1. Introduction

Power generation has been shifting over the years toward non conventional renewable energy resources such as wind, solar, hydro, and geothermal [

1]. Of all the available renewable energy resources, hydroelectric power has been a key generation method for many decades. The US has a long history of using hydropower, which currently provides about 6% of the nation’s total electricity (and 29% of its renewable electricity), with a total installed capacity of roughly 80,000 MW [

2]. Previously, hydroelectric power provided stability while reliably meeting demand through established load forecasting and grid operations. However, the increasing contribution from other renewable has fundamentally altered grid operations by introducing greater variability into the power grid [

3]. To accommodate grid variability, hydropower must rapidly adjust its power generation, often by requiring large power output changes over short periods to maintain grid reliability and resilience; such an adjustment may require advanced technology integration in an already changing energy landscape. This dynamic operation scenarios is made more complex because the underlying dynamics of hydroturbines are generally nonlinear and not fully characterized [

4].

Accomplishing real-time adaptive control of hydropower generation with a fast response to changing grid needs requires the development of parameter optimization algorithms that can adaptively learn hydroturbine dynamics and provide optimal tuning parameters critical for controller design, operational optimization and daily maintenance [

5]. Use of Kaplan hydroturbines—among the common forms of turbines in hydropower systems for variable power generation—requires operating across a large range, resulting in nonlinear dynamics, particularly in mechanical torque; the variables include water head, shaft speed, blade angle, and guide vane opening (or sometimes referred to as gate opening).

Prior research on adaptive hydroturbine modeling has explored linearizing nonlinear dynamics of Kaplan hydroturbines of hydropower systems into a six-coefficient model for system identification with proportional–integral–derivative (PID) control. Prior research also has explored employing deep-learning models, with parameters linked to operating conditions, for adaptive self-tuning control [

6]. Recently, the optimization of the Kaplan hydroturbine using a machine-learning-based surrogate model was proposed in [

7], whereas a comprehensive review and optimization of a runner wheel of a Kaplan hydroturbine is presented in [

8]. Multiple Kaplan hydroturbine models were developed and evaluated for large grid frequency disturbances in [

9]. Literature reviews reveal that most hydroturbine models have been developed and validated using simulation data [

10]. However, recent work has addressed modeling deficiencies, particularly the misrepresentation of Kaplan turbines, by analyzing dynamic blade effects and utilizing real-world field data for validation [

11]; this work relies on representing the dynamics with a static model.

Precise modeling of the Kaplan turbine governing system is essential for analyzing power system stability and maintaining grid security. The changing energy generation landscape requires advance technology integration and adaptive parameter optimization for hydropower systems via digital twin effort [

12]. However, this is difficult owing to the lack of characterization and modeling for the nonlinear nature of hydroturbines. Although many past works have focused on the accurate modeling of Kaplan hydroturbine model, validation with real-plant operational data is missing. Using real-time operating data from a plant’s distributed control system (shaft speed, water pressure, and guide vane opening), the goal is to create a nonlinear optimization method for tuning open-loop hydroturbine model parameters. This method attempts to match the model’s power output with real-time plant data by tuning model parameters depending on the guide vane opening input, thus effectively learning and adapting to the turbine’s nonlinear behavior. The aim of this paper is to derive the six-coefficient linearized dynamic Kaplan hydroturbine model and formulate the optimization problem to estimate the six coefficients based on the input as gate vane-opening real-time data to match the mechanical power output from real Kaplan hydroturbine hydropower systems.

The rest of the paper is organized as follows: the basic concept of a Kaplan hydroturbine and dynamic modeling is presented in

Section 2;

Section 3 presents details of the formulation and implementation of the optimization-based algorithm;

Section 5 presents the experimental setup and results; and finally,

Section 6 concludes the study with future directions.

3. Optimization Problem Formulation

The cost function can be formulated by considering the sum of power square error (

14) from the measurement and the simulation. Moreover, to account for the worst-case deviations across all time steps, the cost function also accounts for the maximum absolute error (

15), avoiding the large peak errors and the rate of change of error (

16) to penalize the large changes in the error. Therefore, the total cost function is then formulated as:

where

are the weights given to reflect the relative importance of the error metrics. The power error terms in the above equation are given by

which is the quadratic error term between the modelled power and the actual power.

is the peak error term reflecting the maximum error between the modelled power and the actual power.

where it has been denoted that

To estimate the parameters

, the optimization problem is formatted using the Nelder–Mead Algorithm 1. This is a gradient-free optimization method designed to minimize objective functions in

n-dimensional space. It works by iteratively refining the solution through evaluation of the objective function at several points and applying geometric transformations on a simplex consisting of

points. This algorithm is particularly effective for solving optimization problems that do not rely on gradient information, making it ideal for non-differentiable, noisy, or complex objective functions. The optimization problem is formulated as:

The optimization problem seeks to minimize the cost function

, where

is the parameter vector to be estimated. The Nelder–Mead algorithm iteratively updates

by reflecting, expanding, contracting, or shrinking a simplex of candidate solutions until convergence criteria are met.

| Algorithm 1: Nelder-Mead optimization algorithm. |

![Dynamics 05 00020 i001]() |

In this work, the weights were intentionally set to unequal values and were chosen based on empirical evaluation to prioritize the overall match between simulated and measured power, while still penalizing significant transient errors and capturing dynamic mismatches. The selected weights were held constant throughout all experiments for consistency and are summarized in

Table 1.

5. Simulation Setup and Results

The real operational data are taken from Unit C-8 at the Rocky Reach Dam, owned and operated by Chelan County Public Utility District (PUD), Washington. The operational data were collected to accurately model the dynamic performance of the hydroelectric system, including the turbine dynamics, in accordance with the North American Electric Reliability Corporation. The experimental dataset used for parameter identification spans a total duration of 400 s and contains 1492 data points per measured variable (gate opening, net head, and generated power) and the collected data are shown in

Figure 2. Considering the inherently slow dynamics of hydro turbines, this resolution is sufficient to capture the relevant transient and steady-state behavior of the system for parameter identification and model validation. Notably, the gate opening data used in this study represent the real plant control input over the measurement period and exhibits a change of approximately +0.3, p.u. during the event window, which corresponds to typical turbine operating conditions and load demands. These variations capture the dynamic response of the turbine and provide the excitation needed for system identification and parameter optimization. The temporal profile of the gate opening, illustrated in

Figure 2, highlights periods of steady operation as well as transient changes, which are essential for validating the dynamic model against plant data.

Figure 3 shows the simulation setup for the formulation of the optimization problem. The goal is to tune the Kaplan hydroturbine model using the operational data from the Rocky Reach Dam to match the mechanical power output from the plant with the simulated model by optimizing the Kaplan model’s six coefficients. The weights are selected based on the relative importance of each error metric.

Table 1 summarizes the system parameters and simulation settings for this optimization problem formulation. On note, the error tolerance is adaptive throughout the simulation.

The guide vane opening of the hydroturbine system serves as the model’s time-varying control input. To facilitate open-loop simulations, the data are interpolated to align with the solver’s time steps, providing a continuous representation of the gate opening over time. The simplified dynamic model incorporating the relationship of the blade angle and the gate value opening is used as stated in Equation (

11).

Figure 2 shows the data collected from the Chelan County PUD’s Rocky Reach Dam, Unit C-8, under

Hz online perceived frequency step test. For the optimization problem, only the gate (%) was used as an input to the dynamic model to estimate the six unknown coefficients so that the simulation’s mechanical power output matches the measurement (

).

