Effects of Heat Input and Backing Gas on Bead Geometry and Weld Heat Tint in Sanitary Tube Welding

Abstract

1. Introduction

- -

- Welding current and travel speed are the principal factors controlling penetration, tensile strength, and HAZ size;

- -

- Electrode torch geometry, standoff, and pulse time play a decisive secondary role for bead shape and surface quality;

- -

- Methodological approaches that combine screening process (Taguchi/ANOVA) with Response Surface Methodology or the Finite Element approach, Artificial Neural Networks (ANNs), and evolutionary search produce robust, application-relevant optimal welding parameters.

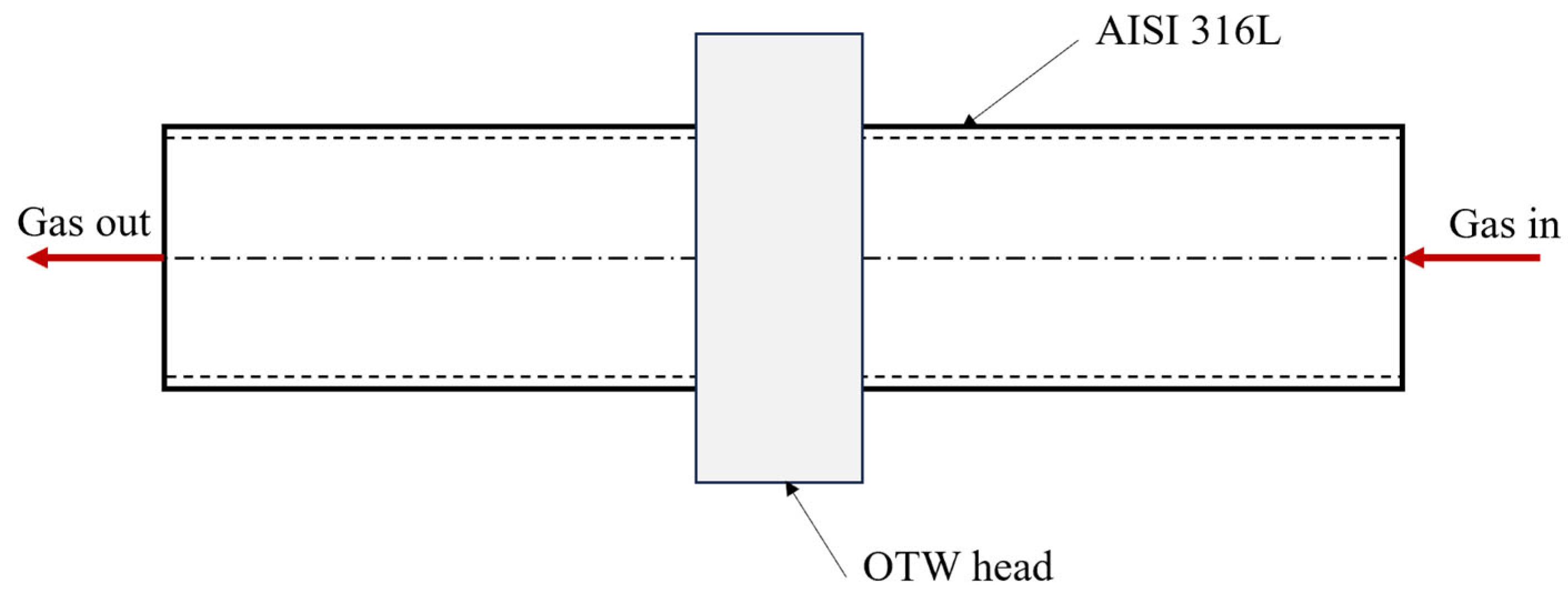

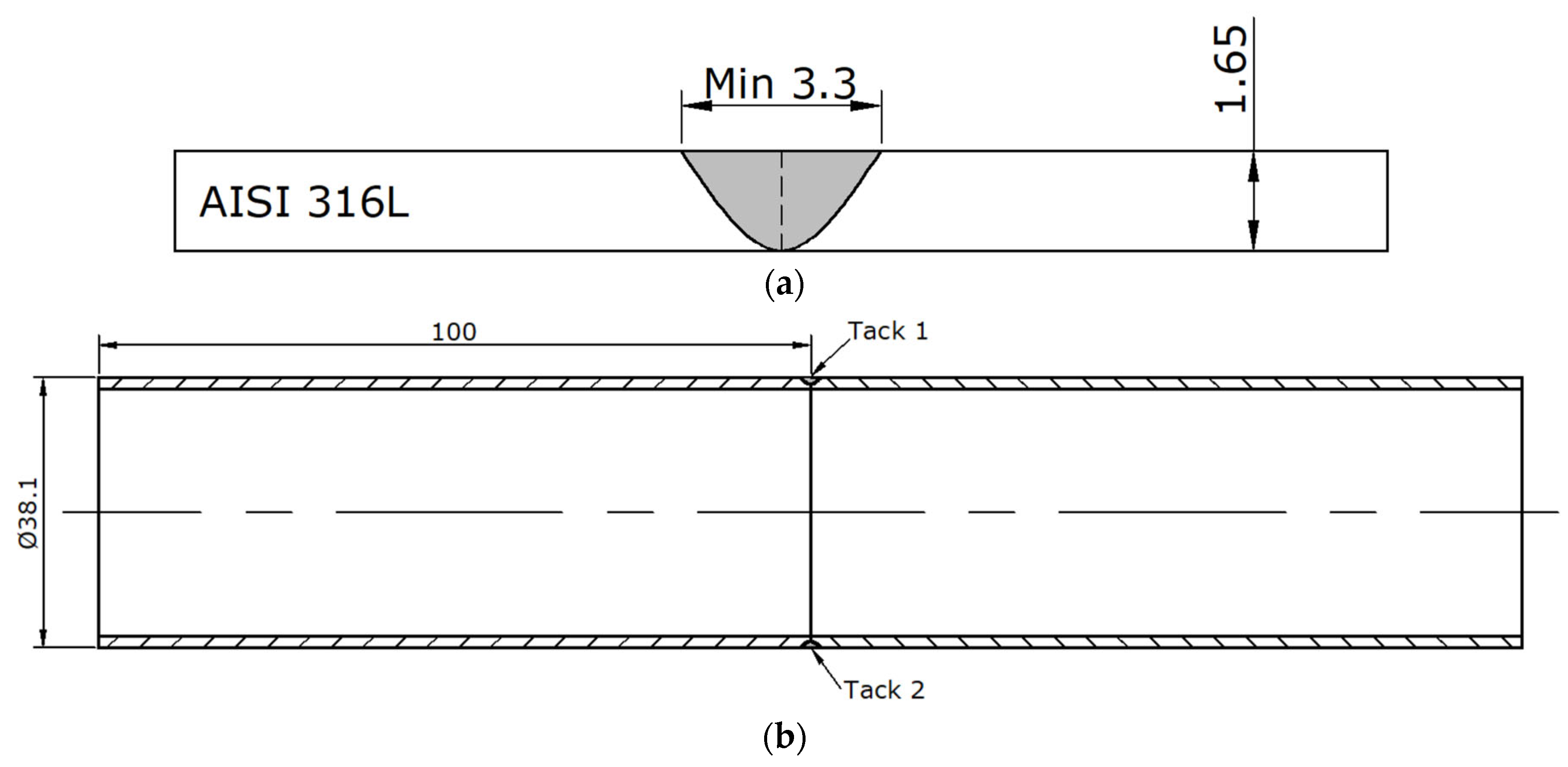

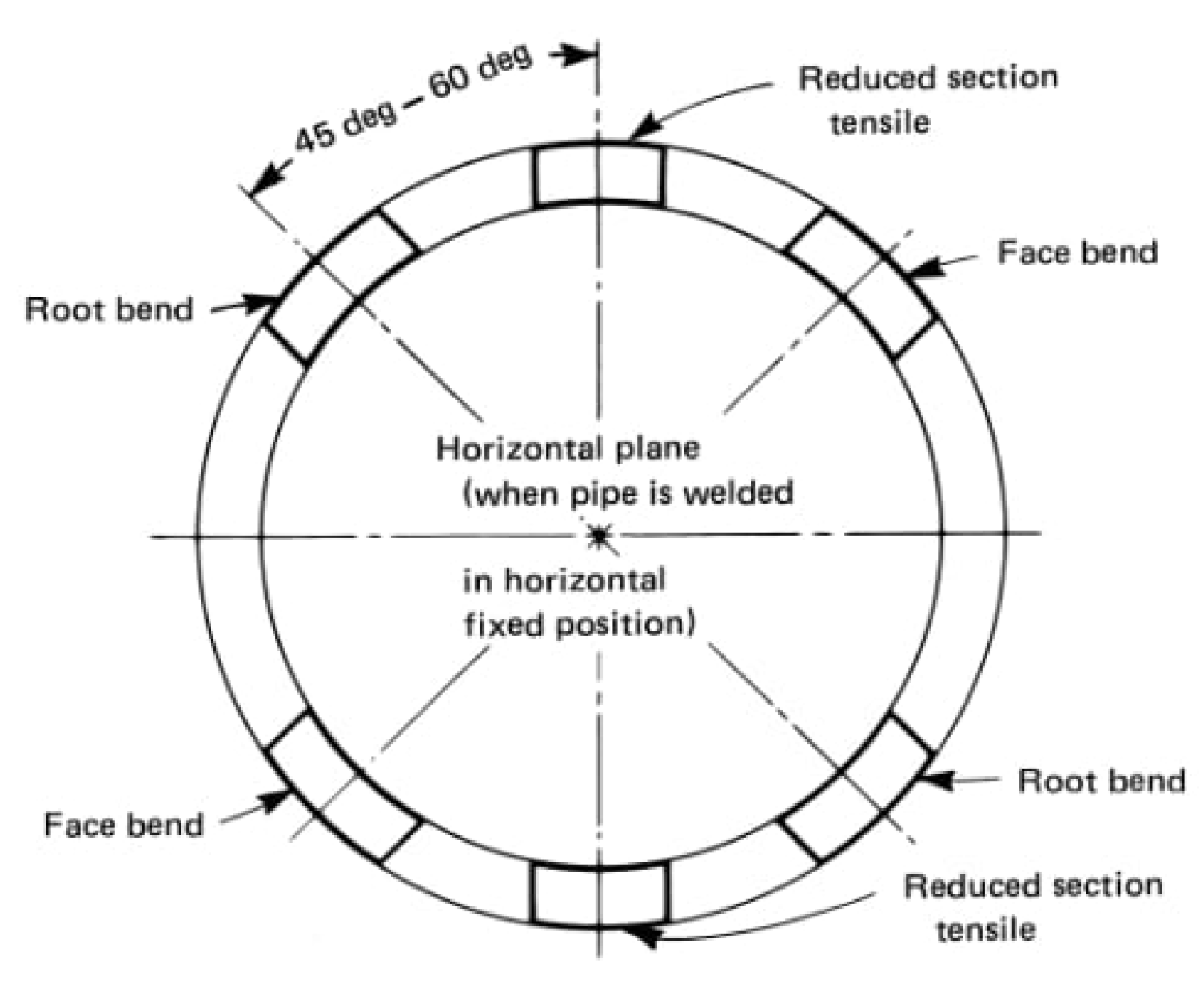

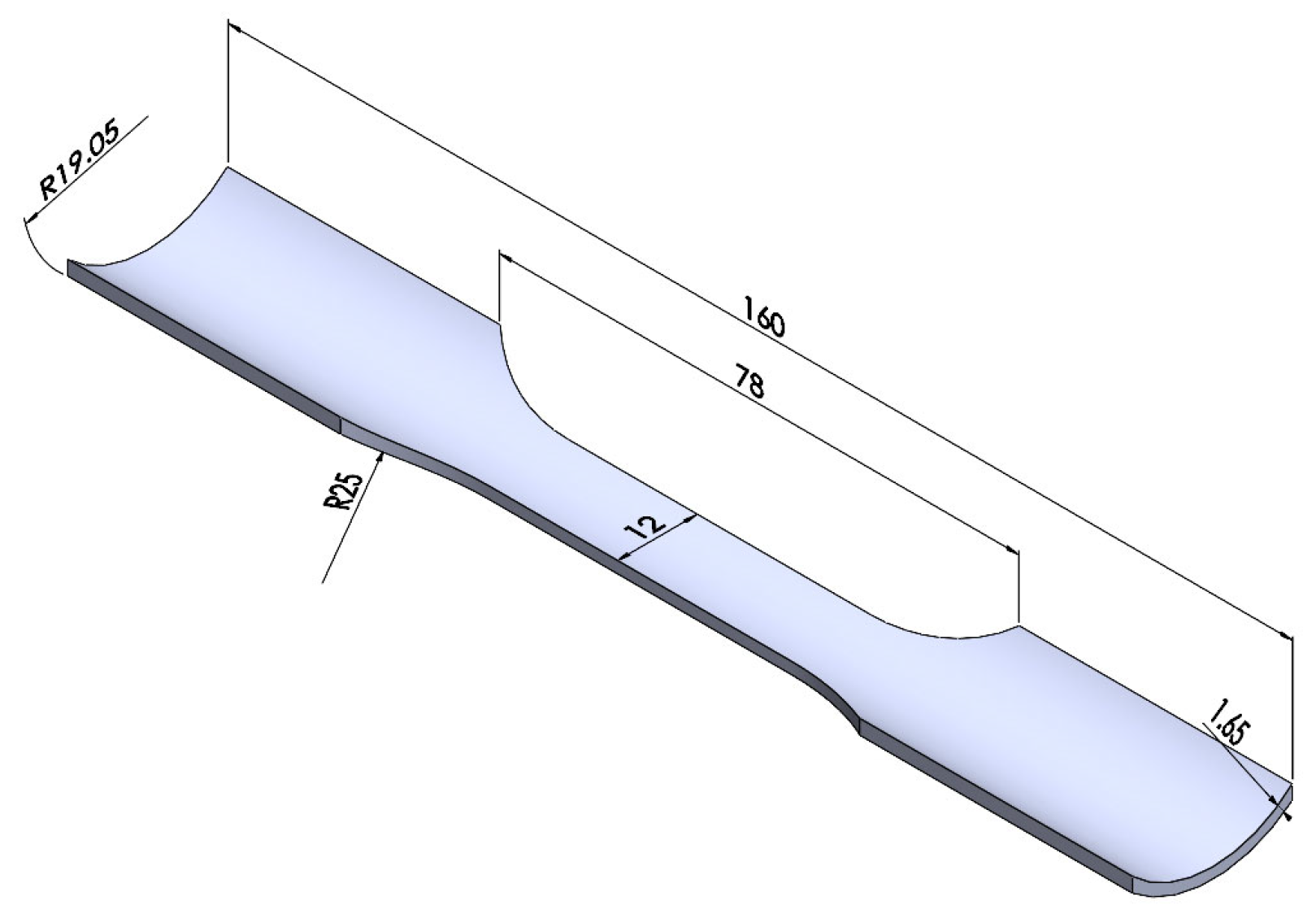

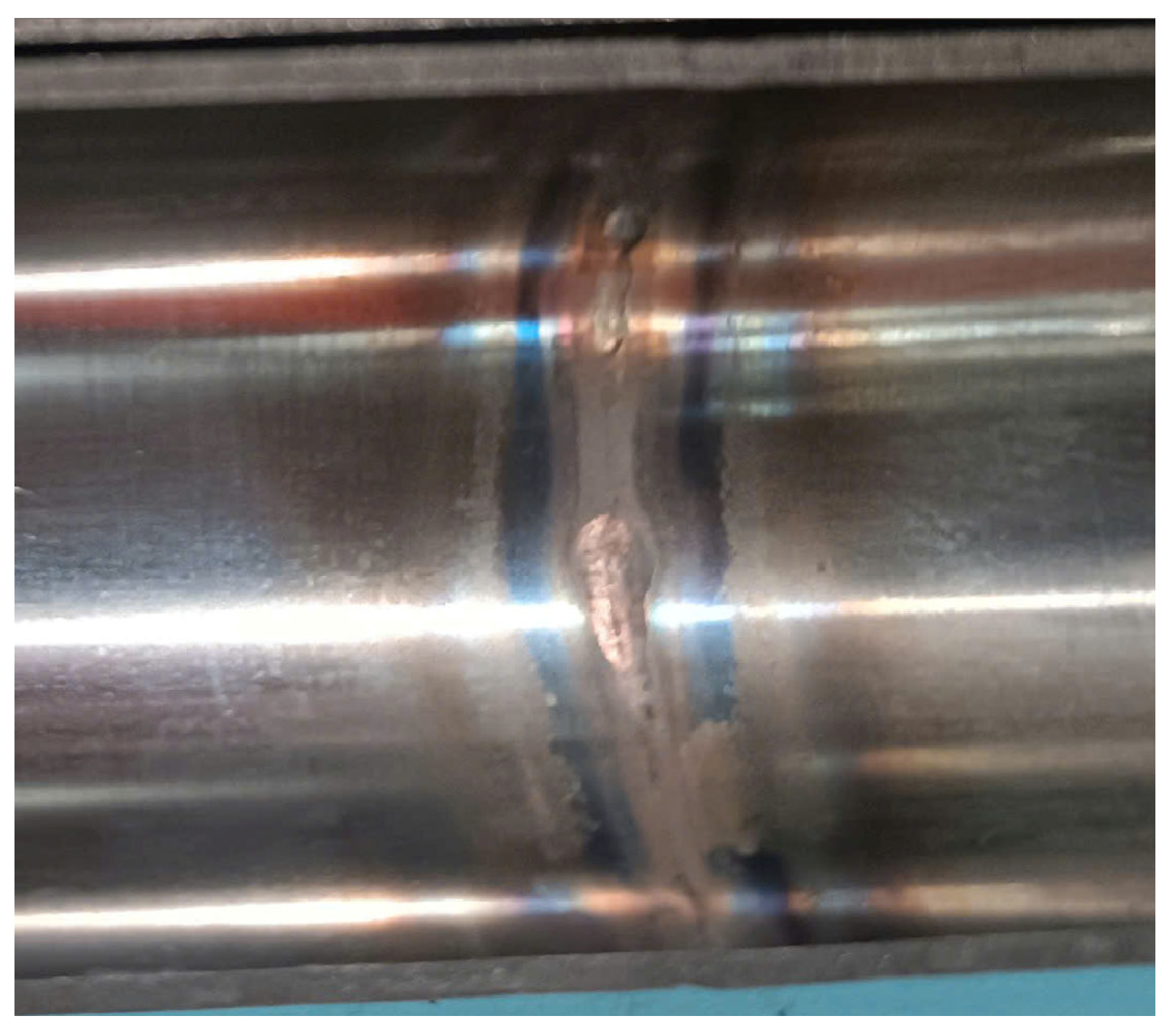

2. Materials and Methods

