Thermoeconomic Evaluation and Sustainability Insights of Hybrid Solar–Biomass Powered Organic Rankine Cycle Systems: A Comprehensive Review

Abstract

1. Introduction

1.1. Background

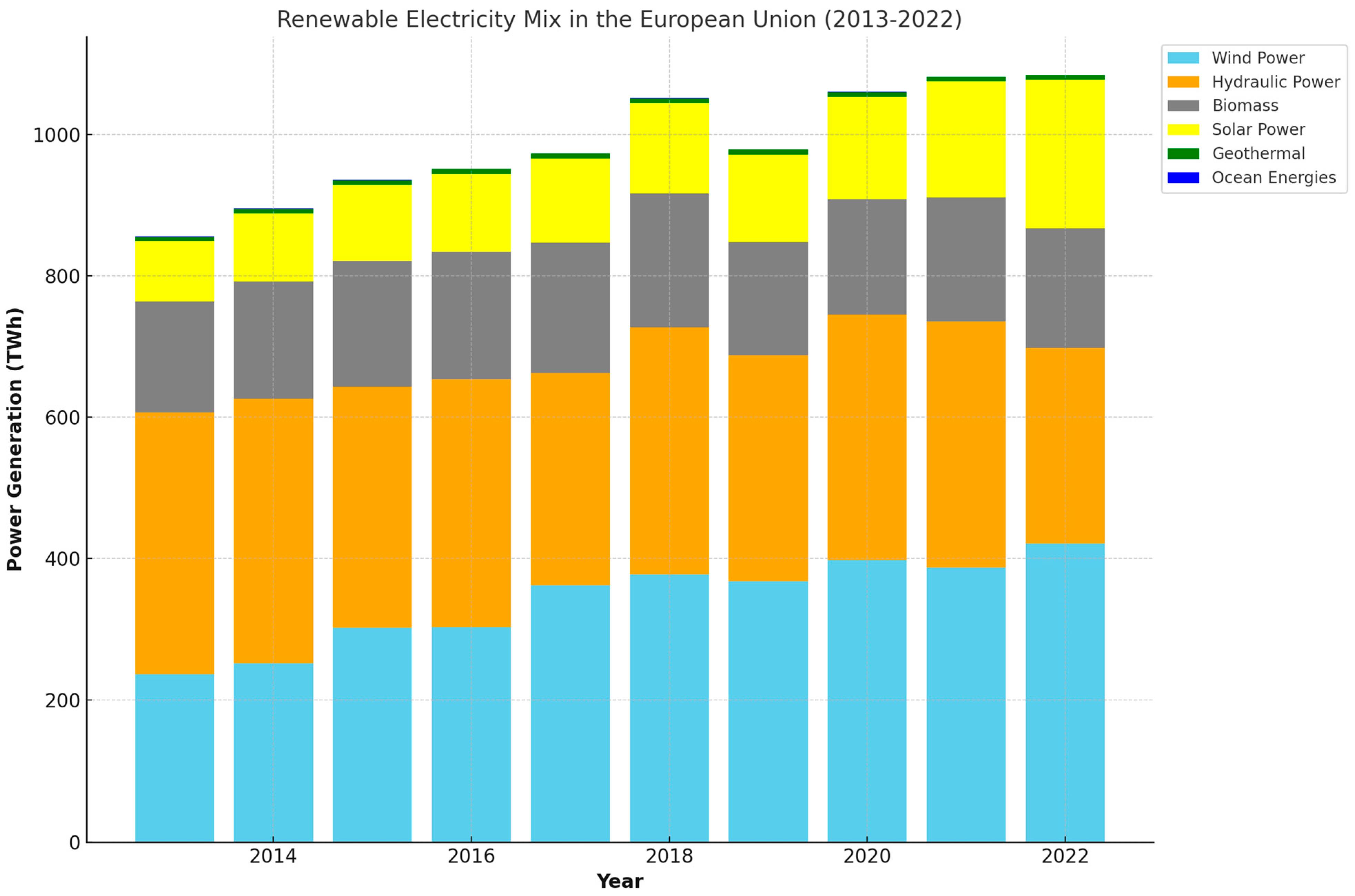

- Overview of renewable energy sources and their importance:

- Introduction to hybrid energy systems, focused on solar and biomass:

- Brief overview of the organic Rankine cycle (ORC) and its uses in energy generation:

1.2. Motivation

- Rationale for mixing solar and biomass for ORC systems:

- Importance of examining the thermoeconomic viability of these systems:

1.3. Objectives

- Aims of the review:

- Scope and structure of the article:

2. Fundamentals of Organic Rankine Cycle (ORC) Systems

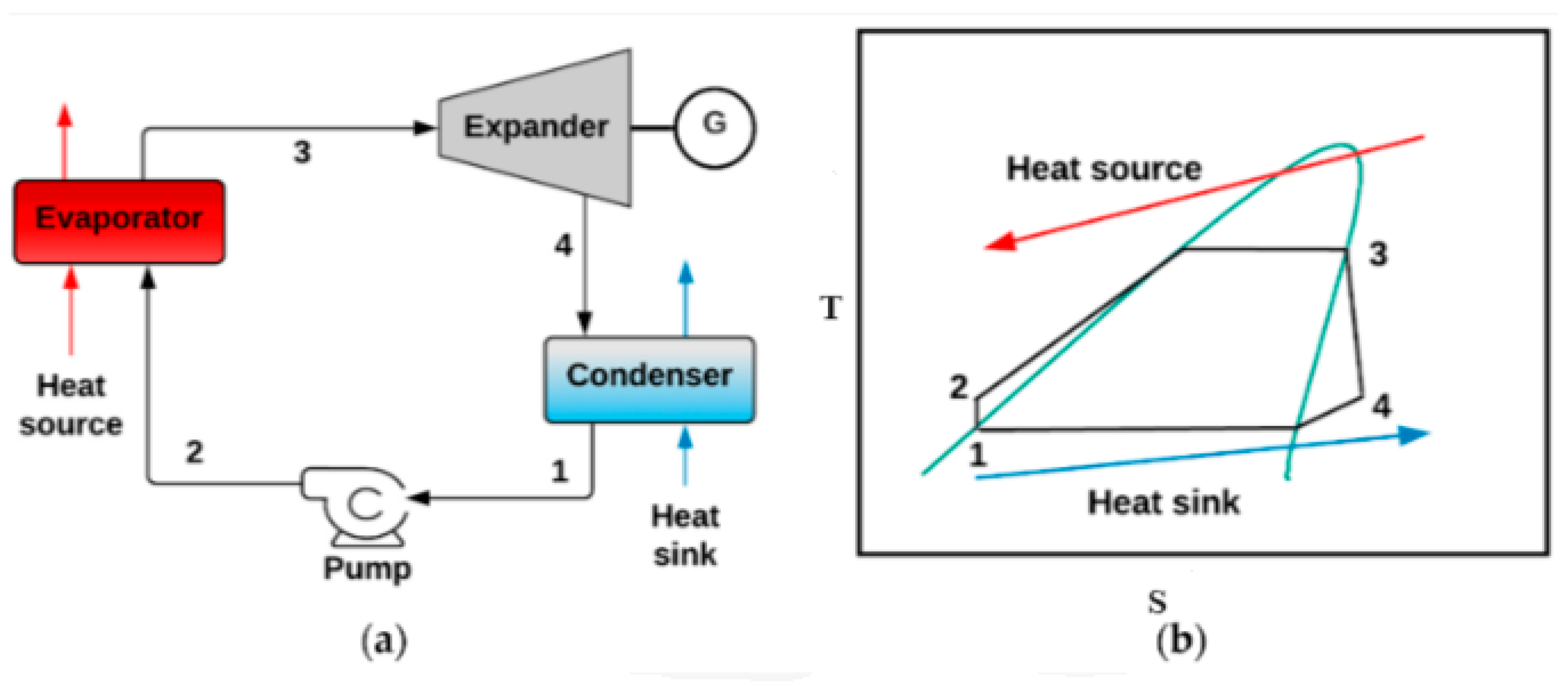

2.1. ORC Technology Overview

- Basic principles and working mechanisms of ORC:

- Common working fluids used in ORC systems:

- Thermodynamic Properties and Suitability for Temperature Ranges:

- Environmental Impact and Low-GWP Alternatives:

- Recent Advances in High-Performance Fluids:

- Impact on Efficiency and Sustainability:

2.2. Applications of ORC

- Overview of ORC applications in various industries:

- Specific focus on power generation from renewable sources:

3. Hybrid Solar and Biomass-Powered ORC Systems

3.1. Solar-Powered ORC Systems

- Mechanism and efficiency of solar-powered ORC systems:

- Key technologies: Parabolic troughs, solar towers, etc.:

- Advantages and limitations of solar-powered ORC:

- Solar Collector Technology in Hybrid Solar–Biomass ORC Systems: Costs and Efficiency:

3.2. Biomass-Powered ORC Systems

- Overview of biomass as a renewable energy source:

- Mechanism and efficiency of biomass-powered ORC systems:

- Feedstock types and their impact on ORC performance:

3.3. Hybrid Solar–Biomass ORC Systems

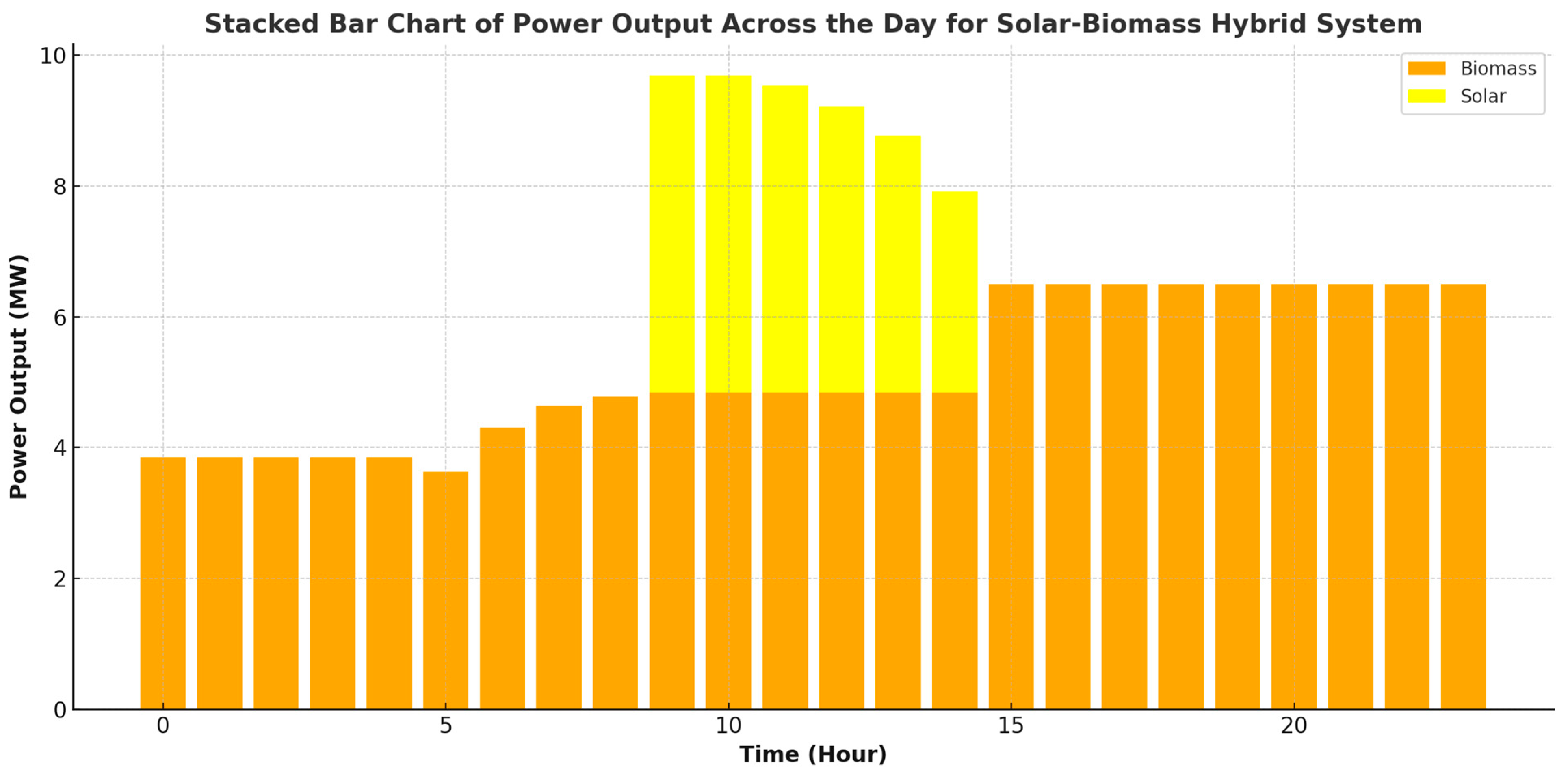

- Synergistic benefits of combining solar and biomass in ORC:

- Specific Application of Hybrid system and Cost Comparison:

- Case studies and examples of existing hybrid systems:

- Cogeneration Potential in Hybrid Solar–Biomass ORC Systems: Improving Overall Efficiency:

- Case Study: Cogeneration in a Hybrid Solar–Biomass ORC System in Tuscany, Italy:

4. Thermodynamic Performance Evaluation

4.1. Performance Metrics

- Definition of key thermodynamic performance metrics (e.g., efficiency, exergy analysis):

