Smart Fasteners and Washers for Preload and Loosening Detection: A Systematic Review of Sensing Technologies

Abstract

1. Introduction

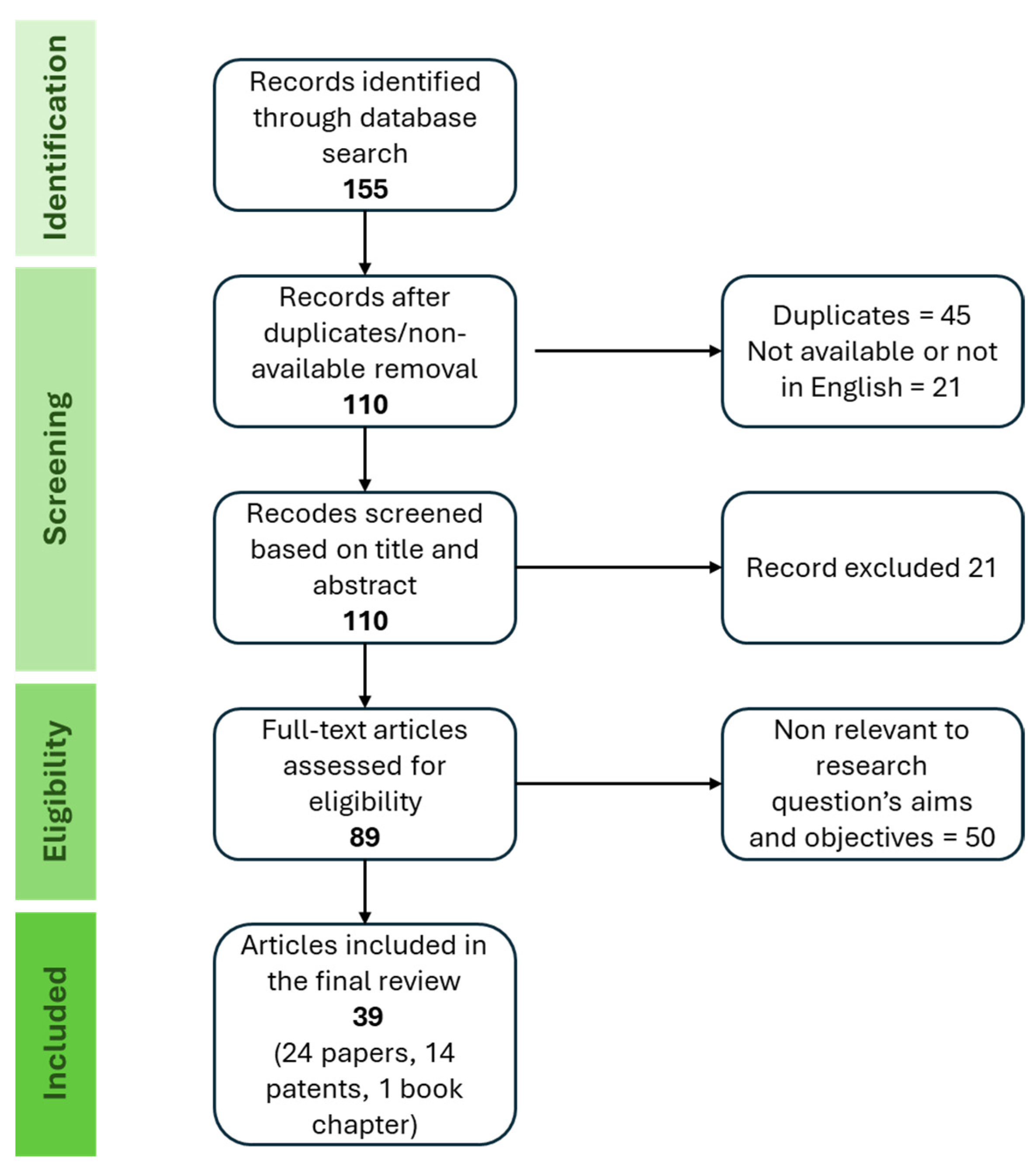

2. Materials and Methods

2.1. Search Strategy

2.2. Eligibility Criteria and Study Selection

- if the document is a duplicate, it is automatically excluded;

- if the document cannot be retrieved or if is not in English language, is excluded;

- if the document does not match the Aim, it is labeled as Irrelevant;

- if the document matches Aim, Context, and Tools, it is labeled as Important;

- if the document matches Aim and Context or Tools, it is labeled as Relevant;

- else it is labelled as Irrelevant.

2.3. Data Synthesis and Analysis

- Quis? (Authors);

- Quando? (Year);

- Ubi? (Context or type of structure);

- Cur? (Aim of the invention/study);

- Quid? (Methods/Tools);

- Quomodo? (Tests and results).

