Integrating Life Cycle Assessment and Response Surface Methodology for Optimizing Carbon Reduction in Coal-to-Synthetic Natural Gas Process

Abstract

1. Introduction

2. Research Methodology

2.1. Objectives and Scope

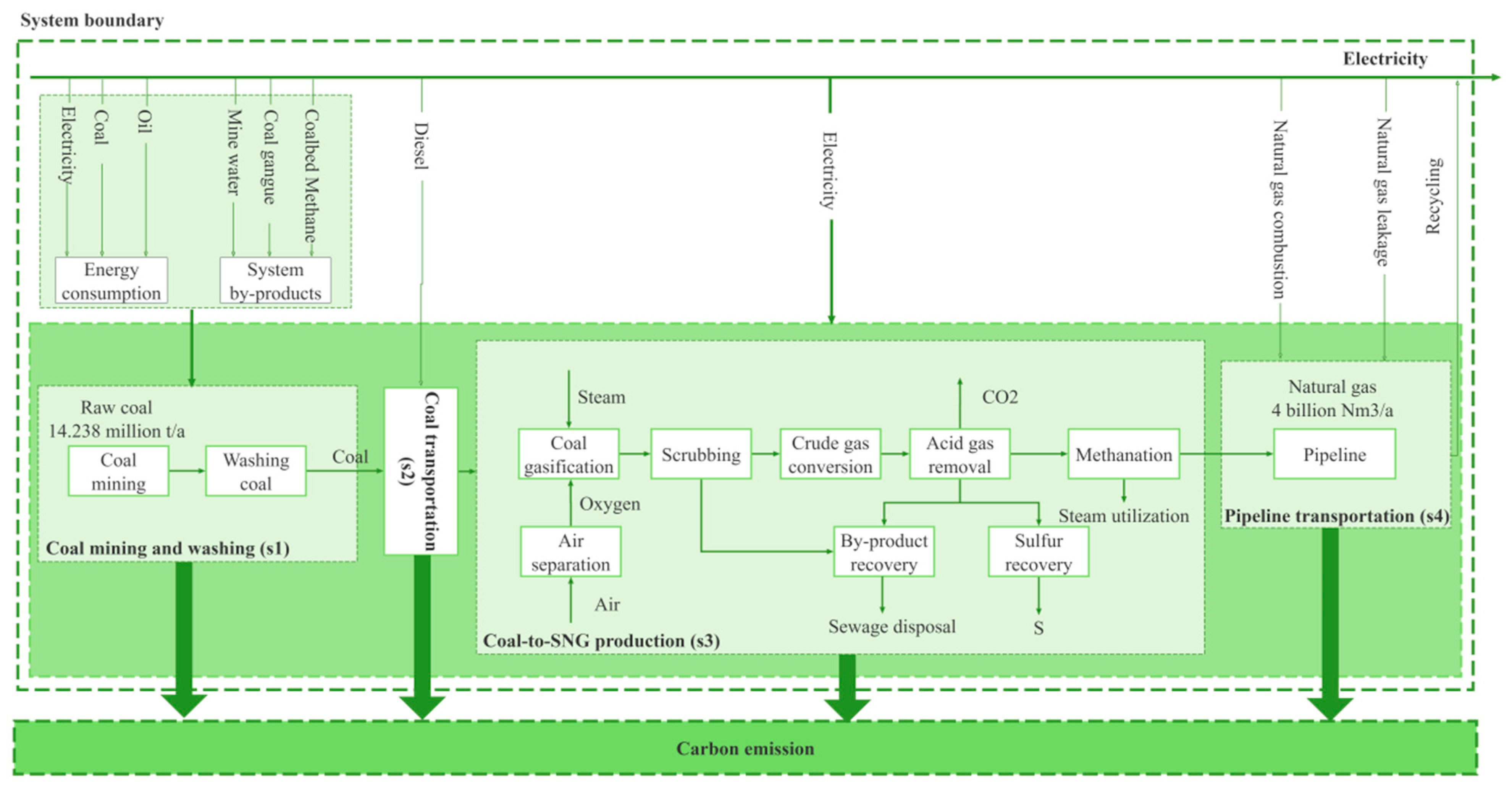

2.2. System Boundary

2.3. Assessment of Carbon Emissions from Coal-to-SNG

2.4. Normalization

2.5. Data Collection

3. Results

3.1. Life Cycle Carbon Emissions Analysis of Coal-to-SNG

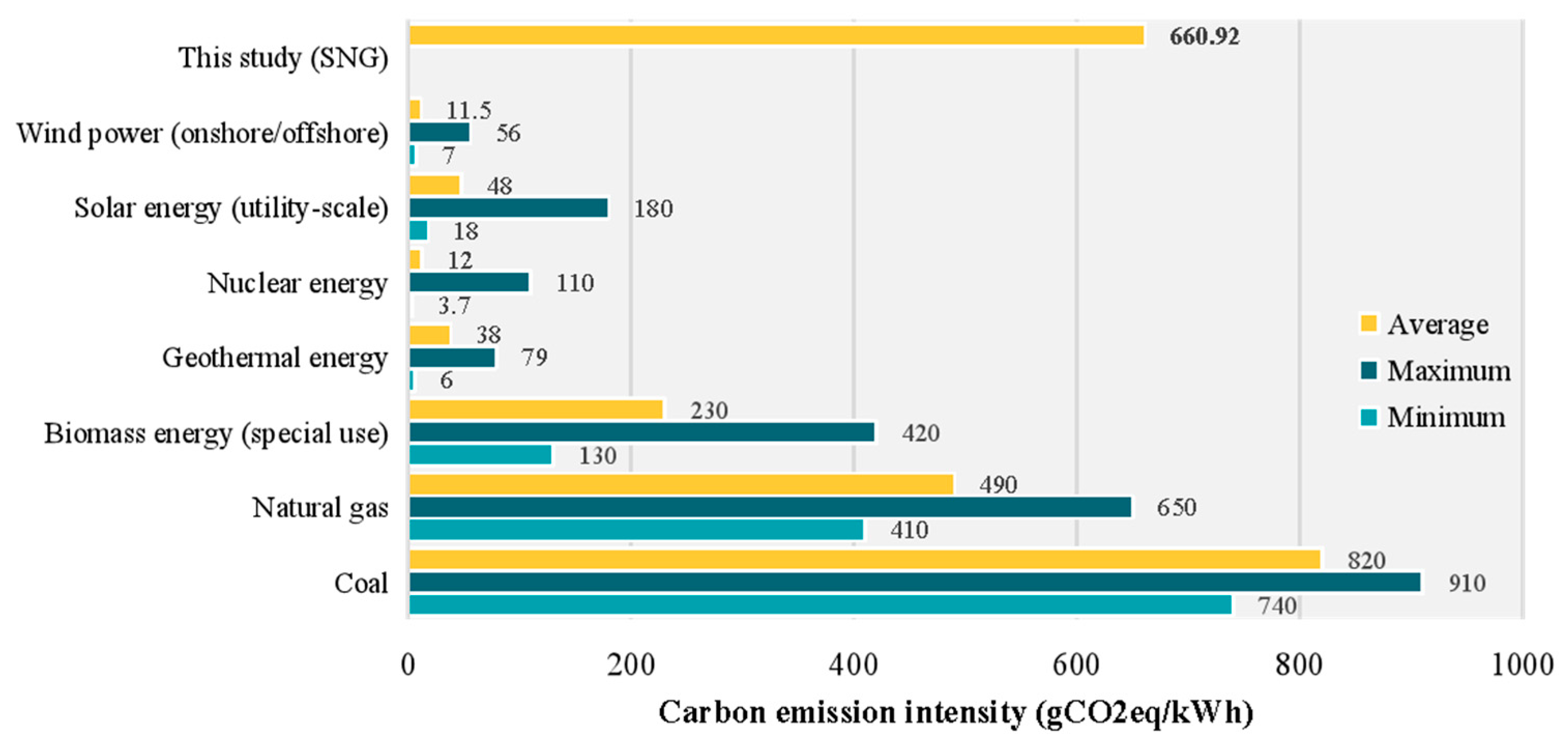

3.2. Comparative Carbon Emission Intensity

4. Discussion

4.1. Response Surface Optimization Design

4.1.1. Identification of Key Influencing Factors and Levels

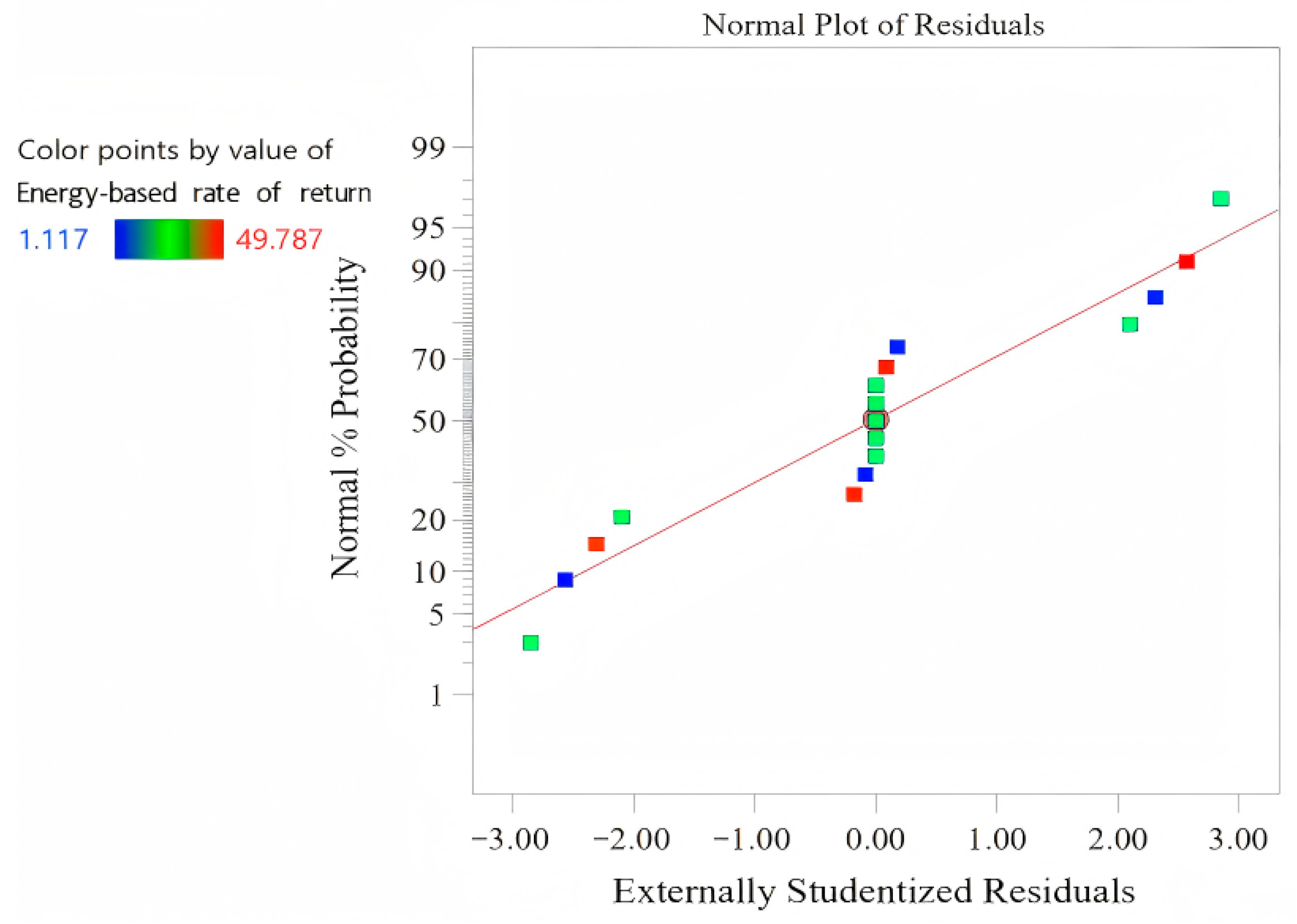

4.1.2. Establishment of Regression Model and Analysis of Variance

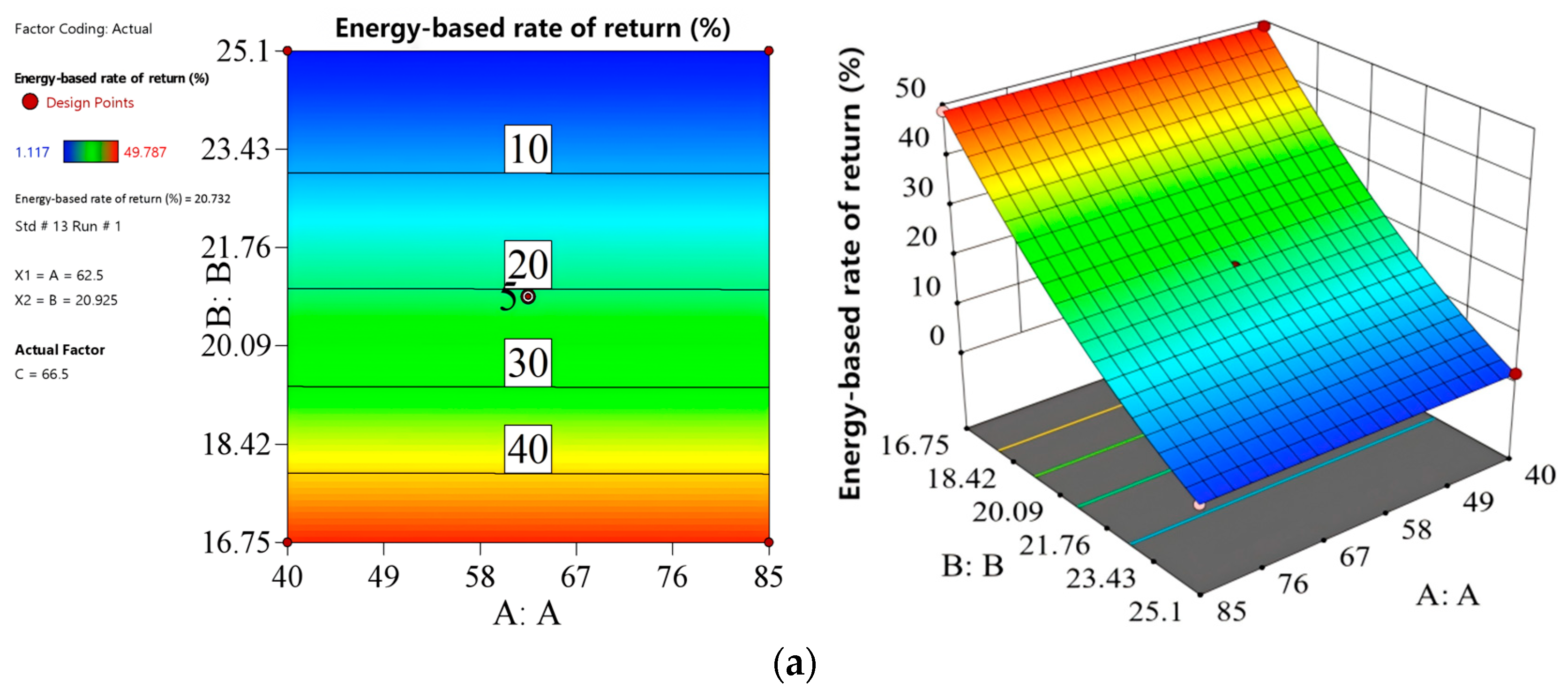

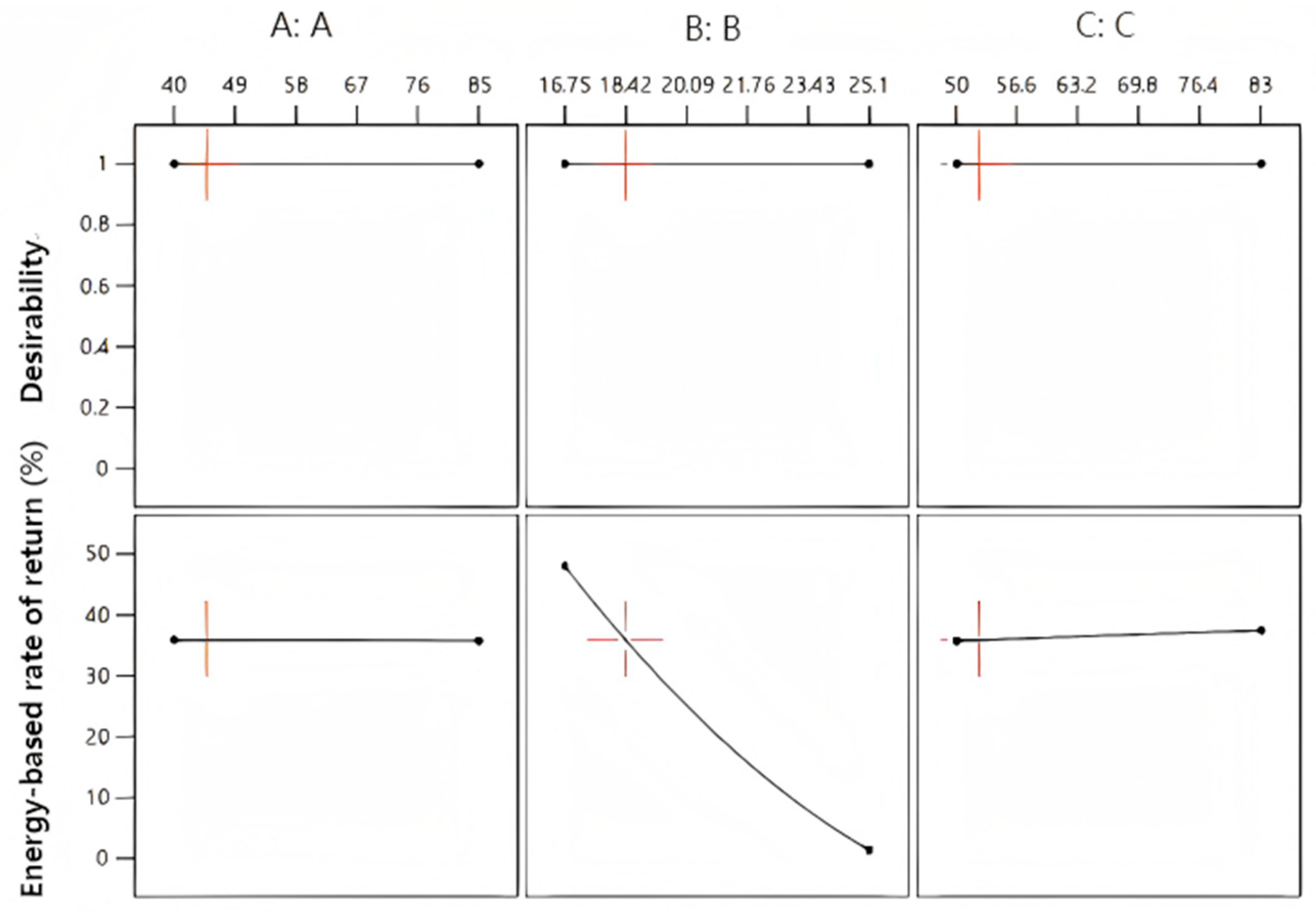

4.2. Box–Behnken Response Surface Analysis of Interactions

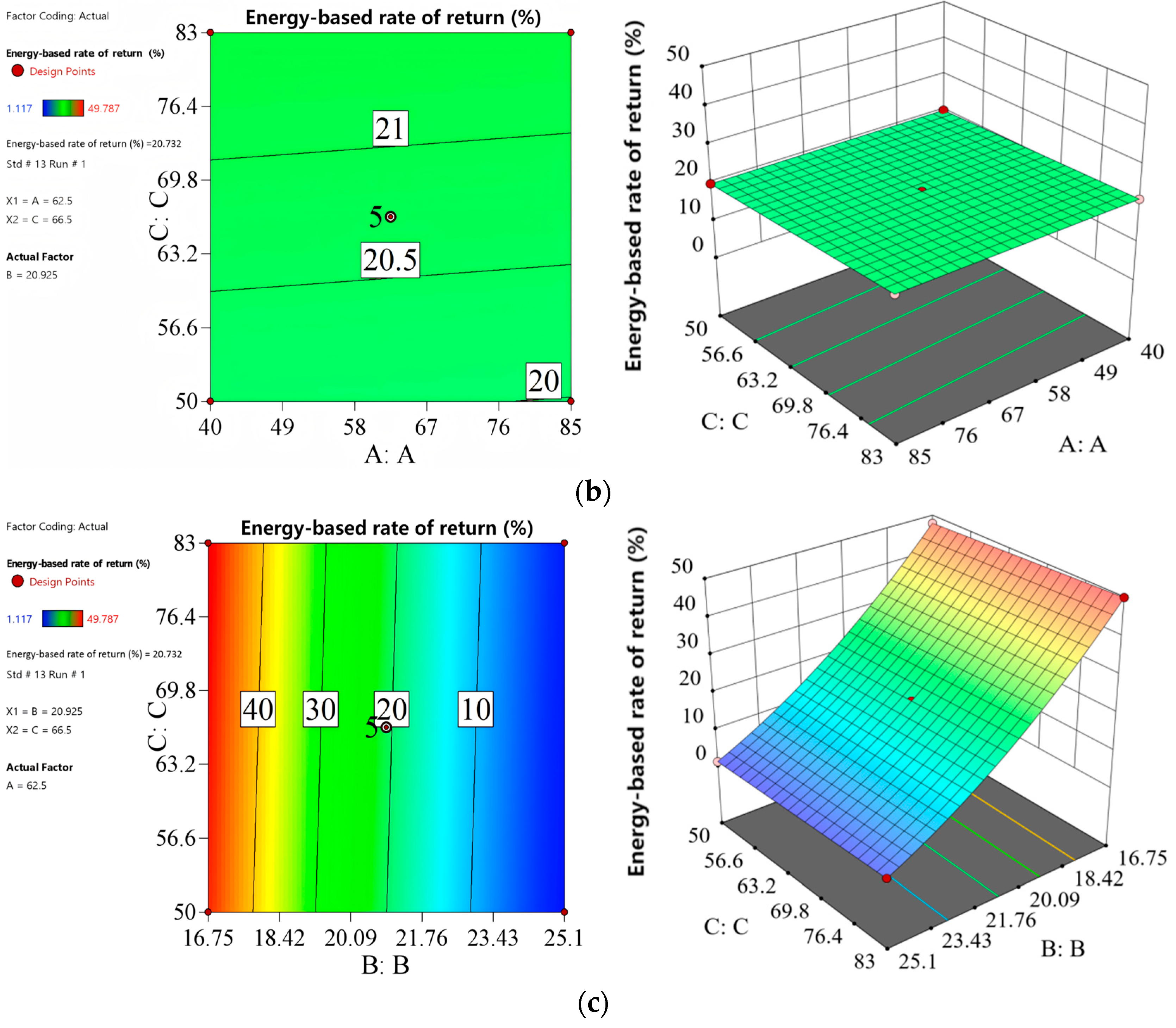

- Figure 4a: The response surface between A and B is relatively flat, indicating no significant interaction. However, the contour plot shows a clear trend: the ERR increases sharply as B decreases, while A remains nearly