Implementation of Carbon Utilization Technologies and Thermodynamic Organic Rankine Cycles in Biogas Combined Cycle Power Plants

Abstract

1. Introduction

2. Materials and Methods

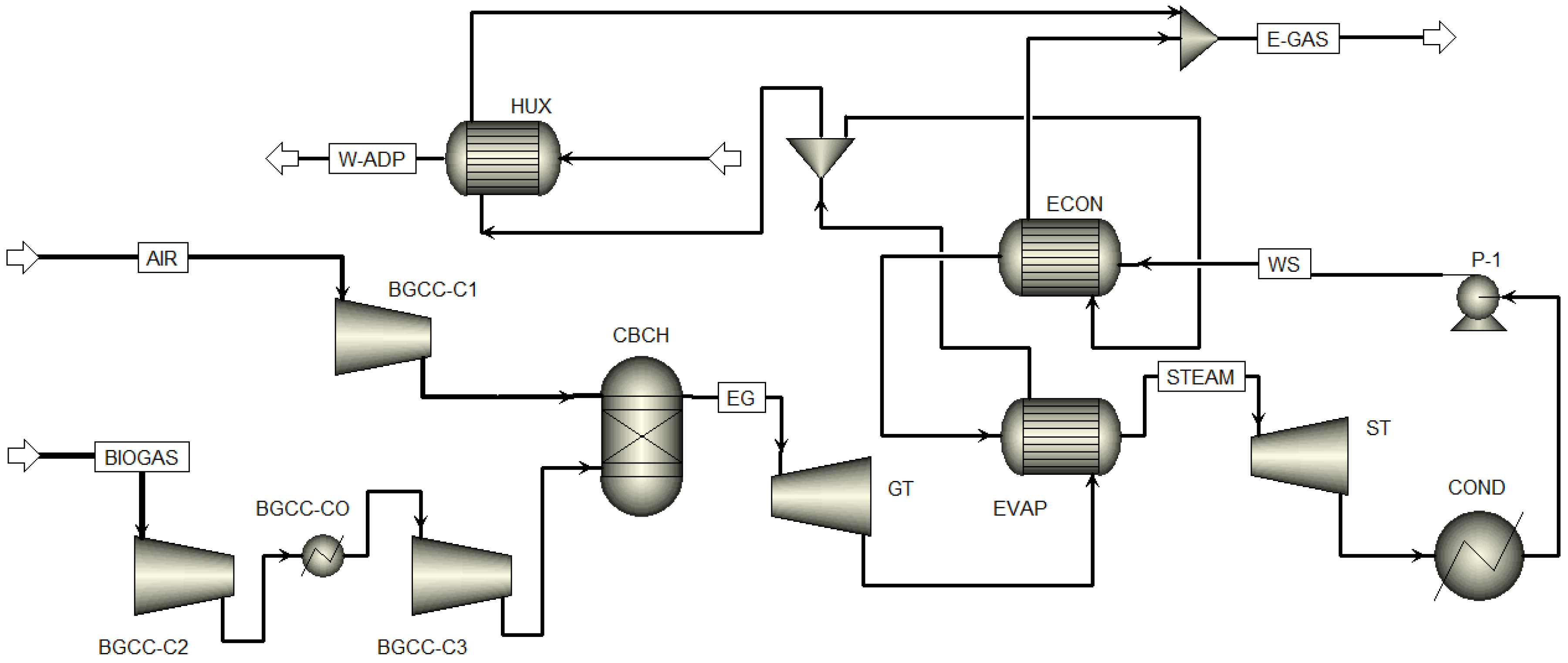

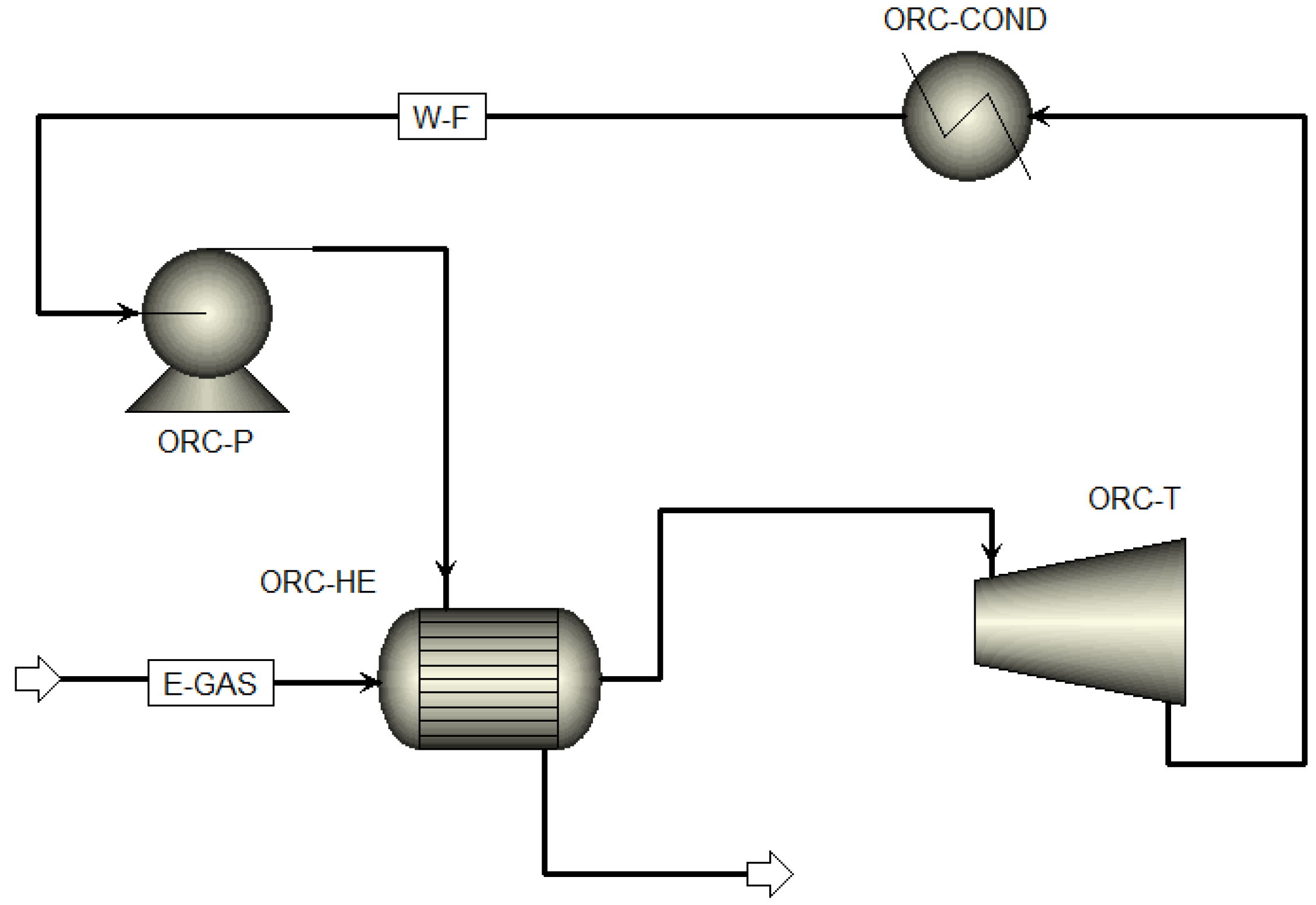

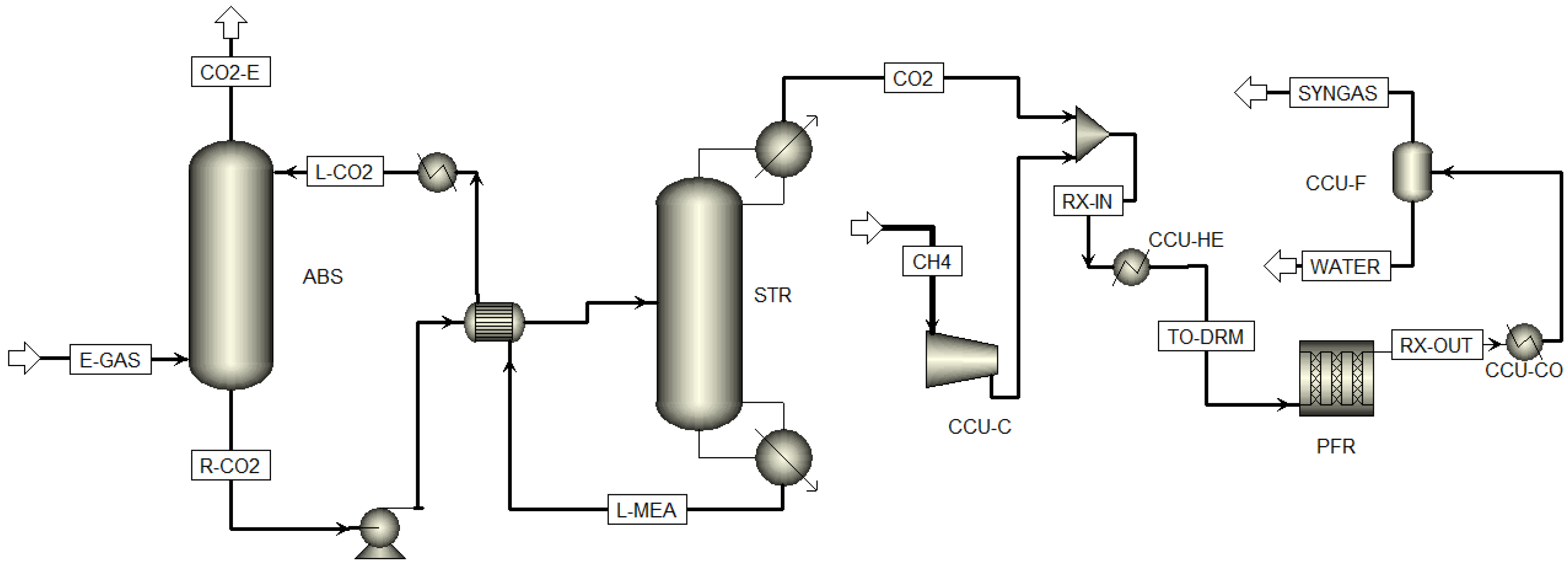

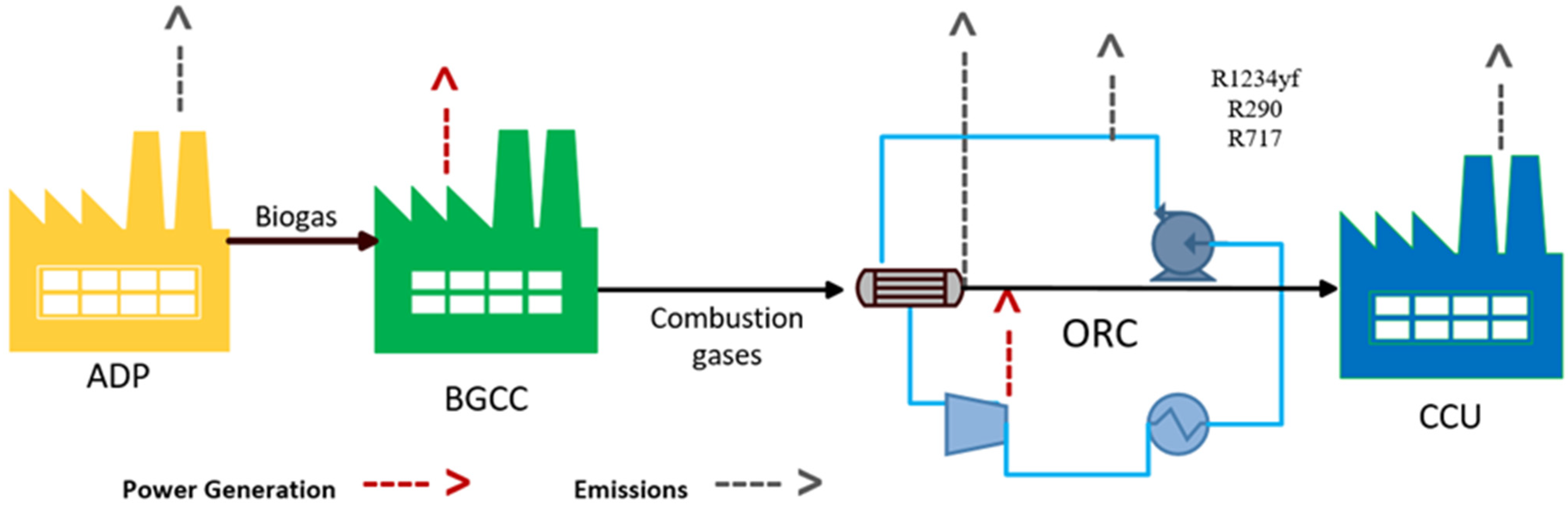

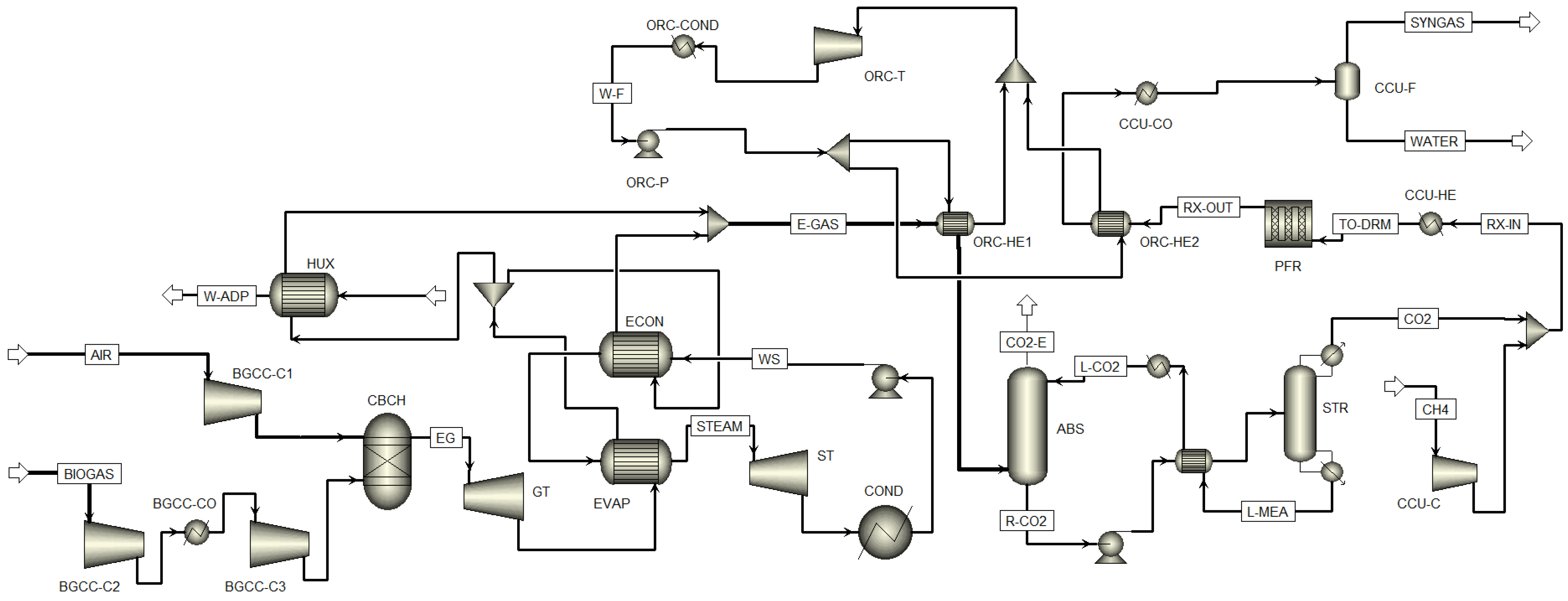

2.1. BGCC, CCU, and ORC Process Simulations

2.2. Energy Analysis

2.3. Environmental and Economic Analysis

2.4. Inherent Safety Analysis

3. Results and Discussion

3.1. Results from the Energy Analysis

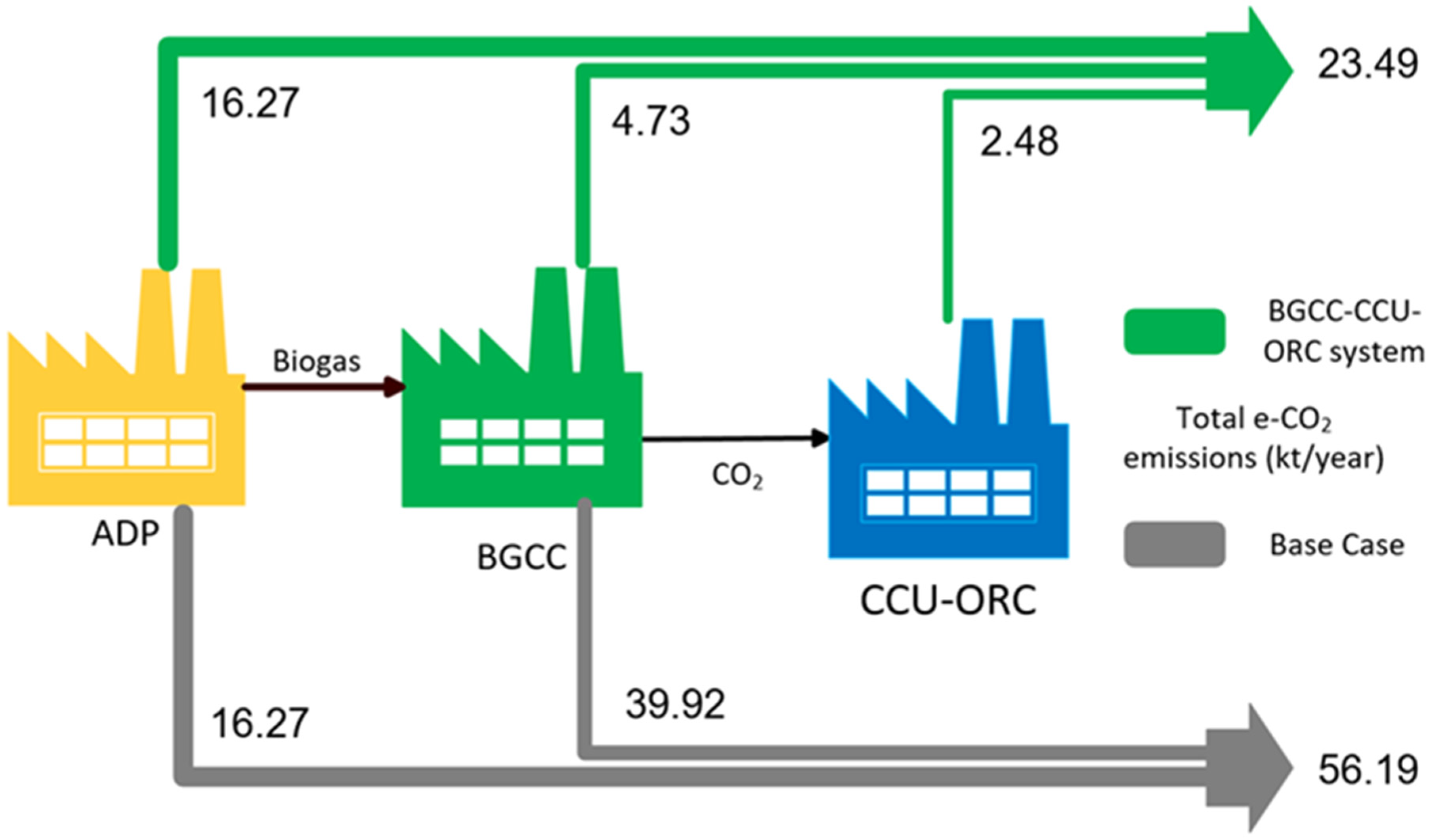

3.2. Environmental and Economic Implications