3. Results

3.1. Literature Search Results

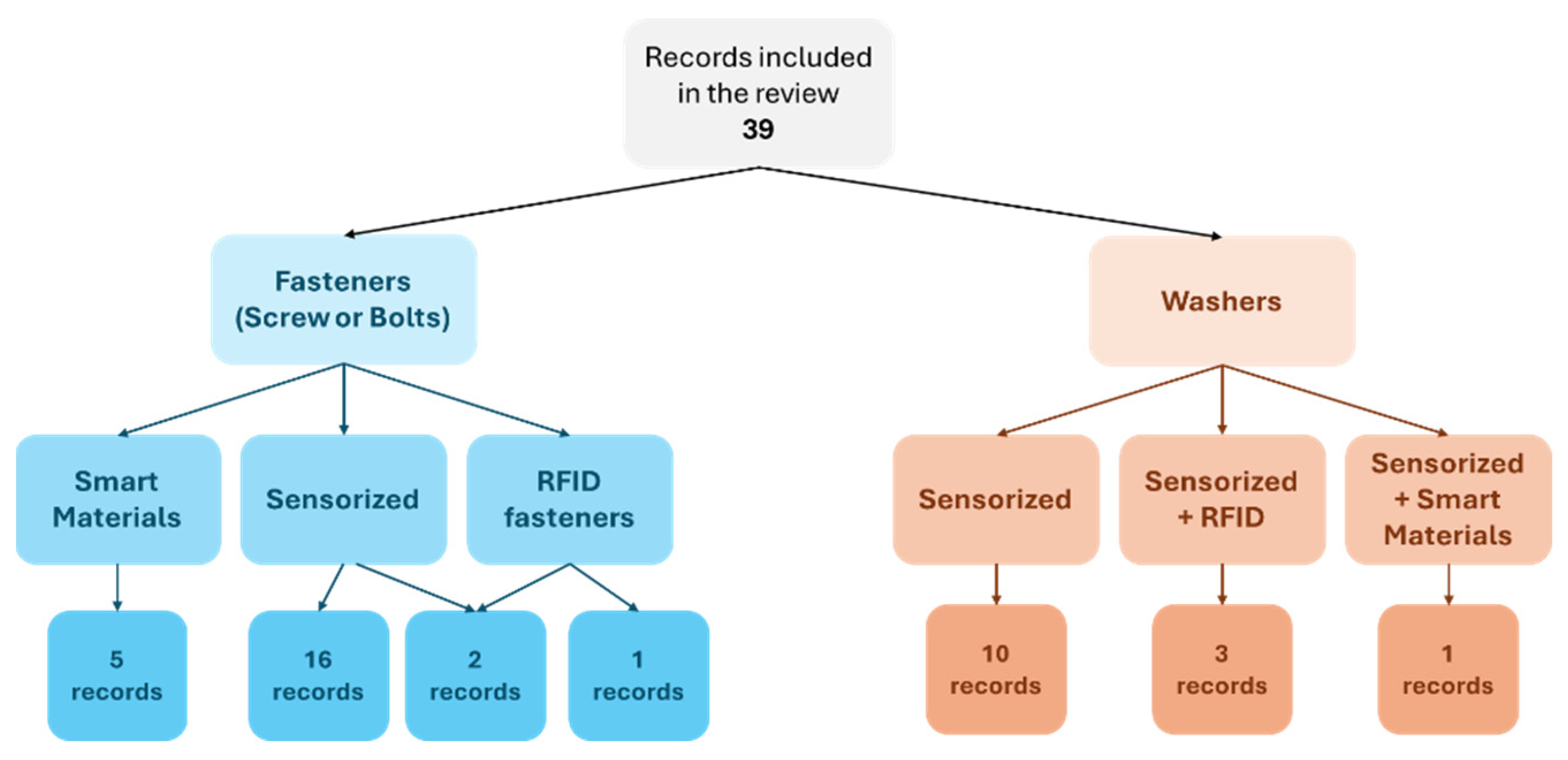

3.2. Description of the Included Documents

- Radio Frequency Identification (RFID) Fasteners use radio frequency to track and identify fasteners wirelessly [14].

- Sensorized + Smart Material Washers, which adapt their material characteristics in response to environmental factors and transmit data via RFID [43].

3.3. Summary of Evidence

3.3.1. Smart Material Fasteners

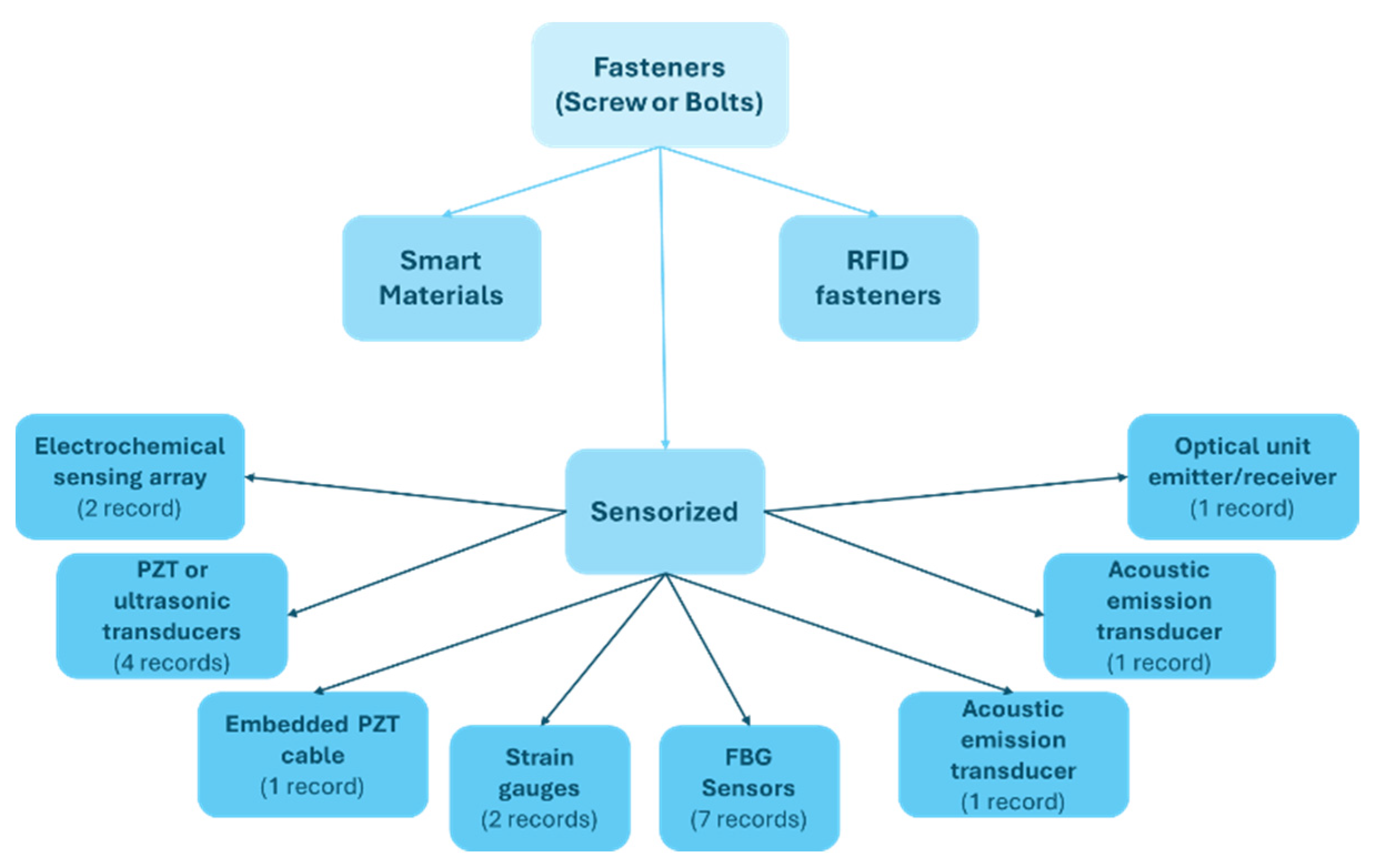

3.3.2. Sensorized Fasteners

- piezoelectric cable embedded in a bolt to monitor structural health by measuring relative displacements of joints and structural vibrations [29]. The key strengths of the presented approach are ease of installation and low cost, making it suitable for retrofitting existing structures. However, its limited sensitivity to static loads, potential calibration drift, and reliance on wired data acquisition restrict its use to short-term or localized monitoring.

- multielement electrochemical sensing array to detect corrosion [13,21]. The system presented in [21] integrates an electrochemical smart sensor directly into an aircraft fastener to enable in situ detection of early-stage corrosion. It autonomously monitors key environmental parameters. The sensor array is embedded within the fastener head and connected to a Common Electronics Unit for data storage and later retrieval via a portable computer.

- broadband acoustic emission transducer to assess structural integrity by identifying signs of metal fatigue and cracking [13];

- optical unit (emitter/receiver) combined with temperature or moisture sensors to measure strain [30]. This patent presents an optical smart bolt with a reflective sensor embedded in an axial cavity to track elongation and preload continuously. The system offers high precision and immunity to electromagnetic interference, but it may weaken the bolt and require temperature compensation. Its complexity and cost restrict its use to critical, high-value applications.

