Abstract

In a circular economy, significant emphasis is given to the energetic valorization of agricultural byproducts. Cotton stalks are suitable as a feedstock for the production of bioenergy due to their high energy content. This study’s main focal areas are the economic viability and environmental implications of a system that can gasify or pyrolyze 25,500 tons of cotton stalk annually. To learn more about how gasification and pyrolysis affect the environment, a life cycle assessment (LCA) was conducted. This analysis evaluates the whole value chain and covers all stages of the cotton supply chain from cradle to gate, including production, harvest, transportation, and utilization. According to the findings, both systems exhibit economic viability, generating sizable profits and having quick payback times. However, despite its larger initial expenditure of EUR 2.74 million, the pyrolysis unit ends up being the better option because it has a payback period of 1.58 years, a return on investment (ROI) of 58% and a net present value (NPV) of EUR 21.5 million. Gasification is still an economically attractive alternative with a lower initial investment (EUR 1.81 million), despite having a lower ROI (36%) and NPV (EUR 10.52 million), as well as a longer payback period (2.41 years). However, the environmental implications of the gasification option are generally higher than those of pyrolysis. The impacts of gasification on fossil depletion (FDP) were estimated to be 5.7 million kg oil eq., compared to 5.3 million kg oil eq. for pyrolysis. Similarly, gasification resulted in 41.55 million kg U235 eq. and pyrolysis in 41.5 million kg U235 eq. related to impacts on ionizing radiation (IRP_HE). Other impact categories that emerge as the most important are freshwater eutrophication (FEP) and marine eutrophication (MEP).

Keywords:

cotton stalks; gasification; pyrolysis; feasibility assessment; LCA; environmental impacts 1. Introduction

Global energy demand has been trending upward in recent years, mostly due to industrialization and population increase. If no significant changes are made in relevant laws or technical practices by 2050, the International Energy Outlook for 2021, published by the U.S. Energy Information Agency [1], projects a roughly 50% rise in energy demand. Currently, fossil fuels including oil, coal, and natural gas account for around 85% of the world’s primary energy supply [2]. However, the heavy reliance on fossil fuels for the generation of electricity has had significant negative effects on the environment, including the emission of greenhouse gases (GHGs), pollutants (including NOx and SOx), and the depletion of natural resources [3].

The use of renewable energy sources (RES) is one of many strategies that have been established to lessen the negative effects of extensive fossil fuel consumption. Bioenergy is a RES alternative that now accounts for 10% of the world’s primary energy consumption [2] and is anticipated to be essential in efforts to mitigate climate change and meet emission reduction targets [4]. Utilizing agricultural waste, food waste, forestry byproducts, and municipal waste to produce power, heat, fuels, and other useful products through thermo-chemical and biochemical processes is referred to as “bioenergy” [5].

The use of fossil fuels continues to dominate Greece’s energy mix. Fossil fuels’ combined percentage of the nation’s total energy supply (TES) fell from 91% to 82% between 2011 and 2021. With its contribution varying at an average of 47% during the same period, oil remained the major contributor to TES. As a result of switching from lignite-fired to gas-fired power generation, the lignite proportion in TES dropped from 29% to 8.4% while gas’s share rose from 15% to 27%. The share of solar and wind energy in TES steadily increased from 2.2% to 8.2%, and the contribution of bioenergy and waste grew from 4.8% to 6% [6]. Additionally, there has been a noticeable increase in Greece’s electrification of energy demand. Greek electrical generation saw substantial changes between 2005 and 2021, with lignite-fired power’s share falling from 60% to 10%. This decline was mostly offset by increased gas-fired generation (14% to 41%), as well as the growth of wind (2% to 20%) and solar PV (0.02% to 10%). Hydro generation and electricity imports also played notable but variable roles during this period [7].

Despite growing interest in RES in Greece, the total adoption of bioenergy is still quite limited. The nation has a substantial agricultural production capacity, producing large amounts of residues that are now unused but have the potential to be used to produce bioenergy. Greece stands out as one of the top cotton producers in the world, constantly producing cotton of the highest quality and experiencing a significant rise in cotton exports. Greece produced 900,746 tons of cotton in 2019, placing it second in Europe and 11th worldwide. In total, 291,710 ha was used for cotton cultivation, with irrigated cotton accounting for the majority of that area due to its superior quality [8]. According to the Hellenic Statistical Authority [9], the Region of Thessaly produces more than 304 thousand tons of cotton annually, followed by the Region of Central Macedonia (212 thousand tons) and the Region of Eastern Macedonia and Thrace (184 thousand tons).

The main agricultural waste products produced in Greece during the cotton harvest season, which normally lasts from early October to late November, are cotton stalks. Currently, the majority of farmers either compost the residues on site or burn them in regulated conditions. These procedures aid in the discharge of different particles into the air and soil, as well as GHG emissions. Instead, cotton stalks can be used in a variety of ways. Given their protein and fiber content, using them as animal feed is one alternative. Additionally, cotton stalks can undergo processing to produce valuable products such as cellulose, paper, and particleboard. Another potential application is their utilization as a raw material for the production of biofuels and other biochemicals [10,11]. Cotton stalks can be effectively used for the production of bioenergy using thermochemical processes like gasification and pyrolysis. Gasification is the process of turning carbonaceous materials like coal, biomass, or waste into syngas. The feedstock is exposed to a controlled amount of oxygen or steam during this process, which happens at temperatures typically between 700 and 1500 °C and triggers a series of intricate chemical reactions. Carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2), and trace amounts of other gases like methane (CH4) and nitrogen (N2) make up the majority of the resulting syngas. Depending on the particular feedstock and processing circumstances, syngas composition varies. The benefit of gasification is that it creates a versatile fuel gas that can be used for heating, power generation, or as a feedstock for the manufacturing of chemicals and transportation fuels. Char, a solid byproduct of gasification, can also be used as a fertilizer in the field [11,12].

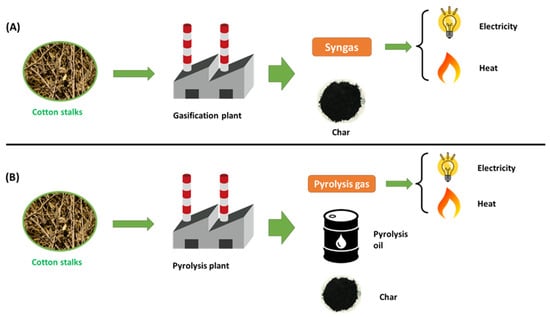

In contrast, pyrolysis is a thermal decomposition process that takes place in the absence of oxygen and yields three main products from organic materials: solid char, liquid bio-oil, and a gas mixture. In pyrolysis, complex organic molecules undergo chemical reactions at temperatures between 300 and 800 °C to produce the desired products. The carbon-rich solid char can be used as fuel or as a source of activated carbon. The liquid bio-oil is a complex mixture of oxygenated compounds that can be processed further to produce biofuel or act as a precursor to the creation of chemicals. The gaseous portion is made up of CO, CO2, CH4, and other hydrocarbons that can be used to produce heat or electricity [13,14]. Figure 1 provides a simplified schematic overview of the potential utilization of cotton stalks through gasification and pyrolysis.

Figure 1.

Simplified schematic overview of cotton stalks utilization via (A) gasification and (B) pyrolysis.

For Greece to increase the percentage of RES in its overall energy mix, an important means is through the gasification or pyrolysis of cotton stalks, which offers a number of benefits. To ensure the sustainability of such systems, it is essential to carefully assess the environmental effects of certain use paths. To do this, the Life Cycle Assessment (LCA) methodology is used, which is a standard means of evaluating the environmental effects of a process, product, or activity. Relevant environmental standards, such as ISO 14040 and 14044, are provided by the International Organization for Standardization (ISO), and they serve as a roadmap for the implementation of LCA. Through LCA, the substances utilized, pollutants released, and trash produced over the course of a system’s lifecycle can be located, measured, and assessed relative to predetermined impact categories. Moreover, by defining appropriate system boundaries and utilizing pertinent real-world data, LCA enables the comparison of ecological sustainability among different systems [3,11].

Several studies have been conducted that estimate the environmental impacts of gasification and pyrolysis pathways for the utilization of agricultural biomass. These studies are based on the LCA methodology and employ the use of specific indicators to assess the environmental impacts of bioenergy production. For example, [3,14] conducted a Life-Cycle Assessment of electricity generation from the combustion and gasification of biomass in Mexico, focusing on the utilization of sugarcane and agave bagasse. Their analysis enclosed a cradle-to-grave approach and assessed environmental and economic impacts. Similarly, [15] carried out a comparative life-cycle assessment of maize cobs, maize stover and wheat stalks for the production of electricity through gasification versus traditional coal power electricity in South Africa. Their aim was to determine the optimal feedstock and utilization route in the context of the study. Moreover, [16] examined the environmental impacts of gasification on the olive oil supply chain, focusing on the gasification of olive pomace for CHP and biochar production. The analysis followed an LCA methodology and a cradle-to-gate approach. The environmental impacts of the pyrolysis of agricultural residues using the LCA approach have also been addressed by several studies, including [17,18,19].