2.1. Materials

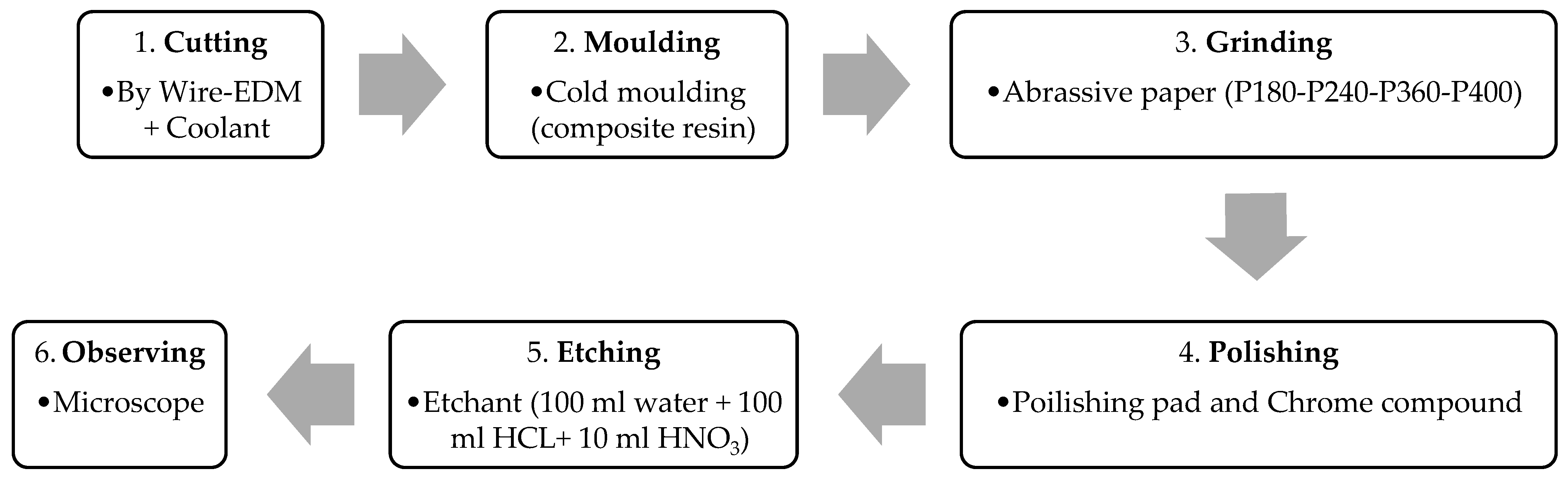

2.2. Methods

- -

- Q is heat input (kJ/mm),

- -

- I is the arc current (A), U is the arc voltage (V), and Vs is the welding speed (mm/s).

- -

- is the efficiency factor is assumed as 0.6 for the GTAW process.

| Code | Welding Parameters | Q (kJ/mm) | Results | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bead Geometry | UTS (MPa) | Heat Tint Level | ||||||||