3.3.3. RFID Fasteners

3.3.4. Smart Washers

4. Summary and Discussion

4.1. Smart Fasteners

4.1.1. What to Measure

4.1.2. Strain Sensors

4.1.3. Corrosion Sensing

4.1.4. Smart Materials and Active Fasteners

4.1.5. Piezoelectric Active and Passive Sensors

4.2. Smart Washers

4.2.1. Advantages

4.2.2. Strain Measurements

4.2.3. Smart Materials

4.3. Data Transmission

4.4. Summary

- Support type

- Technology/sensor

- Measurement type

- Measurement evaluation

- Integration level

- Cost/scalability

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smith, J.D.; Pothier, S.G. Load Sensing System Including RFID Tagged Fasteners. U.S. Patent US 11/460,819, 19 August 2006. [Google Scholar]

- Huo, L.; Chen, D.; Liang, Y.; Li, H.; Feng, X.; Song, G. Impedance based bolt pre-load monitoring using piezoceramic smart washer. Smart Mater. Struct. 2017, 26, 057004. [Google Scholar] [CrossRef]

- Zhu, S.; Huang, S.S. Intelligenter Befestiger. Europe Patent EP2803871A1, 2 November 2016. [Google Scholar]

- Groche, P.; Brenneis, M. Manufacturing and use of novel sensoric fasteners for monitoring forming processes. Measurement 2014, 53, 136–144. [Google Scholar] [CrossRef]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A Smart Washer for Bolt Looseness Monitoring Based on Piezoelectric Active Sensing Method. Appl. Sci. 2016, 11, 320. [Google Scholar] [CrossRef]

- Eslami, B.; Ganye, R.; Bunai, C.; Thamire, C. Smart Fasteners and Their Application in Flanged Joints Available to Purchase. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012. [Google Scholar] [CrossRef]

- Tanaka, T.; Okugawa, M. Adopting supervisor for bolt loosening detection by using smart washer. In Proceedings of the ASME 2008 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Ellicott City, MD, USA, 28–30 October 2008. [Google Scholar] [CrossRef]

- Akdeniz; Kollgaard, J.; Malkin, M. Active Washers for Monitoring Bolted Joints. U.S. Patent US7698949, 20 April 2010.

- Chen, H.-P.; Ni, Y.-Q. Introduction to Structural Health Monitoring. In Structural Health Monitoring of Large Civil Engineering Structures; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Zhao, H.-W.; Zhang, X.; Ding, Y.; Guo, T.; Li, A.; Soh, C.-K. Probabilistic mixture model driven interpretable modeling, clustering, and predicting for physical system data. Eng. Appl. Artif. Intell. 2025, 160, 112069. [Google Scholar] [CrossRef]

- Liu, Z. Smart Sensors for Structural Health Monitoring and Nondestructive Evaluation. Sensors 2024, 24, 603. [Google Scholar] [CrossRef]

- Wang, G. Strain-Gsuged Washer for Measuring Bolt Preload. U.S. Patent US9719900B1, 1 August 2017. [Google Scholar]

- Schoess, J.N.; Havey, G.D. Smart Fastener. U.S. Patent US5549803A, 27 August 1996. [Google Scholar]

- Aske, J.; Wilson, J.; Smith, R.; Berden, M. Intelligent Fasteners. U.S. Patent 11,074,490, 27 July 2021. [Google Scholar]

- Yoon, H.-S. A new design concept for multifunctional fasteners using smart materials. In SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring; SPIE: Bellingham, WA, USA, 2009. [Google Scholar] [CrossRef]

- White, P. Stress Induced Connecting Assembly. U.S. Patent US20010028148A1, 4 February 2003. [Google Scholar]

- Wu, M.H.; Schetky, L.M. Industrial Application for Shape Memry Alloy. In Proceedings of the International Conference on Shape Memory and Superelastic Technologies, Pacific Grove, CA, USA, 30 April–4 May 2000; Available online: https://api.semanticscholar.org/CorpusID:10721921 (accessed on 30 October 2025).

- Park, G.; Muntges, D.E.; Inman, D.J. Self-repairing joints employing shape-memory alloy actuators. Smart Struct. Mater. 2003, 55, 33–37. [Google Scholar] [CrossRef][Green Version]

- Menna, C.; Auricchio, F.; Asprone, D. Chapter 13—Applications of Shape Memory Alloys in Structural Engineering. In Shape Memory Alloy Engineering; Elsevier: Amsterdam, The Netherlands, 2015; pp. 369–403. [Google Scholar] [CrossRef]

- Thompson, L.D.; Westermo, B.D.; Crum, D.B.; Law, W.; Trombi, R.; Waldbusser, R. Smart structural fasteners for the aircraft and construction industries. In Smart Structures and Materials 1999: Smart Structures and Integrated Systems; SPIE: Bellingham, WA, USA, 1999. [Google Scholar] [CrossRef]

- Schoess, J.N.; Seifert, G. Smart fastener for KC-135 structural integrity monitoring. In Smart Structures and Materials 1997: Smart Sensing, Processing, and Instrumentation; SPIE: Bellingham, WA, USA, 1997. [Google Scholar] [CrossRef]

- Kibblewhite, E.; Molsbergen, R. Thread Forming Fasteners for Ultrasonic Load Measurement and Control. WO Patent WO2004027271A3, 1 July 2004. [Google Scholar]

- Yoon, H.-S.; DeCicco, R. Lamb Wave Excitation and Detection with Smart Fasteners for Structural Health Monitoring. In Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security; SPIE: Bellingham, WA, USA, 2010. [Google Scholar] [CrossRef]

- Gräbner, D.; Dödtmann, S.; Dumstorff, G.; Lucklum, F. 3-D-printed smart screw: Functionalization during additive fabrication. Sens. Sens. Syst. 2018, 7, 143–151. [Google Scholar] [CrossRef]

- Ren, L.; Feng, T.; Ho, M.; Jiang, T.; Song, G. A smart “shear sensing” bolt based on FBG sensors. Measurement 2018, 122, 240–246. [Google Scholar] [CrossRef]

- Sun, Q.; Yuan, B.; Mu, X.; Sun, W. Bolt preload measurement based on the acoustoelastic effect using smart piezoelectric bolt. Smart Mater. Struct. 2019, 28, 055005. [Google Scholar] [CrossRef]

- Shah, N.; Chandler, W.K.; Madsen, C.; Way, D.R. Smart Fastener and Smart Insert for a Fastener Using Fiber Bragg Gratings to Measure Strain and Temperature. U.S. Patent US8433160B2, 30 April 2013. [Google Scholar]