constant. The almost vertical contour lines confirm that B exerts a much stronger effect than A. This implies that reducing the effective calorific value of coal substantially improves the ERR, whereas variations in the raw coal selection rate have minimal influence under the tested conditions.

- Figure 4b: The interaction between A and C is also weak. The response surface is smooth, and the contour plot shows only slight gradients, suggesting limited interaction. Increasing C modestly enhances the ERR, but this improvement occurs independently of A. These results indicate that while conversion efficiency contributes to better performance, the raw coal selection rate remains a less influential factor.

- Figure 4c: In contrast, the interaction between B and C is highly significant. The response surface exhibits pronounced curvature, and the contour plot reveals steep gradients and dense contour lines. The ERR reaches its maximum when B is minimized and C is maximized, underscoring the synergistic effect of fuel quality and process efficiency. This finding highlights that joint optimization of B and C is essential for achieving the greatest economic benefit.

4.3. Optimized Process and Verification Tests

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nakao, A.; Morlando, D.; Knuutila, H.K. Techno-Economic Assessment of the Multi-Absorber Approach at an Industrial Site with Multiple CO2 Sources. Int. J. Greenh. Gas Control 2025, 142, 104326. [Google Scholar] [CrossRef]

- Zhao, W.; Hao, J.L.; Gong, G.; Ma, W.; Zuo, J.; Di Sarno, L. Decarbonizing Prefabricated Building Waste: Scenario Simulation of Policies in China. J. Clean. Prod. 2024, 458, 142529. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, B.; Li, Y.; Zhang, J. Towards Carbon Neutrality: Optimizing Generation and Storage Capacities in Germany and Carbon Pricing in China. Sustain. Prod. Consum. 2024, 46, 703–716. [Google Scholar] [CrossRef]

- Gao, D.; Qiu, X.; Zheng, X.; Zhang, Y. Life Cycle Analysis of Coal-Based Synthetic Natural Gas for Heat Supply and Electricity Generation in China. Chem. Eng. Res. Des. 2018, 131, 709–722. [Google Scholar] [CrossRef]

- Haider, J.; Lee, B.; Choe, C.; Abdul Qyyum, M.; Shiung Lam, S.; Lim, H. SNG Production with Net Zero Outflow of CO2 in an Integrated Energy System: An Energy and Economic Aspects. Energy Convers. Manag. 2022, 270, 116167. [Google Scholar] [CrossRef]

