1. Introduction

Fluid flowing along a wall (plate) experiences “skin-friction drag” (or “resistance”) opposing its flow. Related to skin-friction, “forced convection heat transfer” is the heat transfer to or from a surface induced by fluid flow along that surface. Skin-friction and forced convection are fundamental processes with applications from engineering to geophysics.

This investigation seeks to develop formulas to predict the skin-friction coefficient and forced convection heat transfer from rough and smooth plates.

1.1. Pipe-Plate Analogy

Circa 1930, Prandtl [

1] and von Kármán [

2] developed theories for resistance along (smooth) plates from the results of research on flow through pipes; this is the “pipe-plate analogy”.

In 1934, Prandtl and Schlichting [

3] developed a theory of skin-friction resistance for rough plates based on their analysis of Nikuradse’s [

4] measurements of sand glued inside pipes (“sand-roughness”). The conclusion of the (translated) paper states:

“The resistance law just derived for rough plates has chiefly validity for a very specific type of roughness, namely a smooth surface to which sand grains have been densely attached and where the Nikuradse pipe results have been taken as the basis…

A single roughness parameter (the relative roughness) will in all likelihood no longer answer the purpose in continued investigations of the roughness problem”.

In 1936, Schlichting [

5] investigated the velocity profiles and resistance of water flowing through a closed rectangular channel having one wall replaced in turn by a series of plates, each having an array of identical protrusions attached: spheres, spherical caps (bumps), or cones. The protrusions were positioned on the plates in a hexagonal array that was elongated 15% in the direction of flow.

With a significant pressure drop between inflow and outflow of the channel, it was not an instance of the isobaric (uniform pressure) flow that can occur along external plates. The similarity of channel and pipe flows is well known, but neither supports nor refutes treating rough pipe interiors and plates analogously.

In 1954, Hama [

6] described three challenges of the pipe-plate analogy:

“Now there is no obvious reason why pipe flow and boundary-layer flow should be identical or even similar. First, a pressure gradient is essential for flow through a pipe but not along a plate. Second, pipe flow is confined and perforce uniform, while flow along a plate develops semi-freely and bears no such a priori guarantee of displaying similar velocity profiles at successive sections. Finally, the diameter and roughness size are the only geometrical dimensions of established flow in pipes, whereas at least three linear quantities are necessary to characterize the boundary-layer”.

1.2. Boundary Layer

Schlichting [

7] describes the boundary layer: “In that thin layer the velocity of the fluid increases from zero at the wall (no slip) to its full value which corresponds to external frictionless flow”.

Hama attempted to confirm the rough pipe-plate analogy with measurements of wire screens affixed to smooth plates, but concluded that it was confirmed only in the fully rough regime (defined below).

1.3. Sand-Roughness

Prior works [

3,

4,

5,

6,

7,

8,

9,

10,

11] specify sand-roughness

, the height of “coarse and tightly placed roughness elements such as, for example, coarse sand grains glued on the surface” (Schlichting [

7]).

Testing a machined analogue of sand-roughness circa 1975, Pimenta, Moffat, and Kays [

8] stated that, while agreement with the Prandtl–Schlichting model was “rather good” in the fully rough regime, the apparatus’s behavior differed from “Nikuradse’s sand-grain pipe flows in the transition region”.

Modeling the wake component of the velocity profile, in 1985 Mills and Hang [

9] presented a formula improving the match with data from Pimenta et al. in the rough regime; however, it did not address other flow regimes.

1.4. Flow Regimes

Along with laminar flow, the theory for flow within pipes (and channels) distinguishes three turbulent flow regimes: smooth, (fully) rough, and transitional. Smooth-regime pipe flow encounters viscous resistance varying inversely with the fluid velocity per viscosity ratio. Rough pipe flow encounters resistance varying with the height-of-roughness, while being largely insensitive to viscosity. The transitional regime describes the range of fluid velocities where both viscosity and roughness affect the resistance (Colebrook [

12]).

1.5. Reynolds Number

The Reynolds number () represents the bulk fluid velocity (far from the plate); with a subscript represents other fluid velocities. The local Reynolds number , where x is the distance from the leading edge of the plate in the direction of flow, and characteristic length L is the length scale for the physical system. Local measurements are made at distance x from the leading edge. Unless stated otherwise, L is the plate length in the direction of flow.

1.6. Skin-Friction Coefficient

Skin-friction in prior works is represented by the (dimensionless) local drag coefficient or , a function of the relative sand-roughness and or a subscripted .

Prandtl and Schlichting [

3] specified the boundaries between flow regimes using the “sand-roughness Reynolds number”

. For plates, it assigned the boundaries between smooth, transitional, and rough regimes at

and

. Pimenta et al. [

8] gave

as the transitional-to-rough boundary.

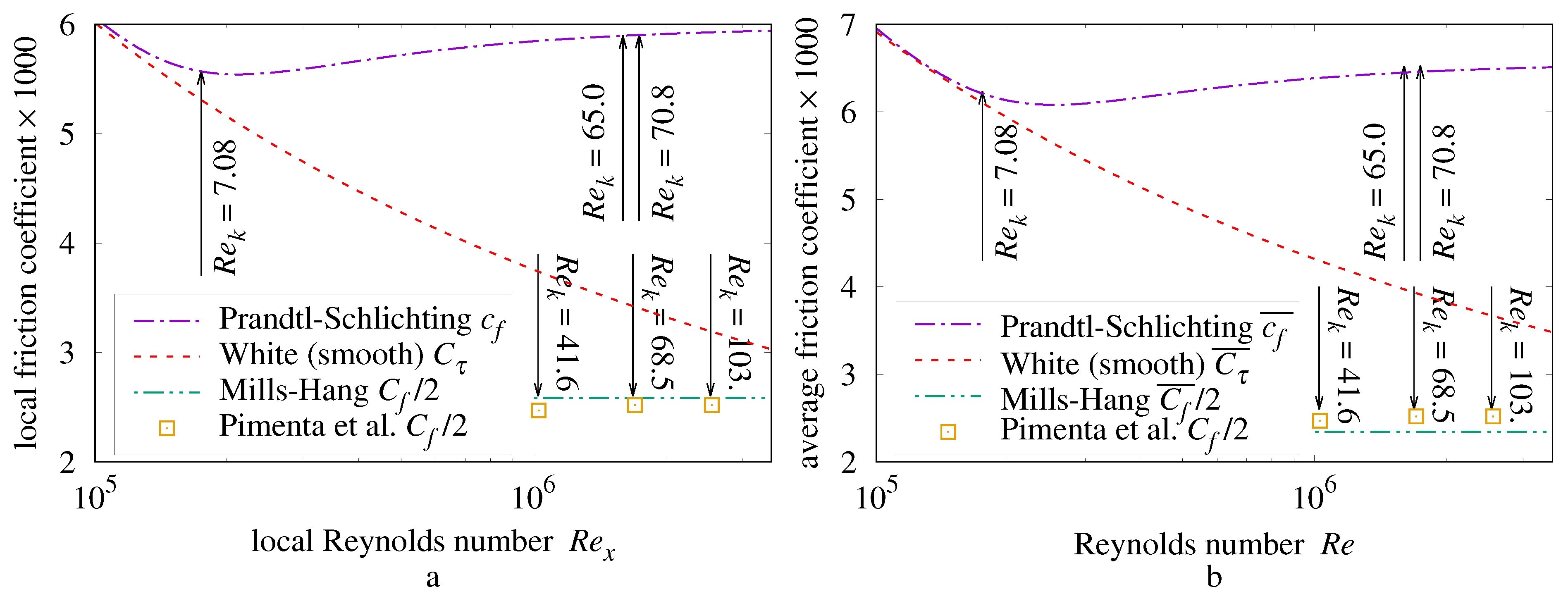

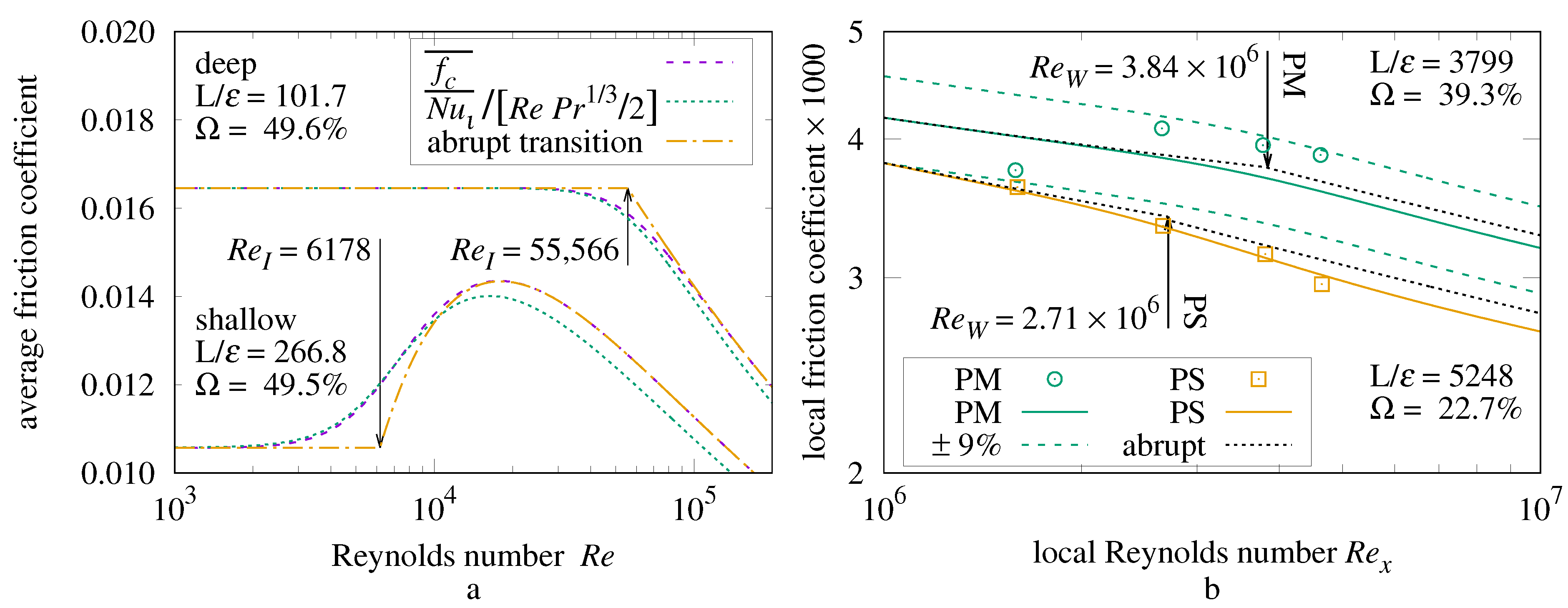

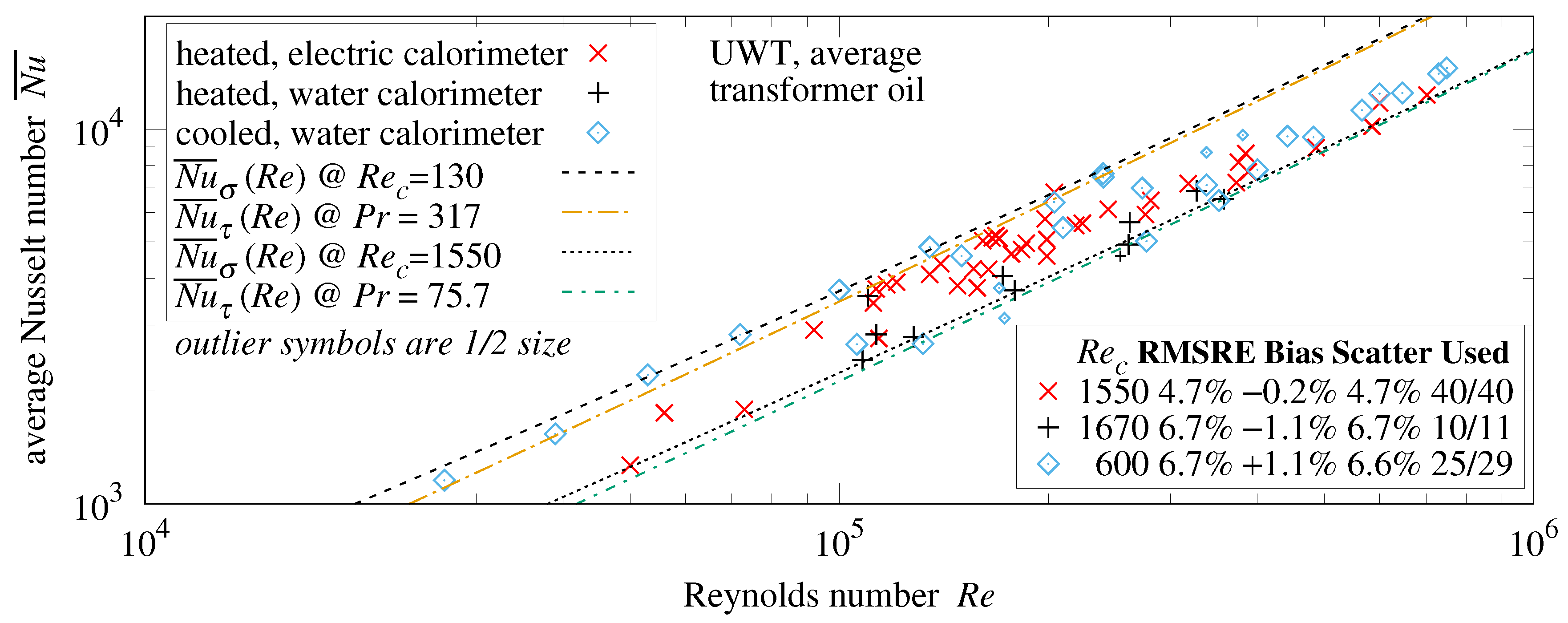

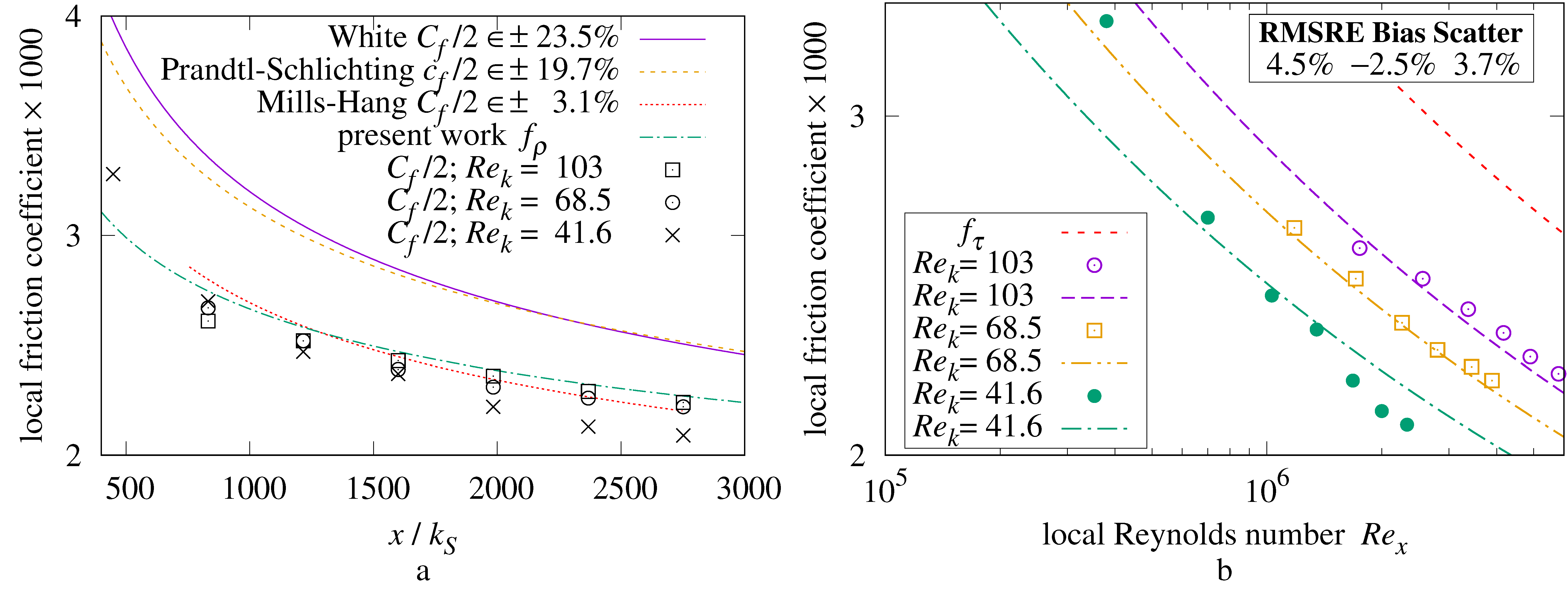

Figure 1a presents local skin-friction coefficient curves,

regime boundaries, and measurements from the Pimenta et al. [

8] plate having

at

.

Figure 1b presents the (whole-plate) average skin-friction coefficients with

m.

1.7. Plate Flow versus Pipe Flow

Schlichting [

7] states: “The resistance to flow offered by rough walls [of pipes] is larger than that …for smooth pipes”.

The rough pipe-plate analogy holds that this rule also applies to rough, external plates. For example, the “Prandtl-Schlichting

” curve is never less than the “White (smooth)

” curve in

Figure 1a.

The Pimenta et al. measurements are much closer to

than they are to

. (The Bergstrom, Akinlade, and Tachie [

13] local friction coefficient (

) measurements of woven wire meshes and perforated sheets (present work

Section 14) are also much closer to

than

.) Pimenta et al. [

8] and Mills and Hang [

9] both designated

as the friction coefficient. All three measurements in

Figure 1 are less than the smooth regime coefficient

. If rough friction is never less than smooth friction, then these measurements must not be in any turbulent flow regime; the remaining alternative is laminar flow. Laminar flow coefficients have a steeper slope than

; yet these measurements are near the constant level predicted by Mills–Hang

for the rough regime.

1.8. More Recent Work

With the rough pipe-plate analogy’s failure obscured by the factor of 2, research based on the pipe-plate analogy continued. The 2004 survey article Jiménez [

14] did not question the rough pipe-plate analogy, writing: “The theoretical arguments are sound, but the experimental evidence is inconclusive”.

Circa 2005, Bergstrom, Akinlade, and Tachie [

13], performed experiments with sandpapers, woven wire meshes, and perforated sheets attached onto a flat plate, reporting that:

, where

is the displacement thickness and

is the 99% velocity boundary layer thickness. As a function of a roughness metric, this formula has no predictive value because both

and

must be inferred from velocity measurements along the surface under test. Fortunately, Bergstrom et al. included free-stream velocity in their tables, allowing comparisons of their skin-friction data with the present theory.

The 2021 survey article Chung, Hutchins, Schultz, and Flack [

15] summarizes studies for predicting the drag, (boundary layer) velocity profiles, or convection from rough walls or pipes in terms of turbulence theory. Several roughness metrics were introduced, however none convert to the “isotropic spatial period” introduced in

Section 8 of the present work.

The studies cited by [

15] generally rely on turbulence theory, sand-roughness, Prandtl and Schlichting [

3], and the pipe-plate analogy. The present theory relies on none of these.

Sand-roughness’s lack of generality and the failure of the pipe-plate analogy for roughness motivate a fresh theoretical analysis of isobaric flow along a rough plate, an analysis derived from traceable roughness metrics.

Prior works analyze turbulence in the boundary layer. The central premise of this investigation is that plate roughness disrupts its boundary layer. The present theory does not utilize turbulence theory.

The present theory is about plates; it has no implications for smooth or rough pipe flow.

1.9. Approach

Flow along flat, smooth plates can be laminar or turbulent with a continuous boundary layer. This investigation uses the term “rough flow” for disrupted boundary layer flow from a rough plate.

Figure 1a,b shows that the skin-friction from smooth and rough plates are substantially different. Roughness disrupts what would otherwise be a viscous sub-layer adjacent to the plate. Lienhard and Lienhard [

16] teaches: “Even a small wall roughness can disrupt this thin sublayer, causing a large decrease in the thermal resistance (but also a large increase in the wall shear stress)”.

With a sufficiently large roughness, the nascent boundary layers forming after each disruption will be smaller than the roughness. The momentum can thus transfer directly between the fluid flow and the plate’s roughness. In order for these transfers to constitute most of the skin-friction, there must be no significant pressure gradients acting on the plate. Thus, this approach works only with a thin plate parallel to an isobaric fluid flow. It is not applicable to pipes, for example, because the pressure decreases as fluid flows through a cylindrical pipe.

Shearing stress can be determined from the free-stream velocity, ignoring turbulent velocity perturbations. Thus, the skin-friction can be derived without turbulence theory.

