Abstract

The apparel industry is changing dynamically and quickly to manufacturing sustainable fashion products and the development of sustainable design strategies that minimize material consumption at the source. This study addresses a critical research gap by quantitatively evaluating the impact of fusing traditional South Asian garment construction (the kameez) with varied, Western-inspired sleeve geometries on key manufacturing metrics. Thirty-three distinct women’s garment styles, comprising three kameez types (simple, princess-cut, open-front) each paired with eleven different sleeve designs, were developed in the apparel industry to study the effect of fabric efficiency, wastage, and cost-effectiveness. The virtual patterns and markers were drafted and accomplished through Garment Gerber Technology (GGT) software to analyze fabric consumption, fabric efficiency, and cost-effectiveness. The results revealed that paneled kameez styles, such as the princess-cut and open-front, are significantly more material-efficient, achieving average fabric efficiencies of up to 83.95%, compared to the monolithic simple kameez, which averaged only 75.68%. Among sleeve types, multi-constructions like the slit sleeve and cuff sleeve proved most efficient (achieving up to 86.91% efficiency), while voluminous, single-piece designs like the umbrella sleeve consumed the most fabric and were the least efficient. Open-front kameez slit sleeves (OFSL3), simple kameez slit sleeves (SSL3), and princess-cut kameez slit sleeves (PCSL3), were better and more sustainable selections since they were most efficient in fabric efficiency (i.e., 86.91%, 86.17%, and 86.09%). Furthermore, the simple kameez style has the highest fabric wastage (above 22%), while the princess kameez style has the least (below 19%). The simple kameez slit sleeves design (SSL3) has the minimum wastage, while the simple kameez umbrella sleeves design (SSL4) has the maximum wastage. From a cost perspective, the open-front kameez slit sleeve (OFSL1) was identified as the most economical design, whereas the simple kameez with an umbrella sleeve (SSL4) was the most expensive. Statistical analysis confirmed that the differences between kameez styles were significant (p < 0.05). Thus, adoption of specific, sustainable, deliberate design choices and incorporating paneling into the garment body and utilizing multi-piece sleeve constructions offer a quantifiable and strategic approach for manufacturers to reduce material waste, optimize fabric utilization, and improve production cost-effectiveness.

1. Introduction

The apparel industry is a vast and dynamic sector that encompasses clothing manufacturing, retail fashion design trends, and sustainability [1]. However, this industry deals with significant complications concerning the wastage of depleted resources, the improper use of new designs, high fabric consumptions, and its impact on consumers and the environment [2,3]. To meet the challenges of the modern world and end consumers, manufacturers are continuously striving to produce more useful and esthetic clothing with a reduction in wastage [4]. Furthermore, the industry needs to improve its methodologies through sustainable practices, skill development, the selection of effective designs, and optimum material usage strategies [5]. Addressing these issues would boost the sector’s competitiveness, attract investments, and contribute significantly toward the national economy of many countries [6].

Recently, many researchers have made contributions to improve the efficiencies of fabric utilization in the apparel industry through new concepts, techniques, technology upgrades, process optimization, and work measurements [7,8,9,10,11,12,13]. For instance, Sweta and Asis (2017) conducted a study on the impact of garment manufacturing, covering reasons, strategies, and industry trends [14]. They examined that the rise of fast fashion has driven the shift toward automation for quicker, higher quality, and cost-effective production to meet evolving consumer demands. Similarly, Jhanji (2017) examined how globalization and consumer demands drive technological adoption in the textile and fashion industries [15]. The adoption of CAD, from 2D to 3D, highlights efficiency gains, customization, and improved integration across design, manufacturing, and preproduction stages. In addition, Haque 2013 [16], in his research, evaluated the impact of using computer-aided design (CAD) and computer-aided manufacturing (CAM) systems compared to manual methods in the apparel industry of Bangladesh. The study assessed factors like time, wastage, quality, productivity, and lead time, finding that CAD/CAM systems led to significant improvements in productivity, quality, fabric utilization, and time savings in garment manufacturing processes [16]. In another study, Chaudhary et al. (2020) [17] investigated the adoption of CAD technology in India’s textile and apparel manufacturing sector. The study examined how CAD enhances design efficiency, reduces costs, and accelerates production through integration with CAM, while also assessing its impact on design, productivity, and business outcomes [17]. Furthermore, the research focuses on the underutilization of CAD/CAM systems in the apparel and textile industry despite their potential benefits. It discusses the technology’s applicability, benefits, and slow adoption, highlighting its role in enabling customization and shifting industries toward mass customization and personalization [18].