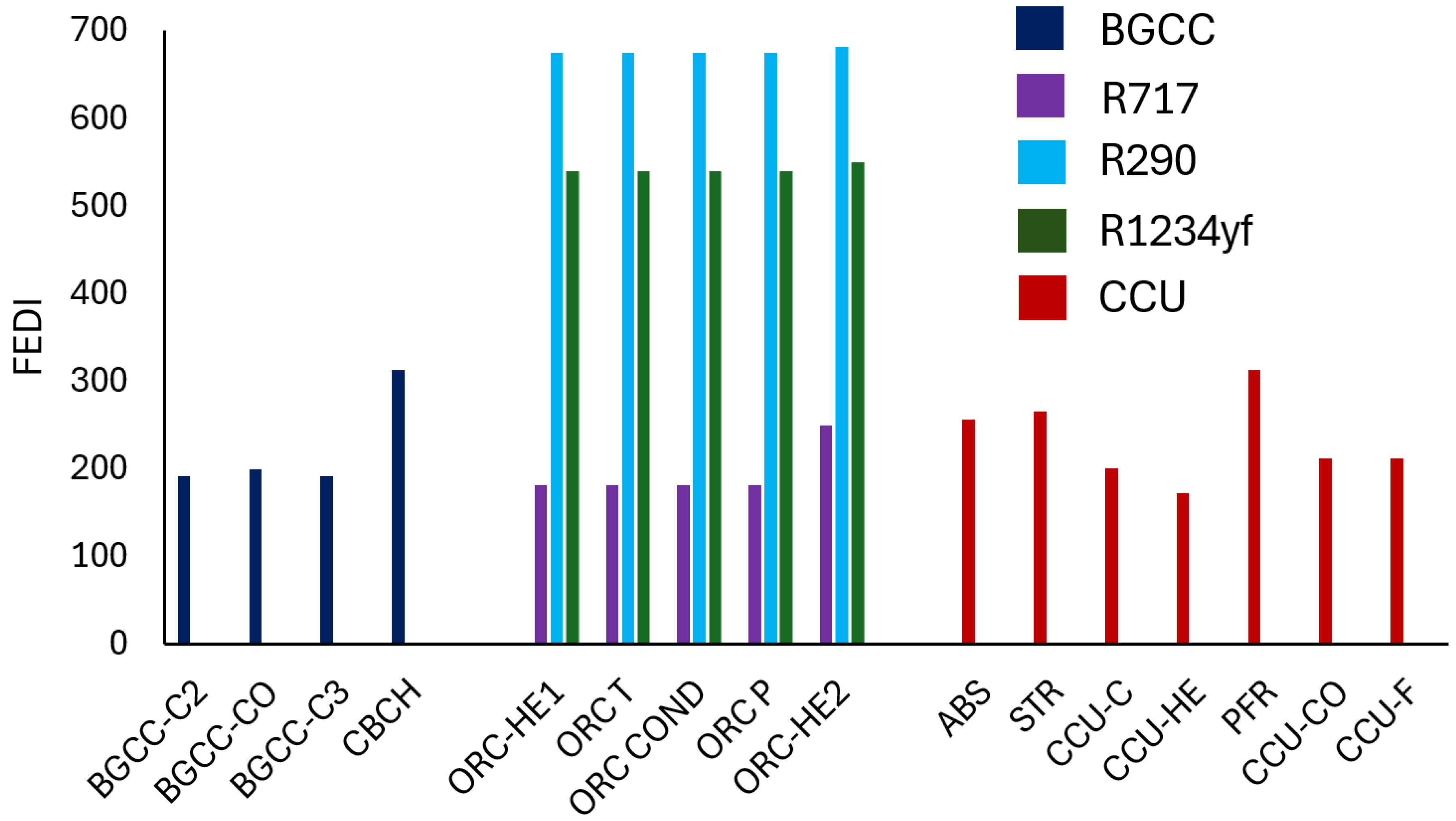

3.3. Inherent Safety Implications

3.4. Energy, Environment, Economics, and Safety System Performance Comparison

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADP | Anaerobic digestion plant |

| BGCC | Biogas combined cycle |

| CCU | Carbon capture and utilization |

| DRM | Dry reforming of methane |

| FEDI | Fire and explosion damage index |

| MEA | Monoethanolamine |

| ORC | Organic Rankine cycle |

| TCI | Total capital investment |

References

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources: An Introduction, 2nd ed.; Wiley VCH Verlag: Weinheim, Germany, 2011. [Google Scholar]