The present study’s main goal is to compare the valorization of cotton stalks in the Karditsa district of the Region of Thessaly using two alternative processes, pyrolysis and gasification. The two processes are compared in terms of technical performance, environmental impact, and economic viability. The study presents a cradle-to-gate analysis, encompassing the resource consumption, bioenergy generation, and emissions associated with the field preparation, cultivation, harvest, transportation, and conversion of cotton stalks for bioenergy production.

2. Materials and Methods

The methodology includes a literature review (Section 3) that identifies the best operating conditions for the two processes to ensure optimal product yields. The two conversion methods are evaluated for viability in Section 4, which also lists the necessary inputs and their associated costs. Additionally, the study uses the LCA technique and a set of particular indicators to assess and compare the environmental impacts of the two options.

2.1. Literature Review

A comprehensive literature review was conducted to investigate the parameters that influence the performance, product yields, and product quality of cotton stalk gasification and pyrolysis. The goal was to identify the optimal conditions for both processes.

2.2. Technoeconomic Feasibility Assessment

A technoeconomic assessment was performed for two different units, a gasification and a pyrolysis unit, to look at the economic performance of the gasification and pyrolysis of cotton stalks. Based on the results of the literature review, the best conditions were chosen, and mass and energy balances were estimated to establish the quantities (inputs) of materials, water, electricity, and thermal energy that the plants would need. Then, using the initial investment, operating costs, and net earnings, the plants’ economic performance was assessed. In order to evaluate the two options, additional economic metrics, including Return on Investment (ROI), Pay-out Time (POT), and Net Present Value (NPV), were computed.

2.3. Life Cycle Assessment

The environmental implications of both units were determined through a thorough life cycle evaluation. The LCA compared the two thermochemical processes, and the functional unit (FU) was the utilization of 5% of the annual cotton stalk production of Karditsa (i.e., 25,500 tons cotton stalk/year). This study presents a cradle-to-gate analysis, encompassing the resource consumption, bioenergy production, and emissions associated with the field preparation, cultivation, harvest, irrigation, fertilizer use, cotton stalk transportation, and conversion of cotton stalks to bioenergy production. The transmission, distribution, and actual usage of the final products, the construction and maintenance of the power plant and infrastructure, and material storage are not included, though. The study makes no mention of emissions connected to waste management, the economic and social components of the life cycle, and the direct effects on workers’ and laborers’ health, odor, waste heat, or noise.

The Ecoinvent database and the technoeconomic analysis methodology were used to generate the inventory data, which included energy inputs, ancillary materials (water, seeds, fertilizers, pesticides, and herbicides), and emissions to air, water, and land. The report makes no mention of the environmental and social components of the life cycle, as well as the noise, odor, waste heat, direct effects on worker health, or emissions connected to waste management.

The LCA was conducted using the Life Cycle Assessment Simulations Engine, developed within the framework of the KYKLOS 4.0 H2020 project. This engine provides an interface for conducting the life cycle assessment and calculating impact indicator scores based on static and dynamic data sources. As shown in Table 1, the environmental performance of converting biomass via pyrolysis and gasification was evaluated in this study by using 18 key indicators. A more thorough presentation of the data used for the analysis is shown in Section 5.

Table 1.

List of indicators used in this study.

3. Optimal Operating Parameters Assessment

3.1. Cotton Stalk Production and Characteristics

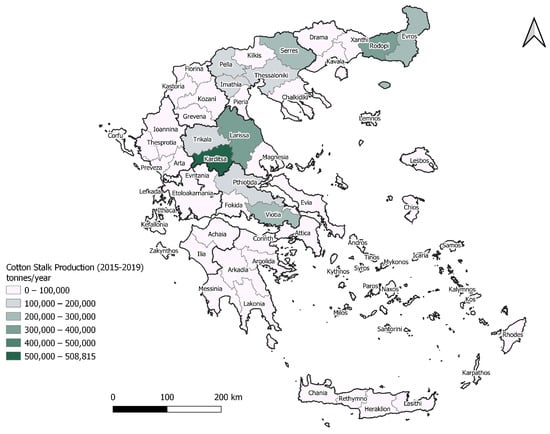

The exact amount of cotton stalks that is produced in Greece varies depending on the yield and cultivation practices, but it can be estimated using the Residue to Crop Ratio (RCR) [20]. The RCR is used to express the amount (in tons) of residue that is generated from 1 ton of produced crop. Assuming a RCR of 3.4 [21], the overall cotton stalk production in Greece in 2019 can be estimated at approximately 2.8 million tons. In order to identify the locations with the greatest potential, it was possible to divide cotton stalk production among regions and their associated districts using data from the Hellenic Statistical Authority [9]. The districts of Karditsa and Larissa, with average output volume levels of 508,000 tons and 375,000 tons of cotton stalks annually, respectively, can be shown in Figure 2. These large amounts of cotton stalks are typically underutilized and could potentially be used in a variety of applications, including bioenergy production, due to their high energy content. The proximate and ultimate analyses of cotton stalks, as well as their Lower Heating Value (LHV), are presented in Table 2 and Table 3.

Figure 2.

Average cotton stalk production in Greece, 2015–2019.

Table 2.

Proximate analysis of cotton stalks.

Table 3.

LHV and ultimate analysis of cotton stalks.

3.2. Utilization of Cotton Stalks

It is essential to set the ideal operating conditions for gasification and pyrolysis in order to optimize the advantages of using cotton stalks in these processes. In order to investigate the critical factors affecting the yields and characteristics of the final products in the gasification and pyrolysis of cotton stalks, a literature survey was carried out.

The abundance of cotton stalks in Greece presents both an environmental challenge and an opportunity. Currently, the improper disposal of these stalks leads to adverse effects on the environment. However, due to their high energy content, cotton stalks hold significant potential for bioenergy generation through gasification or pyrolysis. The utilization of cotton stalks through these processes offers several advantages. Firstly, it provides a renewable energy source that can reduce reliance on fossil fuels and contribute to the mitigation of greenhouse gas emissions. Secondly, it presents a new income source for cotton farmers who can sell their stalks to energy producers. Lastly, it facilitates a more sustainable disposal method for agricultural waste, thereby reducing the environmental impact of cotton production [11,28,29].

3.2.1. Gasification of Cotton Stalks

The results of the literature review are shown in Table 4, with particular attention paid to the gasification of cotton stalks and the effects of temperature, the gasifying agent, and equivalence ratio (ER) on the syngas output and energy content. The findings offer information that facilitates the selection of the optimal conditions for syngas production. The majority of research studies suggest using air as the gasifying agent and gasification temperatures between 750 °C and 850 °C. At a gasification temperature of 720 °C, Khalil et al. [30] recorded a syngas output of 61.7 v.v% and a lower heating value (LHV) of 4.34 MJ/Nm3. To achieve a yield of 87.5 v.v% and an LHV of 6.63 MJ/Nm3, Dhaka et al. [31] discovered that slightly higher temperatures (about 760 °C) improved syngas yields and characteristics. However, Pal [12] observed that a significant increase in the temperature to 950 °C seemed to have a negative impact on syngas yield, obtaining a syngas yield of approximately 75% with an LHV of 5.23 MJ/Nm3. The best energy content (7.38 MJ/Nm3) was found by Voultsos et al. [11] at 850 °C and with an ER of 0.2, where the syngas yield reached 70%.

Table 4.

Literature review results on cotton stalk gasification.

3.2.2. Pyrolysis of Cotton Stalks

In Table 5, which summarizes the findings of the literature review on the pyrolysis of cotton stalks, it is clear that temperatures between 500 and 600 °C are the optimal for producing pyrolysis oil. The pyrolysis process was carried out at 500 °C by Cheng et al. [20], Chen et al. [32], and Shah and Valaki [33], who reported oil yields of 42%, 43.7%, and 36.6%, respectively. According to Kataria et al. [13], an increase in the temperature to 550 °C resulted in a similarly high oil production rate of 40%. At 600 °C, Chen et al. [34] recorded the highest oil output, with gas and char production remaining at 22% and 28%, respectively, while oil production reached 50%.

Table 5.

Literature review results on cotton stalk pyrolysis.

