Abstract

In recent years, the field of drug delivery has seen a significant shift towards the exploration and utilization of nanoparticles (NPs) as versatile carriers for therapeutic agents. With its ability to provide exact control over NPs’ characteristics, microfluidics has emerged as a potent platform for the efficient and controlled synthesis of NPs. Microfluidic devices designed for precise fluid manipulation at the micro-scale offer a unique platform for tailoring NP properties, enabling enhanced control over NP properties such as size, morphology, and size distribution while ensuring high batch-to-batch reproducibility. Microfluidics can be used to produce liposomes, solid lipid nanoparticles, polymer-based NPs, and lipid-polymer hybrid NPs, as well as a variety of inorganic NPs such as silica, metal, metal oxide, quantum dots, and carbon-based NPs, offering precise control over composition and surface properties. Its unique precision in tailoring NP properties holds great promise for advancing NP-based drug delivery systems in both clinical and industrial settings. Although challenges with large-scale production still remain, microfluidics offers a transformative approach to NP synthesis. In this review, starting from the historical development of microfluidic systems, the materials used to create the systems, microfabrication methods, and system components will be discussed in order to provide the reader with an overview of microfluidic systems. In the following, studies on the fabrication of nanoparticles such as lipid NPs, polymeric NPs, and inorganic NPs in microfluidic devices are included.

1. Introduction

Nanotechnology, or the production of systems/devices at the molecular level, is a multidisciplinary scientific field that has shown significant development in recent years. The potential applications of nanotechnology cover a very wide area and a wide variety of applications. These range from communications and robotics to construction, defense, education, and beyond. However, one of the most important contributions of nanotechnology to humanity is that it enables the creation of new and effective medical treatments [1]. Named nanomedicine by the National Institutes of Health, these groundbreaking technological advances span a number of subfields. These include nano drug delivery systems, gene therapies, vaccine studies, tissue engineering, the creation of artificial receptors, and the development of medical imaging systems [2].

Until the early 1970s, the intravenous administration of pharmaceutical suspensions consisting of solid particles dispersed in liquid was considered impractical due to the risk of embolism. However, the development of drug-loaded nanoparticle suspensions, also referred to as nanopharmaceuticals, revolutionized this problem. Nanopharmaceuticals include nano-sized powdered drugs, drug delivery systems, and vehicles. Developments in the fields of nanomedicine and nanopharmaceuticals have enabled the use of active substances (such as single molecule drugs, proteins, nucleic acids, etc.) that are difficult to use as drug active ingredients due to their insolubility or inability to be directed to specific parts of the body. Therapeutic agents that were incompatible with conventional drug formulations in the past can now be “nano-formulated” to precisely target specific biological sites due to improved pharmacokinetics/pharmacodynamics or accurate intracellular delivery. These methods, currently referred to as ‘drug targeting’ or ‘nano drug delivery systems’, have the potential to reduce toxicity by directing the active ingredient to target tissues and cells, and increase the concentration of the drug in the intended site of action, thereby increasing efficacy and improving patient compliance. Nanotechnology, and in particular the field of nanopharmaceuticals, has brought about a revolutionary change in the field of pharmaceutical applications [3,4]. In the field of nanomedicine, the use of nanoparticles (NPs) offers remarkable potential for diseases that are difficult to treat effectively using conventional therapies. However, fully realizing systems with this significant potential requires a rigorous approach: precise design, manufacturing, and rigorous testing in appropriate models are essential [5,6]. NPs for the intended purpose must be specifically designed with full regulation of their size, shape, composition, and characteristics such as surface charges and chemistry [7]. Many production methods have been developed since nanoparticles first appeared. Generally, the synthesis methods of nanomaterials (NMs) can be categorized into two approaches: top-down and bottom-up. In the top-down approach, bulk materials are meticulously downsized into nano-sized particles, resulting in NMs that are susceptible to oxidation and prone to dense agglomeration. This method potentially alters the inherent physical and surface properties of NMs by introducing surface defects and crystallographic irregularities. In contrast, the bottom-up approach, often using wet chemical synthesis, is used as the predominant method for producing NMs. In particular, the widespread use of this approach can be attributed to its simplicity, adaptability, use of cost-effective chemicals, and capacity to produce stable NMs at appreciable production rates compared to other methods. However, the limitations of this method stem from the difficulty of precisely controlling the reaction kinetics and achieving the desired NM properties [8]. Traditional nanoparticle production methods often struggle to consistently replicate the size, size distribution, and quality of nanomaterials from one batch to another, and rapid screening and the optimization of synthesis conditions are difficult to implement. In addition, scaling up production procedures to the quantities required for product development and optimization creates a separate set of challenges [9]. Given the inherent shortcomings of these traditional methods, the search for new alternatives for the production of nanoparticles has emerged. The search for a superior approach has led researchers to produce NPs using microfluidic technologies that offer the prospect of improving performance and overcoming the drawbacks observed in previous methods (Figure 1).

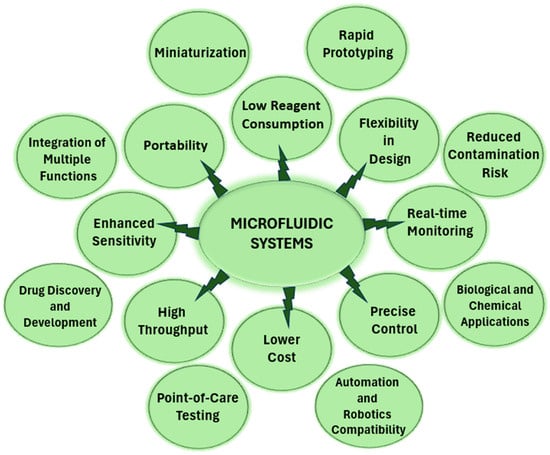

Figure 1.

Advantages of microfluidic systems.

Microfluidic technology involves the manipulation and processing of small liquid volumes ranging from 10−9 to 10−18 L through channels ranging in size from tens to hundreds of microns [10]. Microfluidic technology enables the meticulous management of the particle-forming environment and the minimal use of reagents in a continuous flow model with distinct flow characteristics not found in conventional production methods [8]. The power of microfluidics, which allows masterful control over microchannel architectures, flow and mixing velocities, interfacial viscosity, heat, and mass transfer processes, facilitates the synthesis of diverse micro/nanoparticles with distinctive properties [11]. The specific features of microfluidic applications, such as quick sample handling and fine liquid control in analyses, have made them favorable candidates to substitute conventional nanoparticle manufacturing processes. Micro- and nanoparticles synthesized in carefully designed microfluidic devices show significant potential for controlling size, shape, and size distribution. They also offer new ways to create sophisticated engineering nanostructures and innovative material systems by extending synthesis conditions (e.g., temperature, pressure, and reagents) to situations that are difficult to achieve with conventional techniques [9].

The primary focus in this review is the role of microfluidic devices in producing various nanoparticles such as lipids, polymers, and others. First, we will briefly touch upon microfluidic devices and their historical development. Next, the materials used in microfluidic devices, microfabrication methods and microfluidic system components will be discussed. Finally, we aim to provide readers with a brief understanding of nanoparticle production, particularly using microfluidic techniques, by summarizing current research in this field.

