Flexible Electricity Dispatch of an Integrated Solar Combined Cycle through Thermal Energy Storage and Hydrogen Production

Abstract

:1. Introduction

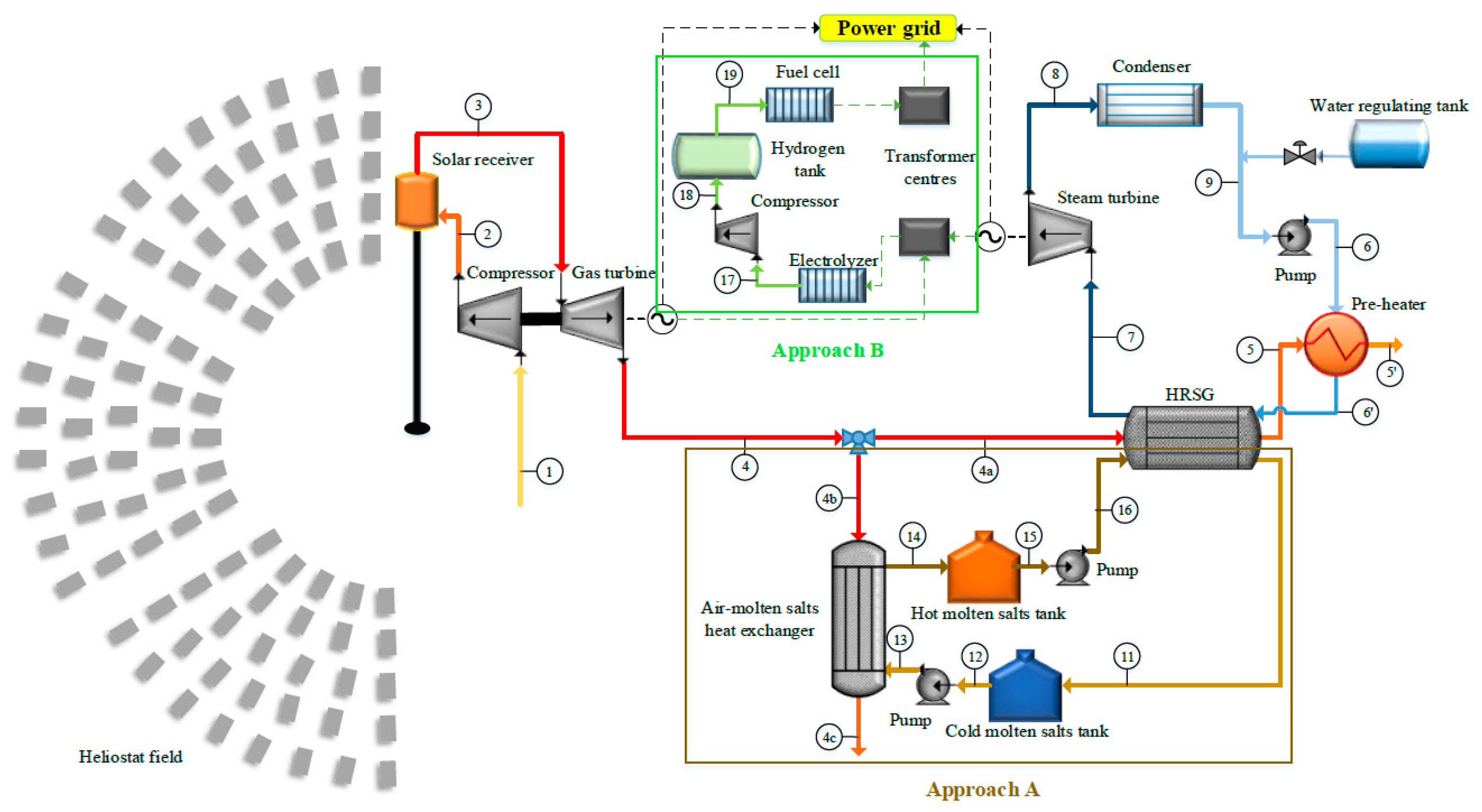

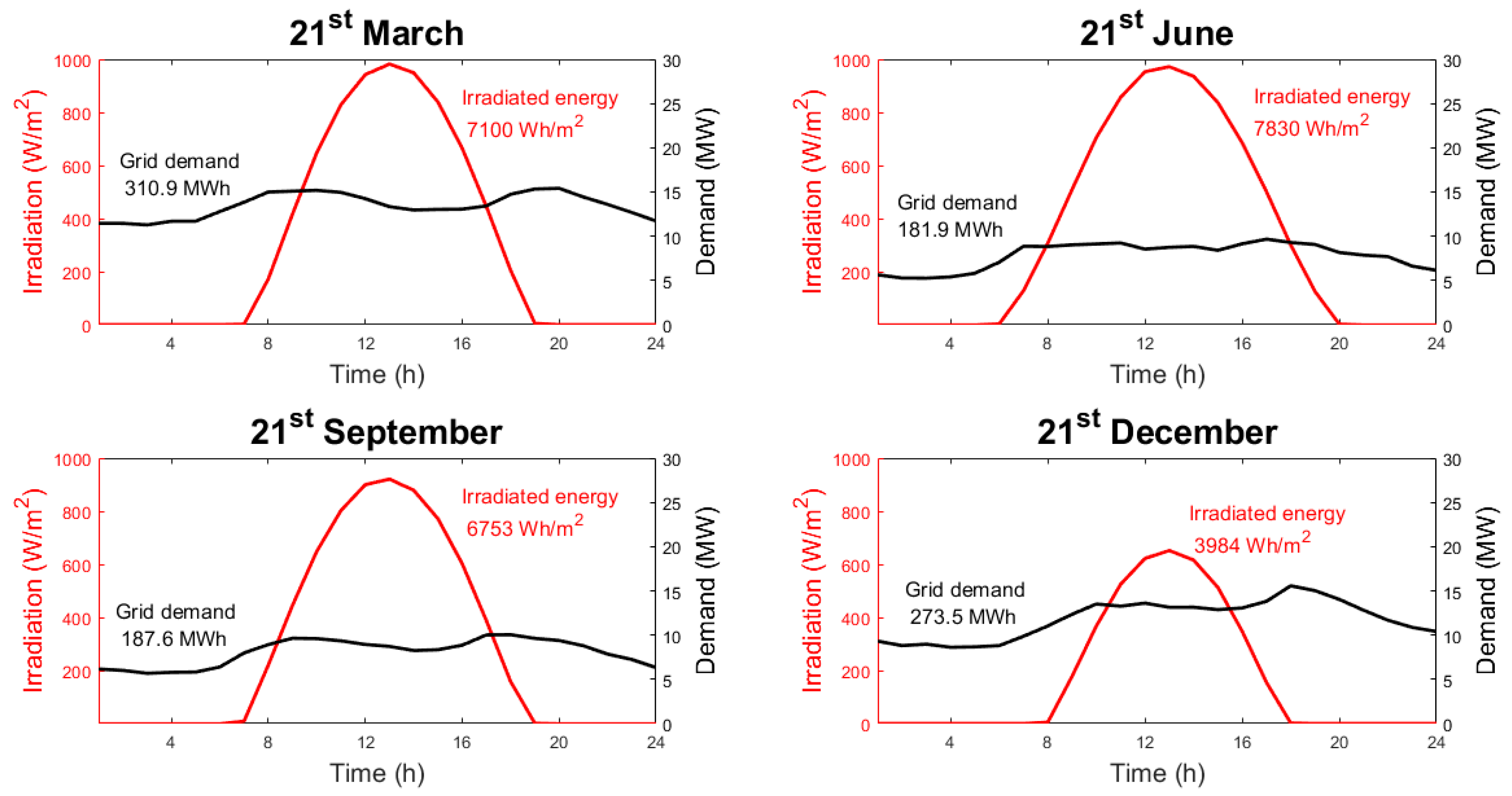

2. Materials and Methods

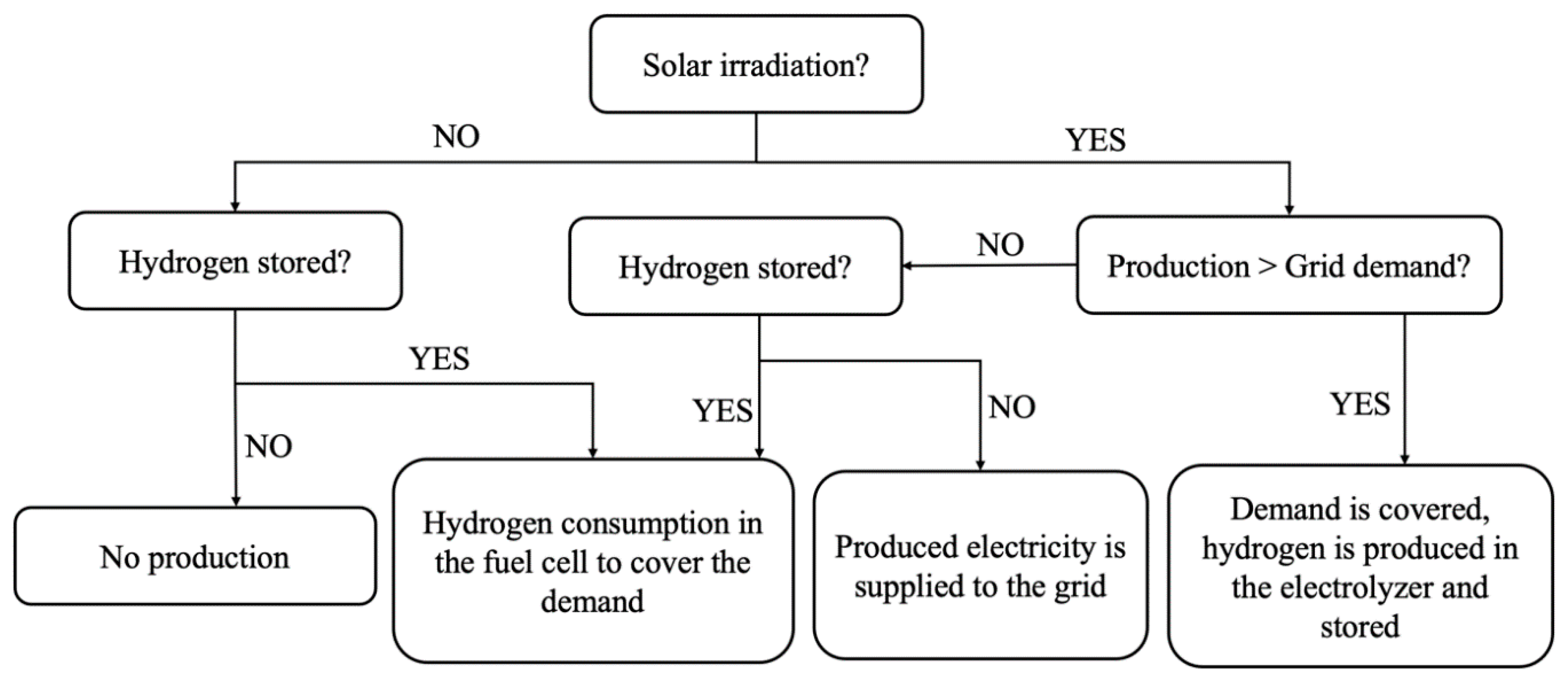