1.10. Not Empirical

Empirical theories derive their coefficients from measurements, inheriting the uncertainties from those measurements. Theories developed from first principles derive their coefficients mathematically. For example, Incropera, DeWitt, Bergman, and Lavine [

17] gives the thermal conductance of one face of a diameter

D disk into a stationary, uniform medium having thermal conductivity

k (

) as

. The present theory derives from first principles; it is not empirical. Each formula is tied to aspects of the plate geometry, fluid, and flow.

1.11. Mathematics

Familiarity with calculus is assumed. Computational geometry, probability, self-similar recurrences, the Lambert function, vector-space norms, and Fourier transforms are also employed; each is briefly introduced or illustrated graphically. Differential equations are not explicitly used.

1.12. Overview

After a comparison of roughness metrics in

Section 3, a thought experiment about flow along self-similar roughness is solved using computational geometry in

Section 5. The resulting skin-friction coefficient formula’s range of validity does not extend to 0 height-of-roughness. However, analyzing the case of a roughness which induces skin-friction midway between that of a self-similar rough surface and that of a smooth surface in

Section 6 produces a formula with unprecedented accuracy for smooth plates.

The self-similar roughness was designed to produce the most boundary layer disruption possible within a given RMS height-of-roughness. A self-similar roughness could be fabricated, but measuring its skin-friction could confirm predictions only for self-similar roughness. Instead,

Section 7 and

Section 8 turn to isotropic, periodic roughness, which applies in many practical use cases. Fourier analysis and computational geometry result in a quantitative test for periodic isotropy which computes the isotropic period

from a sufficiently large height map of roughness.

Section 8 computationally tests arrays of posts and wells to find the upper/lower area ratio spans which qualify as isotropic, periodic roughness.

Section 9 presents formulas for converting between local and average friction coefficients, and tests them on measurements from Pimenta et al. [

8], Churchill [

11], and Žukauskas and Šlančiauskas [

18].

Section 10 derives formulas for forced convection heat transfer from rough and smooth plates.

Periodicity enables the derivation of formulas for the onset of rough flow from an isotropic, periodic rough surface in

Section 11.

Section 12 finds that the skin-friction coefficient of isotropic, periodic roughness is the same as for self-similar roughness, except when the periodic roughness peaks are all co-planar (at the same elevation) plateaus. Plateau roughness is an isotropic, periodic roughness with most of its area at its peak elevation.

Section 12 derives a quantitative test for plateau roughness from a height map of roughness. It also develops formulas for the

thresholds separating rough flow and turbulent flow along the plate. These thresholds are tested in

Section 14 and

Section 15.

Section 13 derives formulas for skin-friction coefficients and convection heat transfer from a plateau roughness shedding rough and turbulent flow from regions of the plate separated at the

thresholds developed in

Section 12.

Section 14 tests the present theory on measurements from Bergstrom et al. [

13].

Section 15 tests the present theory on measurements from the present apparatus.

Section 16 analyzes fluid flow along isotropic, periodic roughness at

smaller than the rough flow thresholds found in

Section 11. This flow strongly resembles the “oscillations […] discovered in the laminar boundary layer along a flat plate” by Schubauer and Skramstad [

19]. The present work treats them identically. Although measurements of flows over such small roughnesses are lacking, smooth plate skin-friction measurements from Gebers [

20,

21] and uniform-wall-temperature convection measurements by Žukauskas and Šlančiauskas [

18] support the present theory.

2. Data-Sets and Evaluation

Table 1 and

Table 2 list the data-sets to be compared with the present theory.

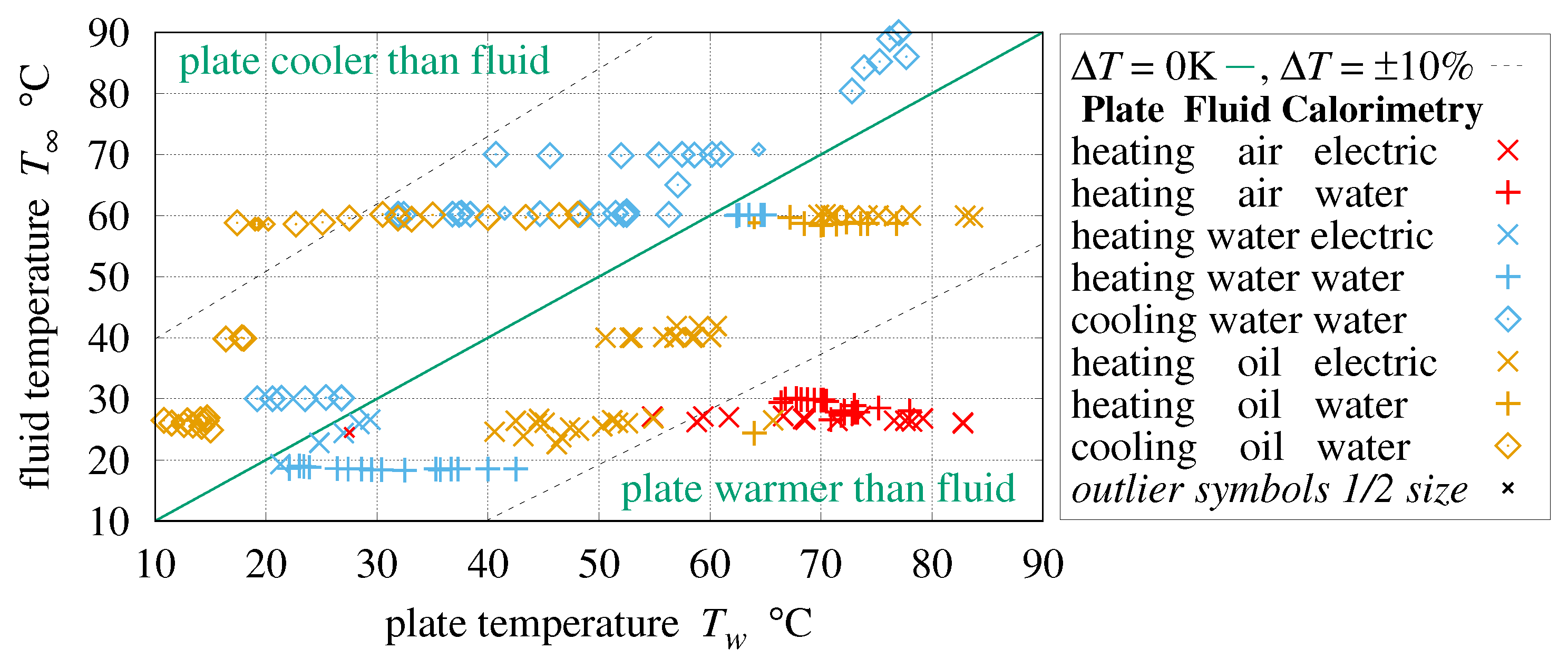

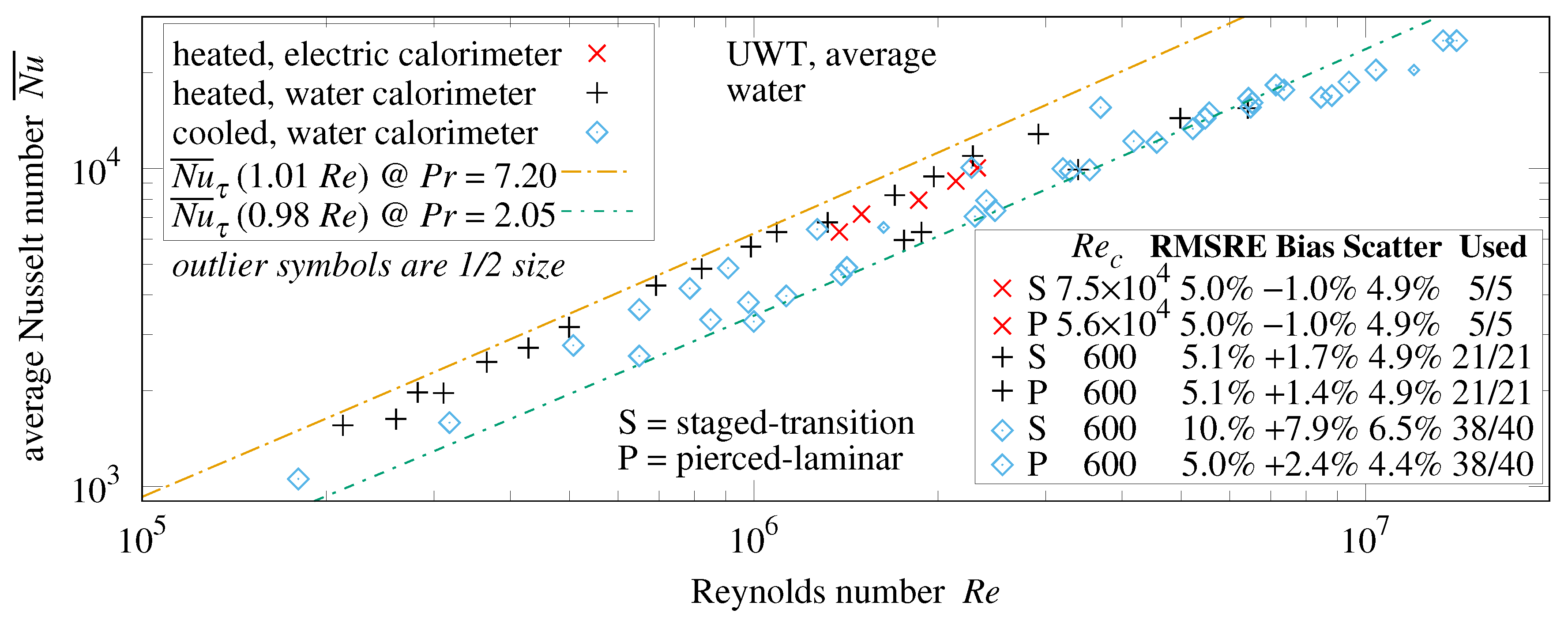

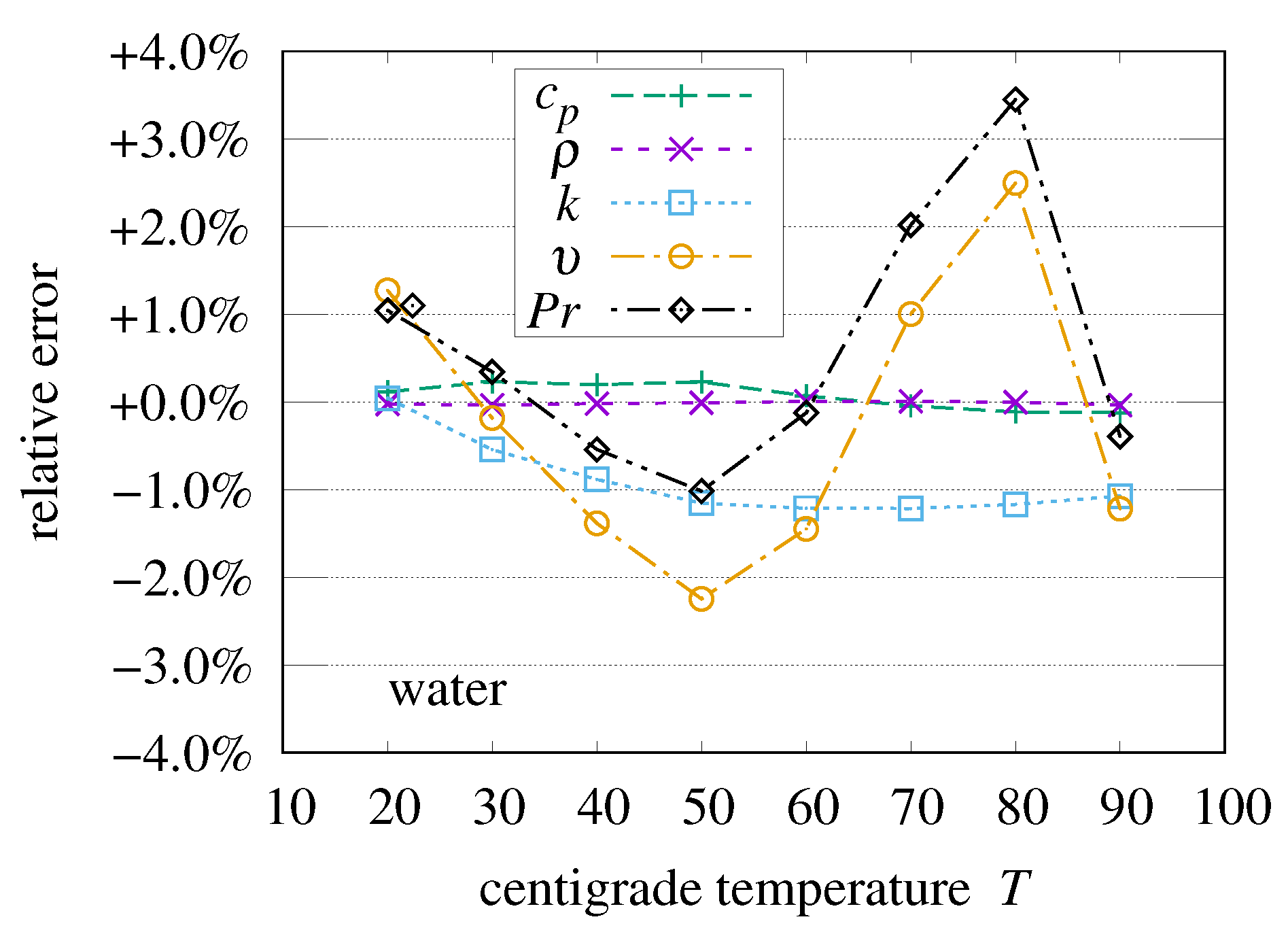

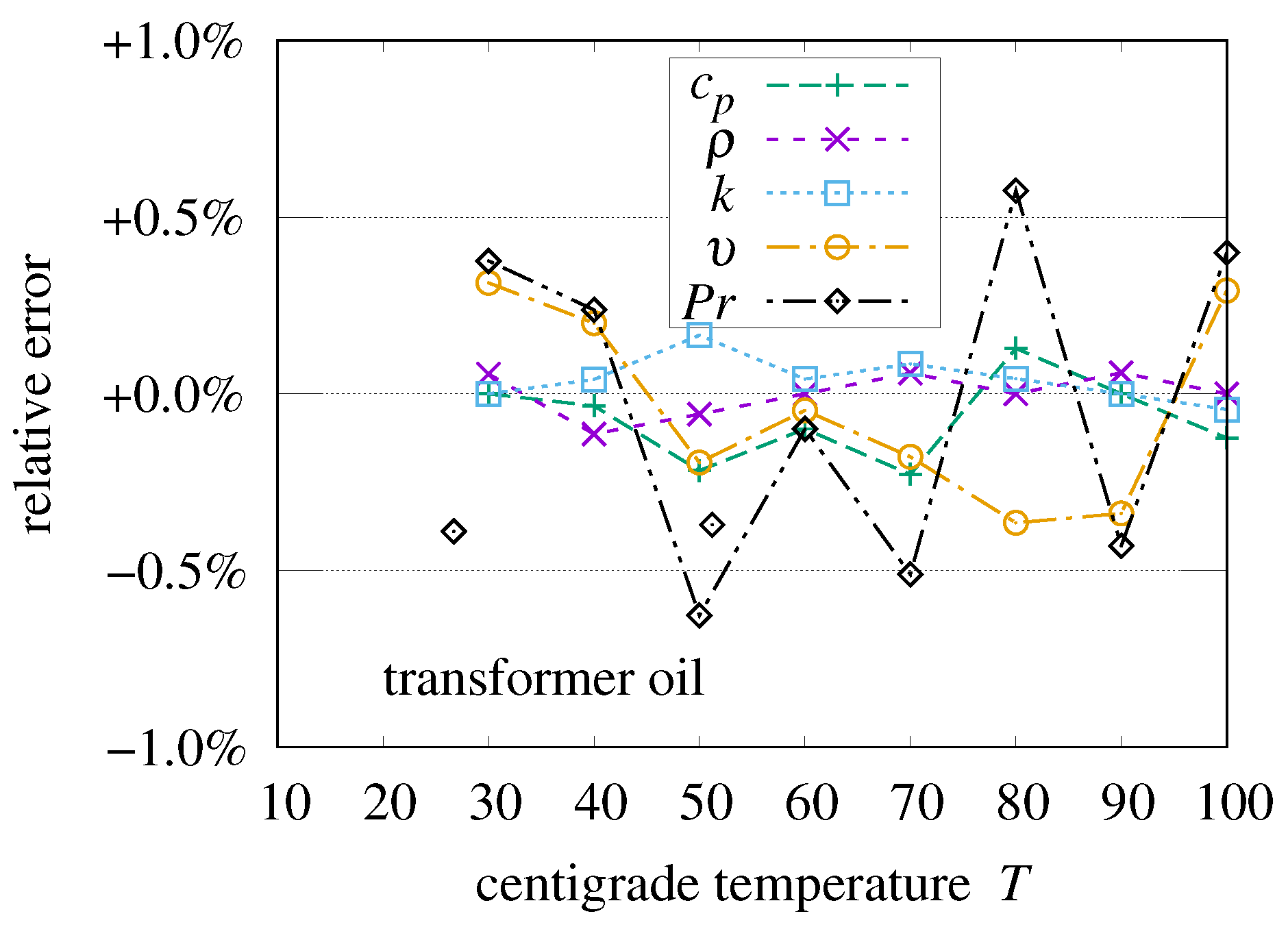

Rough surface convection measurements were obtained from an apparatus built for this investigation, which measured (whole-plate) average convection heat transfer in air at

93,000.

Appendix A describes this apparatus and its measurement methodology.

Section 15 presents its measurements.

The Gebers [

20,

21] skin-friction measurements were captured from a graph in Schlichting [

7] by measuring the distance from each point to the graph’s axes, then scaling to the graph’s units using the “Engauge” software (version 12.1). The remaining measurement data-sets were manually entered from tables in the cited works. Several obvious single-digit typographical errors were corrected.

Two non-obvious single digit errors in the text of a prior work are detailed in

Section 14.

RMS Relative Error

The “±” column of

Table 1 and

Table 2 lists the estimated measurement uncertainties stated by the cited studies. While essential to empirical theories, these estimates are only indicative for non-empirical theories.

Root-mean-squared relative error (RMSRE) provides an objective, quantitative evaluation. It gauges the fit of measurements

to function

, giving each of the

n samples equal weight in Formula (

1).

Along with presenting RMSRE, charts in the present work split RMSRE into the bias and scatter components defined in Formula (

2). The root-sum-squared (RSS) of bias and scatter is RMSRE.

