Observation of Blue Particles Formed by Photosensitizing Reaction on Paper Fibres of Cyanotypes

Abstract

1. Introduction

2. Materials and Methods

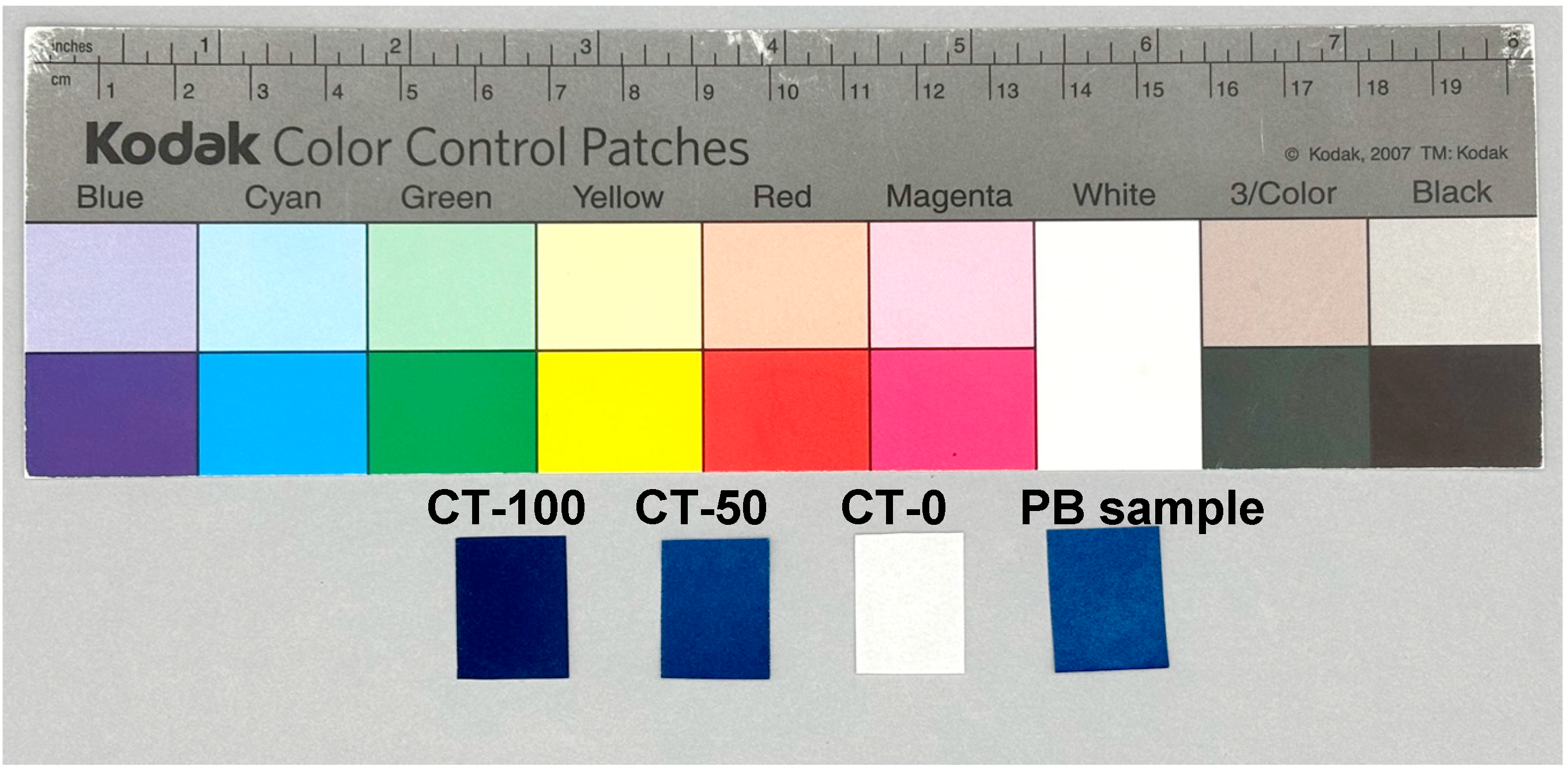

