Influence of Hydrogen Reduction Stage Conditions on the Microwave Properties of Fine Iron Powders Obtained via a Spray-Pyrolysis Technique

Abstract

1. Introduction

2. Materials and Methods

2.1. Hematite Powder Preparation Using an Ultrasonic Spray-Pyrolysis

2.2. Iron Powder Preparation by the Hematite Reduction in Hydrogen

2.3. Characterization

3. Results and Discussion

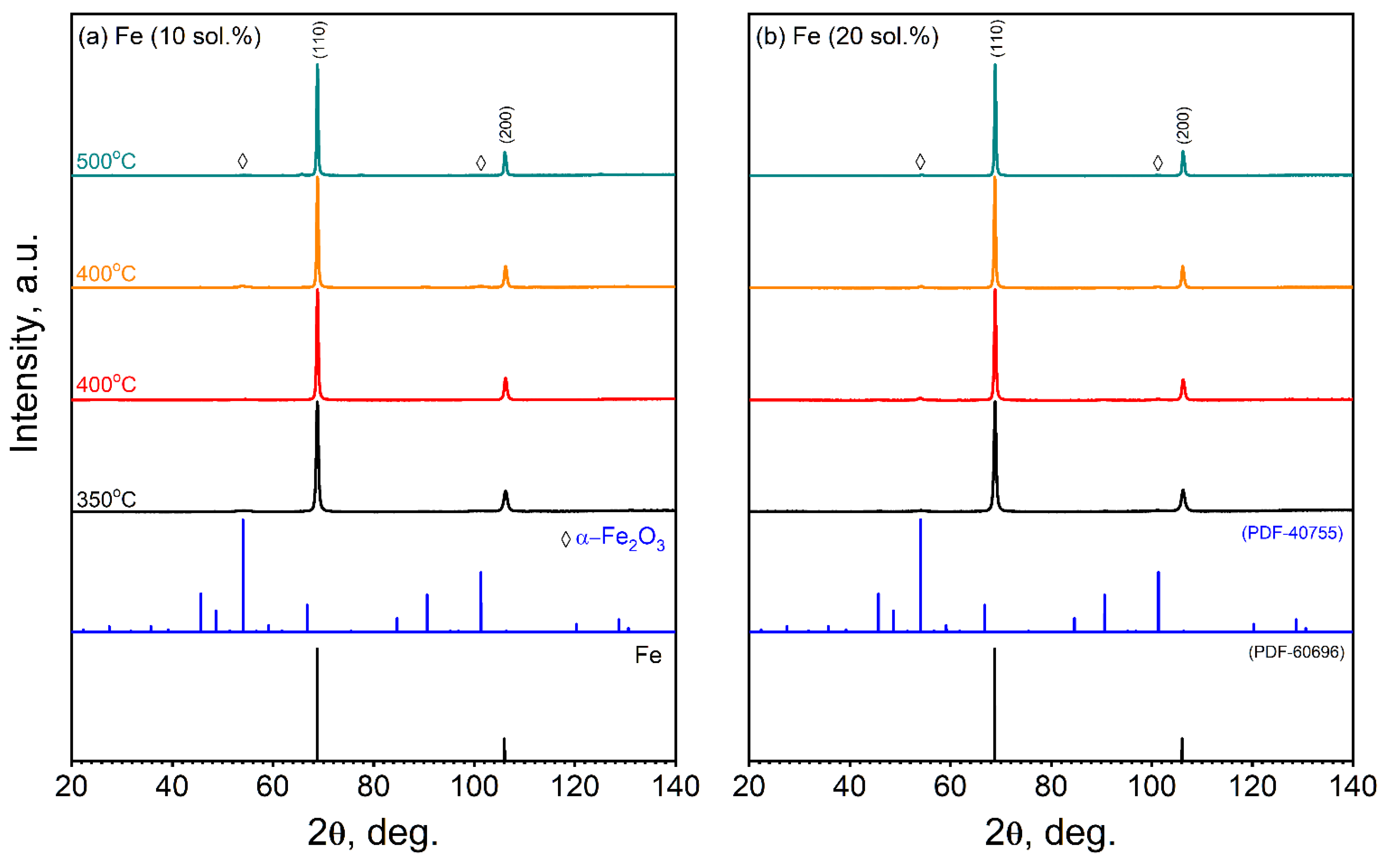

3.1. X-ray Diffraction Analysis

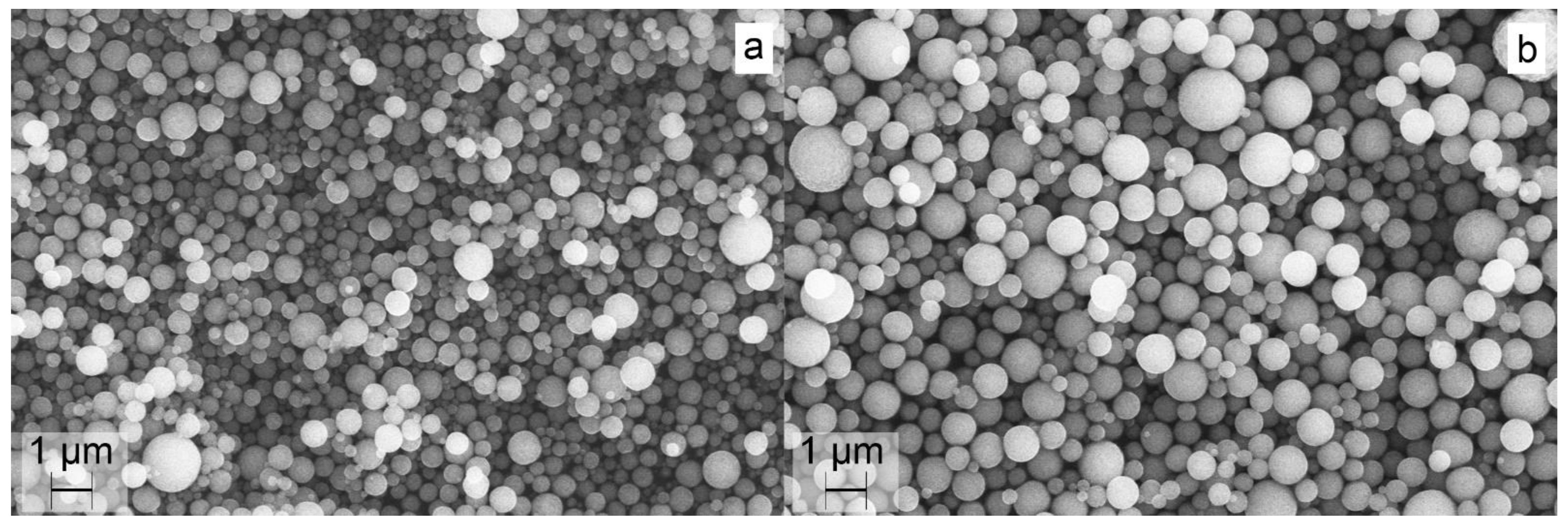

3.2. Scanning Electron Microscopy