2. Historical Perspective on Microfluidic Systems

The history of microfluidics relates to many other fields and technologies that contributed to its development before it became an independent science. Even hundreds of years before the concept of microfluidics emerged, researchers were studying the properties of small amounts of body fluids and trying to extract information from them and understand their behavior. Researchers such as Hippocrates (400 BC), Galen (200 AD), and Theophilus (700 AD) placed urine samples in vials known as “matulae”, examined the color and appearance of urine, and tried to match various disorders and symptoms using diagrams. In 1717, Jurin published his work explaining the rise and suspension of water in capillaries [12]. Researchers such as James Jurin (1684–1750), Jean Léonard Marie Poiseuille (1799–1869), and Gotthilf Heinrich Ludwig Hagen (1797–1884) carried out studies to describe the behavior of fluids [13,14]. In 1839, Hagen published his work on water flow in cylindrical tubes [15]. Between 1838 and 1841, Poiseuille shared the results of his studies on the flow of water through glass tubes and the effects of tube length, tube diameter, temperature, and pressure [16,17]. The result of these studies was the famous Hagen–Poiseuille equation describing the pressure drop in a fluid flowing through a cylindrical pipe, which was later theoretically justified by George Stokes (1819–1903). This formed the basis of the theory describing the behavior of fluids at reduced scales [18]. In 1879, Lord Rayleigh (1842–1919) published his observations on the physics of droplet formation [19]. Rayleigh’s invention revealed that as a liquid flows through an orifice, it undergoes hydrodynamic instability, resulting in the formation of droplets. These droplets cumulatively exhibit a lower surface area and reduced surface tension than the initial fluid flow [20].

The events leading to the emergence of microfluidic technology continued with the development of materials and material-processing technologies. In 1859, John Walter Osborne (1828–1902) patented the photolithography process [21]. Photolithography, also known as optical lithography, is a type of printing using light-sensitive materials [22]. The field then continued to evolve with the development of soft lithography. The first example of the so-called “soft” method, which uses elastomeric stamps, molds, and conformable photo masks, is believed to have been applied in 1993 by Kumar et al. [23,24]. These methods have played an important role in the development of microfluidic devices, especially as they allow for the fine processing of polymers such as polydimethylsiloxane (PDMS). At this point, the development of polymer science should also be mentioned. In 1901, the concept of silicone was introduced by Frederic Kipping (1863–1949) [25]. This is an important development as silicone has been the primary material used to fabricate microfluidic devices for a long time. However, other materials were later used to overcome the disadvantages of using silicone, such as high cost and opaque structure. As the materials used and their applications evolved, more specific terminology was developed, and the most widely known silicone became PDMS [26,27]. Currently, PDMS is one of the most widely used materials for fabricating microfluidic devices/systems in research laboratories [28].

The factors that most influenced the development of microfluidics can be summarized in four points: microelectronics, molecular analysis, biodefense, and molecular biology. It can be said that the developments caused by these four factors led to a leap in microfluidics [10].

The foundation of microfluidics can be traced back to developments in the field of microelectronics. In 1947, Walter Brattain (1902–1987), John Bardeen (1908–1991), and William Shockley (1910–1989) invented the transistor in response to the need to improve the reliability of mechanical relay systems in telephone lines. Building on this work, in 1955, Jules Andrus and Walter L. Bond began adapting existing photolithographic techniques to produce much finer and more detailed designs on silicon [29,30]. This is an important development as the photolithography technique becomes a standard in microelectronics manufacturing. The year 1959 is considered to be the beginning of microtechnologies and nanotechnologies, especially because of RP Feynman’s speech “There is plenty of room at the bottom” at the American Physical Society meeting at Caltech. In his speech, Feynman emphasized the importance of studies in micro and nano dimensions [31]. In 1964, Jack Kilby took these technologies to the next level by explaining how many different components, including transistors, capacitors, and resistors, can be built into a single silicon crystal and create an oscillator circuit. This breakthrough in integrated circuits revolutionized microelectronics and heralded the beginning of the “silicon age” when companies competed to develop compact and secure electronic devices [29]. These developments gave birth to a new technology that has had a major impact on the microfluidics industry: inkjet printing. In 1965, Richard Sweet combined flow principles and materials science advances and applied them to inkjet printing technology [20,29]. In 1977, Bassous et al. took this technology even further and showed, through photolithography, that many inkjet nozzles could be produced in a single silicon wafer [32]. This process also showed that silicon could be used as a material for the mass production of microfluidic devices. In 1979, Terry et al. published the paper “A gas chromatographic air analyzer fabricated on a silicon wafer” [33]. Although concepts such as “lab-on-a-chip” or “micro total analysis system” did not yet exist at that time, this device is now recognized as the first example in this field. It is also considered to be the first publication in which microfluidics was recognized as a field in its own right [29]. The overarching goal and concept of the broad field of “lab-on-a-chip” was that microtechnology for the treatment of fluids would become as ubiquitous as “microelectronics”. The first breakthroughs in the development of what is now called “microfluidics” were based on miniaturization, i.e., reducing the size and complexity of analytical systems [34]. The science of miniaturization, which aims to miniaturize traditional macroscopic devices into microscopic devices, initially began with the development of miniature silicon-based electronic devices, and was later extended to the fabrication of mechanical devices known as microelectromechanical systems (MEMS) [35]. When these small devices were designed to handle liquids at sub-milliliter scales, they became known as microfluidic devices. The fabrication of microfluidic devices utilized the microelectronics manufacturing infrastructure as a subset of MEMS technology adapted for fluid processing. Silicon was predominantly used as the primary substrate material for microfluidic devices. The direct applicability of photolithography and related technologies (including thin film deposition and etching) to microfluidics, which have been highly successful in silicon microelectronics and MEMS, has played a crucial role in advancing this field. Silicon and glass, which were mostly used in the early stages of microfluidic system studies, were replaced by polymer materials in the 2000s due to their unsuitability for the analysis of biological samples for various reasons. The majority of experimental work in microfluidic devices has predominantly utilized a polymer called PDMS. PDMS has unique properties different from silicon, so it would be wrong to characterize microfluidic devices as mere replicas of silicon microelectronic devices. As an optically transparent, soft elastomer, PDMS has become a crucial material for early-stage discovery research and engineering, offering exceptional versatility for testing new concepts and assembling valuable components such as pneumatic valves. However, microelectronic techniques have played an essential role in the advancement of microfluidics. As the area has progressed, materials such as glass, steel, and silicon have re-emerged as viable options for building specialized systems that require chemical and thermal stability. Silicon and glass, in particular, are prized for their mechanical strength, which is highly valued in the field of nanofluidics, where hard-walled channels are highly advantageous [10,28]. MEMS technology has continued to advance with the development of devices for applications in medicine and life sciences. Biological microelectromechanical systems (BioMEMS) were coined to describe such devices and systems. BioMEMS are differentiated from traditional MEMS devices. BioMEMS may not have every component normally found in MEMS, and may include modernized definitions and applications [36]. The provision of a comprehensive solution from sample application to the presentation of analytical data is one of the goals of developing microfluidic systems. A microfluidic system is sometimes known as a lab-on-a-chip (LOC), biochip, or micro total analysis system (μTAS) for this reason. LOC and μTAS applications were first primarily utilized in the biomedical, food, and environmental domains, but more recently, they have also found usage in the synthesis of novel chemical compounds and the creation of nanostructures. Currently, microfluidic chips may be used to study bodily fluids, cells, tissues, and even complete organs. Both tiny start-ups and big pharmaceutical and biomedical corporations are developing an increasing number of microfluidic-based products that are already hitting the market [13]. The most important analytical developments affecting microfluidics technology are microanalytical methods such as gas phase chromatography, high-pressure liquid chromatography (HPLC), and capillary electrophoresis (CE). These methods have made it possible to obtain fast and highly sensitive data using very small amounts of samples [10]. In 1957, Golay’s research on gas chromatography [37] and Van Deemter’s research on liquid chromatography in 1956 [38] led to the realization that to maintain a high level of performance, the diameter of the column had to be reduced, so columns were produced in the micrometer range [39]. In 1993, Andreas Manz et al. published a paper describing the production of a miniaturized capillary electrophoresis-based chemical analysis system [40]. One year after the publication of this work, the first International Conference on Micro-Collective Analysis Systems took place in Enschede, the Netherlands, and capillary electrophoresis has become popular for separating various biomolecules [13]. As a result of the innovative perspective of this miniaturization, many researchers have invested considerable time and effort to develop microfluidic devices for liquid handling, liquid metering, liquid mixing, separation of liquids, etc. [39].