- Kreuzer, M.; Sommer, M.; Deffner, V.; Bertke, S.; Demers, P.A.; Kelly-Reif, K.; Laurier, D.; Rage, E.; Richardson, D.B.; Samet, J.M.; et al. Lifetime Excess Absolute Risk for Lung Cancer Due to Exposure to Radon: Results of the Pooled Uranium Miners Cohort Study PUMA. Radiat. Environ. Biophys. 2024, 63, 7–16. [Google Scholar] [CrossRef]

- Chyou, Y.P.; Chiu, H.M.; Chen, P.C.; Chien, H.Y.; Wang, T. Coal-Derived Synthetic Natural Gas as an Alternative Energy Carrier for Application to Produce Power—Comparison of Integrated vs. Non-Integrated Processes. Energy 2023, 282, 128958. [Google Scholar] [CrossRef]

- Zhang, J.; Chu, B.; Li, Z.; Yan, B. Optimal Design of a Coal-Based Synthetic Natural Gas (SNG) Process with Different Coal Ranks and Gasification Technologies via Techno-Economic Analysis. Chem. Eng. Res. Des. 2022, 183, 150–159. [Google Scholar] [CrossRef]

- Wei, D.; Jia, Z.; Sun, Z.; Gao, Y.; Wang, G.; Zeng, L. Process Simulation and Economic Analysis of Calcium Looping Gasification for Coal to Synthetic Natural Gas. Fuel Process. Technol. 2021, 218, 106835. [Google Scholar] [CrossRef]

