Transesterification of Castor Oil into Biodiesel: Predictive Modeling with Machine Learning and Genetic Algorithm

Abstract

1. Introduction

2. Materials and Methods

2.1. Tools

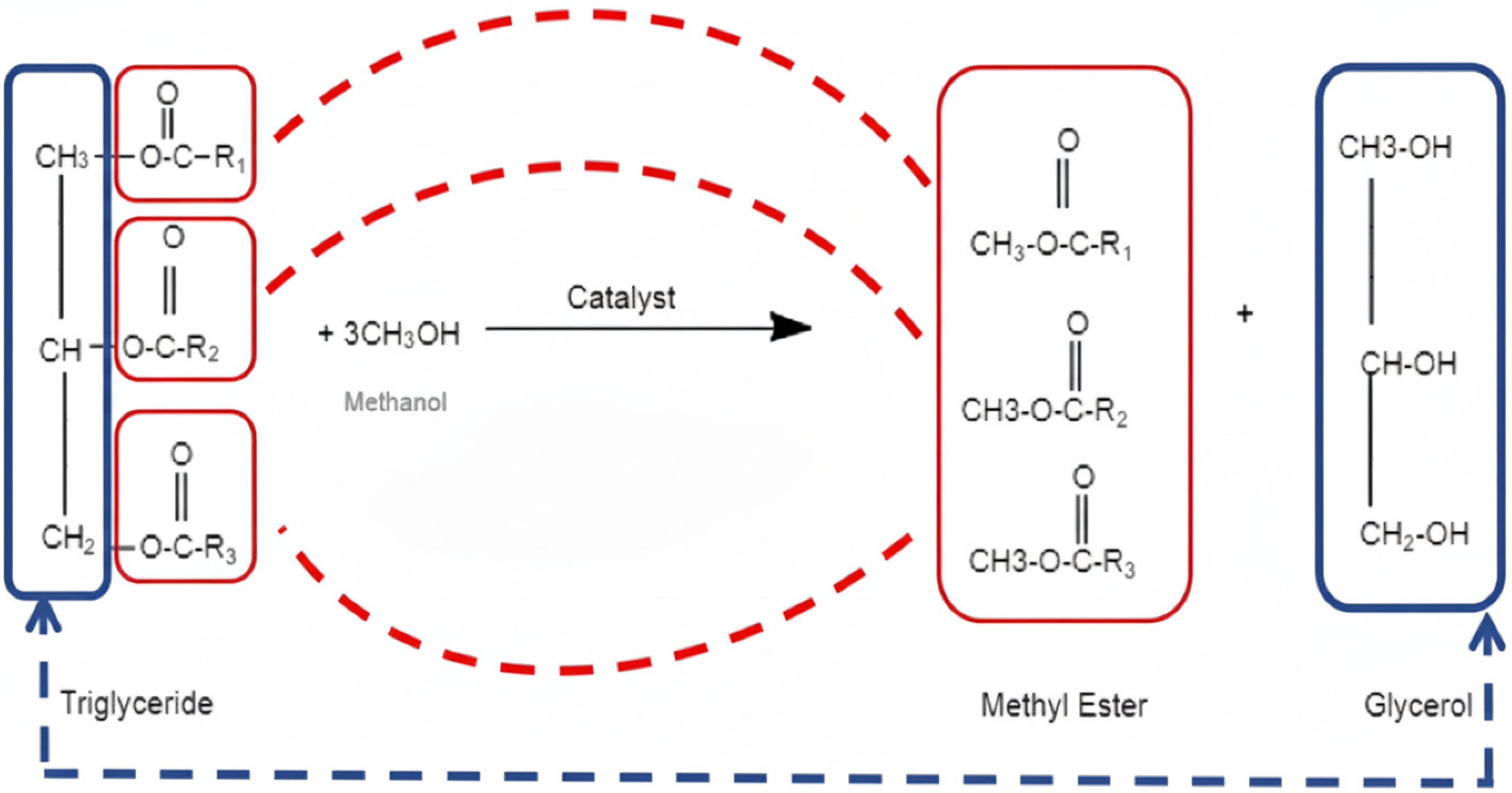

2.2. Kinetic Fundamentals of Transesterification

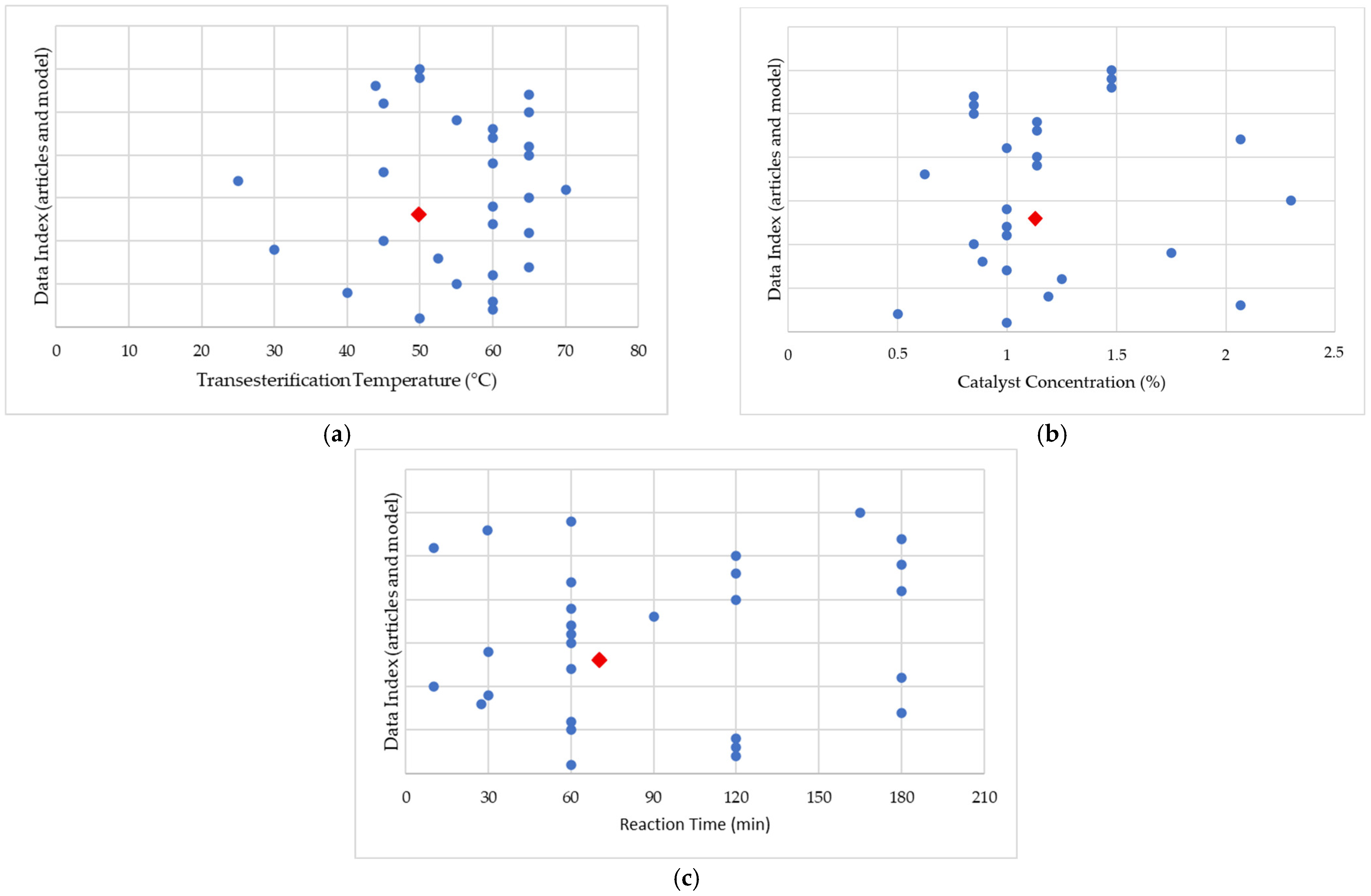

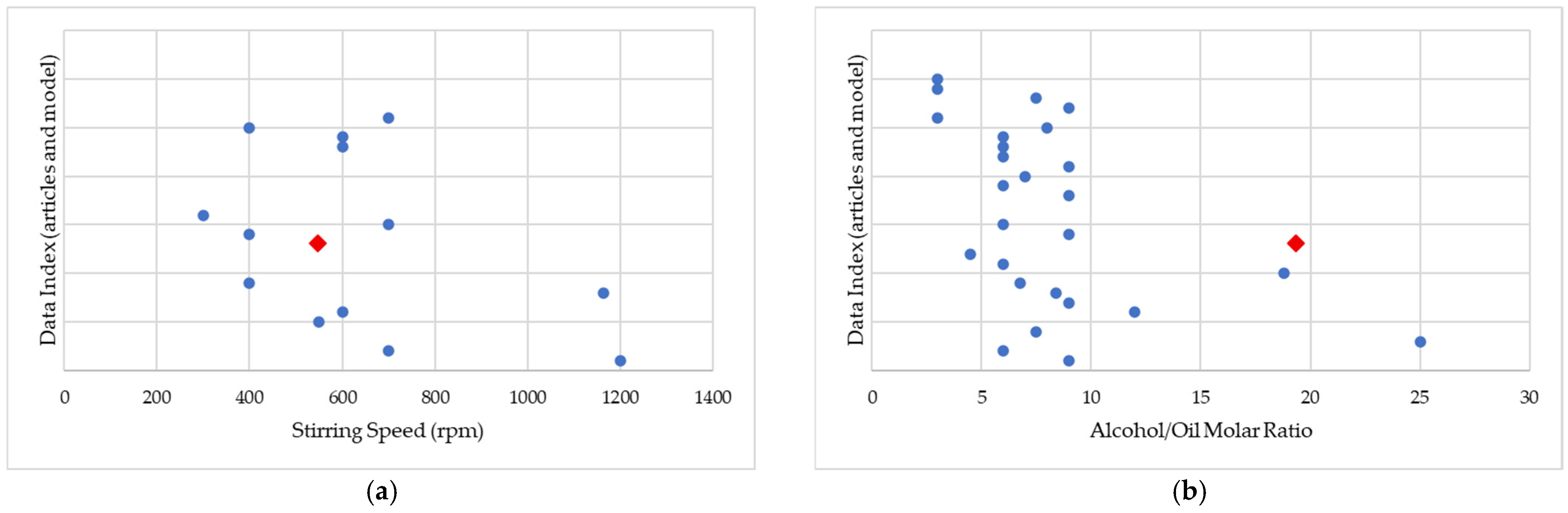

