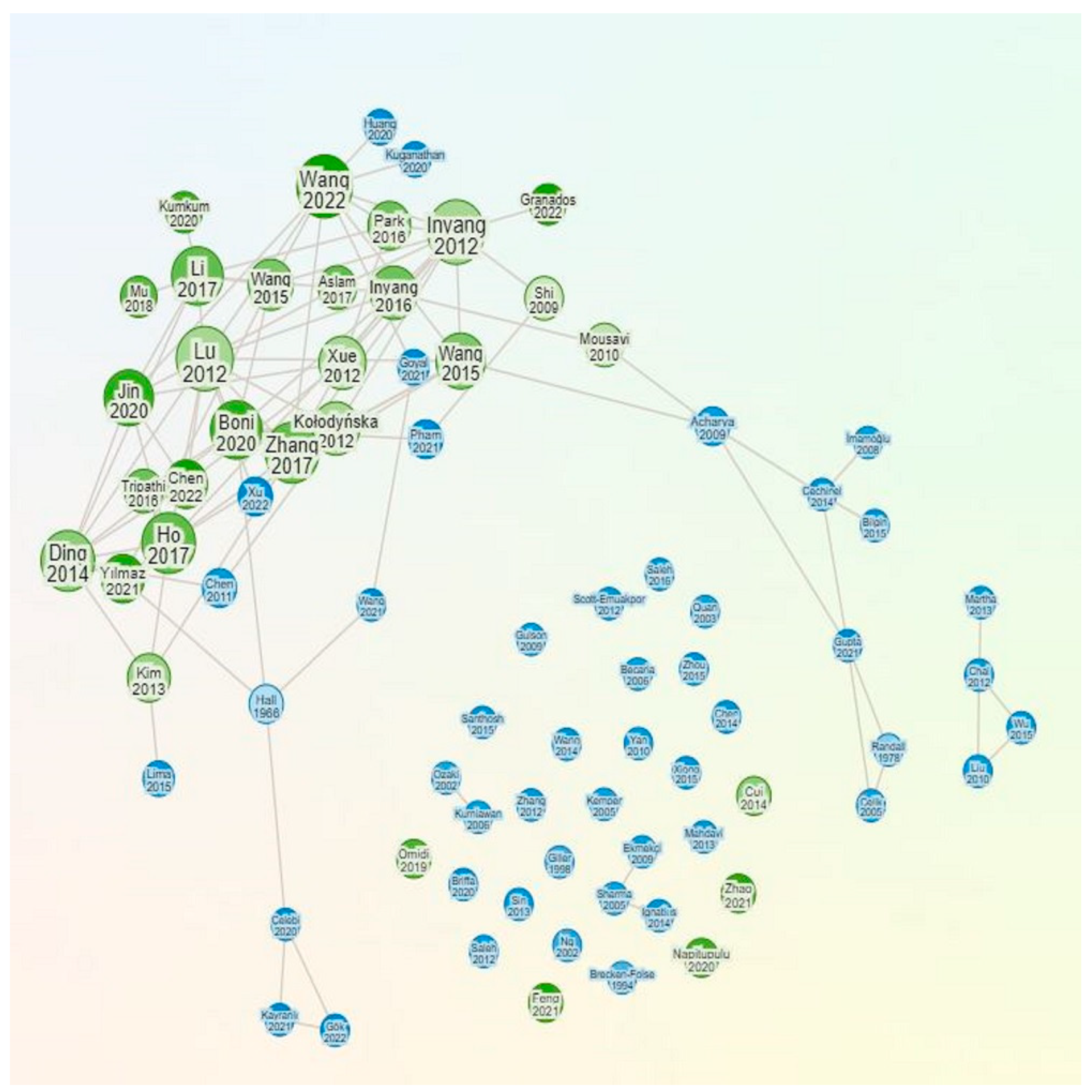

A Review on Biochar as an Adsorbent for Pb(II) Removal from Water

Abstract

1. Introduction

1.1. Biochar

1.2. Pb(II)

2. Pb(II) Removal Using Pristine Biochar

2.1. Feedstock

2.2. Pyrolysis Temperatures/Conditions

2.3. Experimental Method

2.4. Kinetic Modeling

2.5. Isotherm Modeling

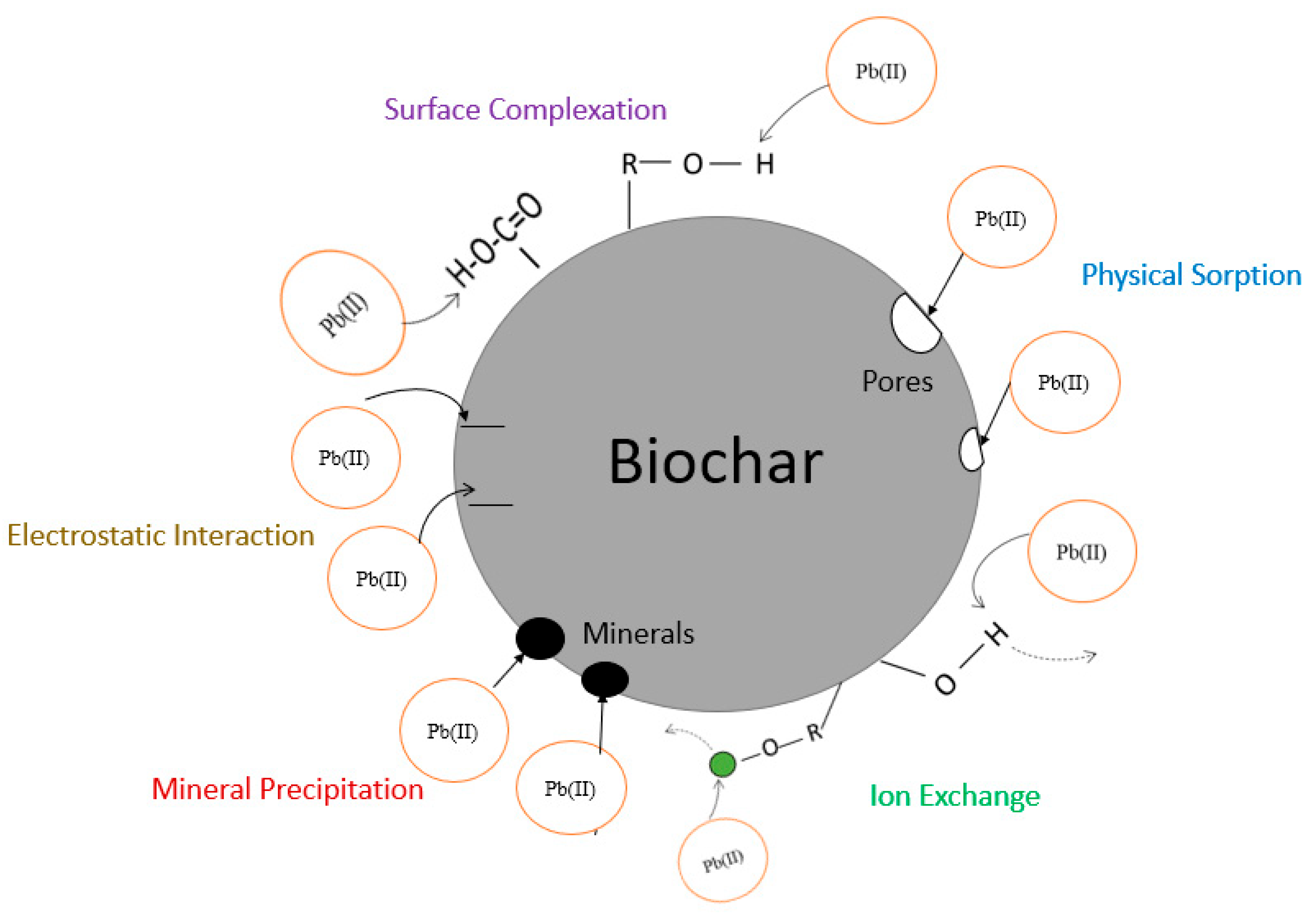

2.6. Sorption Mechanisms

2.6.1. Physical Sorption

2.6.2. Surface Complexation with Functional Groups

2.6.3. Electrostatic Interaction

2.6.4. Mineral Precipitation

2.6.5. Ion Exchange

| Feedstock | Production Method/Pyrolysis Condition | Removal Mechanism/Kinetic Model/Isotherm Model | Maximum Adsoprtion | Key Findings/Notes | Reference |