4. Results

4.1. Technoeconomic Feasibility Assessment of Cotton Stalk Gasification and Pyrolysis Plants

As the main source of cotton stalks in Greece, the Karditsa district occupies a prominent role, being the biggest cotton grower in the country, as seen in Figure 2. There is a significant untapped potential in this region, where the yearly production of cotton stalks is expected to be around 510,000 tons. Utilizing this potential, cotton stalks can be used as a useful resource for the gasification or pyrolysis of bioenergy.

The objective of this assessment was to determine whether it is feasible to use some of the cotton stalks that are available in Karditsa in either of these two directions with environmental safety and economic viability. Thus, the current study investigates the utilization of 5% of the district of Karditsa’s annual cotton stalk production through both gasification and pyrolysis.

The economic viability of the gasification and pyrolysis processes was evaluated by considering various economic indicators, including the initial investment, operating costs, annual cash inflows, gross and net profits, Net Present Value (NPV), Return on Investment (ROI), and Pay-out Time (POT).

The percentage of the initial investment that can be recovered within a year is what is known as the return on investment (ROI), and it is a key metric for evaluating the profitability of a particular project. A positive ROI often denotes a successful investment. However, the preference tends to favor those alternatives when there are other investments with larger ROI values.

POT represents the amount of time needed for an investment to become commercially viable and shows the time needed to return the initial expenditure. An investment opportunity with a shorter POT is thought to be more tempting [36].

NPV is a financial metric used to assess the profitability of a project or an investment. By discounting future cash flows back to the present using a suitable discount rate, it helps to estimate their value. A positive NPV indicates that the project is anticipated to generate profits, while a negative NPV suggests that the venture may not be profitable [37].

4.1.1. Gasification and Pyrolysis Processes

Prior to being used in thermochemical processes, cotton stalks must first go through a pretreatment step in both the gasification and pyrolysis paths to improve their characteristics. Each process runs under certain temperatures and environmental conditions, producing various end-products. Below is a summary of the main prerequisites and presumptions for each step. The following major presumptions form the basis of this study:

- The capacity of each unit is 25,500 tons per year, or about 5% of the district of Karditsa’s annual production of cotton stalks.

- Both units run continuously for 330 days a year, 24 h a day.

- Transportation costs are not taken into account in the analysis.

- Feedstock costs are assumed to be zero because farmers typically discard cotton stalks as waste.

Pretreatment

After the transportation of cotton stalks to the processing facility, it becomes imperative to subject them to pretreatment procedures aimed at enhancing their properties and maximizing their potential for thermochemical utilization. Firstly, it is essential to shred the cotton stalks to increase the surface area of the feedstock. This step serves to augment reaction rates, improve the handling of feedstocks, and overall enhance the efficiency of the process. Moreover, in order to achieve a high conversion efficiency during pyrolysis and gasification, it is necessary for the feedstocks to possess a low moisture content. Typically, cotton stalks obtained from the field exhibit an initial moisture content of approximately 10% wt. However, for cotton stalk pyrolysis and gasification to be optimal, the moisture content should ideally be reduced to 6% wt. [11,38].

Gasification and Pyrolysis Operating Parameters

Following the pretreatment process, the cotton stalks are prepared to undergo gasification, which yields syngas as the primary product. In this study, syngas is utilized for cogeneration purposes, specifically for the combined production of heat and power within a CHP (Combined Heat and Power) system. Additionally, the solid byproduct of gasification, known as char, is sold to generate supplementary revenue. Notably, the char can be effectively utilized as a fertilizer in agricultural fields, thereby promoting the implementation of a circular economy model.

The optimal temperature for gasification is chosen to be 850 °C, in accordance with the results of the literature review, as shown in Table 4. Cotton stalks enter the reactor with a moisture content of 7 wt.%. The gasification process produces syngas with a weight percentage of 70% at this temperature. The syngas’ lower heating value (LHV) is determined to be 7.38 MJ/Nm3. Following the generation of syngas, it is used to generate both heat and power (CHP). The system’s electrical efficiency is considered to be 30% and its thermal efficiency to be 56% [11].

As an alternative, cotton stalks can be pyrolyzed following pretreatment to reduce their moisture content to 6 wt.%, in order to yield three distinct compounds. The primary product of pyrolysis is oil, which can be further processed to make fuels. Char and gas can also be sold as fuels for additional revenue. According to the literature review, the ideal temperature for the pyrolysis process to produce oil is 600 °C, which is shown in Table 5. The yields for oil, gas, and char are calculated to be 50%, 22%, and 28% by weight, respectively, at this temperature.

Table 6 gives a thorough breakdown of the features of each of the two bioenergy units under examination.

Table 6.

Characteristics of the gasification and pyrolysis units.

4.1.2. Preliminary Economic Assessment

A preliminary economic assessment was carried out for both units, considering the initial investment, the operating costs, annual cash inflows, gross and net profits, as well as three economic indicators, namely NPV, R.O.I and P.O.T.

Initial Investment (CAPEX)

The Chemical Engineering Plant Cost Index (CEPCI) was used to calculate the investment requirements for the two plants. The initial investment of one unit for 2023 is calculated from Equation (1):

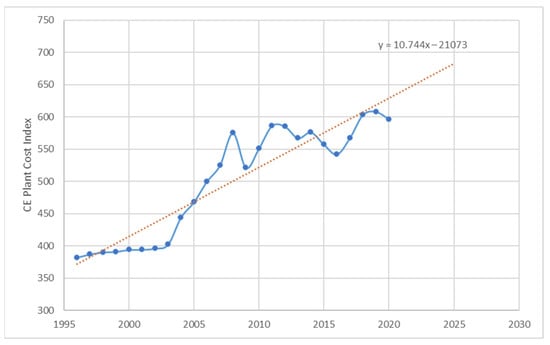

where IF,2023 is the investment for the year 2023 and IF,X the investment for the year X, for which bibliographic data are available. As no values are available for the CEPCI index for 2023, it is possible to make an estimate based on the data presented in Figure 3, showing that CEPCI2023 = 662.112.

Figure 3.

CEPCI indicators for 1996–2020 [39].

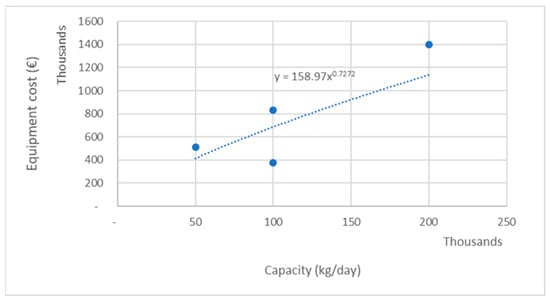

The equipment cost (Cp) is directly related to the capacity of the gasification and pyrolysis plant. Table 7 shows the equipment costs for units of different capacities, based on the literature review. Using the CEPCI indicators, all values are transposed and refer to 2023.

Table 7.

Equipment costs for gasification and pyrolysis units of different capacities.

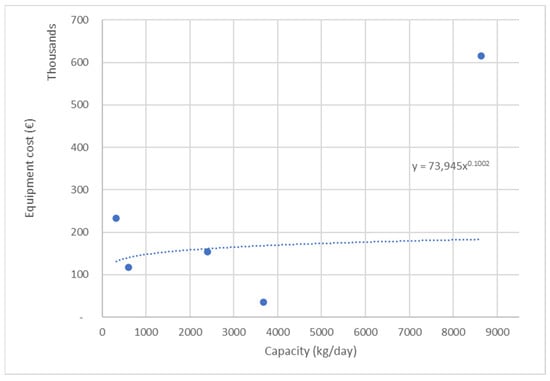

Using the data from Table 7, it is possible to make an estimate of the relationship between the capacity and the equipment costs for cotton stalk gasification and pyrolysis plants. This can be performed based on the equations obtained from Figure 4 and Figure 5. Consequently, for a plant capacity of 25,500 tons/year, the equipment costs for gasification are estimated at EUR 321,630 and those for pyrolysis at EUR 486,936.

Figure 4.

Gasification equipment cost versus capacity.

Figure 5.

Pyrolysis equipment cost versus capacity.

According to the method recommended [46], it is possible to determine the total initial expenditure for the two plants based on the equipment costs. Table 8 lists every cost associated with the gasification and pyrolysis plants.

Table 8.

Investment costs for the cotton stalk gasification and pyrolysis units.

Operating Costs (OPEX)

Based on the methodology presented in [47], it is possible to estimate the operating costs for the gasification and pyrolysis plants. This type of expense includes feedstock costs, labor costs, utilities, as well as some additional costs, as seen in Table 9.

Table 9.

Overview of operating costs for the gasification and pyrolysis plants.