The influence of biodefense on microfluidic technology became prominent following the conclusion of the Cold War, when it was recognized that potentially deadly weapons that utilize chemical or biological agents posed significant military and terrorist risks. During the 1990s, the Defense Advanced Research Projects Agency (DARPA) launched initiatives aimed at developing microfluidic systems capable of detecting both chemical and biological hazards. This funding and support from DARPA played a pivotal role in expediting academic research in microfluidics and significantly contributed to the advancement of this technology [10].

The field of molecular biology has played an important role in the growth of microfluidics, especially with the genomics boom in the 1980s and the subsequent development of other microanalysis fields tied to molecular biology, including high-throughput DNA sequencing. These developments have created a demand for analytical techniques with significantly greater efficiency, sensitivity, and resolution than previously required in biology. This demand has extended to the development of commercial instruments for sequencing genomic nucleic acids and methods for handling very small liquid volumes. Microfluidics has emerged as a promising solution to overcome these challenges and has led to increased research activity in this field [10,34].

In summary, the advent of microfluidics has had a transformative impact on fields as diverse as biology, chemistry, analytical biochemistry, medical sciences, biotechnology, and tissue engineering. Microfluidics facilitates the manipulation and flow control of very small fluid volumes within complex channel networks. Widely adopted across scientific disciplines, microfluidic systems serve as fundamental tools for researchers and have established themselves as a multidisciplinary arena in science and engineering. Microfluidics has significantly enhanced drug discovery, drug delivery, biomedical research, and other lab-on-a-chip approaches, offering distinct advantages over traditional laboratory techniques by integrating various functions on a single microchip. This technology has made significant research contributions, especially in combining electronic, mechanical, and chemical processes in a miniaturized substrate. Furthermore, microfluidic devices enable the efficient production of micro- and nanoparticles characterized by exceptional morphology and size distribution. Microfluidics enhances a range of chemical reactions, often achieving higher yields and adapting to more demanding conditions than conventional methods [39]. Due to these factors, microfluidics’ utilization is on the rise across diverse fields, spanning fundamental domains like chemistry, biology, and physics, as well as encompassing a multitude of engineering disciplines [36]. The extensive influence of microfluidics in the scientific field is evident through the substantial and ongoing increase in publications across academic journals and conferences, a trend that has persisted from the mid-1990s to the present [10].

3. Microfluidic Devices

Microfluidic and lab-on-a-chip devices have been extensively studied and developed in recent years due to their inherent advantages of low chemical consumption, rapid analysis, biocompatibility, low cost, and automation in biological, biomedical, and analytical chemistry studies [41]. Microfluidics, an interdisciplinary field, has a wide range of applications, including environmental sensing, medical diagnostics, microscale genetic and proteomic analysis, drug discovery, drug delivery, high-throughput drug screening platforms, cell culture and manipulation platforms, microscale chemical production, combinatorial synthesis and assays, biosensors and pathogen detection systems, water purification, separation of various substances such as nanoparticles, microparticles, and cells, artificial organs, and micro propulsion microscale energy systems [42,43,44,45]. Emerging microfluidic technology has also led to rapid progress and success in the development of nanoparticle production. By taking advantage of the unique properties of fluid mechanics observed at micro dimensions, microfluidic technology can produce nanoparticles of appropriate size and precisely controllable shape that can be used for various applications in drug delivery, and in the biosciences, healthcare, and food industries [46]. In order to provide the reader with an overview of microfluidic devices, this section summarizes the types of materials used in the production of microfluidic devices, microfabrication methods, and the components that can be found in a microfluidic device, before moving on to the sections summarizing the studies where microfluidics are used in nanoparticle production.

3.1. Materials

This subsection presents various common materials used for fabricating microfluidic devices (microfabrication) with emphasis on their advantages and disadvantages.

Many materials have been used in the fabrication of microdevices, depending on the chosen technique, and devices have been fabricated on various substrates. Silicon, glass, polymers, hydrogels, paper, and various inorganic materials are among the materials commonly used to fabricate microfluidic systems [47,48].

One of the key steps in microfluidic applications is selecting the most suitable material for the device manufacturing and the process to be performed. To select the type of material for the microfluidic system to be used, many properties should be taken into account, such as surface functionalization potential, processability, ease of manufacture, surface charge, molecular adsorption, non-specific adsorption, electrical conductivity, cellular compatibility, biocompatibility, electroosmotic flow mobility, optical properties and transparency, air permeability, flexibility, the price of the material (especially if disposable devices are produced in processes where there is a risk of contamination), resistance to chemical compatibility with the solvents used (chemical stability), resistance to temperature changes and high temperatures (thermal stability), and resistance to pressure and other physical forces (mechanical stability). These properties must be chosen to be compatible with the properties of the reaction to be treated. Each material has both advantages and disadvantages depending on its intended use. It should not be forgotten that the materials used may influence the process. The miniaturization of the channels that form the basis of the microfluidic technique makes it necessary to pay special attention to the materials that make up the device [49]. In microfluidic systems in particular, shorter contact times, laminar flow, enhanced heat and mass transfer, and large surface-to-volume ratios result in unique phenomena that are not present in macro-scale systems [50]. Compared to macro-samples, in reactions taking place in the micro-scale environment, it is necessary to consider all variables that can influence the manufacturing process, including the wettability of the material of the device and the contact angle formed between the liquid phase and the microchannel.

The variety and quality of materials are constantly increasing due to developing technology and research. At the same time, these materials can also be combined in hybrid devices to utilize their advantages synergistically. However, the advancement of microfluidic device technology and their fabrication depends on the materials used, and requires a deeper evaluation and more experimental work. LOC systems, including microfluidics, MEMS/NEMS (nanoelectromechanical systems), and related microsystem families should focus more on challenges such as integration, standardization, economics of commercialization, and applicability of targeted systems, as well as improved functionality.