3. Roughness Metrics

Two established, traceable roughness metrics are the root-mean-squared (RMS) height-of-roughness and the arithmetic-mean height-of-roughness. For an elevation function

defined on area

A having a convex perimeter, its mean elevation

and RMS height-of-roughness

are:

The arithmetic-mean height-of-roughness is defined in terms of the same mean elevation

Formula (

3):

3.1. Sand-Roughness

Modeling sand-roughness grains as diameter

spheres sitting in a pool of depth

g glue, the mean elevation

of a cell of area

A containing one sphere is:

With the cell’s RMS height-of-roughness

computed from Formula (

4),

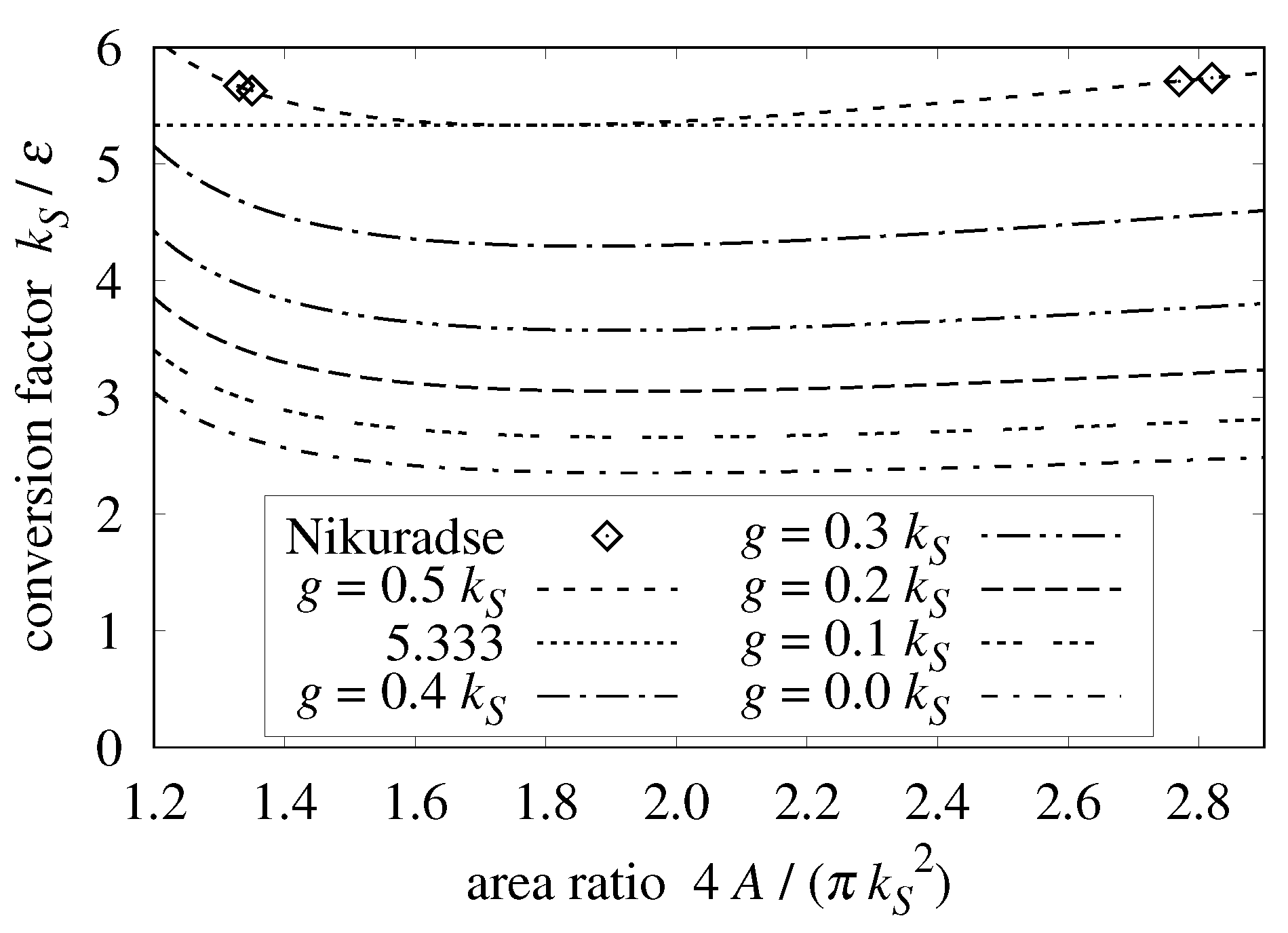

Figure 2 shows

versus the ratio of cell area to the sphere’s shadow area, at six glue-levels between 0% and 50% of

.

Table 3 lists

, grain densities, and

conversion factors for Nikuradse’s [

4] sand coatings, assuming

.

3.2. Conversions

Afzal, Seena, and Bushra [

26] fitted 5.333 as the RMS to sand-roughness conversion factor

, and 6.45 as the arithmetic-mean to sand-roughness conversion factor (both in pipes).

is a broad minimum of the

curve in

Figure 2.

The “

” column values in

Table 3 (“Nikuradse” in

Figure 2) match each other within 2%. The tightest spread on

Table 3 data with the arithmetic-mean height-of-roughness exceeds 20%. Thus, sand-roughness correlates an order of magnitude more strongly with RMS than arithmetic-mean height-of-roughness.

Flack, Schultz, Barros, and Kim [

27] measured skin-friction from grit-blasted surfaces in a duct, writing “The root-mean-square roughness height is shown to be most strongly correlated with the equivalent sand-roughness height (

) for the grit-blasted surfaces”.

3.3. Packed Spheres Roughness

The Pimenta et al. [

8] plate was composed of 11 layers of closely packed 1.27 mm diameter metal spheres “arranged such that the surface has a regular array of hemispherical roughness elements”. Joined by brazing, there was no pool of glue surrounding the spheres. Shrinking the cell to the sphere’s shadow,

, the RMS height-of-roughness of the top half of the 1.27 mm sphere is 0.150 mm. Pimenta et al. gave

;

, which matches 0.150 mm within 1%.

4. Formulas from Prior Works

Several prior works gave formulas for skin-friction coefficient in the fully rough regime.

4.1. Prandtl and Schlichting

In boundary layer theory [

7], Prandtl and Schlichting gave formulas for fully rough local (

) and plate average (

) skin-friction coefficient for a rough plate as a function of

and

, respectively:

4.2. Mills and Hang

Mills and Hang [

9] gave a Formula (

9) which is more accurate than Formula (

7) on the local skin-friction measurements from Pimenta et al. [

8]. Their local (

) and average (

) coefficient formulas were:

4.3. White

White [

10] gave Formula (

11) for fully rough local skin-friction coefficient:

White is also the source of widely used formulas for turbulent skin-friction coefficients of a smooth plate:

4.4. Average Coefficient

Mills and Hang [

9] derived the average Formula (

10) from the local Formula (

9) by fitting a curve to the result of a numerical integration such as Formula (

13):

The local Formulas (

7), (

9), and (

11) each have a singularity where the expression containing the logarithm is 0. The lower limit of integration (

) must be large enough to avoid this; but the lower limit is not revealed in the prior works. The averaging Formula (

13) is quite sensitive to the lower limit because the largest value of the local formula occurs there.

For the Mills–Hang Formula (

9), with lower bound

and initial

, integration of the local

is within

of the average

in Formula (

10) over the range

.

For the Prandtl–Schlichting Formula (

7), with lower bound

and initial

, integration of the local

is within

of the average

in Formula (

8) over the range

.

4.5. Churchill

Churchill [

11] compared eight formulas from diverse sources versus the data from Pimenta et al. [

8], finding none significantly closer to the measurements than the Mills–Hang local Formula (

9).

Section 9 compares the local fully rough regime formulas with measurements from Pimenta et al. [

8].

5. Flow over Obstacles

Jiménez [

14] wrote “In flows with

, the effect of the roughness extends across the boundary layer, and is also variable. There is little left of the original wall-flow dynamics in these flows, which can perhaps be better described as flows over obstacles”.

This investigation focuses first on a case where flow over obstacles dominates the dynamics. It models the shearing stress of flow along a roughness which disrupts that flow at a succession of scales: L, , , , …. While simpler surfaces may produce rough flow, a roughness which disrupts at all these scales surely will.

5.1. Profile Roughness

Simpler than surface roughness, profile roughness is nonetheless informative.

Let a “profile roughness” be a function

with

; its mean elevation

and RMS height-of-roughness

are computed similarly to surface roughness

:

5.2. Self-Similar Profile Roughness

Let a “self-similar profile roughness” be a profile roughness function such that the RMS height-of-roughness of over an open interval is twice the RMS height-of-roughness of over each half of that interval (leaving out the midpoint).

These x intervals are open (not containing the endpoints); the value for each endpoint contributes to the height-of-roughness of its parent interval, but not to any sub-interval. This definition is designed so that will have the following property:

5.3. Ramp Permutation

An additional constraint is needed to reduce the uncountable variety of possible functions to a manageable number. Experience with self-similar curves suggests a restriction to profile roughnesses, which are permutations of the linear ramp with . Each elevation from 0 to peak height occurs exactly once.

The only occurrence of

x in Formulas (

14) and (

15) is

; hence, the RMS height-of-roughness calculation depends only on the

z values, not on their relation to

x. Thus, the height-of-roughness of any ramp-permutation is identical to the height-of-roughness of the linear ramp:

5.4. Self-Similar Ramp Permutation

A self-similar integer sequence from integers allows self-similar behavior to be explored with a finite approximation. Letting constructs a profile roughness from a sequence by .

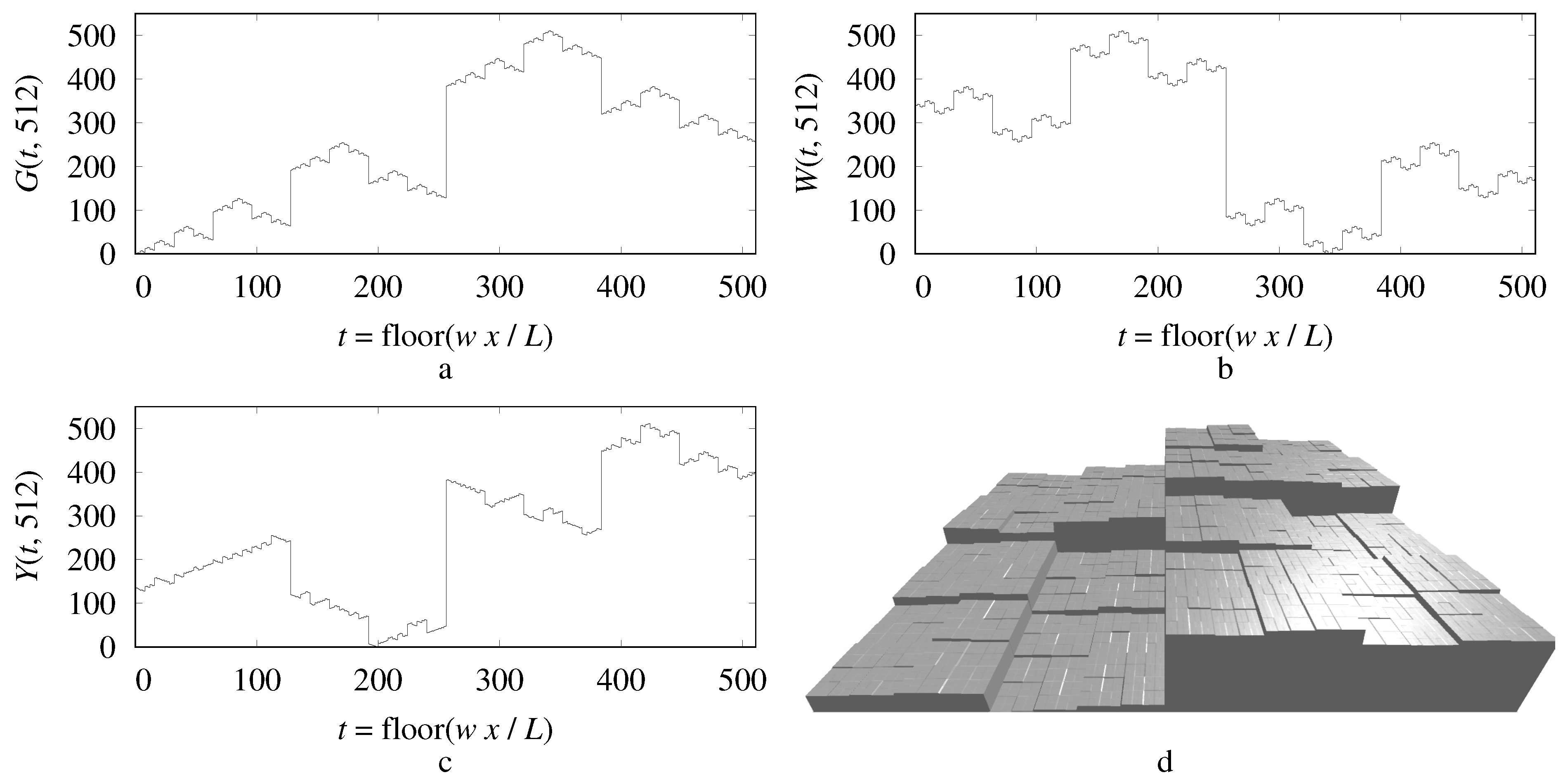

The following three examples are self-similar ramp-permutation sequences. Each element of the sequence is generated by calling its recurrence function with a sequence index and w, an integer power of 2. Each recursive call divides w by 2, terminating (and returning) when w reaches 1.

Self-similar recurrence (

17) defines the integer Gray-code sequence

shown in

Figure 3a.

Recurrence (

18) defines the integer sequence

shown in

Figure 3b; it reverses direction at each bifurcation, yielding a wiggliest-possible self-similar ramp-permutation sequence.

Figure 3c shows a sequence generated by randomly reversing or not at each bifurcation in recurrence (

19).

Figure 3d shows a random reversal, self-similar, ramp-permutation surface roughness.

5.5. Cardinality

The goal is to characterize self-similar roughnesses in general. The theory should work for the vast majority of self-similar roughness functions, with few outliers. For a given number of points , there are distinct self-similar ramp-permutation sequences, of which there are only two distinct ramps and two distinct wiggliest sequences.

5.6. Friction Travel and Velocity

When the fluid flow encounters roughness, some particles of fluid must move in directions not parallel to the bulk flow. Such movement results from deflections of flow by roughness peaks, pits, ridges, and valleys; the extent of deflections should grow with the RMS height-of-roughness.

Let “run” be the horizontal axis and “friction” be the vertical axis of a profile roughness such as in

Figure 3c. For an integer ramp-permutation sequence

, the sum of the (dimensionless) lengths of all its run segments is simply

. The sum of its friction segment lengths is:

If a particle of fluid traces the ramp-permutation sequence

between

and

, then

is the run travel, while Formula (

20) is the friction travel.

Figure 4 shows the friction per run travel ratio versus

. The linear ramp trace has slope 0; the Gray-code trace has slope 1/2; the random reversal cases have slope of approximately 1/2; and the wiggliest roughness trace has slope 2/3.

5.7. Roughness Sequence Outliers

A wiggliest roughness sequence is an extreme case; it reverses friction direction at each increment of run (t). For each wiggliest roughness sequence with there are other random reversal roughness sequences. In contrast, the linear ramp never reverses direction. For each linear ramp sequence there are other random reversal sequences.

5.8. Dimensional Analysis

Excluding the outliers,

Figure 4’s friction per run ratios are about:

,

t, and

w are dimensionless. The friction per run ratio (

21) needs to be reformulated in terms of

and

L, which have length units. Turning to dimensional analysis, the argument to

must be dimensionless, involve

, and be greater than 1, so that the logarithm will be positive. This friction per run ratio must increase with increasing

. Thus,

and the logarithm will be in denominators, yielding:

Scaling Formula (

22) by

from Formula (

16) converts it into the RMS friction per run travel ratio:

Considering the run travel and friction travel with respect to time lets Formula (

23) also serve as the friction velocity per bulk fluid velocity ratio:

.

5.9. Isotropy

Fluid particles stay within the vertical plane of profile roughness. Surface roughness deflects particles in all directions. Therefore, this investigation will use

instead of

and restrict its attention to “isotropic” roughness, where rotating the flow azimuth (direction) in the plane of the rough surface does not substantially affect its behavior.

Section 8 develops a decision procedure for roughness isotropy.

The friction-to-run-length ratio should not be tied only to ramp-permutations based on successive halving. Instead, use the expected value of a continuous random variable

having a Pareto distribution whose probability density function is

:

5.10. Shearing Stress

The skin-friction coefficient

is the ratio of the shearing stress

per the fluid flow’s dynamic pressure (kinetic energy density)

, where

is the fluid’s density:

Both

and

have units of pressure,

. From Formula (

24):

Eliminating

from Formulas (

25) and (

26) yields the average skin-friction coefficient of an isotropic, self-similar roughness:

Note that Prandtl and Schlichting [

3] calculated

, not

. As a result,

and

. Pimenta et al. [

8] and Mills and Hang [

9] designated

as the friction coefficient.

6. Turbulent Friction

Formula (

27) is not defined for

, a smooth plate.

Given there must be an ratio so large that a length L plate with a self-similar roughness of RMS height induces skin-friction midway between that of a rough surface and that of a smooth surface.

6.1. Roughness Reynolds Number

Let the “roughness Reynolds number”

derive from friction velocity

at scale

:

where

is the fluid’s kinematic viscosity (with units

) and

. The

strength at which rough plate friction transitions to smooth plate friction should have the same

value at all

.

when

. Combining

with Formula (

28) relates

and

at transition:

This link between

and

suggests that the turbulent friction coefficient

can be inferred by combining Formulas (

27) and (

29). However, there being no roughness on a smooth plate, the coefficients must be different from

Formula (

27). Scaling

by

, and its argument by

:

Euler’s number

is a fixed point of

, which appears in Formula (

32). The etiology of

is unclear, but the present work’s tiny

bias in

Section 6.3 makes mere coincidence unlikely.

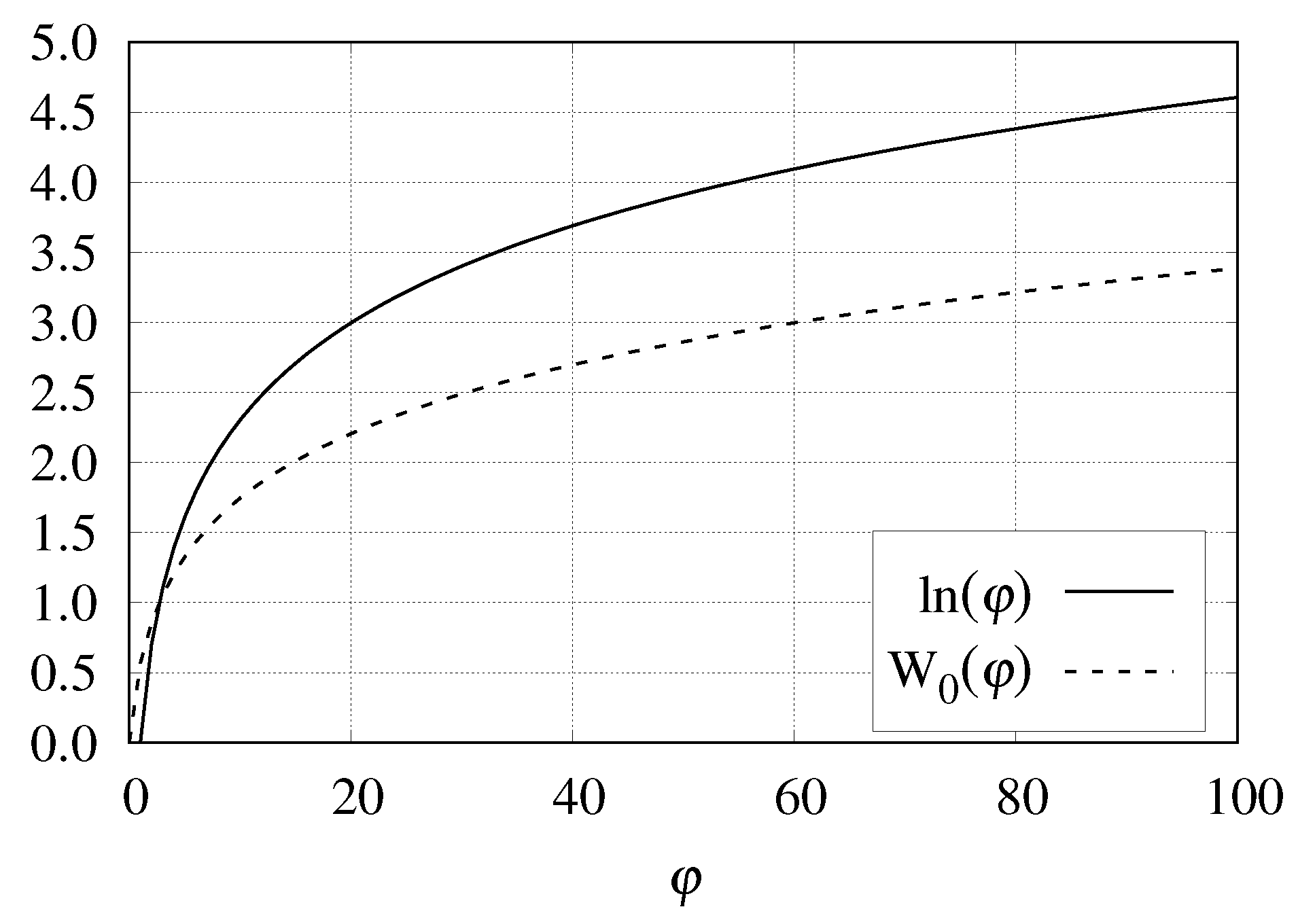

6.2. Lambert Function

The (natural) logarithm function ln is the inverse of

. Similarly, the Lambert

function is the inverse of

.

can be eliminated from Formulas (

29) and (

30) using the Lambert

function’s principal branch

, which is defined by equivalence (

31) and plotted in

Figure 6.

The related equivalence (

32) acting on Formula (

29) lets

replace

in Formula (

30) when

.