2.3. Data and Preprocessing

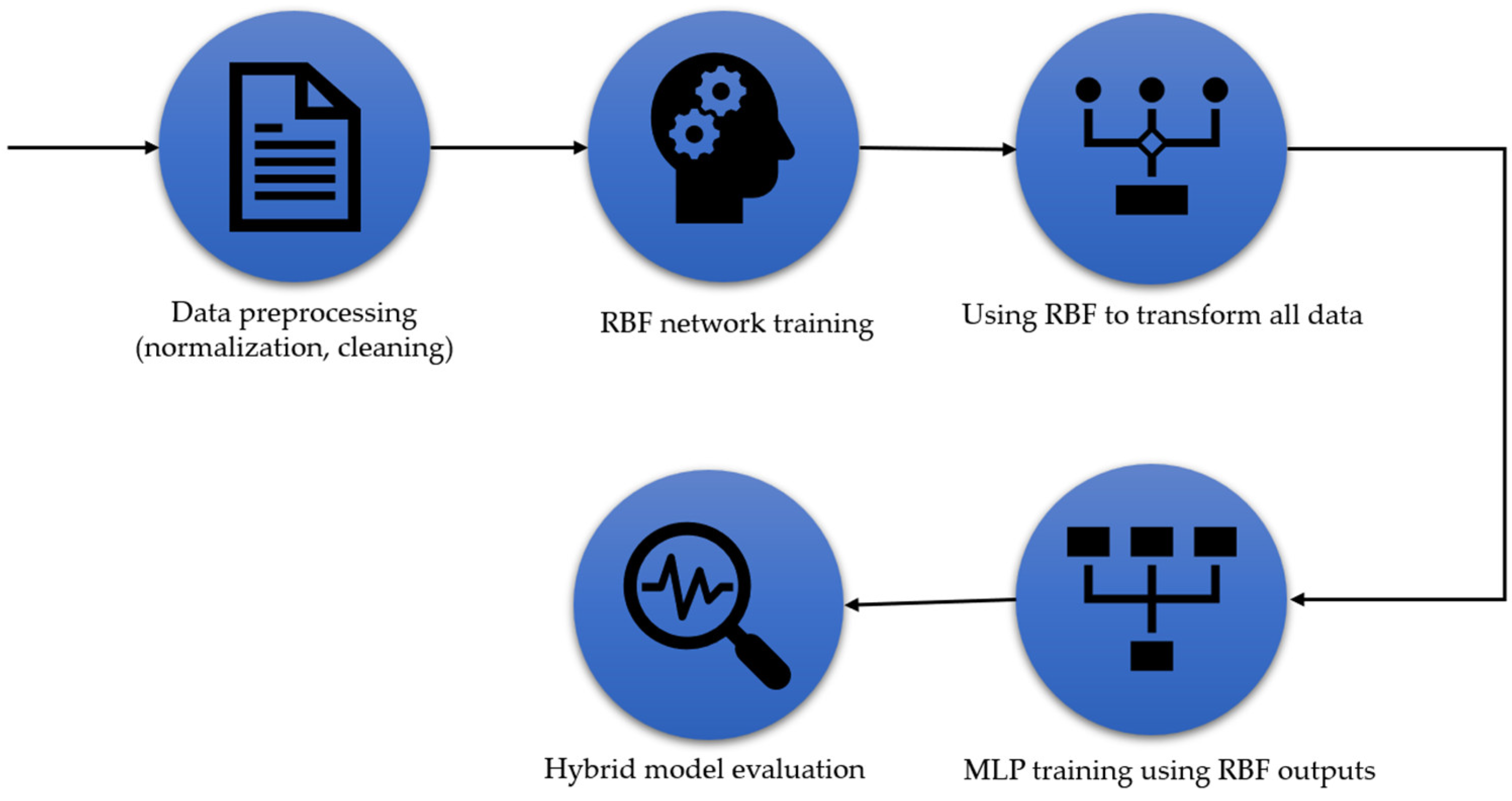

2.4. Network Architectures

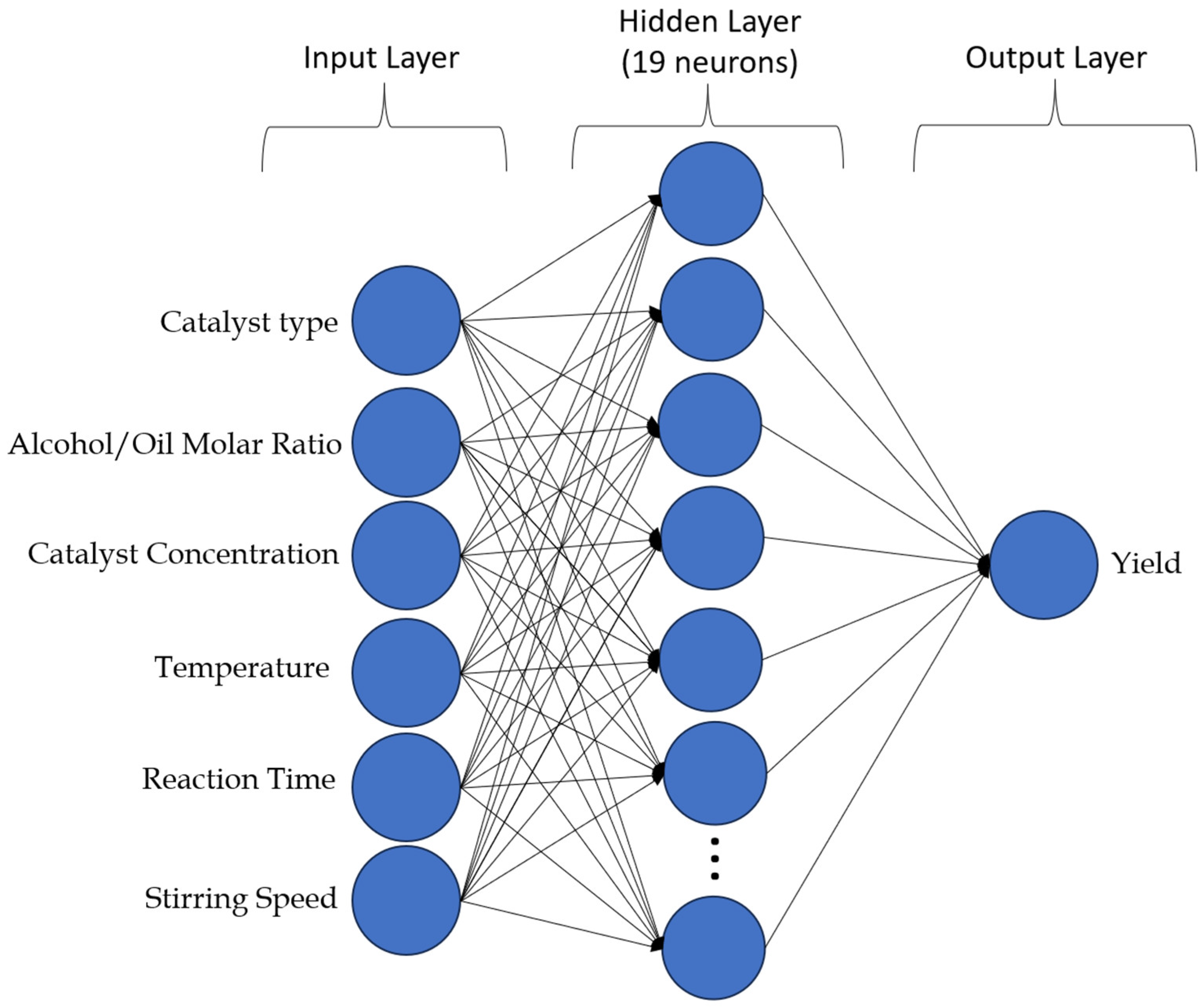

2.4.1. Multilayer Perceptron (MLP)

2.4.2. Radial Basis Function Networks (RBF)

2.4.3. Hybrid Network

2.4.4. Random Forest

- Number of trees in the forest (TreeBagger parameter): 50 to 500;