3.1.1. Silicon

From the early 1990s, silicon has been an important material used in creating microfluidic devices. Its widespread use in semiconductors is due to its well-documented attributes and advanced manufacturing techniques. Silicon has unique characteristics that make it the preferred choice for making microfluidic systems, particularly silicon microfluidic chips. These chips have exceptional surface stability, efficient thermal conductivity, resistance to organic solvents, semiconductor attributes, and the ability to integrate sensors and electronics onto a unified platform. They are readily available, easy to manufacture, adaptable to different designs, and compatible with various chemicals [51]. Despite its advantages, silicon has several limitations that must be considered when using it in practical applications. One of the most significant drawbacks of silicon is its inability to transmit visible light and ultraviolet radiation, making it incompatible with optical sensing in these spectral regions. This hinders its usefulness in detecting fluorescent labels, a commonly used technique in immunoassays. For in situ imaging, it is essential to ensure that the imaging portion of the device is not made from silicon. Moreover, the intrinsic hardness and brittleness of silicon create challenges when using active components like valves and pumps, or integrating such elements into a silicon-based platform [52]. Other limitations, such as the tendency of biological molecules to adsorb on silicon surfaces and its relatively expensive nature, have led to the exploration of different materials for fabricating microfluidic devices. However, today, the use of silicon for fabricating microfluidic platforms is found in biological applications such as medical diagnostics and organ-on-chip devices, especially for drug toxicity screening [50]. Surface micromachining, the synthesis of micromechanical structures from deposited thin films, or bulk micromachining, where the microstructure is synthesized by etching the substrate, can be used to produce silicon structures [39]. Most silicon-based devices, especially sensors based on electrical-based sensing methods, have a thermally grown SiO2 layer on the surface [47]. Silicon dioxide, or SiO2, is one of the top choices for microfabrication processes such as etching and deposition. It boasts impressive thermal and electrical insulation characteristics, making it a cost-effective option for molds. Its high selectivity to various silicon etchants is another advantage. Additionally, SiO2 is well suited for sealing microchannels. When paired with silicon nitride (Si3N4), it allows for the creation of complex three-dimensional structures via multi-step etching. Si3N4 is a formidable insulator that serves as an impermeable barrier against water and ion diffusion. Its exceptional thermal insulation properties make it ideal for suspending heater structures on silicon nitride membranes or fixtures. Furthermore, its resistance to oxidation and abrasives makes it an outstanding material for molds in deep etching processes. It is also commonly used as a high-strength electrical insulator [31].

3.1.2. Glass

Glass offers several distinct advantages over silicon, including outstanding optical transparency, compatibility with biological materials, lower cost, easy availability, and the potential for active component integration. As a result, glass substrate microreactors offer an alternative to their silicon-based counterparts. One of the primary strengths of glass in microfluidic systems is its optical transparency. Glass and quartz substrates blend smoothly with microfluidic practices due to their advantageous optical properties, making them well suited for biosensors utilizing optical sensing methods such as fluorescence or surface plasmon resonance (SPR) [39,47,48]. Glass-based microfluidic devices offer high solvent resistance and chemical robustness [53]. Glass is a remarkable material with outstanding qualities such as durability, electrical insulation, heat resistance, and potential for surface modification. Its compatibility with biological substances makes it highly valuable for biochemical analyses. Furthermore, its low coefficient of thermal expansion makes it an ideal material for microreactors designed to facilitate chemical reactions under extreme conditions. Glass can also be efficiently cleaned after experiments using chip heating or chemical washing. The ability to combine complementary elements made of glass or other materials makes it a preferred choice for microfluidic chip fabrication [50]. Although these materials are suitable for microfluidic arrays, the manufacturing techniques can be time-consuming, labor-intensive, and expensive. Although glass itself is an inexpensive material, the processing of glass into chips is expensive, time-consuming, labor-intensive, and in some cases requires preparation in clean rooms [49]. However, due to the poor O2/CO2 exchange, it is not suitable for long-term cell culture as it is impermeable to gases. The glass material, which is also hard and brittle, suffers from the difficulty of creating micro-pumps or valves on chips [51]. In terms of composition, glass is divided into soda-lime glass, borosilicate glass, and fused quartz. One of the most popular types of glass is soda-lime; however, it contains many contaminants such as aluminum, so microfluidic devices often use borosilicate. Due to its good optical properties, quartz or fused silica can sometimes also be used [47]. The main material used for these devices is borosilicate glass, which is made from boron trioxide and silica. It stands out because of its low coefficient of thermal expansion and its impressive resistance to thermal shocks. Recently, borosilicate glass capillaries have become a popular alternative to glass for creating nanoparticles. These capillaries work well with a variety of organic solvents. They are also very strong and resist physical deformation better than elastic polymeric devices, which allows them to operate stably and for a longer period of time [53]. In microfluidics and MEMS, Foturan is a material that is widely used. It is a photosensitive glass that contains silver oxides and cerium oxides, and is enriched with lithium-aluminosilicate. Foturan is a unique material that combines the characteristics of glass, such as thermal and hardness resistance, with the ability to create highly structured designs with substantial aspect ratios. The process of producing microfluidic arrays using glass or quartz substrates involves various microfabrication techniques such as plasma etching, reactive ion etching, lithography, etching, and lithography [39,51].

3.1.3. Polymers

In the past, microfluidic devices were primarily made of silicon and glass materials due to their excellent thermal conductance and resistance to temperature changes, respectively. However, due to the numerous disadvantages already mentioned, these materials have been increasingly substituted by polymers. The versatility of polymers has attracted the attention of researchers. This has led to a shift away from silicon and glass chips, and the widespread use of polymers in microfluidic device fabrication [50]. One of the biggest advantages of polymers is that they are cheap. Compared to other MEMS devices, microfluidic devices tend to be larger in size. This means that the cost of substrate materials is an important factor to consider. Polymers are a more cost-effective alternative to inorganic materials, and also offer the benefit of simpler and less expensive manufacturing techniques. Another advantage is that many different polymers with different surface chemistries are available and can be optimized according to the properties required for the desired application [31]. Polymers are available in transparent or semi-transparent varieties. Depending on the composition of the polymer, transparent or semi-transparent devices can be obtained, applicable to all processes where optical visibility is required [49]. Furthermore, easy manufacturing techniques and various surface modification methods are available to improve the efficiency of these devices. Techniques used to produce polymeric microfluidic channels and networks in a microfluidic system include soft lithography, UV laser ablation, hot embossing, injection molding, and direct micro-milling [39]. Polymers do not have a fixed melting temperature. Polymeric materials are softer and moldable above glass transit tempers. Their softness facilitates the manufacture of microanalytical system components, especially pumps and valves, using elastomers instead of hard materials [49]. The low cost, versatility, and ease of use of polymers have made them attractive materials for use in microfluidic systems. Polymers offer the advantage of biocompatibility compared to glass and silicon. Many polymers are compatible with tissue and blood, making them well suited for implantable microfluidic devices in drug delivery. These devices excel in applications, including DNA analysis, cell processing, clinical diagnostics, and polymerase chain reactions. They can also be used as photoresists or passivation layers in conventional microelectronic applications [31]. Polymer microfluidic platforms can be used in applications ranging from nanoparticle synthesis to fluid manipulation. Polymer-based microfluidic systems can provide reliable production under various temperature conditions, depending on the properties of the polymer used. Polymers are suitable for applications at room temperature or higher temperatures, and are very useful for large-scale production. However, polymers have some disadvantages, such as small molecule absorption, high sensitivity to organic solvents, and problems with vapor permeability, which can affect cell signaling dynamics [50]. One of the main issues with polymers is that they tend to exhibit natural fluorescence at low excitation wavelengths. This can pose a problem in microfluidic applications where fluorescence-based detection is used, potentially leading to a decrease in instrument sensitivity. Another challenge with polymers is that they generally possess a lower charge density due to the absence of ionizable groups commonly found in glass. As a result, achieving a stable and controllable electroosmotic flow, which relies heavily on a high surface charge density, can be more difficult with polymers compared to other materials. They cannot be used in microanalyses where the required surface properties are not compatible with the surface properties of the polymers, as in the case of electroosmosis [31].