4.2. Comparative Analysis of Solar, Biomass, and Hybrid Systems

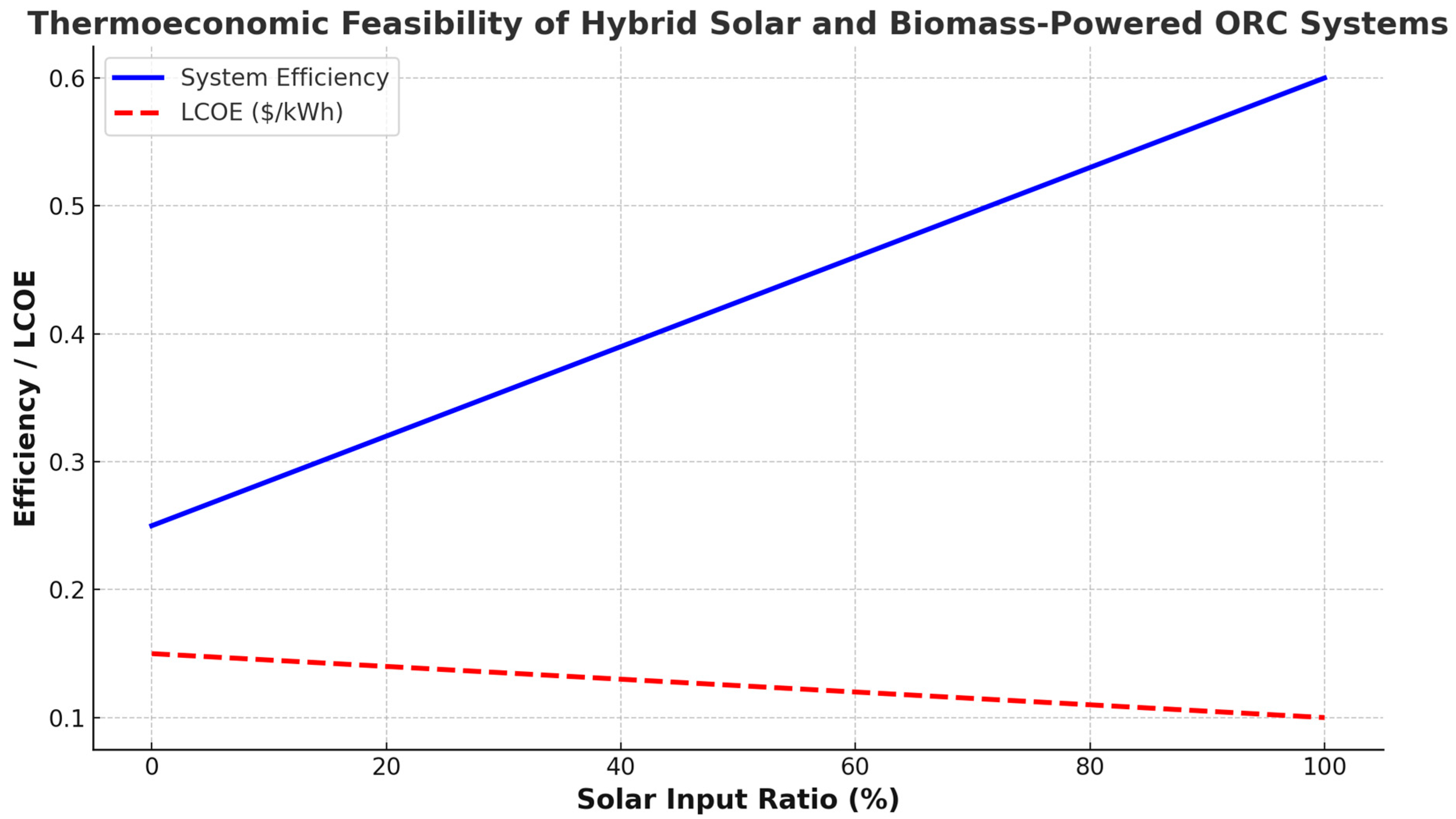

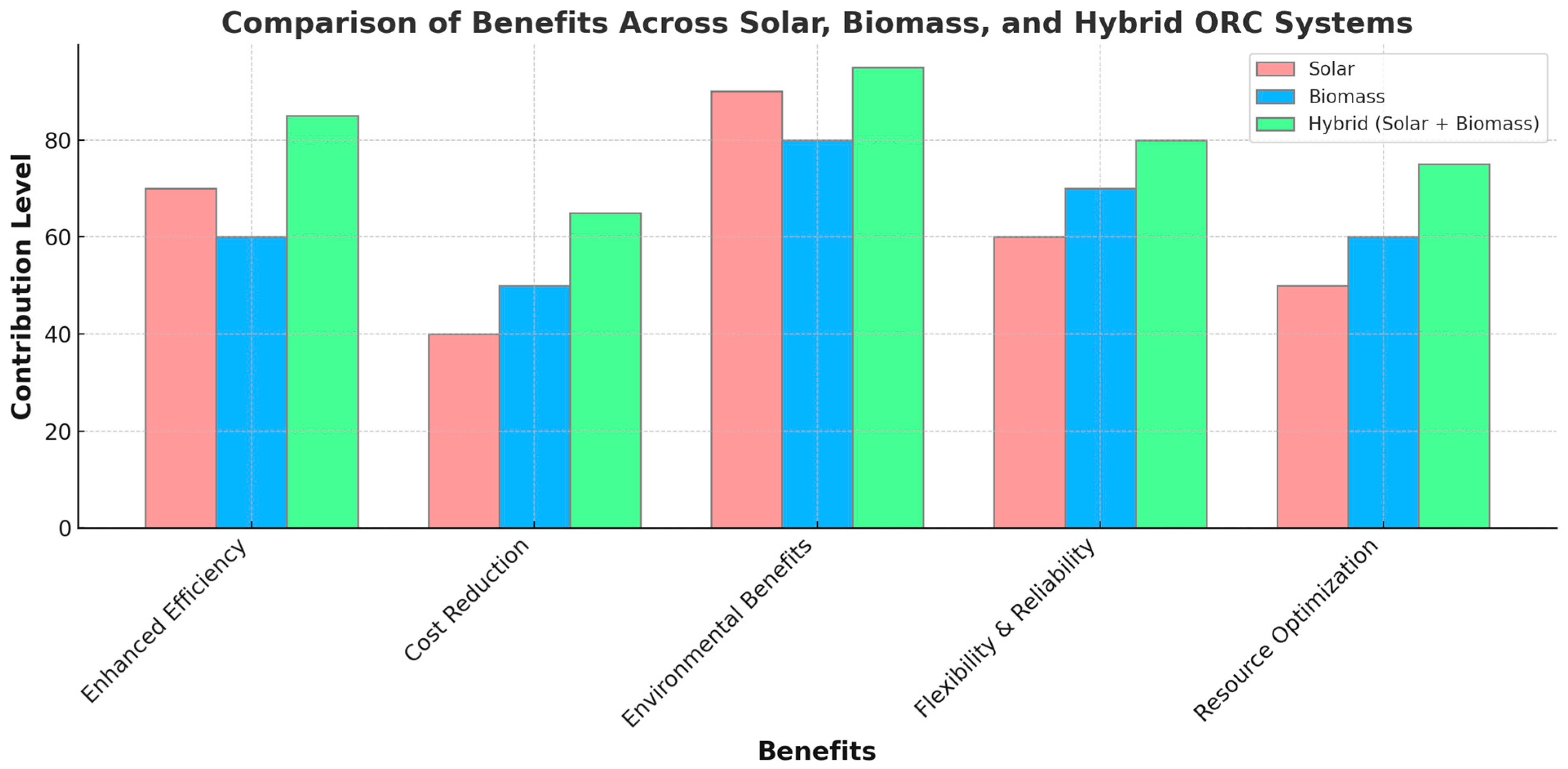

- Performance comparison between solar, biomass, and hybrid ORC systems:

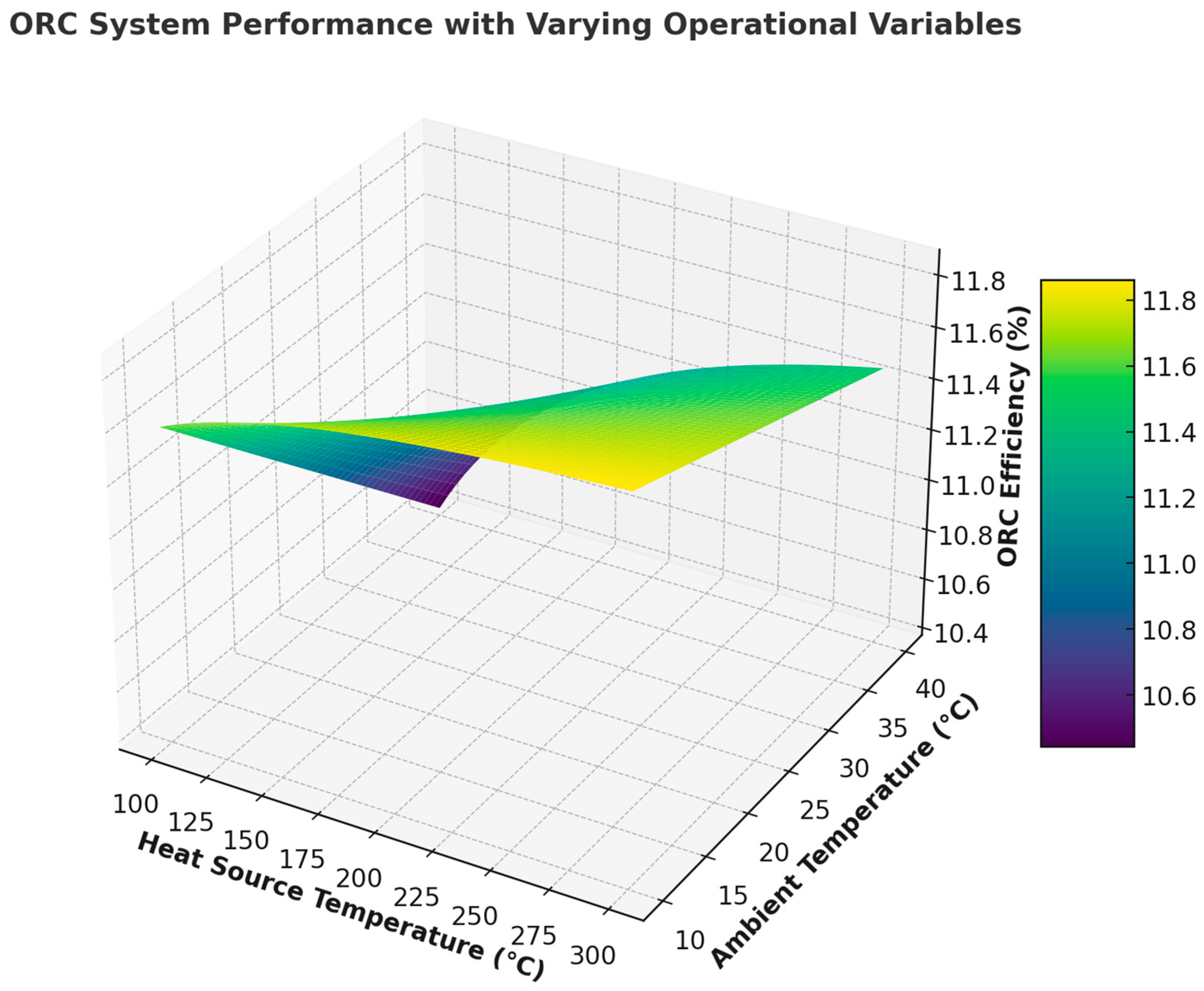

- Impact of various operating conditions on system performance:

4.3. Optimization Techniques

- Overview of optimization methods for enhancing thermodynamic performance:

- Role of simulation tools and software in system design and analysis:

5. Economic Assessment

5.1. Capital and Operational Costs

- Analysis of capital costs for solar, biomass, and hybrid ORC systems:

- Operational and maintenance costs associated with each system type:

5.2. Economic Viability

- Payback period, levelized cost of energy (LCOE), and other economic indicators:

- Sensitivity analysis for different cost parameters:

5.3. Market Potential

- Market trends and potential for hybrid solar–biomass ORC systems:

- Policy incentives and subsidies for renewable energy systems:

6. Environmental Impact and Sustainability

6.1. Environmental Benefits

- Reduction in greenhouse gas emissions with hybrid ORC systems:

- Comparison of the environmental footprint of solar, biomass, and hybrid systems:

6.2. Sustainability Assessment

- Long-term sustainability of hybrid solar–biomass ORC systems:

- Life cycle analysis and resource availability:

7. Challenges and Future Prospects

7.1. Technical Challenges

- Key technical barriers in the development of hybrid ORC systems:

- Reliability and durability concerns in hybrid systems:

7.2. Economic and Market Barriers

- Economic challenges and market acceptance of hybrid systems:

- Barriers related to policy and regulation:

7.3. Research and Development Opportunities

- Emerging technologies and innovations in ORC systems:

- Future research directions for improving thermoeconomic viability:

8. Conclusions

8.1. Summary of Key Findings

- Recap of the thermodynamic and economic performance of hybrid ORC systems:

- Overview of environmental and sustainable aspects:

8.2. Recommendations

- Policy and research recommendations for the advancement of hybrid solar–biomass ORC systems:

8.3. Final Thoughts

- The future of renewable energy systems and the role of hybrid ORC technology:

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Østergaard, P.A.; Duic, N.; Noorollahi, Y.; Kalogirou, S. Renewable energy for sustainable development. Renew. Energy 2022, 199, 1145–1152. [Google Scholar] [CrossRef]

- Guchhait, R.; Sarkar, B. Increasing Growth of Renewable Energy: A State of Art. Energies 2023, 16, 2665. [Google Scholar] [CrossRef]

- Gawusu, S.; Zhang, X.; Ahmed, A.; Jamatutu, S.A.; Miensah, E.D.; Amadu, A.A.; Osei, F.A.J. Renewable energy sources from the perspective of blockchain integration: From theory to application. Sustain. Energy Technol. Assess. 2022, 52, 102108. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Meng, X.; Wu, J. Multi-Objective Optimization Based on Life Cycle Assessment for Hybrid Solar and Biomass Combined Cooling, Heating and Power System. J. Therm. Sci. 2024, 33, 931–950. [Google Scholar] [CrossRef]

- Algarni, S.; Tirth, V.; Alqahtani, T.; Alshehery, S.; Kshirsagar, P. Contribution of renewable energy sources to the environmental impacts and economic benefits for sustainable development. Sustain. Energy Technol. Assess. 2023, 56, 103098. [Google Scholar] [CrossRef]

- Seminario-Córdova, R.; Rojas-Ortega, R. Renewable Energy Sources and Energy Production: A Bibliometric Analysis of the Last Five Years. Sustainability 2023, 15, 499. [Google Scholar] [CrossRef]

- Othman, K.; Khallaf, R. Identification of the Barriers and Key Success Factors for Renewable Energy Public-Private Partnership Projects: A Continental Analysis. Buildings 2022, 12, 1511. [Google Scholar] [CrossRef]

- Khalid, M. Smart grids and renewable energy systems: Perspectives and grid integration challenges. Energy Strateg. Rev. 2024, 51, 101299. [Google Scholar] [CrossRef]

- Qadir, S.A.; Ahmad, F.; Al-Motairi, H.; bin Saleh Al-Sada, M.; Al-Fagih, L. Renewable energy incentives for project owners representing communities with heavily subsidised fossil fuel-based electricity. Sustain. Cities Soc. 2024, 101, 105152. [Google Scholar] [CrossRef]

- Ang, T.Z.; Salem, M.; Kamarol, M.; Das, H.S.; Nazari, M.A.; Prabaharan, N. A comprehensive study of renewable energy sources: Classifications, challenges and suggestions. Energy Strateg. Rev. 2022, 43, 100939. [Google Scholar] [CrossRef]

- Hassan, Q.; Algburi, S.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. A review of hybrid renewable energy systems: Solar and wind-powered solutions: Challenges, opportunities, and policy implications. Results Eng. 2023, 20, 101621. [Google Scholar] [CrossRef]

- Candra, O.; Chammam, A.; Alvarez, J.R.N.; Muda, I.; Aybar, H.Ş. The Impact of Renewable Energy Sources on the Sustainable Development of the Economy and Greenhouse Gas Emissions. Sustainability 2023, 15, 2104. [Google Scholar] [CrossRef]

- Hemeida, M.G.; Hemeida, A.M.; Senjyu, T.; Osheba, D. Renewable Energy Resources Technologies and Life Cycle Assessment: Review. Energies 2022, 15, 9417. [Google Scholar] [CrossRef]

- Bany Issa, M.A.; Al Muala, Z.A.; Bello Bugallo, P.M. Grid-Connected Renewable Energy Sources: A New Approach for Phase-Locked Loop with DC-Offset Removal. Sustainability 2023, 15, 9550. [Google Scholar] [CrossRef]

- EU Renewable Electricity Mix|Statista. Available online: https://www.statista.com/statistics/610362/renewable-electricity-mix-in-eu-28 (accessed on 17 August 2024).

- Huang, Y.; Wang, Q.; Xu, J. A Stackelberg-based biomass power trading game framework in hybrid-wind/solar/biomass system: From technological, economic, environmental and social perspectives. J. Clean. Prod. 2023, 403, 136806. [Google Scholar] [CrossRef]

- Baghel, N.; Manjunath, K.; Kumar, A. Assessment of solar-biomass hybrid power system for decarbonizing and sustainable energy transition for academic building. Process Saf. Environ. Prot. 2024, 187, 1201–1212. [Google Scholar] [CrossRef]

- Xin, Y.; Xing, X.; Li, X.; Hong, H. A biomass–solar hybrid gasification system by solar pyrolysis and PV– Solid oxide electrolysis cell for sustainable fuel production. Appl. Energy 2024, 356, 122419. [Google Scholar] [CrossRef]

- Altayib, K.; Dincer, I. Development of a hybrid integrated energy system driven by solar-thermochemical and pyrolysis processes for useful commodities with hydrogen. Energy Convers. Manag. 2023, 298, 117793. [Google Scholar] [CrossRef]

- Li, J.; Alvi, J.Z.; Pei, G.; Ji, J.; Li, P.; Fu, H. Effect of working fluids on the performance of a novel direct vapor generation solar organic Rankine cycle system. Appl. Therm. Eng. 2016, 98, 786–797. [Google Scholar] [CrossRef]

- Alvi, J.Z.; Imran, M.; Pei, G.; Li, J.; Gao, G.; Alvi, J. Thermodynamic comparison and dynamic simulation of direct and indirect solar organic Rankine cycle systems with PCM storage. Energy Procedia 2017, 129, 716–723. [Google Scholar] [CrossRef]

- Li, J.; Li, P.; Pei, G.; Alvi, J.Z.; Ji, J. Analysis of a novel solar electricity generation system using cascade Rankine cycle and steam screw expander. Appl. Energy 2016, 165, 627–638. [Google Scholar] [CrossRef]

- Alvi, J.Z.; Feng, Y.; Wang, Q.; Imran, M. Modelling, simulation and comparison of phase change material storage. Appl. Therm. Eng. 2019, 170, 114780. [Google Scholar] [CrossRef]