As cotton stalks are waste that would otherwise be disposed of by the farmers, the feedstock costs in this study are considered to be zero. Labor costs are determined based on the Wessels methodology and by taking into account that the cost of a manhour in Greece is EUR 16.4/h [48].

Power is needed to shred the cotton stalks, natural gas is utilized to dry the feedstock to the right moisture content, and power, water, and natural gas are all needed to run the pyrolysis or gasification process (utilities). Table 10 and Table 11 for gasification and pyrolysis, respectively, give an overview of the necessary utilities and their costs. The amount of water and power needed per ton of feedstock is determined using the mass and energy balances of the processes, whereas the amount of heating required is based on the literature.

Table 10.

Utilities cost for the gasification unit.

Table 11.

Utilities cost for the pyrolysis unit.

Cash Inflows

The revenue of the gasification and the pyrolysis plants comes from the sale of the products that are generated. The main product of the gasification plant is syngas, which is used to produce electricity and heat via a CHP system. Additionally, the char can also be sold for additional profit. In the case of the pyrolysis plant, the main product is the pyrolysis oil, while the gas and char can also be sold. Based on the quantities produced and their respective selling prices, it is possible to calculate the annual cash inflow of the installations, as shown in Table 12 and Table 13.

Table 12.

Cash inflows for the gasification unit.

Table 13.

Cash inflows for the pyrolysis unit.

Net Profit

Based on the total cash inflows (S) and the operating costs (C), it is possible to calculate the annual gross profit (R) of the cotton stalk gasification and pyrolysis plants, based on Equations (2) and (3):

The net annual profit of the installation is calculated with Equations (4) and (5):

The following assumptions were made for this calculation:

- The economic life of the plant is N = 20 years.

- Depreciation is linear.

- The uniform tax rate is t = 0.4.

- The depreciation rate for tax purposes is d = 1/N = 0.05.

- The depreciation rate of the fixed investment is e = d.

Financial Indicators

To assess the viability of the pyrolysis plant, three economic indicators were also used, namely the Net Present Value (NPV), the Return Based on the Initial Investment (R.O.I) and Pay-out Time (P.O.T). These indicators are calculated using Equations (6)–(8):

where Rt = net cash inflow–outflows during a single period t; i = discount rate or return that could be earned in alternative investments; and t = number of time periods. The discount rate used for the calculation of NPV was taken as 10%.

Overview of Results

The economic performance of the two facilities, each of which has a capacity of 25,500 tons annually, is summarized in Table 14. According to the analysis’ findings, both facilities have significant economic viability, as seen by their sizable revenues and quick payback times. Generally speaking, the pyrolysis plant seems to be the better choice, largely because of its greater annual revenues and better economic indicators. The pyrolysis plant, however, requires a substantially higher initial investment, which might operate as a disincentive.

Table 14.

Overview of the feasibility of the gasification and pyrolysis plants.

The gasification plant exhibits a highly profitable outlook, with a net present value (NPV) of EUR 10.52 million and annual profits reaching up to EUR 658 thousand. The generation of electricity and thermal energy from the syngas significantly contributes to the unit’s feasibility, constituting 49% and 43% of the total profits, respectively. Conversely, the production of char, although in smaller quantities, contributes to the overall profitability to a somewhat limited extent. Utilities, particularly the substantial thermal energy requirements of the reactor, account for a significant portion of the total operating costs, representing nearly 17% of the overall expenses.

In the case of the pyrolysis plant, the primary product is pyrolysis oil, which contributes to approximately 80% of the total revenue. The pyrolysis gas also plays a significant role in the plant’s feasibility, being sold for substantial profits. Alternatively, it has the potential to be utilized for fulfilling the thermal energy demand of the reactor, thereby reducing the operating costs of the plant. The plant exhibits promising results in terms of feasibility, with a return on investment (ROI) of 58% and a payback period (POT) of merely 1.58 years.

4.2. Comparative LCA Assessment

It is also crucial to examine the environmental implications of gasification and pyrolysis. This includes identifying which processes and steps along the value chain have the most adverse effects on the environment. In this sense, it is also possible to evaluate the two utilization paths and choose the best one after doing your research.

A Life Cycle Assessment was carried out for both plants that have been analyzed. The methodological framework for an LCA consists of four main steps [3,4], which are analyzed in detail in the following sections.

4.2.1. Goal and Scope Definition of Quantifying the Environmental Impacts

This study is a cradle-to-gate analysis towards quantifying the environmental impacts of these processes, including all supply chain steps, from preparation in the field and resource harvesting, transportation, energy use, emissions, and bioenergy production. The analysis’ overarching goal is to quantify the environmental effects of the pyrolysis and gasification units, which were examined in Section 4. Therefore, the LCA’s functional unit (FU) is the use of 5%, or 25,500 tons, of Karditsa’s annual cotton stalk production. It is assumed for the analysis that the typical transportation distance of the cotton stalks to the bioenergy unit is 20 km.

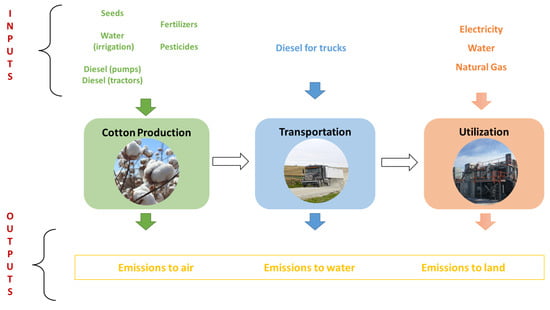

The production and harvesting of cotton, the collection and delivery of cotton stalks to the plant for gasification or pyrolysis, and the use of cotton stalks for bioenergy (through gasification or pyrolysis) make up the three key steps of the value chain. Energy inputs (such as fuel and electricity), the usage of auxiliary materials (such as water, seeds, fertilizer, insecticides, and herbicides), and emissions to the air, water, and land are all considered system inputs. The transmission, distribution, and actual usage of the final products are not included in the study. Additionally ignored were the infrastructure, material storage, and the construction and maintenance of the power plant.

An overview of the value chain, system boundaries, as well as the inputs and outputs is presented in Figure 6. The three main steps of the value chain are as follows: (i) the production and harvest of cotton, (ii) the collection and transportation of cotton stalks to the gasification or pyrolysis plant, and (iii) the utilization of cotton stalks for bioenergy (via gasification or pyrolysis).

Figure 6.

Overview of the system boundaries, inputs and outputs.

4.2.2. Life Cycle Inventory

The life cycle inventory (LCI) is a crucial component of a life cycle assessment (LCA). It involves identifying, quantifying, and documenting all the inputs, outputs, and environmental impacts associated with a product, process, or service throughout its entire life cycle. The LCI encompasses the extraction of raw materials, manufacturing and production processes, distribution, use, and the disposal or recycling stages. It includes data on energy consumption, resource use, emissions to air, water, and soil, waste generation, and other relevant environmental indicators. Its purpose is to provide a comprehensive inventory of all material and energy flows, as well as the environmental burdens associated with the analyzed system. This inventory serves as the foundation for the further impact assessment and interpretation stages of the LCA, which evaluate the environmental performance of the product or process being assessed and its potential areas for improvement [17].

All material and energy flows in the product’s lifecycle are determined and quantified based on the system’s FU using the Ecoinvent database. The number of specific inputs, such as electricity and heat, for the gasification and pyrolysis process were determined based on the technoeconomic analysis conducted in Section 4 (see Table 10 and Table 11). The quantities required for the inputs during the production and harvest of cotton were determined based on the literature data. An overview of the inputs for the LCA analysis of the two plants is presented in Table 15.

Table 15.

Inputs required for the LCA analysis.

4.2.3. Life Cycle Impact Assessment

The life cycle impact assessment (LCIA) is a phase in a life cycle assessment (LCA) that evaluates the potential environmental impacts associated with the inputs and outputs identified in the life cycle inventory (LCI). During the LCIA, the LCI data are translated into environmental impact categories that are assessed using established impact assessment methods and characterization models, which assign values to different environmental indicators based on their potential to cause harm to human health, ecosystems, or natural resources. The assessment of the environmental impacts of the cotton stalk gasification and pyrolysis plants was carried out based on the indicators shown in Table 1, following the ReCiPe Midpoint method and using the LCA Simulations Engine developed in the context of the KYKLOS 4.0 H2020 project.

4.2.4. Results Interpretation

The selected indicators were determined for the two alternative options and the results are presented in Table 16. These indicators refer to the environmental impact of the whole value chain in each scenario, including the production and harvest of cotton, the transportation of cotton stalks and their utilization via gasification or pyrolysis.

Table 16.

Environmental impact indicators of the gasification and pyrolysis options (FU: 25,500 tonnes cotton stalk/year).