- Minimum number of observations per leaf (MinLeafSize parameter): 1 to 10;

- Maximum number of splits per tree (MaxNumSplits parameter): 10 to 100;

- Number of features evaluated at each split (NumPredictorsToSample parameter): 1 to 10.

2.4.5. Adaptive Neuro-Fuzzy Inference System (ANFIS)

2.5. Performance Indicators

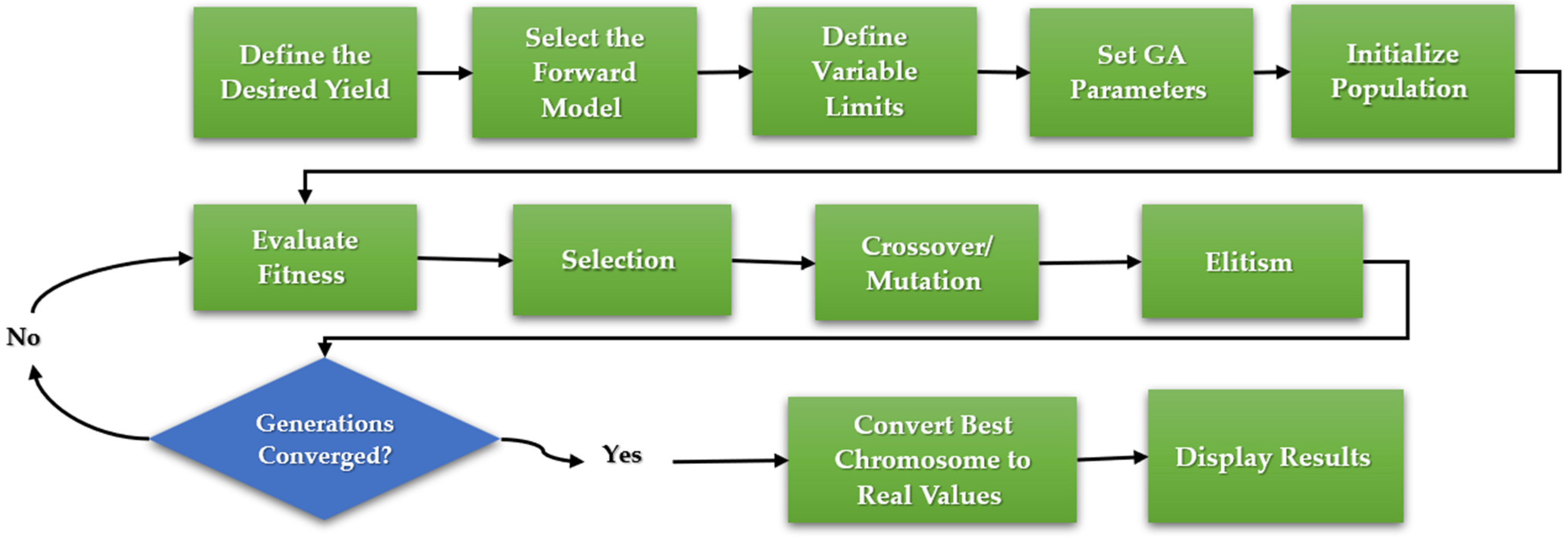

2.6. Optimization Model: Genetic Algorithm

3. Results

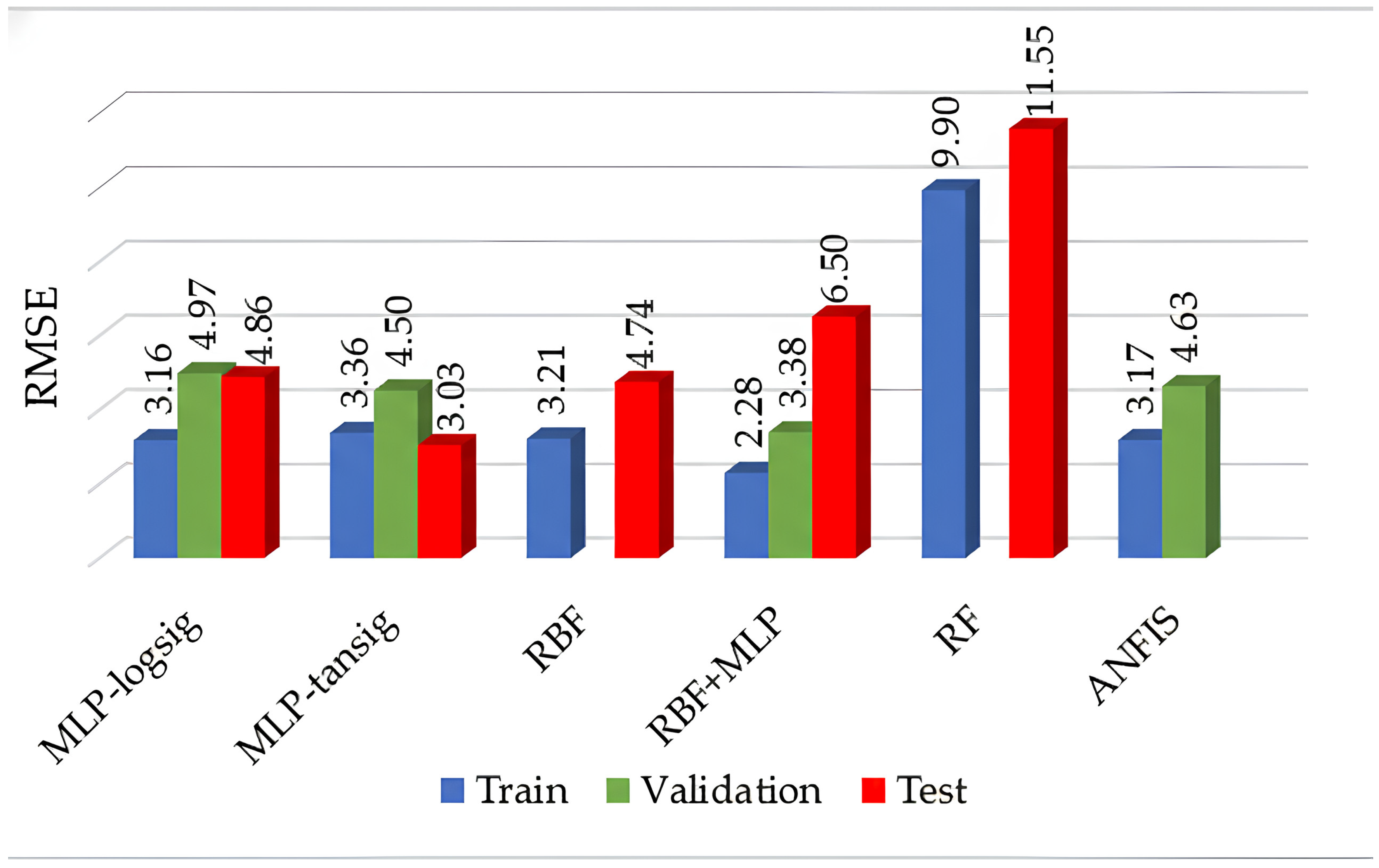

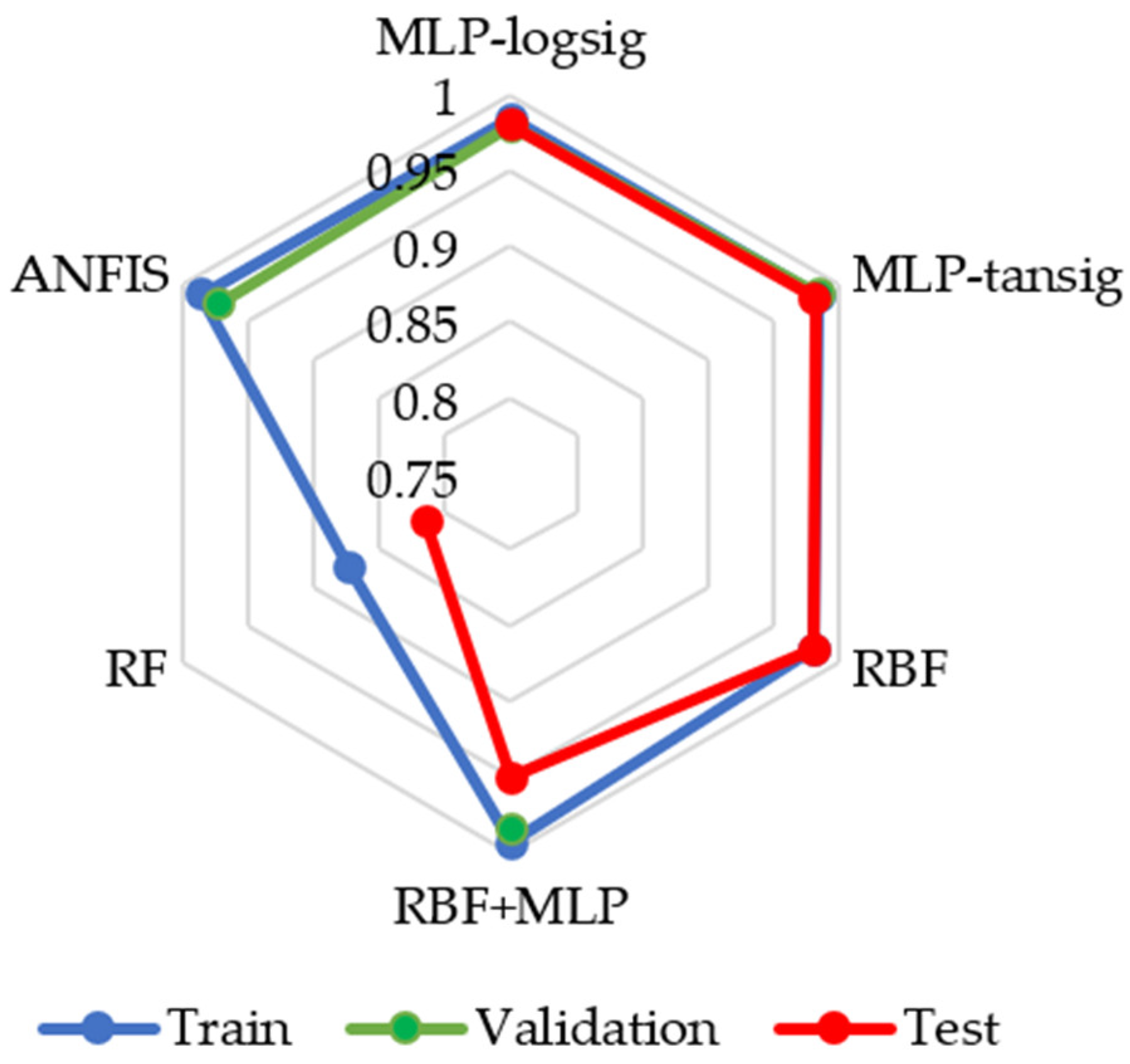

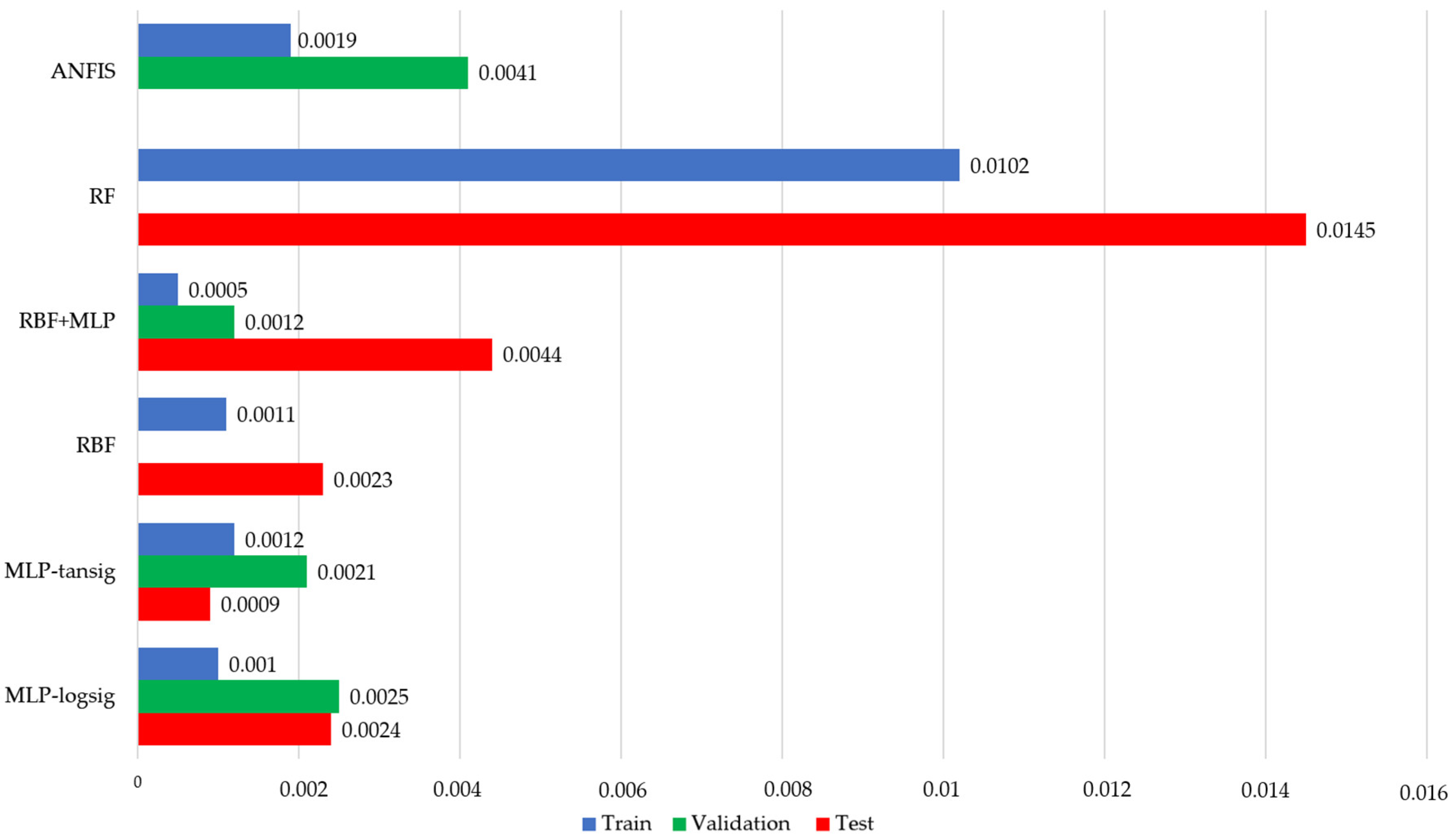

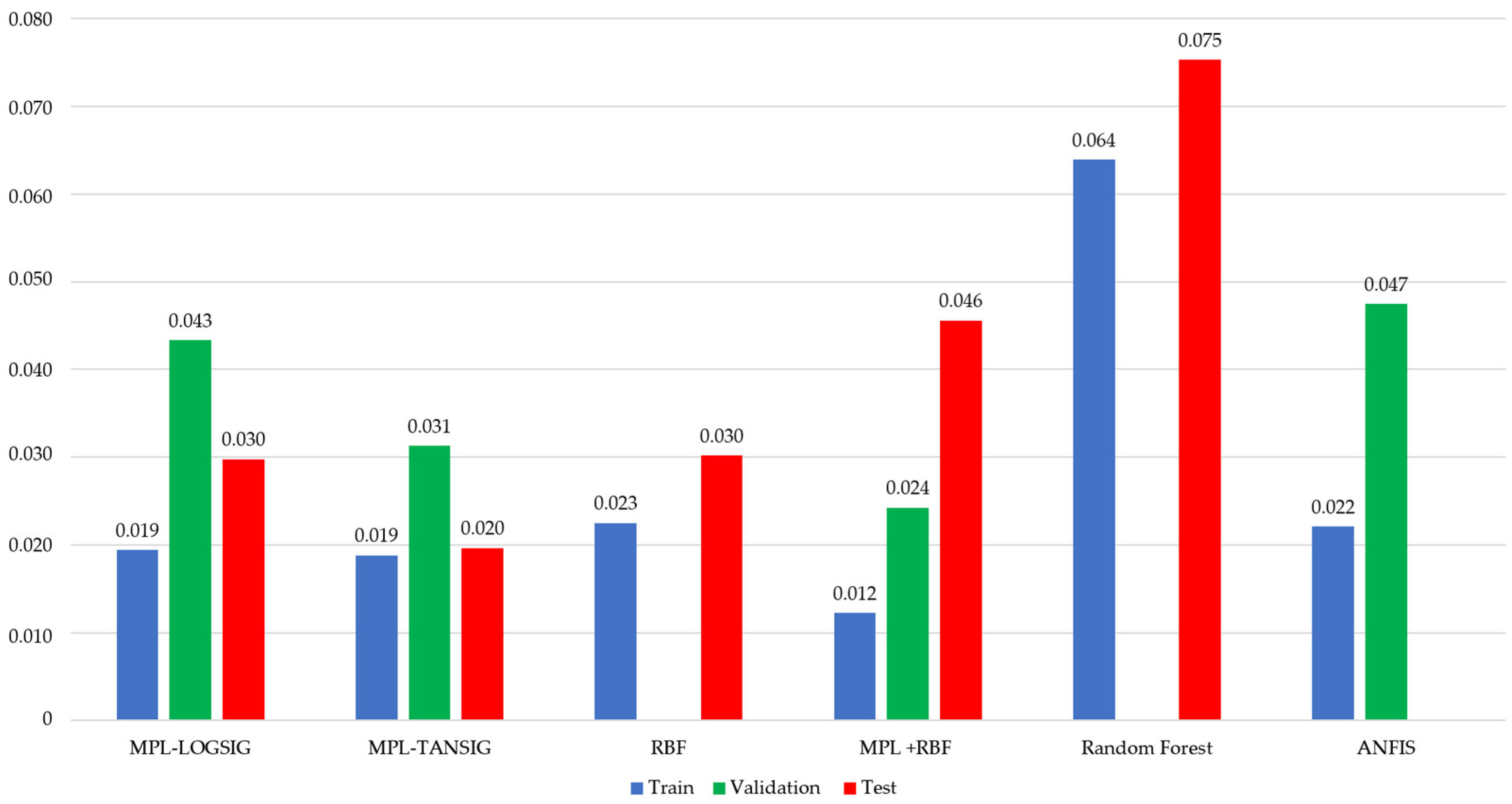

3.1. Model Comparison

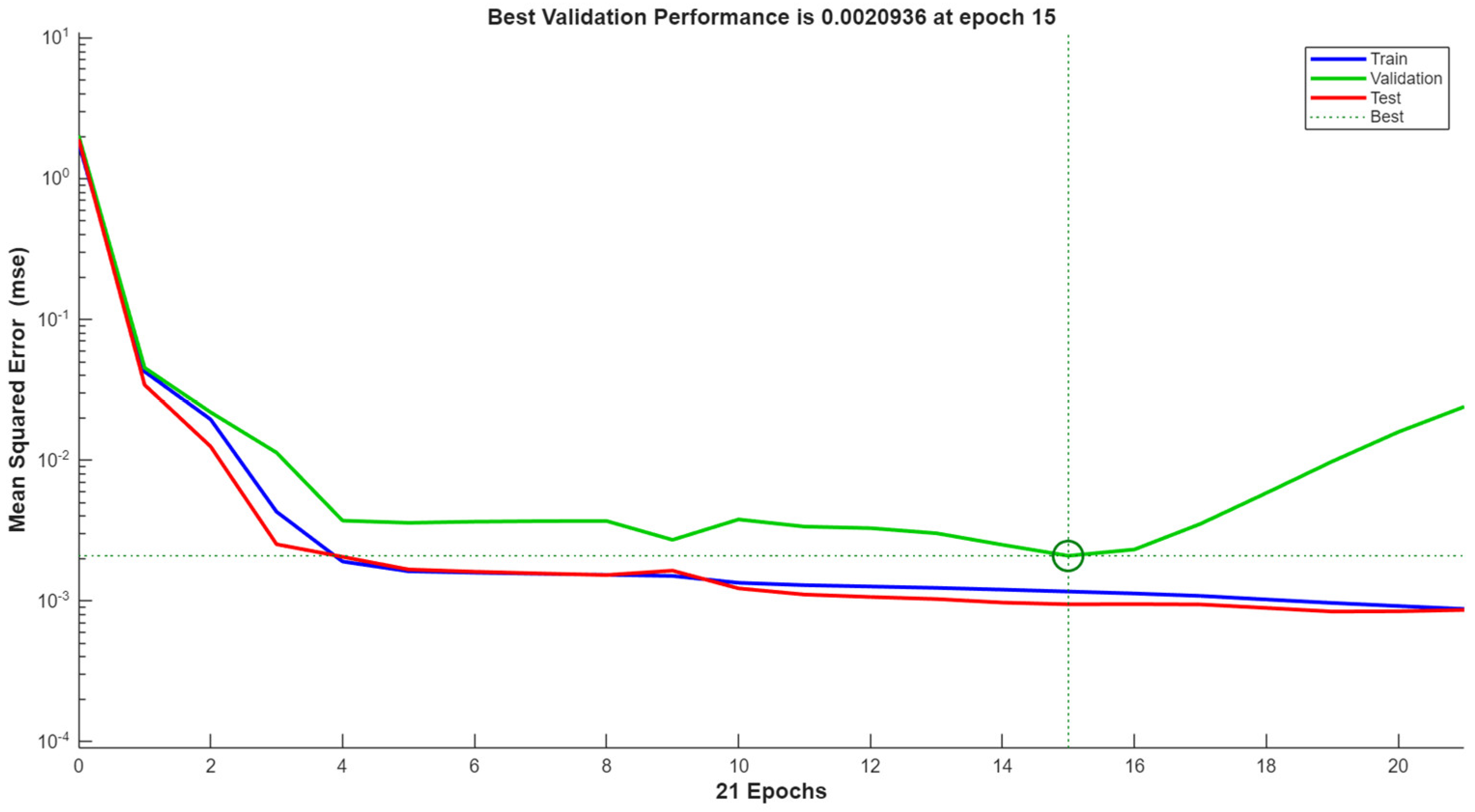

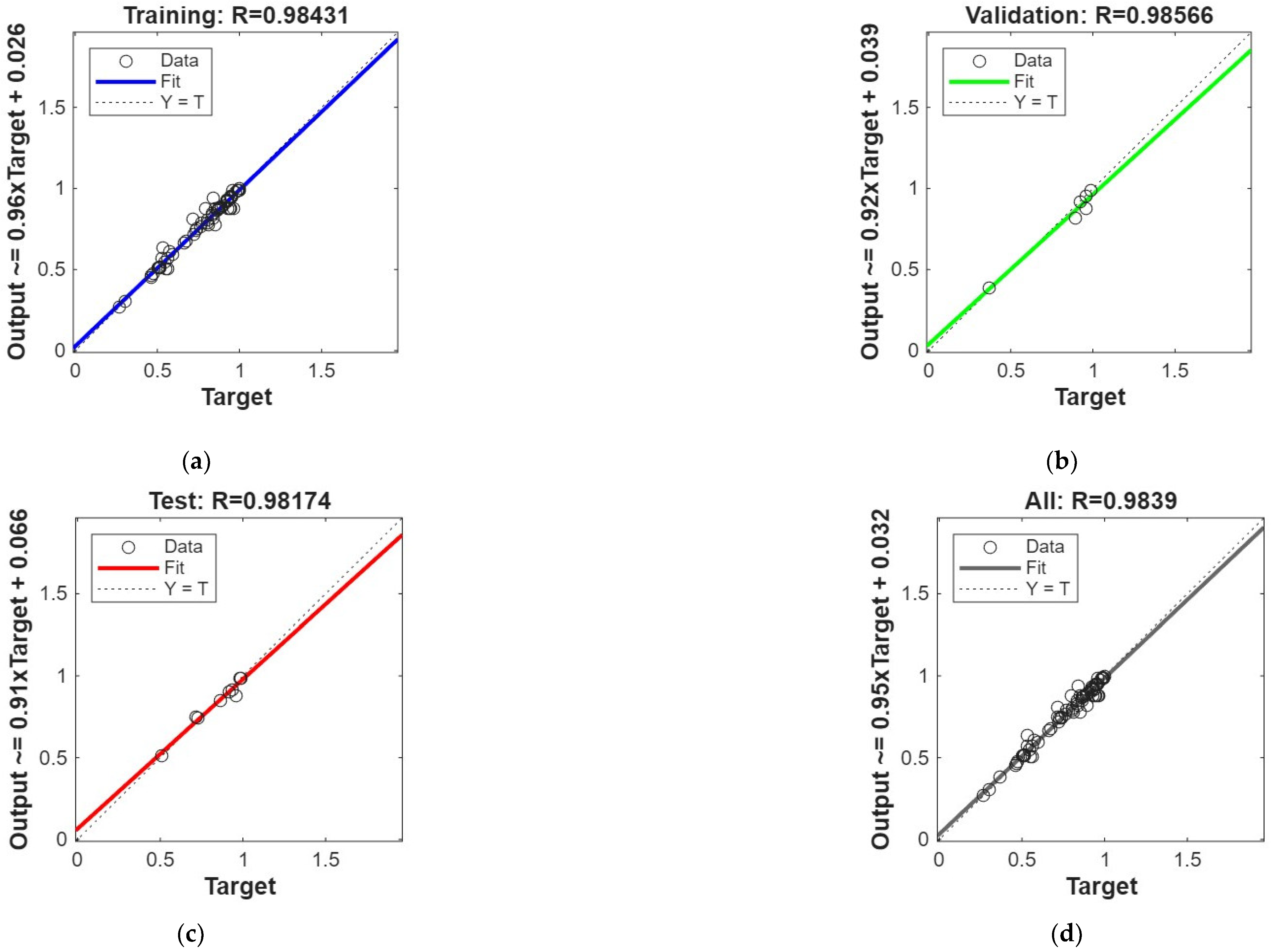

3.2. Best-Performing Network in the Training Phase

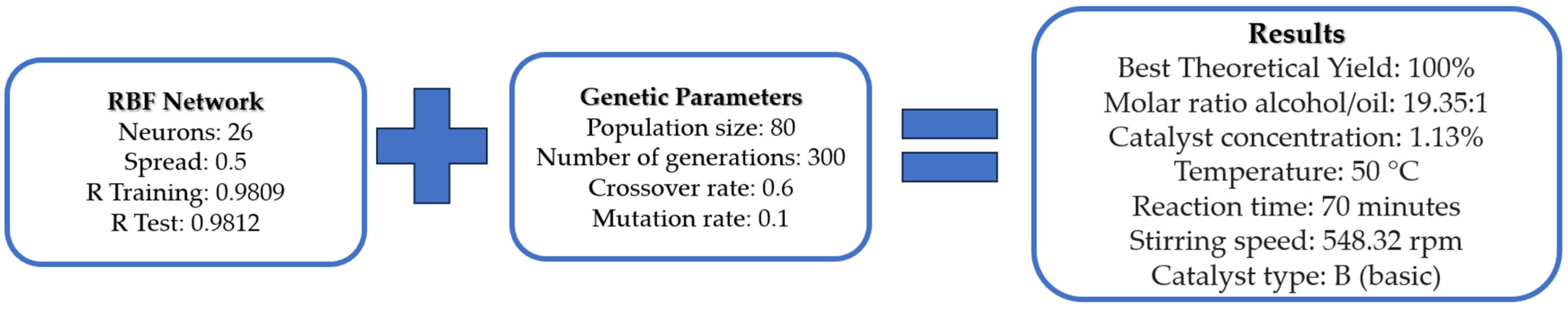

3.3. Applying the GA

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ML | Machine Learning |

| MLP | Multilayer Perceptron |

| RBF | Radial Basis Function |

| RF | Random Forest |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| GA | Genetic Algorithm |

| FAME | Fatty Acid Methyl Esters |

| MSE | Mean Squared Error |

| RMSE | Root Mean Squared Error |

| MAE | Mean Absolute Error |

| R | Coefficient of Correlation |

References

- Zhu, D. New Advances in Oil, Gas, and Geothermal Reservoirs. Energies 2023, 16, 477. [Google Scholar] [CrossRef]

- Al-Fattah, S.M. Non-OPEC conventional oil: Production decline, supply outlook and key implications. J. Pet. Sci. Eng. 2020, 189, 107049. [Google Scholar] [CrossRef]