- Pran, K.; Farsund, O.; Wang, G. Fibre Bragg grating smart bolt monitoring creep in bolted GRP composite. In Proceedings of the 15th IEEE Optical Fiber Sensors Conference Technical Digest, Portland, OR, USA, 10 May 2002. [Google Scholar] [CrossRef]

- Shimoi, N.; Cuadra, C.H.; Madokoro, H.; Saijo, M. Simple Smart Piezoelectric Bolt Sensor for Structural Monitoring of Bridges. Int. J. Instrum. Sci. 2013, 1, 78–83. [Google Scholar] [CrossRef]

- Klasén, W. Intelligent Bolt and System Therefor. U.S. Patent US10066930B2, 4 September 2018. [Google Scholar]

- Li, T.; Liu, W.; Gao, H.; Wang, N.; Xia, K.; Li, R.; Tan, Y.; Zhou, Z. FBG-Based Force Sensing with Temperature Self-Compensation for Smart Bolts. Sens. Actuators 2024, 379, 115872. [Google Scholar] [CrossRef]

- Yang, W.S.; Chiang, C.C.; Hsu, H.C. Monitoring torque in bolts using an embedded fiber Bragg grating sensor. Optik 2023, 291, 171294. [Google Scholar] [CrossRef]

- Khomenko, A.; Koricho, E.G.; Haq, M.; Cloud, G.L. Bolt tension monitoring with reusable fiber Bragg-grating sensors. J. Strain Anal. Eng. Des. 2015, 51, 101–108. [Google Scholar] [CrossRef]

- Chen, D.; Huo, L.; Li, H.; Song, G. A Fiber Bragg Grating (FBG)-Enabled Smart Washer for Bolt Pre-Load Measurement: Design, Analysis, Calibration, and Experimental Validation. Sensors 2018, 8, 2586. [Google Scholar] [CrossRef]

- Kamentser, B.; Kamentser, E. Washer Having Stressed and Unstressed Strain Gauges. U.S. Patent US6250863B1, 26 June 2001. [Google Scholar]

- Ito, H.; Okugawa, M. Natural frequency identification of smart washer by using adaptive observer. In SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring; SPIE: Bellingham, WA, USA, 2014. [Google Scholar] [CrossRef]

- Huo, L.; Chen, D.; Kong, Q.; Li, H.; Song, G. Smart washer—A piezoceramic-based transducer to monitor looseness of bolted connection. Smart Mater. Struct. 2017, 26, 025033. [Google Scholar] [CrossRef]

- Okugawa, M.; Tanaka, T. Effect on detection sensitivity for smart washer configuration and ambient temperature characteristics on bolted joint. In SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring; SPIE: Bellingham, WA, USA, 2007. [Google Scholar] [CrossRef]

- Yeager, M.; Whitaker, A.; Todd, M. A method for monitoring bolt torque in a composite connection using an embedded fiber Bragg grating sensor. J. Intell. Mater. Syst. Struct. 2017, 29, 335–344. [Google Scholar] [CrossRef]

- White, D.J.; Velderman, M.J.; Seman, A.E.; Lemieux, C.W.; Hill, G. System for Wireless Retrieval of Measured Component Data. U.S. Patent US11937032B2, 19 March 2024. [Google Scholar]

- Zhu, S.S.; Huang, S.S. Intelligent Washer. U.S. Patent US10941802B2, 9 March 2017. [Google Scholar]

- Jaffrey, A. McNaney. Smart Washer for Preload Monitoring. U.S. Patent US9964135B2, 5 August 2018. [Google Scholar]

- Raghunath, G.; Barkley, B.; Flatau, A.B. Smart washers to measure bolt loads using magnetostrictive galfenol. In Proceedings of the 23rd AIAA/AHS Adaptive Structures Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar] [CrossRef]

- You, R.; Ren, L.; Song, G. A Novel Comparative Study of European, Chinese and American Codes on Bolt Tightening Sequence Using Smart Bolts. Int. J. Steel Struct. 2020, 20, 910–918. [Google Scholar] [CrossRef]

- Seyoum, B.; Rossi, M.; Brunelli, D. A self-powered wireless bolt for smart critical fastener. In Proceedings of the 2017 Global Internet of Things Summit (GIoTS), Geneva, Switzerland, 6–9 June 2017. [Google Scholar] [CrossRef]

- Evans, K.E.; Alderson, K.L. Auxetic materials: The positive side of being negative. Eng. Sci. Educ. J. 2000, 9, 148–154. [Google Scholar] [CrossRef]

- Hemingway, T.L.; Jackson, N.; Murray, T.; Pipp, W.B., Jr.; Danby, M.R.; Reznar, J.F. Smart Material Actuated Fasteners. U.S. Patent US20140017025A1, 8 November 2016. [Google Scholar]

- Rudduck, D.; Blattmann, L.D. Development in Beam Type Fasteners. U.S. Patent US8066462B2, 29 November 2011. [Google Scholar]

- Kim, J.S.; Lee, D.Y.; Koh, J.S.; Jung, G.P.; Cho, K.J. Component assembly with shape memory polymer fastener for microrobots. Smart Mater. Struct. 2013, 23, 015011. [Google Scholar] [CrossRef]

- Dementyev, A.; Vega Gálvez, T.; Olwal, A. SensorSnaps: Integrating Wireless Sensor Nodes into Fabric Snap Fasteners for Textile Interfaces. In Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technolog, New Orleans, LA, USA, 20–23 October 2019. [Google Scholar] [CrossRef]

- Vokoun, D.; Sedlák, P.; Frost, M.; Pilch, J.; Majtás, D.; Šittner, P. Velcro-like fasteners based on NiTi micro-hook arrays. Smart Mater. Struct. 2011, 20, 085027. [Google Scholar] [CrossRef]

- Duval, L. Intelligent Fasteners. U.S. Patent US6671185B2, 30 December 2003. [Google Scholar]

- Blier, K.M. Surgical Fastener. U.S. Patent US20120043367A1, 1 January 2013. [Google Scholar]

- Criscuolo, C.J.; Heinrich, R.S.; Azarbarzin, K. Absorbable Fastener and Applying Apparatus. U.S. Patent US8034076B2, 11 October 2011. [Google Scholar]

- Jeffries, L.; Lentink, D. Design Principles and Function of Mechanical Fasteners in Nature and Technology. Appl. Mech. Rev. 2020, 72, 050802. [Google Scholar] [CrossRef]

- Sorensen, E.; Coffland, D.W.; Song, H.J.; Chang, C.-M. Radio-Frequency-Identification-Based Smart Fastener. U.S. Patent US20210159943A1, 28 February 2023. [Google Scholar]

- Choi, Y.-T.; Purekar, A.S.; Wereley, N.M. Torque Loss and Crack Monitoring Near Fasteners for Isotropic and Composite Helicopter Tail Boom Structural Models. In Proceedings of the Smart Materials, Adaptive Structures and Intelligent Systems, Oxnard, CA, USA, 21–23 September 2009. [Google Scholar] [CrossRef]