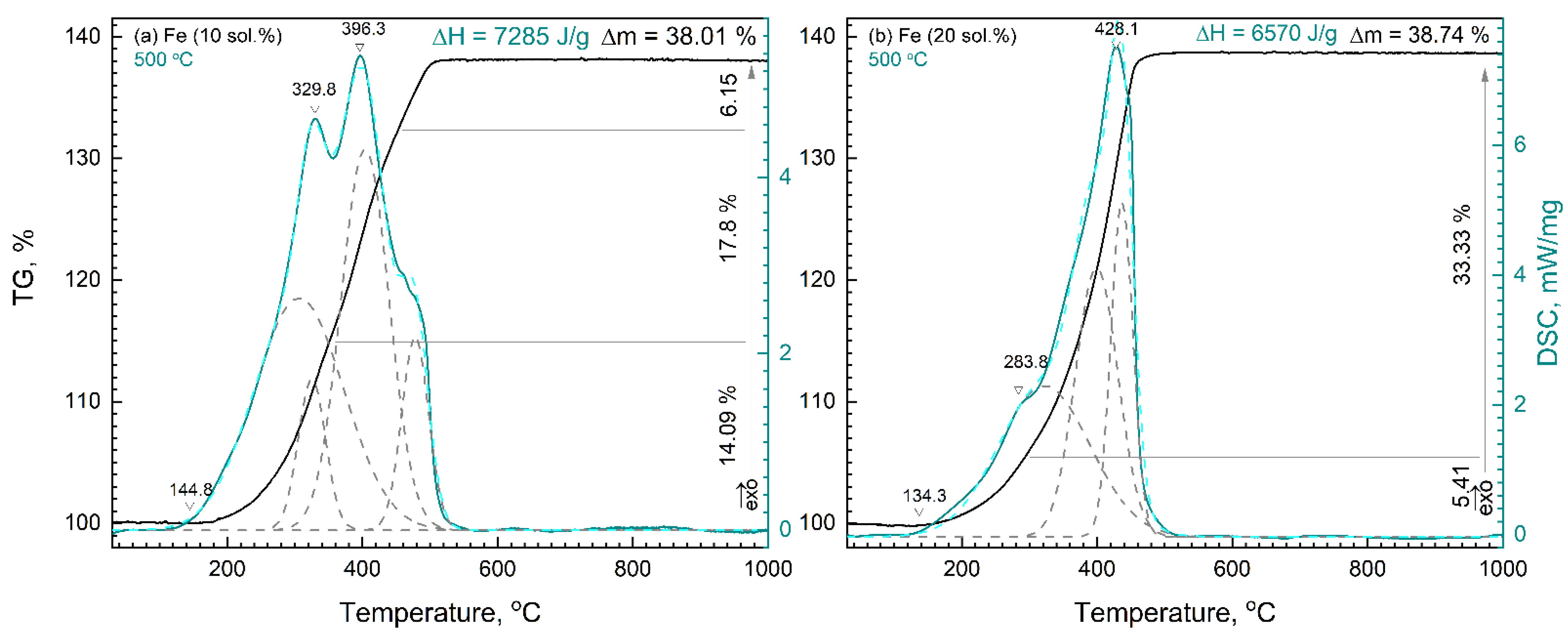

3.3. Thermal Analysis

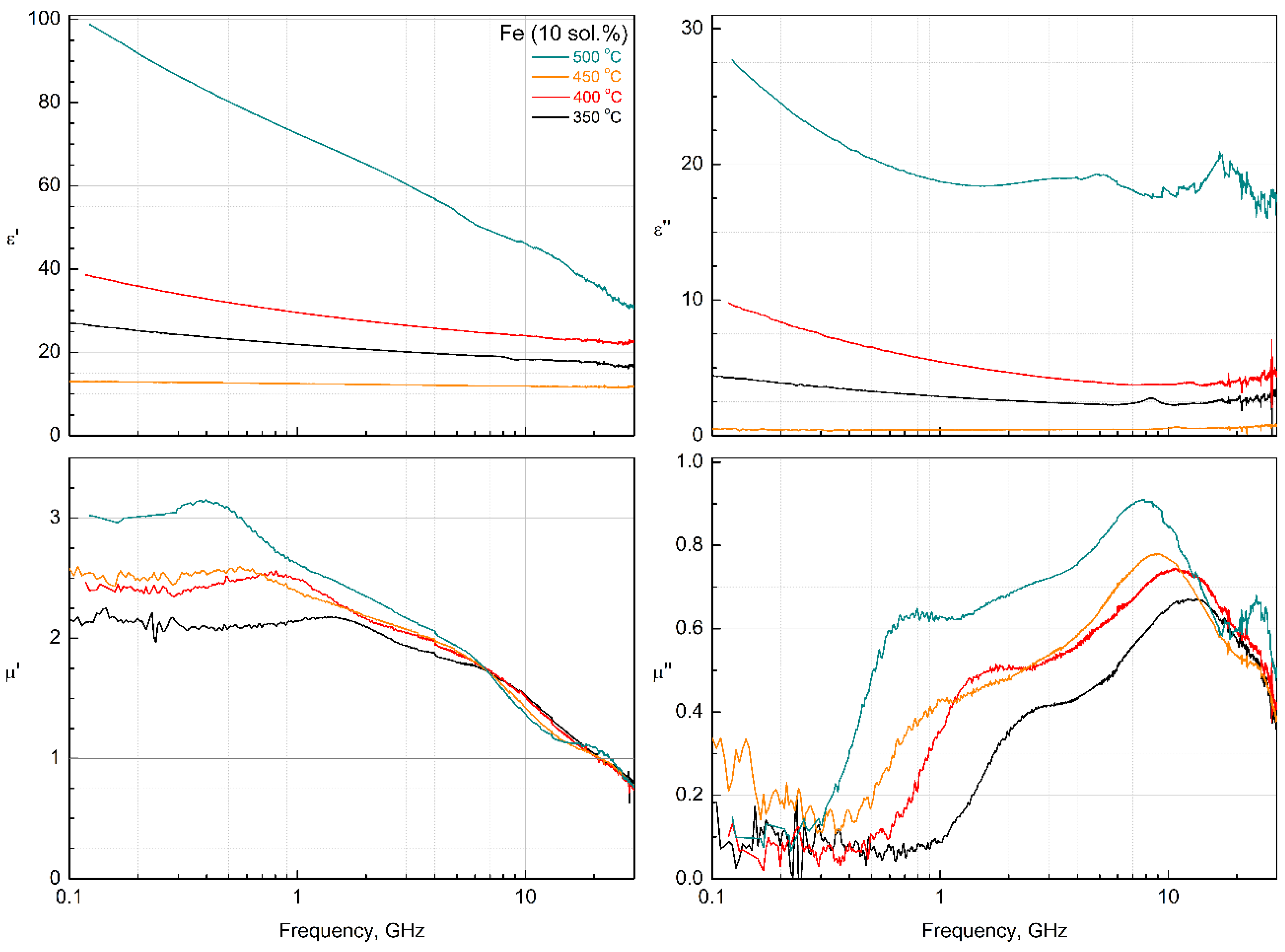

3.4. Microwave Measurement

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Acher, O. Frequency Response Engineering of Magnetic Composite Materials. In Advances in Electromagnetics of Complex Media and Metamaterials; Springer: Dordrecht, The Netherlands, 2002; pp. 39–59. [Google Scholar]

- Rozanov, K.N.; Koledintseva, M.Y. Application of Generalized Snoek’s Law over a Finite Frequency Range: A Case Study. J. Appl. Phys. 2016, 119, 073901. [Google Scholar] [CrossRef]