- Shah, N.; Markides, C.N.; Pina, A.; Ferrão, P.; Fournier, J.; Lacarrière, B.; Corre, O. Le ORC: System integration and economic analysis on District storage Solar/biomass hybrid cycles with thermal and ORC: System integration and economic analysis Assessing the feasibility using heat temperature function for a Camporeale district heat deman. Energy Procedia 2017, 129, 724–731. [Google Scholar] [CrossRef]

- Fiaschi, D.; Lifshitz, A.; Manfrida, G.; Tempesti, D. An innovative ORC power plant layout for heat and power generation from medium-to low-temperature geothermal resources. Energy Convers. Manag. 2014, 88, 883–893. [Google Scholar] [CrossRef]

- Renno, C.; Petito, F.; D’Agostino, D.; Minichiello, F. Modeling of a CPV/T-ORC combined system adopted for an industrial user. Energies 2020, 13, 3476. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Khosravanifard, Y.; Sohani, A. Solutions for thermal energy exploitation from the exhaust of an industrial gas turbine using optimized bottoming cycles. Energy Convers. Manag. 2020, 207, 112523. [Google Scholar] [CrossRef]

- Jradi, M.; Riffat, S. Experimental investigation of a biomass-fuelled micro-scale tri-generation system with an organic Rankine cycle and liquid desiccant cooling unit. Energy 2014, 71, 80–93. [Google Scholar] [CrossRef]

- Liu, H.; Qiu, G.; Shao, Y.; Daminabo, F.; Riffat, S.B. Preliminary experimental investigations of a biomass-fired micro-scale CHP with organic Rankine cycle. Int. J. Low-Carbon Technol. 2010, 5, 81–87. [Google Scholar] [CrossRef]

- Ammar, Y.; Joyce, S.; Norman, R.; Wang, Y.; Roskilly, A.P. Low grade thermal energy sources and uses from the process industry in the UK. Appl. Energy 2012, 89, 3–20. [Google Scholar] [CrossRef]

- Su, W.; Han, Y.; Liu, Z.; Jin, X.; Liu, Z.; Yang, D.; Zhang, X. Absorption heat pumps for low-grade heat utilization: A comprehensive review on working pairs, classification, system advances and applications. Energy Convers. Manag. 2024, 315, 118760. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, J.; Gao, L. Parametric optimization and comparative study of organic Rankine cycle (ORC) for low grade waste heat recovery. Energy Convers. Manag. 2009, 50, 576–582. [Google Scholar] [CrossRef]

- Osintsev, K.; Aliukov, S. ORC Technology Based on Advanced Li-Br Absorption Refrigerator with Solar Collectors and a Contact Heat Exchanger for Greenhouse Gas Capture. Sustainability 2022, 14, 5520. [Google Scholar] [CrossRef]

- Kane, M.; Larrain, D.; Favrat, D.; Allani, Y. Small hybrid solar power system. Energy 2003, 28, 1427–1443. [Google Scholar] [CrossRef]

- Cinocca, A.; Di Bartolomeo, M.; Cipollone, R.; Carapellucci, R. A Definitive Model of a Small-Scale Concentrated Solar Power Hybrid Plant Using Air as Heat Transfer Fluid with a Thermal Storage Section and ORC Plants for Energy Recovery. Energies 2020, 13, 4741. [Google Scholar] [CrossRef]

- Soulis, K.X.; Manolakos, D.; Ntavou, E.; Kosmadakis, G. A geospatial analysis approach for the operational assessment of solar ORC systems. Case study: Performance evaluation of a two-stage solar ORC engine in Greece. Renew. Energy 2022, 181, 116–128. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpur, F. Energy and exergy analyses of a biomass trigeneration system using an organic Rankine cycle. Energy 2012, 45, 975–985. [Google Scholar] [CrossRef]

- Cruz, I.; Johansson, M.T.; Wren, J. Assessment of the potential for small-scale CHP production using Organic Rankine Cycle (ORC) systems in different geographical contexts: GHG emissions impact and economic feasibility. Energy Rep. 2022, 8, 7680–7690. [Google Scholar] [CrossRef]

- Li, Y.R.; Du, M.T.; Wu, C.M.; Wu, S.Y.; Liu, C.; Xu, J.L. Economical evaluation and optimization of subcritical organic Rankine cycle based on temperature matching analysis. Energy 2014, 68, 238–247. [Google Scholar] [CrossRef]

- Hu, S.; Yang, Z.; Li, J.; Duan, Y. A review of multi-objective optimization in organic Rankine cycle (ORC) system design. Energies 2021, 14, 6492. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Y.; Li, B.; Yang, J.; Shi, Y. Comparison between regenerative organic Rankine cycle ( RORC ) and basic organic Rankine cycle ( BORC ) based on thermoeconomic multi-objective optimization considering exergy efficiency and levelized energy cost ( LEC ). Energy Convers. Manag. 2015, 96, 58–71. [Google Scholar] [CrossRef]

- Calli, O.; Colpan, C.O.; Gunerhan, H. Thermoeconomic analysis of a biomass and solar energy based organic Rankine cycle system under part load behavior. Sustain. Energy Technol. Assess. 2021, 46, 101207. [Google Scholar] [CrossRef]

- Li, J.; Li, P.; Pei, G.; Ji, J.; Alvi, J.Z.; Xia, L. A Novel Hybrid Solar Power Generation System Using a-Si Photovoltaic/Thermal Collectors and Organic Rankine Cycle. In Proceedings of the 3rd International Seminar on ORC Power Systems, Brussels, Belgium, 12–14 October 2015; pp. 1–10. [Google Scholar]

- Delgado-Torres, A.M.; García-Rodríguez, L. Design recommendations for solar organic Rankine cycle (ORC)–powered reverse osmosis (RO) desalination. Renew. Sustain. Energy Rev. 2012, 16, 44–53. [Google Scholar] [CrossRef]

- Desai, N.B.; Bandyopadhyay, S. Thermo-economic analysis and selection of working fluid for solar organic Rankine cycle. Appl. Therm. Eng. 2016, 95, 471–481. [Google Scholar] [CrossRef]

- Rayegan, R.; Tao, Y.X. A procedure to select working fluids for Solar Organic Rankine Cycles (ORCs). Renew. Energy 2011, 36, 659–670. [Google Scholar] [CrossRef]

- Asim, M.; Kashif, F.; Umer, J.; Alvi, J.Z.; Imran, M.; Khan, S.; Zia, A.W.; Leung, M.K.H. Performance assessment and working fluid selection for novel integrated vapor compression cycle and organic rankine cycle for ultra low grade waste heat recovery. Sustainability 2021, 13, 11592. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P. Thermo-economic Investigation of Solar-Biomass Hybrid Cogeneration Systems based on Small-Scale Transcritical Organic Rankine Cycles. Appl. Therm. Eng. 2022, 210, 118312. [Google Scholar] [CrossRef]

- Eyerer, S.; Wieland, C.; Vandersickel, A.; Spliethoff, H. Experimental study of an ORC (Organic Rankine Cycle) and analysis of R1233zd-E as a drop-in replacement for R245fa for low temperature heat utilization. Energy 2016, 103, 660–671. [Google Scholar] [CrossRef]

- Vuppaladadiyam, A.K.; Antunes, E.; Vuppaladadiyam, S.S.V.; Baig, Z.T.; Subiantoro, A.; Lei, G.; Leu, S.-Y.; Sarmah, A.K.; Duan, H. Progress in the development and use of refrigerants and unintended environmental consequences. Sci. Total Environ. 2022, 823, 153670. [Google Scholar] [CrossRef] [PubMed]

- Dawo, F.; Fleischmann, J.; Kaufmann, F.; Schifflechner, C.; Eyerer, S.; Wieland, C.; Spliethoff, H. R1224yd (Z), R1233zd (E) and R1336mzz (Z) as replacements for R245fa: Experimental performance, interaction with lubricants and environmental impact. Appl. Energy 2021, 288, 116661. [Google Scholar] [CrossRef]

- Albatati, F.A.S. Investigation of Environmentally Friendly Power Generation Systems for Low-Grade Waste Heat Recovery. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2015. [Google Scholar]