6.3. Comparison with Measurements

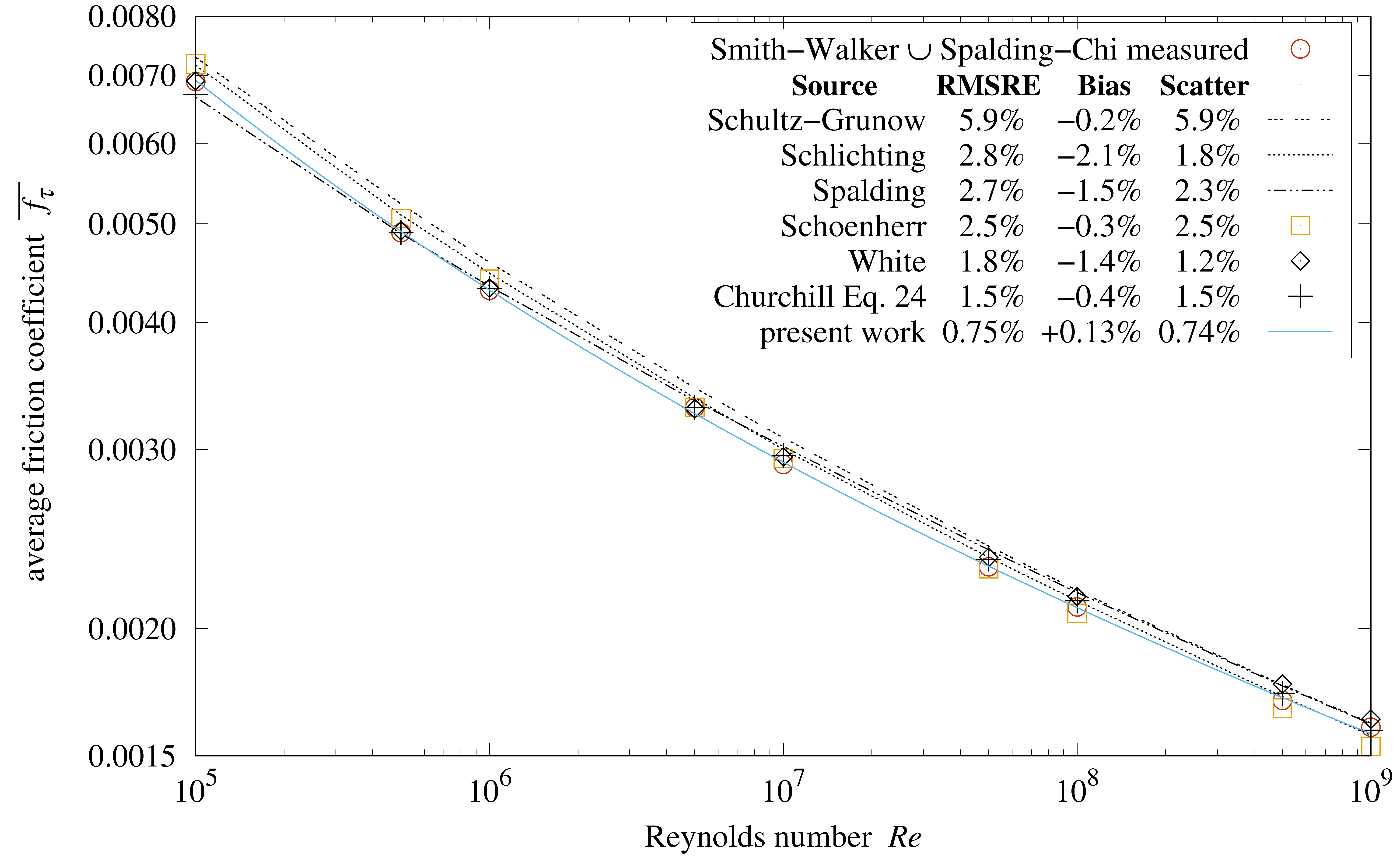

Churchill [

11] compared turbulent friction formulas from multiple studies with measurements from Smith and Walker [

22], and Spalding and Chi [

23].

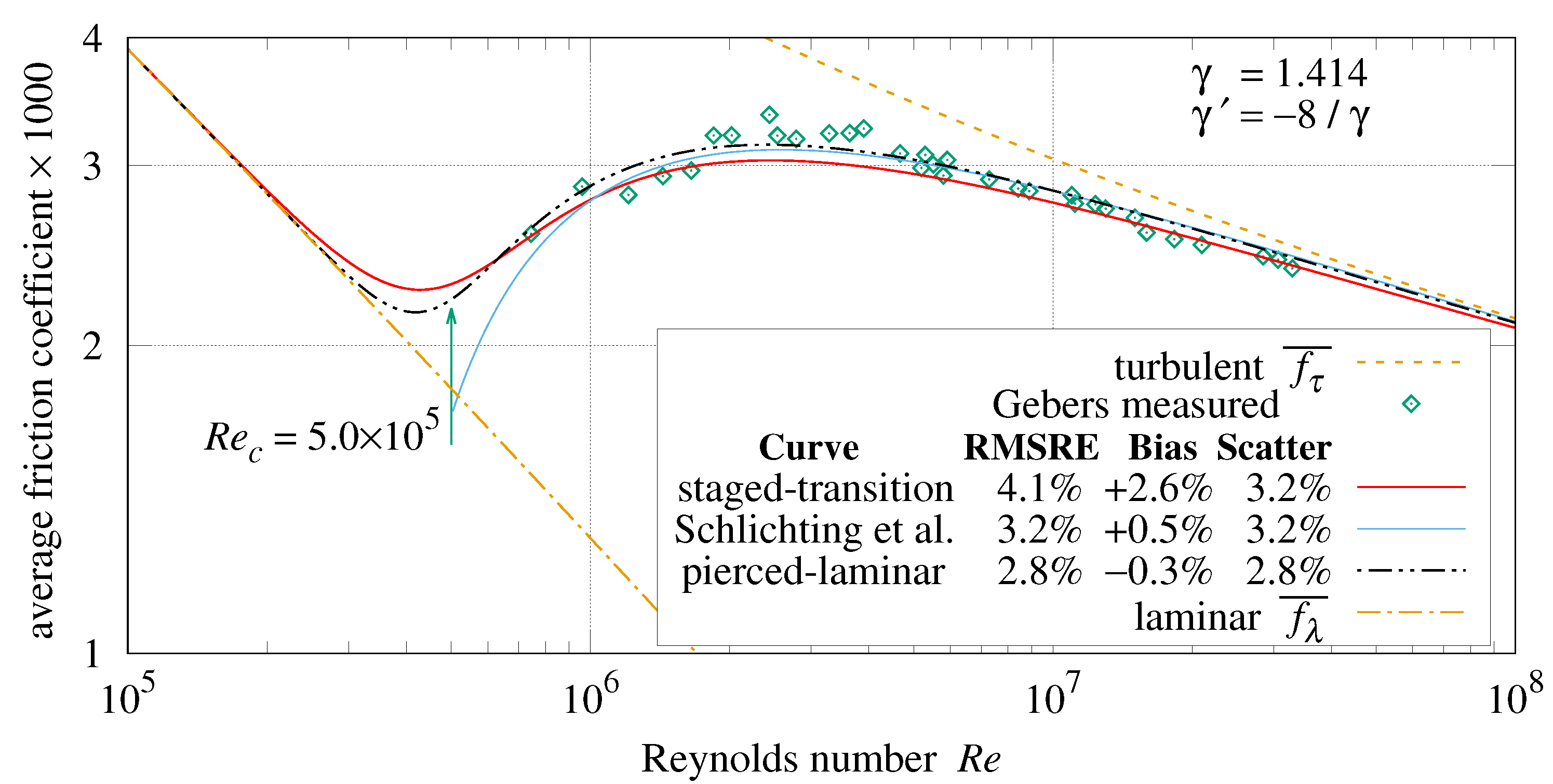

Figure 7 plots them and

Formula (

33); the key gives the RMS error of the measurements relative to each formula (RMSRE was introduced in

Section 2).

With 0.75% RMSRE,

Formula (

33) has less error than any formula evaluated by Churchill.

7. Spectral Roughness

Several prior works [

4,

5,

6,

9,

12] use the term “uniform roughness” to describe sand-roughness, implying that its height-of-roughness is the same at all scales. This concept of uniform roughness is incompatible with self-similarity; the RMS height-of-roughness of a portion of a self-similar surface must shrink with its succession of scales.

Sand-roughness can be described as “repeated roughness”. However, a roughness composed of parallel rows of 1000 sand grains spanning its length can also be described as having 500 sand grain pairs spanning its length. An unambiguous method for determining the spatial period is needed.

7.1. Discrete Fourier Transform

The discrete Fourier transform (

34) converts a series of equally spaced samples of a function into a complex-number coefficient

for each of its harmonic sinusoidal components:

A complex number consists of two real numbers as , where ; b is called the imaginary part. The amplitude of , written .

There is a profound connection between

and the RMS height-of-roughness

:

because all the elevations have imaginary parts ; hence there are distinct ; only needs to be considered in the developments which follow.

7.2. Dominant Component of Roughness

The

term, the mean value of

, is the only

term not included in the Formula (

35) sum for

. Hence, the dominant component of roughness will be the

(

) having the largest amplitude.

Let the “period index” be the nonzero index j of the having the largest amplitude .

When one is dominant, is well-defined and the profile roughness’s spatial period is .

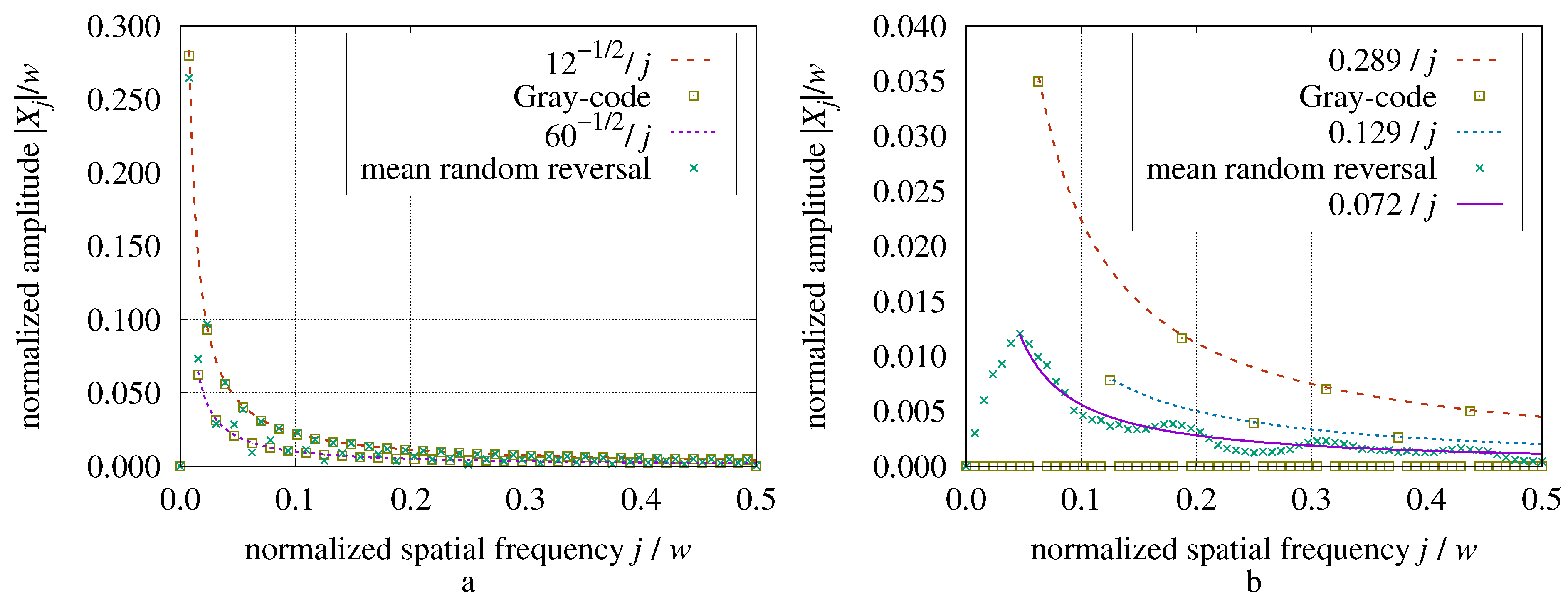

Figure 8a shows the

amplitude spectrum of the Gray-code profile roughness from

Figure 3a, as well as the mean Fourier spectrum amplitudes from 187 instances of 128-point random reversal profiles (

). For both spectra,

has the largest amplitude; thus

, indicating that neither spectrum is from repeated roughness.

Figure 8b shows the spectrum of eight concatenated repetitions of a Gray-code sequence, as well as the mean Fourier spectrum amplitudes from 187 instances of eight concatenated random reversal sequences. The period index

of the Gray-code eighths is 8, as expected; but the random reversal sequences have

because their amplitudes are not correlated between the random eighths.

This use of the discrete Fourier transform was able to determine the spatial period of profile roughness.

Section 8 generalizes this spatial period metric to isotropic surface roughness.

8. Periodic Roughness

Let a “periodic roughness” be a flat surface tiled with many isotropic, uniformly sized patches, all sharing the same mean elevation and RMS height-of-roughness .

The mean elevation and RMS height-of-roughness of the entire surface will therefore be and .

8.1. Discrete Spatial Fourier Transform

Let

be a

matrix of mean elevations from a

square grid of an

region of a rough surface. Its two-dimensional discrete spatial Fourier transform is:

Let the two-dimensional period index , where and are the indexes of the coefficient having the largest amplitude, excluding .

The two-dimensional spatial period .

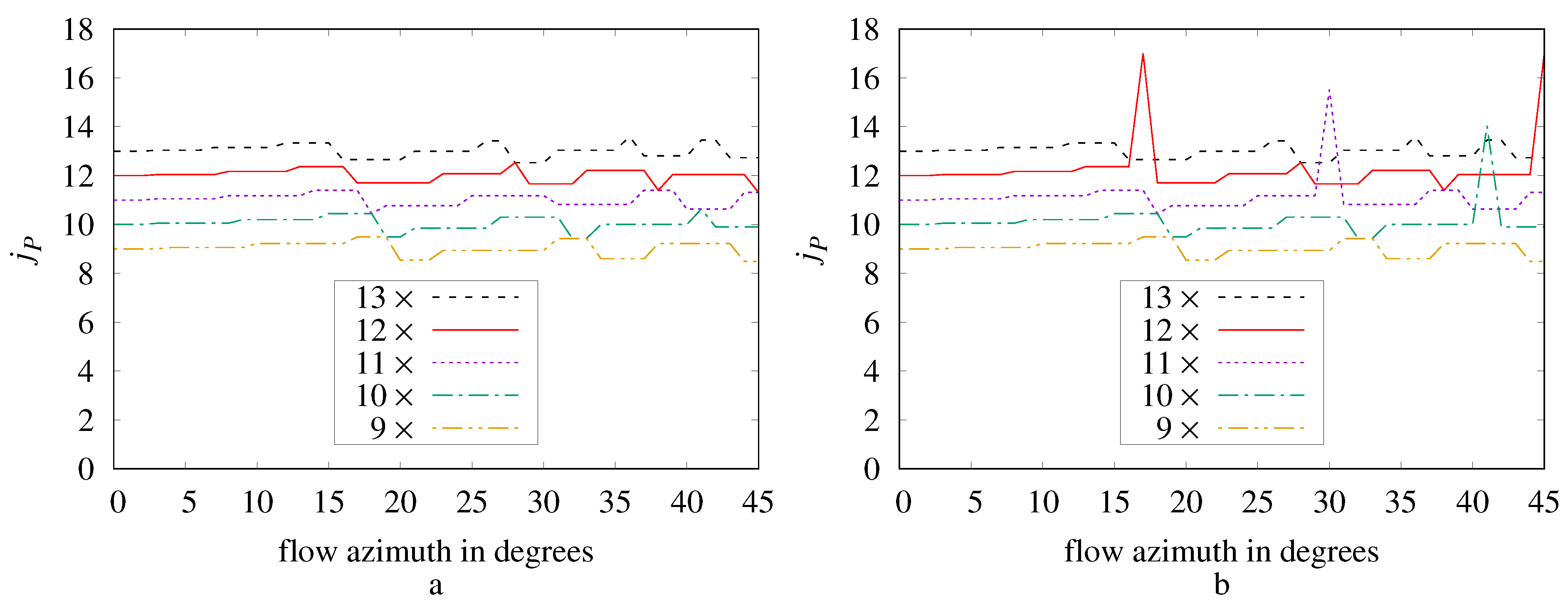

Figure 9a shows the

values of a square equal-area bi-level surface (regular array of square posts on a flat plate) computing

from a

interpolated sampling of that surface with azimuth from

through

, and which is scaled between 9 and 13 cells per side. At each scale,

varies within a

range as the azimuth is rotated.

Figure 9b shows

values of a 25% high, 75% low, bi-level surface; some of its

traces have peaks outside of the

range. This suggests a quantitative criterion for surface roughness isotropy:

A surface roughness is isotropic if varies no more than through its full flow azimuth rotation.

More specifically, using () samplings of roughness at nine scales over a 2:1 range such that most of the calculated values satisfy at each scale, we carry out 56 sampling trials with randomized offset and randomized azimuth rotation per scale. A roughness is considered isotropic if no more than 5 of the trials have varying more than from its scale.

8.2. Exploring Isotropy

Tests of this criterion applied to interpolated samplings found the following roughnesses to be isotropic:

Square arrays of aligned square posts having an upper area fraction between 27% and 76%;

Square arrays of circular columns having an upper area fraction between 24% and 78%;

Hexagonal arrays of circular columns having an upper area fraction between 6% and 75%;

Hexagonal arrays of circular wells (depressions) having an upper area fraction between 25% and 94%;

Hexagonal arrays of aligned square posts having an upper area fraction between 4% and 49%;

Hexagonal arrays of aligned square wells having an upper area fraction between 51% and 96%;

15% elongated hexagonal arrays of cone or bump protrusions described in Schlichting [

5].

8.3. Visual Isotropy

This isotropy test is not equivalent to the visual appearance of isotropy. Square post arrays having upper area fractions of 20% fail the isotropy test, while those with 30% pass. Plates from Schlichting [

5] having elongated hexagonal arrays of cones are not visually isotropic, yet pass the test.

9. Local Skin-Friction Coefficients

Conversions between local and average skin-friction are needed in order to compare prior work with the present work.

9.1. Continuous Local to Average Skin-Friction

The ratio of average to local skin-friction

of a continuous boundary layer is calculated from

by Formula (

37). Using

as the integration lower-bound avoids the division-by-zero singularity at the leading edge of the plate.

The Blasius laminar model in Schlichting [

7] derives the local drag coefficient:

Applying transform (

37) to Formula (

38) and factoring the denominator produces a novel formula for the average laminar friction coefficient that lacks the leading-edge singularity:

Lienhard and Lienhard [

16] estimates

, leading to

.

9.2. Disrupted Local to Average Skin-Friction

The local skin-friction coefficient is not well-defined for self-similar roughness because of its constant . Periodic roughness has varying ; conveniently, it also provides as the lower-bound of integration.

A crucial distinction between periodic roughness and smooth surfaces is that periodic roughness disrupts the boundary layer repeatedly. Thus, the local skin-friction coefficients being averaged are independent. Instead of

scaling linearly, it should scale as the square:

Applying Formula (

40) to the Mills–Hang local Formula (

9) yields the average skin-friction coefficient:

where

and

are from Equations (

9) and (

10), respectively.

9.3. Average Formulas from Prior Work

Figure 10 compares fully rough regime average skin-friction formulas with

Formula (

27). To the right of each “

” is the maximum discrepancy from

over the Mills–Hang range

, which is

14,666. The Mills–Hang range boundaries are marked by red arrows in

Figure 10.

Note that

Section 12 establishes that

Formula (

27) applies to sand-roughness.

“

” is 1/2 of Formula (

41), the disrupted boundary layer averaging Formula (

40) applied to the Mills–Hang local Formula (

9); it matches

within

.

“

” is 1/2 of the Prandtl–Schlichting average Formula (

8).

“

” is 1/2 of the Mills–Hang average Formula (

10).

9.4. Disrupted Average to Local Skin-Friction

For disrupted boundary layers, the transform for local friction

given average friction

is:

Applying Formula (

42) to

Formula (

27) with

yields the local friction coefficient:

9.5. Local Formulas from Prior Work

Figure 11a plots the local friction coefficients from White (

11), Prandtl–Schlichting (

7), Mills–Hang (

9), and the present work’s

Formula (

43).

Mills–Hang matches

Formula (

43) within 3.1% over

.

9.6. Comparison with Local Drag Measurements

The points labeled “

” in

Figure 11a show the local drag coefficient measurements versus

for the sphere-roughened plate at three rates of flow.

Table 4 presents RMSRE of this set of 19 measurements to each of the rough regime formulas.

Formula (

62) calculates

from the

and

values supplied by Pimenta et al. [

8].

Figure 11b plots local

versus

for the sphere-roughened plate.

These measurements have an RMSRE of

from

Formula (

43).

9.7. Continuous Average to Local Skin-Friction

For continuous boundary layers, the transform for local friction

given average friction

is:

The local skin-friction coefficient for turbulent flow

can be derived from

Equation (

33), Formula (

44), and

identity (

45), provided that

and

:

9.8. Comparison with Local Measurements

Table 5 compares measurements at

made by Smith and Walker [

22] and Spalding and Chi [

23] with “present work” Formula (

46) and formulas collected by Churchill [

11].