Solving Scheme—Flexible Dispatch Strategy

3. Results

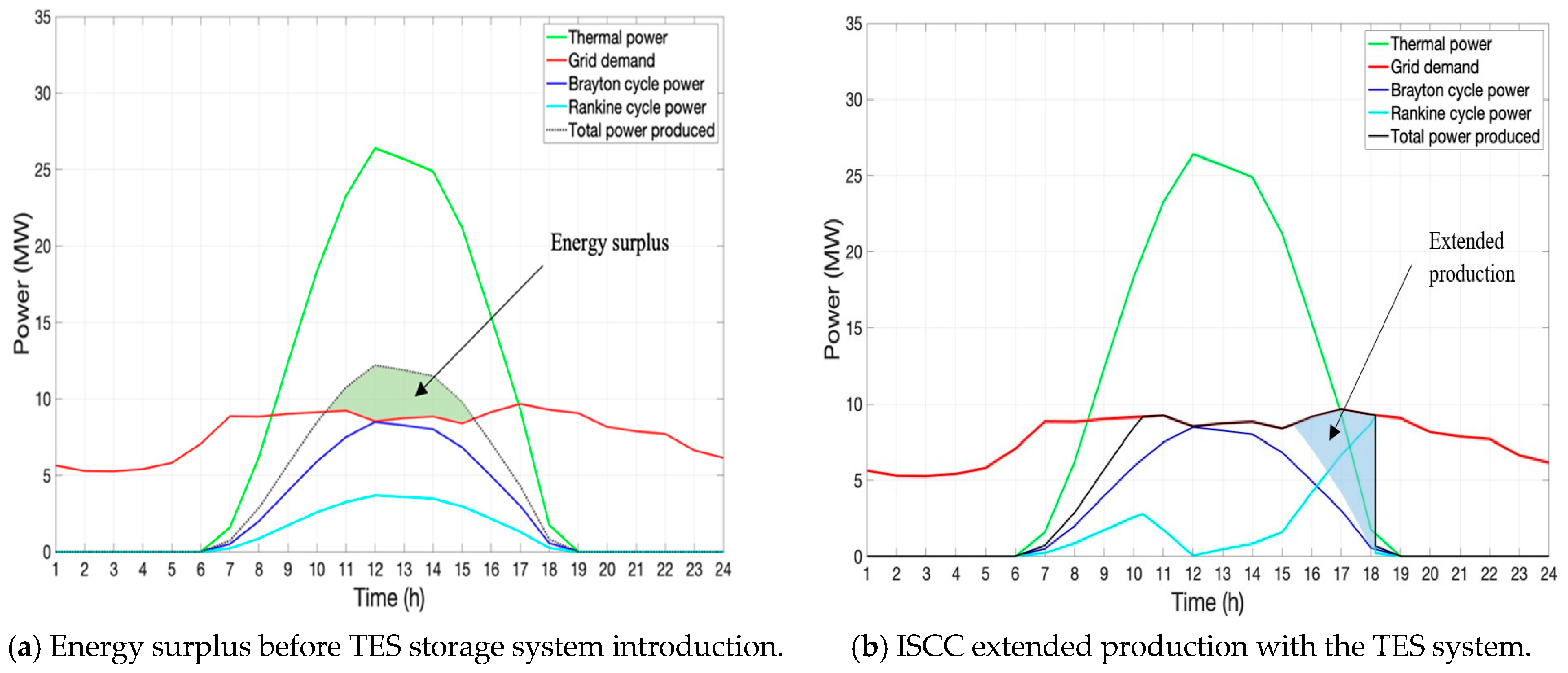

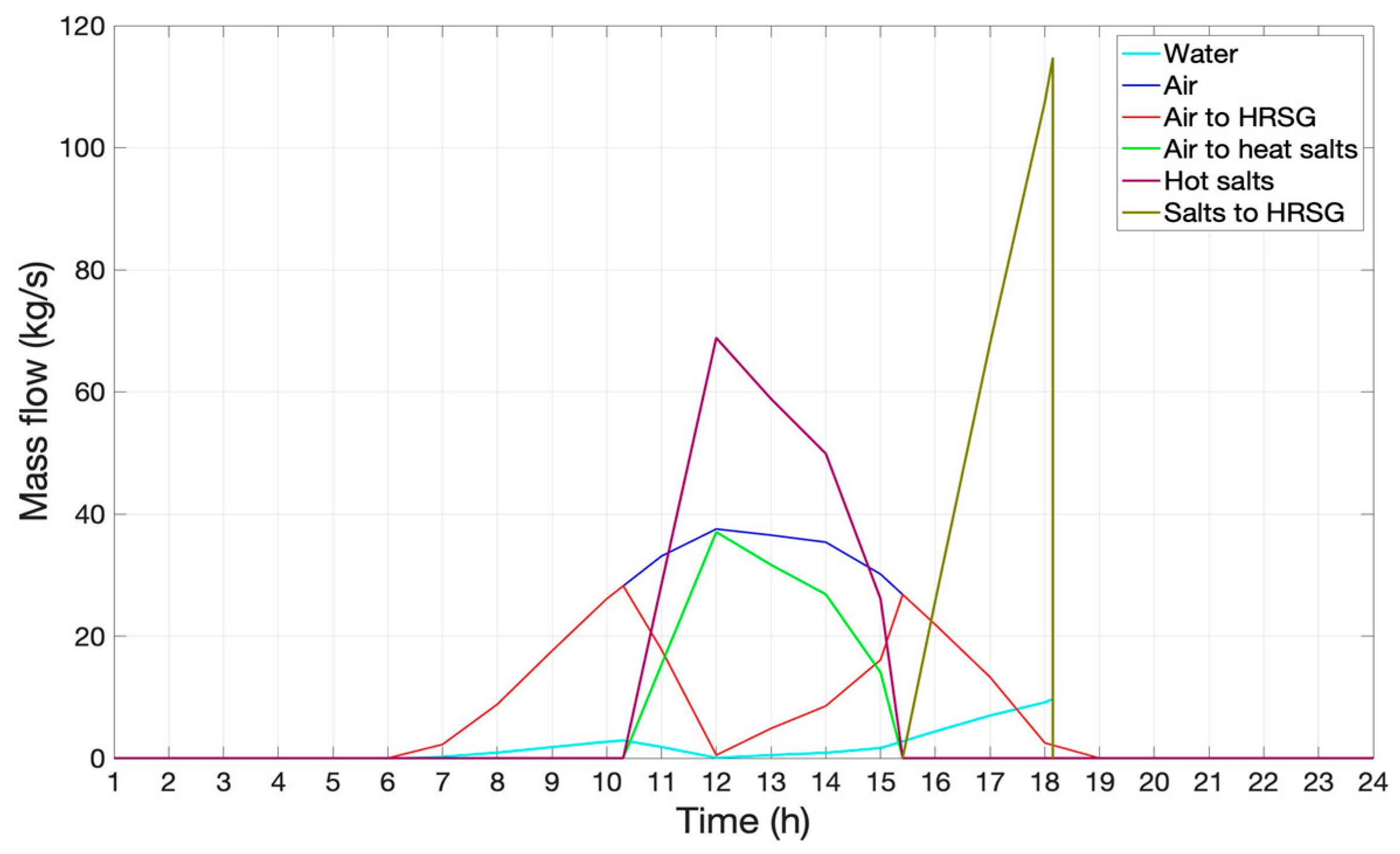

3.1. Instantaneous Performance of the Storage Approach A—Molten Salts TES

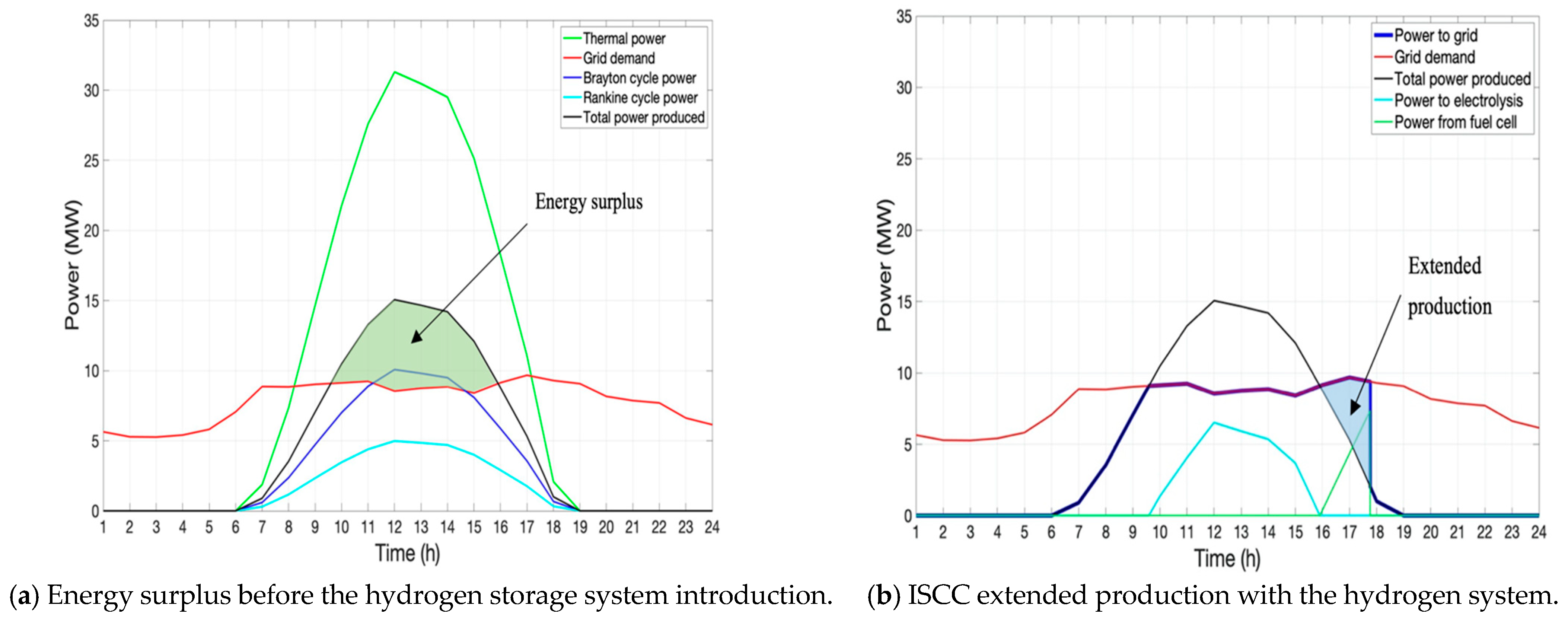

3.2. Storage Approach B—Hydrogen Generation and Storage System

3.3. ISCC Plant Components Sizing and Selection

- Type I: Metal pressure vessel (200 bar);

- Type II: Thick metallic liner hoop pressure vessel wrapped with fiber-resin composite (200 bar);

- Type III: Metallic liner pressure vessel fully wrapped with fiber-resin composite (700 bar);

- Type IV: Polymeric liner pressure vessel fully wrapped with fiber-resin composite.

4. Discussion

4.1. Annual Performance

4.2. Economic Analysis

5. Conclusions

- Molten salts TES system can be charged using the exceeding exhaust energy from the Brayton turbine during central hours of the day, which enables ISCC online power output regulation to meet users’ grid demand.