- Pérez-Uresti, S.I.; Martín, M.; Jiménez-Gutiérrez, A. Superstructure approach for the design of renewable-based utility plants. Comput. Chem. Eng. 2019, 123, 371–388. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). 2025. Available online: https://www.iea.org/reports/global-energy-review-2025/co2-emissions (accessed on 25 September 2025).

- Zhi, K.; Li, Z.; Wang, B.; Klemeš, J.J.; Guo, L. A review of CO2 utilization and emissions reduction: From the perspective of the chemical engineering. Process Saf. Environ. Prot. 2023, 172, 681–699. [Google Scholar] [CrossRef]

- Song, Y.; Ahmad, S.F.; Abou Houran, M.; Agrawal, M.K.; Kumar Nutakki, T.U.; Siddiqui, M.R.; Albani, A.; Su, O. Multi-variable study of a novel multigeneration system using biogas separation unit and LNG cold energy utilization, producing electricity, cooling, heat, fresh water, liquid CO2, biomethane, and methanol. Process Saf. Environ. Prot. 2023, 189, 616–638. [Google Scholar] [CrossRef]

- Wu, C.; Huang, Q.; Xu, Z.; Sipra, A.T.; Gao, N.; Vandenberghe, L.P.d.S.; Vieira, S.; Soccol, C.R.; Zhao, R.; Deng, S.; et al. A comprehensive review of carbon capture science and technologies. Carbon Capture Sci. Technol. 2024, 11, 100178. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). 2025. Available online: https://www.iea.org/energy-system/renewables/bioenergy (accessed on 25 September 2025).

- Calise, F.; Cappiello, F.L.; Cimmino, L.; Napolitano, M.; Vicidomini, M. Analysis of the Influence of Temperature on the Anaerobic Digestion Process in a Plug Flow Reactor. Thermo 2022, 2, 92–106. [Google Scholar] [CrossRef]

- Eller, F.; Ehde, P.M.; Oehmke, C.; Ren, L.; Brix, H.; Sorrell, B.K.; Weisner, S.E.B. Biomethane Yield from Different European Phragmites australis Genotypes, Compared with Other Herbaceous Wetland Species Grown at Different Fertilization Regimes. Resources 2020, 9, 57. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Y.; Dai, Y.J.; Wang, R.Z. Design and analysis of a biogas production system utilizing residual energy for a hybrid CSP and biogas power plant. Appl. Therm. Eng. 2016, 109, 423–431. [Google Scholar] [CrossRef]