Numerous polymers, including polypropylene, polycarbonate, polyethylene, polymethylmethacrylate (PMMA), and polystyrene, are widely utilized in both research and industrial settings. When it comes to creating microfluidic devices, the most commonly employed polymers include PDMS, PMMA, fluoropolymers, cyclo-olefin polymers, and copolymers (COPS/COCs), as well as thiol-ene polymers (TES). PDMS, also referred to as polydimethylsiloxane, has become particularly popular in recent years [48,50].

PDMS is the best example of the elastomer group that is frequently used in the production of microfluidics due to its mechanical properties such as flexibility. PDMS has attracted much attention for various reasons, and has been the most frequently used and reliable material in microdevice production since the beginning of the 21st century [52]. The favorable physical properties and easy manufacturing process of PDMS contribute to easy microfabrication at low cost. In addition, it is easy to mold. Multilayer channels, microvalves, or micropumps can be easily formed on PDMS chips. Using a multilayer design in PDMS-based microfluidic devices, internal channels can be customized and modified in both 2D and 3D [53]. PDMS is a crucial material in the production of highly flexible and biodegradable organ-on-a-chip platforms. Its optical transparency down to 280 nm allows high-quality microscopic imaging of cultured cells. Its inertness to biomolecules makes it ideal for creating micro-flow channels, while its biocompatibility, gas permeability, and autoclavability make it advantageous for biological studies. PDMS also inherently prevents cellular adhesion, enabling long-term on-chip cultures and fluorescence/chemiluminescence studies. All these properties make PDMS a valuable material for cellular research [48]. PDMS is a type of polymer with a remarkable tensile strength that enables it to tolerate high hydraulic pressure. This high-pressure tolerance is a crucial property required in microfluidic devices, especially in microfluidic-based nanoparticle synthesis, where optimal mixing requires a consistently high total flow rate. Despite these obvious advantages of PDMS-based microfluidic devices, they also have some significant disadvantages, such as poor solvent compatibility, surface fouling, and deformation problems under high-pressure conditions [52,53]. The porous nature of PDMS allows it to absorb small molecules, making it difficult to use organic solvents such as hexane, toluene, and chloroform. This is because these molecules can easily stick to the channel walls and cause swelling, leading to changes in the flow rate and concentration of the solution. Another issue with using PDMS is the evaporation of water along the channel walls, which can alter the solution’s concentration. Additionally, PDMS can create bubbles when gas flows through it, which can cause experimental errors and lead to inaccurate results. To address these problems, scientists have been exploring alternative polymeric materials with specific properties and intended uses for microfluidic applications. These materials may offer improved resistance to the absorption of small molecules and better chemical compatibility with organic solvents. However, despite these challenges, it is important to acknowledge that the introduction of PDMS has significantly advanced the practical development of microfluidic devices for both technological and biomedical research. Its unique properties, such as its optical transparency and ease of fabrication, have made it a popular choice for microfluidic device manufacturing [39].

The production of microchips also employs PMMA, an amorphous thermoplastic substance that offers certain benefits over PDMS. PMMA is appropriate for various applications because it has superior compatibility with solvents and does not absorb small molecules. Additionally, its thermoplastic nature means it can be easily fashioned using methods such as surface bonding or injection molding. PMMA has numerous desirable properties, including optical transparency, affordability, low permeability to gases, wettability of inner channel walls, and good mechanical characteristics. These attributes make it an exceptional choice for microfluidic research, particularly in developing micro-physiological systems and organ-on-chip devices. However, PMMA does have some factors to consider, such as a low-resolution limit, challenges in modifying surfaces, and difficulties bonding two substrates together. These factors should be taken into account when selecting materials for specific microfluidic applications [50,53].

Teflon, which is also referred to as polytetrafluoroethylene (PTFE), is a substance that provides clearness when it comes to optics and a moderate level of gas permeability. It is versatile enough to create valves with diaphragms, and it effectively prevents the absorption of molecules on the walls of channels. Additionally, PTFE has superior compatibility with solvents and is thermally stable because of its high melting point. This material is recommended for applications in cell cultures, experiments that require high precision, instruments that need to be kept very clean, and for the fabrication of valves and pumps. PTFE is also used in synthesis devices because it can withstand a wide range of chemicals and temperatures up to 240 °C. It is naturally resistant to the clogging of channels with aqueous solutions due to its hydrophobic characteristics. Despite its many benefits, current samples of fluoropolymer microdevices are seldom used in device fabrication because they do not provide for easy micro-modeling during fabrication and do not have the required flexibility [50,53].

3.1.4. Hydrogels

Hydrogels/hydrocolloids are three-dimensional networks of hydrophilic polymer chains that are porous and cross-linked. They allow small molecules and bioparticles to diffuse through them. These colloids are made up of hydrophilic polymers immersed in an aqueous medium. They have easily controlled pore sizes that can mimic the extracellular matrix (ECM). Unlike PDMS, which is suitable for tissue-level microfluidics, hydrocolloids are used as substrates for cell culture in tissue engineering. These colloids have a structural similarity to the extracellular matrix, making them useful for simulating physiological tissues in bio-microfluidic devices. Hydrogels can also be used to create microfluidic component functionalities such as semipermeable barriers and intelligent valves within a chip made of a harder material. The advantages of hydrocolloids include their low cytotoxicity, biocompatibility, biodegradability, high permeability, controllable pore size, and aqueous nature. They are also inexpensive and widely accessible. These properties make hydrocolloids ideal for encapsulating cells for 3D culture in tissue engineering research, for delivering solutions, cells, and other substances, and for sensors and actuators. However, using hydrogels as a primary production material is limited due to the difficulty in maintaining the integrity of the device produced with hydrogels [49,50].

3.1.5. Metals

Metals are a crucial category of materials when it comes to the production of MOEMS (microoptoelectromechanical systems) and MEMS, which are utilized in various applications, such as microfluidic devices. The use of metals in these applications is an essential factor in ensuring their reliability, efficiency, and longevity [39]. Metals are generally inexpensive, widely available, easily machinable, and withstand high working pressures, many strong chemicals (except strong acids), and high temperatures. They are mechanically and chemically strong and easy to clean. They are particularly suitable for use in the production of microfluidic systems when it is necessary to use materials that are incompatible with other materials [49,50]. The thermoelectric properties of metals can be used for temperature sensing [31]. When it comes to producing electromagnetic coils and sensors, microstamps, and structures that conduct magnetic fields, metallic parts are frequently employed. In spite of the multitude of advantages that metals offer, including their broad application in various industries, there exist certain drawbacks associated with micromachining that have impeded their widespread use in this particular area [48]. The most frequently utilized metals for microfluidic gadgets are Al, Cu, and Fe. Nonetheless, they are frequently blended with other metals in alloys to boost their chemical durability [50]. Aluminum is commonly employed for electrical connections and as a protective layer in surface micro-machining. Certain metals, such as permalloy, an iron-nickel alloy, are used for magnetic sensing and activation. Platinum and palladium, both possessing catalytic properties, are advantageous in chemical sensors and microreactors. In microdevice applications with elevated operating pressures, stainless steel can be a superior choice compared to silicon or glass [31].