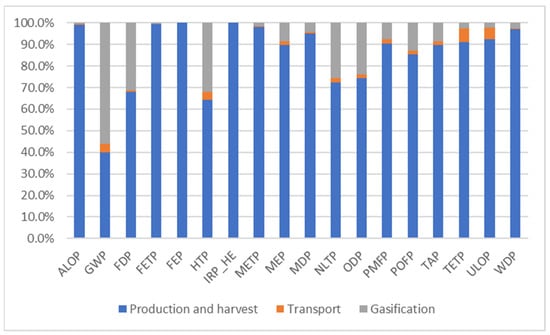

The value chain stages’ contributions to the impact indicators for the gasification option are shown in Figure 7. As can be seen, cotton production and harvest account for the largest portion of the majority of indicators. Generally, the use of water for irrigation leads to the production stage having a high impact regarding Water Depletion (WD), Freshwater Ecotoxicity (FETP), Freshwater Eutrophication (FEP), Marine Ecotoxicity (METP) and Marine Eutrophication (MEP). The use of fossil fuels and minerals also adds to impacts related to Climate Change (GWP), Fossil Depletion (FDP) and Metal Depletion (MDP).

Figure 7.

Contribution of each stage of the value chain to the impact indicators for the gasification option (FU: 25,500 tonnes cotton stalk/year).

Additionally, essential to the chain’s total environmental impact is the gasification process. The gasification process itself contributes 1.5 million tons of CO2eq, or more than 50% of the entire impact, particularly in terms of the impact on climate change (GWP). The substantial usage of natural gas for heating also assumes a sizable portion of the overall impact on fossil depletion (FDP). The gasification process contributed 32% of the total impacts on human toxicity (HTP), whereas cotton production accounted for 64.5% of the total (21.3 million kg 1,4-DCB-eq. Additionally, the gasification unit had a 14% (3902 kg NMVOC) participation in Photochemical Oxidant Formation (POFP), which has a major influence.

It is clear that compared to the other steps in the supply chain, transportation generally has a smaller overall environmental impact. The impact categories GWP, TETP, and ULOP, with respective shares of 4%, 6.4%, and 5.3% (i.e., 21.3 million kg 1,4-DCB-eq.), are where the influence of transportation is rather considerable.

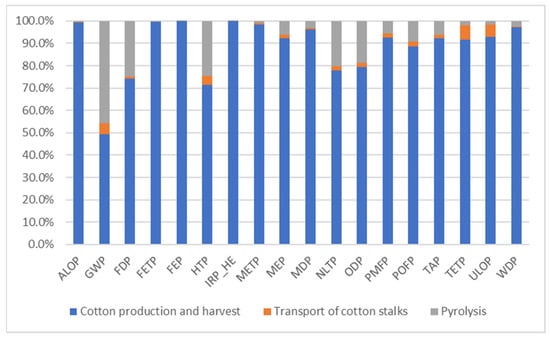

Figure 8 shows a breakdown of the overall effects of the pyrolysis option according to the value chain stage. Again, it is clear that practically every category of impact is dominated by the cotton production stage. Furthermore, it may be said that, in comparison to gasification, the pyrolysis process has somewhat less of an impact on the environment. Assuming that the greatest contribution in GWP is 45.6%, pyrolysis generates roughly 1 million tons of CO2 equivalent per year. Furthermore, the pyrolysis plant accounts for 25% of Fossil Depletion (FDP), 24.6% of Human Toxicity (HTP) and 20.3% of Natural Land Transformation (NLT).

Figure 8.

Contribution of each stage of the value chain to the impact indicators for the pyrolysis option (FU: 25,500 tonnes cotton stalk/year).

4.2.5. Normalization of Impacts

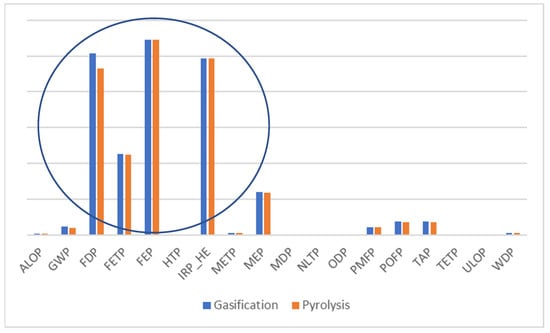

Normalization is a step in the life cycle impact assessment (LCIA) that involves putting the environmental impacts into context by comparing them to a reference value or benchmark. During normalization, the impacts calculated in the LCIA are divided by a reference value, which can be a regional or global average, a specific threshold, or a sustainability target. This normalization process allows for a relative comparison of different impact categories and helps to identify which impacts are relatively more significant or critical. The impacts that were calculated for the two alternative options (see Table 16) were normalized based on the reference values found in [60]. The results of the normalization are presented in Figure 9. It should be noted that the impacts from all steps of the chain (i.e., production, transportation and utilization) are taken into account.

Figure 9.

Normalized impact indicators for the gasification and pyrolysis options (FU: 25,500 tonnes cotton stalk/year).

Based on the normalization, the most significant impact categories for both scenarios are Fossil Depletion (FDP), Freshwater Eutrophication (FEP), Ionizing Radiation (IRP_HE) and Freshwater Ecotoxicity (FETP). Both options also contribute to Marine Ecotoxicity (MEP). The impacts on Human Toxicity (HTP), Metal Depletion (MDP), Natural Land Transformation (NLTPP), Ozone Depletion (ODP) and Terrestrial Ecotoxicity (TETP) are comparatively insignificant.

Overall, the gasification option has slightly more negative effects on the environment across all major impact categories. Due to gasification’s higher energy intensity, more natural gas is used, resulting in a 5.79 million kg oil equivalent impact on FDP as opposed to a 5.31 million kg oil equivalent for pyrolysis. Similarly, the gasification option leads to 1.32 million kg 1,4-DCB-eq (FETP), while pyrolysis accounts for 1.30 million kg 1,4-DCB-eq. The impact that both utilization options have on FEP is nearly identical at approximately 709,260 kg P-eq. Gasification also has a slightly higher impact on IRP_HE, contributing 41.6 million kg U235-eq.

5. Discussion

This study presents a cradle-to-gate analysis, encompassing the resource consumption, bioenergy production, and emissions associated with the field preparation, cultivation, harvest, irrigation, fertilizer use, cotton stalk transportation, and conversion of cotton stalks for bioenergy production. The transmission, distribution, and actual usage of the final products, the construction and maintenance of the power plant and infrastructure, and material storage are not included.

While the cradle-to-grave approach would require collecting further data to strengthen the analysis, with the cradle-to-gate approach, it is possible to obtain a clear picture of which stages are the most important in terms of environmental strains and therefore identify which technological pathway appears to be a preferable option.

5.1. Greenhouse Gas Emissions

This study presents a cradle-to-gate analysis, encompassing the resource consumption, bioenergy production, and emissions associated with the field preparation, cultivation, harvest, irrigation, fertilizer use, cotton stalk transportation, and conversion of cotton stalks for bioenergy production, while the transmission, distribution, and actual usage of the final products, the construction and maintenance of the power plant and infrastructure, and material storage are not included. With the use of specific indicators, this study considers the GHG emissions that are generated throughout the value chain, until the utilization of cotton stalks via gasification or pyrolysis pathways.

For the above, the Ecoinvent database and a preliminary technoeconomic analysis were used to generate the inventory data, which included energy inputs, ancillary materials (water, seeds, fertilizers, pesticides, and herbicides), and emissions to air, water, and land.

5.2. Energy Efficiecny

The energy efficiency of gasification and biomass pyrolysis is an important factor to be considered. Evaluating the amount of energy produced in the presented study in relation to the energy required to operate the process is essential to determine its viability. Furthermore, comparing the efficiency of the processes presented in the manuscript with other biomass conversion technologies or energy sources is also relevant. In this study, the energy efficiency of the two processes is taken into account, as the energy that is used within them, as well as the energy that they produce, were considered. Furthermore, the environmental impacts of each were determined. Comparing the efficiency of the processes presented in the manuscript with other biomass conversion technologies or energy sources would also be very relevant in another context. However, the scope of this work focused on a specific case study, with a specific feedstock and two potential utilization routes, and the aim was to compare between these two. Including different technologies/feedstocks would be very useful for further work on this subject.

5.3. Waste Management

The gasification and pyrolysis of biomass can generate byproducts and waste that need to be properly managed. For the comparative feasibility of gasification and pyrolysis processes, the evaluation of the methods treating and disposing these residues can provide a comparison of their environmental impacts and the associated costs. In this study, the use of the byproducts of the two processes (char for gasification, and char and gas for pyrolysis) is taken into account, as they are either sold, used to cover the energy demand of the process, or are returned to the field (Table 12 and Table 13). However, as this study presents a cradle-to-gate analysis, the environmental impacts of the transmission, distribution, and actual usage of the final products are not included.