The design (creates the outfit) and style (coordinates the esthetic choices for the visual or outer look with accessories) of any garment holds significant importance for women’s clothing [19]. In the 13th century, the kameez style (long kameez or tunic) was introduced in South Asia [20]. Historically, it was more open and had straight traditional cuts, which helps with greater freedom of movement [21]. However, modern kameez are more likely to have Western-style cuts and collars, to be collarless and more fitted, and to have European-inspired set-in sleeves to enhance the esthetics of an outfit. Further variations express personal styles, create balance in their body proportions, and make fashion statements [22]. They also reflect cultural and historical influences and contribute to the ever-evolving trends in women’s fashion [21,23]. By focusing on the type and styles of sleeves, it should ensure suitability for different occasions, express individuality, and create visually appealing, cohesive ensembles with the required dynamic comfortability [24]. For instance, Kazlacheva et al. underscore the importance of sleeve design in women’s clothing by examining diverse sleeve types like raglan, semi-raglan, kimono, and dropped shoulder sleeves. The study showcased how altering design constructional seams influences the esthetic and functional aspects of ladies’ jacket patterns. Through this exploration, the research has highlighted the creative potential and versatility that different sleeve designs bring to women’s fashion [25]. Venkatasamy et al. (2015) [26] conducted a study to explore how fashion serves as a means of self-expression and reflects societal beliefs and cultural norms. The study emphasizes the importance of fashion trends in shaping individuals’ self-image and their pursuit of personal and social identity. Kazlacheva et al. (2016) [25] explored a variety of sleeve types and their importance in fashion with academic rigor, elaborating on their significance beyond their functional aspect. Different sleeve styles were discussed for their impact on a garment’s silhouette, style, movement, and structure, contributing to the overall design and esthetics of the clothing piece.

Technological upgrades, such as the adoption of computer-aided design (CAD), pattern-making software, and manufacturing systems, have been adapted by the apparel industry to improve precision, accuracy and the highest possible efficiencies for fabric cutting, and marker making (efficient nesting of patterns) with a decrease in fabric wastage [27]. Studies have consistently shown that CAD/CAM systems lead to significant improvements in productivity, quality, and fabric utilization compared to manual methods. However, a critical research gap persists; while these technologies have been extensively applied to optimize Western garment patterns, there is a notable lack of quantitative data on the manufacturing efficiency of hybrid garments that blend traditional South Asian construction with Western design elements.

This study aims to fill that gap by providing a systematic, quantitative analysis of one such hybrid garment, i.e., women’s kameez. The kameez, a tunic traditionally featuring straight cuts, has evolved to incorporate more fitted, European-inspired set-in sleeves and varied constructional lines to enhance its esthetic appeal. The scientific novelty of this research lies not merely in optimizing pattern layouts but in quantifying the direct causal link between specific geometric design choices—such as the use of paneling in the kameez body and the complex shapes of different sleeves—and their impact on manufacturing metrics like fabric consumption, efficiency, and cost. By establishing this link, the study moves beyond a simple comparative analysis to provide a predictive framework for sustainable design, offering principles that can be generalized and applied by designers and manufacturers. The primary aims of this research are to systematically quantify the fabric consumption, efficiency, and wastage for 33 distinct kameez-sleeve combinations, representing a fusion of South Asian and Western design cuts, to determine the statistical significance of the kameez body style and sleeve geometry on these key production metrics using analysis of variance (ANOVA) and to identify the most cost-effective and materially efficient design principles that can be implemented for sustainable mass production in the apparel industry.