- Miller, M.R.; Landrigan, P.J.; Arora, M.; Newby, D.E.; Münzel, T.; Kovacic, J.C. Environmentally Not So Friendly: Global Warming, Air Pollution, and Wildfires. J. Am. Coll. Cardiol. 2024, 83, 2291–2307. [Google Scholar] [CrossRef]

- European Union. DIRECTIVE (EU) 2024/2881 of 23 October 2024 on Ambient Air Quality and Cleaner Air for Europe (Recast). Official Journal of the European Union. 2024. L 2024/2881. Available online: http://data.europa.eu/eli/dir/2024/2881/oj (accessed on 16 July 2025).

- Canadian Council of Ministers of the Environment. Canadian Ambient Air Quality Standards Handbook; Canadian Council of Ministers of the Environment: Winnipeg, MB, Canada, 2025. [Google Scholar]

- Conselho Nacional do Meio Ambiente (CONAMA). Resolution Conama No. 491, 19 November 2018. Establishes National Air Quality Standards and Guidelines. Diário Oficial da União. 19 November 2018; p. 155, Revised in June 2024. Available online: https://www.siam.mg.gov.br/sla/download.pdf?idNorma=51160 (accessed on 16 July 2025).

- Conselho Nacional de Política Energética (CNPE). Resolução Nº 3, de 20 de Março de 2023. Altera a Resolução CNPE nº 16, de 29 de Outubro de 2018, Que Dispõe Sobre a Evolução da Adição Obrigatória de Biodiesel ao Óleo Diesel Vendido ao Consumidor Final. Diário Oficial da União. 20 March 2023, p. 2. Available online: https://www.legisweb.com.br/legislacao/?id=443705 (accessed on 16 July 2025).