3.1.6. Paper

Since 2007, paper-based microfluidics have been developed as a more sustainable and cheaper alternative system to polymer chips for microfluidic applications. Paper microfluidics is considered a slightly different technology than polymeric and inorganic microfluidics [47]. Microfluidic paper-based chips have been well received due to several advantages inherent in these devices. Paper-based devices are simple, inexpensive, and user-friendly. Apart from this, they have advantages such as biocompatibility, bio-affinity, biodegradability, easy handling, easy portability, mechanical properties including flexibility, lightweight and low thickness, high stacking, storage and handling capabilities, easy modification chemically or biologically, ease of manipulation and sterilization, high rate of disposable use, high porosity, high physical absorption, ability to absorb liquids by capillary action without any external power supply, and ability to operate without support equipment. Paper-based systems with colorimetric or electrochemical readings are becoming versatile and valuable for rapid diagnostic testing and medical screening in developing countries. Paper microfluidic systems can be operated on-site without technical infrastructure, making them a promising solution for field analysis or home testing. Microfluidic paper-based analytical devices (µPADs) are reliable and sensitive, making them useful in the fields of medicine, healthcare, and environmental monitoring [39,50]. However, despite these advantages, some disadvantages should also be mentioned. Paper has little resistance to high humidity conditions and mechanical forces, and is not easily applicable to manufacturing processes. When working with fluid samples that have low surface tension on microfluidic paper chips, the hydrophobicity of the channels may not be adequate. To prevent any sample leakage, it is essential to integrate hydrophobic barriers that are thick enough. It should be noted that the precision of colorimetric analyses on microfluidic paper chips is typically not very high, but this can be slightly enhanced through special channel design [49,50,51].

3.1.7. Epoxy

Microfluidic devices can be fabricated using epoxy resins, which are often used in combination with glass or silicon chips, but can also be used on their own to create organ-on-chip devices. These resins provide excellent stability at high temperatures, chemical resistance, and transparency, making them ideal for observing cell growth in biological samples. Additionally, they offer high resolution with small properties. However, a major drawback of using these materials is their high cost [50]. SU-8 is a type of photoresist that is epoxy-based and specifically designed for microelectronic applications where a thicker layer is needed that can withstand both thermal and chemical stress. The main components of SU-8 are Bisphenol A Novolac epoxy and an organic solvent, along with up to 10% hexafluoroantimonate-triaryl sulfonium salt. The viscosity of SU-8 varies depending on the amount of solvent used, which in turn affects the thickness of the layers it can create [39].

3.1.8. Ceramics

Inorganic materials used in microfluidic devices include low-temperature fired ceramics [47]. These ceramics have unique surface chemistry that enables them to withstand corrosive environments and high temperatures. However, their integration into a complete microsystem can be difficult due to their poor dimensional stability, porosity, and brittleness. Despite their limitations, aluminum oxide ceramics remain a promising material for microfluidic applications [50].

3.2. Microfabrication Methods

The field of microfluidic device fabrication initially relied on silicon micromachining, which involved creating microfluidic devices with integrated sensors and actuators from silicon substrates. Over time, the range of available microfabrication techniques has significantly expanded. These microtechnologies, primarily employing hard materials like silicon and glass, are categorized as hard technologies and involve processes such as etching, lithography, and deposition. Conversely, plastic microtechnologies, referred to as soft technologies, typically use polymer materials and offer the advantage of rapid prototyping. Soft technologies bring additional benefits such as surface effects, transparency, and a wider range of available materials. However, hard microfabrication technologies tend to be more complex and challenging to implement. These processes demand a highly controlled and clean environment. A clean room is meticulously regulated in terms of temperature, humidity, and airflow. This controlled setting is essential because, in dusty environments, standard micrometer-sized particles can adhere to surfaces, altering the microstructures being fabricated. To maintain cleanliness, preliminary surface preparation may be necessary before microfabrication. This preparation could involve the use of distilled water at various temperatures, different types of acids, or specific buffers, depending on the requirements for general cleaning, particle removal, oxide removal, and contaminant elimination [31].

The wide range of materials available for microfluidic device manufacturing has different properties that influence their behavior during processing. As a result, the manufacturing methods must be carefully adapted to the specific material properties and desired end product characteristics. Cost considerations also play an important role in selecting the appropriate manufacturing technique. Furthermore, it is crucial for the widespread adoption of chips that they can be manufactured in an accessible and scalable manner. As the field of microfluidics has progressed, numerous manufacturing techniques have emerged to create channels with the required size and properties. These techniques can be classified according to whether they involve material removal (referred to as removal techniques) or material deposition (known as deposition techniques). Another classification categorizes manufacturing methods according to the nature of the processes used and covers chemical, mechanical, laser-based, and various other processes. Starting a project with the right manufacturing technique can significantly accelerate project timelines and improve device performance. A significant amount of work in the field of microfluidics has been performed using soft lithography, with particular emphasis on soft lithography methods involving polydimethylsiloxane (PDMS). In addition to soft lithography, microfluidics engineers have developed various methods for fabricating sub-millimeter channels for a variety of reasons, including cost-effectiveness, faster turnaround times, availability of more affordable materials and tools, and the ability to offer greater functionality. These developments, coupled with the fabrication of microfluidic devices using a variety of materials and geometries, have unlocked new and advantageous physical behaviors and properties in microfluidic devices [54].

Material removal techniques involving chemical processes include wet etching, dry etching, and electrochemical discharge machining. These microfabrication techniques have long been widely used to fabricate glass and silicon microfluidic channels. Material deposition techniques involving chemical processes include silicon surface micromachining, lithography, inkjet 3D printing, powder 3D printing, direct writing, and two-dimensional virtual hydrophilic channels. Material removal techniques involving mechanical processes include techniques such as micro-milling, micro-grinding, micro-abrasive air-jet machining, micro-abrasive water jet machining, ultrasonic machining, and xurography. Material deposition techniques involving mechanical processes include injection molding and hot embossing. Material removal techniques involving laser-based processes are the photothermal process, ultra-short pulse process, absorbent material process, photochemical modification process, and laser direct machining. Material deposition techniques involving laser-based processes are selective laser sintering, stereolithography, and two-photon polymerization. Among other processes, the focused ion beam technique has been recorded as a material removing technique, while the forming process, soft lithography, layer-to-layer manufacturing, layer-on-layer manufacturing, fused deposition modeling, and 2.5-dimensional printing as material depositing techniques [50]. Since this review focuses on the use of microfluidic devices in nanoparticle production, we will discuss the methods used to produce PDMS-based devices, which are the most commonly used for nanoparticle production today. Other methods and more detailed descriptions are given elsewhere [54,55,56,57,58,59,60,61,62,63,64,65,66].