- Dolmatov, A.V.; Maklakov, S.S.; Zezyulina, P.A.; Osipov, A.V.; Petrov, D.A.; Naboko, A.S.; Polozov, V.I.; Maklakov, S.A.; Starostenko, S.N.; Lagarkov, A.N. Deposition of a Sio2 Shell of Variable Thickness and Chemical Composition to Carbonyl Iron: Synthesis and Microwave Measurements. Sensors 2021, 21, 4624. [Google Scholar] [CrossRef] [PubMed]

- Maklakov, S.S.; Lagarkov, A.N.; Maklakov, S.A.; Adamovich, Y.A.; Petrov, D.A.; Rozanov, K.N.; Ryzhikov, I.A.; Zarubina, A.Y.; Pokholok, K.V.; Filimonov, D.S. Corrosion-Resistive Magnetic Powder Fe@SiO 2 for Microwave Applications. J. Alloys Compd. 2017, 706, 267–273. [Google Scholar] [CrossRef]

- Abbas, S.M.; Dixit, A.K.; Chatterjee, R.; Goel, T.C. Complex Permittivity, Complex Permeability and Microwave Absorption Properties of Ferrite–Polymer Composites. J. Magn. Magn. Mater. 2007, 309, 20–24. [Google Scholar] [CrossRef]

- Lagarkov, A.N.; Rozanov, K.N. High-Frequency Behavior of Magnetic Composites. J. Magn. Magn. Mater. 2009, 321, 2082–2092. [Google Scholar] [CrossRef]