2. Experimental Work

2.1. Preparation of Garment Samples

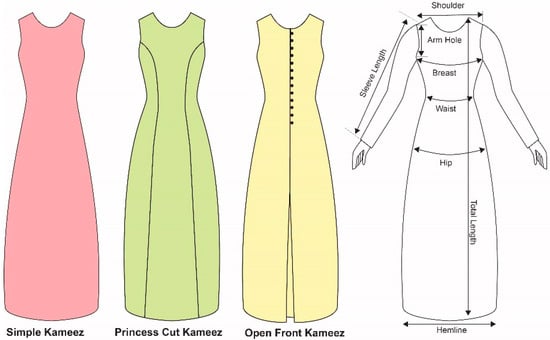

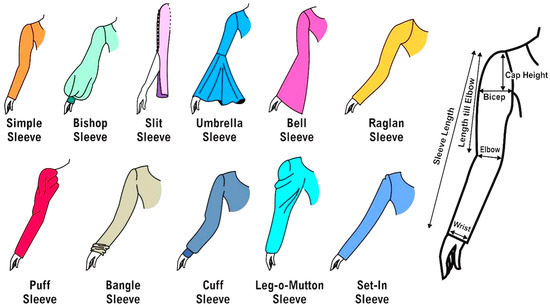

Figure 1 shows the three types of kameez designs, i.e., simple; (S), princess-cut (PC) and open-front (OF), most often used by local brands. The simple kameez has monolithic front and back panels with straight side seams. A simple kameez is comprised of one-piece full front width and cut on the fold or closed, whereas an open kameez has two symmetrical front panels which are cut in two parts with a center opening; i.e., each half is cut separately (add seam allowance at center front). There are no differences in the pattern of the back panels of both kameez. In a princess-cut kameez, the entire front is constructed with 3 panels: center + 2 princess panels and shaped with vertical seam lines (princess seams) running from the shoulder or armhole down to the hem. The three designs were configured with the eleven styles of sleeves, i.e., simple (SL1), bishop (SL2), slit (SL3), umbrella (SL4), bell (SL5), raglan (SL6), puff (SL7), bangle (SL8), cuff (SL9), leg-o-mutton (SL10), and set-in (SL11), as shown in Figure 2. So, 33 garment samples were prepared, as detailed in Table 1. Simple sleeve (SL1) refers to a basic sleeve pattern with minimal shaping. It is loose, more relaxed, does not contour the shoulder precisely and therefore is easier to sew with fewer pieces or seams. Its silhouette is sleek, close to the arm. Bishop sleeve (SL2) is wider and more flared toward the wrist with gathers creating romantic, soft, flowy, and dramatic silhouette. Slit sleeve (SL3) with one or more vertical slits (openings), usually along the outer or inner seam (slit added seam allowance). It creates a sense of movement and elegance due to its silhouette (loose, open and flowing, airy shape or structure). Umbrella sleeve (SL4) is a wide, circular, flowy and draping sleeve shaped like an umbrella or half-circle with flare at the hem. Bell sleeve (SL5) is a wide, circular, fitted at the armhole and upper arm, but flared-out hem at the lower part like a bell-shaped one. Raglan sleeve (SL6) extends to the neckline and is slightly relaxed, forming part of the shoulder and allowing more freedom of movement. Puff sleeve (SL7) has extra fullness at the top (cap), bottom (hem), or both, gathered to create a puffy and rounded look. Bangle sleeve (SL8) is tapered more sharply at the wrist, often with full gathers, pleats, or attached cuffs to resemble bangles or bracelets. Cuff sleeve (SL9) ends with a separate cuff piece attached at the wrist. Leg-o-mutton sleeve (SL10) is a voluminous sleeve with exaggerated fullness at the upper arm (wide and puffy at the top), narrowing sharply to a fitted wrist (slim at the bottom), creating a dramatic hourglass effect, while set-in sleeve (SL11) is shaped and sewn into a defined armscye. It is tailored and more fitted, contours naturally over the shoulder and hence is technically more complex, requiring accurate notching, easing, and sometimes gathering at the cap. Thus, each of the complex sleeve shapes was developed from the basic sleeve pattern. For instance, for sleeves that require added fullness or flare (such as the umbrella sleeve (SL4) and bell sleeve (SL5)), the classic slash-and-spread technique was employed in pattern drafting—cutting and spreading the basic sleeve pattern at specific angles to introduce the desired flare. Moreover, during pattern sketching, the necessary angles and expansion distances were used to achieve the new geometry (e.g., the umbrella sleeve was created by spreading the pattern evenly to form a circular shape, which increases the hem circumference significantly). For the leg-o-mutton sleeve (SL10), fullness was added near the shoulder (sleeve cap) by slashing and spreading in the upper part of the sleeve, creating the characteristic puff at the top. In the case of sleeves with additional pieces, like the bishop sleeve (SL2) and cuff sleeve (SL9), the lower portion of the sleeve was gathered or fitted into a separate cuff piece. The cuff pattern was drafted (with the cuff length equal to the sleeve hem circumference after gathering, etc.).

Figure 1.

Three selected kameez styles: simple kameez; princess-cut kameez; open-front kameez.

Figure 2.

Types of selected sleeve designs.

Table 1.

Preparation of garment samples.