| I (A) | AL (mm) | Vs (mm/s) | Gb (LPM) | At (ms) | W (mm) | P (mm) | ||||

| 38-1 | 80 | 1.5 | 5 | 6 | 200 | 0.08 | 3.1 | 1.1 | 379 | 2 |

| 38-2 | 80 | 1.5 | 6 | 8 | 300 | 0.07 | 3.0 | 0.8 | 239 | 1 |

| 38-3 | 80 | 1.5 | 7 | 10 | 400 | 0.06 | 2.9 | 0.9 | 228 | 3 |

| 38-4 | 80 | 2.0 | 5 | 8 | 400 | 0.09 | 2.9 | 1.0 | 279 | 2 |

| 38-5 | 80 | 2.0 | 6 | 10 | 200 | 0.07 | 1.9 | 0.4 | 451 | 1 |

| 38-6 | 80 | 2.0 | 7 | 6 | 300 | 0.06 | 2.8 | 0.6 | 278 | 3 |

| 38-7 | 80 | 2.5 | 5 | 10 | 300 | 0.09 | 2.7 | 0.8 | 257 | 3 |

| 38-8 | 80 | 2.5 | 6 | 6 | 400 | 0.08 | 2.6 | 0.8 | 116 | 3 |

| 38-9 | 80 | 2.5 | 7 | 8 | 200 | 0.07 | 2.3 | 0.6 | 107 | 3 |

| 38-10 | 90 | 1.5 | 5 | 8 | 400 | 0.10 | 2.8 | 1.2 | 394 | 4 |

| 38-11 | 90 | 1.5 | 6 | 10 | 200 | 0.08 | 3.5 | 0.7 | 343 | 2 |

| 38-12 | 90 | 1.5 | 7 | 6 | 300 | 0.07 | 2.3 | 0.7 | 271 | 1 |

| 38-13 | 90 | 2.0 | 5 | 10 | 300 | 0.10 | 3.1 | 1.0 | 243 | 2 |

| 38-14 | 90 | 2.0 | 6 | 6 | 400 | 0.09 | 2.8 | 0.9 | 401 | 2 |

| 38-15 | 90 | 2.0 | 7 | 8 | 200 | 0.07 | 2.0 | 0.6 | 197 | 1 |

| 38-16 | 90 | 2.5 | 5 | 6 | 200 | 0.11 | 3.5 | 1.7 | 542 | 4 |

| 38-17 | 90 | 2.5 | 6 | 8 | 300 | 0.09 | 2.5 | 0.6 | 195 | 2 |

| 38-18 | 90 | 2.5 | 7 | 10 | 400 | 0.08 | 2.4 | 0.6 | 128 | 1 |

| 38-19 | 100 | 1.5 | 5 | 10 | 300 | 0.11 | 3.5 | 1.2 | 390 | 4 |