- Lv, Q.; Zhu, S.; Zhao, X.; Liu, X.; Feng, S.; Kan, X.; Yujie, Y.; Cheng, Y. Magnetic Permeability Stability of Composite Material with Nominal Composition Ni0.6Fe2.4O4. J. Magn. Magn. Mater. 2022, 553, 169179. [Google Scholar] [CrossRef]

- Battle, P.D.; Grandjean, F.; Long, G.J.; Oldham, S.E. The Influence of Chemical Composition on the Magnetic Properties of Fe1.5–XCoxRh0.5Mo3N (0 ≤ x ≤ 1.5). J. Mater. Chem. 2007, 17, 4785. [Google Scholar] [CrossRef]

- Zezyulina, P.A.; Petrov, D.A.; Rozanov, K.N.; Vinnik, D.A.; Maklakov, S.S.; Zhivulin, V.E.; Starikov, A.Y.; Sherstyuk, D.P.; Shannigrahi, S. Study of the Static and Microwave Magnetic Properties of Nanostructured BaFe12−xTixO19. Coatings 2020, 10, 789. [Google Scholar] [CrossRef]

- Maklakov, S.S.; Naboko, A.S.; Maklakov, S.A.; Bobrovskii, S.Y.; Polozov, V.I.; Zezyulina, P.A.; Osipov, A.V.; Ryzhikov, I.A.; Rozanov, K.N.; Filimonov, D.F.; et al. Amorphization of Thin Supermalloy Films Ni79Fe17Mo4 with Oxygen during Magnetron Sputtering. J. Alloys Compd. 2021, 854, 157097. [Google Scholar] [CrossRef]

- Howlader, R.K.; Shil, S.K.; Shekher Sikder, S.; Kumar Saha, D. Effect of Annealing Temperature on the Complex Permeability of (Fe0.95Co0.05)73.5Cu1Nb3Si13.5B9 Nanocrystalline Amorphous Ribbon. Res. Rev. J. Mater. Sci. 2017, 05, 144–148. [Google Scholar] [CrossRef]

- Sanna Angotzi, M.; Mameli, V.; Zákutná, D.; Kubániová, D.; Cara, C.; Cannas, C. Evolution of the Magnetic and Structural Properties with the Chemical Composition in Oleate-Capped Mn(x)Co(1–x)Fe2O4 Nanoparticles. J. Phys. Chem. C 2021, 125, 20626–20638. [Google Scholar] [CrossRef]

- Yudin, A.; Shatrova, N.; Khaydarov, B.; Kuznetsov, D.; Dzidziguri, E.; Issi, J.-P. Synthesis of Hollow Nanostructured Nickel Oxide Microspheres by Ultrasonic Spray Atomization. J. Aerosol Sci. 2016, 98, 30–40. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Okuyama, K. Progress in Developing Spray-Drying Methods for the Production of Controlled Morphology Particles: From the Nanometer to Submicrometer Size Ranges. Adv. Powder Technol. 2011, 22, 1–19. [Google Scholar] [CrossRef]

- Gurmen, S.; Ebin, B.; Stopić, S.; Friedrich, B. Nanocrystalline Spherical Iron–Nickel (Fe–Ni) Alloy Particles Prepared by Ultrasonic Spray Pyrolysis and Hydrogen Reduction (USP-HR). J. Alloys Compd. 2009, 480, 529–533. [Google Scholar] [CrossRef]

- Septiani, E.L.; Kikkawa, J.; Cao, K.L.A.; Hirano, T.; Okuda, N.; Matsumoto, H.; Enokido, Y.; Ogi, T. Direct Synthesis of Submicron FeNi Particles via Spray Pyrolysis Using Various Reduction Agents. Adv. Powder Technol. 2021, 32, 4263–4272. [Google Scholar] [CrossRef]

- Halim, K.S.A.; El-Geassy, A.A.; Ramadan, M.; Nasr, M.I.; Hussein, A.; Fathy, N.; Alghamdi, A.S. Reduction Behavior and Characteristics of Metal Oxides in the Nanoscale. Metals 2022, 12, 2182. [Google Scholar] [CrossRef]