- Stored molten salts can be used on demand to increase the steam generation and to extend demand coverage when solar incident energy reduces.

- The hydrogen storage system can be charged on demand using the surplus electricity that is produced by the ISCC but not required by users’ grid demand.

- Stored hydrogen can be used on demand in a fuel cell to extend demand coverage when solar incident energy reduces.

- According to energy production and economic findings, a 30% reduction in LCoE can be achieved with a molten salts TES storage approach compared to a hydrogen solution based on its lower CAPEX despite the lower energy dispatch. However, greater coverage of the electrical demand can be met with a hydrogen storage approach based on the higher gas turbine generation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jorgenson, A.K.; Alekseyko, A.; Giedraitis, V. Energy consumption, human well-being and economic development in central and eastern European nations: A cautionary tale of sustainability. Energy Policy 2014, 66, 419–427. [Google Scholar] [CrossRef]

- Li, Z.D. An econometric study on China’s economy, energy and environment to the year 2030. Energy Policy 2003, 31, 1137–1150. [Google Scholar] [CrossRef]

- Gomez-Echeverri, L. Climate and development: Enhancing impact through stronger linkages in the implementation of the Paris Agreement and the Sustainable Development Goals (SDGs). Philos. Trans. A 2018, 376. [Google Scholar] [CrossRef] [Green Version]

- Murphy, C.; Sun, Y.; Cole, W.; Maclaurin, G.; Turchi, C.; Mehos, M.; Murphy, C.; Sun, Y.; Cole, W.; Maclaurin, G.; et al. The Potential Role of Concentrating Solar Power within the Context of DOE’s 2030 Solar Cost Targets; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2019; 137p. [Google Scholar] [CrossRef]

- Mehos, M.; Turchi, C.; Vidal, J.; Wagner, M.; Ma, Z.; Ho, C.; Kolb, W.; Andraka, C.; Kruizenga, A. Concentrating Solar Power Gen3 Demonstration Roadmap; Office of Scientific and Technical Information (OSTI): Golden, CO, USA, 2017. [Google Scholar]

- Islam, M.; Alam, A.M.S.; Das, C.K. Multi-agent system modeling for managing limited distributed generation of microgrid. In Proceedings of the 2nd International Conference on Electrical Information and Communication Technologies, EICT 2015, Khulna, Bangladesh, 10–12 December 2015; Institute of Electrical and Electronics Engineers Inc.: Manhattan, NY, USA, 2016; pp. 533–538. [Google Scholar]

- Patel, K.; Das, N.; Khan, M.M.K. Optimization of hybrid solar, wind and diesel energy systems from economic point of view. In Proceedings of the 2019 29th Australasian Universities Power Engineering Conference, AUPEC 2019, Nadi, Fiji, 26–29 November 2019; Institute of Electrical and Electronics Engineers Inc.: Manhattan, NY, USA, 2019. [Google Scholar]

- Ho, C.K.; Iverson, B.D. Review of high-temperature central receiver designs for concentrating solar power. Renew. Sustain. Energy Rev. 2014, 29, 835–846. [Google Scholar] [CrossRef] [Green Version]

- Romero, M.; González-Aguilar, J. Next generation of liquid metal and other high-performance receiver designs for concentrating solar thermal (CST) central tower systems. Adv. Conc. Sol. Therm. Res. Technol. 2016, 129–154. [Google Scholar] [CrossRef]

- Zaversky, F.; Les, I.; Sorbet, P.; Sánchez, M.; Valentin, B.; Brau, J.F.; Siros, F. The challenge of solar powered combined cycles—Providing dispatchability and increasing efficiency by integrating the open volumetric air receiver technology. Energy 2020, 194, 116796. [Google Scholar] [CrossRef]

- Reyes-Belmonte, M.A.; Pino, F.J.; Romero, M.; Suarez, C.; González-Aguilar, J.; Guerra, J. Optimization of an integrated solar combined cycle. AIP Conf. Proc. 2018, 2033, 210012. [Google Scholar]

- Ho, C.K. A review of high-temperature particle receivers for concentrating solar power. Appl. Therm. Eng. 2016, 109, 958–969. [Google Scholar] [CrossRef] [Green Version]

- Benoit, H.; Pérez López, I.; Gauthier, D.; Sans, J.-L.; Flamant, G. On-sun demonstration of a 750 °C heat transfer fluid for concentrating solar systems: Dense particle suspension in tube. Sol. Energy 2015, 118, 622–633. [Google Scholar] [CrossRef]

- Lantelme, F.; Groult, H. (Eds.) Molten Salts Chemistry: From Lab to Applications; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-0-12-398538-5. [Google Scholar]

- Crespi, F.; Gavagnin, G.; Sánchez, D.; Martínez, G.S. Supercritical carbon dioxide cycles for power generation: A review. Appl. Energy 2017, 195, 152–183. [Google Scholar] [CrossRef]

- Turchi, C.S.; Ma, Z.; Dyreby, J. Supercritical carbon dioxide power cycle configurations for use in concentrating solar power systems. In Proceedings of the ASME Turbo Expo, Copenhagen, Denmark, 11–15 June 2012; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2012; Volume 5, pp. 967–973. [Google Scholar]

- Di Maio, D.V.; Boccitto, A.; Caruso, G. Supercritical Carbon Dioxide Applications for Energy Conversion Systems. Energy Procedia 2015, 82, 819–824. [Google Scholar] [CrossRef] [Green Version]

- Reyes-Belmonte, M.A.; Sebastián, A.; Romero, M.; González-Aguilar, J. Optimization of a recompression supercritical carbon dioxide cycle for an innovative central receiver solar power plant. Energy 2016. [Google Scholar] [CrossRef]

- SOLARSCO2OL Project. Available online: https://www.solarsco2ol.eu/ (accessed on 6 April 2021).