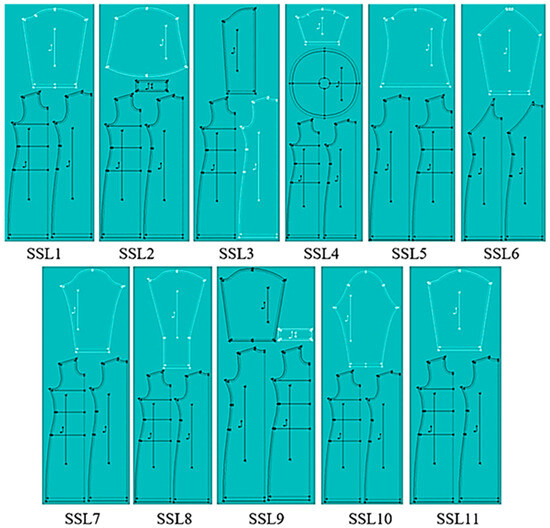

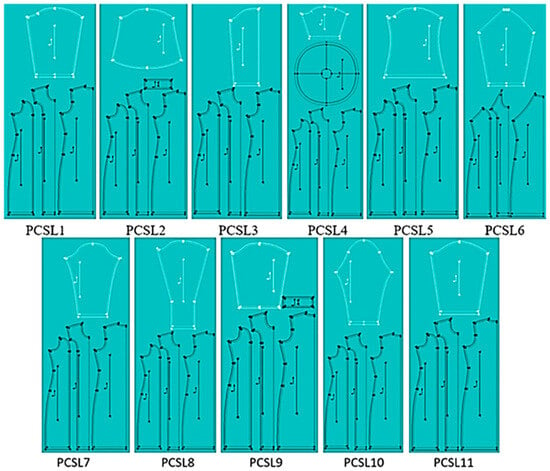

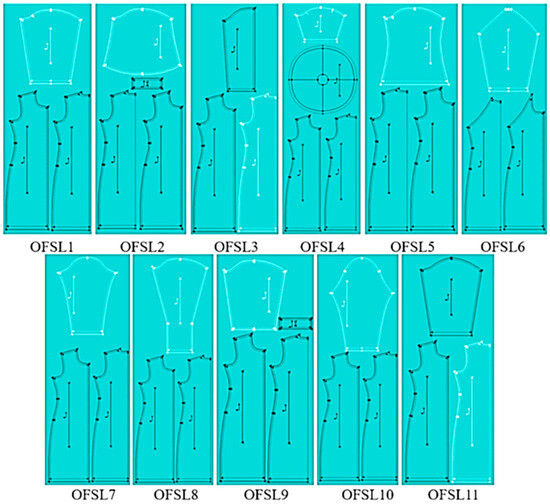

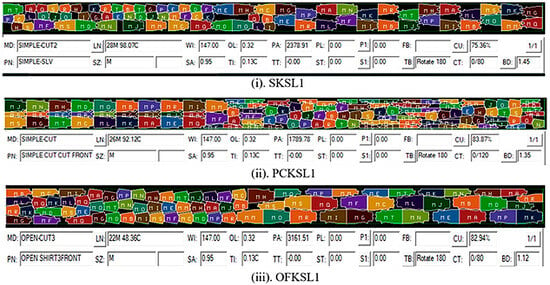

Flat pattern drafting method was used for developing all kameez and sleeve patterns. This involved drafting the basic pattern blocks on paper (pattern sheets) through pattern-making techniques and then digitizing these patterns into the Gerber CAD system (GGT AccuMark v9.0) for further modification and marker making, i.e., after manual drafting and adjustments, all pattern pieces were input into Gerber AccuMark and checked against the intended measurements (ensuring that the geometric parameters—angles, added widths, lengths—match the design). In particular, the use of CAD for pattern development and efficient marker layout followed modern industry practices. This digitization is legitimate to accurately compute fabric usage for each new sleeve geometry. Figure 3, Figure 4 and Figure 5 shows the transformation of virtual patterns of three styles of kameez with different sleeves drafted through GGT software. All virtual patterns were processed further for drafting markers (nested well) for the fabric efficiency. Figure 6 shows the pattern markers of the simple (SSL1), princess-cut (PCSL1) and open-front (OFSL1) designs. Similarly, the pattern markers of all the styles were drawn subsequently.

Figure 3.

Virtual patterns of simple (S) kameez style with different sleeves drafted on GGT software.

Figure 4.

Virtual patterns of princess-cut (PC) kameez style with different sleeves drafted on GGT software.

Figure 5.

Virtual patterns of open-front (OF) kameez style with different sleeves drafted on GGT software.

Figure 6.

Virtual pattern markers of women’s kameez styles: (i). Simple kameez sleeve design one (SKSL1); (ii). Princess-cut kameez sleeve design one (PCKSL1); (iii). Open-front kameez sleeve design one (OFKSL1).

2.2. Selection of Fabric

Plain 100% cotton fabric (203 g/m2) was chosen for the research work. The usable width for drawn pattern markers was 147 cm, excluding the selvedge.

2.3. Selection of Size

Garment measurements for basic cuts were received from the local brand, i.e., Sana Safinaz. The medium-size standard measurements for women (shown in Table 2) were used for drafting the flat patterns with the assistance of GGT (AccuMark 9.0) software. Tolerances ± 1.27 cm were considered for all finished garments.

Table 2.

Standard medium-size measurements of women’s kameez.

Table 3 explicates the comparative geometry parameters of sleeve types (SL1–SL11), including cap height (CH, cm), upper arm circumference (UAC, cm), forearm circumference (FAC, cm), wrist circumference (WC, cm), extra fullness/gather factor (GF, %), flare/taper angle (° per side). It provides a quantitative framework for defining sleeve geometry, calculated taper/flare angle per side between two sleeve sections using [α = arctan (∣w2 − w1∣v) × 180/π], where w1, w2 are half-widths at adjacent levels, and v is the vertical separation. Fabric consumption calculated via trapezoidal approximation; Area (cm2): [A ≈ v × (C1 + C2/2)]. For instance, in the set-in sleeve (SL11), the taper between bicep and elbow was 13° per side and between elbow and wrist 10° per side. Similarly, for other models, bell sleeve (SL5): flare at hem ≈ 20° per side; umbrella sleeve (SL4): circular flare ≈ 40°; bishop sleeve (SL2): hem flare ≈ 15° per side, reduced by gathering into cuff; simple sleeve (SL1): gentle taper ≈ 8° per side; puff sleeve (SL7) and leg-o-mutton sleeve (SL10): flare values at cap are not purely angular but defined by gather factor (GF = 2.0 or more), creating volumetric expansion rather than linear taper. Moreover, total fabric consumption for each kameez–sleeve combination is the sum of the body panel areas plus the two sleeve panel areas, where every panel area was calculated using trapezoidal integration between measured circumferences (cm). Mathematically (Equation (1)), fabric consumption (FC) for kameez k and sleeve i is as follows:

where FCbody(k) and FCsleeve(i) defined by the trapezoidal formulas above, λsa is the seam/hem/facing allowance area (cm2), and λcut is the layout/cutting waste.

FCtotalcut(k,i) = [(FCbody(k) + 2 FCsleeve(i) + λsa) (1 + λcut)]

Table 3.

Comparative geometric parameters of sleeve types (SL1–SL11).

For a typical two-panel kameez (front + back): FCbody ≈ FCfront panel + FCback panel + Aplacket/facing, and for one-panel approximation (front or back): FCpanel ≈ ⋅(Cj + Cj+1/2).

2.4. Tools, Equipment and Methods

Patterns were drafted through pattern-making tools on a pattern sheet. A 2% shrinkage margin and ±1.27 cm sewing allowance for all patterns was included to avoid the destabilizing of the finished size measurements. The patterns were digitized (transformed virtually), and markers were generated, each comprising 20 garment pieces.