| 38-20 | 100 | 1.5 | 6 | 6 | 400 | 0.10 | 2.9 | 1.7 | 626 | 2 |

| 38-21 | 100 | 1.5 | 7 | 8 | 200 | 0.08 | 3.6 | 1.5 | 652 | 2 |

| 38-22 | 100 | 2.0 | 5 | 6 | 200 | 0.12 | 3.2 | 1.7 | 626 | 4 |

| 38-23 | 100 | 2.0 | 6 | 8 | 300 | 0.10 | 4.1 | 1.7 | 606 | 4 |

| 38-24 | 100 | 2.0 | 7 | 10 | 400 | 0.09 | 2.5 | 0.8 | 220 | 3 |

| 38-25 | 100 | 2.5 | 5 | 8 | 400 | 0.13 | 3.2 | 1.1 | 349 | 2 |

| 38-26 | 100 | 2.5 | 6 | 10 | 200 | 0.11 | 3.1 | 0.8 | 132 | 1 |

| 38-27 | 100 | 2.5 | 7 | 6 | 300 | 0.09 | 2.9 | 0.8 | 228 | 2 |

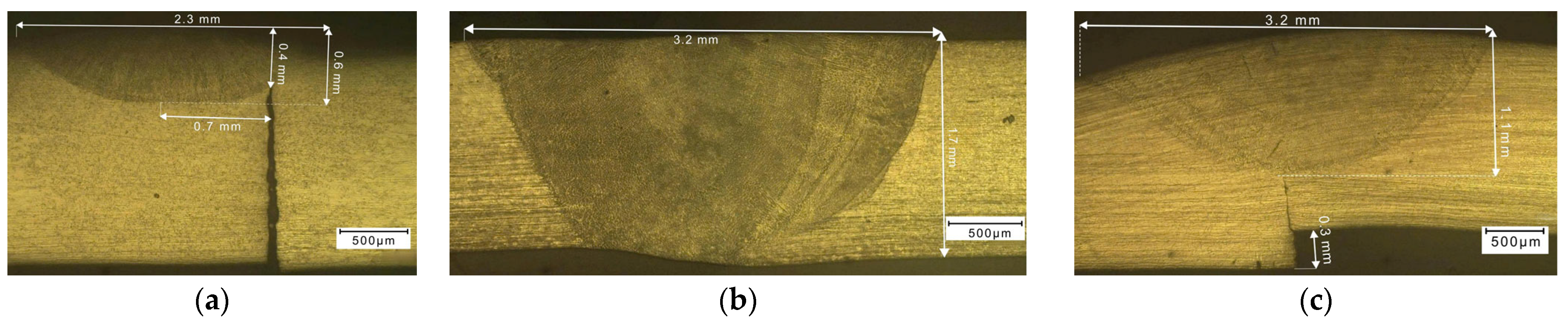

3. Results and Discussion

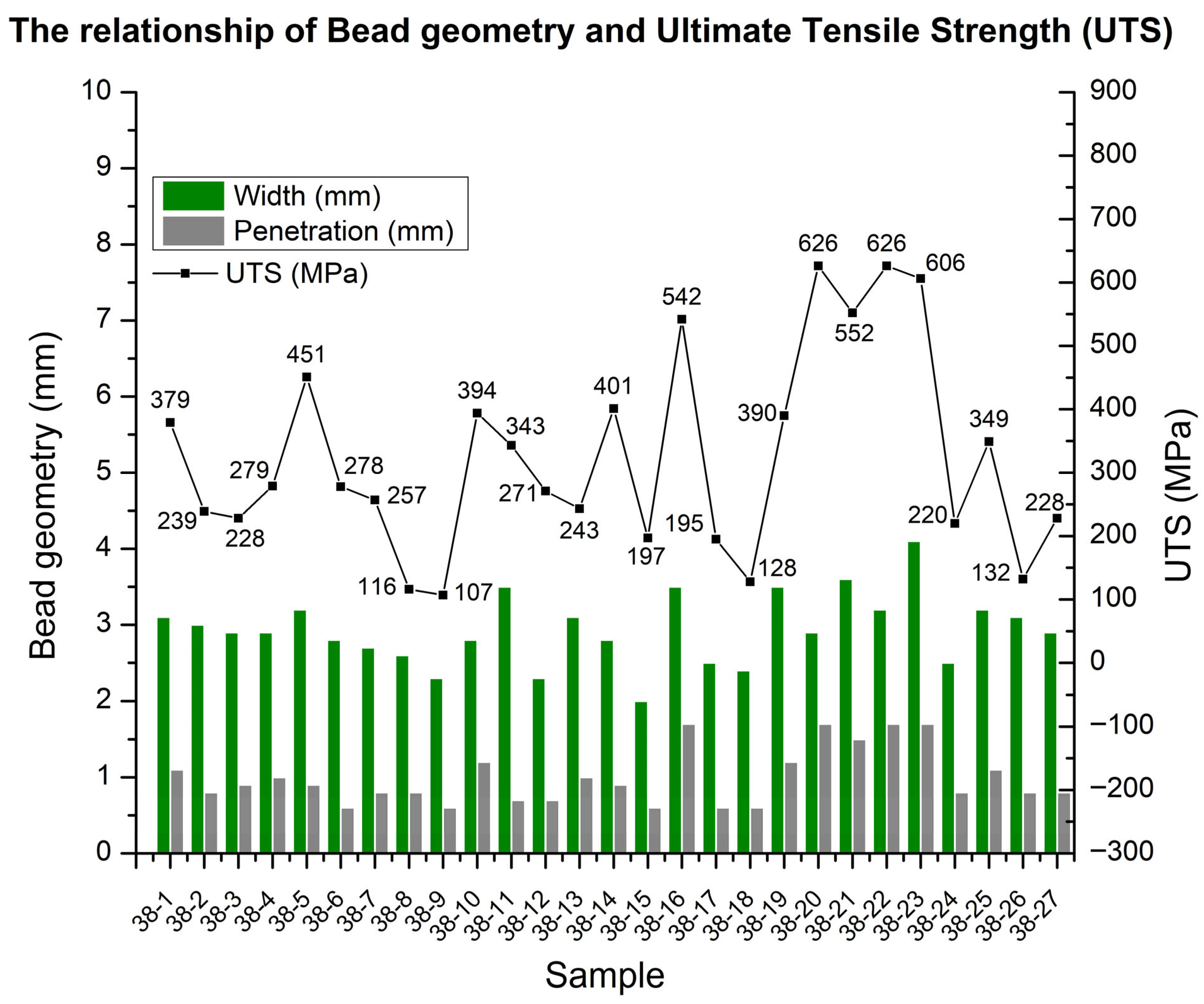

3.1. Bead Geometry and Ultimate Tensile Strength

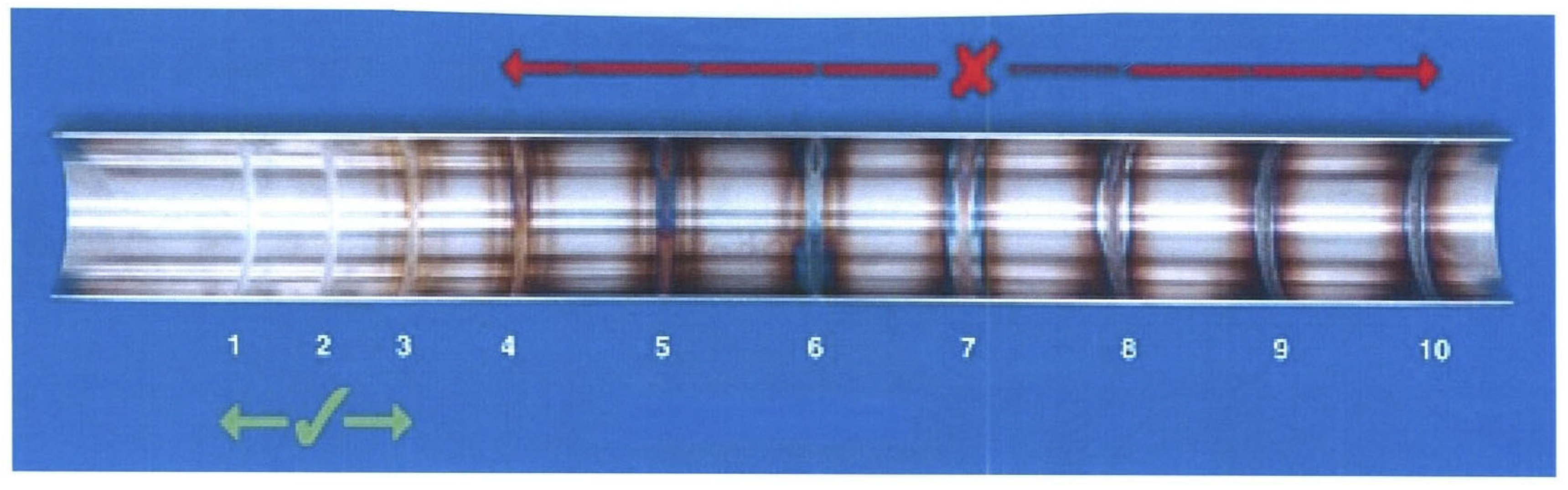

3.2. Heat Tint Level

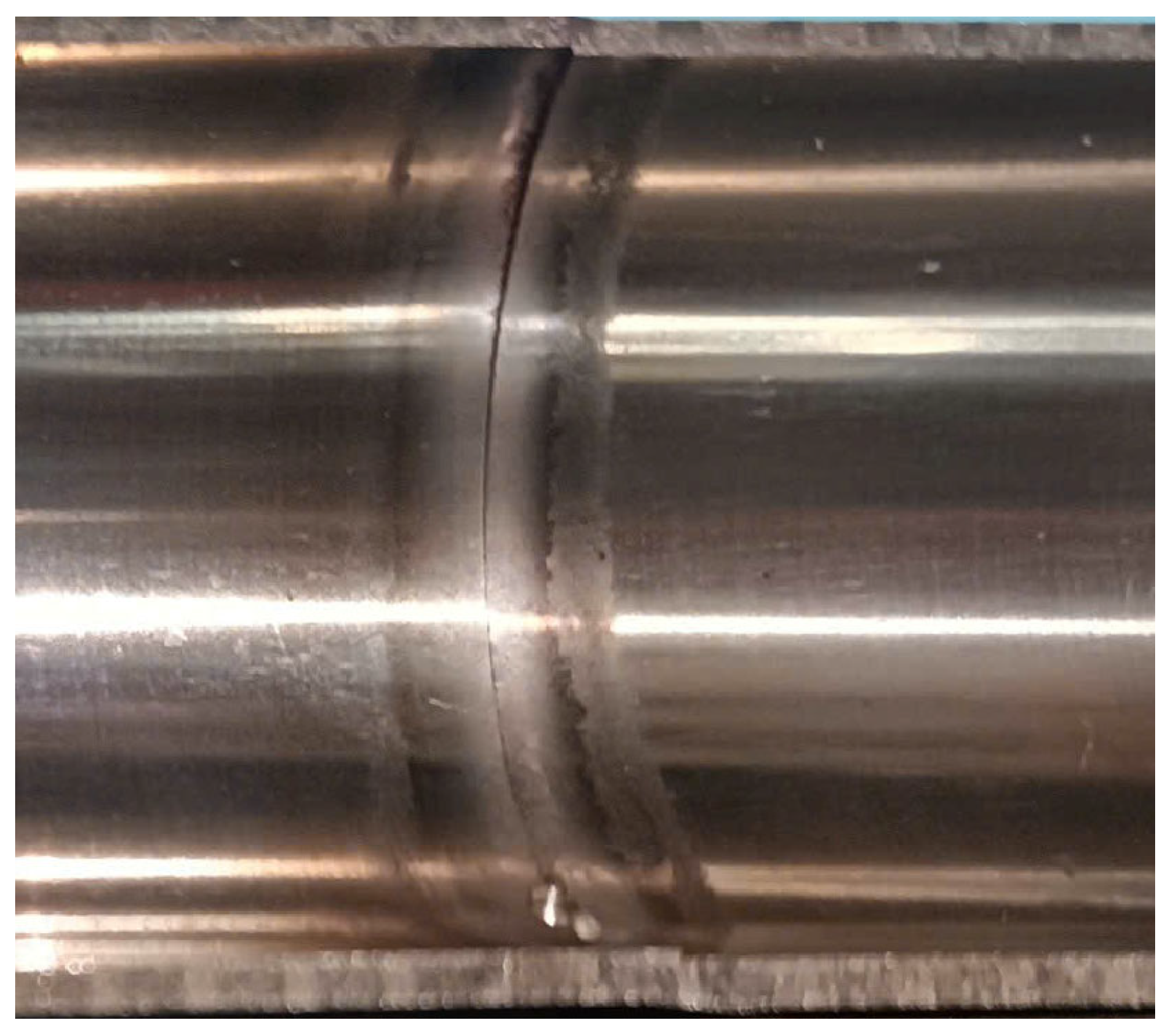

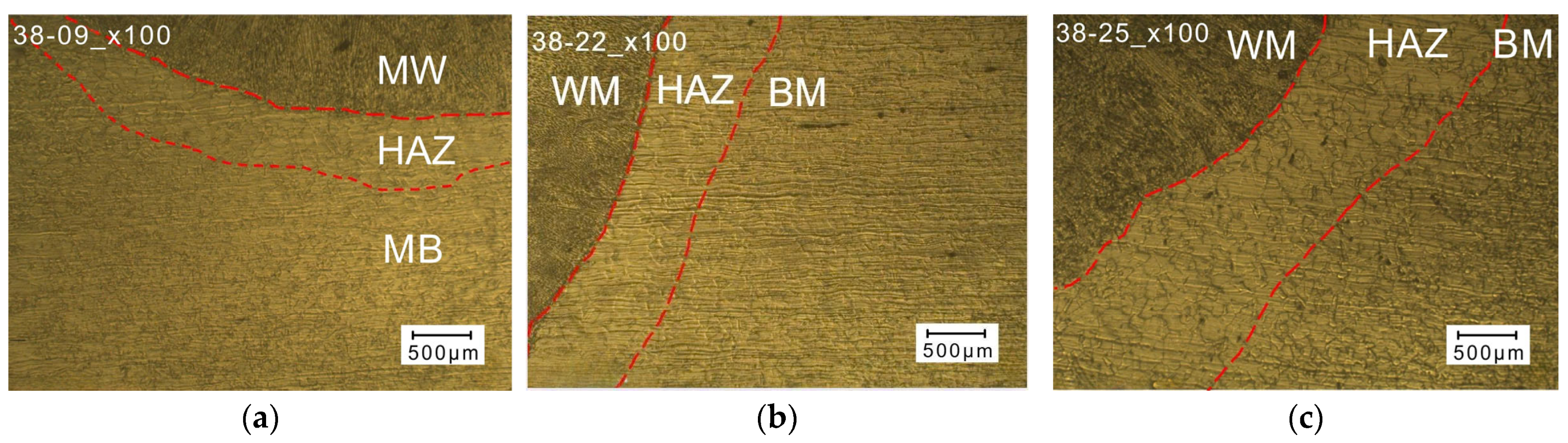

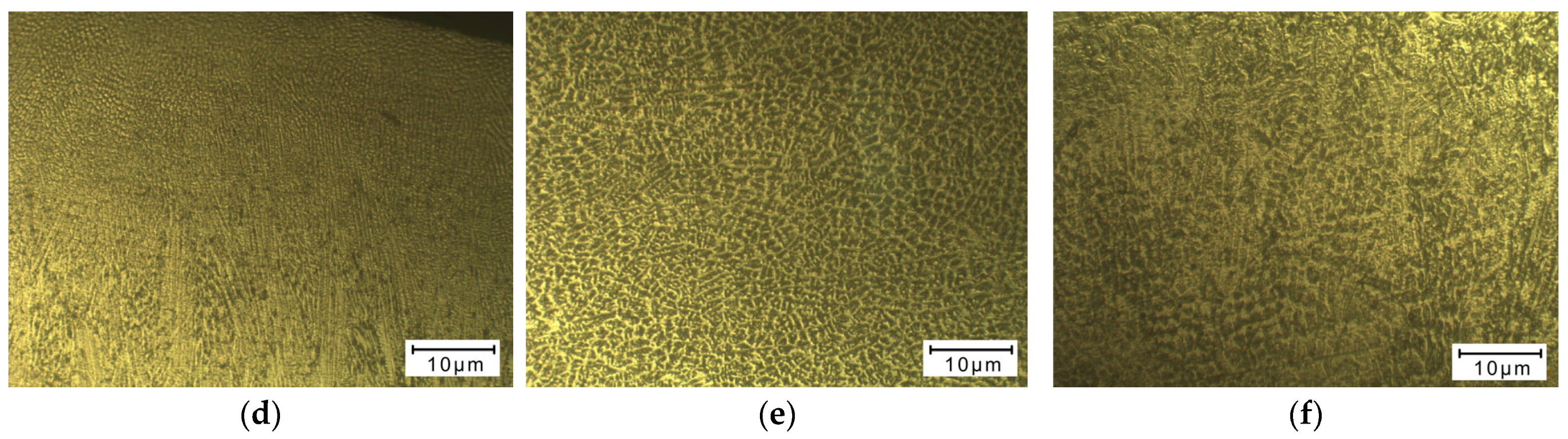

3.3. Microstructural Analysis

3.4. Taguchi Analysis

4. Conclusions

- -

- Heat input is the dominant factor affecting both penetration and heat tint levels. For full penetration and improved tensile properties, the most influential factors were current (I) and welding speed (Vs). Moreover, backing gas (Gb) and arc time (At) played significant roles in reducing weld discoloration.