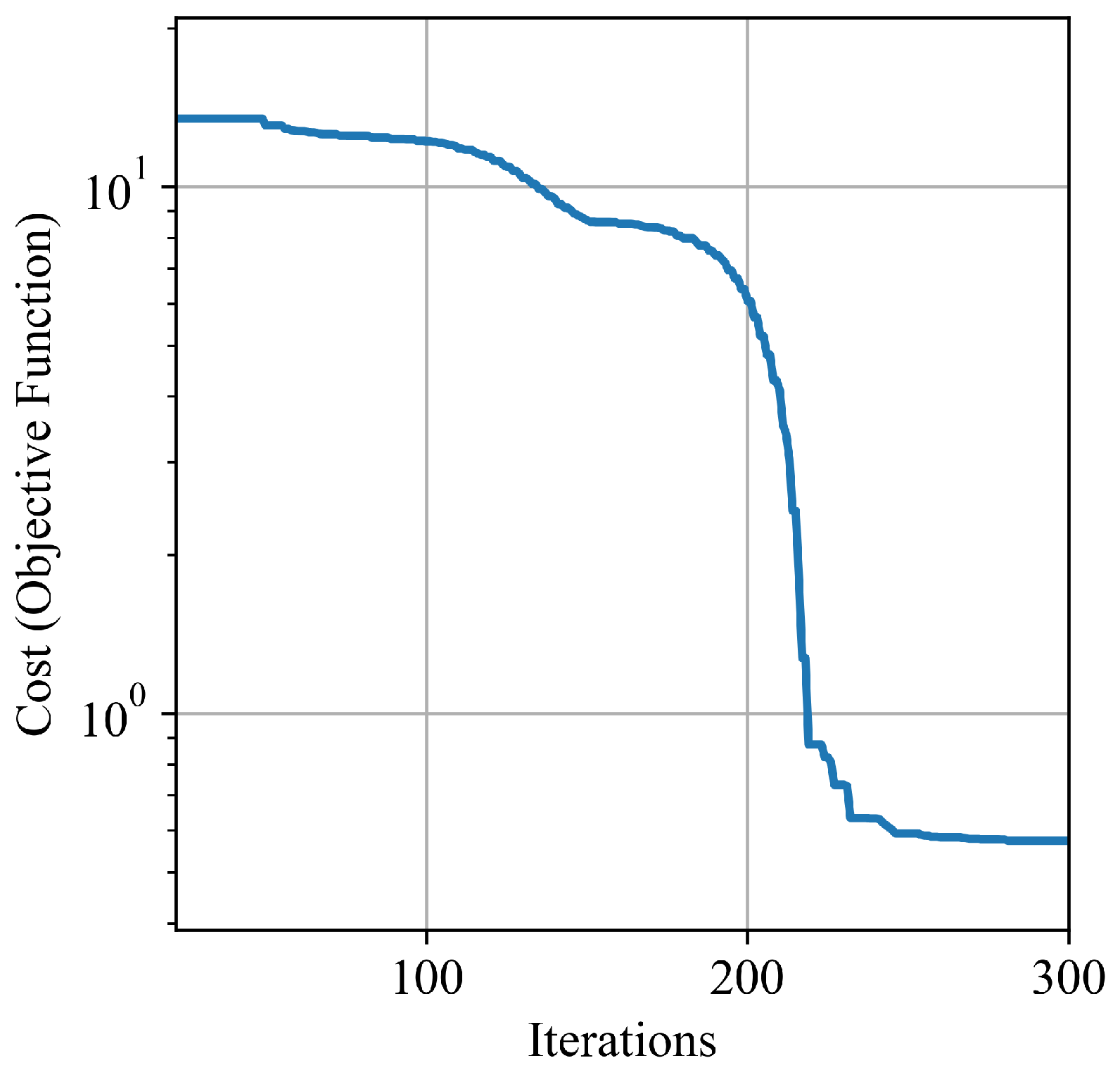

The convergence performance of the Nelder–Mead optimization on minimizing the cost function over the number of iterations is shown in