- Browne, L.; Johnson, N.L. Active Material Based Fasteners Including Cable Ties and Twist Ties. U.S. Patent US8230555B2, 31 July 2009. [Google Scholar]

- David, H.A.; Sarh, B.; Zanteson, W.P. Intelligent Fastener Installation System. U.S. Patent US7703669B2, 27 April 2010. [Google Scholar]

- Xu, L.; Zhang, J.; Luo, J. Simulation Study on Intelligent Bolt Monitoring System Based on Cloud Service. J. Phys. Conf. Ser. 2021, 1746, 012022. [Google Scholar] [CrossRef]

- Gamboa, J.D.; Slesinski, R.J.; Zanteson, W.P.; Hoeckelman, L.A. Intelligent Fastener System. U.S. Patent US20110113613A1, 17 March 2015. [Google Scholar]

- Eshghinejad, A.; Elahinia, M.; Goel, V.K. Functionality Evaluation of a Novel Smart Expandable Pedicle Screw to Mitigate Osteoporosis Effect in Bone Fixation: Modeling and Experimentation. Smart Mater. Res. 2013, 2013, 840413. [Google Scholar] [CrossRef]

- Deress, D.; Martin, Z. Development and testing of an innovative fastener for use with cladding over foam sheathed wood framed walls. In Proceedings of the Structures Congress 2015, Portland, OR, USA, 23–25 April 2015. [Google Scholar] [CrossRef]

- Martinez, P.; Al-Hussein, M.; Ahmad, R. Ahmad. Intelligent vision-based online inspection system of screw-fastening operations in light-gauge steel frame manufacturing. Int. J. Adv. Manuf. Technol. 2020, 109, 645–657. [Google Scholar] [CrossRef]

- Guru, S.M.; Fernando, S.; Halgamuge, S.; Chan, K. Intelligent fastening with A—BOLT TM technology and sensor networks. Assem. Autom. 2004, 24, 386–393. [Google Scholar] [CrossRef]

- White, S.M.; Rousseau, M.S. The Use of an Innovative Mechanical Fastening Technology to Replace Failed Fixing Bolts and Extend the Useful Life of Anchored Steel Bulkheads; ASCE: Reston, VA, USA, 2001. [Google Scholar] [CrossRef]

- Sevostianov, V. Magnetostrictive self-diagnosing smart bolts. In Proceedings of the ASME International Mechanical Engineer-ing Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar] [CrossRef]

- Baroudi, U.; Mekid, S.; Bouhraoua, A. Bolt Tension Monitoring System. U.S. Patent US20130139604A1, 28 May 2013. [Google Scholar]

- Kurtz, D. Load Washer Transducer Assembly. U.S. Patent US4079624A, 21 March 1978. [Google Scholar]

- Kropp, H.C. Load Washer. U.S. Patent US5222399A, 29 June 1993. [Google Scholar]

- Sang-yoon, O.; Seong-min, K.; Jung-Hoon, K. RFID Tag Type Washer. U.S. Patent KR102079937B1, 24 February 2024. [Google Scholar]

- Takeuchi, K. Washer-Type Pressure Sensor. U.S. Patent US4566316A, 28 January 1986. [Google Scholar]

- Van Est, J.; Chauprade, F.; Sartelet, M. Piezoelectric Washer for Accelerometer Sensor with Resistive Path on Its External Contour. U.S. Patent FR3074361B1, 29 October 2019. [Google Scholar]

- Wang, B.; Huo, L.; Chen, D.; Li, W.; Song, G. Impedance-Based Pre-Stress Monitoring of Rock Bolts Using a Piezoceramic-Based Smart Washer-A Feasibility Study. Sensirs 2017, 17, 250. [Google Scholar] [CrossRef]

- Seneviratne, L. On the use of mechatronics for intelligent screw insertions. In Proceedings of the IEEE Conference on Emerging Technologies and Factory Automation. ETFA ’96, Kauai, HI, USA, 18–21 November 1996. [Google Scholar] [CrossRef]

- Brown, J.; Rich, A.M.; Gorkom, A.R.V. Smart Surgical Screwdriver. U.S. Patent 11871975, 16 January 2024. [Google Scholar]

- Parhar, S. Artificial Intelligent Washer System. U.S. Patent US20210355621A1, 18 November 2021. [Google Scholar]

- Stergiopoulou, A.; Stergiopoulos, V.; Kalkani, E. Contributions to the study of hydrodynamic behaviour of innovative Archimedean screw turbines recovering the Hydropotential of watercourses and of coastal currents. In Proceedings of the 13th International Conference on Environmental Science and Technology, Athens, Greece, 5–7 September 2013. [Google Scholar]

- Wei, T.-C.; Yen, C.-Y.; Kuo, K.-L. Intelligent Screw Supplier with Auto-Count and Alarm Function and Method Thereof. U.S. Patent US20070298650A1, 27 December 2007. [Google Scholar]

- Menon, M.G.; Harder, R.T.; Narasimaiah, P.S.; Mulinti, M. Occupant Weight Sensing Using Intelligent Fastener and Vertical Load Transmitting Brackets. U.S. Patent US8766112B2, 1 July 2014. [Google Scholar]

- Belkoff, S.; Langdale, E.; Knight, T. Smart Screw-Driver for Preventing Inadvertent Screw Stripping in Bone. U.S. Patent US9743971B2, 29 August 2017. [Google Scholar]

- Gallucci, G.O.; Finelle, G.; Papadimitriou, D.E.V.; Lee, S.J. Innovative approach to computer-guided surgery and fixed provisionalization assisted by screw-retained transitional implants. Int. J. Oral Maxillofac. Implant. 2015, 30, 403–410. [Google Scholar] [CrossRef]

- Antony, S.; Drissi-Habti, M.; Raman, V. Numerical Analysis to Enhance Delamination Strength around. Adv. Mater. Sci. Eng. 2018, 2018, 3154904. [Google Scholar] [CrossRef]

- Indartono, Y.S.; Heriawan, H.; Kartika, I.A. Innovative and flexible single screw press for the oil extraction of Calophyllum seeds. Res. Agric. Eng. 2019, 65, 91–97. [Google Scholar] [CrossRef]

- Pachner, S.; Miethlinger, J. Smart data analysis for optimized manufacturing of powder coatings on co-rotating twin screw extruders. AIP Conf. Proc. 2019, 2055, 070010. [Google Scholar] [CrossRef]

- Lekhaa, T.; Rajeshwari, S.; Sequeira, J.A.; Akshayaa, S. Intelligent Shopping Cart Using Bolt Esp8266 Based on Internet of Things. In Proceedings of the 2019 5th International Conference on Advanced Computing & Communication Systems (ICACCS), Coimbatore, India, 15–16 March 2019. [Google Scholar] [CrossRef]

- Azamfar, M.; Li, X.; Lee, J. Intelligent ball screw fault diagnosis using a deep domain adaptation methodology. Mech. Mach. Theory 2020, 151, 103932. [Google Scholar] [CrossRef]