|---|---|---|---|---|---|

| Carbon Wheat Straw and Natural Straw | 300 °C for 60 min |

| 149.7 mg/g |

| [56] |

| Cinnamon cannabis | 300, 400, and 600 °C for 120 min |

| 135.68–168.05 mg/g |

| [47] |

| Phyllostachys pubescens (PP) | 0–4% oxygen content atmosphere—slow pyrolysis—450 °C and 700–60 min |

| 67.4 mg/g |

| [19] |

| Rice husk Dairy manure | 350 °C for 4 h |

| Not quantified |

| [29] |

| Sesame straw | 700 °C for 4 h |

|

|

| [22] |

| Peanut hull | 450 °C |

| 63.09 mg/g |

| [72] |

|

| This study did not discuss the adsorption mechanism, but the authors guessed the chemisorption processes—precipitation, ion exchange, electrostatic attraction, and surface complexation. However, in this study is unique in a sense that the authors compared lab-made biochar and home-made (temperature uncontrolled) biochar | Not quantified; used % removal |

| [62] |

| 350 °C and 650 °C at 8–9 °C min−1 |

| 44.42 mg/g |

| [57] |

| Grape pomance | 300–700 °C at 10 °C min−1 |

| 134 mg/g | Uniqueness: experiment with low Pb(II) concentration to mimic practical scenarios. | [87] |

| 400–800 °C at 15 °C min−1 |

| 53.96 mg/g |

| [49] |

| 300–600 °C |

| 82.5 mg/g |

| [54] |

| Sugarcane bagasse | 250, 400, 500, and 600 °C at 10 °C min−1 |

| 21 mg/g |

| [95] |

| Sludge | 550 °C for 2 h |

| 30.88 mg/g |

| [96] |

| Wheat straw | 400 °C for 2 h |

| 185.19 mg/g | This study explored the potential of hydroxide complex formation at higher pH levels, although it did not delve into the possibility of metal precipitation as a result of this mechanism. | [85] |

| 600 °C for 2 h |

| 200 mg/g |

| [50] |

| Red fruit peel | 300 °C for 2 h |

| 61.86 mg/g |

| [86] |

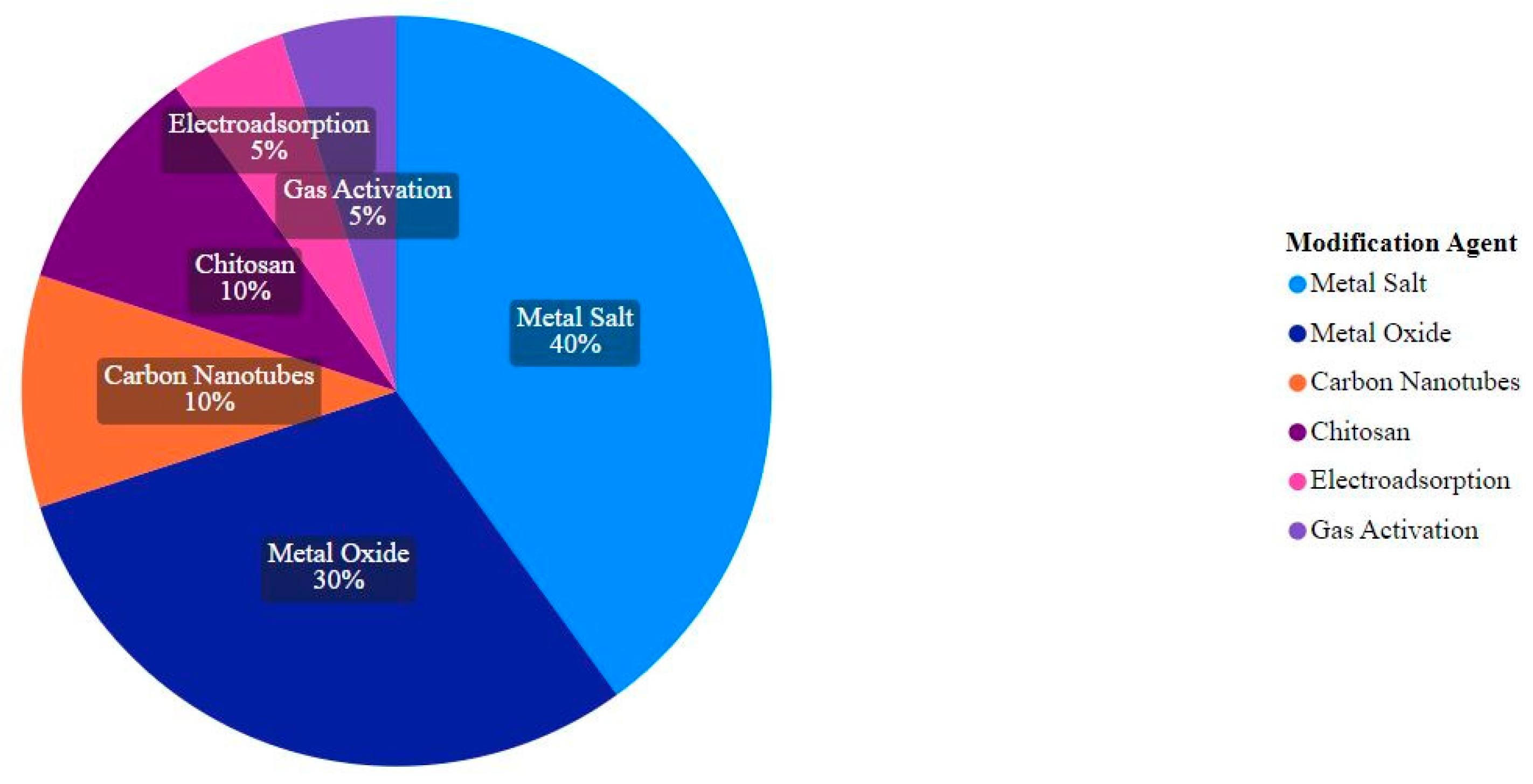

3. Pb(II) Removal by Modified/Functionalized Biochar

| Feedstock | Modifying Agent/Compound | Pre-Pyrolysis/Post-Pyrolysis | Production Method | Sorption Increase | Maximum Adsorption | Removal Mechanism/Kinetic Model/Isotherm Model | Key Findings/Notes | Reference |