- Chauvy, R.; Dubois, L.; Thomas, D.; De Weireld, G. Environmental Impacts of the Production of Synthetic Natural Gas from Industrial Carbon Dioxide. Sustain. Prod. Consum. 2022, 30, 301–315. [Google Scholar] [CrossRef]

- Prasad, V.; Almara, L.M.; Wang, G.-X. Ultra-Long-Distance Transport of Supercritical Natural Gas (SNG) at Very-High Mass Flow Rates via Pipelines through Land, Underground, Water Bodies, and Ocean. Gas Sci. Eng. 2023, 117, 205053. [Google Scholar] [CrossRef]

- Djettene, R.; Dubois, L.; Duprez, M.E.; De Weireld, G.; Thomas, D. Integrated CO2 Capture and Conversion into Methanol Units: Assessing Techno-Economic and Environmental Aspects Compared to CO2 into SNG Alternative. J. CO2 Util. 2024, 85, 102879. [Google Scholar] [CrossRef]

- Lee, K.; Sun, P.; Elgowainy, A.; Baek, K.H.; Bobba, P. Techno-Economic and Life Cycle Analysis of Synthetic Natural Gas Production from Low-Carbon H2 and Point-Source or Atmospheric CO2 in the United States. J. CO2 Util. 2024, 83, 102791. [Google Scholar] [CrossRef]

- Peng, H.T.; Zhang, D.; Zhong, J.T.; Guo, L.F.; Guo, S.Y.; Huang, J.L.; Wang, D.Y.; Miao, C.H.; Zhang, X.L.; Zhang, X.Y. Representative CO2 Emissions Pathways for China’s Provinces toward Carbon Neutrality under the Paris Agreement’s 2 °C Target. Adv. Clim. Change Res. 2024, 15, 1096–1106. [Google Scholar] [CrossRef]

- Cormos, C.C.; Dragan, M.; Petrescu, L.; Cormos, A.M.; Dragan, S.; Bathori, A.M.; Galusnyak, S.C. Synthetic Natural Gas (SNG) Production by Biomass Gasification with CO2 Capture: Techno-Economic and Life Cycle Analysis (LCA). Energy 2024, 312, 133507. [Google Scholar] [CrossRef]

- Liu, J.; Zhuang, Y.; Wang, C.; Du, J. Life Cycle Carbon Footprint Assessment of Coal-to-SNG/Methanol Polygeneration Process. Sci. Total Environ. 2024, 908, 168409. [Google Scholar] [CrossRef]

- Zeng, S.; Gu, J.; Yang, S.; Zhou, H.; Qian, Y. Comparison of Techno-Economic Performance and Environmental Impacts between Shale Gas and Coal-Based Synthetic Natural Gas (SNG) in China. J. Clean. Prod. 2019, 215, 544–556. [Google Scholar] [CrossRef]

- Kolb, S.; Plankenbühler, T.; Hofmann, K.; Bergerson, J.; Karl, J. Life Cycle Greenhouse Gas Emissions of Renewable Gas Technologies: A Comparative Review. Renew. Sustain. Energy Rev. 2021, 146, 111147. [Google Scholar] [CrossRef]

- Szima, S.; Cormos, C.C. CO2 Utilization Technologies: A Techno-Economic Analysis for Synthetic Natural Gas Production. Energies 2021, 14, 1258. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, R.; Wang, L.; Zhang, C.; Jun, K.W.; Kim, S.K.; Zhao, T.; Wan, H.; Guan, G. Carbon-Neutral Light Olefins Production for Energy Decarbonization: Process Development and Techno-Econo-Environmental Analysis. Chem. Eng. J. 2023, 471, 144611. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Chong, C.T.; Milano, J.; Tiong, S.K.; Cui, Y.; Ng, J.-H. Response Optimisation of TiO2-Supported Bimetallic NiCo Catalyst for the Cracking and Deoxygenation of Waste Cooking Oil into Jet-Fuel Range Hydrocarbon Fuels under Non-Hydrogen Environment. Energy 2024, 309, 133057. [Google Scholar] [CrossRef]

- Zhu, L.; Song, Y.; Chen, H.; Wang, M.; Liu, Z.; Wei, X.; Zhao, C.; Ai, T. Optimization of Power Generation and Sewage Treatment in Stacked Pulsating Gas-Liquid-Solid Circulating Fluidized Bed Microbial Fuel Cell Using Response Surface Methodology. Int. J. Hydrog. Energy 2025, 101, 161–172. [Google Scholar] [CrossRef]

- Chahdoura, S.; Bahloul, R.; Tlija, M.; Tahan, A. Multi-Objective Optimization of PLA-FDM Parameters for Enhancement of Industrial Product Mechanical Performance Based on GRA-RSM and BBD. Prog. Addit. Manuf. 2025, 10, 1355–1383. [Google Scholar] [CrossRef]

- Chetia, B.; Debbarma, S.; Ahmed, F. Parametric Optimization of Variable Compression Ratio Diesel Engine Run on Waste Cooking Biodiesel with CeO2 Nanoparticles Using Response Surface Methodology (RSM) Technique. Fuel 2025, 389, 134544. [Google Scholar] [CrossRef]

- Nazerifard, R.; Mohammadpourfard, M.; Heris, S.Z. Optimization of the Integrated ORC and Carbon Capture Units Coupled to the Refinery Furnace with the RSM-BBD Method. J. CO2 Util. 2022, 66, 102289. [Google Scholar] [CrossRef]

- Bhatia, P.; Cummis, C.; Draucker, L.; Rich, D.; Lahd, H.; Brown, A. Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard; World Resources Institute: Washington, DC, USA, 2011. [Google Scholar]

- ISO 14067:2018(En), Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:14067:ed-1:v1:en (accessed on 18 September 2024).

- PAS 2050:2011; Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services. BSI British Standards Institution: London, UK, 2011.

- Hao, J.L.; Zhao, W.; Gong, G.; Ma, W.; Li, L.; Zhang, Y. Catalyzing Sustainability through Prefabrication: Integrating BIM-LCA for Assessing Embodied Carbon in Timber Formwork Waste. Sustain. Chem. Pharm. 2024, 41, 101698. [Google Scholar] [CrossRef]

- Huo, J.; Yang, D.; Xia, F.; Tang, H.; Zhang, W. Feasibility Analysis and Policy Recommendations for the Development of the Coal Based SNG Industry in Xinjiang. Energy Policy 2013, 61, 3–11. [Google Scholar] [CrossRef]

- Laurier, D.; Marsh, J.W.; Rage, E.; Tomasek, L. Miner Studies and Radiological Protection against Radon. Ann. ICRP 2020, 49, 57–67. [Google Scholar] [CrossRef]

- Wang, X.; Sun, X.; Ahmad, M.; Zhang, H. Does Low Carbon Energy Transition Impede Air Pollution? Evidence from China’s Coal-to-Gas Policy. Resour. Policy 2023, 83, 103723. [Google Scholar] [CrossRef]