- Riaz, N.; Shah, S.I.A.; Rehman, F.; Khan, M.J. An Intelligent Hybrid Scheme for Identification of Faults in Industrial Ball Screw Linear Motion Systems. IEEE Access 2021, 9, 35136–35150. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Mashiri, F.; Mirza, O.; Hart, B. Structural performance of steel-concrete composite bridges utilising innovative blind bolt shear connectors. Steel Compos. Struct. 2021, 40, 581–600. [Google Scholar] [CrossRef]

- Lin, W.-J.; Chen, J.-W.; Young, H.-T.; Hung, C.-L.; Li, K.-M. Developing the Smart Sorting Screw System Based on Deep Learning Approaches. Appl. Sci. 2021, 11, 9751. [Google Scholar] [CrossRef]

- Fu, P.; Chen, Y.-L.; Zeng, Q.-K.; Xiang, L.-K. Research on an intelligent ball-screw measuring instrument. In Measurement Technology and Intelligent Instruments; SPIE: Wuhan, China, 1993. [Google Scholar] [CrossRef]

- Eliasson, J.; Delsing, J.; Raayatinezhad, A.; Kyusakov, R. A SOA-based framework for integration of intelligent rock bolts with internet of things. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Cape Town, South Africa, 25–28 February 2013. [Google Scholar] [CrossRef]

- ISO 16047; Fasteners—Torque/Clamp Force Testing. International Organization for Standardization: Geneva, Switzerland, 2005.

- ASTM F606; Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets. ASTM International: West Conshohocken, PA, USA, 2023.

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

| [15] | A new Design Concept for Multifunctional Fasteners Using Smart Materials. |

|---|---|

| Relevance: | IMPORTANT |

| Authors: | Hwan-Sik Yoon |

| Year: | 2009 |

| Context: | Structural Members |

| Summary: | These smart fasteners, which integrate a piezoelectric element and control unit, function like conventional fasteners while monitoring structural response and actively generating counterforces to improve dynamic performance and suppress vibrations. |

| Aim: | A new design concept for piezoceramic actuators is presented to simplify the installation and removal of patch-type actuators for active vibration control of flexible structures. Integrated with a dedicated control algorithm, these multifunctional actuators can fasten structural members and generate control forces to enhance structural dynamics. |

| Methods and tools: | Two smart fastener configurations have been developed. In the first, a ring-shaped piezoceramic actuator is integrated beneath the bolt head to induce axial strain in the fastener and perpendicular deformation in the clamped component. In the second, a compact piezoceramic element is positioned between the bolt head and a proof mass. When driven at high frequency, the proof mass produces an inertial force on the jointed structure, while a sensing transducer embedded in the nut detects the resulting compressive or inertial loads. In both configurations, the measured response is processed by a control unit embedded in the bolt head, which generates the corresponding actuation signal. A Lyapunov-based control algorithm ensures robust suppression of structural vibrations in flexible members. Beyond vibration mitigation, the smart fastener concept also enables structural health monitoring through an impedance-based technique. By applying electrical signals of varying frequencies to the piezoceramic element and measuring the resulting current, the system computes the electromechanical impedance spectrum. Deviations of this impedance from its nominal baseline over time serve as indicators of local damage or degradation near the fastener or within the connected structure. |

| Tests and results: | A simulation study was carried out on a clamped–clamped beam to evaluate the effectiveness of smart fasteners in active vibration suppression. An impact applied at the beam’s midpoint was modeled as a disturbance input to excite structural vibrations. In the closed-loop configuration, the vibration amplitude decreased to below 4% of its initial value within 0.8 s, whereas in the open-loop case, oscillations persisted for more than 5 s. These results demonstrate that, despite the limited actuation displacement, Active Boundary Control using smart fasteners can effectively attenuate structural vibrations. |

| # | Document | Category | Type | Cluster | Relevance Index |

|---|---|---|---|---|---|

| 1 | [3] | Fastener | Patent | Sensorized + RFID | Important |

| 2 | [4] | Fastener | Paper | Sensorized | Important |

| 3 | [13] | Fastener | Patent | Sensorized | Important |

| 4 | [15] | Fastener | Paper | Sensorized | Important |

| 5 | [21] | Fastener | Paper | Sensorized | Important |

| 6 | [22] | Fastener | Patent | Sensorized | Important |

| 7 | [23] | Fastener | Paper | Sensorized | Important |

| 8 | [24] | Fastener | Paper | Sensorized | Important |

| 9 | [25] | Fastener | Paper | Sensorized | Important |

| 10 | [26] | Fastener | Paper | Sensorized | Important |

| 11 | [27] | Fastener | Patent | Sensorized | Important |

| 12 | [29] | Fastener | Paper | Sensorized | Important |

| 13 | [31] | Fastener | Paper | Sensorized | Important |

| 14 | [32] | Fastener | Paper | Sensorized | Important |

| 15 | [33] | Fastener | Paper | Sensorized | Important |

| 16 | [7] | Washer | Paper | Sensorized | Important |

| 17 | [8] | Washer | Patent | Sensorized | Important |

| 18 | [12] | Washer | Patent | Sensorized | Important |

| 19 | [34] | Washer | Paper | Sensorized | Important |

| 20 | [36] | Washer | Paper | Sensorized | Important |

| 21 | [37] | Washer | Paper | Sensorized | Important |

| 22 | [38] | Washer | Paper | Sensorized | Important |

| 23 | [39] | Washer | Paper | Sensorized | Important |

| 24 | [40] | Washer | Patent | Sensorized + RFID | Important |

| 25 | [41] | Washer | Patent | Sensorized + RFID | Important |

| 26 | [43] | Washer | Paper | Sensorized + Smart Material | Important |

| 27 | [16] | Fastener | Patent | Smart Material | Relevant |

| 28 | [17] | Fastener | Paper | Smart Material | Relevant |

| 29 | [18] | Fastener | Paper | Smart Material | Relevant |

| 30 | [19] | Fastener | Book | Smart Material | Relevant |

| 31 | [1] | Fastener | Patent | Sensorized + RFID | Relevant |

| 32 | [14] | Fastener | Patent | RFID | Relevant |

| 33 | [20] | Fastener | Paper | Smart Material | Relevant |

| 34 | [28] | Fastener | Paper | Sensorized | Relevant |

| 35 | [30] | Fastener | Patent | Sensorized | Relevant |

| 36 | [44] | Fastener | Paper | Sensorized | Relevant |

| 37 | [5] | Washer | Paper | Sensorized | Relevant |

| 38 | [35] | Washer | Patent | Sensorized | Relevant |

| 39 | [42] | Washer | Patent | Sensorized + RFID | Relevant |

| 40 | [2] | Washer | Paper | Sensorized | Irrelevant |

| 41 | [6] | Fastener | Paper | Visual Indicator | Irrelevant |

| 42 | [45] | Fastener | Paper | Sensorized + RFID | Irrelevant |

| 43 | [46] | Fastener | Paper | Smart Material | Irrelevant |

| 44 | [47] | Fastener | Patent | Smart Material | Irrelevant |

| 45 | [48] | Fastener | Patent | Smart Material | Irrelevant |

| 46 | [49] | Fastener | Paper | Smart Material | Irrelevant |

| 47 | [50] | Fastener | Paper | Sensorized | Irrelevant |

| 48 | [51] | Fastener | Paper | Smart Material | Irrelevant |

| 49 | [52] | Fastener | Patent | Data Transfer + Storage + Computation | Irrelevant |