5.4. Availability of Biomass and Sustainability

The feasibility of the gasification and pyrolysis of biomass depends on the availability of adequate and sustainably sourced biomass. For this, the assessment of biomass availability for a long-term supply is important for the sustainable operation of the thermochemical processes and the overall sustainability of the systems. However, as data were not available on the current uses of cotton stalks in the case study area, a very conservative approach was taken, assuming the utilization of only 5% of the produced cotton stalks in the region. Additional recommendations were made, proposing that a thorough availability assessment of the biomass would be a vital next step of the analysis to allow for a clear indication of whether there is an adequate long-term supply of biomass that can be used for feeding the gasification or pyrolysis system.

5.5. Economic Viability

In addition to the environmental aspects, the economic viability of gasification and pyrolysis of biomass was considered. This involves assessing investment, operating and maintenance costs, as well as comparing them with other energy sources in terms of cost. These costs are considered for the gasification and pyrolysis units. Additionally, economic metrics including Return on Investment (ROI), Pay-out Time (POT), and Net Present Value (NPV) were computed. Regarding the costs for the rest of the value chain (production, transport), an LCC is proposed, as well as a potential next step for the analysis. A comparison with other energy sources in terms of cost was deemed outside the scope of this work, as our focus was to compare two specific alternatives, namely gasification and pyrolysis.

5.6. Costs of the Initial Investment

Regarding the costs of initial investment, the CEPCI is an interesting parameter for a preliminary approach. This study focused on an approximate feasibility assessment, and the CEPCI helped to transfer all prices at the present time. The use of the CEPCI can potentially result in an over- or under-estimation of the prices. For a more detailed and accurate estimation, it is necessary to consider each type of equipment separately. For this reason, a suggestion is made to conduct detailed technoeconomic assessments for the two processes, in order to obtain more accurate data.

5.7. Operating Costs

Related to the operating costs, the shredding and drying of cotton stalks, as well as the electricity required for all the processes, are taken into account. Moreover, the separation cost, which is required to separate the products obtained and to fulfill the environmental requirements, is also included in the OPEX calculations.

5.8. Potential for Using Waste

The gasification and pyrolysis of biomass can be an efficient way to take advantage of organic waste, such as agricultural waste, forestry waste and urban biomass waste. The results of the feasibility assessment clearly indicate the potential energy produced from the utilization of cotton stalks in the case study region.

5.9. Recommendations

This study is a preliminary approach to the assessment of the environmental sustainability and economic viability of cotton stalk conversion to energy via the gasification or pyrolysis process for supporting decision making regarding the best technological choice. Suggestions for further research are as follows:

- To conduct detailed technoeconomic assessments.

- To conduct a detailed biomass availability assessment. In this sense, it is vital to examine the current uses of cotton stalks in the region and outline the amounts that can be sustainably sourced for bioenergy production. In turn, this will allow for a clear indication of whether there is an adequate long-term supply of biomass that can be used within the gasification or pyrolysis system.

- To use the ‘cradle-to-grave’ approach for the LCA and consider the use of the final products from the two plants (i.e., electricity, thermal energy, fuel).

- To perform a Life Cycle Costing (LCC) assessment for the entire value chain, including the costs associated with production, transportation, and conversion of cotton stalks to energy. This will enable an evaluation of the economic sustainability of both options.

- To perform a Social Life Cycle Assessment (S-LCA) to assess and compare the social impacts and sustainability of the two options.

- Assess the efficiency, feasibility and environmental impact of other utilization routes for cotton stalks, in order to make a more informed decision on the optimal solution.

6. Conclusions

Being one of the main crops grown in Greece, cotton has a great agricultural significance. The district of Karditsa in the Thessaly region emerged as the top producer in 2019, when the yearly cotton production totaled a significant 900,746 tons. Cotton stalks, the primary byproduct of cotton production, may still only be used in a restricted and ineffective way. Currently, farmers either dispose of stalks or burn them in the field. Given their considerable energy content, cotton stalks can be effectively utilized as feedstock for thermochemical conversion to bioenergy via gasification or pyrolysis.

The two options for using this promising agricultural residue in Greece to produce bioenergy were examined in this study. Preferable options can be chosen while highlighting possible areas for improvement by examining the environmental implications across the full value chain and the economic performance of bioenergy plants. The gasification of cotton stalks yields a gaseous product known as syngas, which can be utilized in combined heat and power (CHP) systems for the cogeneration of electricity and heat. A survey of the literature revealed that 850 °C is the optimal temperature for gasifying cotton stalks, producing syngas with a yield of 70% by weight. Pyrolysis is another effective technique for using cotton stalks to produce biofuels. Pyrolysis oil, which can be improved and further used as fuel, is the main byproduct of pyrolysis. In addition to oil, solid and gaseous byproducts are also generated, providing a variety of potential applications. Char, the solid product of pyrolysis, can also be used as fertilizer in fields. The optimal conditions for pyrolysis oil production were determined to be 600 °C, resulting in yields of 50% wt. for the oil, 22% wt. for the gas, and 28% wt. for the char.

Both processes were evaluated to determine the economic viability and efficiency of both gasification and pyrolysis processes. Each facility has the ability to use 5% of the 25,500 tons of cotton stalks produced annually in the Karditsa district. The initial investment for the gasification plant was estimated to be EUR 1.81 M, significantly lower than the investment required for the pyrolysis plant, which amounted to EUR 2.74 M. However, although gasification entailed slightly higher operating costs due to its energy-intensive nature, totaling EUR 2.55 M compared to EUR 2.50 M for pyrolysis, the pyrolysis plant emerged as the preferable choice. This preference was primarily due to its significantly higher annual cash inflows, reaching EUR 5.3 M, with pyrolysis oil contributing approximately 81% of the total. In contrast, the gasification plant had annual cash inflows of EUR 3.74 M, with the electricity and heat generated from the syngas sharing an equal contribution and char accounting for a minimal share.

Overall, both bioenergy units demonstrate economic viability, offering high annual revenue and short payback periods. The pyrolysis plant stands out as the most favorable option, boasting a payback period of 1.58 years, a return on investment (ROI) of 58%, and a net present value (NPV) of EUR 21.5 M. The gasification plant, while slightly less remarkable in its performance, remains highly profitable, with a payback period of 2.41 years, an ROI of 36%, and an NPV of EUR 10.52 M. It should be noted, though, that the pyrolysis plant entails a significantly higher initial investment, which may be a deterrent factor in the decision making of investors.

To choose the best choice, it is necessary to evaluate both options’ environmental effects in addition to economic ones. For both units, a life cycle assessment (LCA) was performed using a cradle-to-gate methodology and examining 18 impact indicators. The gasification option, which includes cotton cultivation, the transportation of cotton stalks, and final conversion, might be determined to have somewhat greater total environmental consequences based on the LCA assessment.

The main causes of many impact categories were found to be the cotton production and harvesting stages. Notably, Fossil Depletion (FDP) emerged as one of the most significant impact categories due to the extensive use of natural gas for heating and diesel for irrigation pumps during the production stage. Gasification contributed around 5.7 million kg oil equivalent, slightly higher than the 5.3 million kg oil equivalent contributed by pyrolysis. Similarly, both options had substantial contributions to Freshwater Eutrophication, totaling approximately 709,000 kg of phosphorus equivalent. The gasification option contributed nearly 41.6 million kg U235 equivalent to Ionizing Radiation (IRP_HE), slightly exceeding the contribution of the pyrolysis option. Conversely, both options had insignificant effects on impact categories such as Metal Depletion (MDP), Ozone Depletion (ODP), Water Depletion (WDP), and Terrestrial Ecotoxicity (TETP).

The importance of this study, although preliminary, is that it provides valuable insights that suggest that cotton stalk pyrolysis is a better choice for bioenergy production compared to gasification. Overall, to the authors’ knowledge, there is no other study that compares the economic feasibility and environmental impacts of cotton stalk gasification and pyrolysis in Greece. The study aimed to provide a clear overview of the potential advantages and disadvantages of both utilization pathways and suggest a preferred option. The overall results suggest that the pyrolysis process is the slightly better choice. The majority of the available literature compares gasification with combustion or the use of fossil fuels [14,15,16]. There is a limited number of studies comparing the environmental impacts of the gasification and pyrolysis of agricultural biomass, but their results are in accordance with the results presented within this analysis [61,62].