- Scarabeus Project. Available online: https://www.scarabeusproject.eu/ (accessed on 6 April 2021).

- Le Moullec, Y.; Qi, Z.; Zhang, J.; Zhou, P.; Yang, Z.; Wang, X.; Chen, W.; Wang, S. Shouhang—EDF 10 MWe Supercritical CO2 Cycle for CSP Demonstration Project. In Proceedings of the 3rd European Supercritical CO2 Conference, Paris, France, 19–20 September 2019. [Google Scholar]

- Reyes-Belmonte, M.Á. A Bibliometric Study on Integrated Solar Combined Cycles (ISCC), Trends and Future Based on Data Analytics Tools. Sustainability 2020, 12, 8217. [Google Scholar] [CrossRef]

- Rovira, A.; Sánchez, C.; Valdés, M.; Abbas, R.; Barbero, R.; Montes, M.; Muñoz, M.; Muñoz-Antón, J.; Ortega, G.; Varela, F. Comparison of Different Technologies for Integrated Solar Combined Cycles: Analysis of Concentrating Technology and Solar Integration. Energies 2018, 11, 1064. [Google Scholar] [CrossRef] [Green Version]

- Khandelwal, N.; Sharma, M.; Singh, O.; Shukla, A.K. Recent Developments in Integrated Solar Combined Cycle Power Plants. J. Therm. Sci. 2020, 29, 298–322. [Google Scholar] [CrossRef]

- Behar, O.; Khellaf, A.; Mohammedi, K.; Ait-Kaci, S. A review of integrated solar combined cycle system (ISCCS) with a parabolic trough technology. Renew. Sustain. Energy Rev. 2014, 39, 223–250. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Tosang, E.; Dadak, A. Investigation of a combined cycle power plant coupled with a parabolic trough solar field and high temperature energy storage system. Energy Convers. Manag. 2018, 171, 1662–1674. [Google Scholar] [CrossRef]

- Hosseini, R.; Soltani, M.; Valizadeh, G. Technical and economic assessment of the integrated solar combined cycle power plants in Iran. Renew. Energy 2005, 30, 1541–1555. [Google Scholar] [CrossRef]

- Nezammahalleh, H.; Farhadi, F.; Tanhaemami, M. Conceptual design and techno-economic assessment of integrated solar combined cycle system with DSG technology. Sol. Energy 2010, 84, 1696–1705. [Google Scholar] [CrossRef]

- Kang, Q.; Dewil, R.; Degrève, J.; Baeyens, J.; Zhang, H. Energy analysis of a particle suspension solar combined cycle power plant. Energy Convers. Manag. 2018, 163, 292–303. [Google Scholar] [CrossRef]

- Reyes-Belmonte, M.A.; Romero, M.; González-Aguilar, J. Integrated solar combined cycle using particles as heat transfer fluid and thermal energy storage medium for flexible electricity dispatch. AIP Conf. Proc. 2020, 2303. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P.; Rovense, F. Energetic analysis of innovative hybrid biomass/solar organic Rankine cycles (ORCS) for micro-scale CHP applications. In Proceedings of the 25th European Biomass Conference and Exhibition, Stockholm, Sweden, 12–15 June 2017. [Google Scholar]

- Siros, F.; Campos, G.F. Optimisation of a low-tit combined cycle gas turbine with application to new generation Solar Thermal Power Plants. In Proceedings of the ASME Turbo Expo, Charlotte, NC, USA, 26–30 June 2017; Volume 3, pp. 1–10. [Google Scholar] [CrossRef]

- Rovense, F.; Reyes-Belmonte, M.A.; González-Aguilar, J.; Amelio, M.; Bova, S.; Romero, M. Flexible electricity dispatch for CSP plant using un-fired closed air Brayton cycle with particles based thermal energy storage system. Energy 2019. [Google Scholar] [CrossRef]

- Rovense, F.; Amelio, M.; Scornaienchi, N.M.; Ferraro, V. Performance analysis of a solar-only gas micro turbine, with mass flow control. Energy Procedia 2017, 126, 675–682. [Google Scholar] [CrossRef]

- Sioshansi, R.; Denholm, P. The value of concentrating solar power and thermal energy storage. IEEE Trans. Sustain. Energy 2010, 1, 173–183. [Google Scholar] [CrossRef] [Green Version]

- Schöniger, F.; Thonig, R.; Resch, G.; Lilliestam, J. Making the sun shine at night: Comparing the cost of dispatchable concentrating solar power and photovoltaics with storage. Energy Sources Part B Econ. Plan. Policy 2021, 16, 55–74. [Google Scholar] [CrossRef]

- Rovense, F.; Reyes-Belmonte, M.A.; González-Aguilar, J.; Amelio, M.; Bova, S.; Romero, M. Application of un-fired closed Brayton cycle with mass flow regulation and particles based thermal energy storage systems for CSP. AIP Conf. Proc. 2019, 2126. [Google Scholar] [CrossRef]

- Serrano-López, R.; Fradera, J.; Cuesta-López, S. Molten salts database for energy applications. Chem. Eng. Process. Process Intensif. 2013, 73, 87–102. [Google Scholar] [CrossRef] [Green Version]

- Vaka, M.; Walvekar, R.; Jagadish, P.; Khalid, M.; Mubarak, N.M.; Panchal, H. High-temperature molten salts optimisation using mixture design for energy storage application. J. Energy Storage 2020, 32, 101981. [Google Scholar] [CrossRef]

- Herrmann, U.; Kelly, B.; Price, H. Two-tank molten salt storage for parabolic trough solar power plants. Energy 2004, 29, 883–893. [Google Scholar] [CrossRef]