- Gorimbo, J.; Muvhiiwa, R.; Llane, E.; Hildebrandt, D. Cobalt Catalyst Reduction Thermodynamics in Fischer Tropsch: An Attainable Region Approach. Reactions 2020, 1, 115–129. [Google Scholar] [CrossRef]

- Kosevich, A.; Petrusevich, E.; Maklakov, S.; Naboko, A.; Kolesnikov, E.; Petrov, D.; Zezyulina, P.; Pokholok, K.; Filimonov, D.; Han, M. Low Weight Hollow Microspheres of Iron with Thin Dielectric Coating: Synthesis and Microwave Permeability. Coatings 2020, 10, 995. [Google Scholar] [CrossRef]

- Artemova, A.V.; Maklakov, S.S.; Osipov, A.V.; Petrov, D.A.; Shiryaev, A.O.; Rozanov, K.N.; Lagarkov, A.N. The Size Dependence of Microwave Permeability of Hollow Iron Particles. Sensors 2022, 22, 3086. [Google Scholar] [CrossRef]

- Konyukhov, Y.V.; Kamali, S.; Nguyen, T.H.; Alymov, M.I.; Lileev, A.S.; Karpenkov, D.Y.; Zakharova, E.V. Size Dependence of Magnetic Properties of Fe, Co and Ni Nanoparticles Prepared by the Chemical-Metallurgical Method Using Surfactants. Nano-Struct. Nano-Objects 2023, 33, 100943. [Google Scholar] [CrossRef]

- Dolmatov, A.V.; Maklakov, S.S.; Artemova, A.V.; Petrov, D.A.; Shiryaev, A.O.; Lagarkov, A.N. Deposition of Thick SiO2 Coatings to Carbonyl Iron Microparticles for Thermal Stability and Microwave Performance. Sensors 2023, 23, 1727. [Google Scholar] [CrossRef] [PubMed]

- Shiryaev, A.; Rozanov, K.; Naboko, A.; Artemova, A.; Maklakov, S.; Bobrovskii, S.; Petrov, D. Splitting of the Magnetic Loss Peak of Composites under External Magnetic Field. Physics 2021, 3, 678–688. [Google Scholar] [CrossRef]

- Starostenko, S.N.; Petrov, D.A.; Shiryaev, A.O. Effect of Temperature on Microwave Permeability Spectrum of Composite with Gadolinium Powder. Mod. Electrodyn. 2022, 2, 23–31. [Google Scholar]

- Starostenko, S.N.; Petrov, D.A.; Rozanov, K.N.; Shiryaev, A.O.; Lomaeva, S.F. Effect of Temperature on Microwave Permeability of an Air-Stable Composite Filled with Gadolinium Powder. Sensors 2022, 22, 3005. [Google Scholar] [CrossRef]

- Nakamura, T. Snoek’s Limit in High-Frequency Permeability of Polycrystalline Ni–Zn, Mg–Zn, and Ni–Zn–Cu Spinel Ferrites. J. Appl. Phys. 2000, 88, 348–353. [Google Scholar] [CrossRef]

- Iakubov, I.T.; Lagarkov, A.N.; Maklakov, S.A.; Osipov, A.V.; Rozanov, K.N.; Ryzhikov, I.A.; Starostenko, S.N. Microwave Permeability of Composites Filled with Thin Fe Films. J. Magn. Magn. Mater. 2006, 300, e74–e77. [Google Scholar] [CrossRef]

- Lagarkov, A.N.; Rozanov, K.N.; Simonov, N.A.; Starostenko, S.N. Microwave Permeability of Magnetic Films. In Handbook of Advanced Magnetic Materials; Springer: Boston, MA, USA, 2006; pp. 1742–1773. [Google Scholar]

- Petrov, D.A.; Rozanov, K.N.; Koledintseva, M.Y. Influence of Higher-Order Modes in Coaxial Waveguide on Measurements of Material Parameters. In Proceedings of the 2018 IEEE Symposium on Electromagnetic Compatibility, Signal Integrity and Power Integrity (EMC, SI & PI), Long Beach, CA, USA, 30 July–3 August 2018; IEEE: New York, NY, USA, 2018; pp. 66–70. [Google Scholar]