|---|---|---|---|---|---|---|---|---|

| Pinewood | Hydrous manganese oxide (HMO) | Post | Feedstock was first converted to biochar by pyrolysis—100 °C for 1 h and then 700 °C for 3 h. Prepared biochar was then modified by manganese nitrate and KMnO4. | 92.50% | Not specified |

| Modification increased the number of hydroxyl groups, decreased pH at point of zero charge (pHPZC), and increased the number of mesopores and macropores. | [97] |

| Coconut shell | MgCl2 | Pre | Feedstock was first impregnated with MgCl2 and then pyrolyzed at 400 °C. | 20 times | 532.28 mg/g |

| Modification increased the OFG content. | [55] |

| Corn straw | MgCl2 | Post | Feedstock was first converted to biochar by pyrolysis—250 °C for 2 h. Prepared biochar was then modified by MgCl2. | More than 2 times | 5.15 mg/g |

| Physical/chemical property changes associated with the modification were not investigated. No comparative analysis based upon the characteristic features were explored. | [101] |

| Swine manure | MnO2 | Post | Feedstock was first converted to biochar by pyrolysis—400 °C for 2 h. Prepared biochar was then modified by KMnO4. | 2 times | 268 mg/g |

| Adsorption was dependent on pH, which is similar to other studies. Modification increased the surface area and pore volume. | [98] |

| Oak wood and Oak bark | Metal salt impregnation followed by alkali (NaOH) treatment | Post | Fe2(SO4)3.nH2O and FeSO4 were used to make Fe2+/Fe3+ SO42−, 400–450 °C. Fast pyrolysis. | 2.5 times | 55.91 mg/g |

| Introduction of iron oxide on the surface of biochar influenced the adsorption process. | [109] |

| Antibiotic residue | CO2 gas activation | During pyrolysis | 300–800 °C for 2 h | 3 times | 454 mg/g | Highest Pb(II) adsorption occurred by the biochar produced at 700 °C | Study focused on increasing the carbon and ash component (carbonate and phosphate) of biochar to improve Pb(II) removal through mineral precipitation. | [105] |

| Lotus leaf | (NH4)2HPO4 (diammonium hydrogen phosphate) | Pre | 600 °C for 1 h | 2 times | 1936.2 mg/g |

| Modified biochar (NP-BC) had -COOH, -NH2, P=O, and -OH, which co-ordinated with Pb(II) to form complexation. | [110] |

| Date seed | Electro-adsorption | Post | Pyrolyzed biochar was used as an electrode—550 °C for 3 h | 21% | 179.64 mg/g |

| Electro-assistance improved adsorption by increasing the surface charge density and bringing ions into closer contact with the biochar. Additionally, the electric current increased the pore structure. | [111] |

| Rice husk | Metal salt and metal oxide: rice husk biochar (BC) ---> magnetic rice husk biochar (FBC) ---> KMnO4-treated magnetic biochar (FMBC) | Pre and post | Pre-pyrolysis (600 °C for 1.5 h) magnetization and post-pyrolysis (600 °C for 0.5 h) KMnO4 activation. | 7 times | 148 mg/g |

| KMnO4 treatment increased OFGs, because KMnO4 oxidized and produced more OFGs, and MnO has a greater affinity for heavy metals (HMs). | [79] |

| Cassava root husk | ZnO Nanoparticles | Post | Pyrolysis (400 °C for 2 h) and wet impregnation. | 28% or 1.39 times | 42.05 mg/g |

| Modification increased the number of -OH, which dropped after adsorption, indicating that precipitation took part in Pb(II) removal. It also increased the -CO- that took part in surface complexation. Modification reduced aromaticity, which is favorable for Pb(II) adsorption. | [107] |

| Sugarcane straw | FeCl3 | Post | Pyrolysis: 350 and 750 °C at 5 °C min−1. Modification: wet impregnation. | 2–11% | 92.81 mg/g |

| Modification increased the specific surface area and exposed functional groups. | [102] |

| FeCl3 | Post | Pyrolysis: 600 °C for 30 min. Modification: wet impregnation. | 461% | 179 mg/g |

| Magnetization increased sorption by improving the structure of biochar. Fe oxides promoted stronger chemical bonds with Pb(II). Fe oxides increased CEC value significantly, and CEC is an important feature for Pb(II) adsorption. | [103] |

| Raw cypress sawdust (RCS) | MgCl2 | Pre | 600 °C for 1 h | 7.4 times | 202.2 mg/g |

| Modification increased the surface area, amount of OFGs, and the CEC associated with Mg ions. | [112] |

| Commercial biochar | FeSO4 and FeCl3 | Post | Pyrolysis: 500 °C. Magnetization: chemical precipitation and wet impregnation. | Modification decreased adsorption | 35 mg/g |

| This study showed a decrease in adsorption capacity. | [89] |

| Pinewood | MnCl2.4H2O and birnessite (KMnO4 precipitate) | Pre and post | Pyrolysis in the presence of MnCl2.4H2O (MPB): 600 °C for 1 h. Impregnated with birnessite via precipitation following pyrolysis (BPB). | 2–20 times | 17 mg/g |

| The modification process using MnCl2 resulted in an increase in the surface area and pore volume, potentially due to the formation of Mn-bearing minerals. | [113] |

| Silkworm excrement | Chitosan combined with pyromellitic dianhydride (GBC) | Post |

| 12% | 9.54 mg/g |

| Modification increased the surface area pore volume, and OFG content. | [114] |

| Hickory wood | NaOH | Post/during | Wet impregnation, followed by pyrolysis at 600 °C for 2 h. | 4.7 times | 19.1 mg/g |

| Modification promoted more adsorption sites and increased OFGs. | [58] |

| Rice straw | KMnO4 | Post | Wet impregnation. | 2.5 times | 304.5 mg/g |

| Modification increased OFGs, surface area, and pore volume. | [99] |

| Hickory wood | KMnO4 | Pre | Wet impregnation. | 3.5 times | 153.1 mg/g |

| Modification provided more binding sites and introduced more OFGs. | [115] |

| Hickory wood and sugarcane bagasse | Carbon nanotubes (CNT) with the aid of a surfactant | Pre | Pyrolysis: 600 °C for 1 h and wet impregnation of surfactant and CNT. | 25–28% | 15 mg/g |

| Sodium dodecylbenzenesulfonate (SDBS), the surfactant, played a crucial role in preventing the aggregation of CNTs and promoting their distribution and stabilization on the BC surface. This resulted in the provision of binding sites for Pb(II) adsorption through CNT nanoparticle interactions. | [116] |

| Chitosan | Post | Feedstock was first converted to biochar by pyrolysis—600 °C for 2 h. Prepared biochar was then modified by chitosan. | 5 times | 71.5 mg/g |

| Chitosan enhanced the adsorption process by providing binding sites. | [106] |

| Corncob | MgCl2 | Pre | 450 °C for 1 h | 9.34 times | 526.20 mg/g |

| Modification increased the crystalline CaCO3 and OFGs, as well as the surface area and pore volume. | [100] |

| Peanut shell | MnSO4 and KHCO3 | Pre and post | Pyrolysis: 600 °C for 1 h. Wet impregnation. | 225 mg/g |

| Although MnO is used to provide additional adsorption advantages, its micropores can sometimes hinder the diffusion of heavy metals within them. To overcome this limitation, KHCO3 was added to increase the pore channel of biochar. This facilitated the adsorption of Pb(II) by the formation of a new composite, HMO-K-BC. | [104] |