2.1. Sample Preparation

2.2. Observation by Microscopes

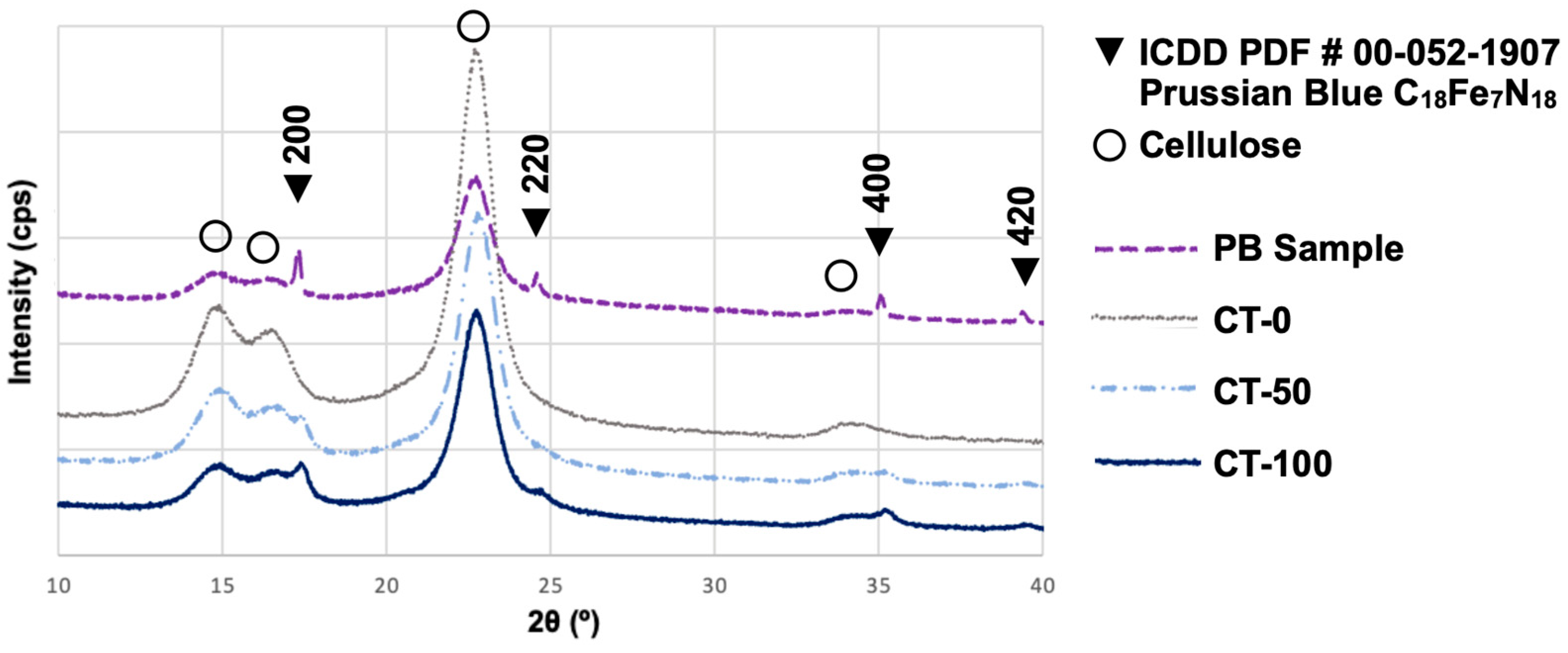

2.3. XRD Analysis

2.4. Micro-Raman Spectroscopy Analysis

3. Results and Discussion