One of the most important methods for creating microchannel geometries and cavities in PDMS-based microfluidic devices is soft lithography. Depending on the resolution of the master mold, this technology enables fine microfluidic pattern resolution ranging from micrometers to nanometers. Typically, a negative mold is used into which PDMS is poured, filling the regions left open by the mold. The master mold used to pour the PDMS can be made from a variety of materials, with SU-8 being the most common choice. The fabrication of the master mold usually involves conventional photolithography techniques. In this process, the negative photoresist SU-8 is patterned onto a silicon wafer to form the ridges of the microchannel network. Alternative lithography methods such as reactive ion etching, electron beam lithography, wet etching, multiphoton lithography, direct laser writing, focused ion beam, and stereolithography can also be used to fabricate master molds. These methods enable high-resolution production, and some of them, such as direct laser writing, electron beams, and focused ion beams, do not require a physical mask, potentially reducing costs, although they tend to be slower. Master molds can also be produced using techniques such as the micromachining of materials such as PMMA, brass, glass, and steel, and 3D printing. While these processes are generally more cost-effective than the lithography methods, they may not achieve the same high resolution, limiting their applicability for commercial and research purposes. Advances in 3D printing technology have enabled relatively high-resolution master molds to be printed directly by a 3D printer. Once the master mold has been produced using any of the methods mentioned, it is typically fluorosilanized to make it hydrophobic. This hydrophobicity facilitates the peeling of the PDMS after the casting process. In the PDMS casting process, the crosslinker and curing agent are mixed; Dow and Corning’s Sylgard 184 is a common choice with a crosslinker-to-curing agent ratio of 1/10. Changing this ratio can change the hardness of the resulting PDMS. The mixture is degassed under vacuum to remove air bubbles and then cured in the master mold at a temperature higher than 70 °C, typically for times ranging from 15 min to 6 h. This process solidifies the polymer and transfers the pattern of the positive mold to the PDMS layer. PDMS exhibits ease of demolding, the ability to replicate nanoscale features, minimal shrinkage during curing (approximately 1%), and excellent elastic properties during these processes. Alternatively, microchannel arrays in the PDMS layer can be formed directly using a laser cutting machine. Inlets and outlets are drilled into the cast PDMS layer to provide access to the channels. The PDMS part with the channels is then bonded to a substrate, usually PDMS or other materials, to form the device. Oxygen or air plasma activation, ultraviolet/ozone (UVO) therapy, employing uncured or partially cured PDMS as an adhesive, or the corona discharge method are common methods for joining PDMS layers. These procedures guarantee a strong link between the layers. The device can then be modified on its surface and functionalized, utilizing a variety of techniques depending on the demands of the work [67,68].

3.3. System Components

The most basic components required to operate a microfluidic device are microchannels where the flow takes place, input and output ports to the microchannels, a pump that will allow the fluids to flow, and active or passive mixers that will allow them to mix. Apart from these, various internal or external components can be added to the system according to the requirements of the protocol to be applied. For example, valves, filters, micropumps, switches, lenses, membranes, heaters, motors, optical fibers, various other actuators and devices, various sensors for different applications, sealing gaskets, compressed gas lines, micro overpasses to prevent the mixing of liquids, and microflow meters are some of the components that can be used according to needs and purposes [69,70,71,72,73].

The main component of any microfluidic device is the channel network. Microchannels are channels with a hydraulic diameter of less than 1 mm, usually 1–99 μm. The channel structure can be formed using various design and fabrication methods. Microchannels can be in various shapes such as coil-shaped, rectangular, zigzag, or spiral. Although a simple channel network can be useful in some applications, for other applications it is necessary to add various components to the system to increase functionality [74,75].

The accurate control of liquid flow within microfluidic devices relies on various pumping schemes, which can be classified as either external or internal to the fluidic pathway. Each of these methods possesses distinct characteristics tailored to specific application requirements. Several types of external pump types are employed for microfluidic applications. Syringe pumps offer the advantage of delivering steady and precise flow rates. Peristaltic pumps are well suited for handling viscous and shear-sensitive fluids. Piezoelectric (diaphragm) pumps provide a rapid dynamic response, possess a simple structure, and are lightweight. Nanopump designs are ideal for handling very small fluid quantities, ensuring consistent continuous flow rates and allowing for the intermittent introduction or removal of several nanoliters of fluid per revolution. Pressure-driven pumps exhibit minimal time to achieve steadiness with no observed periodic fluctuations. High-performance liquid chromatography (HPLC) pumps, known for their high-pressure operation and increased flow rates, are also commonly used in microfluidics. However, due to possible valve failures, HPLC pumps might not be appropriate for viscous liquids [76,77,78,79,80,81,82]. On the other hand, the establishment and maintenance of flows are made possible by internal micropumps implanted into microfluidic chips. They produce a continuous laminar flow rather than a turbulent one, unlike micromixers. These micropumps depend on outside forces to function, frequently using optical forces for quick remote control and the ability to run numerous rotors at once. By depending on changes in internal pressure, passive pumping systems move fluid by using surface tension in tiny liquid drops. In order to provide effective fluid manipulation within microfluidic devices, the choice of pump type depends on certain system requirements, such as liquid characteristics, flow rate precision, and application needs [52,70,74].

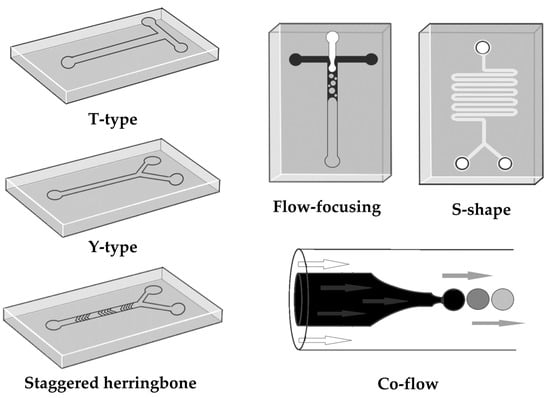

From the point of view of nanoparticle production in microfluidic systems, the ability of this system to mix the liquids that are the formulation components will be essential. Therefore, various microfluidic mixing techniques are used. Micromixers are included in the channel network. Micromixers can be two- or three-dimensional and are usually classified as active or passive [50]. Most micromixers are passive devices. Passive micromixers employ their shape and geometry to create turbulence and chaotic advancement of the liquid, and the mixing of fluids occurs by diffusion. They do not require any external force to drive fluids or to orientate or segregate particles in the liquid. Given that mixing happens by diffusion, the effectiveness of mixing is influenced by the fluids’ contact area and the duration of their contact. Different designs of passive micromixers can be created to reduce laminar flow, increase the surface area of contact between the fluids, and enhance mixing efficiency. These designs can include T-type microreactors, Y-type microreactors, flow-focusing microreactors, co-flow microreactors, S-shaped microchannels, and staggered herringbone micromixers (Figure 2). In some microfluidic systems, various geometries can be combined. According to their mixing structure, these microreactors can also be divided into simple, split-and-recombined, curved, spiral, or multilayer configurations. Although it is simple to build superficial designs like T-type, Y-type, or cross micromixers, they perform poorly. Split-and-recombined micromixers are better for viscous and multiphase fluids, while helical and curved structures perform best at high flow rates. The potential of multilayer structures to offer outstanding mixing performance at both high and low flow rates in a few of milliseconds has recently gained a great deal of attention. Compared to active micromixers, passive ones are less expensive, more portable, and simpler to integrate into lab-on-a-chip systems. Passive mixers have significant drawbacks despite being simpler and more affordable. Increasing the contact surface of the liquids by prolonging the channel increases fluid resistance to the track, decreasing the efficiency of the microfluidic device. In an active micromixer, the mixing event is initiated or accelerated by an external force or physical field (such as magnetic, electrokinetic, thermal, acoustic, or ultrasonic), which enhances performance. In general, active stirrers are more effective than passive stirrers. However, given the undesirable complexity and additional expenses, the requirement to integrate an external force or field into the platform makes it a less practical alternative for rapid prototyping and commercial translation [52,83]. The optimal agitator type typically depends on the reagents to be mixed and the flow regime (i.e., Re number) during operation. While several mixers perform better at greater rates of flow, some perform better at slower rates of flow.

Figure 2.

Types of micromixers with different designs.

Another type of component that can be used to regulate flow properties are microvalves. A microvalve is a microscale valve, i.e., a two-port component that regulates the flow between sections within a microfluidic system. Microvalves serve as one of the fundamental parts of microfluidic devices and regulate fluid transfer. There are two different kinds of valves: active valves, which take energy to operate, and passive valves, which do not. The kind of valve a device uses is determined by the kind and quantity of control required for the application [84]. In recent years, Tesla valves have garnered significant attention as a notable example of valve technology. The distinctive architecture of Tesla valves is defined by their asymmetrical design and an arc-shaped channel. Tesla valve structures have found applications in various fields, leading to advancements in technologies like medical instruments, lab-on-a-chip systems, and chemosensors [85,86].