- Anika, O.C.; Nnabuife, S.G.; Bello, A.; Okoroafor, E.R.; Kuang, B.; Villa, R. Prospects of low and zero-carbon renewable fuels in 1.5-degree net zero emission actualisation by 2050: A critical review. Carbon Capture Sci. Technol. 2022, 5, 100072. [Google Scholar] [CrossRef]

- Liang, P.; Guo, Y.; Chauhdary, S.T.; Agrawal, M.K.; Ahmad, S.F.; Ahmad, A.Y.A.B.; Ifseisi, A.A.; Ji, T. Sustainable development and multi-aspect analysis of a novel polygeneration system using biogas upgrading and LNG regasification processes, producing power, heating, fresh water and liquid CO2. Process Saf. Environ. Prot. 2024, 183, 417–436. [Google Scholar] [CrossRef]

- Tian, H.; Chen, X.; Ahmad, S.F.; Agrawal, M.K.; Seikh, A.H.; Shah, N.A.; Su, Q. Modeling and 4E analysis of a new combined cooling, heating, and power energy system based on biogas combustion and hot oil for heat supply. Process Saf. Environ. Prot. 2024, 184, 1484–1502. [Google Scholar] [CrossRef]

- Tsita, K.G.; Kiartzis, S.J.; Ntavos, N.K.; Pilavachi, P.A. Next generation biofuels derived from thermal and chemical conversion of the Greek transport sector. Therm. Sci. Eng. Prog. 2020, 17, 100387. [Google Scholar] [CrossRef]

- Agustini, C.B.; Spier, F.; da Costa, M.; Gutterres, M. Biogas production for anaerobic co-digestion of tannery solid wastes under presence and absence of the tanning agent. Resour. Conserv. Recycl. 2018, 130, 51–59. [Google Scholar] [CrossRef]

- Kaushal, R.; Sandhu, S.; Soni, M.K. Anaerobic co-digestion of food waste, algae, and cow dung for biogas yield enhancement as a prospective approach for environmental sustainability. Sustain. Energy Technol. Assess. 2022, 52, 102236. [Google Scholar] [CrossRef]

- Silva, C. Greenhouse Gas Emission Assessment of Simulated Wastewater Biorefinery. Resources 2021, 10, 78. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Li, J.; Lin, J.G.; Zhang, N.; Cao, W. Biogas energy generated from livestock manure in China: Current situation and future trends. J. Environ. Manag. 2021, 297, 113324. [Google Scholar] [CrossRef]

- Guo, M.; Wu, C.; Chapman, S.; Yu, X.; Vinestock, T.; Hastings, A.; Smith, P.; Shah, N. Advances in biorenewables-resource-waste systems and modelling. Carbon Capture Sci. Technol. 2023, 9, 100142. [Google Scholar] [CrossRef]

- Frijns, J.; Hofman, J.J.; Nederlof, M. The potential of (waste) water as energy carrier. Energy Convers. Manag. 2013, 65, 365–373. [Google Scholar] [CrossRef]

- Global Methane Initiative (GMI). The U.S. Government’s Global Methane Initiative Accomplishments; Annual Report December 2013; Global Methane Initiative: Washington, DC, USA, 2013; pp. 1–16. [Google Scholar]

- Wang, Y.; Fang, M.; Lou, Z.; He, H.; Guo, Y.; Pi, X.; Wang, Y.; Yin, K.; Fei, X. Methane emissions from landfills differentially underestimated worldwide. Nat. Sustain. 2024, 7, 496–507. [Google Scholar] [CrossRef]

- dos Santos, I.F.S.; Vieira, N.D.B.; Barros, R.M.; Filho, G.L.T.; Soares, D.M.; Alves, L.V. Economic and CO2 avoided emissions analysis of WWTP biogas recovery and its use in a small power plant in Brazil. Sustain. Energy Technol. Assess. 2016, 17, 77–84. [Google Scholar] [CrossRef]

- Kythavone, L.; Chaiyat, N. Life cycle assessment of a very small organic Rankine cycle and municipal solid waste incinerator for infectious medical waste. Therm. Sci. Eng. Prog. 2020, 18, 100526. [Google Scholar] [CrossRef]

- Li, H.; Tan, Y.; Ditaranto, M.; Yan, J.; Yu, Z. Capturing CO2 from biogas plants. Energy Procedia 2017, 114, 6030–6035. [Google Scholar] [CrossRef]

- Mondol, J.D.; Carr, C. Techno-economic assessments of advanced Combined Cycle Gas Turbine (CCGT) technology for the new electricity market in the United Arab Emirates. Sustain. Energy Technol. Assess. 2017, 19, 160–172. [Google Scholar] [CrossRef]

- Kang, J.K.; Kang, D.W.; Kim, T.S.; Hur, K.B. Comparative economic analysis of gas turbine-based power generation and combined heat and power systems using biogas fuel. Energy 2014, 67, 309–318. [Google Scholar] [CrossRef]

- Michaelides, E.E. Power and Energy Requirements for Carbon Capture and Sequestration. Thermo 2025, 5, 8. [Google Scholar] [CrossRef]

- Roumpedakis, T.C.; Fostieris, N.; Braimakis, K.; Monokrousou, E.; Charalampidis, A.; Karellas, S. Techno-Economic Optimization of Medium Temperature Solar-Driven Subcritical Organic Rankine Cycle. Thermo 2021, 1, 77–105. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Ghorbani, B.; Ziabasharhagh, M. Exergy and economic analyses of an innovative integrated system for cogeneration of treated biogas and liquid carbon dioxide using absorption–compression refrigeration system and ORC/Kalina power cycles through geothermal energy. Process Saf. Environ. Prot. 2022, 158, 257–281. [Google Scholar] [CrossRef]