3. Results and Discussion

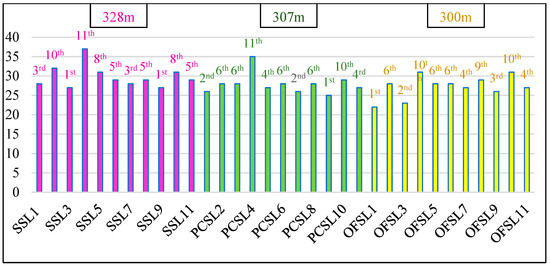

3.1. Results of Total Fabric Consumed in All Garment Samples

The comparative analysis of fabric consumption for different kameez styles revealed notable variations across the 33 stitched garments. Among all styles, the simple kameez (S) consumed the highest total fabric (328 m), followed by the princess-cut kameez (PC) at 307 m and the open-front kameez (OF) at 300 m, as shown in Figure 7. This established the following order in terms of fabric consumption (fabric usage trend): open-front kameez (OF) < princess-cut kameez (PC) < simple kameez (S).

Figure 7.

Results of fabric consumed in all garment samples.

Within the simple kameez category, the least fabric was used by garments SSL9 (cuff sleeve) and SSL3 (slit sleeve); each required only 27 m. These designs ranked first due to their compact sleeve structures and efficient layout in pattern drafting. SSL1 (simple sleeve) and SSL7 (puff sleeve) ranked third, with a slightly higher consumption of 28 m, largely because of their modest shaping. Garments featuring raglan (SSL6), bangle (SSL8), and set-in sleeves (SSL11) exhibited moderate fabric consumption. The highest fabric usage, 37 m, was recorded for SSL4 (umbrella sleeve), which required larger cuts due to its flared silhouette, positioning it last in fabric consumption among the simple kameez designs.

In the princess-cut kameez group, the lowest fabric consumption (25 m) was observed in PCSL9 (cuff sleeve), which ranked first due to a streamlined construction that integrated well with the princess seam silhouette. Several other styles including PCSL1 (simple), PCSL7 (puff), PCSL2 (bishop), PCSL3 (slit), and PCSL4 (umbrella) consumed moderate amounts of fabric (26–28 m). Among these, the umbrella sleeve variant PCSL4 required the highest amount of fabric (35 m) due to its expanded hem width and shaping needs, making it the least efficient in this group.

For the open-front kameez, the most fabric-efficient design was OFSL1 (simple sleeve), using only 22 m due to its minimal pattern complexity. OFSL3 (slit sleeve) and OFSL9 (cuff sleeve) followed closely, requiring 23 and 26 m, respectively. While the cuff sleeve design required extra material for the folded component, its overall efficiency remained high. Sleeves such as puff (OFSL7), set-in (OFSL11), bishop (OFSL2), bell (OFSL5), and raglan (OFSL6) fell in the middle range, consuming 27 to 28 m. The least fabric-efficient styles in this group were OFSL4 (umbrella sleeve) and OFSL10 (leg-o-mutton sleeve), each using 31 m due to their wide flared shapes and elaborated cuts.

Overall, it was evident that sleeve style and garment cut significantly influenced fabric usage. Styles with streamlined silhouettes and minimal flare proved most economical, whereas voluminous or multi-panel sleeves required greater fabric yardage. A consolidated view of sleeve performance rankings and fabric consumption across all garments has been provided in Table 4.

Table 4.

Positioning of garment samples in relation to fabric consumption.

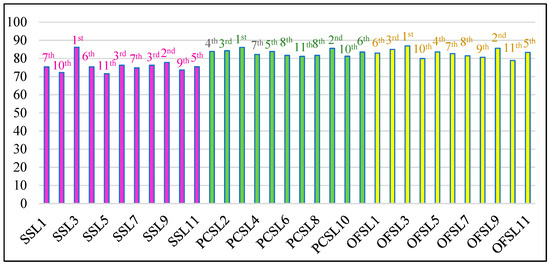

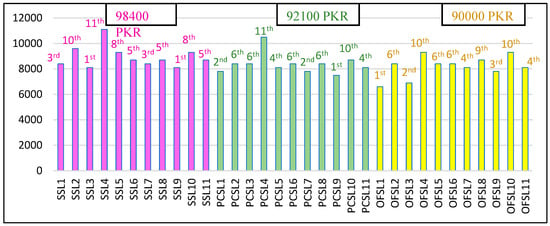

3.2. Results of Fabric Efficiency in All Garment Samples

Among the simple kameez designs in Figure 8, the simple kameez slit sleeves (SSL3) achieved the highest fabric efficiency (86.17%) due to optimized pattern adjustments that minimized fabric wastage. In contrast, simple kameez bell sleeves (SSL5) exhibited the lowest efficiency (71.60%) due to the flared patterns that increased fabric consumption and hindered effective pattern nesting. Simple kameez cuff sleeves (SSL9) ranked second (77.77%), while both simple kameez raglan sleeve (SSL6) and simple kameez bangle sleeve (SSL8) shared the third rank (76.27%), benefiting from complementary panel layouts that improved fabric utilization. Mid-tier designs such as SSL11 and SSL4 exhibited moderate fabric efficiencies but did not significantly increase fabric consumption. SSL1 and SSL7, despite consuming less fabric (28 m), ranked seventh and eighth in efficiency due to design-related pattern gaps, while SSL10 and SSL2, with high fabric consumption (31 m and 32 m), ranked among the least efficient.

