for IBC solar cells. Energy Procedia 2016, 92, 450–456. [Google Scholar] [CrossRef] [Green Version]

- Kopecek, R.; Libal, J.; Lossen, J.; Mihailetchi, V.D.; Chu, H.; Peter, C.; Buchholz, F.; Wefringhaus, E.; Halm, A.; Ma, J.; et al. ZEBRA technology: Low cost bifacial IBC solar cells in mass production with efficiency exceeding 23.5%. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Virtual meeting, 15 June–21 August 2020; pp. 1008–1012. [Google Scholar]

- Galbiati, G.; Chu, H.; Mihailetchi, V.D.; Libal, J.; Kopecek, R. Latest Results in Screen-Printed IBC-ZEBRA Solar Cells. In Proceedings of the IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC), Hilton Waikoloa Village Resort, HI, USA, 10–15 June 2018; pp. 1540–1543. [Google Scholar]

- Sinton, R.A.; Cuevas, A.; Stuckings, M. Quasi-Steady-State Photoconductance, A New Method for Solar Cell Material and Device Characterization. In Proceedings of the 25th IEEE Photovoltaic Specialists Conference, Washington, DC, USA, 13–17 May 1996; pp. 457–460. [Google Scholar]

- Hassan, M.; Dahlinger, M.; Köhler, J.R.; Zapf-Gottwick, R.; Werner, J.H. Unified Model for Laser Doping of Silicon from Precursors. Materials 2021, 14, 2322. [Google Scholar] [CrossRef] [PubMed]

- Köhler, J.; Eisele, S. Influence of precursor layer ablation on laser doping of silicon. Prog. Photovolt: Res. Appl. 2010, 18, 334–339. [Google Scholar] [CrossRef]

- Eisele, S. Laser Doping of Silicon Solar Cells. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2011. [Google Scholar]

- Available online: http://SCHMID-group.com/en/business-units/thermal-processing/apcvd-system/#Benefits (accessed on 15 May 2021).

- Liehr, M.; Lewis, J.E.; Rubloff, G.W. Kinetics of high-temperature thermal decomposition of SiO2 on Si (100). J. Vac. Sci. Technol. A Vac. Surf. Films 1987, 5, 1559–1562. [Google Scholar] [CrossRef]

- Blum, A.L.; Swirhun, J.S.; Sinton, R.; Kimmerle, A. An Updated Analysis to the WCT-120 QSSPC measurement system using advanced device physics. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Paris, France, 30 September–4 October 2013; pp. 1521–1523. [Google Scholar]

- Kimmerle, A.; Rothhardt, P.; Wolf, A.; Sinton, R.A. Increased reliability for J0-analysis by QSSPC. Energy Procedia 2014, 55, 101–106. [Google Scholar] [CrossRef]

- Cuevas, A. The effect of emitter recombination on the effective lifetime of silicon wafers. Sol. Energy Mat. Sol. Cells 1999, 57, 277. [Google Scholar] [CrossRef]

- Ametowobla, M. Characterization of a Laser Doping Process for Crystalline Silicon Solar Cells. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2010. [Google Scholar]

- Min, B.; Dastgheib-Shirazi, A.; Altermatt, P.P.; Kurz, H. Accurate determination of the emitter saturation current density for industrial P-diffused emitters. In Proceedings of the 29th EUPVSEC, Amsterdam, The Netherlands, 22–26 September 2014; pp. 463–466. [Google Scholar]

- Mihailetchi, V.; Halm, A.; Chu, H.; Libal, J.; Kopecek, R.; Jikui, M.; Jianda, L.; Yonggang, G.; Peng, D. Bifacial IBC (ZEBRA) Technology. In Proceedings of the 6th BifiPV Workshop, Amsterdam, The Netherlands, 31 March–1 April 2019. [Google Scholar]

- Kitamura, R.; Pilon, L.; Jonasz, M. Optical constants of silica glass from extreme ultraviolet to far infrared at near room temperature. Appl. Opt. 2007, 46, 8118. [Google Scholar] [CrossRef] [PubMed]

- Avramov, I.; Vassilev, T.; Penkov, I. The glass transition temperature of silicate and borate glasses. J. Non-Cryst. Solids 2005, 351, 472–476. [Google Scholar] [CrossRef]

| Cell-Emitter | Area Acell [cm2] | Efficiency ηmax and η [%] | Current Density Jsc [mA/cm2] | Open Circuit Voltage Voc [mV] | Fill Factor FF [%] |

|---|---|---|---|---|---|

| Sputtered B2O3 best cell | 2 × 2 | 23.2 | 40.1 | 697.6 | 82.8 |

| Sputtered B2O3 mean (26 cells) | 2 × 2 | 22.36 ± 0.97 | 40.28 ± 0.25 | 694.9 ± 2.5 | 79.57 ± 3.09 |

| BSG/USG Best cell | 244.3 | 23 | 41.5 | 690.7 | 80.3 |

| BSG/USG mean (13 cells) | 244.3 | 22.63 ± 0.33 | 41.35 ± 0.12 | 683.6 ± 7.0 | 80.04 ± 0.17 |

| Furnace diffused B Best cell | 244.3 | 23.3 | 41.6 | 701.4 | 79.9 |

| Furnace diffused B mean (18 cells) | 244.3 | 23.17 ± 0.07 | 41.61 ± 0.03 | 700.4 ± 0.96 | 79.50 ± 0.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zapf-Gottwick, R.; Seren, S.; Fernandez-Robledo, S.; Wete, E.-P.; Schiliro, M.; Hassan, M.; Mihailetchi, V.; Buck, T.; Kopecek, R.; Köhler, J.; et al. Solar Cells with Laser Doped Boron Layers from Atmospheric Pressure Chemical Vapor Deposition. Solar 2022, 2, 274-292. https://doi.org/10.3390/solar2020015

Zapf-Gottwick R, Seren S, Fernandez-Robledo S, Wete E-P, Schiliro M, Hassan M, Mihailetchi V, Buck T, Kopecek R, Köhler J, et al. Solar Cells with Laser Doped Boron Layers from Atmospheric Pressure Chemical Vapor Deposition. Solar. 2022; 2(2):274-292. https://doi.org/10.3390/solar2020015

Chicago/Turabian StyleZapf-Gottwick, Renate, Sven Seren, Susana Fernandez-Robledo, Evariste-Pasky Wete, Matteo Schiliro, Mohamed Hassan, Valentin Mihailetchi, Thomas Buck, Radovan Kopecek, Jürgen Köhler, and et al. 2022. "Solar Cells with Laser Doped Boron Layers from Atmospheric Pressure Chemical Vapor Deposition" Solar 2, no. 2: 274-292. https://doi.org/10.3390/solar2020015

APA StyleZapf-Gottwick, R., Seren, S., Fernandez-Robledo, S., Wete, E.-P., Schiliro, M., Hassan, M., Mihailetchi, V., Buck, T., Kopecek, R., Köhler, J., & Werner, J. H. (2022). Solar Cells with Laser Doped Boron Layers from Atmospheric Pressure Chemical Vapor Deposition. Solar, 2(2), 274-292. https://doi.org/10.3390/solar2020015