- -

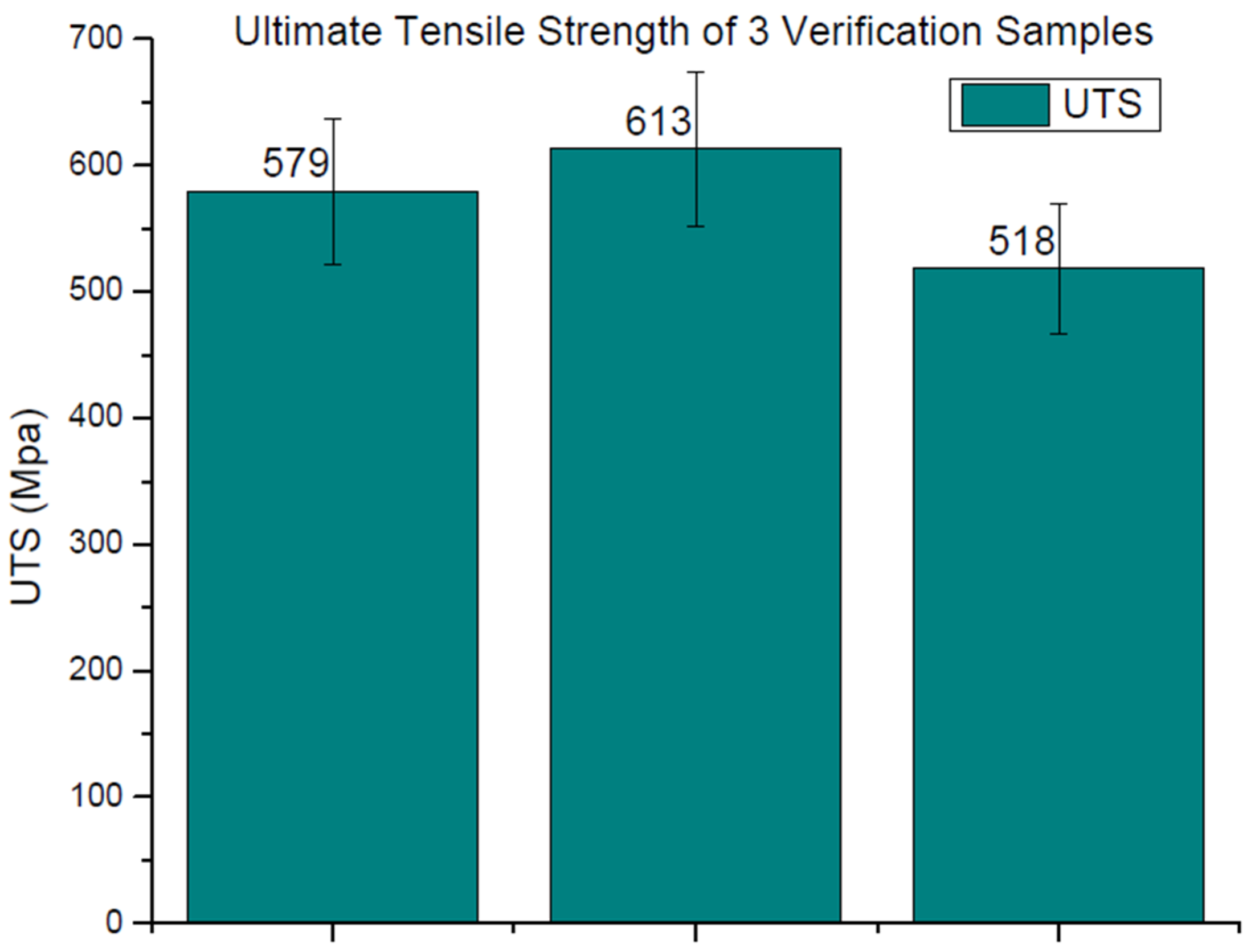

- Two optimization strategies were established: one prioritizing UTS with heat input (Q) ≈ 0.11 kJ/mm, and another minimizing heat tint with heat input (Q) ≈ 0.09 kJ/mm. By combining both approaches, the optimal parameter set was identified as I = 100 A, Al = 1.5 mm, Vs = 5 mm/s, Gb = 10 LPM, and At = 200 ms. Experimental validation confirmed the effectiveness of this parameter set, yielding an average UTS of 570 MPa and a heat tint level of 2, satisfying AWS D18.2 requirements.

- -

- Overall, this study highlights that the balance between adequate penetration and acceptable weld discoloration can be achieved by carefully controlling heat input and optimizing process parameters. The findings provide practical guidelines for the sanitary tubing industry, contributing to improved mechanical performance and corrosion resistance of OTW joints in AISI 316L stainless steel. In addition, the validation results demonstrate that the optimized parameter set not only maximizes the UTS but also maintains robust performance under repeated trials. This consistency supports the applicability of the Taguchi approach in determining parameter combinations that yield high-quality welds with minimal variability. Future work may incorporate additional replications or hybrid modeling (e.g., Taguchi–Response Surface Methodology or Artificial Neural Networks -based refinement) to improve prediction accuracy, better correlate with microstructural characteristics, and further enhance the tensile strength of the welds.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mannion, B. Orbital Welding: A Comprehensive Guide; Emerald Publishing: Leeds, UK, 2004. [Google Scholar]

- Joshi, O.P.; Arunkumar, P. Overview of orbital welding technology. Int. J. Innov. Sci. Eng. Technol. 2015, 2, 958–959. [Google Scholar]

- Polysoude Nantes France SAS. The Orbital Welding Handbook; Polysoude Nantes France SAS: Nantes, France, 2016; Available online: https://www.polysoude.com/wp-content/uploads/2017/01/DOC_Orbital-welding-Handbook_EN.pdf (accessed on 30 October 2025).

- Singh, N.K.; Pradhan, S.K. Experimental and numerical investigations of pipe orbital welding process. Mater. Today Proc. 2020, 27, 2964–2969. [Google Scholar] [CrossRef]

- Baskoro, A.S.; Widyianto, A.; Prasetyo, E.; Kiswanto, G. The Taguchi and Response Surface Method for optimizing orbital pipe welding parameters in pulsed Current Gas tungsten arc welding (PC-GTAW) for SS316L. Trans. Indian Inst. Met. 2024, 77, 1607–1620. [Google Scholar] [CrossRef]

- Minh, P.S.; Nguyen, V.T.; Do, T.T.; Uyen, T.M.T.; Toan, H.D.S.; Linh, H.T.T.; Nguyen, V.T.T. Parameter optimization in orbital TIG welding of SUS 304 stainless steel pipe. Metals 2023, 14, 5. [Google Scholar] [CrossRef]

- Mengistie, A.K.; Bogale, T.M. Development of automatic orbital pipe MIG welding system and process parameters’ optimization of AISI 1020 mild steel pipe using hybrid artificial neural network and genetic algorithm. Int. J. Adv. Manuf. Technol. 2023, 128, 2013–2028. [Google Scholar] [CrossRef]

- Huitt, W.M. Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE Standard; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Unnikrishnan, R.; Idury, K.S.; Ismail, T.; Bhadauria, A.; Shekhawat, S.; Khatirkar, R.K.; Sapate, S.G. Effect of heat input on the microstructure, residual stresses and corrosion resistance of 304L austenitic stainless steel weldments. Mater. Charact. 2014, 93, 10–23. [Google Scholar] [CrossRef]

- Patro, R.; Pradhan, S.K. Finite element simulation and optimization of orbital welding process parameters. Mater. Today Proc. 2018, 5, 12886–12900. [Google Scholar] [CrossRef]

- Rajakumar, J. Numerical investigation of heat transfer behaviour during TIG welding of stainless steel pipes for various welding heat input conditions. Am. J. Mech. Ind. Eng. 2017, 2, 117. [Google Scholar] [CrossRef]

- Ghumman, K.Z.; Ali, S.; Khan, N.B.; Khan, M.I.; Ali, H.T.; Ashurov, M. Optimization of TIG welding parameters for enhanced mechanical properties in AISI 316L stainless steel welds. Int. J. Adv. Manuf. Technol. 2024, 136, 353–365. [Google Scholar] [CrossRef]

- Rodriguez-Vargas, B.R.; Stornelli, G.; Hernandez-Flores, J.E.; Imbimbo, E.; Di Schino, A. Influence of heat input on austenite/ferrite ratio in the weld zone of robotic GTAW duplex stainless steel 2205 weld bead. Acta Metall. Slovaca 2025, 31, 124–128. [Google Scholar] [CrossRef]

- Hussein, N.I.S.; Ayof, M.N.; Nordin, S. Tensile Strength of Orbital Welded Mild Steel Tubes with Dissimilar Thickness. Int. J. Mater. Mech. Manuf. 2015, 4, 56–59. [Google Scholar] [CrossRef]

- Ai, Y.; Dong, G.; Yuan, P.; Liu, X.; Yan, Y. The influence of keyhole dynamic behaviors on the asymmetry characteristics of weld during dissimilar materials laser keyhole welding by experimental and numerical simulation methods. Int. J. Therm. Sci. 2023, 190, 108289. [Google Scholar] [CrossRef]

- Engineering Department, Arc Machines, Inc. Maximizing the Weldability of Stainless Steel with Orbital Welding. Arc Machines. 30 September 2021. Available online: https://resources.arcmachines.com/maximizing-the-weldability-of-stainless-steel-with-orbital-welding (accessed on 30 October 2025).

