Toward the Inclusion of Waste Materials at Road Upper Layers: Integrative Exploration of Critical Aspects

Abstract

1. Introduction

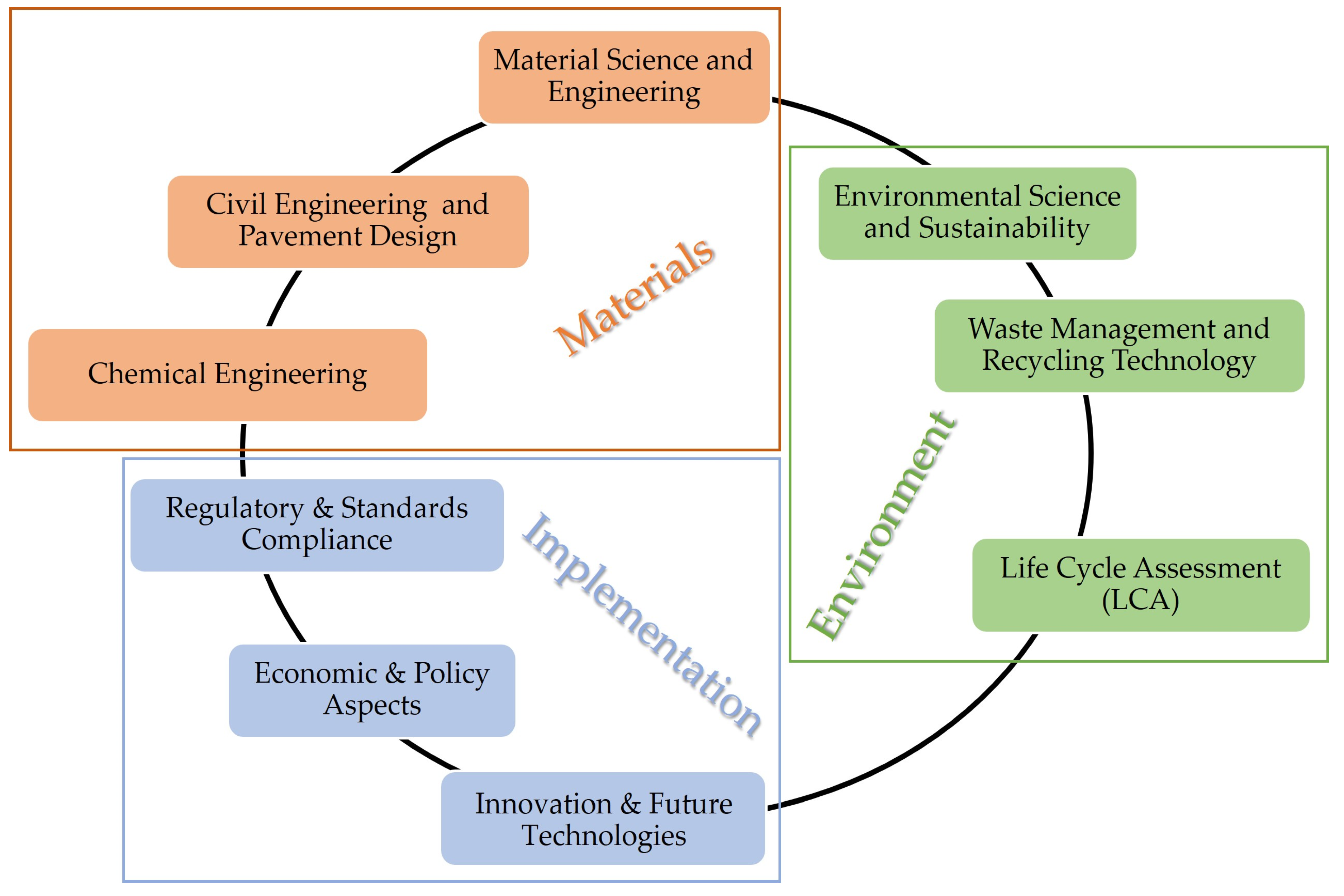

2. Multi-Disciplinary Aspects of Reutilizing Waste Materials

2.1. Condition Status Comparison

2.2. Availability, Local Aspects, and Concerns

2.2.1. Waste Materials

2.2.2. The Case of RAP

2.3. Lifecycle Assessment

2.4. Legislative and Health Concerns

3. Discussion and Future Directions

4. Conclusions

4.1. Main Remarks

- Despite the existing studies on recycled mixtures mainly in laboratories and/or field-scale tests (to a lesser extent), the lack of specific requirements and documented guidelines consistently fuels the need for new research efforts on a continuous basis.