| 50 | [53] | Fastener | Patent | Surgical | Irrelevant |

| 51 | [54] | Fastener | Patent | Surgical | Irrelevant |

| 52 | [55] | Fastener | Paper | Probabilistic Fastener | Irrelevant |

| 53 | [56] | Fastener | Patent | Sensorized + RFID | Irrelevant |

| 54 | [57] | Fastener | Paper | Sensorized | Irrelevant |

| 55 | [58] | Fastener | Patent | Smart Material | Irrelevant |

| 56 | [59] | Fastener | Patent | Logistics | Irrelevant |

| 57 | [60] | Fastener | Paper | External sensor | Irrelevant |

| 58 | [61] | Fastener | Patent | Logistics | Irrelevant |

| 59 | [62] | Fastener | Paper | Surgical | Irrelevant |

| 60 | [63] | Fastener | Paper | Structural | Irrelevant |

| 61 | [64] | Fastener | Paper | Inspection | Irrelevant |

| 62 | [65] | Fastener | Paper | External sensor | Irrelevant |

| 63 | [66] | Fastener | Paper | Structural | Irrelevant |

| 64 | [67] | Fastener | Paper | Material | Irrelevant |

| 65 | [68] | Washer | Patent | Sensorized | Irrelevant |

| 66 | [69] | Washer | Patent | Sensorized | Irrelevant |

| 67 | [70] | Washer | Patent | Sensorized | Irrelevant |

| 68 | [71] | Washer | Patent | RFID | Irrelevant |

| 69 | [72] | Washer | Patent | Sensorized | Irrelevant |

| 70 | [73] | Washer | Patent | Sensorized | Irrelevant |

| 71 | [74] | Washer | Paper | Sensorized | Irrelevant |

| 72 | [75] | - | Paper | Screwdriver | Irrelevant |

| 73 | [76] | - | Patent | Screwdriver | Irrelevant |

| 74 | [77] | - | Patent | Out of scope | Irrelevant |

| 75 | [78] | - | Paper | Out of scope | Irrelevant |

| 76 | [79] | - | Patent | Out of scope | Irrelevant |

| 77 | [80] | - | Patent | Out of scope | Irrelevant |

| 78 | [81] | - | Patent | Screwdriver | Irrelevant |

| 79 | [82] | - | Paper | Out of scope | Irrelevant |

| 80 | [83] | - | Paper | Out of scope | Irrelevant |

| 81 | [84] | - | Paper | Out of scope | Irrelevant |

| 82 | [85] | - | Paper | Out of scope | Irrelevant |

| 83 | [86] | - | Paper | Out of scope | Irrelevant |

| 84 | [87] | - | Paper | Out of scope | Irrelevant |

| 85 | [88] | - | Paper | Out of scope | Irrelevant |

| 86 | [89] | - | Paper | Out of scope | Irrelevant |

| 87 | [90] | - | Paper | Out of scope | Irrelevant |

| 88 | [91] | - | Paper | Out of scope | Irrelevant |

| 89 | [92] | - | Paper | Out of scope | Irrelevant |

| Ref. | Support Type | Technology/Sensor | Measurement Type | Measurement Evaluation | Integration Level | Cost/Scalability | Notes | |||

|---|---|---|---|---|---|---|---|---|---|---|

| [3] | Screw or BScolt | RFID tag and two-state Microswitch | Torque state | NA (Provides binary compliance check) | Sensor body, RFID tag, and antenna are inserted in the fastener head | Low cost and high scalability | Easy installation | Easy torque check but Limited to status check | ||

| [4] | Fastener (screw or bolt) | Strain gauges and temperature sensor | Pretension forces and operating loads. (Capable of identifying axial forces and bending torques independently. measures combined force and torque signals in individual spatial directions) | NA (the achieved prestressing force after forming was calculated with a range of 1900 N to 2900 N ± 250 N) | Integrated into the metallic fastener structure during manufacture | Possibility of cost-effective production. | High scalability | The system measures multi-axis loads, providing reliable insights into the manufacturing process and the condition of machines and tools, as well as enabling compliance evaluation. The load-bearing capacity of the structure is reduced by about 20% due to the required central hole. | ||

| [13] | Fastener (screw or bolt) | Corrosion sensing array based on a reference electrode and at least one sensing electrode | Corrosion | NA | Integrated within said fastener body. The sensors are exposed to an electrolyte that enters through a capillary tube in the bolt. | NA | The system includes an analogue storage array and a clock for recording corrosion signals and their respective times, allowing access to data externally of said fastener. | |||

| [15] | Fastener | Piezoelectric element and control unit | Structural response based on vibrational control | NA | Embedded | NA | ||||

| [21] | Bolt | Electrochemical microsensor array and a time-of-wetness sensor | Corrosion-related symptoms: pH, temperature, chloride, free potential, time-of-wetness | NA | Integrated in the bolt | NA | Early warning detection of corrosion-related symptoms in hidden and inaccessible locations. Provides a condition-based corrosion detection system. | |||

| [22] | Fastener | Ultrasonic load measurement transducer. | Load in the thread-forming fastener | NA | Coupled externally to the fastener head | NA | Used to measure and control the load during tightening and to inspect the load after assembly | |||

| [23] | Fastener | Piezoelectric element and control unit | Structural response detection | NA | Embedded into the bolt | NA | ||||

| [24] | ISO M6 screw | Resistive strain gauges | Torsional strain in the screw head to compute force and torsional moment | NA | Integrated: sensor foil is interposed/embedded between the printed layers of the screw head/spacer disk | Low cost (if 3D printer available) | Enables the direct integration of sensing elements into additively manufactured parts, allowing material characterization and determination of the screw’s breaking limit. However, for some materials such as ABS Flex, poor adhesion between the material and the sensor foil can reduce mechanical durability, sometimes causing failure above the foil. Manual misalignment of the sensor foil is also a noticeable issue. | |||

| [25] | Bolt | FBG sensor | Axial and shear forces | axial force monitoring with a measurement error ranging from 2.1% to 3.6%. The shear force monitoring error ranges from 2.4% to 4.4% | Embedded. The four packaged FBG sensors are longitudinally embedded in pre-machined through holes of the smart bolt using epoxy | NA | Can simultaneously monitor both axial preload and shear loads. FBG sensors offer high accuracy and immunity to electromagnetic interference. | |||