When calculating RMSRE, the error due to the variation in a single sample tends to be larger than the error when that variation is distributed among multiple samples. Thus, local measurements tend to have a larger RMSRE than average measurements do. Other than “Churchill Equation (

18)”, this is the case when comparing

Table 5 with

Figure 7.

The Churchill local data-set has 1.9% RMSRE versus “present work” Formula (

46).

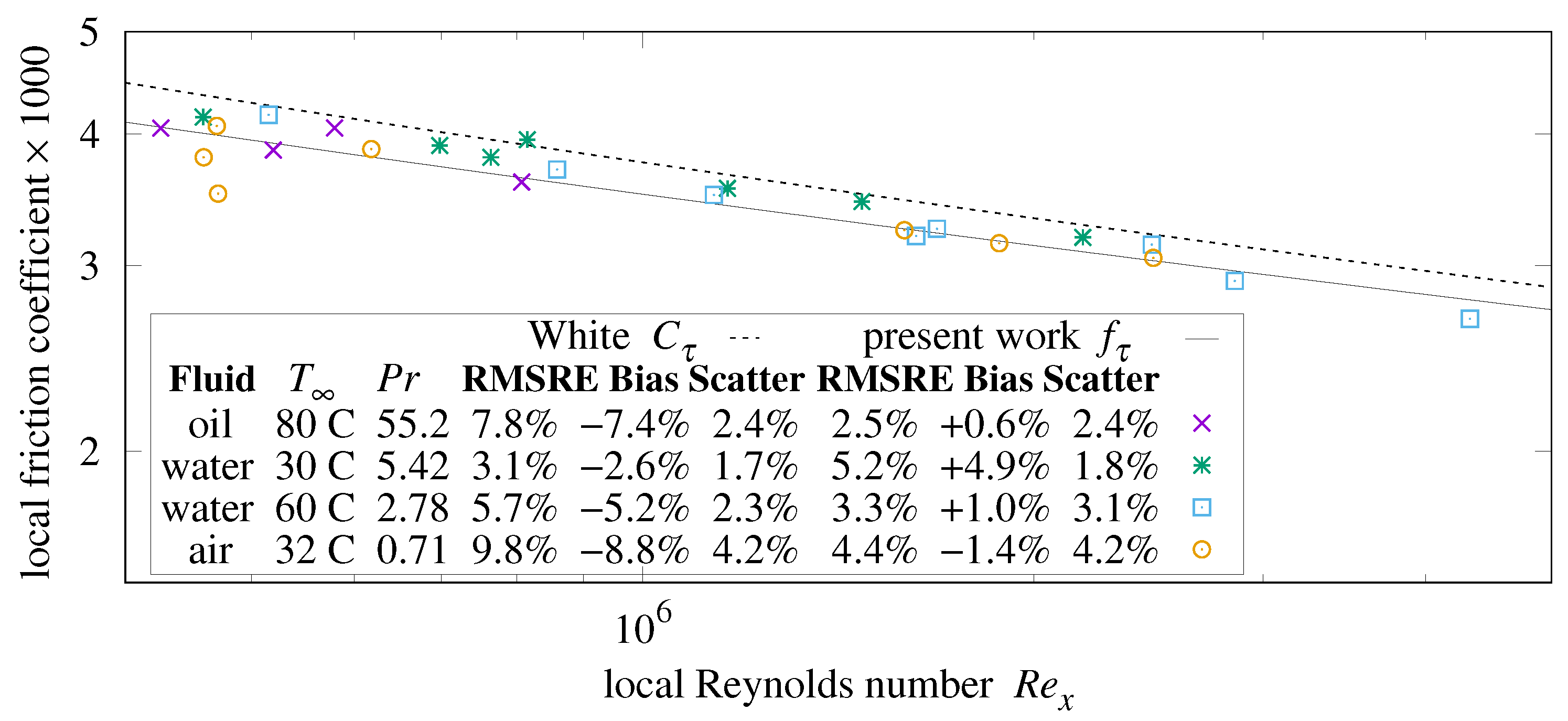

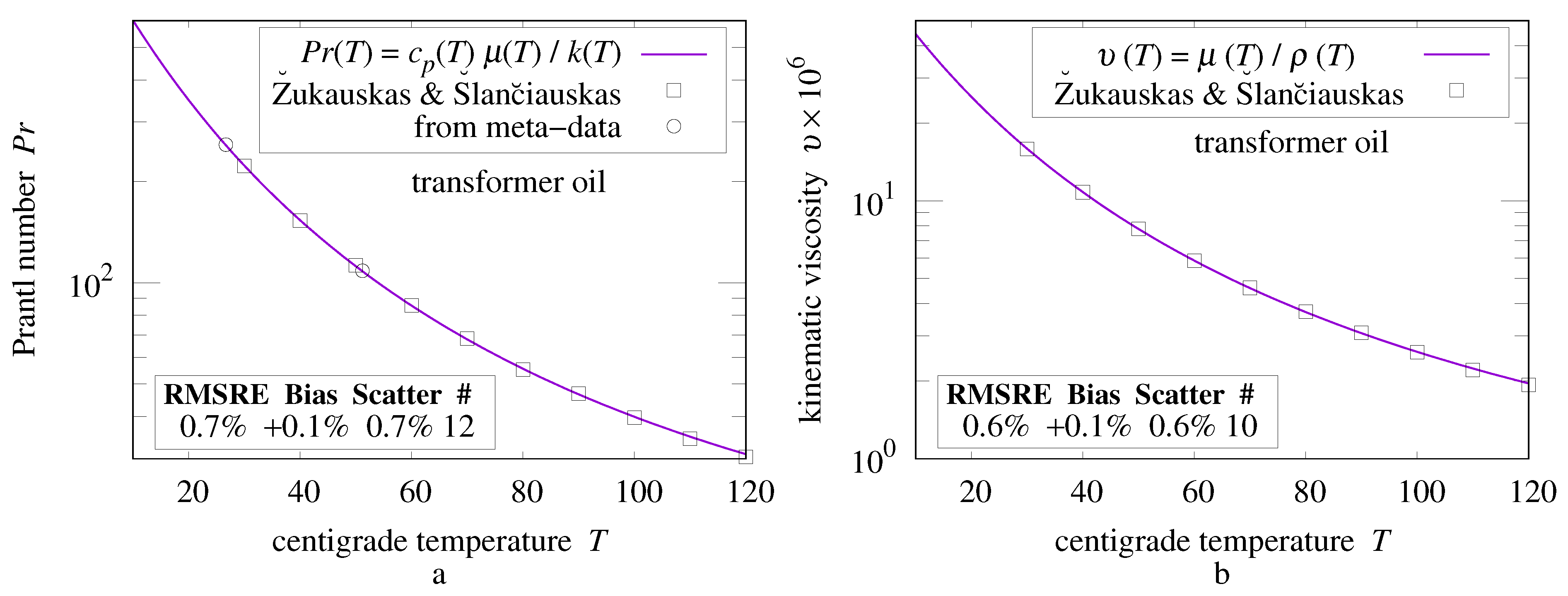

9.9. Skin-Friction in Liquids

Figure 12 compares

Formula (

46) with skin-friction measurements in several fluids from Žukauskas and Šlančiauskas [

18].

A fluid’s Prandtl number () is its kinetic viscosity per thermal diffusivity ratio. Fluids with transport heat primarily via fluid flow; conduction dominates heat transfer in fluids with .

10. Forced Convection

Forced convective heat transfer is expressed as the (dimensionless) average Nusselt number , where k is the fluid’s thermal conductivity () and is the plate’s average convective surface conductance in that fluid (). The local version, , has the same units.

10.1. Rough Plate

The disruption which transfers momentum can also transfer heat. Hence, heat transfer will grow with .

Jaffer [

28] finds that the natural convection boundary layer of an upward-facing plate is disrupted by collision of the flows and their detachment from the plate’s center; the other plate orientations have continuous boundary layers. Boundary layer disruption being the essence of rough flow, this investigation proposes that heat transfer grows with the same

dependence as upward-facing natural convection.

Fluid heating by the leading part of the plate reduces heat transfer from the trailing part; hence, heat transfer is scaled by 1/2. Expanding

from Equation (

27) yields Formula (

47) for rough average forced convection heat transfer, provided that

and

:

The present analysis for self-similar

did not involve continuous boundary layers; hence, it avoids the

restriction affecting Formula (

48). Formula (

47) is compared with measurements in

Section 15.

10.2. Smooth Plate

For turbulent convection, Lienhard [

29] recommends composing the Gnielinski Formula (

48) with the White

Formula (

12), subject to

:

Lienhard states that

Formula (

49) has similar accuracy for gases with

:

Smooth plate forced convection is similar to natural convection from a vertical plate; in both, fluid flows parallel to the plate’s characteristic length axis, and is uniform across the plate’s other axis. Jaffer [

28] finds that stationary fluid conducts heat from the vertical plate with an effective Nusselt number

;

is a coefficient factor of both the static and flow-induced heat transfer terms.

Flow-induced heat transfer grows with

. Because this heat traverses boundary layers, the

dependence is more complex than

. In Jaffer [

28], the vertical-plate natural convection dependence is

, where

is defined using

-norm (discussed in

Section 13) Formula (

51) with

:

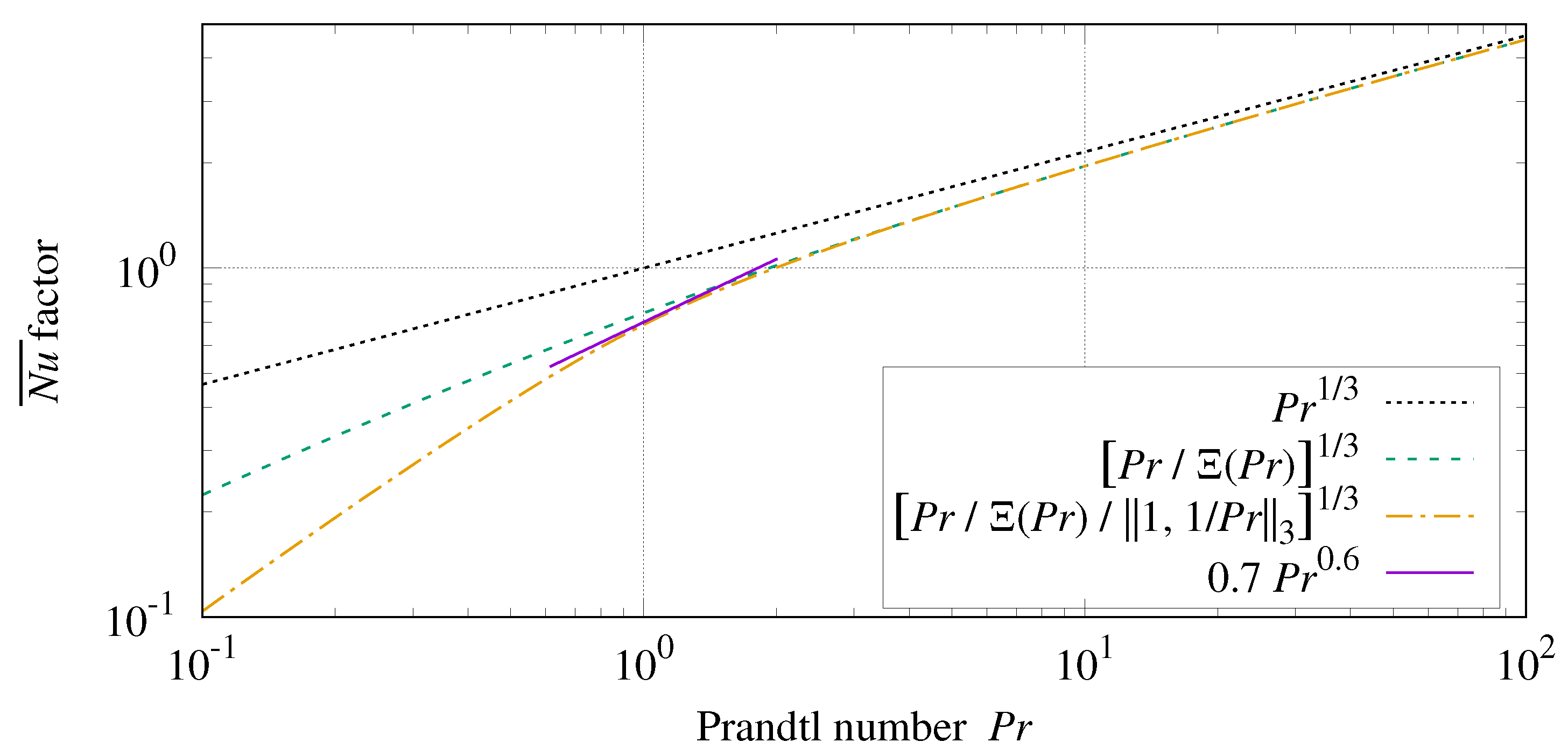

In

Figure 13,

is asymptotically

at large

, and

at small

. At small

, conduction does not amplify forced convection as it does for natural convection; the

exponent should be 1. An additional factor using the

-norm accomplishes this. Formula (

53) is asymptotically

when

. The “

” trace shows that Formula (

53) has a slope close to Formulas (

49) and (

50) for gases.

The slope of Formula (

48)

decreases with increasing

; at large

,

is proportional to

(

). Recall from Equations (

25) and (

26) that

; hence

. This indicates that transport through the boundary layer restricts heat transfer at large

. In order to reduce the asymptotic dependence from

to

, the convection formula will include a factor which takes the square-root of an expression gating

by

:

Note that 12.7 is a coefficient in the Gnielinski Formula (

48).

The scaling for upstream heating was 1/2 in

Formula (

47) for disruptive roughness; the turbulent boundary layer reduces this interaction;

appears correct in the smooth case.

Formula (

55) is proposed for turbulent convection for all

and

:

10.3. Performance

Section 16 compares

Formula (

55) with measurements over a wide range of

.

Lienhard [

29] compares the Gnielinski–White convection formula with local measurements from studies of fluids with

spanning

. The smallest turbulent

was ≈

. Gas Formula (

49) is more accurate than Gnielinski–White for turbulent air (

) at

.

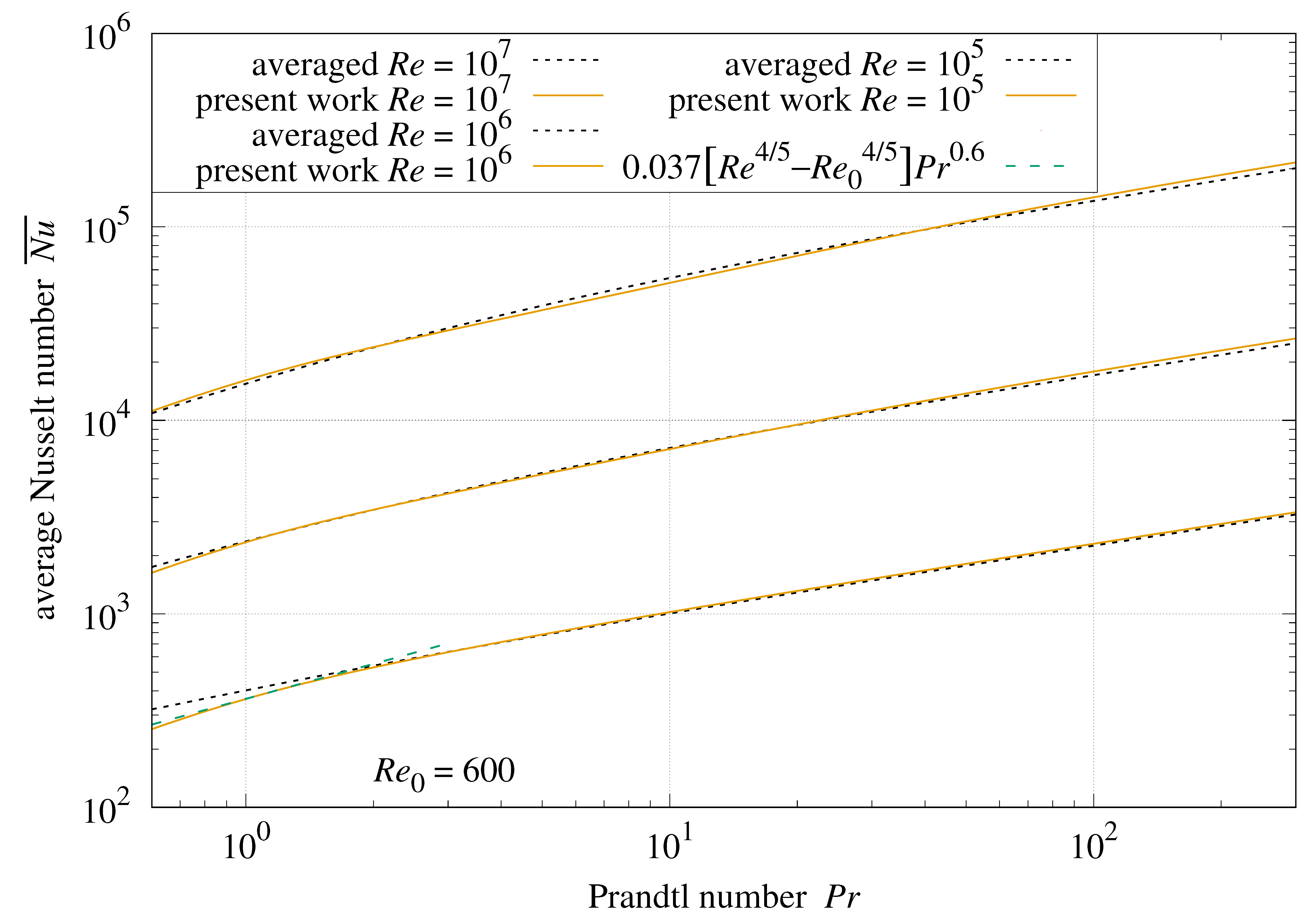

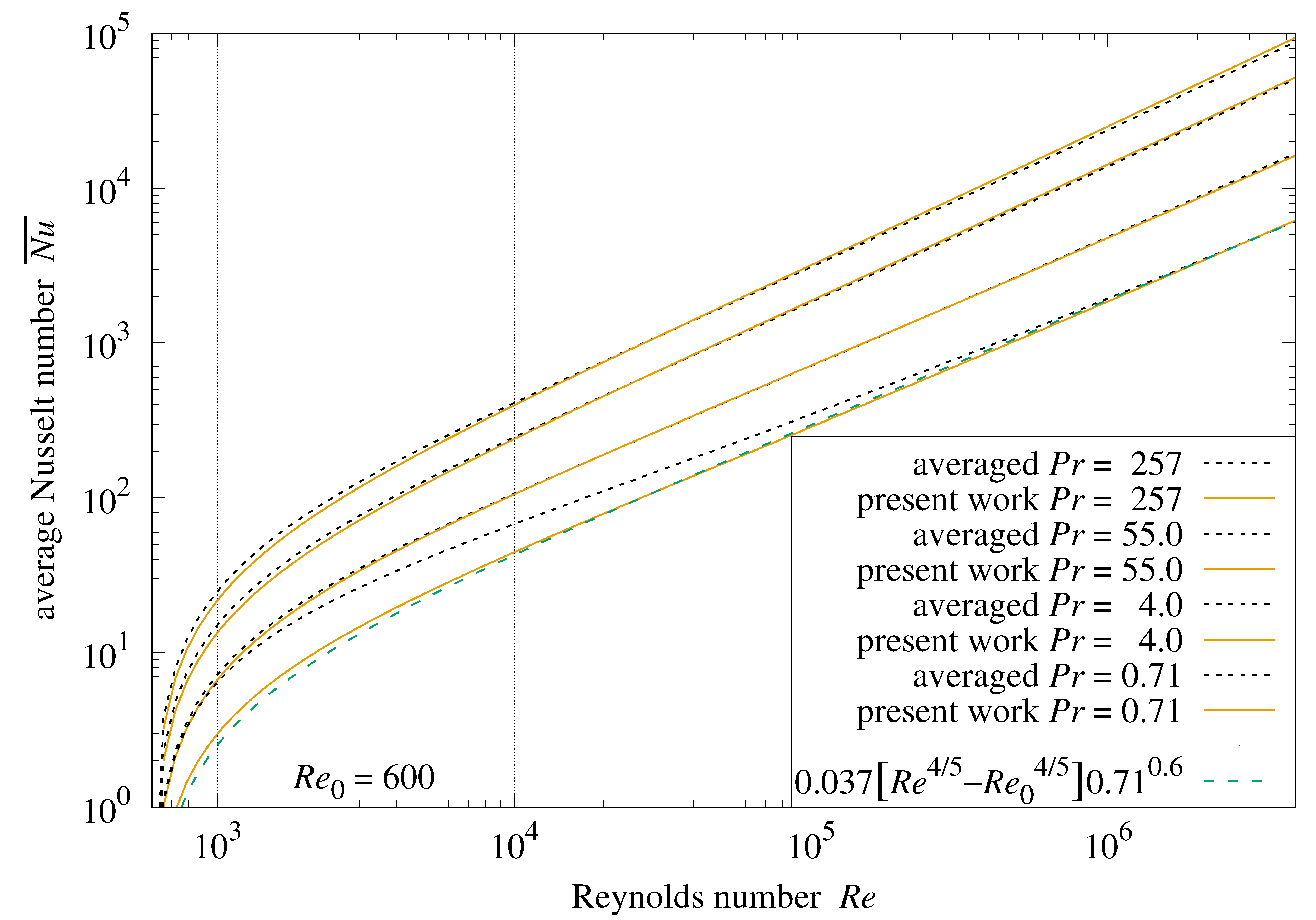

Figure 14 and

Figure 15 show

versus

and

, respectively. The “present work” traces are Formula (

55). The “averaged” traces use Formula (

56) to numerically average the composition of the Gnielinski Formula (

48) with the White Formula (

12).