Figure 8.

Results of fabric efficiency in all garment samples. The pink color represents the fabric efficiency results of simple kameez with sleeves, green color display the princess cut kameez and yellow color shows the open front kameez results.

Only SSL3 surpassed 80% efficiency among simple kameez samples, largely due to favorable pattern structuring. Generally, increased fabric consumption correlated with lower efficiency, although exceptions were observed in SSL1, SSL7, and SSL4. SSL4 demonstrated moderate efficiency (75.39%) despite high fabric consumption, attributed to the circular umbrella sleeve pattern that allowed close nesting with other components.

In the princess-cut kameez group, princess-cut kameez slit sleeves (PCSL3) achieved the highest efficiency (86.09%) with 28 m of fabric, attributed to the four-panel sleeve design that facilitated tight nesting. Conversely, PCSL7, with puff sleeves and extended top flare, ranked lowest (81.15%) despite consuming only 26 m. PCSL9, featuring cuff sleeves with small, easily nested components, ranked second in efficiency (85.58%) and had the lowest fabric consumption (25 m). PCSL2 (bishop sleeves), PCSL1 (simple sleeves), and PCSL5 (bell sleeves) ranked third to fifth, with efficiencies of 84.28%, 83.87%, and 83.81%, respectively. The two-piece cuffed bishop sleeve in PCSL2 allowed better space utilization than the single-piece simple and bell sleeves, the latter suffering from greater flare-induced waste. Mid-range designs such as PCSL11 and PCSL4 also demonstrated reasonable efficiencies (83.53% and 82.21%). Raglan (PCSL6) and bangle sleeve (PCSL8) variants showed equal efficiencies (81.73%), with pattern geometry limiting nesting potential. PCSL10, with leg-o-mutton sleeves, ranked 10th in efficiency (81.26%) due to the wide top flare, despite high fabric usage (29 m). All princess-cut samples achieved efficiencies above 80%, likely due to the segmented front panel structure that facilitated more efficient pattern placement. Notably, PCSL3 and PCSL7 deviated from the consumption–efficiency trend, underscoring the influence of sleeve design on marker optimization.

Among the open-front kameez designs, open-front kameez slit sleeves (OFSL3) demonstrated the highest efficiency (86.91%) and lowest fabric consumption (23 m), indicative of excellent pattern nesting. In contrast, open-front kameez leg-o-mutton-sleeves (OFSL10) exhibited the lowest efficiency (78.88%) with the highest fabric consumption (31 m) due to the wide flare of the sleeve design. OFSL9 (cuff sleeves), OFSL2 (bishop sleeves), and OFSL5 (bell sleeves), ranked second to fourth with efficiencies of 85.64%, 85.00%, and 83.61%, respectively, reflected the efficiency of compact sleeve components. OFSL11 and OFSL1 followed with mid-range efficiencies (83.3% and 82.94%). All open-front designs surpassed 80% efficiency, except OFSL4 and OFSL10, whose sleeve designs involved substantial flare, thereby increasing fabric consumption and reducing efficiency. A general trend was observed in this group: increased fabric consumption typically resulted in decreased efficiency due to diminished nesting viability. All these established the order (PC > OF > S) in terms of fabric efficiency.

Overall, fabric efficiency was significantly influenced by sleeve type, pattern segmentation, and garment construction. Designs with multiple small components, such as slit or cuff sleeves, facilitated better pattern nesting and minimized wastage. In contrast, styles with large, flared, or single-piece sleeves, such as bell or leg-o-mutton sleeves, consistently underperformed in fabric efficiency despite varying fabric consumption levels. The overall ranking of the 33 garment samples based on fabric efficiency revealed that open-front kameez slit sleeves (OFSL3), simple kameez slit sleeves (SSL3), and princess-cut kameez slit sleeves (PCSL3) secured the top three positions across all design groups due to their highly efficient pattern layouts. These were followed by OFSL9, PCSL9, and OFSL2, which also demonstrated high efficiencies through minimal fabric wastage and optimal component nesting. Subsequent rankings included PCSL2, PCSL1, PCSL5, and OFSL5, all of which exhibited moderate efficiencies influenced by sleeve design and structural segmentation. Middle-tier placements were occupied by PCSL11, OFSL11, OFSL1, OFSL6, and PCSL4. Notably, designs such as PCSL7, PCSL6, and PCSL8 showed reduced efficiencies due to complex or wide-pattern sleeves. The least efficient samples included OFSL4, OFSL10, SSL9, SSL6, SSL8, SSL11, SSL4, SSL1, SSL7, SSL10, SSL2, and SSL5—largely due to one-piece or flared sleeve designs that limited efficient marker placement. These rankings demonstrated the critical role of sleeve type, garment segmentation, and pattern shape in determining fabric efficiency across different kameez styles. A consolidated view of style and design performance rankings and fabric efficiency across all garments is provided in Table 5.

Table 5.

Positioning of garment samples in relation to fabric efficiency.