- Gianoutsos, N.J.; Haase, K.B.; Birdwell, J.E. Geologic Sources and Well Integrity Impact Methane Emissions from Orphaned and Abandoned Oil and Gas Wells. Sci. Total Environ. 2024, 912, 169584. [Google Scholar] [CrossRef] [PubMed]

- Yeo, Y.; Yoo, T.; Yoo, S.; Ahn, Y.H. 2050 Net-Zero Scenarios and Well-to-Wheel Greenhouse Gas Emissions Assessment of South Korea’s Road Sector. J. Clean. Prod. 2025, 492, 144809. [Google Scholar] [CrossRef]

- Boothroyd, I.M.; Almond, S.; Worrall, F.; Davies, R.K.; Davies, R.J. Assessing Fugitive Emissions of CH4 from High-Pressure Gas Pipelines in the UK. Sci. Total Environ. 2018, 631–632, 1638–1648. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.; Zhang, W.; Li, Y.; Zhang, Y.; Zhang, Z.; Zhao, Y.; Gao, J.; Sun, S. Study on Biochar and Silicon Co-Production Technology of Rice Husk Based on the New Ammonia CO2 Capture Method and Its Comprehensive Benefits. Sustain. Energy Technol. Assess. 2023, 60, 103558. [Google Scholar] [CrossRef]

- Tsuchiya, Y.; Swai, T.A.; Goto, F. Energy Payback Time Analysis and Return on Investment of Off-Grid Photovoltaic Systems in Rural Areas of Tanzania. Sustain. Energy Technol. Assess. 2020, 42, 100887. [Google Scholar] [CrossRef]

- Yu, X.; Tan, C. China’s Process-Related Greenhouse Gas Emission Dataset 1990–2020. Sci Data 2023, 10, 55. [Google Scholar] [CrossRef]

- Martínez-López, A.; Ballester-Falcón, P.; Mazorra-Aguiar, L.; Marrero, A. Solar Photovoltaic Systems for the Short Sea Shipping’s Compliance with Decarbonization Regulations in the European Union. Sustain. Energy Technol. Assess. 2023, 60, 103506. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life Cycle Assessment of Sustainable Concrete with Recycled Aggregate and Supplementary Cementitious Materials. Resour. Conserv. Recycl. 2023, 193, 106947. [Google Scholar] [CrossRef]

- Li, H.; Yang, S.; Zhang, J.; Qian, Y. Coal-Based Synthetic Natural Gas (SNG) for Municipal Heating in China: Analysis of Haze Pollutants and Greenhouse Gases (GHGs) Emissions. J. Clean. Prod. 2016, 112, 1350–1359. [Google Scholar] [CrossRef]

- Li, J.; Tian, Y.; Zhang, Y.; Xie, K. Assessing Spatially Multistage Carbon Transfer in the Life Cycle of Energy with a Novel Multi-Flow and Multi-Node Model: A Case of China’s Coal-to-Electricity Chain. J. Clean. Prod. 2022, 339, 130699. [Google Scholar] [CrossRef]

- MTPRC. Transport Industry Development Statistical Bulletin 2016; MTPRC: Beijing, China, 2017. [Google Scholar]

- Li, J.; Zhang, Y.; Tian, Y.; Cheng, W.; Yang, J.; Xu, D.; Wang, Y.; Xie, K.; Ku, A.Y. Reduction of Carbon Emissions from China’s Coal-Fired Power Industry: Insights from the Province-Level Data. J. Clean. Prod. 2020, 242, 118518. [Google Scholar] [CrossRef]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006. [Google Scholar]

- Stocker, T.F. IPCC Climate Change 2013: The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Haran, S.; Rao, A.B.; Banerjee, R. Life Cycle Energy-Carbon-Water Footprint Assessment of an Existing Coal Power Plant Retrofitted with Calcium Looping (CaL) Based CCS System. Int. J. Greenh. Gas Control 2023, 130, 104015. [Google Scholar] [CrossRef]

- Wolf, N.; Kühn, L.; Höck, M. International Supply Chains for a Hydrogen Ramp-up: Techno-Economic Assessment of Hydrogen Transport Routes to Germany. Energy Convers. Manag. X 2024, 23, 100682. [Google Scholar] [CrossRef]

- Chauvy, R.; Verdonck, D.; Dubois, L.; Thomas, D.; De Weireld, G. Techno-Economic Feasibility and Sustainability of an Integrated Carbon Capture and Conversion Process to Synthetic Natural Gas. J. CO2 Util. 2021, 47, 101488. [Google Scholar] [CrossRef]

- Cong, N.; Song, Y.; Zhang, M.; Wu, W. Life Cycle Assessment of Carbon Reduction Potential of EoL Wind Turbine Blades Disposal Scenarios in China. Environ. Impact Assess. Rev. 2023, 100, 107072. [Google Scholar] [CrossRef]

- Li, H.; Jiang, H.-D.; Dong, K.-Y.; Wei, Y.-M.; Liao, H. A Comparative Analysis of the Life Cycle Environmental Emissions from Wind and Coal Power: Evidence from China. J. Clean. Prod. 2020, 248, 119192. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Du, H.; Zuo, J.; Yi Man Li, R.; Zhou, Z.; Bi, F.; Garvlehn, M.P. A Comparative Life-Cycle Assessment of Hydro-, Nuclear and Wind Power: A China Study. Appl. Energy 2019, 249, 37–45. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Wu, F. Research on Carbon Emission Reduction Benefit of Wind Power Project Based on Life Cycle Assessment Theory. Renew. Energy 2020, 155, 456–468. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, Q.; Zhang, S.; Luo, K. The Substitution of Wind Power for Coal-Fired Power to Realize China’s CO2 Emissions Reduction Targets in 2020 and 2030. Energy 2017, 120, 164–178. [Google Scholar] [CrossRef]

- Malode, S.; Prakash, R.; Mohanta, J.C. Sustainability Assessment of Rooftop Solar Photovoltaic Systems: A Case Study. Environ. Impact Assess. Rev. 2024, 108, 107609. [Google Scholar] [CrossRef]

- Marashli, A.; Gasaymeh, A.M.; Shalby, M. Comparing the Global Warming Impact from Wind, Solar Energy, and Other Electricity Generating Systems through Life Cycle Assessment Methods (A Survey). Int. J. Renew. Energy Res. 2022, 12, 899–920. [Google Scholar] [CrossRef]

- Pu, Y.; Wang, P.; Wang, Y.; Qiao, W.; Wang, L.; Zhang, Y. Environmental Effects Evaluation of Photovoltaic Power Industry in China on Life Cycle Assessment. J. Clean. Prod. 2021, 278, 123993. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental Impacts of Solar Photovoltaic Systems: A Critical Review of Recent Progress and Future Outlook. Sci. Total Environ. 2021, 759, 143528. [Google Scholar] [CrossRef]