4. Regeneration/Desorption Study

5. Limitation of Studies and Future Scope of Work for Using Biochar as an Adsorbent

6. Conclusions and Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science, Technology and Implementation; Routledge: Oxfordshire, UK, 2015. [Google Scholar] [CrossRef]

- Hornung, A.; Stenzel, F.; Grunwald, J. Biochar—Just a Black Matter Is Not Enough. Biomass Convers. Biorefinery 2021, 1–12. [Google Scholar] [CrossRef]

- Woolf, D.; Lehmann, J.; Cowie, A.; Cayuela, M.L.; Whitman, T.; Sohi, S. Biochar for Climate Change Mitigation: Navigating from Science to Evidence-Based Policy. Nat. Geosci. 2018, 219–248. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew. Sustain. Energy Rev. 2015, 45, 359–378. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Mishra, R.K.; Misra, M.; Mohanty, A.K. Value-Added Bio-carbon Production through the Slow Pyrolysis of Waste Bio-oil: Fundamental Studies on Their Structure-Property-Processing Co-relation. ACS Omega 2022, 7, 1612–1627. [Google Scholar] [CrossRef] [PubMed]

- Cheah, S.; Jablonski, W.S.; Olstad, J.L.; Carpenter, D.L.; Barthelemy, K.D.; Robichaud, D.J.; Andrews, J.C.; Black, S.K.; Oddo, M.D.; Westover, T.L. Effects of thermal pretreatment and catalyst on biomass gasification efficiency and syngas composition. Green Chem. 2016, 18, 6291–6304. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Kim, K.-H. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Guo, M. Quality variations of poultry litter biochar generated at different pyrolysis temperatures. J. Anal. Appl. Pyrolysis 2012, 94, 138–145. [Google Scholar] [CrossRef]

- Basic Principles of Biochar Production. Available online: https://biochar.international/guides/ (accessed on 17 February 2024).

- Cárdenas-Aguiar, E.; Gascó, G.; Paz-Ferreiro, J.; Méndez, A. The effect of biochar and compost from urban organic waste on plant biomass and properties of an artificially copper polluted soil. Int. Biodeterior. Biodegrad. 2017, 124, 223–232. [Google Scholar] [CrossRef]

- Rafiq, M.K.; Bachmann, R.T.; Rafiq, M.T.; Shang, Z.; Joseph, S.; Long, R. Influence of Pyrolysis Temperature on Physico-Chemical Properties of Corn Stover (Zea mays L.) Biochar and Feasibility for Carbon Capture and Energy Balance. PLoS ONE 2016, 11, e0156894. [Google Scholar] [CrossRef]

- Li, X.; Shen, Q.; Zhang, D.; Mei, X.; Ran, W.; Xu, Y.; Yu, G. Functional Groups Determine Biochar Properties (pH and EC) as Studied by Two-Dimensional 13C NMR Correlation Spectroscopy. PLoS ONE 2013, 8, e65949. [Google Scholar] [CrossRef]

- Ippolito, J.A.; Laird, D.A.; Busscher, W.J. Environmental benefits of biochar. J. Environ. Qual. 2012, 41, 967–972. [Google Scholar] [CrossRef] [PubMed]

- Panwar, N.L.; Pawar, A.; Salvi, B.L. Comprehensive review on production and utilization of biochar. SN Appl. Sci. 2019, 1, 1–19. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Li, N.; Tao, J.; Yan, B.; Cui, X.; Chen, G. Adsorption of Lead from Aqueous Solution by Biochar: A Review. Clean Technol. 2022, 4, 629–652. [Google Scholar] [CrossRef]

- Zhang, C.; Shan, B.; Tang, W.; Zhu, Y. Comparison of cadmium and lead sorption by Phyllostachys pubescens biochar produced under a low-oxygen pyrolysis atmosphere. Bioresour. Technol. 2017, 238, 352–360. [Google Scholar] [CrossRef]

- Qiu, M.; Liu, L.; Ling, Q.; Cai, Y.; Yu, S.; Wang, S.; Fu, D.; Hu, B.; Wang, X. Biochar for the removal of contaminants from soil and water: A review. Biochar 2022, 4, 19. [Google Scholar] [CrossRef]

- Inyang, M.; Gao, B.; Yao, Y.; Xue, Y.; Zimmerman, A.R.; Mosa, A.; Pullammanappallil, P.; Kim, K.-H.; Ok, Y.S.; Cao, X. A review of biochar as a low-cost adsorbent for aqueous heavy metal removal. Crit. Rev. Environ. Sci. Technol. 2016, 46, 406–433. [Google Scholar] [CrossRef]

- Park, J.H.; Ok, Y.S.; Kim, S.H.; Cho, J.S.; Heo, J.S.; Delaune, R.D.; Seo, D.C. Competitive adsorption of heavy metals onto sesame straw biochar in aqueous solutions. Chemosphere 2016, 142, 77–83. [Google Scholar] [CrossRef]

- Shi, T.; Jia, S.; Chen, Y.; Wen, Y.; Du, C.; Du, C.; Guo, H.; Wang, Z. Adsorption of Pb(II), Cr(III), Cu(II), Cd(II) and Ni(II) onto a vanadium mine tailing from aqueous solution. J. Hazard. Mater. 2009, 169, 838–846. [Google Scholar] [CrossRef] [PubMed]

- Scott, H.L.; Ponsonby, D.; Atkinson, C.J. Biochar: An improver of nutrient and soil water availability-what is the evidence? Cab Rev. Perspect. Agric. Vet. Sci. Nutr. Nat. Resour. 2014, 9, 1–19. [Google Scholar] [CrossRef]

- Jindo, K.; Mizumoto, H.; Sawada, Y.; Sánchez-Monedero, M.Á.; Sonoki, T. Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences 2014, 11, 6613–6621. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science and Technology; Routledge: London, UK, 2009; pp. 321–332. [Google Scholar] [CrossRef]

- Lu, T.; Yuan, H.; Wang, Y.; Huang, H.; Chen, Y. Characteristic of heavy metals in biochar derived from sewage sludge. J. Mater. Cycles Waste Manag. 2016, 18, 725–733. [Google Scholar] [CrossRef]

- Singh, B.P.; Hatton, B.J.; Singh, B.; Cowie, A.L.; Kathuria, A. Influence of biochars on nitrous oxide emission and nitrogen leaching from two contrasting soils. J. Environ. Qual. 2010, 39, 1224–1235. [Google Scholar] [CrossRef]

- Xu, X.; Cao, X.; Zhao, L. Comparison of rice husk- and dairy manure-derived biochars for simultaneously removing heavy metals from aqueous solutions: Role of mineral components in biochars. Chemosphere 2013, 92, 955–961. [Google Scholar] [CrossRef]

- Collin, M.S.; Venkatraman, S.K.; Vijayakumar, N.; Kanimozhi, V.; Arbaaz, S.M.; Stacey, R.S.; Anusha, J.; Choudhary, R.; Lvov, V.; Tovar, G.I.; et al. Bioaccumulation of lead (Pb) and its effects on human: A review. J. Hazard. Mater. Adv. 2022, 7, 100094. [Google Scholar] [CrossRef]

- Rabin, R. The lead industry and lead water pipes “A Modest Campaign”. Am. J. Public Health 2008, 98, 1584–1592. [Google Scholar] [CrossRef]

- Wani, L.; Ara, A.; Usmani, J.A. Lead toxicity: A review. Interdiscip. Toxicol. 2015, 8, 55–64. [Google Scholar] [CrossRef] [PubMed]

- States with the Most Lead Pipes|Best States|U.S. News. Available online: https://www.usnews.com/news/best-states/articles/states-with-the-most-lead-pipes (accessed on 30 July 2023).