3.3. Results of Cost-Effectiveness in All Garment Samples

An analysis of cost-effectiveness in Figure 9 across 33 garment samples revealed that open-front kameez (OF) styles were the most cost-effective, followed by princess-cut kameez (PC), with simple kameez (S) styles being the least cost-effective overall. This trend corresponded directly with fabric consumption and efficiency metrics, where OF samples demonstrated the lowest fabric usage and highest efficiency, while S styles consumed the most fabric and produced more waste; i.e., this hierarchy was largely influenced by fabric consumption, efficiency of pattern nesting, and associated fabric wastage (OF < PC < S). Within the OF group, the most cost-effective design was open-front kameez simple sleeves (OFSL1), requiring only 22 m of fabric and costing PKR 6600 (PKR 333 per garment)—the lowest among all samples—due to minimal wastage and relatively high efficiency (82.94%). Open-front kameez slit sleeves (OFSL3) followed closely, with 23 m fabric usage, 86.91% efficiency, and the lowest wastage (3.01 m), resulting in a garment cost of PKR 6900 (PKR 300 per garment). Other efficient OF samples included OFSL9 and OFSL2, both costing PKR 7800–8400, depending on design complexity and fabric utilization.

Figure 9.

Results of fabric cost-effectiveness.

In the PC group, princess-cut kameez cuff sleeves (PCSL9) were the most cost-effective, requiring 25 m of fabric, yielding 85.58% efficiency, and incurring a total cost of PKR 7400. PCSL1 and PCSL7 followed, with equal fabric usage (26 m) and costs of PKR 7800, although their efficiencies differed—83.87% and 81.15%, respectively. This variation illustrates that low fabric consumption was a more critical determinant of cost-effectiveness than efficiency alone. PCSL5 and PCSL11 were also cost-effective, each consuming 27 m, with efficiencies exceeding 83%, and costing approximately PKR 8100–8400. In contrast, PCSL4 (umbrella sleeves) was the least cost-effective among PC styles, with 35 m of fabric, 82.21% efficiency, the highest wastage (6.23 m), and a total garment cost of PKR 10,500.

Simple kameez designs showed the widest cost range, with simple kameez slit sleeves (SSL3) and simple kameez cuff sleeves (SSL9) being the most economical at PKR 8100, due to their low fabric usage (27 m) and high efficiencies of 86.17% and 77.77%, respectively. SSL1 and SSL7, each using 28 m, ranked second in cost-effectiveness (PKR 8400) despite moderate efficiency, underscoring the primacy of fabric usage in cost reduction. In contrast, SSL4 (set-in sleeves with umbrella features) was the least cost-effective S style sample, consuming 35 m, yielding 75.39% efficiency, and costing PKR 10,500 per garment. Similarly, SSL2 and SSL10 had high consumption (32 m and 31 m), low efficiencies (72.26% and 73.64%), and high costs (PKR 9600–9900).

Across all 33 samples, cost-effectiveness was primarily driven by fabric consumption, with high efficiency and low wastage reinforcing lower costs. The top five most cost-efficient samples were OFSL1, OFSL3, PCSL9, OFSL9, and PCSL1, all of which required ≤26 m of fabric and cost less than PKR 8000 per garment. In contrast, designs with flared or single-piece sleeve structures, such as SSL4, PCSL4, and OFSL10, demonstrated high fabric usage (≥31 m), reduced efficiencies, and elevated costs (≥PKR 9300). This comprehensive analysis confirmed that optimizing sleeve design and pattern layout significantly enhanced fabric economy, which directly reduced garment production costs.

In the overall comparison for all 33 samples, Table 6 summarizes the positioning and ranking of samples in relation to cost-effectiveness (ranking of designs from most to least cost-efficient). It provides which designs are most cost-effective and how others compare, likely by grouping them or listing them in order (for example, noting which specific designs fell into the top group versus the bottom). Samples at the top (e.g., OFSL1, OFSL3, PCSL9, OFSL9) combine low material usage, high efficiency, and minimal waste, making them optimal for cost-saving production. Samples at the bottom (e.g., SSL4, PCSL4, OFSL10) had large, flared sleeves or one-piece structures that reduced nesting efficiency, increased consumption, and raised costs. These findings confirmed that cost-effectiveness is primarily determined by fabric consumption, with efficiency and waste acting as secondary but reinforcing factors.

Table 6.

Positioning of garment samples in relation to cost-effectiveness (ranking of designs from most to least cost-efficient).