- Gao, C.; Na, H.; Song, K.; Dyer, N.; Tian, F.; Xu, Q.; Xing, Y. Environmental Impact Analysis of Power Generation from Biomass and Wind Farms in Different Locations. Renew. Sustain. Energy Rev. 2019, 102, 307–317. [Google Scholar] [CrossRef]

- Guidi, G.; Violante, A.C.; De Iuliis, S. Environmental Impact of Electricity Generation Technologies: A Comparison between Conventional, Nuclear, and Renewable Technologies. Energies 2023, 16, 7847. [Google Scholar] [CrossRef]

- Mello, G.; Ferreira Dias, M.; Robaina, M. Wind Farms Life Cycle Assessment Review: CO2 Emissions and Climate Change. Energy Rep. 2020, 6, 214–219. [Google Scholar] [CrossRef]

- O’Sullivan, M.; Gravatt, M.; Popineau, J.; O’Sullivan, J.; Mannington, W.; McDowell, J. Carbon Dioxide Emissions from Geothermal Power Plants. Renew. Energy 2021, 175, 990–1000. [Google Scholar] [CrossRef]

- Paulillo, A.; Striolo, A.; Lettieri, P. The Environmental Impacts and the Carbon Intensity of Geothermal Energy: A Case Study on the Hellisheiði Plant. Environ. Int. 2019, 133, 105226. [Google Scholar] [CrossRef]

- Foong, S.Y.; Chan, Y.H.; Yek, P.N.Y.; Lock, S.S.M.; Chin, B.L.F.; Yiin, C.L.; Lan, J.C.-W.; Lam, S.S. Microwave-Assisted Pyrolysis in Biomass and Waste Valorisation: Insights into the Life-Cycle Assessment (LCA) and Techno-Economic Analysis (TEA). Chem. Eng. J. 2024, 491, 151942. [Google Scholar] [CrossRef]

- Wu, T.; Liu, K.; Cheng, X.; Zhang, J. Analysis of Energy, Carbon Emissions and Economics during the Life Cycle of Biomass Power Generation: Case Comparison from China. Biomass Bioenergy 2024, 182, 107098. [Google Scholar] [CrossRef]

- Song, Q.; Wang, Z.; Li, J.; Duan, H.; Yu, D.; Liu, G. Comparative Life Cycle GHG Emissions from Local Electricity Generation Using Heavy Oil, Natural Gas, and MSW Incineration in Macau. Renew. Sustain. Energy Rev. 2018, 81, 2450–2459. [Google Scholar] [CrossRef]

- Rasheed, R.; Javed, H.; Rizwan, A.; Sharif, F.; Yasar, A.; Tabinda, A.B.; Ahmad, S.R.; Wang, Y.; Su, Y. Life Cycle Assessment of a Cleaner Supercritical Coal-Fired Power Plant. J. Clean. Prod. 2021, 279, 123869. [Google Scholar] [CrossRef]

- Tao, Y.; Brander, M. A Comparative Prospective Life Cycle Assessment of Coal-Fired Power Plants in the US with MEA/MOF-Based Carbon Capture. J. Clean. Prod. 2024, 456, 142418. [Google Scholar] [CrossRef]

- Wang, N.; Ren, Y.; Zhu, T.; Meng, F.; Wen, Z.; Liu, G. Life Cycle Carbon Emission Modelling of Coal-Fired Power: Chinese Case. Energy 2018, 162, 841–852. [Google Scholar] [CrossRef]

- Zalazar-Garcia, D.; Román, M.C.; Fernandez, A.; Asensio, D.; Zhang, X.; Fabani, M.P.; Rodriguez, R.; Mazza, G. Exergy, Energy, and Sustainability Assessments Applied to RSM Optimization of Integrated Convective Air-Drying with Pretreatments to Improve the Nutritional Quality of Pumpkin Seeds. Sustain. Energy Technol. Assess. 2022, 49, 101763. [Google Scholar] [CrossRef]

- Sabbagh, O.; Fanaei, M.A.; Arjomand, A.; Hossein Ahmadi, M. Multi-Objective Optimization Assessment of a New Integrated Scheme for Co-Production of Natural Gas Liquids and Liquefied Natural Gas. Sustain. Energy Technol. Assess. 2021, 47, 101493. [Google Scholar] [CrossRef]

- Lei, Y.; Yin, Z.; Lu, X.; Zhang, Q.; Gong, J.; Cai, B.; Cai, C.; Chai, Q.; Chen, H.; Chen, R.; et al. The 2022 Report of Synergetic Roadmap on Carbon Neutrality and Clean Air for China: Accelerating Transition in Key Sectors. Environ. Sci. Ecotechnology 2024, 19, 100335. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Fan, Y.; Cheng, Z.; Wang, F.; Shi, X.; Yi, H.; Zhang, A.; Dong, Y. Thermodynamic Analysis of an Air Liquid Energy Storage System Coupling Rankine Cycle and Methane Steam Reforming to Improve System Electrical Conversion and Energy Efficiency. Renew. Energy 2023, 219, 119586. [Google Scholar] [CrossRef]

- Cenușă, V.-E.; Opriș, I. Design Optimization of Cogeneration Steam Power Plants with Supercritical Parameters. Sustain. Energy Technol. Assess. 2024, 64, 103727. [Google Scholar] [CrossRef]

- Tang, J.; Long, Y.; Zhang, L.; Zeng, S.; Tian, S.; Zhang, C. Experimental Study of Coal Rank Effect on Carbon Dioxide Injection to Enhance CBM Recovery. Fuel 2023, 354, 129393. [Google Scholar] [CrossRef]

- Emeji, I.C.; Patel, B. Box-Behnken Assisted RSM and ANN Modelling for Biodiesel Production over Titanium Supported Zinc-Oxide Catalyst. Energy 2024, 308, 132765. [Google Scholar] [CrossRef]

- Jain, A.; Jyoti Bora, B.; Sharma, P.; Kumar, R.; Jyoti Medhi, B.; Balakrishnan, D.; Senthilkumar, N. Statistical Analysis of Mesua Ferrea Seed Oil Biodiesel Fueled Diesel Engine at Variable Injection Timings Using Response Surface Methodology. Sustain. Energy Technol. Assess. 2023, 60, 103476. [Google Scholar] [CrossRef]