- U.S. Environmental Protection Agency. Basic Information about Lead in Drinking Water. Available online: https://www.epa.gov/ground-water-and-drinking-water/basic-information-about-lead-drinking-water (accessed on 30 July 2023).

- How Can Lead Get into My Drinking Water?|US EPA. Available online: https://www.epa.gov/lead/how-can-lead-get-my-drinking-water (accessed on 30 July 2023).

- Health Effects of Lead Exposure. 2022. Available online: https://www.cdc.gov/nceh/lead/prevention/health-effects.htm (accessed on 10 February 2024).

- Markowitz, M.; Knollmann-Ritschel, B.E.C. Educational Case: Lead Poisoning. Acad. Pathol. 2017, 4, 2374289517700160. [Google Scholar] [CrossRef]

- Learn about Lead|US EPA. Available online: https://www.epa.gov/lead/learn-about-lead (accessed on 30 July 2023).

- Navas-Acien, A.; Guallar, E.; Silbergeld, E.K.; Rothenberg, S.J. Lead exposure and cardiovascular disease—A systematic review. Environ. Health Perspect. 2007, 115, 472–482. [Google Scholar] [CrossRef]

- Florea, A.M.; Taban, J.; Varghese, E.; Alost, B.T.; Moreno, S.; Büsselberg, D. Lead (Pb2+) neurotoxicity: Ion-mimicry with calcium (Ca2+) impairs synaptic transmission. A review with animated illustrations of the pre- and post-synaptic effects of lead. J. Local Glob. Health Sci. 2013, 2013, 4. [Google Scholar] [CrossRef]

- Biden-Harris Administration Announces New Get the Lead Out Initiative; USEPA: Washington, DC, USA, 2023.

- WHO. Lead in Drinking-Water. 2003. Available online: https://iris.who.int/handle/10665/75370 (accessed on 11 February 2024).

- Komkiene, J.; Baltrenaite, E. Biochar as adsorbent for removal of heavy metal ions [Cadmium(II), Copper(II), Lead(II), Zinc(II)] from aqueous phase. Int. J. Environ. Sci. Technol. 2016, 13, 471–482. [Google Scholar] [CrossRef]

- Qu, J.; Zhang, B.; Tong, H.; Liu, Y.; Wang, S.; Wei, S.; Wang, L.; Wang, Y.; Zhang, Y. High-efficiency decontamination of Pb(II) and tetracycline in contaminated water using ball-milled magnetic bone derived biochar. J. Clean. Prod. 2023, 385, 135683. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, B.; Wu, P.; Feng, Q.; Chen, M.; Zhang, X.; Wang, S. Calcium alginate-nZVI-biochar for removal of Pb/Zn/Cd in water: Insights into governing mechanisms and performance. Sci. Total Environ. 2023, 894, 164810. [Google Scholar] [CrossRef]

- Ahmed, W.; Mehmood, S.; Mahmood, M.; Ali, S.; Shakoor, A.; Núñez-Delgado, A.; Asghar, R.M.; Zhao, H.; Liu, W.; Li, W. Adsorption of Pb(II) from wastewater using a red mud modified rice-straw biochar: Influencing factors and reusability. Environ. Pollut. 2023, 326, 121405. [Google Scholar] [CrossRef]

- Omidi, A.H.; Cheraghi, M.; Lorestani, B.; Sobhanardakani, S.; Jafari, A. Biochar obtained from cinnamon and cannabis as effective adsorbents for removal of lead ions from water. Environ. Sci. Pollut. Res. 2019, 26, 27905–27914. [Google Scholar] [CrossRef] [PubMed]

- Saravanakumar, K.; Sathyamoorthy, M.; Prasad, D.M.; Senthilkumar, R.; Prasad, B.S. Prasad Continuous removal of cadmium and lead ions by biochar derived from date seeds in a packed column reactor. Desalination Water Treat. 2022, 250, 126–135. [Google Scholar] [CrossRef]

- Ho, S.H.; Yang, Z.K.; Nagarajan, D.; Chang, J.S.; Ren, N.Q. High-efficiency removal of lead from wastewater by biochar derived from anaerobic digestion sludge. Bioresour. Technol. 2017, 246, 142–149. [Google Scholar] [CrossRef]

- Inyang, M.; Gao, B.; Yao, Y.; Xue, Y.; Zimmerman, A.R.; Pullammanappallil, P.; Cao, X. Removal of heavy metals from aqueous solution by biochars derived from anaerobically digested biomass. Bioresour. Technol. 2012, 110, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, H.Z.; Hosseynifar, A.; Jahed, V.; Dehghani, S.A.M. Removal of lead from aqueous solution using waste tire rubber ash as an adsorbent. Braz. J. Chem. Eng. 2010, 27, 79–87. [Google Scholar] [CrossRef]

- Mohan, D.; Singh, P.; Sarswat, A.; Steele, P.H.; Pittman, C.U. Lead sorptive removal using magnetic and nonmagnetic fast pyrolysis energy cane biochars. J. Colloid Interface Sci. 2015, 448, 238–250. [Google Scholar] [CrossRef] [PubMed]

- Uchimiya, M.; Lima, I.M.; Klasson, K.T.; Chang, S.; Wartelle, L.H.; Rodgers, J.E. Immobilization of Heavy Metal Ions (CuII, CdII, NiII, and PbII) by Broiler Litter-Derived Biochars in Water and Soil. J. Agric. Food Chem. 2010, 58, 5538–5544. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liu, G.; Zheng, H.; Li, F.; Ngo, H.H.; Guo, W.; Liu, C.; Chen, L.; Xing, B. Investigating the mechanisms of biochar’s removal of lead from solution. Bioresour. Technol. 2015, 177, 308–317. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wang, T.; Wang, J.; Zhang, Y.; Pan, W.P. A novel modified method for the efficient removal of Pb and Cd from wastewater by biochar: Enhanced the ion exchange and precipitation capacity. Sci. Total Environ. 2020, 754, 142150. [Google Scholar] [CrossRef] [PubMed]

- Mu, R.M.; Wang, M.X.; Bu, Q.W.; Liu, D.; Zhao, Y.L. Adsorption of Pb(II) from aqueous solutions by wheat straw biochar. IOP Conf. Ser. Earth Environ. 2018, 191, 012041. [Google Scholar] [CrossRef]

- Aslam, Z.; Khalid, M.; Naveed, M.; Shahid, M.A.; Aon, M. Evaluation of Green Waste and Popular Twigs Biochar Produced at Low and High Pyrolytic Temperature for Efficient Removal of Metals from Water. Water. Air. Soil Pollut. 2017, 228, 432. [Google Scholar] [CrossRef]

- Ding, Z.; Ok, Y.S.; Hu, X.; Wan, Y.; Wang, S.; Gao, B. Removal of lead, copper, cadmium, zinc, and nickel from aqueous solutions by alkali-modified biochar: Batch and column tests. J. Ind. Eng. Chem. 2016, 33, 239–245. [Google Scholar] [CrossRef]