3.1. Mechanism of the Cyanotype Method

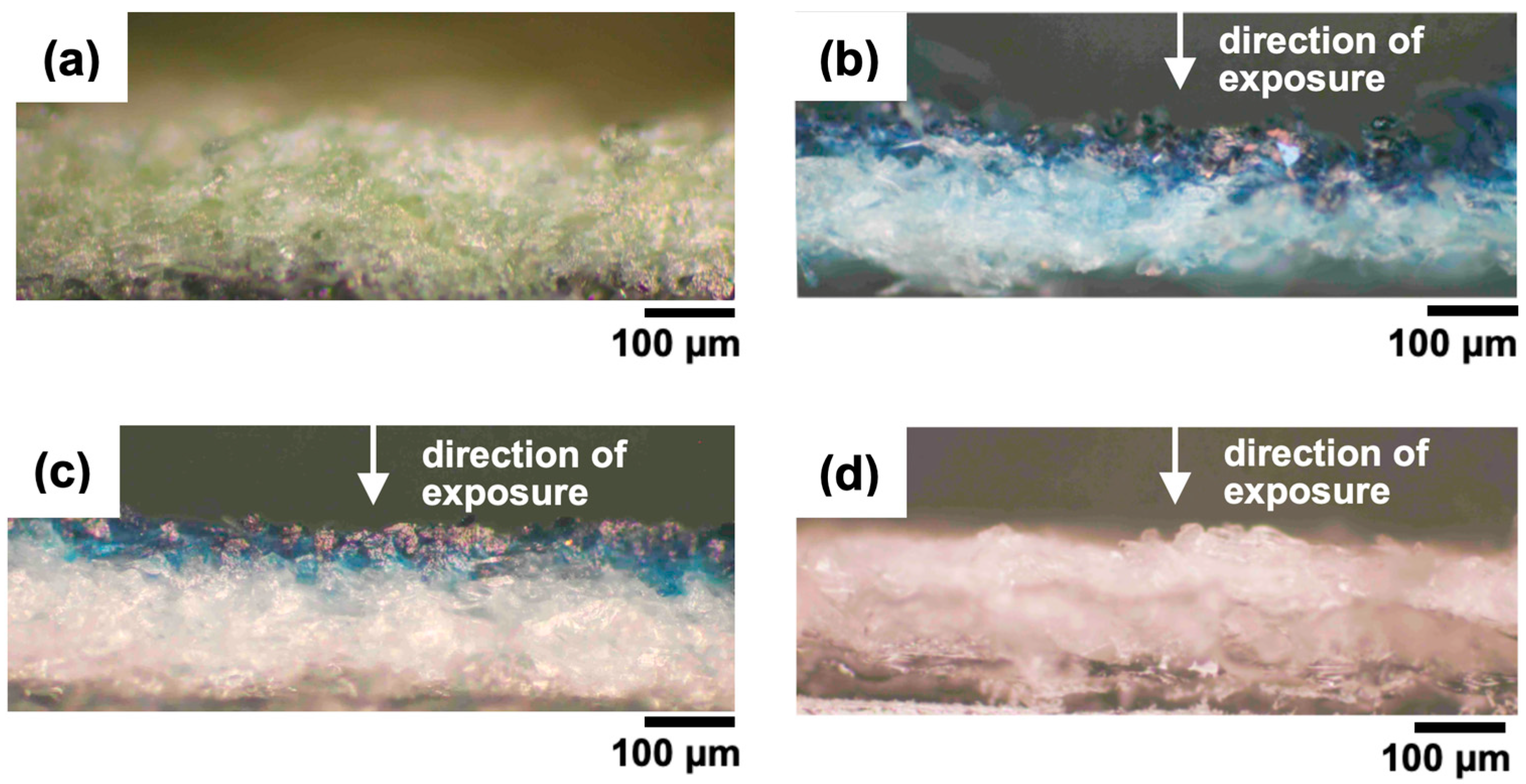

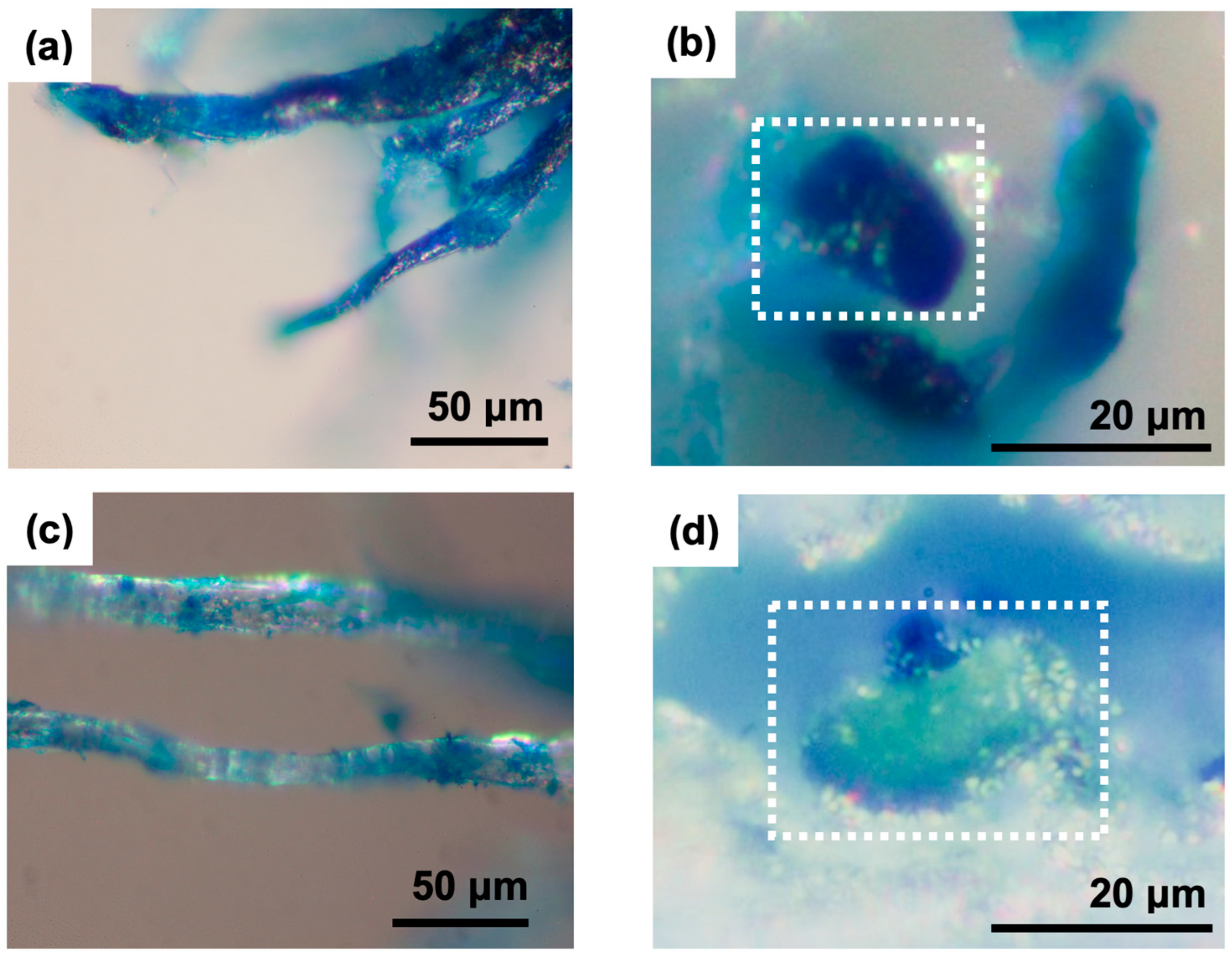

3.2. Comparison of Cyanotype Sample and PB Sample Using Optical Microscope