- Yang, J.; Ye, Z.; Yu, B.; Ouyang, H.; Chen, J. Simultaneous experimental comparison of low-GWP refrigerants as drop-in replacements to R245fa for Organic Rankine cycle application: R1234ze (Z), R1233zd (E), and R1336mzz (E). Energy 2019, 173, 721–731. [Google Scholar] [CrossRef]

- Wang, X.; Levy, E.K.; Pan, C.; Romero, C.E.; Banerjee, A.; Rubio-Maya, C.; Pan, L. Working fluid selection for organic Rankine cycle power generation using hot produced supercritical CO2 from a geothermal reservoir. Appl. Therm. Eng. 2019, 149, 1287–1304. [Google Scholar] [CrossRef]

- Razzaq, M.E.; Ahamed, J.; Hossain, M.; Hossain, S. A review on hydrocarbon (HCs) as an alternative refrigerant: Based on thermodynamic and environmental approach. Mech. Eng. Res. J. 2018, 11, 86–96. [Google Scholar]

- Yu, G.; Shu, G.; Tian, H.; Wei, H.; Liang, X. Multi-approach evaluations of a cascade-Organic Rankine Cycle (C-ORC) system driven by diesel engine waste heat: Part B-techno-economic evaluations. Energy Convers. Manag. 2015, 108, 596–608. [Google Scholar] [CrossRef]

- Gu, W.; Weng, Y.; Wang, Y.; Shaoqin, S. Heat recovery efficiency analysis of waste heat driven organic Rankine cycle. Acta Energiae Solaris Sin. 2011, 32, 662–668. [Google Scholar]

- Shu, G.; Zhao, M.; Tian, H.; Wei, H.; Liang, X.; Huo, Y.; Zhu, W. Experimental investigation on thermal OS/ORC (Oil Storage/Organic Rankine Cycle) system for waste heat recovery from diesel engine. Energy 2016, 107, 693–706. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Camporeale, S.M.; Miliozzi, A.; Russo, V.; Shah, N.; Markides, C.N. Novel hybrid CSP-biomass CHP for flexible generation: Thermo-economic analysis and profitability assessment. Appl. Energy 2017, 204, 994–1006. [Google Scholar] [CrossRef]

- Obernberger, I. Biomass CHP plant based on an ORC process—Realised EU—Demonstration project in Admont/Austria. In Proceedings of the Meeting of IEA Bionergry, TASK, Zagreb, Croatia, 22–26 May 2000; pp. 6–8. [Google Scholar]

- Calise, F.; D’Accadia, M.D.; Vicidomini, M.; Scarpellino, M. Design and simulation of a prototype of a small-scale solar CHP system based on evacuated flat-plate solar collectors and Organic Rankine Cycle. Energy Convers. Manag. 2015, 90, 347–363. [Google Scholar] [CrossRef]

- Xu, G.; Song, G.; Zhu, X.; Gao, W.; Li, H.; Quan, Y. Performance evaluation of a direct vapor generation supercritical ORC system driven by linear Fresnel reflector solar concentrator. Appl. Therm. Eng. 2015, 80, 196–204. [Google Scholar] [CrossRef]

- Ferrara, F.; Gimelli, A.; Luongo, A. Small-scale concentrated solar power ( CSP ) plant: ORCs comparison for different organic fluids. Energy Procedia 2014, 45, 217–226. [Google Scholar] [CrossRef]

- Drescher, U.; Brüggemann, D. Fluid selection for the Organic Rankine Cycle (ORC) in biomass power and heat plants. Appl. Therm. Eng. 2007, 27, 223–228. [Google Scholar] [CrossRef]

- Quoilin, S. Sustainable Energy Conversion Through the Use of Organic Rankine Cycles for Waste Heat Recovery and Solar Applications. Ph.D. Thesis, University of Liège, Liège, Belgium, 2011; pp. 1–183. Available online: http://orbi.ulg.ac.be/handle/2268/96436 (accessed on 8 August 2024).

- Pei, G.; Li, J.; Ji, J. Effect of working fluids on the efficiency of low-temperature solar-thermal-electric power generation system. Taiyangneng Xuebao/Acta Energiae Solaris Sin. 2010, 5, 571–573. [Google Scholar]

- Li, J.; Alvi, J.Z.; Pei, G.; Su, Y.; Li, P.; Gao, G.; Ji, J. Modelling of organic Rankine cycle efficiency with respect to the equivalent hot side temperature. Energy 2016, 115, 668–683. [Google Scholar] [CrossRef]

- Liu, H.-L.; He, Y.-L.; Cheng, Z.-D.; Cui, F.-Q. Simulation of Parabolic Trough Solar Thermal Generation with Organic Rankine Cycle. J. Eng. Thermophys. 2010, 10, 5. [Google Scholar]

- Dabwan, Y.N.; Mokheimer, E.M.A. Optimal integration of linear Fresnel reflector with gas turbine cogeneration power plant. Energy Convers. Manag. 2017, 148, 830–843. [Google Scholar] [CrossRef]

- Cocco, D.; Cau, G. Energy and economic analysis of concentrating solar power plants based on parabolic trough and linear Fresnel collectors. Proc. Inst. Mech. Eng. Part A J. Power Energy 2015, 229, 677–688. [Google Scholar] [CrossRef]

- Lakhani, S.; Raul, A.; Saha, S.K. Dynamic modelling of ORC-based solar thermal power plant integrated with multitube shell and tube latent heat thermal storage system. Appl. Therm. Eng. 2017, 123, 458–470. [Google Scholar] [CrossRef]

- Casartelli, D.; Binotti, M.; Silva, P.; Macchi, E.; Roccaro, E.; Passera, T. Power Block Off-design Control Strategies for Indirect Solar ORC Cycles. Energy Procedia 2015, 69, 1220–1230. [Google Scholar] [CrossRef]

- Tzivanidis, C.; Bellos, E.; Antonopoulos, K.A. Energetic and financial investigation of a stand-alone solar-thermal Organic Rankine Cycle power plant. Energy Convers. Manag. 2016, 126, 421–433. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Z.; Zhao, P.; Dai, Y. Off-design performance analysis of a solar-powered organic Rankine cycle. Energy Convers. Manag. 2014, 80, 150–157. [Google Scholar] [CrossRef]

- Liu, M.; Steven Tay, N.H.; Bell, S.; Belusko, M.; Jacob, R.; Will, G.; Saman, W.; Bruno, F. Review on concentrating solar power plants and new developments in high temperature thermal energy storage technologies. Renew. Sustain. Energy Rev. 2016, 53, 1411–1432. [Google Scholar] [CrossRef]

- Manikandan, G.K.; Iniyan, S.; Goic, R. Enhancing the optical and thermal efficiency of a parabolic trough collector—A review. Appl. Energy 2019, 235, 1524–1540. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, S.; Yue, W.; Tian, Z.; Yang, C.; Gao, W. Energy, exergy, economic and environmental (4E) evaluation of a solar-integrated energy system at medium–high temperature using CO2 as the parabolic trough collector (PTC) working medium. Energy Convers. Manag. 2023, 296, 117683. [Google Scholar] [CrossRef]

- Yuanjing, W.; Cheng, Z.; Yanping, Z.; Xiaohong, H. Performance analysis of an improved 30 MW parabolic trough solar thermal power plant. Energy 2020, 213, 118862. [Google Scholar] [CrossRef]

- Hornea, S.; Lasichb, J. Concentrating photovoltaic systems and applications. Conc. Sol. Power Technol. Princ. Dev. Appl. 2020, 357–397. [Google Scholar]

- Li, J. Structural Optimization and Experimental Investigation of the Organic Rankine Cycle for Solar Thermal Power Generation; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 3662456230. [Google Scholar]

- Purohit, I.; Purohit, P. Technical and economic potential of concentrating solar thermal power generation in India. Renew. Sustain. Energy Rev. 2017, 78, 648–667. [Google Scholar] [CrossRef]

- Alexopoulos, S.; Hoffschmidt, B. Concentrating receiver systems (solar power tower). In Solar Thermal Energy; Springer: New York, NY, USA, 2022; pp. 63–110. [Google Scholar]

- Munir, A.; Alvi, J.Z.; Ashfaq, S.; Ghafoor, A. Performance evaluation of a biomass boiler on the basis of heat loss method and total heat values of steam. Pak. J. Agric. Sci. 2014, 51, 209–215. [Google Scholar]