- Xue, Y.; Gao, B.; Yao, Y.; Inyang, M.; Zhang, M.; Zimmerman, A.R.; Ro, K.S. Hydrogen peroxide modification enhances the ability of biochar (hydrochar) produced from hydrothermal carbonization of peanut hull to remove aqueous heavy metals: Batch and column tests. Chem. Eng. J. 2012, 200, 673–680. [Google Scholar] [CrossRef]

- Saleh, T.A. Surface Science of Adsorbents and Nanoadsorbents. In Interface Science and Technology; Academic Press: Cambridge, MA, USA, 2022. [Google Scholar] [CrossRef]

- Largitte, L.; Pasquier, R.J. Pasquier A review of the kinetics adsorption models and their application to the adsorption of lead by an activated carbon. Chem. Eng. Res. Des. 2016, 109, 495–504. [Google Scholar] [CrossRef]

- Granados, P.; Mireles, S.; Pereira, E.; Cheng, C.-L.; Kang, J. Effects of Biochar Production Methods and Biomass Types on Lead Removal from Aqueous Solution. Appl. Sci. 2022, 12, 5040. [Google Scholar] [CrossRef]

- Lagergren, S. About the theory of so-called adsorption of soluble substances. K. Sven. Vetenskapsakademiens Handl. 1898, 24, 1–39. [Google Scholar]

- Ho, Y.S.; McKay, G. A Comparison of Chemisorption Kinetic Models Applied to Pollutant Removal on Various Sorbents. Process Saf. Environ. Prot. 1998, 76, 332–340. [Google Scholar] [CrossRef]

- Kajjumba, G.W.; Emik, S.; Öngen, A.; Özcan, H.K.; Aydın, S. Modelling of Adsorption Kinetic Processes—Errors, Theory and Application. In Advanced Sorption Process Applications; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Kołodyńska, D.; Wnetrzak, R.; Leahy, J.J.; Hayes, M.H.B.; Kwapinski, W.; Hubicki, Z. Kinetic and adsorptive characterization of biochar in metal ions removal. Chem. Eng. J. 2012, 197, 295–305. [Google Scholar] [CrossRef]

- Gwenzi, W.; Chaukura, N.; Noubactep, C.; Mukome, F.N. Mukome Biochar-based water treatment systems as a potential low-cost and sustainable technology for clean water provision. J. Environ. Manag. 2017, 197, 732–749. [Google Scholar] [CrossRef]

- Rosales, E.; Meijide, J.; Pazos, M.; Sanromán, M.Á. Challenges and recent advances in biochar as low-cost biosorbent: From batch assays to continuous-flow systems. Bioresour. Technol. 2017, 246, 176–192. [Google Scholar] [CrossRef] [PubMed]

- Boni, M.R.; Chiavola, A.; Marzeddu, S. Remediation of Lead-Contaminated Water by Virgin Coniferous Wood Biochar Adsorbent: Batch and Column Application. Water. Air. Soil Pollut. 2020, 231, 1–16. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, X.; Fan, G.; Wang, X.; Li, H.; Li, H.; Xu, X. Enhanced adsorption of Pb(II) by phosphorus-modified chicken manure and Chinese medicine residue co-pyrolysis biochar. Microsc. Res. Tech. 2022, 85, 3589–3599. [Google Scholar] [CrossRef]

- Yılmaz, C.; Güzel, F. Performance of wild plants-derived biochar in the remediation of water contaminated with lead: Sorption optimization, kinetics, equilibrium, thermodynamics and reusability studies. Int. J. Phytoremediation 2021, 24, 177–186. [Google Scholar] [CrossRef]

- Cui, L.; Yan, J.; Li, L.; Quan, G.; Ding, C.; Chen, T.; Yin, C.; Gao, J.; Hussain, Q. Does Biochar Alter the Speciation of Cd and Pb in Aqueous Solution. Bioresources 2014, 10, 88–104. [Google Scholar] [CrossRef]

- Kalam, S.; Abu-Khamsin, S.A.; Mahmoud, M.; Kamal, M.S.; Patil, S. Surfactant Adsorption Isotherms: A Review. ACS Omega 2021, 6, 32342–32348. [Google Scholar] [CrossRef]

- Fahmi, A.H.; Jol, H.; Singh, D. Physical modification of biochar to expose the inner pores and their functional groups to enhance lead adsorption. RSC Adv. 2018, 8, 38270–38280. [Google Scholar] [CrossRef]

- Chatterjee, A.; Abraham, J. Desorption of heavy metals from metal loaded sorbents and e-wastes: A review. Biotechnol. Lett. 2019, 41, 319–333. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, A.; Patra, B.R.; Podder, J.; Dalai, A.K. Dalai Synthesis of Biochar From Lignocellulosic Biomass for Diverse Industrial Applications and Energy Harvesting: Effects of Pyrolysis Conditions on the Physicochemical Properties of Biochar. Front. Mater. 2022, 9, 870184. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U., Jr.; Bricka, M.; Smith, F.; Yancey, B.; Mohammad, J.; Steele, P.H.; Alexandre-Franco, M.F.; Gómez-Serrano, V.; Gong, H. Sorption of arsenic, cadmium, and lead by chars produced from fast pyrolysis of wood and bark during bio-oil production. J. Colloid Interface Sci. 2007, 310, 57–73. [Google Scholar] [CrossRef] [PubMed]

- Conz, R.F.; Abbruzzini, T.F.; Andrade, C.D.; Milori, D.M.; Cerri, C.E. Effect of Pyrolysis Temperature and Feedstock Type on Agricultural Properties and Stability of Biochars. Agric. Sci. 2017, 8, 914–933. [Google Scholar] [CrossRef]

- Sun, C.; Chen, T.; Huang, Q.; Wang, J.; Wang, J.; Wang, J.; Lu, S.; Yan, J. Enhanced adsorption for Pb(II) and Cd(II) of magnetic rice husk biochar by KMnO 4 modification. Environ. Sci. Pollut. Res. 2019, 26, 8902–8913. [Google Scholar] [CrossRef]

- Major, J.; Steiner, C.; Downie, A.; Lehmann, J. Biochar Effects on Nutrient Leaching. In Biochar for Environmental Management; Routledge: London, UK, 2012; pp. 303–320. [Google Scholar]

- Muoghalu, C.C.; Owusu, P.A.; Lebu, S.; Nakagiri, A.; Semiyaga, S.; Iorhemen, O.T.; Manga, M. Biochar as a novel technology for treatment of onsite domestic wastewater: A critical review. Front. Environ. Sci. 2023, 11, 1095920. [Google Scholar] [CrossRef]

- Jin, J.; Li, Y.; Zhang, J.; Wu, S.; Cao, Y.; Liang, P.; Zhang, J.; Wong, M.H.; Wang, M.; Shan, S.; et al. Influence of pyrolysis temperature on properties and environmental safety of heavy metals in biochars derived from municipal sewage sludge. J. Hazard. Mater. 2016, 320, 417–426. [Google Scholar] [CrossRef]

- Li, H.; Dong, X.; da Silva, E.B.; de Oliveira, L.M.; Chen, Y.; Ma, L.Q. Mechanisms of metal sorption by biochars: Biochar characteristics and modifications. Chemosphere 2017, 178, 466–478. [Google Scholar] [CrossRef]

- Cao, X.; Ma, L.; Liang, Y.; Gao, B.; Harris, W. Simultaneous Immobilization of Lead and Atrazine in Contaminated Soils Using Dairy-Manure Biochar. Environ. Sci. Technol. 2011, 45, 4884–4889. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, Y.; Xu, Z.; Yu, Z.; Yu, Z. Removal mechanisms of Cd(II) and Pb(II) from aqueous solutions using straw biochar: Batch study, Raman and X-ray photoelectron spectroscopy techniques. Desalination Water Treat. 2021, 220, 199–210. [Google Scholar] [CrossRef]