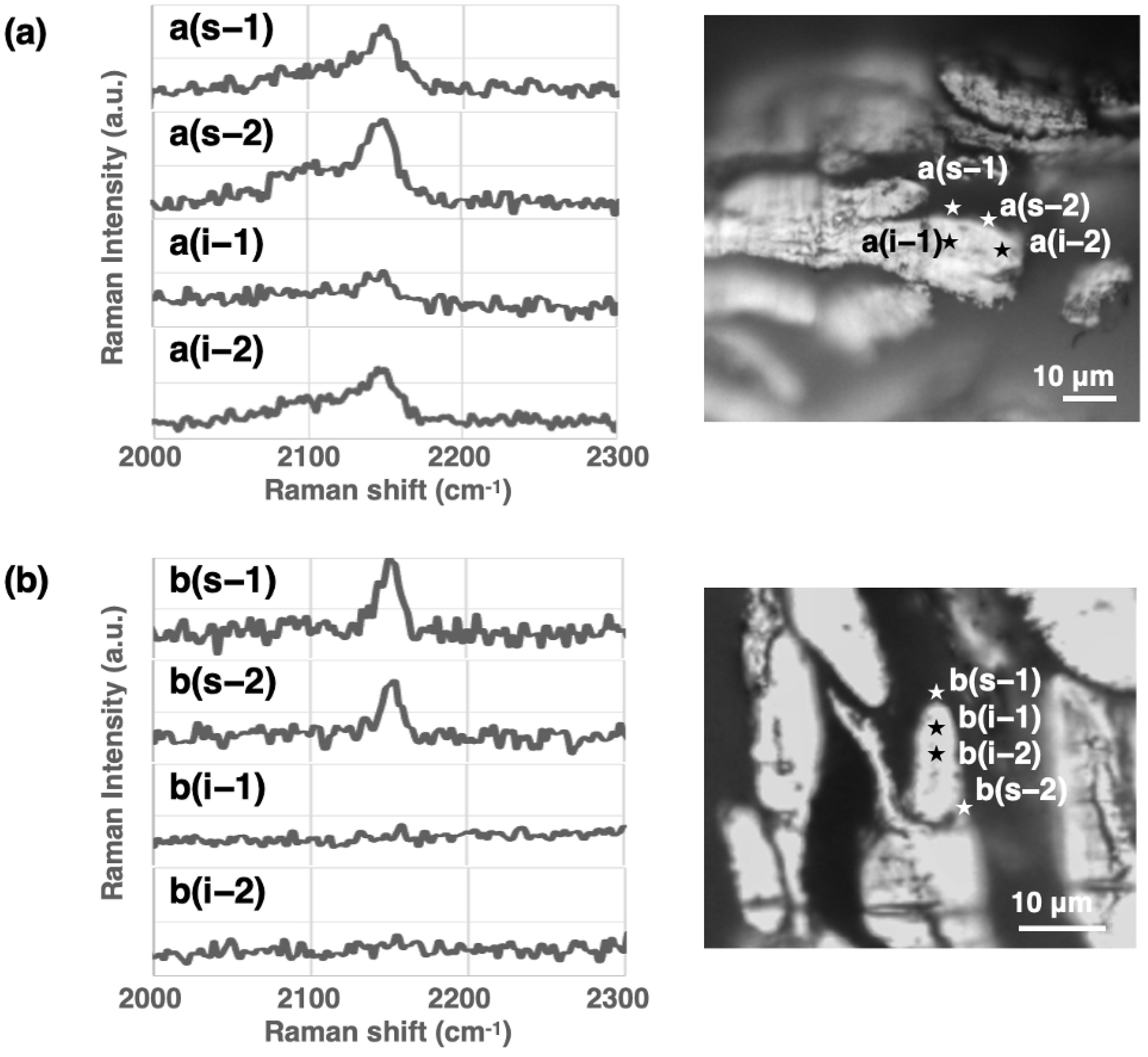

3.3. Micro-Raman Spectroscopy Analysis of the Cross-Section of the Paper Fibres of Cyanotype Sample and PB Sample