Author Contributions

Conceptualization, A.Z. and I.V.; methodology, A.Z. and I.V.; software, I.V.; formal analysis, I.V.; investigation, A.Z. and I.V.; resources, I.V. and A.Z.; data curation, I.V.; writing—original draft preparation, I.V.; writing—review and editing, A.Z.; visualization, A.Z. and I.V.; supervision, A.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to acknowledge Charisios Achillas for his support and for providing access to the LCA Simulations Engine developed within the KYKLOS 4.0 H2020 project (https://lca.efb.gr/ (accessed on 20 May 2023)).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| ALOP | agricultural land occupation |

| CAPEX | capital expenses |

| CEPCI | chemical engineering plant cost index |

| CHP | cogeneration of heat and power |

| FDP | fossil depletion |

| FEP | freshwater eutrophication |

| FETP | freshwater ecotoxicity |

| FU | functional unit |

| GHG | greenhouse gas |

| GWP | climate change |

| HTP | human ecotoxicity |

| IRP_HE | ionizing radiation |

| ISO | International Organization for Standardization |

| LCA | life cycle assessment |

| LCI | life cycle inventory |

| LCIA | life cycle impact analysis |

| LHV | lower heating value |

| MEP | marine eutrophication |

| METP | marine ecotoxicity |

| NLTP | natural land transformation |

| NPV | net present value |

| ODP | ozone depletion |

| OPEX | operating expenses |

| PMFP | particulate matter formation |

| POFP | photochemical oxidant formation |

| POT | pay-out time |

| PV | photovoltaic |

| RCR | residue to crop ratio |

| RES | renewable energy sources |

| ROI | return on investment |

| TAP | terrestrial acidification |

| TES | total energy supply |

| TETP | terrestrial ecotoxicity |

| ULOP | urban land occupation |

| WDP | water depletion |

References

- EIA. International Energy Outlook 2021 (IEO2021); U.S. Energy Information Administration: Washington, DC, USA, 2021.

- IEA. Renewables Information: Overview; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Parascanu, M.M.; Puig-Gamero, M.; Soreanu, G.; Valverde, J.L.; Sanchez-Silva, L. Comparison of three Mexican biomasses valorization through combustion and gasification: Environmental and economic analysis. Energy 2019, 189, 116095. [Google Scholar] [CrossRef]

- Arodudu, O.; Helming, K.; Wiggering, H.; Voinov, A. Towards a more holistic sustainability assessment framework for agro-bioenergy systems—A review. Environ. Impact Assess. Rev. 2017, 62, 61–75. [Google Scholar] [CrossRef]

- Yogalakshmi, K.; Poornima Devi, T.; Sivashanmugam, P.; Kavitha, S.; Yukesh Kannah, R.; Varjani, S.; AdishKumar, S.; Kumar, G.; Rajesh Banu, J. Lignocellulosic biomass-based pyrolysis: A comprehensive review. Chemosphere 2022, 286, 131824. [Google Scholar]

- IRENA. Energy Profile: Greece. International Renewable Energy Agency. 2021. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Statistics/Statistical_Profiles/Europe/Greece_Europe_RE_SP.pdf (accessed on 18 April 2023).

- IEA. Greece Energy Policy Review; International Energy Agency: Paris, France, 2023; Available online: https://iea.blob.core.windows.net/assets/5dc74a29-c4cb-4cde-97e0-9e218c58c6fd/Greece2023.pdf (accessed on 12 April 2023).

- FAOSTAT. Crops and Livestock Products. Food and Agriculture Organization of the United Nations. 2023. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 18 April 2023).

- ELSTAT. Agriculture and Livestock Statistics. Hellenic Statistical Authority. 2023. Available online: https://www.statistics.gr/en/statistics/agr (accessed on 18 April 2023).

- Jing, F.; Kang, Y.; Tan, J.; Tian, B.; Fangxia, M.; Liu, J. Decomposition characteristics of cotton stalks from fall to spring as affected by continuous cropping. Acta Agric. Scand. Sect. B—Soil Plant Sci. 2016, 66, 510–515. [Google Scholar] [CrossRef]

- Voultsos, I.; Katsourinis, D.; Giannopoulos, D.; Founti, M. Integrating LCA with Process Modeling for the Energetic and Environmental Assessment of a CHP Biomass Gasification Plant: A Case Study in Thessaly, Greece. Eng 2020, 1, 2–30. [Google Scholar] [CrossRef]

- Pal, R.K. Gasification of cotton stalk in a downdraft gasifier. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 2973–2985. [Google Scholar] [CrossRef]

- Kataria, G.; Sharma, A.; Joshi, J.B.; Hameed, S.; Amiri, A. A system level analysis of pyrolysis of cotton stalk biomass. Mater. Today Proc. 2022, 57, 1528–1532. [Google Scholar] [CrossRef]

- Parascanu, M.M.; Kaltschmitt, M.; Rodl, A.; Soreanu, G.; Sanchez-Silva, L. Life cycle assessment of electricity generation from combustion and gasification of biomass in Mexico. Sustain. Prod. Consum. 2021, 27, 72–85. [Google Scholar] [CrossRef]

- Tokologo Mdhluli, F.; Harding, K.G. Comparative life cycle assessment of maize cobs, maize stover and wheat stalks for the production of electricity through gasification vs traditional coal power electricity in South Africa. Clean. Environ. Syst. 2021, 3, 100046. [Google Scholar] [CrossRef]

- Fernandez-Lobato, L.; Aguado, R.; Jurado, F.; Vera, D. Biomass gasification as a key technology to reduce the environmental impact of virgin olive oil production: A Life Cycle Assessment approach. Biomass Bioenergy 2022, 165, 106585. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Longo, S.; Cellura, M.; Guarino, F.; Messineo, A.; Mistretta, M.; Volpe, M. Environmental assessment of a waste-to-energy practice: The pyrolysis of agro-industrial biomass residues. Sustain. Prod. Consum. 2021, 28, 866–876. [Google Scholar] [CrossRef]

- Han, D.; Yang, X.; Li, R.; Wu, Y. Environmental impact comparison of typical and resource-efficient biomass fast pyrolysis systems based on LCA and Aspen Plus simulation. J. Clean. Prod. 2019, 231, 254–267. [Google Scholar] [CrossRef]

- Han, J.; Elgowainy, A.; Dunn, J.B.; Wang, M.Q. Life cycle analysis of fuel production from fast pyrolysis of biomass. Bioresour. Technol. 2013, 133, 421–428. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Hu, S.C.; Sun, G.T.; Geng, Z.C.; Zhu, M.Q. The effect of pyrolysis temperature on the characteristics of biochar, pyroligneous acids, and gas prepared from cotton stalk through a polygeneration process. Ind. Crops Prod. 2021, 170, 113690. [Google Scholar] [CrossRef]

- FAO. Renewable Energy Interventions in the Wheat Landscape in Uzbekistan; Food and Agriculture Organization of the United Nations: Roma, Italy, 2023. [Google Scholar]

- Karatas, H.; Olgun, H.; Akgun, F. Experimental results of gasification of cotton stalk and hazelnut shell in a bubbling fluidized bed gasifier under air and steam atmospheres. Fuel 2013, 112, 494–501. [Google Scholar] [CrossRef]

- Abduhani, H.; Tursun, Y.; Zhong, M.; Huang, X. Chemical looping gasification of cotton stalk with Cu/Ni/olivine in a Micro-fluidized bed Reactor: Gaseous products distribution and kinetics. Fuel 2022, 322, 124100. [Google Scholar] [CrossRef]

- Rabea, K.; Bakry, A.I.; Khalil, A.; El-Fakharany, M.K.; Kadous, M. Real-time performance investigation of a downdraft gasifier fueled by cotton stalks in a batch-mode operation. Fuel 2021, 300, 120976. [Google Scholar] [CrossRef]

- Li, F.; Yu, B.; Zhao, W.; Wang, J.; Xu, M.; Fan, H.; Huang, J.; Fang, Y. Investigation on formation mechanisms of ash and deposit from cotton stalk vibrating grate boiler combustion based on their characteristics. Fuel 2022, 323, 124446. [Google Scholar] [CrossRef]

- Gupta, A.; Thengane, S.K.; Mahajani, S. Kinetics of pyrolysis and gasification of cotton stalk in the central parts of India. Fuel 2020, 263, 116752. [Google Scholar] [CrossRef]

- Umesh, D.; Sarsavadiya, P.; Vaja, K.; Mahadeo, K. Physiochemical Properties of Cotton Stalk Biomass from Aricultural Residues. Curr. World Environ. 2015, 10, 343–349. [Google Scholar] [CrossRef]

- Allesina, G.; Pedrazzi, S.; Allegretti, F.; Morselli, N.; Puglia, M.; Santunione, G.; Tartarini, P. Gasification of cotton crop residues for combined power and biochar production in Mozambique. Appl. Therm. Eng. 2018, 139, 387–394. [Google Scholar] [CrossRef]