| [26] | Bolt | Piezoceramic transducer | Blot preload force | Relative error = 1% | The PZT Transducer is embedded in the bolt head at and fixed with epoxy. | Low cost | Eliminates the need for couplants used in traditional ultrasonic probes, resulting in more precise measurements. It offers high accuracy and stability in preload detection, providing a promising method for measuring bolt preload. | |||

| [27] | Fastener | FBG sensor | Strain and temperature | NA | Embedded. The optical fiber is secured within the central opening of the fastener and bonded to with adhesive. It is | NA | Enables periodic or continuous monitoring, overcoming previous limitations by delivering consistent, hysteresis-free data when unloaded. It also allows for remote monitoring. | |||

| [29] | Bolt | PZT sensor with piezoceramic transducer | Structural vibration response | NA | Embedded | Low cost | It is convenient to install or remove compared to conventional patch actuators that require epoxy. | |||

| [31] | Bolt | FBG sensor | Preload force | NA | Embedded | NA | Temperature self-compensation, which significantly improves force measurement accuracy. Enables in situ health monitoring of fasteners in harsh conditions. Provides high sensitivity and EMI | |||

| [32] | Bolt | FBG sensor | Torque | Maximum sensitivity: 0.00298 nm/N-m | Embedded | NA | A linear relationship exists between the FBG wavelength and applied torque, enabling precise measurement and long-term monitoring and control of bolt preload. | |||

| [33] | Bolt shaft | FBG sensor | Preload and retained clamping force | NA | Embedded in the bolt shaft using temporary adhesive | No high costs of permanently embedded FBG through reusability and shows strong potential for easy integration into conventional manufacturing processes. | It allows quick assembly, disassembly, and reassembly of the sensor, providing precise monitoring without affecting the bolt’s intrinsic properties thanks to its compact size. The system is also immune to electromagnetic interference. | |||

| [7] | Washer | Piezoelectric patches | Bolt loosening monitoring and bolt preload | NA | Bonded on the non-contact surface | NA | Active sensing method: one patch serves as an actuator generating ultrasonic waves, while the other functions as a sensor detecting the response. The saturation issue is resolved using convex and concave contact surfaces. | |||

| [8] | Washer | Piezoelectric transducer | Flaw length progression measurement | NA | Applied on the surface or embedded in a cavity | NA | Enable structural inspection in the area immediately surrounding the bolted joint. Configurations with segmented or concentric elements allow imaging and measurement of flaw length progression. | |||

| [12] | Washer | Strain gauges and temperature sensor for compensation | Preload estimation based on compression deformation | NA | Embedded into one or more holes. | NA | High Output Signal Sensitivity (thanks to the series connection of strain gauges and optimal positioning). Detects compression deformation, which is more uniform than surface deformation, improving reliability. Provides real-time preload measurement during tightening. | |||

| [34] | Washer | FBG sensors | Bolt preload force | Max: sensitivity = 0.0151 nm/kN. | Embedded | NA | The method measures preload through changes in the washer’s outer diameter and circumference, offering high sensitivity and EMI immunity. As a load-path element, the washer enables simple and reliable long-term monitoring. | The method measures preload through changes in the washer’s outer diameter and circumference, offering high sensitivity and EMI immunity. As a load-path element, the washer enables simple and reliable long-term monitoring. | ||

| [36] | Cantilever washer | Bolt loosening detection based on natural frequency shift | NA | NA | Bonded to the washer | NA | The system is designed for remote, automated monitoring of bolt loosening. Using an n Adaptive Observer with time-varying gain enables identification of the natural frequency across the full axial tension range. | |||

| [37] | Washer | Piezoceramic transducer used in active sensing method | Bolt looseness monitoring base on rime reversal and energy transfer matrix | NA | Embedded into the washer | NA | Easy to apply to existing bolted joints. The Energy Transfer Matrix technique based on Time Reversal is effective and suitable for in situ application for monitoring bolted connections. | |||

| [38] | Washer | Piezoelectric sensor | Bolt loosening detection vase on natural frequency variation due to bolt tightenind and axial tension | NA | Bonded to the washer | NA | Further investigation is needed to improve repeatability and data quality under varying ambient temperatures. | |||

| [39] | Washer | FBG sensor | Preload torque and uniaxial strain | NA | Embedded into the washer | NA | Create a dual-purpose sensor capable of measuring both preload torque (via bandwidth) and uniaxial deformation (via center wavelength). | |||

| [40] | Washer | Sensor coupled with wireless data retrieval module | Strain, stress, temperature, vibration, loads, torque | NA | Embedded into the washer | NA | Enables wireless retrieval of data from integrated sensors. Allows magnetic or radio frequency coupling for contactless energy and data transfer, facilitating measurement and monitoring. | |||

| [41] | Washer | Variable resistance strain gauges and RFID tag | Preload | NA | Carried by the washer | NA | Enables wireless access to washer-specific data (e.g., ID, installation, and inspection dates) and can control the torque applied by tools linked to the RFID reader. | |||

| [43] | Washer | Magnetostrictive Galfenol (iron and gallium alloy), used with biasing magnets and Hall Effect sensors. | Bolt loads and stresses in bolts | NA | Integrated. The washers are made of Galfenol and are integrated into the joint. The entire system uses the Galfenol washer as a passive sensor, which interacts with external magnets and Hall sensors. | Cost efficient | Accurate, sensitive, and cost-efficient alternative. Enables real-time monitoring of stresses with minimal signal conditioning. Eliminates the need for routine bolt retightening by providing current loads instead. | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Chicca, S.; Lorenzini, G.; Mohamed, R.M.R.; Cattaneo, P.; Manzoni, S.; Tarabini, M. Smart Fasteners and Washers for Preload and Loosening Detection: A Systematic Review of Sensing Technologies. Encyclopedia 2025, 5, 196. https://doi.org/10.3390/encyclopedia5040196

Del Chicca S, Lorenzini G, Mohamed RMR, Cattaneo P, Manzoni S, Tarabini M. Smart Fasteners and Washers for Preload and Loosening Detection: A Systematic Review of Sensing Technologies. Encyclopedia. 2025; 5(4):196. https://doi.org/10.3390/encyclopedia5040196

Chicago/Turabian StyleDel Chicca, Sara, Giuseppe Lorenzini, Rashik Mohamed Raja Mohamed, Paolo Cattaneo, Stefano Manzoni, and Marco Tarabini. 2025. "Smart Fasteners and Washers for Preload and Loosening Detection: A Systematic Review of Sensing Technologies" Encyclopedia 5, no. 4: 196. https://doi.org/10.3390/encyclopedia5040196

APA StyleDel Chicca, S., Lorenzini, G., Mohamed, R. M. R., Cattaneo, P., Manzoni, S., & Tarabini, M. (2025). Smart Fasteners and Washers for Preload and Loosening Detection: A Systematic Review of Sensing Technologies. Encyclopedia, 5(4), 196. https://doi.org/10.3390/encyclopedia5040196