- Kraushofer, F.; Jakub, Z.; Bichler, M.; Hulva, J.; Drmota, P.; Weinold, M.; Schmid, M.; Setvin, M.; Diebold, U.; Blaha, P.; et al. Atomic-Scale Structure of the Hematite α-Fe2O3 (1102) “R-Cut” Surface. J. Phys. Chem. C 2018, 122, 1657–1669. [Google Scholar] [CrossRef]

- Bak, S.-M.; Shadike, Z.; Lin, R.; Yu, X.; Yang, X.-Q. In Situ/Operando Synchrotron-Based X-Ray Techniques for Lithium-Ion Battery Research. NPG Asia Mater. 2018, 10, 563–580. [Google Scholar] [CrossRef]

- Pang, J.; Guo, P.; Zhao, P. Reduction Kinetics of Fine Iron Ore Powder in Mixtures of H2-N2 and H2-H2O-N2 of Fluidized Bed. J. Iron Steel Res. Int. 2015, 22, 391–395. [Google Scholar] [CrossRef]

- El-geassy, A.A.; El-kashif, F.O.; Nasr, M.I.; Omar, A.A. Kinetics and Mechanisms of Com Pacts Re-Oxiation of Freshly Reduced Lron. ISIJ Int. 1994, 34, 541–547. [Google Scholar] [CrossRef]

- Beach, G.S.D.; Parker, F.T.; Smith, D.J.; Crozier, P.A.; Berkowitz, A.E. New Magnetic Order in Buried Native Iron Oxide Layers. Phys. Rev. Lett. 2003, 91, 267201. [Google Scholar] [CrossRef] [PubMed]

- Shatrova, N.; Yudin, A.; Levina, V.; Kuznetsov, D.; Novakova, A.; Dzidziguri, E.; Perov, N.; Issi, J.-P. Characteristics of Co3O4 and Cobalt Nanostructured Microspheres: Morphology, Structure, Reduction Process, and Magnetic Properties. Mater. Res. Bull. 2018, 99, 189–195. [Google Scholar] [CrossRef]

- Lysenko, E.N.; Surzhikov, A.P.; Zhuravkov, S.P.; Vlasov, V.A.; Pustovalov, A.v.; Yavorovsky, N.A. The Oxidation Kinetics Study of Ultrafine Iron Powders by Thermogravimetric Analysis. J. Therm. Anal. Calorim. 2014, 115, 1447–1452. [Google Scholar] [CrossRef]

- Müller, C.M.O.; Pires, A.T.N.; Yamashita, F. Characterization of Thermoplastic Starch/Poly(Lactic Acid) Blends Obtained by Extrusion and Thermopressing. J. Braz. Chem. Soc. 2012, 23, 426–434. [Google Scholar] [CrossRef]

- Chen, R.Y.; Yeun, W.Y.D. Review of the High-Temperature Oxidation of Iron and Carbon Steels in Air or Oxygen. Oxid. Met. 2003, 59, 433–468. [Google Scholar] [CrossRef]

- Spreitzer, D.; Schenk, J. Reduction of Iron Oxides with Hydrogen—A Review. Steel Res. Int. 2019, 90, 1900108. [Google Scholar] [CrossRef]

- Shiryaev, A.O.; Rozanov, K.N.; Artemova, A.V.; Bobrovskii, S.Y.; Naboko, A.S.; Osipov, A.V.; Petrov, D.A.; Zezyulina, P.A. Experimental Study Of Microwave Magnetic Properties Of Composites Under Magnetic Bias. In Proceedings of the 2021 IEEE International Magnetic Conference (INTERMAG), Lyon, France, 26–30 April 2021; IEEE: New York, NY, USA, 2021; pp. 1–5. [Google Scholar]