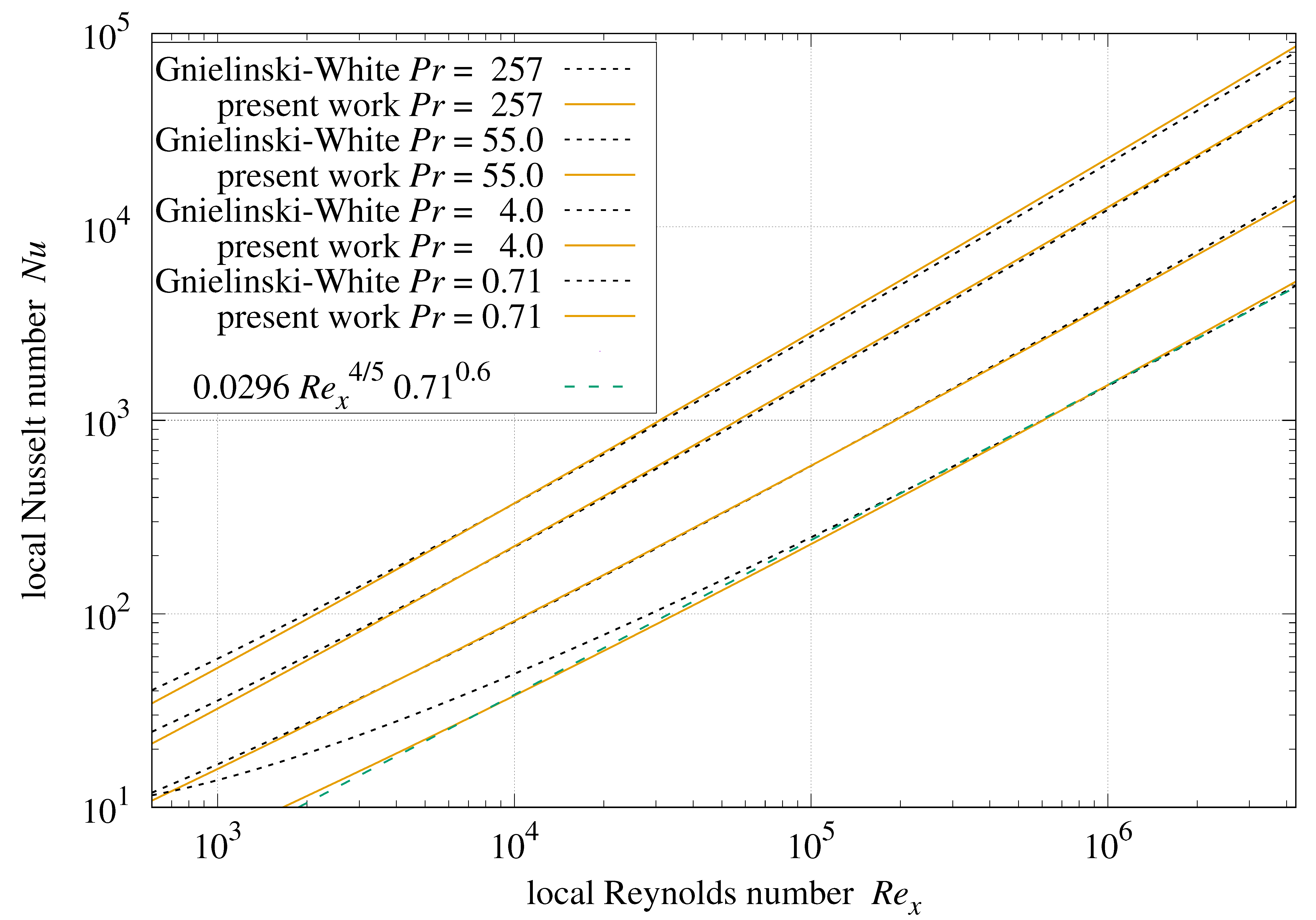

Figure 16 shows the Gnielinski Formula (

48) and local convection

Formula (

57) versus

.

Formula (

55) matches the numerically averaged Gnielinski–White formula within

over the range

with

.

At

,

matches gases Formula (

50) within

over the range

.

Over the same ranges, local convection

Formula (

57) matches Formulas (

48) and (

49) within

.

10.4. Laminar Forced Convection

Formula (

58) is the Reynolds–Colburn [

30] analogy relating laminar friction to forced convective heat transfer. Applying it to

Formula (

39), and scaling by the reduction in characteristic length due to an unheated starting band

, yields the laminar forced convection Formula (

59) given

,

, and

.

Section 16 tests

Formula (

55) and

Formula (

59) extensively.

11. Onset of Rough Flow

For an isotropic, periodic roughness with , there must be some value such that when , there is only laminar or turbulent fluid flow along the plate.

The boundary layer is thinnest at the leading edge. For isotropic, periodic roughness, any disruption will start within the leading band () of roughness. This investigation considers a boundary layer disrupted when , where is the boundary layer momentum thickness at x.

11.1. Momentum Thickness

is the thickness of bulk flow having the same momentum flow rate as the plate’s boundary layer at

x.

is not directly measurable. Schlichting [

7] gives the momentum thickness of laminar and turbulent boundary layers as Formulas (

60) and (

61), respectively:

Laminar derives from the Blasius boundary layer model. Turbulent is less certain.

Momentum thickness

is a local property of the fluid flow. In order to work locally with

Formula (

28), change

and

; then solve

for

:

is proportional to

x (

); hence, the turbulent momentum thickness

should be proportional to the product of

x and

Formula (

24). Eliminating

using Formula (

62):

The proposed Formula (

64) coefficient is

, which may relate to

.

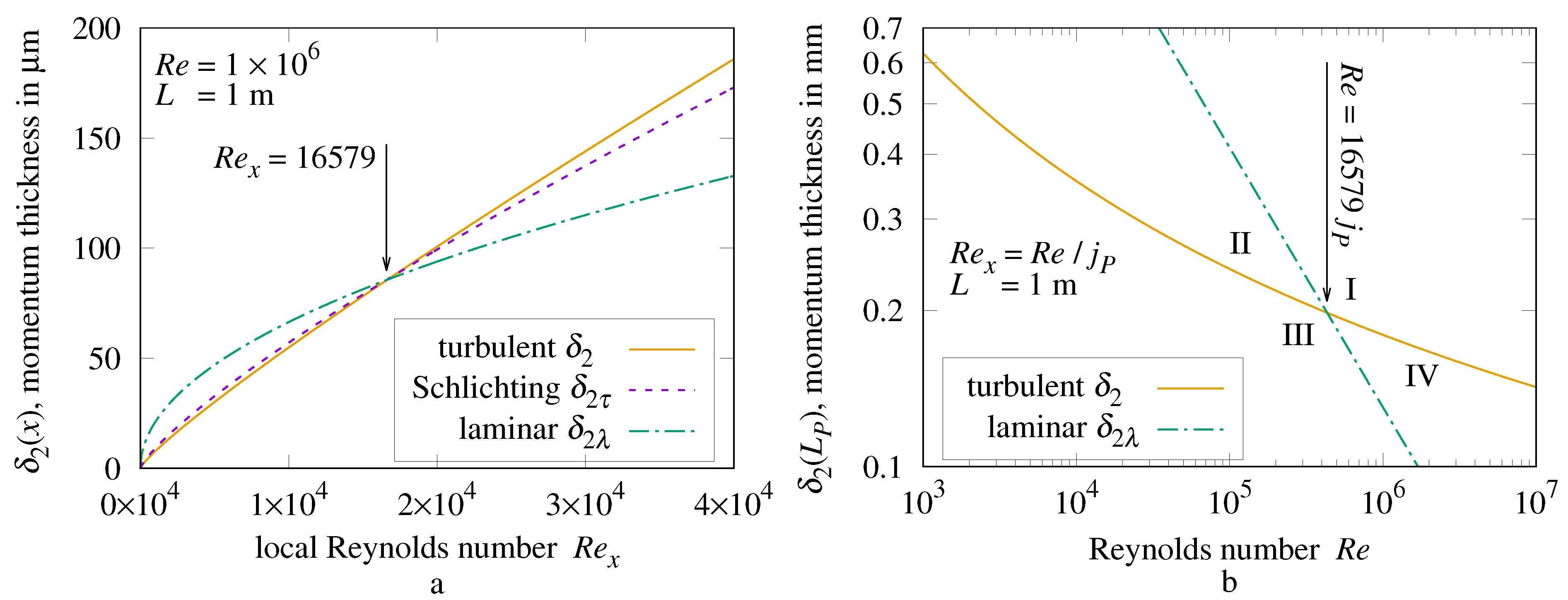

Figure 17a demonstrates that “turbulent

” Formula (

64) and “Schlichting

” Formula (

61) nearly match between the origin and the intersection of the laminar and turbulent curves at:

11.2. Flow Mode Bounds

Figure 17b shows the leading band momentum thickness of laminar and turbulent flows along a 1 m long plate versus

. The intersecting laminar

and turbulent

curves partition the graph into four regions labeled I, II, III, and IV.

When the point at coordinates is in region I, the roughness is sufficient to disrupt both laminar and turbulent flow; hence, the leading band fluid flow will be rough.

When is in regions II or III, the roughness is not large enough to significantly disrupt laminar flow; hence, the leading band fluid flow will be laminar, possibly transitioning to turbulent.

When is in region IV, the roughness would be sufficient to disrupt laminar flow, but not large enough to disrupt turbulent flow; hence, the leading band fluid flow would be turbulent.

With

and

, solve Formula (

60) for the laminar upper-bound

:

With

and

in Formula (

64) with

:

The inverse of

is

. Solving for the turbulent upper-bound

:

Equating and yields their intercept (found numerically) at .

The combination of and required by region IV operation will be rare; will hold for nearly all isotropic, periodic roughnesses.

12. Plateau Roughness

Self-similar roughness disrupts a boundary layer at all scales. At a minimum, isotropic, periodic roughness disrupts a boundary layer only every period . Between these disruptions the RMS height-of-roughness must be smaller than because is the dominant period. If this inter-roughness region is flat, parallel to the flow, and that flat is the tallest feature of each roughness cell, then a boundary layer can grow along it.

If an isotropic, periodic roughness lacks flats parallel to the flow, then its shearing stress comes from the same flow–roughness interaction as a self-similar roughness induces, and the skin-friction coefficient will be

Formula (

27).

Distinct flow mode regions can form along plates whose roughness peaks are all co-planar (at the same elevation) plateaus. With

producing rough flow in the leading band of the plate, turbulent flow occurs downstream from where

is large enough to bridge the gaps. Theskin-friction drag from the downstream portion of the surface will be proportional to

, not the constant

associated with rough flow. The combined skin-friction drag formula is developed in

Section 13.

Informally, a “plateau roughness” is an isotropic, periodic roughness with most of its area at its peak elevation. Of particular interest are plateau roughnesses where each cell contains a single continuous plateau area whose boundary has a convex perimeter within the cell. This will either be an array of “islands” whose tops are all co-planar, or an array of “wells” dropping below an otherwise flat plane.

12.1. Plateau Islands

Consider a smooth flat plate etched with a square grid of grooves subjected to a flow. When the boundary layer is disrupted by a groove perpendicular to the flow, the turbulent boundary layer restarts at the leading edge of the next island. At the scale of the roughness period , the momentum thickness of the boundary layer grows from 0 to nearly the L-scale value (depending on the size of the island). If grows to exceed , then the rest of the plate (to its trailing edge) will have a turbulent friction coefficient proportional to , but with characteristic length .

Along isotropic roughness, the growth of

depends on plateau size, but not on orientation. An isotropic size metric is needed. In natural convection from an upward-facing horizontal plate [

31,

32], the (isotropic) characteristic length metric

, where

is the convex region’s area and

is its perimeter length. For a regular polygon or circle,

, where

r is the minimum radius of the regular polygon or circle.

In order to find the island

threshold

, multiply both sides of Equation (

64) by

. This allows

to be isolated using the Lambert

function identity

:

The boundary layer thickness needed to bridge the gap grows with

and shrinks with increasing

, suggesting

. The

strength needed to reach

thickness at

grows strongly with

. Letting

in Equation (

69), then taking the logarithm of both sides:

The inverse of

is

. Solving Formula (

70) for

:

With wide enough gaps, the islands are too narrow to support turbulent flow bridging the gaps, leading to the inequality in Formula (

71). Formula (

71) is tested against two square-grooved plates in

Section 15.

12.2. Plateau Wells

Laying a perforated sheet on a flat plate turns its holes into wells.

. Fluid is forced up after diving into a well; instead of

in Formula (

70), let

, leading to the wells

threshold

:

With sufficiently wide wells, the flats between them are too narrow to support turbulent flow bridging the wells, leading to the inequality in Formula (

72). Formula (

72) is tested with perforated sheets in

Section 14.

12.3. Openness

Let “openness”

be the non-plateau area per cell area ratio;

is thus the “upper area fraction” of

Section 8. Let

be a

matrix of elevations. The span of elevations accepted as plateau must be a length smaller than

and decrease with increasing

, which suggests

:

This allows a quantitative definition of plateau roughness:

An isotropic, periodic roughness which is not plateau roughness disrupts nascent boundary layers every , but lacks the flat peaks necessary for turbulent layer growth. Thus, this investigation proposes:

Note that

does not replace inequalities (

71) and (

72); it is an additional constraint. However, they are related by “circularity”.

12.4. Circularity

For island area

with perimeter

, circularity

takes its maximum value, 1, in disks; it is

in hexagons,

in squares, and

in equilateral triangles. Similarly, for square cell area

A with perimeter

p, circularity

. Scaling by the circularity ratio derives

from

.

Formula (

74) is the same within a hexagonal cell,

and perimeter

.

The plateau wells roughness formula replaces

with

:

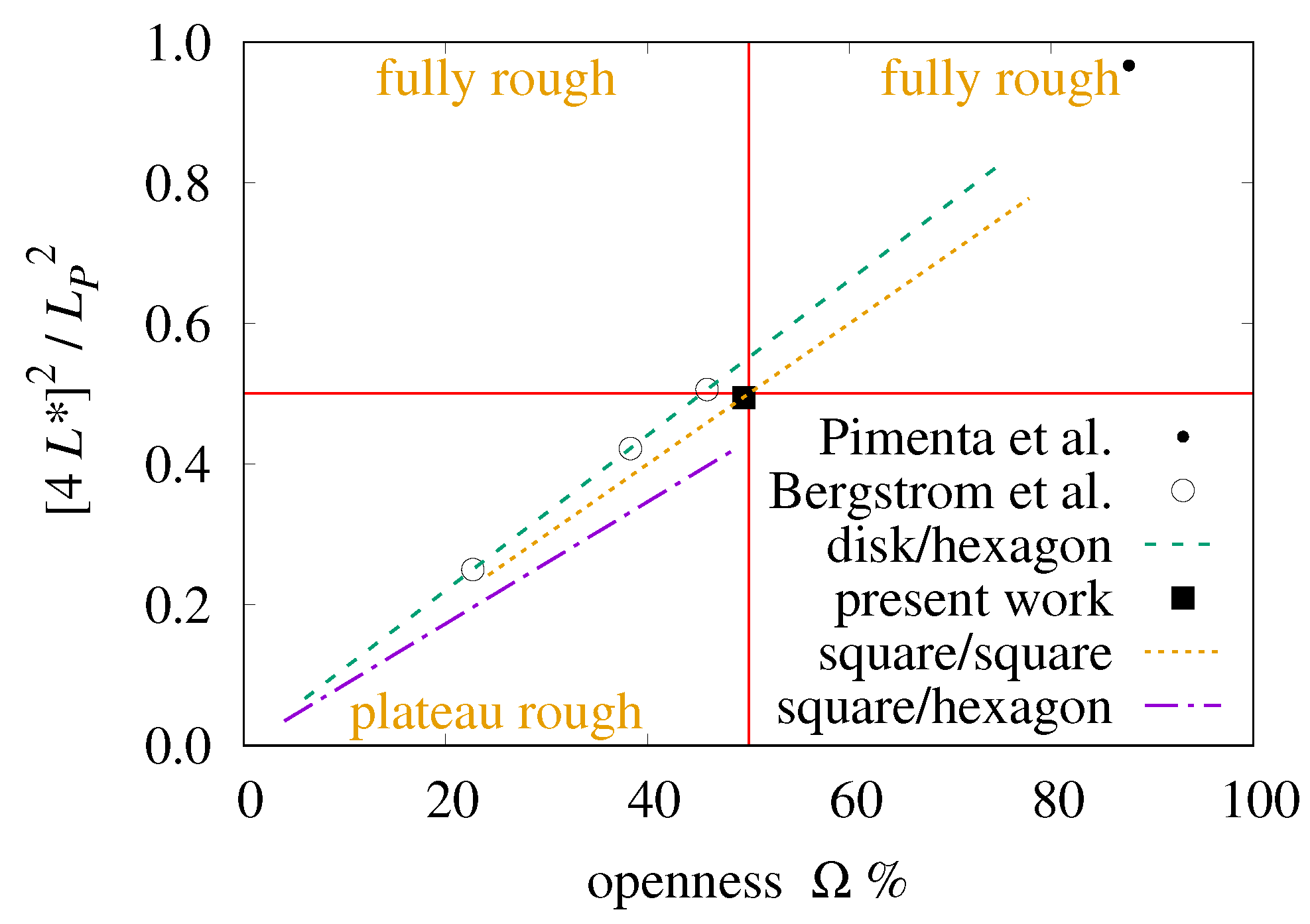

The slope of each trace in

Figure 18 is its

ratio. The “square/square” trace for a square array of square posts has slope 1. The “disk/hexagon” trace for a hexagonal array of circular wells has slope

. The “square/hexagon” trace for a hexagonal array of square posts has slope

. Each trace spans the bounds for that bi-level configuration discovered in

Section 8.

Also plotted are the

values of experiments by Pimenta et al. [

8], Bergstrom et al. [

13], and this investigation. The experiments of

Section 9,

Section 14, and

Section 15 find friction and heat transfer consistent with the type of flow named in three of the quadrants. The lower right quadrant would be reached when the convex region circularity is less than the cell circularity. But

Section 8 found that such bi-level surfaces did not qualify as isotropic, periodic roughness when

. The Pimenta et al. plate did not have bi-level roughness.

13. Combining Transfer Processes

This unnamed form appears frequently in heat transfer formulas:

Churchill and Usagi [

33] stated that such formulas are “remarkably successful in correlating rates of transfer for processes which vary uniformly between these limiting cases”. Convection and skin-friction are transfer processes. Convection transfers heat; skin-friction drag (

) transfers momentum.

13.1. The -Norm

Requiring

and

, and taking the

pth root of both sides of Equation (

76) yields a vector-space functional form known as the

-norm, which is notated

:

Norms generalize the notion of distance. Formally, a vector-space norm obeys the triangle inequality: , which holds only for . The present work finds useful as well.

Let

and

. When

, the processes compete and

; the most competitive is

. The

-norm is equivalent to root-sum-squared; it models perpendicular competitive processes such as forced and natural convection from the present apparatus plate sides in Formula (

A8).

The

-norm models independent processes;

. It appears in Formulas (

85), (

86) and (

87).

When

, the processes cooperate and

. Cooperation between conduction and flow-induced heat transfer uses the

-norm in natural convection [

28]. Formula (

52) uses the

-norm from natural convection in forced convection.

When

,

, with the transition sharpness controlled by

p; the extreme is

. Negative

p can model a single flow through serial processes; the most restrictive process limits the flow. The

-norm appears in the unheated starting length term of Formula (

59), and in fan-speed Formula (

A4). The

-norm appears in laminar-turbulent transition Formulas (

80), (

81), (

84), (

86) and (

87).