- Raghulnath, D.; Saravanan, K.; Mahendran, J.; Ranjith-kumar, M.; Lakshmanan, P. Analysis and optimization of organic Rankine cycle for IC engine waste heat recovery system. Mater. Today Proc. 2020, 21, 30–35. [Google Scholar] [CrossRef]

- Kong, R.; Deethayat, T.; Asanakham, A.; Kiatsiriroat, T. Performance analysis of biomass boiler-organic Rankine cycle with assisted cascade heat pump for combined heat and power generation including exergy-costing. Sustain. Energy Technol. Assess. 2022, 52, 102125. [Google Scholar] [CrossRef]

- Yağlı, H.; Koç, Y.; Koç, A.; Gorgülü, A.; Tandiroğlu, A. Parametric optimization and exergetic analysis comparison of subcritical and supercritical organic Rankine cycle (ORC) for biogas fueled combined heat and power (CHP) engine exhaust gas waste heat. Energy 2016, 111, 923–932. [Google Scholar] [CrossRef]

- Baccioli, A.; Ferrari, L.; Vizza, F.; Desideri, U. Potential energy recovery by integrating an ORC in a biogas plant. Appl. Energy 2019, 256, 113960. [Google Scholar] [CrossRef]

- Aliyu, M.; AlQudaihi, A.B.; Said, S.A.M.; Habib, M.A. Energy, Exergy and Parametric Analysis of a Combined Cycle Power Plant. Therm. Sci. Eng. Prog. 2020, 15, 100450. [Google Scholar] [CrossRef]

- Chang, H.; Li, J. A new exergy method for process analysis and optimization. Chem. Eng. Sci. 2005, 60, 2771–2784. [Google Scholar] [CrossRef]

- Shen, F.; Wang, M.; Huang, L.; Qian, F. Exergy analysis and multi-objective optimization for energy system: A case study of a separation process in ethylene manufacturing. J. Ind. Eng. Chem. 2021, 93, 394–406. [Google Scholar] [CrossRef]

- Fujii, M.; Dou, Y.; Sun, L.; Ohnishi, S.; Maki, S.; Dong, H.; Dong, L.; Chandran, R. Contribution to a low-carbon society from improving exergy of waste-to-energy system by upgrading utilization of waste. Resour. Conserv. Recycl. 2019, 149, 586–594. [Google Scholar] [CrossRef]

- Filiz-Tumen-Ozdil, N.; Tantekin, A. Exergy and exergoeconomic assessments of an electricity production system in a running wastewater treatment plant. Renew. Energy 2016, 97, 390–398. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, B.; Ma, H.; Zhang, L.; Duan, C.; Liu, B.; Zhang, Y.; Chen, S.; Yang, Z. Analysis of lower GWP and flammable alternative refrigerants. Int. J. Refrig. 2021, 126, 12–22. [Google Scholar] [CrossRef]

- Tamburini, F.; Zanobetti, F.; Cipolletta, M.; Bonvicini, S.; Cozzani, V. State of the art in the quantitative risk assessment of the CCS value chain. Process Saf. Environ. Prot. 2024, 191, 2044–2063. [Google Scholar] [CrossRef]

- You, C.; Kim, J. Quantitative risk assessment of an amine-based CO2 capture process. Korean J. Chem. Eng. 2020, 37, 1649–1659. [Google Scholar] [CrossRef]

- Kajurek, J.; Rusowicz, A.; Grzebielec, A.; Bujalski, W.; Futyma, K.; Rudowicz, Z. Selection of refrigerants for a modified organic Rankine cycle. Energy 2019, 168, 1–8. [Google Scholar] [CrossRef]

- Luo, X.; Wang, M.; Chen, J. Heat integration of natural gas combined cycle power plant integrated with post-combustion CO2 capture and compression. Fuel 2015, 151, 110–117. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Chen, C.C.; Plaza, J.M.; Dugas, R.; Rochelle, G.T. Rate-based process modeling study of CO2 capture with aqueous monoethanolamine solution. Ind. Eng. Chem. Res. 2009, 48, 9233–9246. [Google Scholar] [CrossRef]

- Gangadharan, P.; Kanchi, K.C.; Lou, H.H. Evaluation of the economic and environmental impact of combining dry reforming with steam reforming of methane. Chem. Eng. Res. Des. 2012, 90, 1956–1968. [Google Scholar] [CrossRef]

- Barroso-Quiroga, M.M.; Castro-Luna, A.E. Kinetic analysis of rate data for dry reforming of methane. Ind. Eng. Chem. Res. 2007, 46, 5265–5270. [Google Scholar] [CrossRef]

- Ecoinvent 3.3. Dataset Documentation. 2009. Available online: https://v371.ecoquery.ecoinvent.org/Search/Index (accessed on 14 August 2024).

- Gerber, L.; Maréchal, F. Environomic optimal configurations of geothermal energy conversion systems: Application to the future construction of Enhanced Geothermal Systems in Switzerland. Energy 2015, 45, 908–923. [Google Scholar] [CrossRef]

- IPCC. GHG Lifetimes and GWPs. 2014. Available online: https://climatechangeconnection.org/wp-content/uploads/2014/08/GWP_AR4.pdf (accessed on 24 September 2024).