- Zhao, A.; Liu, S.; Yao, J.; Huang, F.; He, Z.; Liu, J. Characteristics of bio-oil and biochar from cotton stalk pyrolysis: Effects of torrefaction temperature and duration in an ammonia environment. Bioresour. Technol. 2022, 343, 126145. [Google Scholar] [CrossRef] [PubMed]

- Khalil, A.; Bakry, A.I.; El-Fakharany, M.; Rabea, K. Experimental Study of Cotton stalks Gasification in a Downdraft Reactor. J. Eng. Res. 2018, 2, 1–15. [Google Scholar] [CrossRef]

- Dhaka, A.K.; Kaushal, R.; Pal, Y. Assessing the power generation potential and quality of producer gas from blended of the cotton stalk and pistachio shell in an open core downdraft gasifier. Int. J. Ambient. Energy 2022, 43, 8351–8360. [Google Scholar] [CrossRef]

- Chen, H.; Liu, X.; Guo, Y.; Wang, Y.; Li, H.; Li, Y. Study on the pyrolysis behavior and kinetic parameters of cotton stalk by thermogravimetric analysis. Bioresour. Technol. 2017, 241, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Shah, J.B.; Valaki, J.B. Technoeconomic analysis of cotton stalk biomass based bio-oil production using slow pyrolysis process. J. Kejuruter. 2022, 34, 495–504. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Chen, Y.; Yang, H.; Chen, W.; Wang, X.; Chen, H. Fast pyrolysis of cotton stalk biomass using calcium oxide. Bioresour. Technol. 2017, 233, 15–20. [Google Scholar] [CrossRef]

- Al Afif, R.; Anayah, S.S.; Pfeifer, C. Batch pyrolysis of cotton stalks for evaluation of biochar energy potential. Renew. Energy 2020, 147, 2250–2258. [Google Scholar] [CrossRef]

- Kagan, J.; Drury, A. Payback Period Definition. Investopedia. 2023. Available online: https://www.investopedia.com/terms/p/paybackperiod.asp (accessed on 8 May 2023).

- Fernando, J.; Mansa, J.; Rathburn, P. Net Present Value (NPV): What It Means and Steps to Calculate It. Investopedia. 2023. Available online: https://www.investopedia.com/terms/n/npv.asp (accessed on 8 May 2023).

- Mandapati, R.N.; Ghodke, P.K. Kinetics of pyrolysis of cotton stalk using model-fitting and model-free methods. Fuel 2021, 303, 121285. [Google Scholar] [CrossRef]

- Turton, R.; Shaeiwitz, J.; Bhattacharyya, D.; Whiting, W. Analysis, Synthesis and Design of Chemical Processes, 5th ed.; Prentice Hall: Boston, MA, USA, 2018. [Google Scholar]

- Coronado, C.R.; Yoshioka, J.T.; Silveira, J.L. Electricity, hot water and cold water production from biomass. Energetic and economical analysis of the compact system of cogeneration run with woodgas from a small downdraft gasifier. Renew. Energy 2011, 36, 1861–1868. [Google Scholar] [CrossRef]

- Indrawan, N.; Kumar, A.; Moliere, M.; Sallam, K.A.; Huhnke, R.L. Distributed power generation via gasification of biomass and municipal solid waste: A review. J. Energy Inst. 2020, 93, 2293–2313. [Google Scholar] [CrossRef]

- Buchholz, T.; Da Silva, I.; Furtado, J. Power from wood gasifiers in Uganda: A 250 kW and 10 kW case study. Energy 2012, 165, 181–196. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Silva Lora, E.E.; Venturini, O.J.; Andrande, R.V.; Leme, M.M.V.; del Olmo, O.A. Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. Energy Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Aguado, R.; Vera, D.; Lopez Garcia, D.A.; Torreglosa, J.P.; Jurado, F. Techno-Economic Assessment of a Gasification Plant for Distributed Cogeneration in the Agrifood Sector. Appl. Sci. 2021, 11, 660. [Google Scholar] [CrossRef]

- Patel, H.; Maiti, P.; Maiti, S. Techno-economic assessment of bio-refinery model based co-pyrolysis of cotton boll crop-residue and plastic waste. Biofuels Bioprod. Biorefining 2021, 16, 155–171. [Google Scholar] [CrossRef]

- Peters, S.M.; Timmerhaus, D.C. Plant Design and Economics for Chemical Engineers; McGraw Hill International Editions: New York, NY, USA, 2003. [Google Scholar]

- Zabaniotou, A.; Vaskalis, I. Economic Assessment of Polypropylene Waste (PP) Pyrolysis in Circular Economy and Industrial Symbiosis. Energies 2023, 16, 593. [Google Scholar] [CrossRef]

- EUROSTAT. Hourly Labour Costs—Statistics Explained. Ec.europa.eu. 2023. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Hourly_labour_costs#Hourly_labour_costs_ranged_between_.E2.82.AC6.5_and_.E2.82.AC45.8_in_2020 (accessed on 5 May 2023).

- Esteves, E.; Vital, B.R.; Carvalho, A.M.; Nascimento, M.F. Mechanical properties of cotton stalk particleboard made from shredded and hammer-milled materials. Ind. Crops Prod. 2015, 77, 857–862. [Google Scholar]

- DEI. Electricity Selling Price. Dei.gr. 2022. Available online: https://www.dei.gr/Documents/xt.tim.1.7.08.pdf (accessed on 5 May 2023).

- Aerio Attikis. Natural Gas Price and Savings. Aerioattikis.blob.core.windows.net. 2021. Available online: https://aerioattikis.blob.core.windows.net/wp-uploads/2021/07/%CE%A4%CE%B9%CE%BC%CE%AD%CF%82_%CE%99%CE%B4%CE%B9%CF%8E%CF%84%CE%B5%CF%82_%CE%99%CE%BF%CF%8D%CE%BB%CE%B9%CE%BF%CF%82_2021-60f1866822637.pdf (accessed on 5 May 2023).

- EYDAP. Pricing EYDAP. Eydap.gr. 2022. Available online: https://www.eydap.gr/userfiles/47614413-661a-4fba-ba7c-a14f00cfa261/Timologio_EYDAP_2.pdf (accessed on 5 May 2023).

- Yang, Y.; Wang, J.; Chong, K.; Bridgwater, A. A techno-economic analysis of energy recovery from organic fraction of municipal solid waste (MSW) by an integrated intermediate pyrolysis and combined heat and power (CHP) plant. Energy Convers. Manag. 2018, 174, 406–416. [Google Scholar] [CrossRef]

- Zhang, T.; Zhai, Y.; Ma, X.; Shen, X.; Bai, Y.; Zhang, R.; Ji, C.; Hong, J. Towards environmental sustainability: Life cycle assessment-based water footprint analysis on China’s cotton production. J. Clean. Prod. 2021, 313, 127925. [Google Scholar] [CrossRef]

- Fu, M.; Guo, B.; Wang, W.; Wang, J.; Zhao, L.; Wang, J. Comprehensive Assessment of Water Footprints and Water Scarcity Pressure for Main Crops in Shandong Province, China. Sustainability 2019, 11, 1856. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G.; Paciarotti, C. Environmental analysis of a cotton yarn supply chain. J. Clean. Prod. 2014, 82, 154–165. [Google Scholar] [CrossRef]

- Cotton Incorporated. Life Cycle Assessment of Cotton Fiber and Fabric. 2012. Available online: http://resource.cottoninc.com/LCA/LCA-Full-Report.pdf (accessed on 12 May 2023).

- Yang, X.; Gao, W.; Zhang, M.; Chen, Y.; Sui, P. Reducing agricultural carbon footprint through diversified crop rotation systems in the North China Plain. J. Clean. Prod. 2014, 76, 131–139. [Google Scholar] [CrossRef]

- Ullah, A.; Perret, S.R.; Gheewala, S.H.; Soni, P. Eco-efficiency of cotton-cropping systems in Pakistan: An integrated approach of life cycle assessment and data envelopment analysis. J. Clean. Prod. 2016, 134, 623–632. [Google Scholar] [CrossRef]

- Sala, S.; Crenna, E.; Secchi, M.; Pant, R. Global Normalisation Factors for the Environmental Footprint and Life Cycle Assessment; EUR (28984); Publications Office of the European Union: Luxembourg, 2017.

- Alcazar-Ruiz, A.; Ortiz, M.L.; Dorado, F.; Sanchez-Silva, L. Gasification versus fast pyrolysis bio-oil production: A life cycle assessment. J. Clean. Prod. 2022, 336, 130373. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).