13.2. Flow Modes

Isotropic, periodic surfaces with

and

shed the rough flow of Formulas (

27), (

43), and (

47) when

. Plateau roughness (

) sheds either smooth or rough flow, or a combination.

Table 6 proposes the behaviors of plateau islands and plateau wells roughnesses. If the

condition is not satisfied, then the

conditions split the plate at distance

x from the leading edge into regions operating in different modes. Formula (

71) is the islands threshold

; Formula (

72) is the wells threshold

.

13.3. Plateau Islands

The “

” flow mode is turbulent with characteristic length

. The island’s plateau area is augmented by 1/2 of the non-plateau area and an area which grows with

, combined using the

-norm because

and

are perpendicular:

and

are active at

;

and

are active at

. The

term transitions between these parts gradually in Formulas (

80) and (

81). The

factor normalizes the characteristic length in Formula (

80).

Figure 19a shows that

and

are closely related in gases.

Section 15 compares convection measurements from two bi-level plates with

Formula (

81).

13.4. Plateau Wells

In “blend” mode, the plateau sheds turbulent flow while its wells shed rough flow. The effective friction coefficient is the area-proportional blend:

where

, the friction is turbulent, but with additional area

. The well walls are perpendicular to the plateau, but only a portion of each well wall is parallel to the flow, which must divert to brush by both. A strength between

and

is needed; their geometric mean is

:

is active at

;

is active at

:

The

plane can split wells; thus the transition between

and

flows must be gradual in Formula (

84). With the

-norm, the PM

(expected uncertainty) curves in

Figure 19b bound the PM measurements from Bergstrom et al. [

13]; the

-norm does not.

Section 14 compares local friction measurements of perforated sheets with Formulas (

83) and (

84).

13.5. Staged-Transition

When laminar and turbulent flow occupy distinct plate regions separated at

, their transfers combine using the

-norm (addition). An abrupt transition at

would behave as Formula (

85). In practice, staged-transitions are not abrupt, behaving as the

-norm in Formulas (

86) and (

87). The subscript 4 is used to identify staged-transition formulas.

Formula (

87) models staged-transition convection. Convection’s positive slope versus friction’s negative slope requires scaling

by

so that the lower edge of the transition is at

. Formula (

87) is tested in

Section 16.

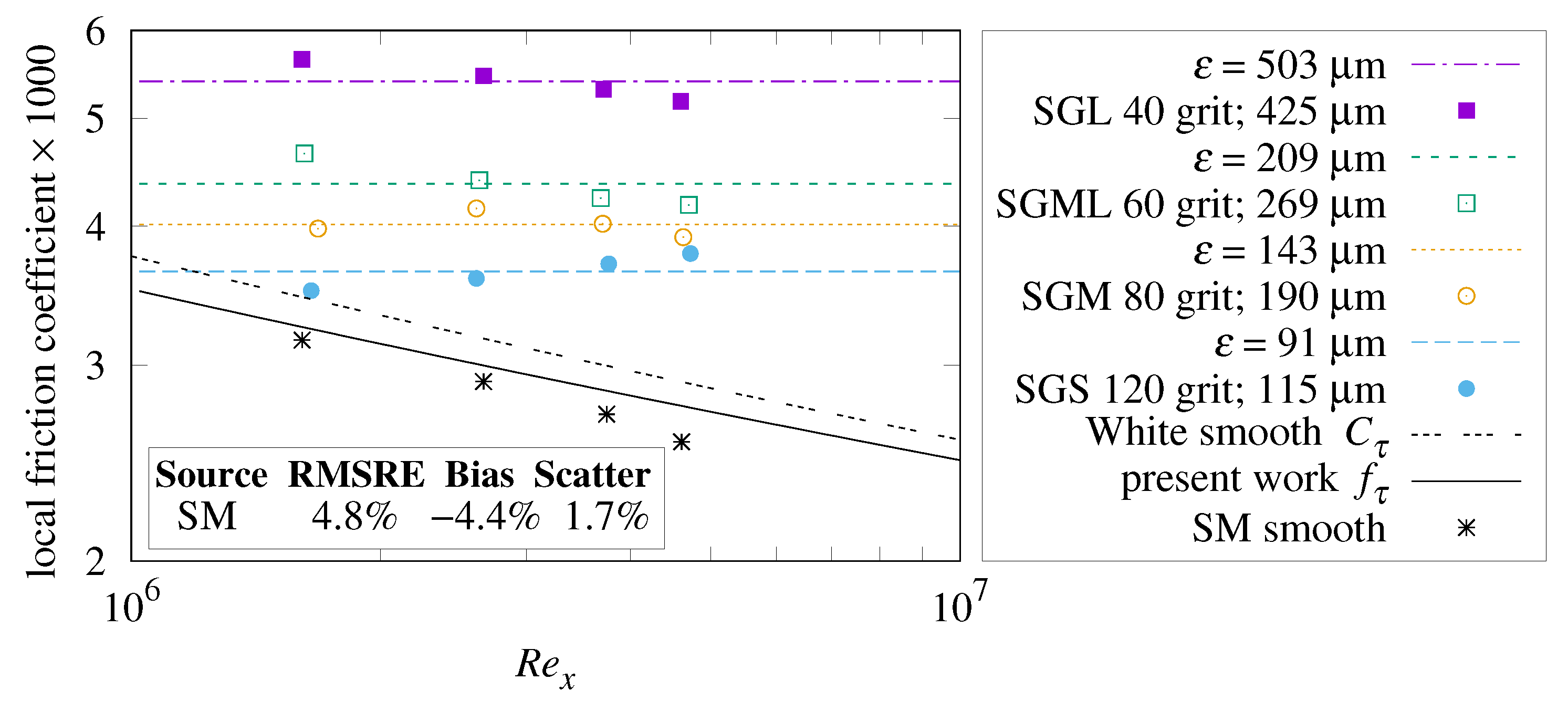

14. Rough Skin-Friction Measurements

Bergstrom et al. [

13] has skin-friction coefficient measurements of sandpapers, woven wire meshes, and perforated sheets attached to a smooth plate, and also the

smooth plate alone. Skin-friction measurements were derived from Pitot probe measurements of air velocity at locations which were 1.3 m downwind from the leading edge of the plate. Bergstrom et al. [

13] estimated 5% as the combined measurement uncertainty of the smooth surface friction coefficient, and 9% for the rough surfaces.

The measurement tables in [

13] include a column for free-stream velocity,

. In order to compute the Reynolds number

, the kinematic viscosity

was calculated for air at

, 25% RH, and 95 kPa, the mean atmospheric pressure at the University of Saskatchewan.

14.1. Smooth Plate

Three of the four measurements labeled “SM smooth” are within 5% of “present work

” in

Figure 20. The RMSRE versus

Formula (

46) is 4.8%; RMSRE versus White’s

Formula (

12) is 9.6%.

14.2. Sandpaper

Microscopic examination of coarse grades of sandpaper reveals glued mounds of grits separated by canyons having depths that are several times the mean grit diameter. Sandpaper grit mean diameter is standardized, but not the height-of-roughness of the mounds; it can vary by manufacturer and lot. The horizontal traces in

Figure 20 show that skin-friction coefficients which are independent of

, as in the present theory, can be within the 9% estimated measurement uncertainty of the data.

14.3. Comparison with Sand-Roughness

The RMS height-of-roughness of sandpaper is much larger than of sand-roughness with the same mean grit diameter. For example, 40 grit sandpaper has a skin-friction coefficient consistent with µm, while µm sand-roughness would have µm.

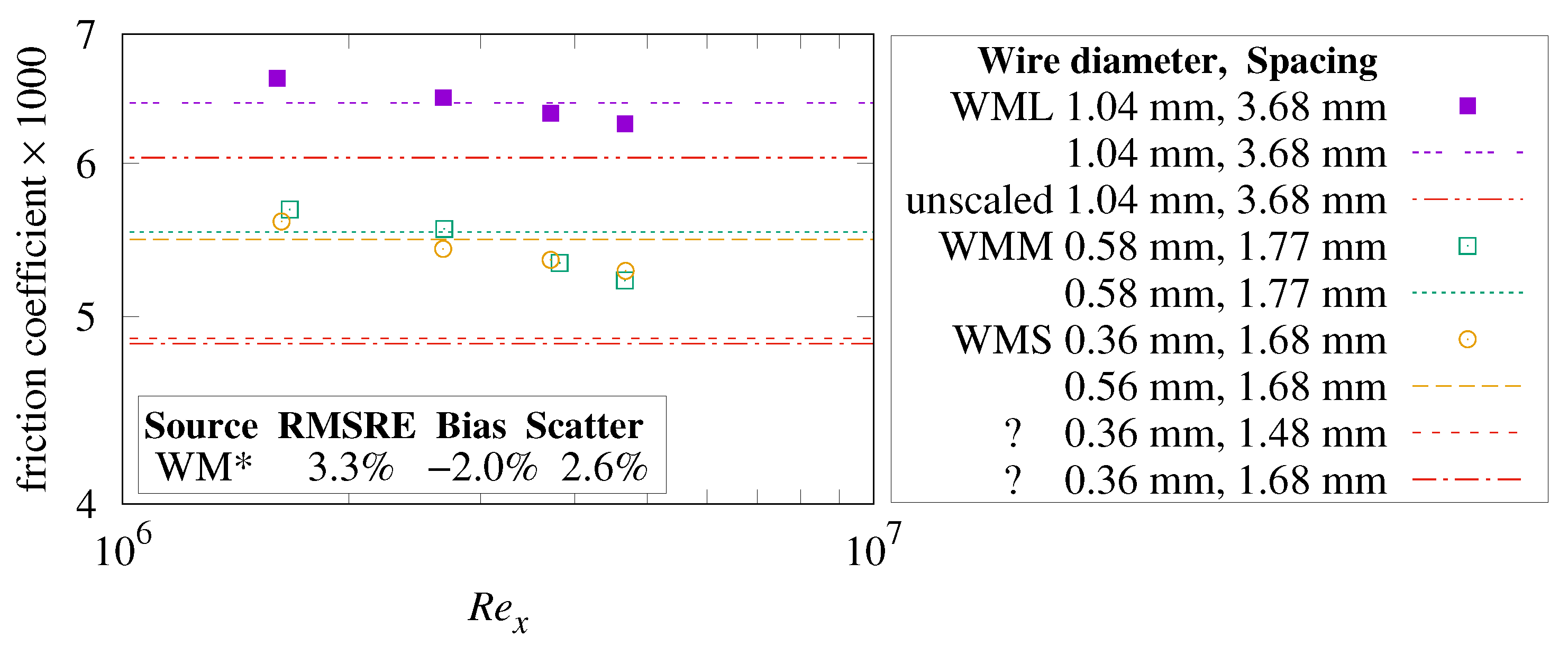

14.4. Woven Wire Mesh

Bergstrom et al. [

13] has local skin-friction coefficient measurements of woven wire meshes attached to a smooth plate.

14.5. Mesh Openness

Woven wire meshes are specified by wire diameter

d and wire center spacing

s. Bergstrom et al. [

13] calculate mesh openness as

instead of the

formula used by manufacturers (neither metric is plateau openness

).

Table 7 lists the dimensions and openness from [

13] along with openness calculated both ways. The WML and WMM meshes have

values close to [

13]. The WMS mesh has

, versus 44% from [

13]. If the 1.68 mm spacing was instead 1.48 mm, WMS would have

, but significantly less friction coefficient than the WMS measurements in

Figure 21. A 0.36 mm wire diameter has conventional openness

and matches the WMS data and the WMM trace and data.

14.6. Gaps

There are periodic gaps between the wires and the plate, so the mesh–plate combination is not strictly a roughness. With the gaps filled, the RMS height-of-roughness

would be:

The periodic gaps between wires and the plate increase the flow’s shearing stress. Scaling

by the square root of the filled-gap per empty-gap side area ratio is an increase of about

for these meshes:

The “unscaled 1.04 mm, 3.68 mm” trace in

Figure 21 shows the predicted WML friction without this scaling.

Using (scaled)

, the WML and WMM measurements match the present theory well within the

estimated measurement uncertainty. The WMS measurements do not match unless a hypothesized single digit misprint in [

13] is corrected, changing the wire diameter from

to

. Taken together, the (corrected) three wire meshes have 3.3% RMSRE versus the present theory.

14.7. Perforated Sheet

Bergstrom et al. [

13] has local skin-friction coefficient measurements of perforated sheets attached to a smooth plate.

14.8. Perforated Sheet Openness

Table 8 checks the openness of the perforated sheets from Bergstrom et al. [

13]. It indicates that the holes were hexagonally arrayed. However, the PS sheet’s calculated openness is 1/2 of the paper’s 22%. There are two single digit changes, either of which results in hexagonal openness near 22%: hole diameter

or center spacing

.

North American suppliers of perforated sheet metal generally specify hole diameter and center spacing in terms of 1/64 of an inch.

Table 8 provides dimensions both ways.

with

is a standard size;

with

is not.

Table 9 uses the parameters from the last row of

Table 8.

14.9. Plateau Wells

Table 9 shows the dimensions and metrics of the

-thick perforated sheets when laid on the flat plate. For PL,

; its flow will be rough. The “

” trace in

Figure 22 shows the predicted local skin-friction coefficient’s close proximity to the PL measurements. The “? 2.00 mm, 2.81 mm, 0.90 mm” trace with transition at “PL?” shows the behavior predicted if

had been the case.

PM and PS have

. As

grows to exceed

, the local drag coefficient gradually transitions from blend Formula (

82) to smooth Formula (

83). The

Formula (

72) transitions are marked by vertical lines.

Figure 19b details the PS and PM abrupt and smooth transitions.

PL and PM measurements match the present theory within the

measurement uncertainty. The PS measurements do not match unless a hypothesized single digit misprint in [

13] is corrected, changing the PS hole spacing from

to

. The “PS?” trace shows the behavior predicted of the original PS. Taken together, the (corrected) three perforated sheets have 4.4% RMSRE versus the present theory.

15. Rough Heat Transfer Measurements

Both the Pimenta et al. [

8] and Bergstrom et al. [

13] measurements are restricted to velocity ranges of less than 3:1. For a novel theory to be persuasive, confirmations over a wider range of fluid velocities are needed.

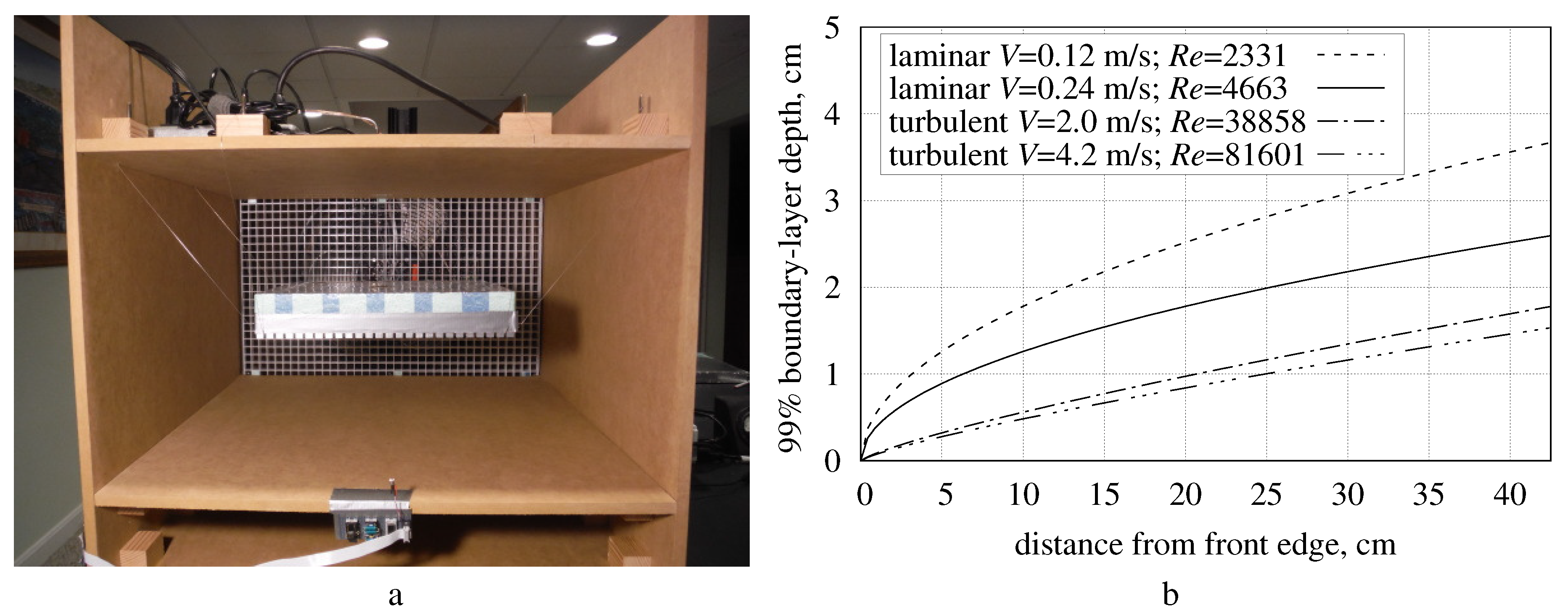

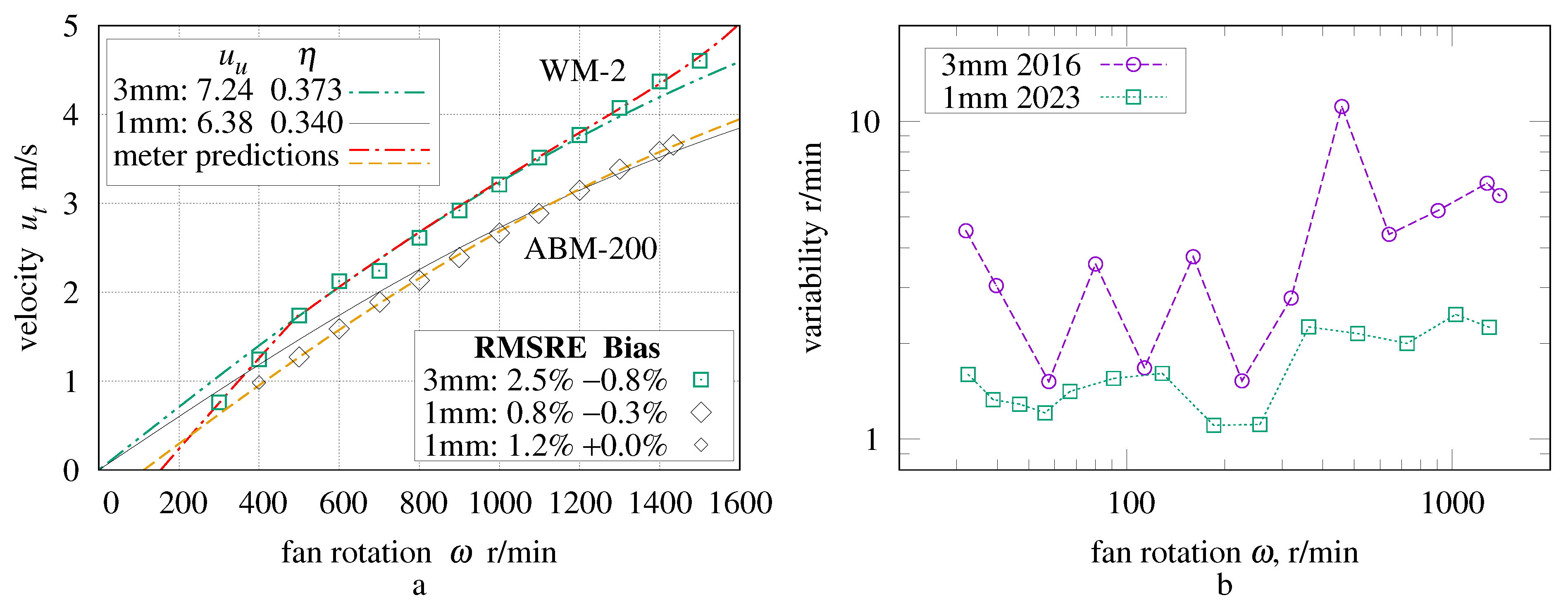

The present apparatus combined an open intake wind-tunnel, software phase-locked loop (PLL) fan control, and a heated aluminum plate. It measured average convection in air at

93,000, a 40:1 range.

Appendix A describes the apparatus and measurement methodology.

15.1. Bi-Level 3 mm Roughness

A square grid of 6 mm deep grooves in a plate created the bi-level roughness.

The two peripheral sides of the bi-level plate roughness which are parallel to the fluid flow also contribute to forced convection. Turning to dimensional analysis, and plate width cooperate weakly, leading to an effective width of , about a 5.4% increase.