- An examination of nearby waste materials, the assessment of local availabilities, local peculiarities, health, and other safety concerns, and the comparison of recycling options can lead to investments on in-place or in-plant facilities for asphalt pavement recycling.

- In this context, collaboration between researchers and practitioners can be promoted for innovative processes that convert waste into construction materials. It is also advisable to thoroughly examine the cost-effectiveness through the perspective of LCA/LCCA studies as well, for a more informative decision-making.

- The issues of environmental sensitivity and circular economy are highlighted so that the use of waste materials into road construction can guarantee the sustainability of the future road infrastructures.

4.2. Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lo Presti, D.; del Barco Carrion, A.J.; Airey, G.; Hajj, E. Towards 100% recycling of reclaimed asphalt in road surface courses: Binder design methodology and case studies. J. Clean. Prod. 2016, 131, 43–51. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Pomoni, M. An Overview of the Recyclability of Alternative Materials for Building Surface Courses at Pavement Structures. Buildings 2024, 14, 1571. [Google Scholar] [CrossRef]

- Di Mino, G.; Vijayan, V.; Eskandarsefat, S.; Venturini, L.; Mantalovas, K. Investigating the Multi-Recyclability of Recycled Plastic-Modified Asphalt Mixtures. Infrastructures 2023, 8, 84. [Google Scholar] [CrossRef]

- Giri, J.P.; Panda, M.; Sahoo, U.C. Performance of bituminous mixes containing treated recycled concrete aggregates and modified by waste polyethylene. J. Mater. Civ. Eng. 2018, 30, 04018184. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Fatigue behavior characterization of bituminous mixtures made with reclaimed asphalt pavement and steel slag. Procedia Soc. Behav. Sci. 2012, 53, 297–306. [Google Scholar] [CrossRef]

- Guo, M.; Liu, H.; Jiao, Y.; Mo, L.; Tan, Y.; Wang, D.; Liang, M. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Putra, A.D.; Hadiwardoyo, S.P.; Sumabrata, R.J. Skid resistance performance against temperature change of hot-mix recycled asphalt pavement with added crumb rubber. AIP Conf. Proc. 2019, 2114, 04112. [Google Scholar]

- Eskandarsefat, S.; Sangiorgi, C.; Dondi, G.; Lamperti, R. Recycling asphalt pavement and tire rubber: A full laboratory and field scale study. Constr. Build. Mater. 2018, 176, 283–294. [Google Scholar] [CrossRef]

- Jiang, L.; Shen, J.; Wang, W. Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design. Materials 2024, 17, 2096. [Google Scholar] [CrossRef] [PubMed]

- Cadar, R.D.; Boitor, R.M.; Dragomir, M.L. An Analysis of Reclaimed Asphalt Pavement from a Single Source—Case Study: A Secondary Road in Romania. Sustainability 2022, 14, 7057. [Google Scholar] [CrossRef]

- Ferne, B.; Nunn, M. The European Approach to Long Lasting Asphalt Pavements: A state-of-the-art review by ELLPAG. In Proceedings of the International Conference on Perpetual Pavements, Columbus, OH, USA, 13–15 September 2006. [Google Scholar]

- Newcomb, D. Perpetual Pavements—A Synthesis; Asphalt Pavement Alliance: Lanham, MD, USA, 2002. [Google Scholar]

- Saberi, K.F.; Fakhri, M.; Azami, A. Evaluation of warm mix asphalt mixtures containing reclaimed asphalt pavement and crumb rubber. J. Clean. Prod. 2017, 165, 1125–1132. [Google Scholar] [CrossRef]

- Valdés, G.; Pérez-Jiménez, F.; Miró, R.; Martínez, A.; Botella, R. Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2011, 25, 1289–1297. [Google Scholar] [CrossRef]

- Hand, A.J.T.; Ragavan, P.; Elias, N.G.; Hajj, E.Y.; Sebaalyand, P.E. Evaluation of Low Volume Roads Surfaced with 100% RAP Millings. Materials 2022, 15, 7462. [Google Scholar] [CrossRef]