- Oyekale, J.; Petrollese, M.; Cau, G. Multi-objective thermo-economic optimization of biomass retrofit for an existing solar organic Rankine cycle power plant based on NSGA-II. Energy Rep. 2020, 6, 136–145. [Google Scholar] [CrossRef]

- Middelhoff, E.; Furtado, L.A.; Peterseim, J.H.; Madden, B.; Ximenes, F.; Florin, N. Hybrid concentrated solar biomass (HCSB) plant for electricity generation in Australia: Design and evaluation of techno-economic and environmental performance. Energy Convers. Manag. 2021, 240, 114244. [Google Scholar] [CrossRef]

- Suresh, N.S.; Thirumalai, N.C.; Dasappa, S. Modeling of solar and biomass hybrid power generation—A techno-economic case study. Process Integr. Optim. Sustain. 2019, 3, 101–114. [Google Scholar] [CrossRef]

- Chen, H.; Xue, K.; Wu, Y.; Xu, G.; Jin, X.; Liu, W. Thermodynamic and economic analyses of a solar-aided biomass-fired combined heat and power system. Energy 2021, 214, 119023. [Google Scholar] [CrossRef]

- Nolan, A.; McDonnell, K.; Devlin, G. Economic analysis of manufacturing costs of pellet production in the Republic of Ireland using non-woody biomass. Open Renew. Energy J. 2010, 3, 1–11. [Google Scholar] [CrossRef]

- Akrami, E.; Ameri, M.; Rocco, M. V Conceptual design, exergoeconomic analysis and multi-objective optimization for a novel integration of biomass-fueled power plant with MCFC-cryogenic CO2 separation unit for low-carbon power production. Energy 2021, 227, 120511. [Google Scholar] [CrossRef]

- Perkins, G. Techno-economic comparison of the levelised cost of electricity generation from solar PV and battery storage with solar PV and combustion of bio-crude using fast pyrolysis of biomass. Energy Convers. Manag. 2018, 171, 1573–1588. [Google Scholar] [CrossRef]

- Libra, M.; Mrázek, D.; Tyukhov, I.; Severová, L.; Poulek, V.; Mach, J.; Šubrt, T.; Beránek, V.; Svoboda, R.; Sedláček, J. Reduced real lifetime of PV panels–Economic consequences. Sol. Energy 2023, 259, 229–234. [Google Scholar] [CrossRef]

- Desalegn, B.; Gebeyehu, D.; Tamrat, B.; Tadiwose, T.; Lata, A. Onshore versus offshore wind power trends and recent study practices in modeling of wind turbines’ life-cycle impact assessments. Clean. Eng. Technol. 2023, 17, 100691. [Google Scholar] [CrossRef]

- Väisänen, J.; Kosonen, A.; Ahola, J.; Sallinen, T.; Hannula, T. Optimal sizing ratio of a solar PV inverter for minimizing the levelized cost of electricity in Finnish irradiation conditions. Sol. Energy 2019, 185, 350–362. [Google Scholar] [CrossRef]

- Klie, L.; Madlener, R. Optimal configuration and diversification of wind turbines: A hybrid approach to improve the penetration of wind power. Energy Econ. 2022, 105, 105692. [Google Scholar] [CrossRef]

- Ogorure, O.J.; Heberle, F.; Brüggemann, D. Thermo-economic analysis and multi-criteria optimization of an integrated biomass-to-energy power plant. Renew. Energy 2024, 224, 120112. [Google Scholar] [CrossRef]

- Teymouri, M.; Sadeghi, S.; Moghimi, M.; Ghandehariun, S. 3E analysis and optimization of an innovative cogeneration system based on biomass gasification and solar photovoltaic thermal plant. Energy 2021, 230, 120646. [Google Scholar] [CrossRef]

- Grange, B.; Dalet, C.; Falcoz, Q.; Ferrière, A.; Flamant, G. Impact of thermal energy storage integration on the performance of a hybrid solar gas-turbine power plant. Appl. Therm. Eng. 2016, 105, 266–275. [Google Scholar] [CrossRef]

- Oyekale, J.; Petrollese, M.; Heberle, F.; Brüggemann, D.; Cau, G. Exergetic and integrated exergoeconomic assessments of a hybrid solar-biomass organic Rankine cycle cogeneration plant. Energy Convers. Manag. 2020, 215, 112905. [Google Scholar] [CrossRef]

- Calise, F.; Costa, M.; Wang, Q.; Zhang, X.; Duić, N. Recent advances in the analysis of sustainable energy systems. Energies 2018, 11, 2520. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; Papadakis, G. Exergy analysis of micro-organic Rankine power cycles for a small scale solar driven reverse osmosis desalination system. Appl. Energy 2010, 87, 1295–1306. [Google Scholar] [CrossRef]

- Mahmoudi, S.M.S.; Sarabchi, N.; Yari, M.; Rosen, M.A. Exergy and Exergoeconomic Analyses of a Combined Power Producing System including a Proton Exchange Membrane Fuel Cell and an Organic Rankine Cycle. Sustainability 2019, 11, 3264. [Google Scholar] [CrossRef]

- Di Cairano, L.; Nader, W.B.; Nemer, M. A simulation and experimental study of an innovative MAC/ORC/ERC system: ReverCycle with an ejector for series hybrid vehicles. Energy 2021, 230, 120830. [Google Scholar] [CrossRef]

- Feng, Y.; Hung, T.; Zhang, Y.; Li, B.; Yang, J.; Shi, Y. Performance comparison of low-grade ORCs (organic Rankine cycles) using R245fa, pentane and their mixtures based on the thermoeconomic multi-objective optimization and decision makings. Energy 2015, 93, 2018–2029. [Google Scholar] [CrossRef]

- Baral, S.; Kim, D.; Yun, E.; Kim, K.C. Experimental and thermoeconomic analysis of small-scale solar organic Rankine cycle (SORC) system. Entropy 2015, 17, 2039–2061. [Google Scholar] [CrossRef]

- Chen, H.; Goswami, D.Y.; Stefanakos, E.K. A review of thermodynamic cycles and working fluids for the conversion of low-grade heat. Renew. Sustain. Energy Rev. 2010, 14, 3059–3067. [Google Scholar] [CrossRef]

- Walraven, D.; Laenen, B.; D’haeseleer, W. Economic system optimization of air-cooled organic Rankine cycles powered by low-temperature geothermal heat sources. Energy 2015, 80, 104–113. [Google Scholar] [CrossRef]

- Preißinger, M.; Schatz, S.; Vogl, A.; König-Haagen, A.; Brüggemann, D. Thermoeconomic analysis of configuration methods for modular Organic Rankine Cycle units in low-temperature applications. Energy Convers. Manag. 2016, 127, 25–34. [Google Scholar] [CrossRef]

- Calise, F.; Capuozzo, C.; Carotenuto, A.; Vanoli, L. Thermoeconomic analysis and off-design performance of an organic Rankine cycle powered by medium-temperature heat sources. Sol. Energy 2014, 103, 595–609. [Google Scholar] [CrossRef]

- Carraro, G.; Bori, V.; Lazzaretto, A.; Toniato, G.; Danieli, P. Experimental investigation of an innovative biomass-fired micro-ORC system for cogeneration applications. Renew. Energy 2020, 161, 1226–1243. [Google Scholar] [CrossRef]

- Ashouri, M.; Razi Astaraei, F.; Ghasempour, R.; Ahmadi, M.H.; Feidt, M. Thermodynamic and economic evaluation of a small-scale organic Rankine cycle integrated with a concentrating solar collector. Int. J. Low-Carbon Technol. 2017, 12, 54–65. [Google Scholar] [CrossRef]

- Roy, J.P.; Mishra, M.K.; Misra, A. Performance analysis of an Organic Rankine Cycle with superheating under different heat source temperature conditions. Appl. Energy 2011, 88, 2995–3004. [Google Scholar] [CrossRef]

- Hajabdollahi, H.; Ganjehkaviri, A.; Mohd Jaafar, M.N. Thermo-economic optimization of RSORC (regenerative solar organic Rankine cycle) considering hourly analysis. Energy 2015, 87, 361–368. [Google Scholar] [CrossRef]