- Napitupulu, M.; Walanda, D.K.; Simatupang, M. Utilization of red fruit’s peel (freycinetia arborea gaudich) as biochar for lead (Pb) adsorption. J. Phys. Conf. Ser. 2020, 1434, 012033. [Google Scholar] [CrossRef]

- Jin, Q.; Wang, Z.; Feng, Y.; Kim, Y.T.; Stewart, A.C.; O’Keefe, S.F.; Neilson, A.P.; He, Z.; Huang, H. Grape pomace and its secondary waste management: Biochar production for a broad range of lead (Pb) removal from water. Environ. Res. 2020, 186, 109442. [Google Scholar] [CrossRef] [PubMed]

- Keiluweit, M.; Kleber, M. Molecular-Level Interactions in Soils and Sediments: The Role of Aromatic π-Systems. Environ. Sci. Technol. 2009, 43, 3421–3429. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Sani, B.; Mrozik, W.; Obst, M.; Beckingham, B.; Karapanagioti, H.K.; Werner, D. Magnetite Impregnation Effects on the Sorbent Properties of Activated Carbons and Biochars. Water Res. 2015, 70, 394–403. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.; Chen, M. Progress in the preparation and application of modified biochar for improved contaminant removal from water and wastewater. Bioresour. Technol. 2016, 214, 836–851. [Google Scholar] [CrossRef]

- Cao, X.; Harris, W.G. Properties of dairy-manure-derived biochar pertinent to its potential use in remediation. Bioresour. Technol. 2010, 101, 5222–5228. [Google Scholar] [CrossRef]

- Hassan, M.; Naidu, R.; Du, J.; Liu, Q.; Liu, Y.; Liu, Y.P.; Qi, F. Critical review of magnetic biosorbents: Their preparation, application, and regeneration for wastewater treatment. Sci. Total Environ. 2020, 702, 134893. [Google Scholar] [CrossRef]

- Sayyadian, K.; Moezzi, A.; Gholami, A.; Panahpour, E.; Mohsenifar, K. Ohsenifar Effect of Biochar on Cadmium, Nickel and Lead Uptake and Translocation in Maize Irrigated with Heavy Metal Contaminated Water. Appl. Ecol. Environ. Res. 2019, 17, 969–982. [Google Scholar] [CrossRef]

- Duku, M.H.; Gu, S.; Hagan, E.B. Biochar production potential in Ghana—A review. Renew. Sustain. Energy Rev. 2011, 15, 3539–3551. [Google Scholar] [CrossRef]

- Ding, W.; Dong, X.; Ime, I.M.; Gao, B.; Ma, L.Q. Pyrolytic temperatures impact lead sorption mechanisms by bagasse biochars. Chemosphere 2014, 105, 68–74. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, W.; Yang, Y.; Huang, X.; Wang, S.; Qiu, R. Relative distribution of Pb2+ sorption mechanisms by sludge-derived biochar. Water Res. 2012, 46, 854–862. [Google Scholar] [CrossRef]

- Wang, M.C.; Sheng, G.D.; Qiu, Y.P. A novel manganese-oxide/biochar composite for efficient removal of lead(II) from aqueous solutions. Int. J. Environ. Sci. Technol. 2015, 12, 1719–1726. [Google Scholar] [CrossRef]

- Liang, J.; Li, X.; Yu, Z.; Zeng, G.; Luo, Y.; Jiang, L.; Yang, Z.; Qian, Y.; Wu, H. Amorphous MnO2 Modified Biochar Derived from Aerobically Composted Swine Manure for Adsorption of Pb(II) and Cd(II). ACS Sustain. Chem. Eng. 2017, 5, 5049–5058. [Google Scholar] [CrossRef]

- Tan, G.; Wu, Y.; Liu, Y.; Xiao, D. Removal of Pb(II) ions from aqueous solution by manganese oxide coated rice straw biochar A low-cost and highly effective sorbent. J. Taiwan Inst. Chem. Eng. 2018, 84, 85–92. [Google Scholar] [CrossRef]

- Deng, Y.; Li, X.; Ni, F.; Liu, Q.; Yang, Y.; Wang, M.; Ao, T.; Chen, W. Synthesis of Magnesium Modified Biochar for Removing Copper, Lead and Cadmium in Single and Binary Systems from Aqueous Solutions: Adsorption Mechanism. Water 2021, 13, 599. [Google Scholar] [CrossRef]

- Huang, K.; Cai, Y.; Du, Y.; Song, J.; Mao, H.; Xiao, Y.; Wang, Y.; Yang, N.; Wang, H.; Han, L. Adsorption of Pb(II) in Aqueous Solution by the Modified Biochar Derived from Corn Straw with Magnesium Chloride. Nat. Environ. Pollut. Technol. 2020, 19, 1273–1278. [Google Scholar] [CrossRef]

- Soares, M.B.; dos Santos, F.H.; Alleoni, L.R. Iron-Modified Biochar from Sugarcane Straw to Remove Arsenic and Lead from Contaminated Water. Water. Air. Soil Pollut. 2021, 232, 1–13. [Google Scholar] [CrossRef]

- Trakal, L.; Veselská, V.; Šafařík, I.; Vítková, M.; Číhalová, S.; Komárek, M. Lead and cadmium sorption mechanisms on magnetically modified biochars. Bioresour. Technol. 2016, 203, 318–324. [Google Scholar] [CrossRef] [PubMed]

- Wan, S.; Qiu, L.; Tang, G.; Weiyang, C.; Li, Y.; Gao, B.; He, F. Ultrafast sequestration of cadmium and lead from water by manganese oxide supported on a macro-mesoporous biochar. Chem. Eng. J. 2020, 387, 124095. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, X.; Wei, X.; Zhang, S.; Jie, J.; Chen, J.; Ren, Z.J. CO2 Activation Promotes Available Carbonate and Phosphorus of Antibiotic Mycelial Fermentation Residue-Derived Biochar Support for Increased Lead Immobilization. Chem. Eng. J. 2018, 334, 1101–1107. [Google Scholar] [CrossRef]

- Zhou, Y.; Gao, B.; Zimmerman, A.R.; Fang, J.; Sun, Y.; Cao, X. Sorption of heavy metals on chitosan-modified biochars and its biological effects. Chem. Eng. J. 2013, 231, 512–518. [Google Scholar] [CrossRef]

- Tho, P.T.; Van, H.T.; Nguyen, L.H.; Hoang, T.K.; Tran, T.N.; Nguyen, T.T.; Nguyen, T.B.; Le Sy, H.; Tran, Q.B.; Sadeghzadeh, S.M.; et al. Enhanced simultaneous adsorption of As(III), Cd(II), Pb(II) and Cr(VI) ions from aqueous solution using cassava root husk-derived biochar loaded with ZnO nanoparticles. RSC Adv. 2021, 11, 18881–18897. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zhang, S.; Fan, M.; Yuan, Y.; Sun, X.; Wang, D.; Xu, Y. High-efficiency adsorption of various heavy metals by tea residue biochar loaded with nanoscale zero-valent iron. Environ. Prog. 2021, 40, e13706. [Google Scholar] [CrossRef]