- Hao, G.; Lim, S.M.; He, M.; Ong, G.P.; Zulkati, A.; Kapilan, S.; Tan, J.H. Long-term performance of porous asphalt pavement incorporating recycled plastics. Resour. Conserv. Recycl. 2025, 212, 107979. [Google Scholar] [CrossRef]

- Chiola, D.; Cirimele, V.; Tozzo, C. An Index for Assessing the Environmental Impact of Pavement Maintenance Operations on the Motorway Network: The Environmental Asphalt Rating. Constr. Mater. 2023, 3, 62–80. [Google Scholar] [CrossRef]

- Jamshidi, A.; White, G. Evaluation of Performance and Challenges of Use of Waste Materials in Pavement Construction: A Critical Review. Appl. Sci. 2020, 10, 226. [Google Scholar] [CrossRef]

- Loizos, A.; Gkyrtis, K.; Plati, C. Modelling Asphalt Pavement Responses Based on Field and Laboratory Data. In Accelerated Pavement Testing to Transport Infrastructure Innovation; Lecture Notes in Civil Engineering; Chabot, A., Hornych, P., Harvey, J., Loria-Salazar, L., Eds.; Springer: Cham, Switzerland, 2020; Volume 96, pp. 438–447. [Google Scholar]

- Gkyrtis, K.; Armeni, A.; Loizos, A. A mechanistic perspective for airfield pavements evaluation focusing on the asphalt layers’ behaviour. Int. J. Pavement Eng. 2022, 23, 5087–5100. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Loizos, A.; Plati, C. A mechanistic framework for field response assessment of asphalt pavements. Int. J. Pavement Res. Technol. 2021, 14, 174–185. [Google Scholar] [CrossRef]

- Gu, S.; Shen, H.; Pang, C.; Li, Z.; Liu, L.; Liu, H.; Wang, S.; Song, Y.; Huang, J. Potential of Repurposing Recycled Concrete for Road Paving: Flexural Strength (FS) Modeling by a Novel Systematic and Evolved RF-FA Model. Sustainability 2023, 15, 3749. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Armeni, A.; Plati, C.; Loizos, A. Structural Performance Assessment of Airfield Concrete Pavements Based on Field and Laboratory Data. Infrastructures 2021, 6, 173. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable Practice in Pavement Engineering through Value-Added Collective Recycling of Waste Plastic and Waste Tyre Rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Zhao, Z.; Xiao, F.; Amirkhanian, S. Recent applications of waste solid materials in pavement engineering. Waste Manag. 2020, 108, 78–105. [Google Scholar] [CrossRef]

- Mashaan, N. Engineering Characterisation of Wearing Course Materials Modified with Waste Plastic. Recycling 2022, 7, 61. [Google Scholar] [CrossRef]

- Piao, Z.; Mikhailenko, P.; Rafiq Kakar, M.; Bueno, M.; Hellweg, S.; Poulikakos, L.D. Urban mining for asphalt pavements: A review. J. Clean. Prod. 2021, 280, 124916. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Eurostat. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/w/ddn-20241024-3 (accessed on 10 May 2025).

- Bernardo, M.; Forehead, H.; De Carvalho Vallin, I.; Gonçalves-Dias, S.L.F. Management of Household Plastic Waste in Wollongong, Australia: The Role of Selective Waste Collection Systems. Sustainability 2023, 15, 1726. [Google Scholar] [CrossRef]

- EUROSLAG. Position Paper on the Status of Ferrous Slag; The European Slag Association: Duisburg, Germany; The European Steel Association: Brussels, Belgium, 2012. [Google Scholar]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical behaviour of ground waste glass when used as partial cement replacement in mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; Nawa, T.; Igarashi, T. Performance of pavements incorporating waste glass: The current state of the art. Renew. Sustain. Energy Rev. 2016, 64, 211–236. [Google Scholar] [CrossRef]

- European Tire & Rubber Manufacturer’s Association (ETRMA). The ETRMA Statistics Report; European Tire & Rubber Manufacturer’s Association: Saint-Josse-ten-Noode, Belgium, 2019. [Google Scholar]

- Bressi, S.; Fiorentini, N.; Huang, J.; Losa, M. Crumb rubber modifier in road asphalt pavements: State of the art and statistics. Coatings 2019, 9, 384. [Google Scholar] [CrossRef]

- Plati, C.; Pomoni, M.; Stergiou, T. From Mean Texture Depth to Mean Profile Depth: Exploring possibilities. In Proceedings of the 7th International Conference on Bituminous Mixtures and Pavements (ICONFBMP), Thessaloniki, Greece, 12–14 June 2019; pp. 639–644. [Google Scholar] [CrossRef]