- Gao, Y.; He, F.; Xu, T.; Meng, X.; Zhang, M.; Yan, L.; Gao, W. Thermal performance analysis of sensible and latent heat thermal energy storage tanks: A contrastive experiment. J. Build. Eng. 2020, 32, 101713. [Google Scholar] [CrossRef]

- Gallandat, N.; Romanowicz, K.; Züttel, A. An Analytical Model for the Electrolyser Performance Derived from Materials Parameters. J. Power Energy Eng. 2017, 05, 34–49. [Google Scholar] [CrossRef] [Green Version]

- Gupta, R.B. Hydrogen Fuel: Production, Transport, and Storage; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-1-4200-4575-8. [Google Scholar]

- Olabi, A.G.; Bahri, A.S.; Abdelghafar, A.A.; Baroutaji, A.; Sayed, E.T.; Alami, A.H.; Rezk, H.; Abdelkareem, M.A. Large-vscale hydrogen production and storage technologies: Current status and future directions. Int. J. Hydrogen Energy 2020. [Google Scholar] [CrossRef]

- Barral, K.; Barthélémy, H. Hydrogen high pressure tanks storages: Overview and new trends due to H 2 Energy specifications and constraints. Int. J. Hydrogen Energy 2011, 36, 11056–11067. [Google Scholar]

- Larminie, J.; Dicks, A. Fuel Cell Systems Explained Second Edition; John Wiley and Sons: Hoboken, NJ, USA, 2003; ISBN 047084857X. [Google Scholar]

- Reyes-Belmonte, M.A.; Sebastián, A.; Spelling, J.; Romero, M.; González-Aguilar, J. Annual performance of subcritical Rankine cycle coupled to an innovative particle receiver solar power plant. Renew. Energy 2019, 130. [Google Scholar] [CrossRef]

- Reyes-Belmonte, M.A.; Sebastián, A.; González-Aguilar, J.; Romero, M. Performance comparison of different thermodynamic cycles for an innovative central receiver solar power plant. AIP Conf. Proc. 2017, 1850, 160024. [Google Scholar]

- Li, Y.; Xiong, Y. Thermo-economic analysis of a novel cascade integrated solar combined cycle system. Energy 2018, 145, 116–127. [Google Scholar] [CrossRef]

- Silveira, J.L.; Tuna, C.E. Thermoeconomic analysis method for optimization of combined heat and power systems. Part I. Prog. Energy Combust. Sci. 2003, 29, 479–485. [Google Scholar] [CrossRef]

- Zaversky, F.; Les, I.; Sánchez, M.; Valentin, B.; Brau, J.-F.; Siros, F.; McGuire, J.; Berard, F. Techno-Economic Optimization and Benchmarking of a Solar-Only Powered Combined Cycle with High-Temperature TES Upstream the Gas Turbine. In Green Energy and Environment; IntechOpen: London, UK, 2019. [Google Scholar]

- IRENA. Green Hydrogen Cost Reduction Scaling up Electrolysers to Meet the 1.5 °C Climate Goal; IRENA: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen storage for mobility: A review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sveshnikova, A. Estimation of Possibility to Implement Fuel Cell Technology for Decentralized Energy Supply in Russia. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2015. [Google Scholar]

- Ma, Z.; Glatzmaier, G.C.; Mehos, M. Development of Solid Particle Thermal Energy Storage for Concentrating Solar Power Plants that Use Fluidized Bed Technology. Energy Procedia 2014, 49, 898–907. [Google Scholar] [CrossRef] [Green Version]

- Hamed, O.A.; Kosaka, H.; Bamardouf, K.H.; Al-Shail, K.; Al-Ghamdi, A.S. Concentrating solar power for seawater thermal desalination. Desalination 2016, 396, 70–78. [Google Scholar] [CrossRef]

- Sarhosis, V.; Jaya, A.A.; Thomas, H.R. Economic modelling for coal bed methane production and electricity generation from deep virgin coal seams. Energy 2016, 107, 580–594. [Google Scholar] [CrossRef] [Green Version]

- Trevisan, S.; Ruan, T.; Wang, W.; Laumert, B. Techno-economic analysis of an innovative purely solar driven combined cycle system based on packed bed TES technology. AIP Conf. Proc. 2020, 2303. [Google Scholar] [CrossRef]

- Christensen, A. Assessment of Hydrogen Production Costs from Electrolysis: United States and Europe; International Council on Clean Transportation: Washington, DC, USA, 2020; pp. 1–73. [Google Scholar]