- Mohan, D.; Kumar, H.; Sarswat, A.; Alexandre-Franco, M.; Pittman, C.U., Jr. Cadmium and lead remediation using magnetic oak wood and oak bark fast pyrolysis bio-chars. Chem. Eng. J. 2014, 236, 513–528. [Google Scholar] [CrossRef]

- Pan, J.; Deng, H.; Du, Z.; Tian, K.; Zhang, J. Design of nitrogen-phosphorus-doped biochar and its lead adsorption performance. Environ. Sci. Pollut. Res. 2022, 29, 28984–28994. [Google Scholar] [CrossRef]

- Mahdi, Z.; Hanandeh, A.E.; Yu, Q.; Yu, Q.J. Electro-assisted adsorption of heavy metals from aqueous solutions by biochar. Water Sci. Technol. 2020, 81, 801–812. [Google Scholar] [CrossRef]

- Jellali, S.; Diamantopoulos, E.; Haddad, K.; Anane, M.; Durner, W.; Mlayah, A. Lead removal from aqueous solutions by raw sawdust and magnesium pretreated biochar: Experimental investigations and numerical modelling. J. Environ. Manag. 2016, 180, 439–449. [Google Scholar] [CrossRef]

- Wang, S.; Gao, B.; Li, Y.; Mosa, A.; Zimmerman, A.R.; Ma, L.Q.; Harris, W.G.; Migliaccio, K.W. Manganese oxide-modified biochars: Preparation, characterization, and sorption of arsenate and lead. Bioresour. Technol. 2015, 181, 13–17. [Google Scholar] [CrossRef]

- Bian, P.; Liu, Y.; Zheng, X.; Shen, W. Removal and Mechanism of Cadmium, Lead and Copper in Water by Functional Modification of Silkworm Excrement Biochar. Polymers 2022, 14, 2889. [Google Scholar] [CrossRef]

- Wang, H.; Gao, B.; Wang, S.; Fang, J.; Xue, Y.; Yang, K.; Yang, K. Removal of Pb(II), Cu(II), and Cd(II) from aqueous solutions by biochar derived from KMnO4 treated hickory wood. Bioresour. Technol. 2015, 197, 356–362. [Google Scholar] [CrossRef] [PubMed]

- Inyang, M.; Gao, B.; Zimmerman, A.R.; Zhou, Y.; Cao, X. Sorption and cosorption of lead and sulfapyridine on carbon nanotube-modified biochars. Environ. Sci. Pollut. Res. 2015, 22, 1868–1876. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Sireesha, S.; Sreedhar, I.; Patel, C.M.; Anitha, K.L. Latest trends in heavy metal removal from wastewater by biochar based sorbents. J. Water Process Eng. 2020, 38, 101561. [Google Scholar] [CrossRef]

- Rajapaksha, A.U.; Chen, S.S.; Kim, K.-H.; Tsang, D.C.W.; Zhang, M.; Zhang, M.; Vithanage, M.; Mandal, S.; Gao, B.; Bolan, N.; et al. Engineered/designer biochar for contaminant removal/immobilization from soil and water: Potential and implication of biochar modification. Chemosphere 2016, 148, 276–291. [Google Scholar] [CrossRef]

- Sizmur, T.; Fresno, T.; Akgül, G.; Frost, H.; Moreno-Jiménez, E. Biochar modification to enhance sorption of inorganics from water. Bioresour. Technol. 2017, 246, 34–47. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Siyu, F.; Yiqiang, Y.; Vogt, R.D.; Li, T.; Ni, Q.; Wang, C.-H.; Yang, X.; He, Z. Potential mechanisms of cadmium removal from aqueous solution by Canna indica derived biochar. Sci. Total Environ. 2016, 562, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Lata, S.; Singh, P.K.; Samadder, S.R. Regeneration of adsorbents and recovery of heavy metals: A review. Int. J. Environ. Sci. Technol. 2015, 12, 1461–1478. [Google Scholar] [CrossRef]

- Odega, C.A.; Ayodele, O.O.; Ogutuga, S.O.; Anguruwa, G.T.; Adekunle, A.E.; Fakorede, C.O. Potential Application and Regeneration of Bamboo Biochar for Wastewater Treatment: A Review. Adv. Bamboo Sci. 2022, 2, 100012. [Google Scholar] [CrossRef]

- Wang, S.Y.; Tang, Y.K.; Chen, C.; Wu, J.T.; Huang, Z.; Mo, Y.Y.; Zhang, K.X.; Chen, J.B. Regeneration of magnetic biochar derived from eucalyptus leaf residue for lead(II) removal. Bioresour. Technol. 2015, 186, 360–364. [Google Scholar] [CrossRef]

- Alsawy, T.; Rashad, E.; El-Qelish, M.; Mohammed, R.H. A comprehensive review on the chemical regeneration of biochar adsorbent for sustainable wastewater treatment. Npj Clean Water 2022, 5, 29. [Google Scholar] [CrossRef]

- Wang, B.; Gao, B.; Fang, J. Recent advances in engineered biochar productions and applications. Crit. Rev. Environ. Sci. Technol. 2017, 47, 2158–2207. [Google Scholar] [CrossRef]

- Zhao, J. Valorization and reuse of waste modified biomass. In Heavy Metal Biosorption Removal from Aqueous Solutions; Universitat Autònoma de Barcelona: Bellaterra, Spain, 2019. [Google Scholar]

- Zhang, W.; Huang, X.; Jia, Y.; Rees, F.; Tsang, D.C.; Qiu, R.; Wang, H. Metal immobilization by sludge-derived biochar: Roles of mineral oxides and carbonized organic compartment. Environ. Geochem. Health 2017, 39, 379–389. [Google Scholar] [CrossRef]

- Tripathi, M.; Sahu, J.N.; Ganesan, P.B. Effect of process parameters on production of biochar from biomass waste through pyrolysis: A review. Renew. Sustain. Energy Rev. 2016, 55, 467–481. [Google Scholar] [CrossRef]

- Uday, V.; Harikrishnan, P.S.; Deoli, K.; Zitouni, F.; Mahlknecht, J.; Kumar, M. Current Trends in Production, Morphology, and Real-World Environmental Applications of Biochar for the Promotion of Sustainability. Bioresour. Technol. 2022, 359, 127467. [Google Scholar] [CrossRef]

- Oliveira, F.R.; Patel, A.K.; Jin, Y.; Jaisi, D.P.; Adhikari, S.; Lu, H.; Khanal, S.K. Environmental application of biochar: Current status and perspectives. Bioresour. Technol. 2017, 246, 110–122. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumkum, P.; Kumar, S. A Review on Biochar as an Adsorbent for Pb(II) Removal from Water. Biomass 2024, 4, 243-272. https://doi.org/10.3390/biomass4020012

Kumkum P, Kumar S. A Review on Biochar as an Adsorbent for Pb(II) Removal from Water. Biomass. 2024; 4(2):243-272. https://doi.org/10.3390/biomass4020012

Chicago/Turabian StyleKumkum, Pushpita, and Sandeep Kumar. 2024. "A Review on Biochar as an Adsorbent for Pb(II) Removal from Water" Biomass 4, no. 2: 243-272. https://doi.org/10.3390/biomass4020012

APA StyleKumkum, P., & Kumar, S. (2024). A Review on Biochar as an Adsorbent for Pb(II) Removal from Water. Biomass, 4(2), 243-272. https://doi.org/10.3390/biomass4020012