- Presidência da República. LEI Nº 13.576, de 26 de dezembro de 2017. Dispõe Sobre a Política Nacional de Biocombustíveis (RenovaBio) e dá Outras Providências. Diário Oficial da União. 26 December 2017. Available online: https://www2.camara.leg.br/legin/fed/lei/2017/lei-13576-26-dezembro-2017-786013-publicacaooriginal-154631-pl.html (accessed on 16 July 2025).

- Takase, M.; Zhao, T.; Zhang, M.; Chen, Y.; Liu, H.; Yang, L.; Wu, X. An expatiate review of neem, jatropha, rubber and karanja as multipurpose non-edible biodiesel resources and comparison of their fuel, engine and emission properties. Renew. Sustain. Energy Rev. 2015, 43, 495–520. [Google Scholar] [CrossRef]

- Sáez-Bastante, J.; Pinzi, S.; Jiménez-Romero, F.J.; Luque de Castro, M.D.; Priego-Capote, F.; Dorado, M.P. Synthesis of biodiesel from castor oil: Silent versus sonicated methylation and energy studies. Energy Convers. Manag. 2015, 96, 561–567. [Google Scholar] [CrossRef]

- Vilas Bôas, R.N.; Mendes, M.F. A review of biodiesel production from non-edible raw materials using the transesterification process with a focus on influence of feedstock composition and free fatty acids. J. Chil. Chem. Soc. 2022, 67, 5433–5444. [Google Scholar] [CrossRef]

- Maheshwari, P.; Haider, M.B.; Yusuf, M.; Klemeš, J.J.; Bokhari, A.; Beg, M.; Al-Othman, A.; Kumar, R.; Jaiswal, A.K. A review on latest trends in cleaner biodiesel production: Role of feedstock, production methods, and catalysts. J. Clean. Prod. 2022, 355, 131588. [Google Scholar] [CrossRef]