4. Advantages and Disadvantages

Thanks to their reduced size scale and larger surface-to-volume ratio, microfluidic technologies have several advantages over conventional macro-scale platforms, such as requiring less sample and reagent volume, operating at higher throughput, higher sensitivity, lower cost, easier portability due to their reduced size, ability to mimic biological systems, faster sample throughput, and decreased human error due to their potential to be automated and highly integrated [87,88,89,90]. The integration of microfluidic technologies into a ‘lab-on-a-chip’ provides a powerful solution for processing and analyzing samples on a single platform, thereby reducing the complexity, bioassay loss, and cross-contamination associated with multiple processing and transfer steps in more traditional benchtop workflows. Integrated multifunctional systems, created through their ability to be parallelized, enable better and faster process control [91]. Some flow characteristics not seen in conventional fluid handling platforms, such as the laminar flow exhibited by micro-sized channels, allow for some creative applications. The capacity of microfluidic devices to selectively collect and release certain cells, macromolecules, germs, and particles is one of their noteworthy characteristics. Microfluidic capture and release systems have a number of benefits over conventional batch analyzers, including non-contact operation, high sensitivity, accurate results, label-free identification, and reduced reagent needs [92]. Microfluidic devices provide an alternate method to traditional biochemical separations. It is beneficial to utilize technologies that make use of dielectrophoretic pressures to differentiate and manipulate cells as they do not need to be functionalized before use [93]. When it comes to the creation of drug-releasing nanoparticles, microfluidic technologies are a very useful method. Many of the problems associated with the limitations of conventional manufacturing techniques are effectively solved by these technologies. Micro/nanoparticles with specific properties such as small size, significant surface area, tunable surface chemistry, high drug loading capacity, and exceptional surface-to-volume ratios are becoming essential in the context of regulated and safe drug production. The production of nanoparticles using conventional techniques such as emulsion polymerization, dispersion polymerization, and spray drying often results in particles with drastic polydispersity, little functional diversity, poor reproducibility, and irregular shape. Microfluidic systems are unique in that they can produce smaller, more homogeneous particles. This accuracy is achieved through the careful regulation of liquid phase flow rates, resulting in higher drug loading levels and improved drug encapsulation efficiency (EE). The design of the structure of the microfluidic device, control of flow rates, manipulation of material composition, and selection of fluid viscosity can be used to precisely vary the size, structure, function, and distribution of particles. It is with this degree of control and accuracy that the efficient creation of a wide variety of particles with different compositions and properties, designed to meet the unique requirements of drug delivery systems and other applications in nanomedicine, is possible. Fundamentally, microfluidic technologies have transformed nanoparticle production, enabling the development of highly customized and precisely manufactured particles for a variety of applications [94,95]. The numerous advantages of microfluidic methods make them a key factor in developments in a variety of industries. These advantages include improved handling and storage safety, improved accuracy, flexibility, higher cost-effectiveness, and reduced raw material consumption due to integration capabilities. The ability of microfluidic systems to integrate seamlessly with a variety of elements such as heaters, sensors, and flow control elements offers a range of benefits including increased heat transfer, accurate temperature and feed flow control, increased repeatability, and real-time reaction monitoring. The use of microfabricated networks of specially designed microchannels and reservoirs enables the execution of several process steps and parallel reactions on a single chip. In addition, synthesis conditions such as temperature, pressure, and reagent compatibility are extended by microfluidic technologies, which is often not possible with conventional batch processes. This expanding field offers intriguing opportunities to create innovative material systems and complex nanostructures, and usher in a new era of innovation [9]. Particles created with microfluidic technologies can have advanced properties such as double partitioning, pH sensitivity, and controlled release [95]. However, there are several inescapable difficulties with micro/nanoparticle creation that microfluidics must overcome. Designing microsystems that can produce desirable materials under desired parameters (pressure, temperature, chemical compatibility, concentration, etc.) without clogging the system is the major problem when using microfluidics to synthesize nanoparticles. The manufacturing of devices with intricate geometries and combinations raises production costs and complicates the manufacturing process [9,94]. Highly competent technicians are needed for both microfluidic device design and production. Biologists and chemists are discouraged from using this technology in their laboratory due to the range of microfluidic devices [96]. Each material chosen to build the system has pros and cons, as has already been explained. Material selection and device construction should be carefully planned while taking the needs of the process into account. For instance, frequently used microfluidic chip components like PDMS can adsorb hydrophobic small molecule medicines, rendering them useless for drug research. It would be essential to reduce adsorption through surface modification to resolve this issue. For some systems, channel clogging during material production continues to be difficult.

5. Polymeric Nanoparticles

Polymer-based nanoparticles have been under scrutiny for drug delivery and imaging applications since the 1970s, and continue to be widely used in contemporary research due to their numerous advantages that contribute to effective drug delivery and targeting. They are favored because of qualities such as biocompatibility, stability, biodegradability, and readiness for preparation, which enables the exact control of NP characteristics and their length of action [97,98].

Polymer NPs are made using both natural and synthetic polymers; however, synthetic polymers provide a greater range of formulation options and more accurate batch-to-batch consistency. Poly(lactide-co-glycolide) (PLGA), poly(alkyl cyanoacrylate) (PACA), poly(ethylene oxide) (PEO), poly(lactic acid) (PLA), poly(L-lysine) (PLL), poly-caprolactone (PCL), and poly anhydrides are examples of synthetic polymers, whereas natural polymers include chitosan, gelatin, hyaluronic acid, and alginate. Among them, PLGA use is relatively widespread. The FDA-approved, biodegradable, and biocompatible polymer PLGA is being extensively used in sustained drug release strategies for the inclusion of both hydrophilic and lipophilic medicines due to its appropriate degrading characteristics and long clinical history [99,100].

The manufacturing processes of polymeric nanoparticles are relatively simple, and since polymers can be synthesized from a wide variety of monomers with different properties, engineered polymeric NPs can be produced in various shapes and sizes or with other surface properties such as porosity. This makes them highly adaptable and customizable for multiple applications, such as drug delivery [7,97]. Depending on the material and technique used, different final NP products with various structures and properties can be obtained [98]. Drug molecules can be encapsulated within the cores of the NP, entrapped or conjugated to polymer matrices, or bound to their surfaces after particle formation. Moreover, they can release therapeutic agents by triggering through the incorporation of specific stimulatory elements [7]. Polymeric nanostructured systems include nanospheres, nanocapsules, nanoemulsions, and nano gels. Nanospheres comprise a compact and homogeneous polymer matrix in which the substance is dispersed and trapped in polymeric networks or adhered to the surface. In contrast, nanocapsules are vesicular systems in which the drug is trapped in an oily liquid surrounded by a single polymeric layer. Well-designed nanocapsule shells protect the encapsulated drugs and release them in the internal structure at any time in response to external stimuli. Nanogels are three-dimensionally cross-linked polymer particles that combine the characteristics of hydrogels and colloidal particles. They are helpful for shielding medications from the outside environment and, through surface modification, can deliver pharmaceuticals to certain tissues and cells. A potential colloidal method for delivering and transporting chemicals is nanoemulsions. They are extensively employed in a variety of sectors, including agriculture, cosmetics, food, and medicines [94,97].