- Kolařík, L.; Kolaříková, M.; Husák, O. Orbital welding of heterogeneous joints. Mater. Sci. Forum 2018, 919, 10–17. [Google Scholar] [CrossRef]

- Łabanowski, J.; Głowacka, M. Heat tint colours on stainless steel and welded joints. Weld. Int. 2011, 25, 509–512. [Google Scholar] [CrossRef]

- Tuthill, A.H.; Avery, R.E.; Nickel Development Institute. Heat Tints on Stainless Steels Can Cause Corrosion Problems. 1999. Available online: https://nickelinstitute.org/media/1696/heattintsonstainlesssteelscancausecorrosionproblems_14050_.pdf (accessed on 30 October 2025).

- Kimbrel, K. Determining Acceptable Levels of Weld Discoloration on Mechanically Polished and Electropolished Stainless Steel Surfaces. 2011. Available online: https://ultracleanep.com/wp-content/uploads/2014/06/Weld-color-Pharmaceutical-Engineeringl.pdf?utm_source=chatgpt.com (accessed on 30 October 2025).

- Tseng, K.H.; Hsu, C.Y. Performance of activated TIG process in austenitic stainless steel welds. J. Mater. Process. Technol. 2010, 211, 503–512. [Google Scholar] [CrossRef]

- Singh, P.K.; Kumar, S.D.; Patel, D.; Prasad, S.B. Optimization of vibratory welding process parameters using response surface methodology. J. Mech. Sci. Technol. 2017, 31, 2487–2495. [Google Scholar] [CrossRef]

- Rocha, V.R.; Lobato, F.S.; de Assis, P.A.Q.; Ribeiro, C.R.; da Cunha, S.S.; Vilarinho, L.O.; Andrade, J.R.; da Silva, L.R.R.; dos Santos Paes, L.E. Parametric optimization of artificial neural networks and machine learning techniques applied to small welding datasets. Processes 2025, 13, 2711. [Google Scholar] [CrossRef]

- Lakache, H.E.; May, A.; Badji, R. Optimization of the RFW Process Parameters by Using the Taguchi Method for the Ti6Al4V grade-5 alloy. Acta Metall. Slovaca 2023, 29, 155–160. [Google Scholar] [CrossRef]

- Nobrega, G.; Souza, M.S.; Rodríguez-Martín, M.; Rodríguez-Gonzálvez, P.; Ribeiro, J. Parametric optimization of the GMAW welding process in thin thickness of austenitic stainless steel by Taguchi Method. Appl. Sci. 2021, 11, 8742. [Google Scholar] [CrossRef]

- Prasetyo, E.; Baskoro, A.S.; Widyianto, A.; Kiswanto, G. Identifying the influence of orbital pipe welding parameters on mechanical properties using SS316L pipe. East. Eur. J. Enterp. Technol. 2023, 5, 72–84. [Google Scholar] [CrossRef]

- Akbari, D.; Sattari-Far, I. Effect of the welding heat input on residual stresses in butt-welds of dissimilar pipe joints. Int. J. Press. Vessel. Pip. 2009, 86, 769–776. [Google Scholar] [CrossRef]

- Kik, T.; Garašić, I.; Perić, M.; Landek, D.; Jurica, M.; Tonković, Z. Modifications of the heat source model in numerical analyses of the metal-cored arc welding process. Energy 2024, 302, 131811. [Google Scholar] [CrossRef]

- ASME Boiler and Pressure Vessel Code, Section IX; Welding, Brazing, and Fusing Qualifications; The American Society of Mechanical Engineers: New York, NY, USA, 2021.

- ISO 4136; Destructive Tests on Welds in Metallic Materials—Transverse Tensile Test. International Organization for Standardization: Geneva, Switzerland, 2021.

- Widyianto, A.; Baskoro, A.S.; Kiswanto, G.; Ganeswara, M.F.G. Effect of welding sequence and welding current on distortion, mechanical properties and metallurgical observations of orbital pipe welding on SS 316L. East. Eur. J. Enterp. Technol. 2021, 2, 22–31. [Google Scholar] [CrossRef]

- Pal, K.; Pal, S.K. Effect of pulse parameters on weld quality in pulsed gas metal arc welding: A review. J. Mater. Eng. Perform. 2010, 20, 918–931. [Google Scholar] [CrossRef]

- Zatkalíková, V.; Uhríčik, M.; Markovičová, L.; Pastierovičová, L.; Kuchariková, L. The effect of sensitization on the susceptibility of AISI 316L biomaterial to pitting corrosion. Materials 2023, 16, 5714. [Google Scholar] [CrossRef]

- Casalino, G.; Angelastro, A.; Perulli, P.; Casavola, C.; Moramarco, V. Study on the fiber laser/TIG weldability of AISI 304 and AISI 410 dissimilar weld. J. Manuf. Process. 2018, 35, 216–225. [Google Scholar] [CrossRef]

- Adigun, O.; Adebayo, A.; Abiola, O. The effect of welding parameter on the tensile and impact properties of weldments. Am. J. Mech. Mater. Eng. 2025, 9, 37–42. [Google Scholar] [CrossRef]

- Baskoro, A.S.; Kiswanto, G.; Widyianto, A. Optimization of PC-GTAW orbital welding parameters of AISI 304L stainless steel pipe using ANOVA and Taguchi method. IOP Conf. Ser. Mater. Sci. Eng. 2020, 727, 012007. [Google Scholar] [CrossRef]

| Sanitary Tube | Composition, Max, % | |||||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Mo | Ni | Cr | |