- Mohiddin, M.N.B.; Tan, Y.H.; Seow, Y.X.; Kansedo, J.; Mubarak, N.M.; Abdullah, M.O.; Chan, Y.S.; Khalid, M. Evaluation on feedstock, technologies, catalyst and reactor for sustainable biodiesel production: A review. J. Ind. Eng. Chem. 2021, 98, 60–81. [Google Scholar] [CrossRef]

- Stanescu, R.-C.; Leahu, C.-I.; Soica, A. Aspects regarding the modelling and optimization of the transesterification process through temperature control of the chemical reactor. Energies 2023, 16, 2883. [Google Scholar] [CrossRef]

- Shinde, P.P.; Shah, S. A Review of Machine Learning and Deep Learning Applications. In Proceedings of the Fourth International Conference on Computing Communication Control and Automation (ICCUBEA), 2018, Pune, India, 16–18 August 2018. [Google Scholar]

- Walsh, J.; Neupane, A.; Koirala, A.; Li, M.; Anderson, N. Review: The evolution of chemometrics coupled with near infrared spectroscopy for fruit quality evaluation. II. The rise of convolutional neural networks. J. Near Infrared Spectrosc. 2023, 31, 109–125. [Google Scholar] [CrossRef]

- Imai, S.; Takekuma, Y.; Kashiwagi, H.; Miyai, T.; Kobayashi, M.; Iseki, K.; Sugawara, M. Validation of the usefulness of artificial neural networks for risk prediction of adverse drug reactions used for individual patients in clinical practice. PLoS ONE 2020, 15, e0236789. [Google Scholar] [CrossRef]