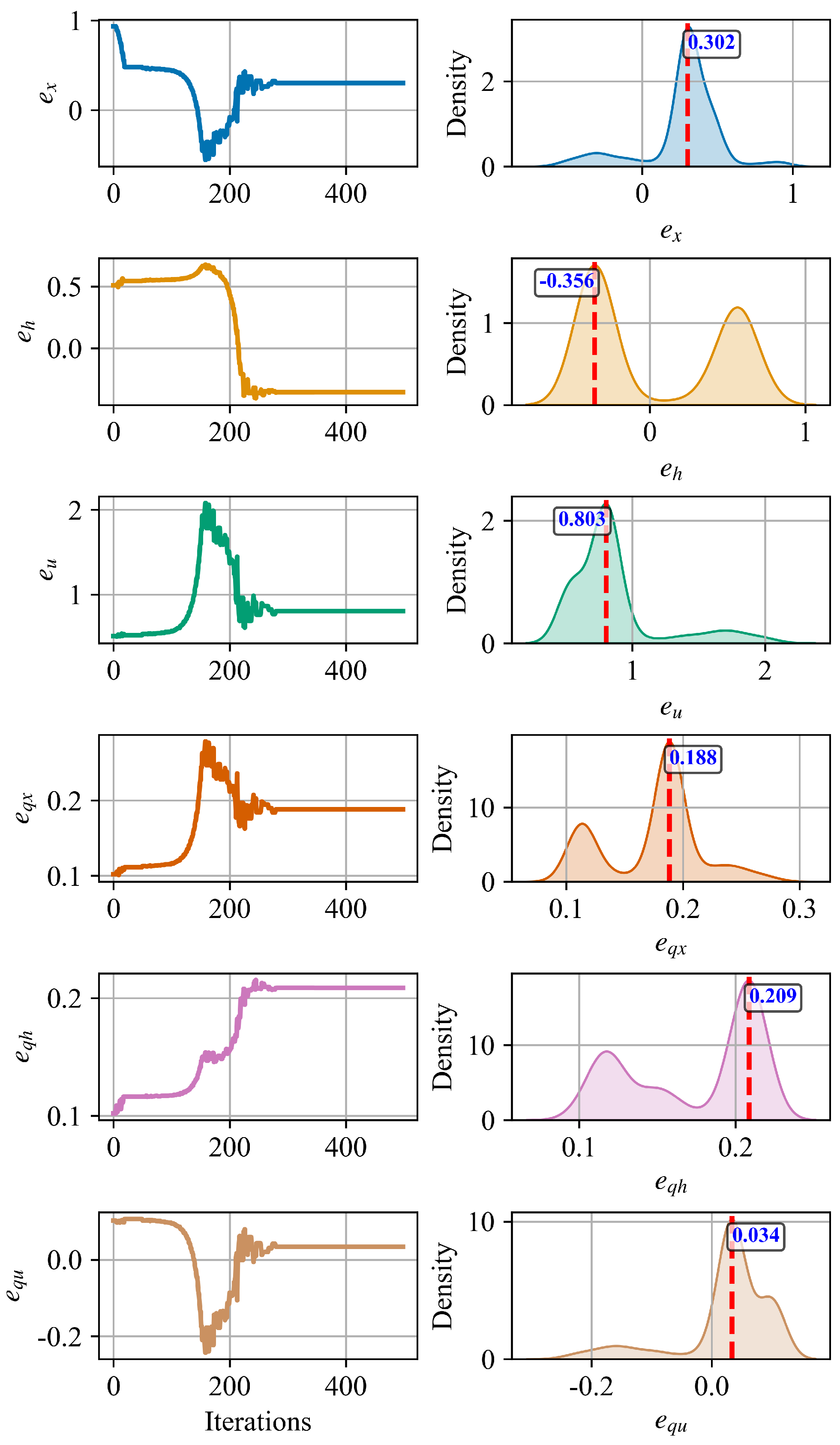

Figure 4. With the optimization problem formulation, the convergence and distribution of the estimated best six coefficients of the Kaplan hydroturbine model that represent the real Kaplan unit in Rocky Reach Dam are shown in

Figure 5. The model was simulated with the initial parameters listed in

Table 1. Results show that the parameters converged after around 200 iterations. The final estimated coefficients’ values are annotated in the probability density function plot and yielded the following estimated parameters for the model, represented by the vector

. Estimated coefficients reflect the contribution of different terms in the governing equations to the simulated power output. Notably, parameters such as

and

exhibit higher values, indicating a stronger influence of the corresponding terms on the model’s response. In contrast, coefficients like

have smaller magnitudes, suggesting a relatively lower impact. This variation highlights which physical relationships are more dominant in the power estimation process. Such information is valuable for model refinement, allowing future efforts to prioritize or simplify certain terms based on their relevance to the overall system dynamics.

Estimated mechanical power output from the simulated model with optimized parameters is shown in

Figure 6. The formulated optimization problem can closely predict the mechanical power output from the real Kaplan hydroturbine unit based on the single gate vane opening as an input while optimizing the coefficients of the developed model. Since parameters can be estimated for given operating condition, these parameters can be used to estimate the power output from the Kaplan hydropower online with given gate-opening as input. Model performance was evaluated using key statistical metrics comparing the simulated power output to the measured plant data and summarized in

Table 2. An RMSE of 0.0118, corresponding to an RMSE percentage of 1.24%, indicates a very low average and relative error, demonstrating excellent accuracy in capturing the measured power profile. The coefficient of determination,

, was 0.9425, signifying that the model explains over 94% of the variance in the measured data, indicating a strong fit. The adjusted

of 0.9422, being very close to

R2, further supports that the chosen parameters are effective and the model complexity is appropriate. The large F-statistic of 5910.3983 confirms the high statistical significance of the model’s fit.

The algorithm is then tested with a dataset covering a longer period. Seven days of data from April 2024 are taken for the validation. The cost function of the optimization is shown in

Figure 7. The optimization process yielded the following estimated parameters for the model, represented by the vector

:

as shown in

Figure 8.

To validate the model under a broader range of operating conditions, we utilized an extended dataset comprising seven consecutive days of real operational data from the plant. The model’s performance over this longer time horizon was evaluated using key statistical metrics, as summarized in

Table 3.

Figure 9 shows the performance of the proposed model with validation data. The RMSE was 0.0394, with an RMSE percentage of 4.93%, indicating low absolute and relative error between the simulated and measured power outputs. The coefficient of determination (

) was 0.9248, demonstrating that the model explains approximately 92.48% of the variance in the measured data—reflecting a strong fit. The adjusted

, also 0.9248, suggests that the model complexity is well-suited to the dataset and the selected parameters are effective. Additionally, the high F-statistic value of 161,921.7939 confirms the model’s strong statistical significance. These results collectively highlight the model’s robustness and reliability when validated against a longer and more diverse dataset.

Accurately modeling the complex nonlinear dynamics inherent in a Kaplan hydroturbine, particularly the relationship between gate opening and power output, presents a significant challenge. The adopted linearized model simplifies these dynamics effectively around an operating point for analytical purposes. Validation of this model using the current available dataset of real plant operational data has demonstrated good performance, evidenced by the high and low RMSE values achieved.