| AISI 316L | 0.026 | 1.48 | 0.41 | 0.032 | 0.0078 | 2.216 | 10.27 | 16.11 |

| Level | I (A) | Al (mm) | Vs (mm/s) | Gb (LPM) | At (ms) | |

|---|---|---|---|---|---|---|

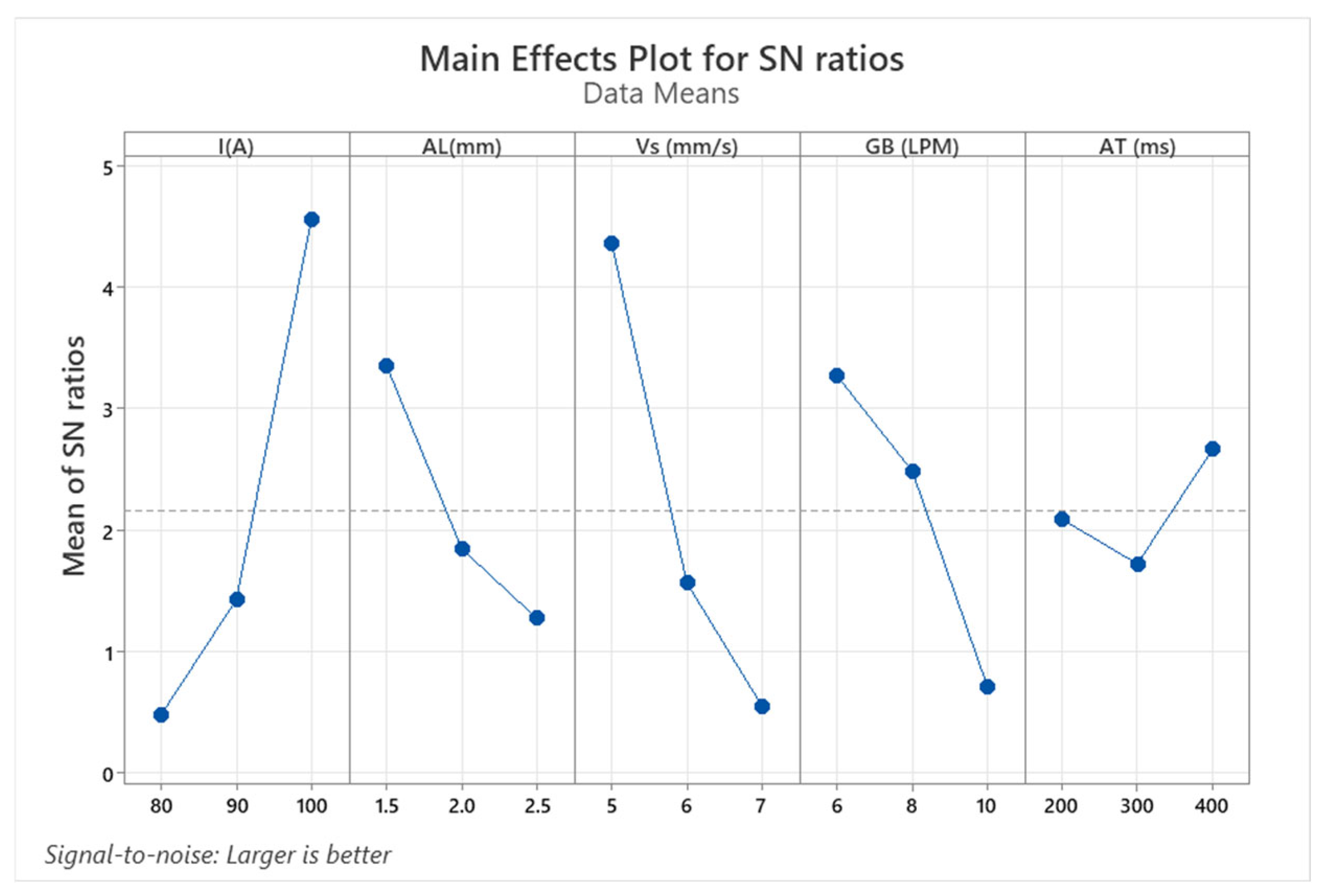

| S/N ratio | 1 | 0.4842 | 3.3521 | 4.3550 | 3.2689 | 2.0879 |

| 2 | 1.4292 | 1.8471 | 1.5652 | 2.4873 | 1.7220 | |

| 3 | 4.5598 | 1.2739 | 0.5529 | 0.7169 | 2.6632 | |

| Delta | 4.0756 | 2.0782 | 3.8021 | 2.5520 | 0.9412 | |

| Rank | 1 | 4 | 2 | 3 | 5 |

| Level | I (A) | Al (mm) | Vs (mm/s) | Gb (LPM) | At (ms) | |

|---|---|---|---|---|---|---|

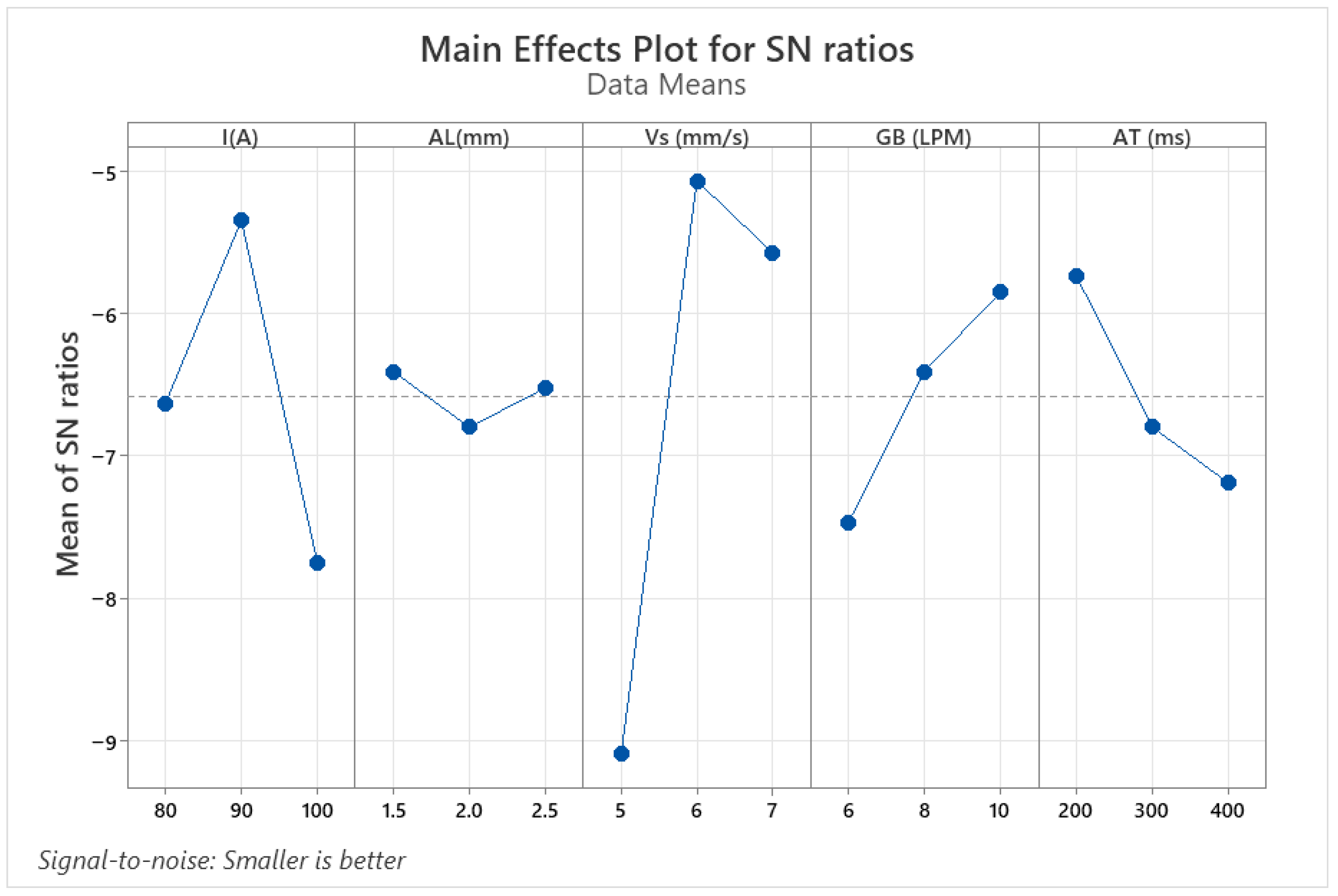

| S/N ratio | 1 | −6.639 | −6.412 | −9.088 | −7.472 | −5.743 |

| 2 | −5.352 | −6.803 | −5.074 | −6.412 | −6.803 | |

| 3 | −7.750 | −6.526 | −5.579 | −5.857 | −7.195 | |

| Delta | 2.398 | 0.391 | 4.014 | 1.616 | 1.452 | |

| Rank | 2 | 5 | 1 | 3 | 4 |

| Variable | Setting | |||

| I (A) | 100 | |||

| Al (mm) | 1.5 | |||

| Vs (mm/s) | 5 | |||

| Response | Fit | SE Fit | 95% CI | 95% PI |

| UTS (MPa) | 548.0 | 55.7 | (432.7, 663.3) | (267.8, 828.3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, N.-T.; Nguyen, V.-T.; Do, T.T.; Nguyen, V.-S. Effects of Heat Input and Backing Gas on Bead Geometry and Weld Heat Tint in Sanitary Tube Welding. Thermo 2025, 5, 49. https://doi.org/10.3390/thermo5040049

Tran N-T, Nguyen V-T, Do TT, Nguyen V-S. Effects of Heat Input and Backing Gas on Bead Geometry and Weld Heat Tint in Sanitary Tube Welding. Thermo. 2025; 5(4):49. https://doi.org/10.3390/thermo5040049

Chicago/Turabian StyleTran, Ngoc-Thien, Van-Thuc Nguyen, Thanh Trung Do, and Van-Sung Nguyen. 2025. "Effects of Heat Input and Backing Gas on Bead Geometry and Weld Heat Tint in Sanitary Tube Welding" Thermo 5, no. 4: 49. https://doi.org/10.3390/thermo5040049

APA StyleTran, N.-T., Nguyen, V.-T., Do, T. T., & Nguyen, V.-S. (2025). Effects of Heat Input and Backing Gas on Bead Geometry and Weld Heat Tint in Sanitary Tube Welding. Thermo, 5(4), 49. https://doi.org/10.3390/thermo5040049