| Sample | Tred, °C | a, Å | ω, wt. % | CS, nm | dav, µm | ||

|---|---|---|---|---|---|---|---|

| Fe | Fe2O3 | Fe | Fe2O3 | ||||

| Fe (10 sol. %) | 350 | 2.8660 | 85 | 15 | 27 | 4 | 0.41 |

| 400 | 2.8659 (8) | 90 | 10 | 37 | 4 | 0.50 | |

| 450 | 2.8655 (7) | 85 | 15 | 39 | 8 | 0.57 | |

| 500 | 2.8672 (3) | 95 | 5 | 49 | 19 | <<0.41 | |

| Fe (20 sol. %) | 350 | 2.8656 (7) | 90 | 10 | 27 | 6 | 0.69 |

| 400 | 2.8649 (8) | 90 | 10 | 36 | 10 | 0.70 | |

| 450 | 2.8664 (9) | 90 | 10 | 41 | 12 | 0.78 | |

| 500 | 2.8647 (5) | 95 | 5 | 49 | 17 | 0.80 | |

| Sample | Tred, °C | Tonset, °C | ΔH, J/g | Δm, % | ωFe, % |

|---|---|---|---|---|---|

| Fe (10 sol. %) | 350 | 128.2 | 6227 | 33.64 | 78 |

| 400 | 104.5 | 5660 | 35.12 | 82 | |

| 450 | 165.0 | 5369 | 32.01 | 74 | |

| 500 | 144.8 | 7285 | 38.04 | 89 | |

| Fe (20 sol. %) | 350 | 118.1 | 5850 | 35.56 | 83 |

| 400 | 128.3 | 6120 | 37.62 | 88 | |

| 450 | 135.8 | 5820 | 36.09 | 84 | |

| 500 | 136.0 | 6570 | 38.64 | 90 |

| Sample | Tred, °C | KA | fLF, GHz | fHF, GHz | ρincl, g/cm3 |

|---|---|---|---|---|---|

| Fe (10 sol. %) | 350 | 0.176 | 2.4 | 13.9 | 6.17 |

| 400 | 0.192 | 1.6 | 10.6 | 5.91 | |

| 450 | 0.178 | 1.0 | 8.5 | 6.10 | |

| 500 | 0.210 | 0.7 | 7.7 | 6.64 | |

| Fe (20 sol. %) | 350 | 0.177 | 2.5 | 13.1 | 6.04 |

| 400 | 0.184 | 1.7 | 11.0 | 6.37 | |

| 450 | 0.185 | 1.0 | 9.0 | 6.18 | |

| 500 | 0.212 | 0.8 | 7.9 | 6.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Artemova, A.V.; Maklakov, S.S.; Shiryaev, A.O.; Osipov, A.V.; Petrov, D.A.; Rozanov, K.N.; Lagarkov, A.N. Influence of Hydrogen Reduction Stage Conditions on the Microwave Properties of Fine Iron Powders Obtained via a Spray-Pyrolysis Technique. Magnetism 2023, 3, 90-101. https://doi.org/10.3390/magnetism3020008

Artemova AV, Maklakov SS, Shiryaev AO, Osipov AV, Petrov DA, Rozanov KN, Lagarkov AN. Influence of Hydrogen Reduction Stage Conditions on the Microwave Properties of Fine Iron Powders Obtained via a Spray-Pyrolysis Technique. Magnetism. 2023; 3(2):90-101. https://doi.org/10.3390/magnetism3020008

Chicago/Turabian StyleArtemova, Anastasia V., Sergey S. Maklakov, Artem O. Shiryaev, Alexey V. Osipov, Dmitry A. Petrov, Konstantin N. Rozanov, and Andrey N. Lagarkov. 2023. "Influence of Hydrogen Reduction Stage Conditions on the Microwave Properties of Fine Iron Powders Obtained via a Spray-Pyrolysis Technique" Magnetism 3, no. 2: 90-101. https://doi.org/10.3390/magnetism3020008

APA StyleArtemova, A. V., Maklakov, S. S., Shiryaev, A. O., Osipov, A. V., Petrov, D. A., Rozanov, K. N., & Lagarkov, A. N. (2023). Influence of Hydrogen Reduction Stage Conditions on the Microwave Properties of Fine Iron Powders Obtained via a Spray-Pyrolysis Technique. Magnetism, 3(2), 90-101. https://doi.org/10.3390/magnetism3020008