Applying average convection Formula (

47) to the bi-level plate geometry, with the 5.4% increase, yields:

Note that this correction applies only to average measurements, not to local measurements.

Figure 23 shows convection measurements made with the plate averaging 11 K warmer than the ambient air.

is Formula (

90);

is Formula (

81). At

, the natural convection component dominates the mixture; hence, measurements at

are excluded from the RMSRE calculations.

Measurements in the range

50,000 match

Formula (

90) with

RMSRE.

At

55,566,

is Formula (

79); its 4/5 slope shows that convection is from turbulent flow. Its height above the

trace shows that it is operating with a shorter characteristic length than

. The

Figure 23 inset shows that

Formula (

81) is a closer match to measurements at 60,000

90,000 than an abrupt transition.

Measurements in the range

90,000 match the plateau islands

Formula (

81) with

RMSRE.

15.2. Bi-Level 1 mm Roughness

After making a variety of convection measurements, the mm plate was machined to reduce its roughness to mm.

In order to preserve the plate’s wire suspension, the four corner posts were not shortened. The

transition involves only the leading portion of the plate.

was calculated by Formula (

71) using

mm, the RMS height-of-roughness of the leading three rows of posts.

The plate’s effective width,

, is about 2.6% larger than

, but affects only

flow at

.

Formula (

81) already accounts for smooth convection from the post sides.

In

Figure 24,

is Formula (

81). At

, the natural convection component dominates the mixture; hence, measurements at

are excluded from the RMSRE calculations.

The

-norm in

Formula (

81) fits very well with the measurements in

Figure 24. Replacing it with the

-norm drives some

values out of the expected uncertainty bounds.

Convection measurements at

match plateau-islands Formula (

81) with 1.5% RMSRE.

15.3. Onset of Rough Flow

Formula (

66) predicts that the flow along the leading band of roughness of the 3 mm bi-level plate transitions from laminar to rough flow at

, which is too slow to test in this apparatus. Formula (

66) predicts

for the 1 mm bi-level plate. The plate was found to have convection consistent with rough flow at

, which is less than

.

16. Smoothness

Thus far, this investigation has focused on rough and turbulent flows. Attention now turns to laminar flows.

Schlichting [

7] describes the behavior of parallel flow of “low turbulence intensity” along a sharp-edged, smooth surface as a “stable laminar flow following the leading edge”, transitioning to a “fully developed turbulent boundary layer” at some

. Lienhard [

29] models a gradual

transition between laminar and turbulent flow along the smooth plate.

16.1. Laminar Flow over Roughness

The amount of laminar flow displaced by a periodic roughness grows with both and . Dimensional analysis suggests that this displacement is significant when . However, the laminar disturbance will be eclipsed by turbulent flow when , leading to a proposed criterion:

A silicon wafer is an isotropic, periodic roughness with

and

. The “silicon wafer” has

in

Table 10; it should behave as a smooth surface when

.

16.2. Pierced-Laminar Flow

Consider “duck tape”, the only row in

Table 10 with

.

Tuck and Kouzoubov [

34] finds that slow laminar flow over a periodic roughness “…represents a shift of the apparent plane boundary toward the flow domain”. At small

, the flow from the apparent boundary plane outward is the same as smooth laminar flow. Thus, the roughness has little effect on shear stress when

.

Consider the boundary layer where . Between the surface and its apparent boundary plane, shearing stress periodically () exceeds that of a smooth surface, spawning vortexes as increases, asymptotically approaching turbulent flow. This investigation terms this mixture “pierced-laminar flow”; the laminar flow is pierced by vortexes.

16.3. Smooth Laminar Flow

Reducing free-stream turbulence to unusually low values, Schubauer and Skramstad [

19] reported that “oscillations were discovered in the laminar boundary layer along a flat plate". These periodic oscillations suggest that rough and smooth laminar flows both spawn vortexes periodically along the plate, controlled by the purely laminar upper-bound

.

16.4. Laminar-Turbulent Mixing

The hypothesized periodic vortexes pierce the laminar boundary layer. The present theory holds that the laminar component is active through the entire

range in pierced-laminar flow, resulting in friction Formula (

91) and convection Formula (

92).

Because laminar and turbulent flows mix in pierced-laminar flow, the

-norm and

-norm of staged-transition Formulas (

86) and (

87) are replaced by the

-norm and

-norm in Formulas (

91) and (

92). The laminar and turbulent flows are in mild competition, so

.

Figure 25a shows

Formula (

91) curves at

and

. Smaller

results in a sharper downward bend, while more negative

results in a sharper upward bend. Letting

links the variables to sharpen the bends together within their respective ranges.

The geometric mean of 1 and 2 is ; for the moment, assume and .

Figure 25b plots Formula (

91) at five

values. Note that traces with smaller

have larger friction coefficients than the turbulent

trace.

Figure 26 compares measurements from Gebers [

20,

21] with staged-transition Formula (

86), pierced-laminar Formula (

91), and Formula (

93) from Schlichting [

7] for an apparatus with

, which is marked with a vertical green arrow.

The Gebers [

20,

21] measurements have 2.8% RMSRE from Formula (

91) with

.

16.5. Duck Tape

The bi-level test plate assembly of the present apparatus has four sides perpendicular to the test-surface, each a wedge of extruded polystyrene foam (XPS) insulation filling a 2.7 cm

chamfer in the metal slab. In order to isolate the convective heat flow of the test-surface from that of the sides, the estimated side convection, between 50% at

and 7% at

90,000 of the measured heat flow, is deducted from that measured heat flow (see

Appendix A for details).

The surface of the XPS foam board in

Figure 27a was not smooth and not an isotropic, periodic roughness. Without a theoretical basis for computing its convective heat transfer, the accuracy of measurements of the surface-under-test would have been limited. Hence, the foam was covered with Intertape AC6 duck tape, a 152 µm thick polyester cloth/polyethylene film with a pressure-sensitive adhesive (shown in

Figure 27a). The geometric mean of its 3.62 mm × 1.47 mm thread cell is

mm; the thread diameter plus the sheet thickness is

mm. The filled-gap woven wire mesh Formula (

88) calculates

mm. These values with

m yielded the “duck tape” row in

Table 10.

16.6. Pierced-Laminar Convection from Roughness

In the present theory, an

m strip of duck tape fails to generate rough flow in the present apparatus because the apparatus’s largest

. Because

in the duck tape row of

Table 10, the critical

in

Formula (

92) convection.

With duck tape applied to the foam faces, the measurements presented in

Section 15 are consistent with the side convection modeled by pierced-laminar Formula (

92). The other curves in

Figure 27b are substantially less than Formula (

92); they do not account for enough heat transfer to keep the surface-under-test measurements within the expected uncertainty bounds presented in

Appendix A.

That consistency rules out laminar

, turbulent

, and staged-transition

as explanations of convection from the duck tape covered sides in combination with plateau islands

convection from the plate. This evidence is not conclusive, but supports pierced-laminar Formula (

92) convection from the duck tape surface.

16.7. Local Skin-Friction and Convection

Average-to-local transform (

44) derives Formulas (

94) and (

96) from Formulas (

86) and (

91), with

scaled by

. Formulas (

95) and (

97) compute the local convections from the average convection Formulas (

87) and (

92), with

scaled by

. These

scale factors are needed to make the local curve transitions align with

.

16.8. Convection Transition

The Lienhard [

29] comprehensive smooth plate convection formula can be expressed using the

-norm:

is the critical

upper-bound for purely laminar flow. Lienhard [

29] states “The value of

should be fit to the dataset, and the value of

c may either be fitted or estimated from” Formula (

100). The Lienhard curves presented here use the

c estimated by Formula (

100).

In the graphs which follow, the

and

c values fit by Lienhard [

29] are marked with a star (∗). The curves are computed and labeled with the

value which minimizes the data-set RMSRE (relative to the formula) using the “Golden section search” algorithm from Kiefer [

35].

Figure 28 plots measurements from two Kestin, Maeder, and Wang [

24] data-sets.

Figure 29 plots data from Reynolds, Kays, and Kline [

25] at

with unheated

. Pierced-laminar Formula (

97) has the closest match (lowest RMSRE) to the measurements in

Figure 28 and

Figure 29.

16.9. Uniform Heat Flux

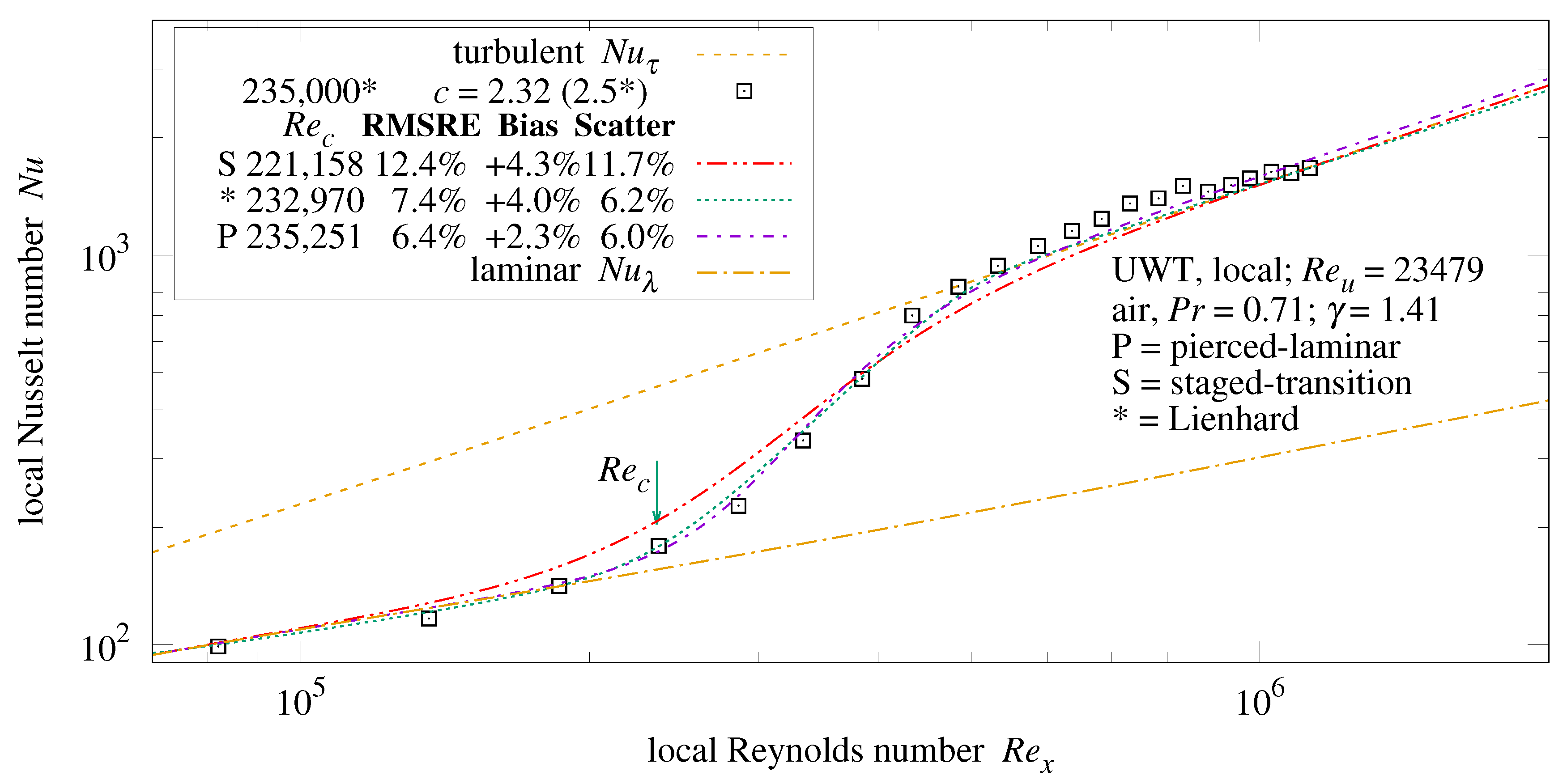

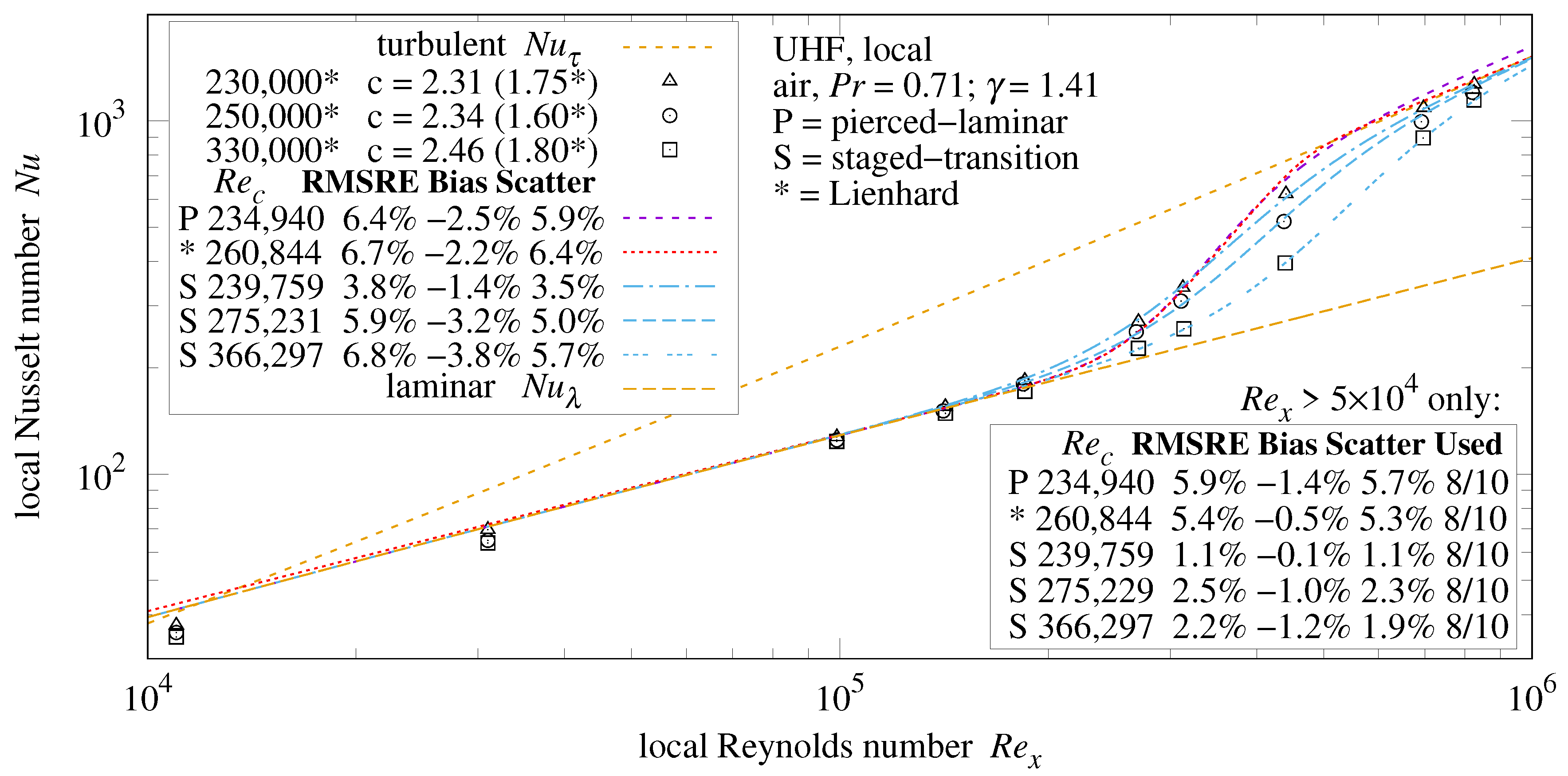

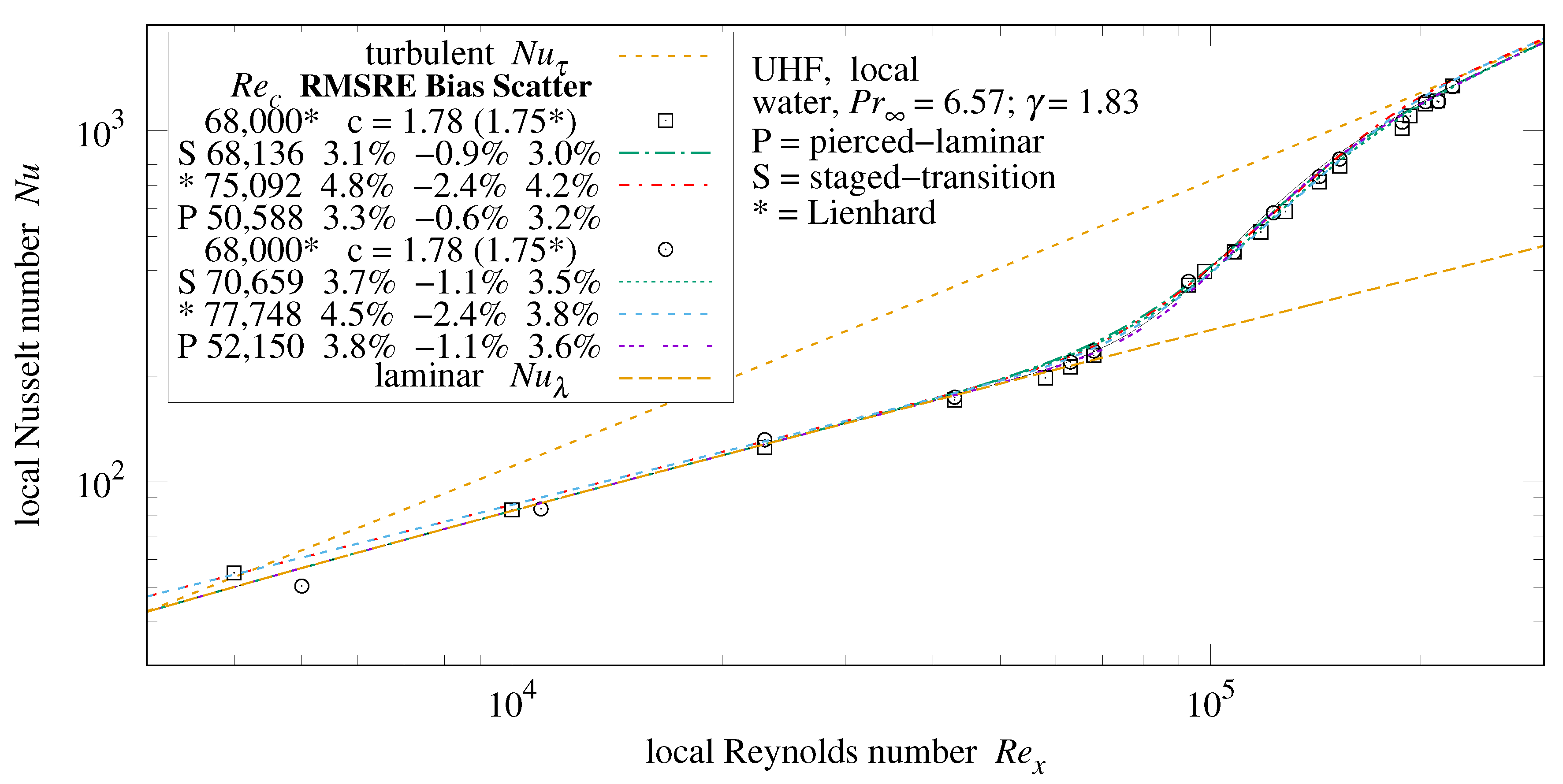

Thus far, this investigation concerned uniform-wall-temperature (UWT, also termed “isothermal”) plates. Žukauskas and Šlančiauskas [

18] measured critical transitions with a uniform-heat-flux (UHF) flowing through a smooth surface. In the present work, each convection graph is labeled UWT or UHF.

Per Lienhard [

29], 0.4587 replaces 0.332 in

Formula (

99) for UHF plates. Similarly,

scales

Formula (

59) when modeling UHF plates.

Lienhard [

29] uses the Gnielinski turbulent Formula (

48) for both UWT and UHF plates. This investigation similarly applies its turbulent Formula (

55) to both UWT and UHF plates.

When a vortex transports fluid away from the surface of a UHF plate, the temperature of the fluid which replaces it increases more slowly than it would from a UWT plate. This reduction in local surface temperatures interferes with laminar heat transfer, largely restricting it to the

region of the plate. Staged-transition Formula (

87) models heat transfer from distinct laminar and turbulent areas, making it appropriate for UHF convection. Note that the fluid flow is the same; only its heat transfer is affected.

Figure 30 compares staged-transition Formula (

95), Lienhard Formula (

98), and pierced-laminar Formula (

97) with measurements by Žukauskas and Šlančiauskas [

18] of UHF plates in air.

The two points of each

Figure 30 data-set at