- Çolak, A.B. Experimental Analysis with Specific Heat of Water-Based Zirconium Oxide Nanofluid on the Effect of Training Algorithm on Predictive Performance of Artificial Neural Network. Heat Transf. Res. 2021, 52, 67–93. [Google Scholar] [CrossRef]

- Santana-Santos, L.; Kam, K.L.; Dittmann, D.; De Vito, S.; McCord, M.; Jamshidi, P.; Fowler, H.; Wang, X.; Aalsburg, A.M.; Brat, D.J.; et al. Validation of Whole Genome Methylation Profiling Classifier for Central Nervous System Tumors. J. Mol. Diagn. 2022, 24, 924–934. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, U.; Naqvi, S.R.; Ali, I.; Saleem, F.; Mehran, M.T.; Sikandar, U.; Juchelková, D. Biolubricant production from castor oil using iron oxide nanoparticles as an additive: Experimental, modelling and tribological assessment. Fuel 2022, 324, 124565. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Etghani, M.M.; Akbari, M.; Khalkhali, A.; Ghobadian, B. Artificial neural networks based prediction of performance and exhaust emissions in direct injection engine using castor oil biodiesel-diesel blends. J. Renew. Sustain. Energy 2012, 4, 063130. [Google Scholar] [CrossRef]

- Yue, X.; Chen, Y.; Chang, G. Accurate modeling of biodiesel production from castor oil using ANFIS. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 432–438. [Google Scholar] [CrossRef]

- Jana, D.K.; Bhattacharjee, S.; Roy, S.; Dostál, P.; Bej, B. The Optimization of Biodiesel Production from Waste Cooking Oil Catalyzed by Ostrich-Eggshell Derived CaO through Various Machine Learning Approaches. Clean. Energy Syst. 2022, 3, 100033. [Google Scholar] [CrossRef]

- Kibar, M.E.; Hilal, L.; Çapa, B.T.; Bahçıvanlar, B.; Abdeljelil, B.B. Assessment of homogeneous and heterogeneous catalysts in transesterification reaction: A mini review. ChemBioEng Rev. 2023, 10, 412–422. [Google Scholar] [CrossRef]

- Ramezani, K.; Rowshanzamir, S.; Eikani, M.H. Castor Oil Transesterification Reaction: A Kinetic Study and Optimization of Parameters. Energy 2010, 35, 4142–4148. [Google Scholar] [CrossRef]

- Haykin, S. Redes Neurais—Princípios e Práticas, 2nd ed.; Bookman: Porto Alegre, Brazil, 2007; pp. 27–59. [Google Scholar]

- Riahi-Madvar, H.; Dehghani, M.; Seifi, A.; Salwana, E.; Shamshirband, S.; Mosavi, A.; Chau, K.W. Comparative analysis of soft computing techniques RBF, MLP, and ANFIS with MLR and MNLR for predicting grade-control scour hole geometry. Eng. Appl. Comput. Fluid Mech. 2019, 13, 529–550. [Google Scholar] [CrossRef]

- Tao, J.; Yu, Z.; Zhang, R.; Gao, F. RBF neural network modeling approach using PCA based LM–GA optimization for coke furnace system. Appl. Soft Comput. 2021, 111, 107691. [Google Scholar] [CrossRef]

- Aggarwal, C.C. Radial Basis Function Networks. In Neural Networks and Deep Learning; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 217–233. [Google Scholar]

- Liu, Y.; Wang, Y.; Zhang, J. New Machine Learning Algorithm: Random Forest. In Proceedings of the ICICA 2012, Chengde, China, 14–16 September 2012; Liu, B., Ma, M., Chang, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7473, pp. 246–252. [Google Scholar]

- Li, H.; Lin, J.; Lei, X.; Wei, T. Compressive strength prediction of basalt fiber reinforced concrete via random forest algorithm. Mater. Today Commun. 2022, 30, 103117. [Google Scholar] [CrossRef]

- Janardhana, K.; Sridhar, S.; Dixit, C.K.; Deivakani, M.; Tamilselvi, S.; Kaladgi, A.R.; Afzal, A.; Baig, M.A.A. ANFIS modeling of biodiesels’ physical and engine characteristics: A review. Heat Transf. 2021, 50, 8052–8079. [Google Scholar] [CrossRef]

- Karaboga, D.; Kaya, E. Adaptive network based fuzzy inference system (ANFIS) training approaches: A comprehensive survey. Artif. Intell. Rev. 2019, 52, 2263–2293. [Google Scholar] [CrossRef]

- Ponkumar, G.; Jayaprakash, S.; Kanagarathinam, K. Advanced Machine Learning Techniques for Accurate Very-Short-Term Wind Power Forecasting in Wind Energy Systems Using Historical Data Analysis. Energies 2023, 16, 5459. [Google Scholar] [CrossRef]

- Lambora, A.; Gupta, K.; Chopra, K. Genetic Algorithm- A Literature Review. In Proceedings of the 2019 International Conference on Machine Learning, Big Data, Cloud and Parallel Computing (Com-IT-Con), Faridabad, India, 14–16 February 2019. [Google Scholar]

- Osorio-González, C.S.; Gómez-Falcon, N.; Sandoval-Salas, F.; Saini, R.; Brar, S.K.; Ramírez, A.A. Production of Biodiesel from Castor Oil: A Review. Energies 2020, 13, 2467. [Google Scholar] [CrossRef]

- Mamona. Available online: https://www.embrapa.br/agencia-de-informacao-tecnologica/tematicas/agroenergia/biodiesel/materias-primas/mamona (accessed on 2 August 2025).

- Akhabue, C.E.; Okwundu, O.S. Monitoring the transesterification reaction of castor oil and methanol by ultraviolet visible spectroscopy. Biofuels 2017, 10, 729–736. [Google Scholar] [CrossRef]

- Masango, S.B.; Ngema, P.T.; Olagunju, O.A.; Ramsuroop, S. The Effect of Reaction Temperature, Catalyst Concentration and Alcohol Ratio in the Production of Biodiesel from Raw and Purified Castor Oil. Adv. Chem. Eng. Sci. 2024, 14, 137–154. [Google Scholar] [CrossRef]

- Elango, R.K.; Sathiasivan, K.; Muthukumaran, C.; Thangavelu, V.; Rajesh, M.; Tamilarasan, K. Transesterification of castor oil for biodiesel production: Process optimization and characterization. Microchem. J. 2019, 145, 1162–1168. [Google Scholar] [CrossRef]

- Armendáriz, J.; Lapuerta, M.; Zavala, F.; García-Zambrano, E.; Ojeda, M.C. Evaluation of eleven genotypes of castor oil plant (Ricinus communis L.) for the production of biodiesel. Ind. Crops Prod. 2015, 77, 484–490. [Google Scholar] [CrossRef]

- Banerjee, A.; Varshney, D.; Kumar, S.; Chaudhary, P.; Gupta, V.K. Biodiesel production from castor oil: ANN modeling and kinetic parameter estimation. Int. J. Ind. Chem. 2017, 8, 253–262. [Google Scholar] [CrossRef]

- Canoira, L.; García Galeán, J.; Alcántara, R.; Lapuerta, M.; García-Contreras, R. Fatty acid methyl esters (FAMEs) from castor oil: Production process assessment and synergistic effects in its properties. Renew. Energy 2010, 35, 208–217. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, M.; Datta, A.; Santra, A. An experimental study on the combustion, performance and emission characteristics of a diesel engine fuelled with diesel-castor oil biodiesel blends. Renew. Energy 2018, 119, 174–184. [Google Scholar] [CrossRef]

- Encinar, J.M.; González, J.F.; Martínez, G.; Sánchez, N.; González, C.G. Synthesis and characterization of biodiesel obtained from castor oil transesterification. RE&PQJ 2011, 1, 1078–1083. [Google Scholar] [CrossRef]

- Soliman, A.; Ismail, A.R.; Khater, M.; Abu Amr, S.A.; El-Gendy, N.S.; Ezzat, A.A. Response surface optimization of a single–step castor oil–based biodiesel production process using a stator–rotor hydrodynamic cavitation reactor. Environ. Sci. Pollut. Res. 2024, 31, 60601–60618. [Google Scholar] [CrossRef] [PubMed]

- Hailegiorgis, S.M.; Hasraff, M.A.; Khan, S.N.; Ayoub, M. Methanolysis of Castor Oil and Parametric Optimization. Procedia Eng. 2016, 148, 546–552. [Google Scholar] [CrossRef]

- Sánchez, N.; Sánchez, R.; Encinar, J.M.; González, J.F.; Martínez, G. Complete analysis of castor oil methanolysis to obtain biodiesel. Fuel 2015, 147, 95–99. [Google Scholar] [CrossRef]