| Brayton Cycle | Rankine Cycle | TES Storage Approach | |||

|---|---|---|---|---|---|

| T1 | 25 °C | T7 | 416.35 °C | T13 | 265 °C |

| T3 | 850 °C | T8 | 40 °C | T14 | 430 °C |

| T5 | 265 °C | pHRSG | 23 bar | ||

| T5′ | 140 °C | ||||

| p1 | 101,300 Pa | ||||

| Π | 6.5 | ||||

| ηcompressor | 90% | ηpump | 90% | ||

| ηGT | 90% | ηST | 90% | ||

| TES Storage (Approach A) | H2 Storage (Approach B) | |

|---|---|---|

| Heliostat field area | 54,000 m2 | 64,050 m2 |

| Binary Molten Salts: 60% NaNO3 + 40% KNO3 | |

|---|---|

| Hot salts specific heat (at 430 °C) | 1.512 kJ/kg °C |

| Cold salts specific heat (at 265 °C) | 1.491 kJ/kg °C |

| Hot salts density | 1836 kg/m3 |

| Cold salts density | 1912 kg/m3 |

| Vapor pressure | <0.01 Pa |

| TES Storage (Approach A) | Hydrogen Storage (Approach B) | |

|---|---|---|

| Net energy for the design day (MWh) | 86.92 | 86.92 |

| Net peak power for design day (MW) | 9.67 | 15.06 |

| GT inlet temperature (°C) | 850 | 850 |

| ST inlet temperature (°C) | 416.35 | 416.35 |

| Storage tank | ||

| Tank type | Fixed Roof | Type I or II |

| Tank volume | 539.5 m3 | 6201.77 Nm3 |

| Tank pressure (bar) | 1 | 200 |

| Hot molten salts temperature (°C) | 430 | - |

| Cold molten salts temperature (°C) | 265 | - |

| Electrolyzer | ||

| Type | - | AEL |

| Operating temperature (°C) | - | 100–150 |

| Pressure (bar) | - | <30 |

| Consumption (kWh/Nm3) | - | 4.6 |

| Capacity (Nm3/h) | - | 1417.39 |

| Fuel cell | ||

| Type | - | PAFC |

| Operating temperature (°C) | - | 150–220 |

| Power (MW) | - | 7.34 |

| Efficiency (%) | - | 42 |

| TES Storage (Approach A) | Hydrogen Storage (Approach B) | |||||||

|---|---|---|---|---|---|---|---|---|

| Heliostat area (m2) | 54,000 | 64,050 | ||||||

| Combined cycle efficiency (%) | 45.21 | 48.12 | ||||||

| Sun-to-electricity efficiency (%) | 20.68 | 19.09 | ||||||

| Storage unit efficiency (%) | 100 | 27.40 | ||||||

| Utility factor (%) | 15.56 | 24.61 | ||||||

| Total energy harvested (MWh) | 126,127.64 | 150,013.57 | ||||||

| Total electricity produced (MWh) | 26,343.42 | 28,636.57 | ||||||

| Total energy stored (MWh) | 2245.87 | 5234.52 | ||||||

| Daily maximum energy stored (MWh) | 12.30 | 26.28 | ||||||

| Grid demand coverage for each season representative day * (h) | SP | SU | AU | WI | SP | SU | AU | WI |

| 0 | 7.85 | 7.09 | 0 | 8.10 | 8.17 | 7.36 | 0 | |

| Total demand coverage (h) | 1363.28 | 2155.75 | ||||||

| Storage volume production | 78,787.33 (m3) (Heated molten salts) | 1,137,978.75 (Nm3) (Hydrogen) | ||||||

| Direct Capital Costs | TES Storage | H2 Storage | ||

|---|---|---|---|---|

| Item | Value | Cost (USD, Millions) | Cost (USD, Millions) | Ref. |

| Gas turbine | 235·PGT (kW) USD | 2.00 | 1.97 | [49] |

| HRSG | 400 USD/kW | 4.58 | 5.01 | [50] |

| Rankine cycle components | 8220·PST (kW)0.7 USD | 4.92 | 3.19 | [51] |

| Tower | 156.63 USD/kW | 2.78 | 2.36 | [23] |

| Receiver | 97.59 × 103 USD | 0.097 | 0.097 | [51] |

| Solar field | 120.48 USD/m2 | 6.51 | 7.72 | [33] |

| Electrolyzer | 1000 USD/kW | - | 6.52 | [52] |

| Hydrogen tanks | 86 USD/kg | - | 0.044 | [53] |

| Fuel cell | 2000 USD/kg | - | 14.67 | [54] |

| Thermal Storage | 21.45 USD/kWh | 1.26 | - | [55] |

| Indirect Capital Cost | ||||

| Surcharge for construction, engineering and contingencies | 10% | 2.21 | 4.36 | [23] |

| Total CAPEX | 24.36 | 48.04 | ||

| Yearly Operating Costs | ||||

| Solar field | 5.4 USD/(m2·year) | 0.292 | 0.346 | [56] |

| Power block | 37,954.26 USD/(MW·year) | 0.674 | 0.576 | [57] |

| Thermal Storage | 62,400 USD/year | 0.625 | - | [58] |

| Electrolyzer | 2%—electrolyzer CAPEX | - | 0.130 | [59] |

| Hydrogen tanks | 1%—tanks CAPEX | - | 0.004 | [49] |

| Fuel cell | 34 USD/kW | - | 0.264 | [49] |

| Total OPEX | 1.59 | 1.31 | - | |

| TES Storage (Approach A) | H2 Storage (Approach B) | |

|---|---|---|

| Plant lifetime (years) | 30 | |

| Inflation rate (%) | 0.212 | |

| Discount rate (%) | 5 | |

| LCoE (USD/kWh) | 0.122 | 0.158 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reyes-Belmonte, M.Á.; Ambrona-Bermúdez, A.; Calvo-Blázquez, D. Flexible Electricity Dispatch of an Integrated Solar Combined Cycle through Thermal Energy Storage and Hydrogen Production. Thermo 2021, 1, 106-121. https://doi.org/10.3390/thermo1010008

Reyes-Belmonte MÁ, Ambrona-Bermúdez A, Calvo-Blázquez D. Flexible Electricity Dispatch of an Integrated Solar Combined Cycle through Thermal Energy Storage and Hydrogen Production. Thermo. 2021; 1(1):106-121. https://doi.org/10.3390/thermo1010008

Chicago/Turabian StyleReyes-Belmonte, Miguel Ángel, Alejandra Ambrona-Bermúdez, and Daniel Calvo-Blázquez. 2021. "Flexible Electricity Dispatch of an Integrated Solar Combined Cycle through Thermal Energy Storage and Hydrogen Production" Thermo 1, no. 1: 106-121. https://doi.org/10.3390/thermo1010008

APA StyleReyes-Belmonte, M. Á., Ambrona-Bermúdez, A., & Calvo-Blázquez, D. (2021). Flexible Electricity Dispatch of an Integrated Solar Combined Cycle through Thermal Energy Storage and Hydrogen Production. Thermo, 1(1), 106-121. https://doi.org/10.3390/thermo1010008