- Loizos, A.; Spiliopoulos, K.; Cliatt, B.; Gkyrtis, K. Structural pavement responses using nonlinear finite element analysis of unbound materials. In Proceedings of the 10th International Conference on Bearing Capacity of Roads, Railways and Airfields (BCRRA), Athens, Greece, 28–30 June 2017; pp. 1343–1350. [Google Scholar]

- Wang, D.; Riccardi, C.; Jafari, B.; Falchetto, A.C.; Wistuba, M.P. Investigation on the effect of high amount of Re-recycled RAP with Warm mix asphalt (WMA) technology. Constr. Build. Mater. 2021, 312, 125395. [Google Scholar] [CrossRef]

- Stroup-Gardiner, M.; Wagner, C. Use of Reclaimed Asphalt Pavement in Superpave Hot-Mix Asphalt Applications. Transp. Res. Rec. 1999, 1681, 1–9. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Neves, J. Investigating aged binder mobilization and performance of RAP mixtures for surface courses. Constr. Build. Mater. 2021, 271, 121511. [Google Scholar] [CrossRef]

- Sukhija, M.; Coleri, E. A systematic review on the role of reclaimed asphalt pavement materials: Insights into performance and sustainability. Clean. Mater. 2025, 16, 100316. [Google Scholar] [CrossRef]

- Marinković, M.; Zavadskas, E.K.; Matić, B.; Jovanović, S.; Das, D.K.; Sremac, S. Application of Wasted and Recycled Materials for Production of Stabilized Layers of Road Structures. Buildings 2022, 12, 552. [Google Scholar] [CrossRef]

- Gong, H.; Huang, B.; Shu, X. Field performance evaluation of asphalt mixtures containing high percentage of RAP using LTPP data. Constr. Build. Mater. 2018, 176, 118–128. [Google Scholar] [CrossRef]

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A. Life cycle assessment applied to bituminous mixtures containing recycled materials: Crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 2017, 117, 204–212. [Google Scholar] [CrossRef]

- Mantalovas, K.; Di Mino, G. Integrating Circularity in the Sustainability Assessment of Asphalt Mixtures. Sustainability 2020, 12, 594. [Google Scholar] [CrossRef]

- Buttitta, G.; Giancontieri, G.; Parry, T.; Lo Presti, D. Modelling the Environmental and Economic Life Cycle Performance of Maximizing Asphalt Recycling on Road Pavement Surfaces in Europe. Sustainability 2023, 15, 14546. [Google Scholar] [CrossRef]

- Medina, T.; Calmon, J.L.; Vieira, D.; Bravo, A.; Vieira, T. Life Cycle Assessment of Road Pavements That Incorporate Waste Reuse: A Systematic Review and Guidelines Proposal. Sustainability 2023, 15, 14892. [Google Scholar] [CrossRef]

- Assaf, H.; Abu Abdo, A. Life cycle assessment of incorporating recycled materials in pavement Design. J. King Saud Univ. Eng. Sci. 2022, 36, 473–484. [Google Scholar] [CrossRef]

- Li, J.; Xiao, F.; Zhang, L.; Amirkhanian, S.N. Life cycle assessment and life cycle cost analysis of recycled solid waste materials in highway pavement: A review. J. Clean. Prod. 2019, 233, 1182–1206. [Google Scholar] [CrossRef]

- Ozbay, K.; Jawad, D.; Parker, N.A.; Hussain, S. Life-cycle cost analysis: State of the practice versus state of the art. Transp. Res. Rec. 2004, 1864, 62–70. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Al Jassmi, H.; Hasan, A. Lifecycle Cost Analysis of Recycled Asphalt Pavements: Determining Cost of Recycled Materials for an Urban Highway Section. Civil Eng. 2022, 3, 316–331. [Google Scholar] [CrossRef]

- Anthonissen, J.; Van den Bergh, W.; Braet, J. Review and environmental impact assessment of green technologies for base courses in bituminous pavements. Environ. Impact Assess. Rev. 2016, 60, 139–147. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Utilization of solid waste materials as alternative fillers in asphalt mixes: A review. Constr. Build. Mater. 2020, 234, 117271. [Google Scholar] [CrossRef]