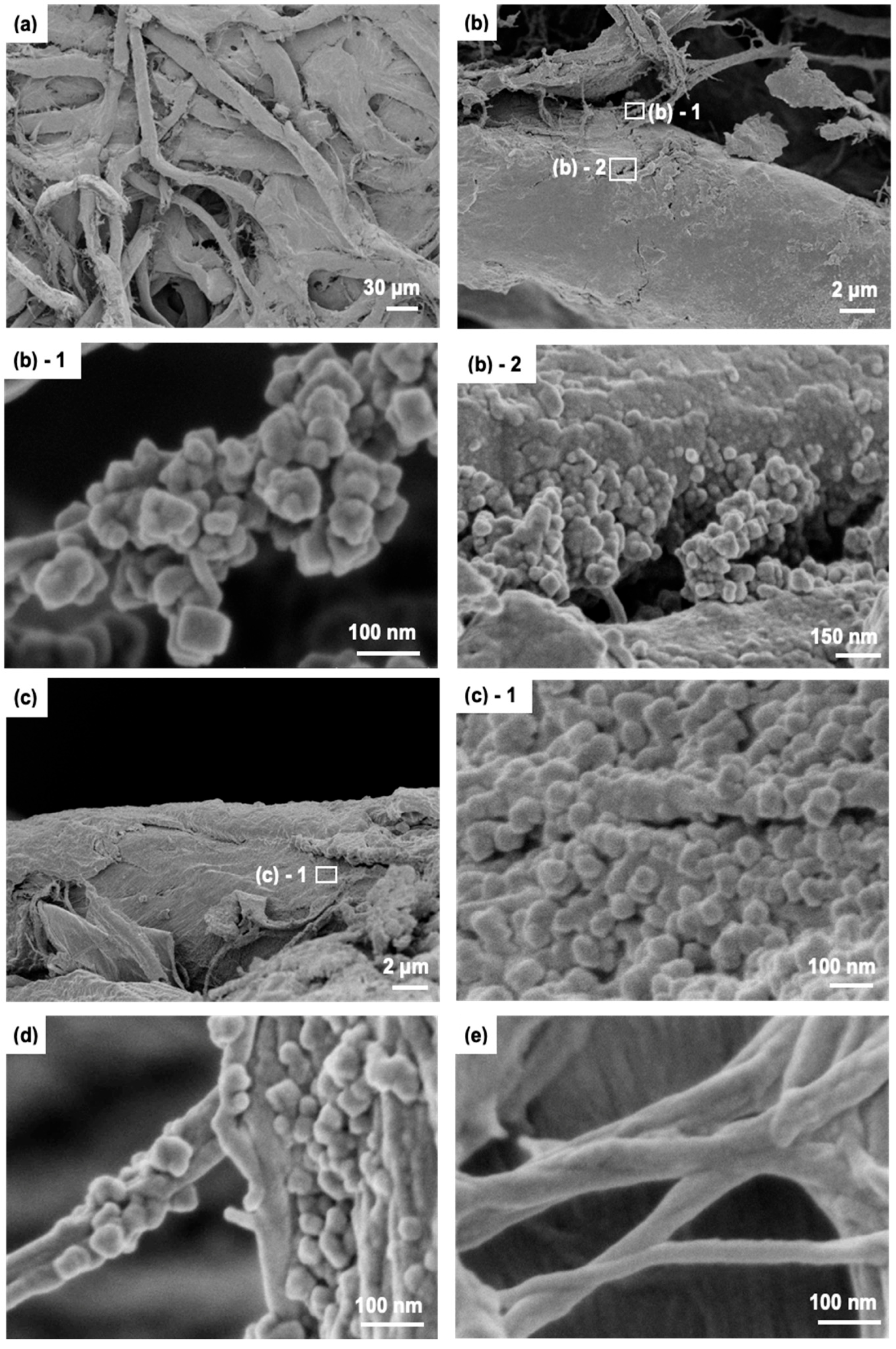

3.4. Comparison of the Surface of Fibres of Cyanotype Sample and PB Sample Using FE-SEM

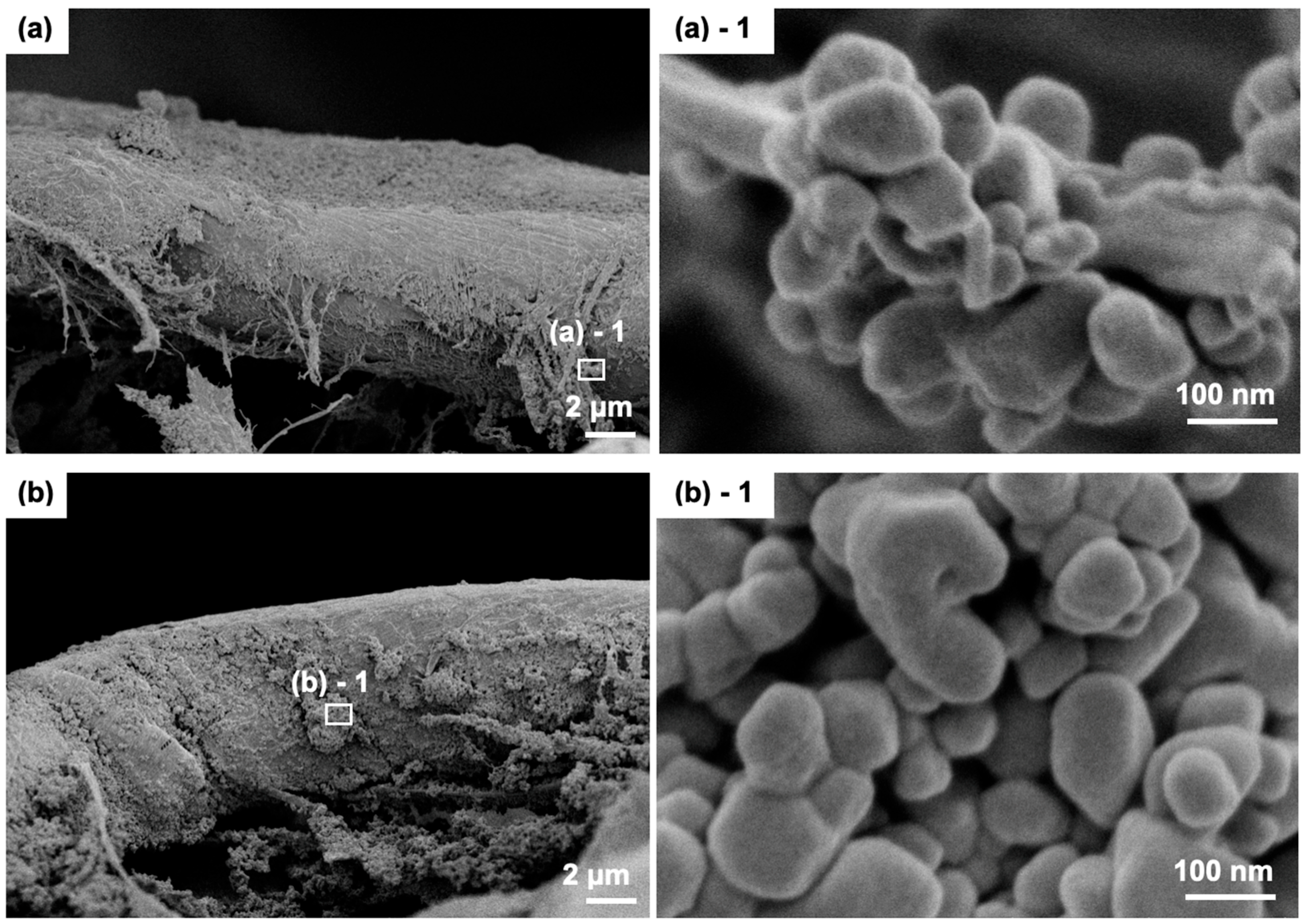

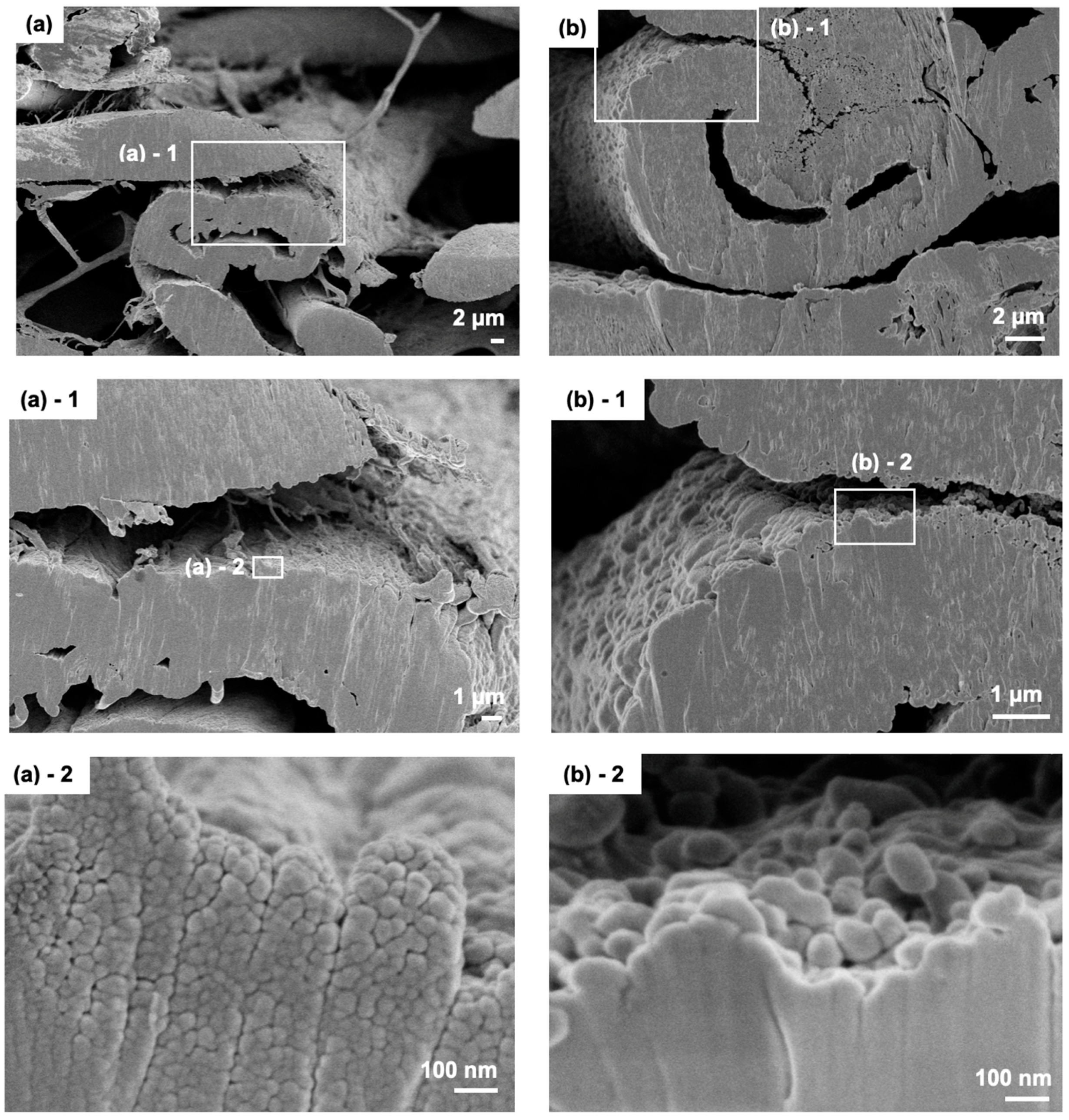

3.5. Comparison of the Cross-Section of Cotton Fibres of Cyanotype Sample and PB Sampleby FE-SEM

4. Possibilities of Further Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stulik, D.C.; Kaplan, A. Cyanotype. The Atlas of Analytical Signatures of Photographic Processes; Getty Conservation Institute: Angeles, Pampanga, 2013; Volume 6. [Google Scholar]