- Imran, M.; Usman, M.; Park, B.-S.; Kim, H.-J.; Lee, D.-H. Multi-objective optimization of evaporator of organic Rankine cycle (ORC) for low temperature geothermal heat source. Appl. Therm. Eng. 2015, 80, 1–9. [Google Scholar] [CrossRef]

- Lyshevski, S.E. Engineering and Scientific Computations Using MATLAB; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; Volume 16, 240p. [Google Scholar] [CrossRef]

- Quoilin, S.; Orosz, M.; Hemond, H.; Lemort, V. Performance and design optimization of a low-cost solar organic Rankine cycle for remote power generation. Sol. Energy 2011, 85, 955–966. [Google Scholar] [CrossRef]

- Imran, M.; Haglind, F.; Lemort, V.; Meroni, A. Optimization of organic rankine cycle power systems for waste heat recovery on heavy-duty vehicles considering the performance, cost, mass and volume of the system. Energy 2019, 180, 229–241. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Camporeale, S.M.; Sorrentino, A.; Miliozzi, A.; Shah, N.; Markides, C.N. Hybrid solar-biomass combined Brayton/organic Rankine-cycle plants integrated with thermal storage: Techno-economic feasibility in selected Mediterranean areas. Renew. Energy 2020, 147, 2913–2931. [Google Scholar] [CrossRef]

- Hoffmann, J.F.; Fasquelle, T.; Goetz, V.; Py, X. A thermocline thermal energy storage system with filler materials for concentrated solar power plants: Experimental data and numerical model sensitivity to different experimental tank scales. Appl. Therm. Eng. 2016, 100, 753–761. [Google Scholar] [CrossRef]

- Pina, E.A.; Serra, L.M.; Lozano, M.A.; Hernández, A.; Lázaro, A. Comparative Analysis and Design of a Solar-Based Parabolic Trough–ORC Cogeneration Plant for a Commercial Center. Energies 2020, 13, 4807. [Google Scholar] [CrossRef]

- Wieland, C.; Schifflechner, C.; Dawo, F.; Astolfi, M. The organic Rankine cycle power systems market: Recent developments and future perspectives. Appl. Therm. Eng. 2023, 224, 119980. [Google Scholar] [CrossRef]

- Gutiérrez-Alvarez, R.; Guerra, K.; Haro, P. Profitability of Concentrated Solar-Biomass hybrid power plants: Dataset of the stochastic techno-economic assessment. Data Brief 2023, 48, 109096. [Google Scholar] [CrossRef] [PubMed]

- Pawar, R.; Dalsania, K.P.; Sircar, A.; Yadav, K.; Bist, N. Renewable energy hybridization: A comprehensive review of integration strategies for efficient and sustainable power generation. Clean Technol. Environ. Policy 2024, 1–18. [Google Scholar] [CrossRef]

- Krarouch, M.; Allouhi, A.; Hamdi, H.; Outzourhit, A. Energy, exergy, environment and techno-economic analysis of hybrid solar-biomass systems for space heating and hot water supply: Case study of a Hammam building. Renew. Energy 2024, 222, 119941. [Google Scholar] [CrossRef]

- Wieland, C.; Schifflechner, C.; Braimakis, K.; Kaufmann, F.; Dawo, F.; Karellas, S.; Besagni, G.; Markides, C.N. Innovations for organic Rankine cycle power systems: Current trends and future perspectives. Appl. Therm. Eng. 2023, 225, 120201. [Google Scholar] [CrossRef]

- Budisulistyo, D. Feasibility Analysis of ORC Systems: Thermo-Economic and Technical Considerations for Flexible Design; University of Canterbury: Christchurch, New Zealand, 2016. [Google Scholar]

- Mai-Moulin, T.; Hoefnagels, R.; Grundmann, P.; Junginger, M. Effective sustainability criteria for bioenergy: Towards the implementation of the european renewable directive II. Renew. Sustain. Energy Rev. 2021, 138, 110645. [Google Scholar] [CrossRef]

- Del Río, P. Assessing the Design Elements in the Spanish Renewable Electricity Auction: An International Comparison; Working Paper 6/2017; Elcano Royal Institute: Madrid, Spain, 2017. [Google Scholar]

- Del Río, P.; Linares, P. Back to the future? Rethinking auctions for renewable electricity support. Renew. Sustain. Energy Rev. 2014, 35, 42–56. [Google Scholar] [CrossRef]

| System Configuration | Thermal Efficiency (%) [103,104,105] | Electrical Output (MW) [24,106,107] | Levelized Cost of Electricity (LCOE) (USD/kWh) [108,109,110] | Solar Input Contribution (%) [103,105,109] | Biomass Consumption (Ton/Day) [106,109] |

|---|---|---|---|---|---|

| Solar-Only ORC System | 15–21 | 2.5–4.0 | 0.12–0.15 | 100% | N/A |

| Biomass-Only ORC System | 18–25 | 3.0–5.0 | 0.10–0.14 | N/A | 25–35 |

| Hybrid Solar–Biomass ORC | 21–31 | 4.0–7.0 | 0.07–0.10 | 50–70% | 15–25 |

| System Configuration | LCOE (USD/kWh) [25,28,40,117] | Capital Costs (USD/kW) [31,37,39,103] | Operational Costs (USD/Year) [21,32,36] | LCOE Reduction in Hybrid (%) [21,117] |

|---|---|---|---|---|

| Solar-Only ORC System | 0.12–0.15 | 2500–4000 | 80,000–120,000 | N/A |

| Biomass-Only ORC System | 0.10–0.14 | 2000–3500 | 70,000–100,000 | N/A |

| Hybrid Solar–Biomass ORC | 0.07–0.10 | 3000–4500 | 90,000–110,000 | 25–33% |

| System Configuration | Carbon Emissions (g CO2/kWh) [31,37,40,59] | Biomass Consumption Reduction (%) [25,28,39] | CO2 Emission Reduction Compared to Conventional Systems (%) [21,36,38] |

|---|---|---|---|

| Solar-Only ORC System | 0–5 [31,59] | N/A | 90–100% [36,38] |

| Biomass-Only ORC System | 150–250 [37,40] | N/A | 40–50% [21,36] |

| Hybrid Solar–Biomass ORC | 50–150 [37,40] | 33% [25,28] | 60–70% [21,38] |

| Geographic Region | Solar Irradiation (kWh/m2/Day) [24,31] | Biomass Availability (Ton/Day) [37,61] | Biomass Consumption Rate (Ton/Day) [25,28] | Solar Usage Efficiency (%) [38,39] | Hybrid System Efficiency (%) [21,36] |

|---|---|---|---|---|---|

| Southern Europe | 4.5–5.5 | 50–100 | 10–20 | 50–60 | 20–28 |

| Northern Europe | 3.0–4.0 | 30–50 | 15–25 | 35–45 | 18–22 |

| South Asia | 5.0–6.5 | 100–150 | 25–35 | 60–70 | 27–32 |

| North America (Southwest) | 6.0–7.0 | 200–250 | 30–40 | 65–75 | 28–35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alvi, J.Z.; Guan, Z.; Imran, M. Thermoeconomic Evaluation and Sustainability Insights of Hybrid Solar–Biomass Powered Organic Rankine Cycle Systems: A Comprehensive Review. Biomass 2024, 4, 1092-1121. https://doi.org/10.3390/biomass4040061

Alvi JZ, Guan Z, Imran M. Thermoeconomic Evaluation and Sustainability Insights of Hybrid Solar–Biomass Powered Organic Rankine Cycle Systems: A Comprehensive Review. Biomass. 2024; 4(4):1092-1121. https://doi.org/10.3390/biomass4040061

Chicago/Turabian StyleAlvi, Jahan Zeb, Zhengjun Guan, and Muhammad Imran. 2024. "Thermoeconomic Evaluation and Sustainability Insights of Hybrid Solar–Biomass Powered Organic Rankine Cycle Systems: A Comprehensive Review" Biomass 4, no. 4: 1092-1121. https://doi.org/10.3390/biomass4040061

APA StyleAlvi, J. Z., Guan, Z., & Imran, M. (2024). Thermoeconomic Evaluation and Sustainability Insights of Hybrid Solar–Biomass Powered Organic Rankine Cycle Systems: A Comprehensive Review. Biomass, 4(4), 1092-1121. https://doi.org/10.3390/biomass4040061