- Kumar, R.; Nadda, R.; Kumar, S.; Razak, A.; Sharifpur, M.; Aybar, H.S.; Ahamed Saleel, C.; Afzal, A. Influence of Artificial Roughness Parametric Variation on Thermal Performance of Solar Thermal Collector: An Experimental Study, Response Surface Analysis and ANN Modelling. Sustain. Energy Technol. Assess. 2022, 52, 102047. [Google Scholar] [CrossRef]

| Projects | Investment Funds (Billion RMB) | Scale (Billion Nm3/a) | Approved Time | Time of Putting into Production | Scale in Production (Nm3/a) |

|---|---|---|---|---|---|

| Datang Keqi | 3.4 | 4.0 | 2009.08 | 2013.12 | 1.3 |

| Xinjiang Qinghua | 19.4 | 5.5 | 2010.08 | 2014.12 | 1.3 |

| Yili Xintian | 18.5 | 2.0 | 2017.05 | 2017.03 | 2.0 |

| Inner Mongolia Huaxing | 22.9 | 4.0 | 2022.04 | Under construction | 4.0 (Plan) |

| Xinjiang Energy | 30.0 | 4.0 | 2022.09 | Under construction | 4.0 (Plan) |

| Xinjiang Qinghua Phase II | 19.4 | 5.5 | 2023.07 | Under construction | 4.0 (Plan) |

| Xinjiang Tianchi Energy | 20.0 | 4.0 | 2023.09 | Under construction | 4.0 (Plan) |

| Xinjiang Qiya Chemical | 40.0 | 6.0 | 2023.10 | Under construction | 4.0 (Plan) |

| Yitai Yili Energy | 2.0 | 2.0 | 2023.10 | Under construction | 4.0 (Plan) |

| Henan Energy | 20.0 | 4.0 | 2023.11 | Under construction | 4.0 (Plan) |

| Stage | Carbon Emissions (t) | Carbon Intensity (g CO2eq/kWh) | Proportion (%) | |

|---|---|---|---|---|

| Coal mining and washing (S1) | Coal mining | 2.48 × 106 | 61.04 | 9.38 |

| Coal washing | 4.38 × 104 | |||

| Subtotal | 2.53 × 106 | |||

| Coal transportation (S2) | 2.81 × 104 | 0.69 | 0.10 | |

| Coal-to-SNG production (S3) | 2.44 × 107 | 598.94 | 90.48 | |

| Pipeline transportation (S4) | 1.02 × 104 | 0.25 | 0.04 | |

| Total | 2.69 × 107 | 660.92 | 100 | |

| Factors | Levels | Unit |

|---|---|---|

| A: Raw coal selection rate | 40~85 | % |

| B: Effective calorific value of coal | 16.750~25.120 | MJ/kg |

| C: Conversion efficiency of coal-to-SNG | 50~83 | % |

| No. | A: Coal Selection Rate (%) | B: Effective Calorific Value of Coal (MJ/kg) | C: Conversion Efficiency (%) | Energy-Based Rate of Return (%) |

|---|---|---|---|---|

| 1 | 62.5 | 25.1 | 50 | 1.12 |

| 2 | 85 | 25.1 | 66.5 | 1.55 |

| 3 | 40 | 25.1 | 66.5 | 1.62 |

| 4 | 62.5 | 25.1 | 83 | 2.06 |

| 5 | 85 | 20.93 | 50 | 20.02 |

| 6 | 40 | 20.93 | 50 | 20.12 |

| 7 | 62.5 | 20.93 | 66.5 | 20.73 |

| 8 | 62.5 | 20.93 | 66.5 | 20.73 |

| 9 | 62.5 | 20.93 | 66.5 | 20.73 |

| 10 | 62.5 | 20.93 | 66.5 | 20.73 |

| 11 | 62.5 | 20.93 | 66.5 | 20.73 |

| 12 | 85 | 20.93 | 83 | 21.35 |

| 13 | 40 | 20.93 | 83 | 21.45 |

| 14 | 85 | 16.75 | 66.5 | 48.7 |

| 15 | 62.5 | 16.75 | 50 | 47.77 |

| 16 | 40 | 16.75 | 66.5 | 48.85 |

| 17 | 62.5 | 16.75 | 83 | 49.79 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 4541.9 | 9 | 504.66 | 3.10 × 105 | <0.0001 | ** |

| A | 0.0211 | 1 | 0.0211 | 12.97 | 0.0087 | * |

| B | 4453.89 | 1 | 4453.89 | 2.74 × 106 | <0.0001 | ** |

| C | 3.93 | 1 | 3.93 | 2414.92 | <0.0001 | ** |

| AB | 0.0016 | 1 | 0.0016 | 0.9581 | 0.3603 | |

| AC | 1.00 × 10−6 | 1 | 1.00 × 10−6 | 0.0006 | 0.9809 | |

| BC | 0.2889 | 1 | 0.2889 | 177.41 | <0.0001 | ** |

| A2 | 1.05 × 10−6 | 1 | 1.05 × 10−6 | 0.0006 | 0.9804 | |

| B2 | 83.28 | 1 | 83.28 | 51,137.71 | <0.0001 | ** |

| C2 | 0.0001 | 1 | 0.0001 | 0.0414 | 0.8446 | |

| Residual | 0.0114 | 7 | 0.0016 | |||

| Lack of Fit | 0.0114 | 3 | 0.0038 | |||

| Pure Error | 0 | 4 | 0 | |||

| Cor Total | 4541.92 | 16 |

| Number | Recommended Parameter | Theoretical Energy-Based Rate of Return (%) | Actual Energy-Based Rate of Return (%) | ||

|---|---|---|---|---|---|

| A: Coal Selection Rate (%) | B: Effective Calorific Value of Coal (MJ/kg) | C: Conversion Efficiency (%) | |||

| 1 | 62.50 | 16.75 | 83.00 | 49.75 | 49.79 |

| 2 | 85.00 | 16.75 | 66.50 | 48.70 | 48.70 |

| 3 | 48.09 | 16.85 | 72.11 | 48.36 | 48.32 |

| 4 | 62.50 | 16.75 | 50.00 | 47.81 | 47.77 |

| 5 | 82.21 | 16.99 | 65.60 | 46.83 | 46.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, C.; Hao, J.; Yu, S.; Di Sarno, L.; Shi, Y.; Han, J. Integrating Life Cycle Assessment and Response Surface Methodology for Optimizing Carbon Reduction in Coal-to-Synthetic Natural Gas Process. Thermo 2025, 5, 47. https://doi.org/10.3390/thermo5040047

Zheng C, Hao J, Yu S, Di Sarno L, Shi Y, Han J. Integrating Life Cycle Assessment and Response Surface Methodology for Optimizing Carbon Reduction in Coal-to-Synthetic Natural Gas Process. Thermo. 2025; 5(4):47. https://doi.org/10.3390/thermo5040047

Chicago/Turabian StyleZheng, Caimiao, Jianli Hao, Shiwang Yu, Luigi Di Sarno, Yuan Shi, and Ji Han. 2025. "Integrating Life Cycle Assessment and Response Surface Methodology for Optimizing Carbon Reduction in Coal-to-Synthetic Natural Gas Process" Thermo 5, no. 4: 47. https://doi.org/10.3390/thermo5040047

APA StyleZheng, C., Hao, J., Yu, S., Di Sarno, L., Shi, Y., & Han, J. (2025). Integrating Life Cycle Assessment and Response Surface Methodology for Optimizing Carbon Reduction in Coal-to-Synthetic Natural Gas Process. Thermo, 5(4), 47. https://doi.org/10.3390/thermo5040047