- Sentoku, S.; Kida, K. Comparison of the Decolorization of the Particles Formed by the Photosensitizing Reaction of Cyanotypes with Prussian Blue Pigment. In Proceedings of the 35th Conference of the Materials Life Society, Tokyo, Japan, 4–5 July 2024. [Google Scholar]

- Ware, M. Cyanotype: The History, Science and Art of Photographic Printing in Prussian Blue; National Museum of Science & I: London, UK, 1999; pp. 61, 65, 101, 104. [Google Scholar]

- How to Preserve Architectural Documents. Available online: http://www.trcc.jp/1st_archives_006.html (accessed on 20 December 2024).

- Conservation Treatments Done on the Architectural Plan of the Land of Katsu from the Collection of Kaishu Katsu Museum. Available online: https://www.hozon.co.jp/koubou/post_17227 (accessed on 20 December 2024).

- Jinushi, T. Recent Achievements and Challenges in Conservation of Historical Documents. In Proceedings of the Seminar on the Current Status of Restoration of Cultural Properties and Its Issues, Tokyo, Japan, 22 November 2018. [Google Scholar]

- Ware, M.A. Blueprint for Conserving Cyanotypes. Top. Photogr. Preserv. 2003, 10, 2–18. [Google Scholar]

- Barandiaran, M. Evaluation of Conservation Treatments Applied to Salted Paper Prints, Cyanotypes and Platinotypes. Stud. Conserv. 2000, 45, 162–168. [Google Scholar] [CrossRef]

- Ware, M. Cyanomicon: History, Science and Art of Cyanotype: Photographic Printing in Prussian Blue; National Museum of Science & I: London, UK, 2017; pp. 79, 136. [Google Scholar]

- DXR3 Raman Microscope. Available online: https://www.thermofisher.com/order/catalog/product/jp/en/IQLAADGABFFAHCMAPB (accessed on 27 December 2024).

- Samain, L.; Grandjean, F.; Long, G.; Martinetto, P.; Bordet, P.; Strivay, D. Relationship Between the Synthesis of Prussian Blue Pigments, Their Color, Physical Properties, and Their Behavior in Paint Layers. J. Phys. Chem. C 2013, 117, 9693–9712. [Google Scholar] [CrossRef]

- JIS P3801; Filter Paper (for Chemical Analysis). Japanese Industrial Standard: Tokyo, Japan, 2021.

- Vera, R.; Zambrano, F.; Suarez, A.; Pifano, A.; Marquez, R.; Farrell, M.; Ankeny, M.; Jameel, H.; Gonzalez, R. Transforming Textile Wastes into Biobased Building Blocks via Enzymatic Hydrolysis: A Review of Key Challenges and Opportunities. Clean. Circ. Bioeconomy 2022, 3, 100026. [Google Scholar] [CrossRef]

- Shuvo, I. Fibre Attributes and Mapping the Cultivar Influence of Different Industrial Cellulosic Crops (Cotton, Hemp, Flax, and Canola) on Textile Properties. Bioresour. Bioprocess. 2020, 7, 51. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sentoku, S.; Kurashina, M.; Kida, K. Observation of Blue Particles Formed by Photosensitizing Reaction on Paper Fibres of Cyanotypes. Photochem 2025, 5, 18. https://doi.org/10.3390/photochem5030018

Sentoku S, Kurashina M, Kida K. Observation of Blue Particles Formed by Photosensitizing Reaction on Paper Fibres of Cyanotypes. Photochem. 2025; 5(3):18. https://doi.org/10.3390/photochem5030018

Chicago/Turabian StyleSentoku, Sawako, Mari Kurashina, and Keiko Kida. 2025. "Observation of Blue Particles Formed by Photosensitizing Reaction on Paper Fibres of Cyanotypes" Photochem 5, no. 3: 18. https://doi.org/10.3390/photochem5030018

APA StyleSentoku, S., Kurashina, M., & Kida, K. (2025). Observation of Blue Particles Formed by Photosensitizing Reaction on Paper Fibres of Cyanotypes. Photochem, 5(3), 18. https://doi.org/10.3390/photochem5030018