- Hiwot, T. Investigation of the Chemical Composition, Characterization and Determination of Energy Content for Renewable Energy Source (Biodiesel) Produced from Non-Edible Ethiopian Seeds’ Particularly Castor Seed (Ricinus communis) Using Homogeneous Catalysis. Int. Lett. Chem. Phys. Astron. 2014, 18, 63–74. [Google Scholar] [CrossRef]

- Hurtado, B.; Posadillo, A.; Luna, D.; Bautista, F.M.; Hidalgo, J.M.; Luna, C.; Calero, J.; Romero, A.A.; Estevez, R. Synthesis, Performance and Emission Quality Assessment of Ecodiesel from Castor Oil in Diesel/Biofuel/Alcohol Triple Blends in a Diesel Engine. Catalysts 2019, 9, 40. [Google Scholar] [CrossRef]

- Keera, S.T.; El Sabagh, S.M.; Taman, A.R. Castor oil biodiesel production and optimization. Egypt. J. Pet. 2018, 27, 979–984. [Google Scholar] [CrossRef]

- Khan, I.U.; Chen, H.; Yan, Z.; Chen, J. Extraction and Quality Evaluation of Biodiesel from Six Familiar Non-Edible Plants Seeds. Processes 2021, 9, 840. [Google Scholar] [CrossRef]

- Lamiel, C.S.J.; Manocan, M.C.C.C.; Marasigan, G.P.M.; Dimaano, M.N.R. Optimization of Transesterification Parameters in Ricinus communis L. (Castor) Seed Oil for Biodiesel Production: Reaction Temperature Based at 70 °C. Int. J. Eng. Res. Technol. 2015, 4, 472–476. [Google Scholar]

- Mahla, S.K.; Dhir, A.; Singla, V.; Rosha, P. Investigations on Environmental Emissions Characteristics of CI Engine Fuelled with Castor Biodiesel Blends. J. Environ. Biol. 2018, 39, 353–357. [Google Scholar] [CrossRef]

- Meneghetti, S.M.P.; Meneghetti, M.R.; Wolf, C.R.; Silva, E.C.; Lima, G.E.S.; Silva, L.L.; Serra, T.M.; Cauduro, F.; Oliveira, L.G. Biodiesel from Castor Oil: A Comparison of Ethanolysis versus Methanolysis. Energy Fuels 2006, 20, 2262–2265. [Google Scholar] [CrossRef]

- Najim, Y.H.; Al-Abdraba, W.M.S.; Ahmad, A.H. Effects of Temperature, Alkaline Catalysts and Molar Ratio of Alcohol to Oil on the Efficiency of Production Biodiesel from Castor Oil. Kirkuk Univ. J. 2016, 11, 56–69. [Google Scholar]

- Nakarmi, A.; Joshi, S. A Study on Castor Oil and Its Conversion into Biodiesel by Transesterification Method. Nepal J. Sci. Technol. 2014, 15, 45–52. [Google Scholar] [CrossRef]

- Pattnaik, S.; Mathur, B.; Desai, A.; Patel, A.; Chowdhury, P. Biodiesel Production from Non-Edible Castor and Sesame Oils via Homogeneous Transesterification: Comparative Physico-Chemical Evaluation. Chem. Pap. 2025, 79, 3951–3961. [Google Scholar] [CrossRef]

- Peña, R.; Romero, R.; Martinez, S.L.; Ramos, M.J.; Martinez, A.; Natividad, R. Transesterification of Castor Oil: Effect of Catalyst and Co-Solvent. Ind. Eng. Chem. Res. 2009, 48, 1186–1189. [Google Scholar] [CrossRef]

- Pradhan, S.; Saha, C. Transesterification and Reactive Extraction of Castor Oil for Synthesis of Biodiesel/Biolubricant. In Proceedings of the International Conference on Innovative Research on Renewable Energy Technologies, Malda, West Bengal, India, 25–27 February 2021; IOP Conf. Ser. Earth Environ. Sci. IOP Publishing: Philadelphia, PA, USA, 2021; Volume 785, p. 012005. [Google Scholar] [CrossRef]

- Sánchez, N.; Encinar, J.M.; Nogales, S.; González, J.F. Biodiesel Production from Castor Oil by Two-Step Catalytic Transesterification: Optimization of the Process and Economic Assessment. Catalysts 2019, 9, 864. [Google Scholar] [CrossRef]

- Setiadji, S.; Tanyela, T.; Sudiarti, T.; Prabowo, E.; Wahid, B. Alternatif Pembuatan Biodiesel Melalui Transesterifikasi Minyak Castor (Ricinus communis) Menggunakan Katalis Campuran Cangkang Telur Ayam dan Kaolin. J. Kim. Val. 2017, 3, 1–10. [Google Scholar]

- Thakkar, K.; Kachhawaha, S.S.; Kodgire, P.; Keshav, M. Effectiveness of RSM Based Central Composite Design for Optimization of In-Situ Biodiesel Production Process from Castor Seeds. In Proceedings of the Advances in Thermal-Fluids Engineering (ATFE 2021), Gandhinagar, India, 25–26 March 2021; IOP Conf. Ser. Mater. Sci. Eng.. IOP Publishing: Philadelphia, PA, USA, 2021; Volume 1146, p. 012008. [Google Scholar] [CrossRef]

- Thomas, T.P.; Birney, D.M.; Auld, D.L. Viscosity Reduction of Castor Oil Esters by the Addition of Diesel, Safflower Oil Esters and Additives. Ind. Crops Prod. 2012, 36, 267–270. [Google Scholar] [CrossRef]

- Thomas, T.P.; Birney, D.M.; Auld, D.L. Optimizing Esterification of Safflower, Cottonseed, Castor and Used Cottonseed Oils. Ind. Crops Prod. 2013, 41, 102–106. [Google Scholar] [CrossRef]

- Jin, X.; Li, S.; Ye, H.; Wang, J.; Wu, Y.; Zhang, D.; Ma, H.; Sun, F.; Pugazhendhi, A.; Xia, C. Investigation and Optimization of Biodiesel Production Based on Multiple Machine Learning Technologies. Fuel 2023, 348, 128546. [Google Scholar] [CrossRef]

- Arunyanart, P.; Simasatitkul, L.; Juyploy, P.; Kotluklan, P.; Chanbumrung, J.; Seeyangnok, S. The Prediction of Biodiesel Production Yield from Transesterification of Vegetable Oils with Machine Learning. Results Eng. 2024, 24, 103236. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V. Application of machine learning technologies in biodiesel production process—A review. Front. Energy Res. 2023, 11, 1122638. [Google Scholar] [CrossRef]

- Buasri, A.; Sirikoom, P.; Pattane, S.; Buachum, O.; Loryuenyong, V. Process optimization of biodiesel from used cooking oil in a microwave reactor: A case of machine learning and Box–Behnken design. ChemEngineering 2023, 7, 65. [Google Scholar] [CrossRef]

- Simonelli, G.; Moraes, C.; Pires, C.A.M.; Santos, L.C.L. Multivariate study and optimization of biodiesel production using commercial surfactants. Chem. Ind. Chem. Eng. Q. 2019, 25, 183–192. [Google Scholar] [CrossRef]

- Mascarenhas, N.O.; Pereira, M.A.; Pires, C.A.M.; Simonelli, G.; Santos, L.C.L. Production, optimization, and evaluation of thermal stability of palm oil biodiesel produced using a natural coconut oil–based surfactant. Biomass Convers. Biorefinery 2024, 14, 9455–9472. [Google Scholar] [CrossRef]

| Input Variable | Range of Variation |

|---|---|

| Molar ratio (alcohol:oil) | 3:1–31.48:1 |

| Catalyst concentration | 0.50–4 wt% |

| Temperature | 25–70 °C |

| Reaction time | 10–600 min |

| Stirring speed | 300–1200 rpm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, V.L.d.; Santos, L.C.L.d.; Simonelli, G. Transesterification of Castor Oil into Biodiesel: Predictive Modeling with Machine Learning and Genetic Algorithm. Biomass 2025, 5, 71. https://doi.org/10.3390/biomass5040071

Santos VLd, Santos LCLd, Simonelli G. Transesterification of Castor Oil into Biodiesel: Predictive Modeling with Machine Learning and Genetic Algorithm. Biomass. 2025; 5(4):71. https://doi.org/10.3390/biomass5040071

Chicago/Turabian StyleSantos, Vivian Lima dos, Luiz Carlos Lobato dos Santos, and George Simonelli. 2025. "Transesterification of Castor Oil into Biodiesel: Predictive Modeling with Machine Learning and Genetic Algorithm" Biomass 5, no. 4: 71. https://doi.org/10.3390/biomass5040071

APA StyleSantos, V. L. d., Santos, L. C. L. d., & Simonelli, G. (2025). Transesterification of Castor Oil into Biodiesel: Predictive Modeling with Machine Learning and Genetic Algorithm. Biomass, 5(4), 71. https://doi.org/10.3390/biomass5040071