- Azadgoleh, M.A.; Mohammadi, M.M.; Ghodrati, A.; Sharifi, S.S.; Palizban, S.M.M.; Ahmadi, A.; Vahidi, E.; Ayar, P. Characterization of contaminant leaching from asphalt pavements: A critical review of measurement methods, reclaimed asphalt pavement, porous asphalt, and waste-modified asphalt mixtures. Water Res. 2022, 219, 118584. [Google Scholar] [CrossRef]

- Yousefi, A.A.; Underwood, B.S.; Ghodrati, A.; Behnood, A.; Vahidi, E.; Nowrouzi, A.; Ayar, P.; Haghshenas, H.F. Towards a durable and sustainable warm mix asphalt: Techno-economic and environmental evaluation considering balanced mix design approach. J. Clean. Prod. 2025, 486, 144311. [Google Scholar] [CrossRef]

- Refaat, A.; Saleh, A.M.; Farag, R.K.; Mostafa, A.E.A. Developing recycled asphalt binder using ecofriendly bio additives. Innov. Infrastruct. Solut. 2025, 10, 37. [Google Scholar] [CrossRef]

- Sharma, A.; Rongmei Naga, G.R.; Kumar, P.; Rai, P. Mix design, development, production and policies of recycled hot mix asphalt: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 765–794. [Google Scholar] [CrossRef]

- Revelli, V.; Ali, A. Understanding the State Agency Policies toward RAP Usage in the United States: State of Practice. Recycling 2023, 8, 100. [Google Scholar] [CrossRef]

- Afshin, A.; Behnood, A. Nanomaterials in asphalt pavements: A state-of-the-art review. Clean. Waste Syst. 2025, 10, 100214. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Y.; Wu, X.; Zhang, J.; Huang, X. Nanomaterials for Modified Asphalt and Their Effects on Viscosity Characteristics: A Comprehensive Review. Nanomaterials 2024, 14, 1503. [Google Scholar] [CrossRef]

- Yao, X.; Xu, T. Fatigue fracture and self-healing behaviors of cold recycled emulsified asphalt mixture containing microcapsules based on semicircular bending test. J. Clean. Prod. 2023, 410, 1377171. [Google Scholar] [CrossRef]

| Country | Percentage (%) of Recycled Asphalt for Use in Reconstruction | ||||

|---|---|---|---|---|---|

| HMA and WMA | Cold Mixtures | Unbound Layers | Other Miscellaneous Works | Landfilling | |

| Austria | 60 | N/A | N/A | N/A | N/A |

| Belgium | 95 | N/A | N/A | N/A | N/A |

| Czech Republic | 14 | 30 | 20 | 10 | 26 |

| Denmark | 66 | 0 | 8 | 0 | 26 |

| Finland | 100 | 0 | 0 | 0 | 0 |

| France | 70 | N/A | N/A | N/A | N/A |

| Germany | 84 | 0 | 16 | 0 | 0 |

| Hungary | 95 | 0 | 0 | 4 | 1 |

| Italy | 23 | N/A | N/A | N/A | N/A |

| Netherlands | 71 | 11 | 0 | 0 | 18 |

| Norway | 30 | 1 | 0 | 0 | 0 |

| Slovakia | 96 | 2 | 1 | 1 | 0 |

| Slovenia | 24 | 6 | 10 | 0 | 60 |

| Spain | 83 | 0 | 14 | 0 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gkyrtis, K.; Kokkalis, A. Toward the Inclusion of Waste Materials at Road Upper Layers: Integrative Exploration of Critical Aspects. Future Transp. 2025, 5, 67. https://doi.org/10.3390/futuretransp5020067

Gkyrtis K, Kokkalis A. Toward the Inclusion of Waste Materials at Road Upper Layers: Integrative Exploration of Critical Aspects. Future Transportation. 2025; 5(2):67. https://doi.org/10.3390/futuretransp5020067

Chicago/Turabian StyleGkyrtis, Konstantinos, and Alexandros Kokkalis. 2025. "Toward the Inclusion of Waste Materials at Road Upper Layers: Integrative Exploration of Critical Aspects" Future Transportation 5, no. 2: 67. https://doi.org/10.3390/futuretransp5020067

APA StyleGkyrtis, K., & Kokkalis, A. (2025). Toward the Inclusion of Waste Materials at Road Upper Layers: Integrative Exploration of Critical Aspects. Future Transportation, 5(2), 67. https://doi.org/10.3390/futuretransp5020067