- Roi, N.; Eljack, F.; Jiménez-Gutiérrez, A.; Zhang, B.; Thiruvenkataswamy, P.; El-Halwagi, M.; Mannan, M.S. A review of safety indices for process design. Curr. Opin. Chem. Eng. 2016, 14, 42–48. [Google Scholar] [CrossRef]

- Khan, F.I.; Abbasi, S.A. Multivariable hazard identification and ranking system. Process Saf. Prog. 1998, 17, 157–170. [Google Scholar] [CrossRef]

- Castillo-Landero, A.; Ortiz-Espinoza, A.P.; Jiménez-Gutiérrez, A. A process intensification methodology including economic, sustainability and inherent safety considerations. Ind. Eng. Chem. Res. 2019, 58, 6080–6092. [Google Scholar] [CrossRef]

- Ortiz-Espinoza, A.P.; Jiménez-Gutiérrez, A.; El-Halwagi, M.M.; Kazantzis, N.K.; Kazantzi, V. Comparison of safety indexes for chemical processes under uncertainty. Process Saf. Environ. Prot. 2021, 148, 225–236. [Google Scholar] [CrossRef]

- National Institutes of Health Database (NIH). 2024. Available online: https://pubchem.ncbi.nlm.nih.gov/ (accessed on 8 September 2024).

- International Energy Agency (IEA). 2023. Available online: https://data.worldbank.org/indicator/EG.USE.ELEC.KH.PC?most_recent_year_desc=false&view=map (accessed on 8 June 2025).

- Energy Information Administration (EIA). 2024. Available online: https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a (accessed on 13 November 2024).

| Parameter | Value | Units |

|---|---|---|

| Biogas flow | 0.8346 | kg/s |

| Biogas methane composition | 65 | %vol |

| Air flow | 21.19 | kg/s |

| Gas turbine (GT) outlet pressure | 1.07 | bar |

| Steam inlet conditions to the turbine | 180/9.8 | °C/bar |

| Steam turbine (ST) outlet pressure | 0.1275 | bar |

| Evaporator (ORC-HE) outlet temperature | 80 | °C |

| ORC condenser outlet temperature | 30 | °C |

| Parameter | Value | Units |

|---|---|---|

| Lean amine inlet conditions | 5.003/34.95 | bar/°C |

| Absorber pressure | 1.5/10 | bar/stages |

| Rich amine inlet conditions | 1.5/10 | bar/°C |

| Stripper pressure | 2.4/10 | bar/stages |

| CO2 flow | 1.27 | kg/s |

| CH4 flow | 0.46 | kg/s |

| PFR operating conditions | 1.97/873 | bar/°K |

| Heater (CCU-HE) outlet temperature | 873 | °K |

| Cooler (CCU-CO) outlet temperature | 25 | °C |

| Flash (CCU-) operating conditions | 1/25 | bar/°C |

| Parameter | Units | R1234yf | R290 | R717 |

|---|---|---|---|---|

| Heat of Combustion | kJ/mol | 1083 | −2220 | 382.8 |

| Autoignition Temperature | °C | 405 | 450 | 651 |

| NFPA Flammability | - | 2 | 4 | 1 |

| NFPA Reactivity | - | 0 | 0 | 0 |

| Flash Point | °C | 114 | −94 | 132 |

| Parameter | Units | This Work | Kang et al. [27] |

|---|---|---|---|

| Biogas flux | kg/s | 0.8346 | 0.8346 |

| Air flux | kg/s | 21.19 | 21.19 |

| Combustion gases temperature | °C | 1017.5 | 1104 |

| Gas turbine (GT) net power | MWe | 5.02 | 5.24 |

| Steam turbine (ST) net power | MWe | 1.244 | 1.165 |

| Combined cycle net power | MWe | 6.26 | 6.405 |

| Plant efficiency | Percent | 37.2 | 38 |

| Parameter | Units | R1234yf | R290 | R717 |

|---|---|---|---|---|

| Gas turbine net power | kWe | 5020 | 5020 | 5020 |

| Steam turbine net power | kWe | 530 | 530 | 530 |

| ORC net power | kWe | 313 | 329 | 355 |

| BGCC-CCU-ORC system net power | kWe | 5863 | 5879 | 5905 |

| Efficiency | % | 34.8 | 34.94 | 35.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esquivel-Patiño, G.G.; Nápoles-Rivera, F.; Jiménez-Gutiérrez, A. Implementation of Carbon Utilization Technologies and Thermodynamic Organic Rankine Cycles in Biogas Combined Cycle Power Plants. Thermo 2025, 5, 43. https://doi.org/10.3390/thermo5040043

Esquivel-Patiño GG, Nápoles-Rivera F, Jiménez-Gutiérrez A. Implementation of Carbon Utilization Technologies and Thermodynamic Organic Rankine Cycles in Biogas Combined Cycle Power Plants. Thermo. 2025; 5(4):43. https://doi.org/10.3390/thermo5040043

Chicago/Turabian StyleEsquivel-Patiño, Gerardo G., Fabricio Nápoles-Rivera, and Arturo Jiménez-Gutiérrez. 2025. "Implementation of Carbon Utilization Technologies and Thermodynamic Organic Rankine Cycles in Biogas Combined Cycle Power Plants" Thermo 5, no. 4: 43. https://doi.org/10.3390/thermo5040043

APA StyleEsquivel-Patiño, G. G., Nápoles-Rivera, F., & Jiménez-Gutiérrez, A. (2025). Implementation of Carbon Utilization Technologies and Thermodynamic Organic Rankine Cycles in Biogas Combined Cycle Power Plants. Thermo, 5(4), 43. https://doi.org/10.3390/thermo5040043