3.4. Analysis of Variance (ANOVA: Single Factor)

Based on the analysis of variance (ANOVA) results presented in Table 7, a scientifically structured explanation for the significance levels for fabric efficiency, fabric consumption, fabric wastage, and cost-effectiveness across the three kameez styles—simple (C1), princess-cut (C2), and open-front (C3) was performed. The test for fabric efficiency yielded an F-value of 23.4009 with a p-value < 0.00001, which was well below the critical value of F (3.316). This indicated a highly significant difference in fabric efficiency across the three kameez styles. The average efficiency was lowest in the simple style (C1: 75.72%), while princess-cut (C2: 83.20%) and open-front (C3: 82.82%) styles exhibited significantly higher and nearly identical efficiencies. The low standard deviations in C2 and C3 (both ≈1.71) compared to C1 (≈3.85) further support the consistency of improved fabric usage in more complex or segmented garment constructions (e.g., multiple-panel layouts in PC and OF styles), likely due to better pattern nesting and reduced fabric gaps. The ANOVA for fabric consumption produced an F-value of 3.39 with a p-value = 0.04698, which was just below the significance threshold (α = 0.05), suggesting a statistically significant difference among the three kameez styles in terms of total fabric used. On average, simple style garments (C1: 29.82 m) consumed more fabric than princess-cut (C2: 27.91 m) and open-front (C3: 27.27 m) garments. Although the differences were modest, they were statistically meaningful, reinforcing the efficiency of segmented panel designs in reducing fabric consumption compared to the more monolithic structure of the simple kameez. Fabric wastage analysis revealed a highly significant difference across the styles, with an F-value of 17.19 and a p-value < 0.00001 (F critical = 3.31583). The simple style (C1) had the highest average fabric wastage (7.23 m), whereas princess-cut (C2: 4.68 m) and open-front (C3: 4.81 m) styles were significantly more conservative in fabric loss. This result was consistent with the patterns observed in fabric efficiency and further emphasizes the impact of garment architecture (paneling, sleeve type, cut complexity) on material utilization. For cost-effectiveness, the ANOVA returned an F-value of 3.36 and a p-value of 0.04811, indicating a statistically significant difference among the styles at the 5% level. The simple style (C1) showed the highest average garment cost (PKR 447.27 per unit), followed by princess-cut (C2: PKR 418.64), with open-front (C3: PKR 409.09) being the most cost-effective style on average. The standard deviation was relatively high across all groups, reflecting some variation due to sleeve design and pattern complexity. Nevertheless, the significant result confirmed that garment style has a direct influence on production cost, largely mediated by differences in fabric consumption and efficiency.

Table 7.

Analysis of variance (ANOVA).

Overall, it is evident that the ANOVA results confirmed that the kameez style has a statistically significant impact on fabric efficiency, consumption, wastage, and cost-effectiveness; i.e., open-front and princess-cut styles consistently outperformed simple styles across all measured parameters. The simple style, while traditional, proved less fabric-efficient and more costly, primarily due to higher wastage and less effective pattern nesting. These findings support the strategic selection of garment styles and sleeve designs to optimize material utilization and minimize production costs, which is critical for sustainable apparel manufacturing.

4. Conclusions

This research study was undertaken to systematically quantify the impact of integrating different garment design geometries on fabric utilization within the apparel industry. By analyzing 33 combinations of kameez and sleeve styles, this research provides a clear, data-driven framework for making sustainable and cost-effective design choices. The medium-size standard measurements of Pakistan’s local brand “Sana Safinaz” for women were used for drafting the flat patterns and markers through the Garment Gerber Technology Software (GGTS). The primary conclusions of this research are as follows:

- Paneling enhances efficiency: Kameez constructions that incorporate paneling (princess-cut and open-front) are statistically superior to monolithic, simple constructions in terms of fabric efficiency, fabric wastage, and overall cost-effectiveness. The princess-cut style, with its three front panels, demonstrated the highest average efficiency.

- Sleeve geometry dictates consumption: Sleeve design is a primary determinant of fabric consumption. Multi-piece sleeves, such as the slit and cuff styles, are the most efficient due to their ability to nest effectively within markers. In contrast, voluminous, single-piece sleeves like the umbrella and leg-o-mutton styles are the least efficient and lead to the highest material costs.

- Actionable design-cost data: The study identifies specific designs with optimal performance. The open-front kameez with simple sleeves (OFSL1) was the most cost-effective combination, while the simple kameez with umbrella sleeves (SSL4) was the most expensive. This provides clear, actionable data for designers and manufacturers aiming to balance esthetics with production costs.

- The p-value (0.00001) provided strong evidence against the null hypothesis, indicating that at least one group mean was significantly different from the others.

The findings of this study have direct and significant implications for the apparel industry. Designers and manufacturers can use this quantitative data as a predictive tool during the product development phase. By understanding the inherent efficiency of certain geometric constructions—such as paneling or multi-piece sleeves—companies can make informed design choices that directly impact profitability and reduce pre-consumer waste. For instance, opting for a princess-cut over a simple kameez, or a slit sleeve over an umbrella sleeve, can lead to substantial material savings in mass production, contributing to both economic and environmental sustainability goals. However, this study has several limitations that should be acknowledged. The analysis was conducted using a single fabric type (100% cotton) and one standard garment size. The results may vary with different fabric widths, weights, or types (e.g., stretch fabrics). Furthermore, the study did not account for printed or patterned fabrics, which introduce additional constraints related to pattern matching that would likely reduce overall fabric efficiency. Future research should build upon these findings to address these limitations and further deepen the scientific understanding of the relationship between design and manufacturing efficiency. Therefore, future work would expand this study to include a wider variety of kameez and sleeve styles, as well as different garment sizes and fabric types, to develop a more comprehensive model to investigate the impact of printed fabrics and pattern-matching constraints on fabric utilization for these hybrid garment styles. Developing a mathematical or algorithmic model will predict fabric consumption based on key geometric parameters of pattern pieces (e.g., area, perimeter, convexity, and number of components). Such a model would transform these findings into a powerful, automated tool for sustainable design and pre-production costing in the apparel industry.

Author Contributions

Conceptualization, T.N. and A.K.; methodology, M.B.R., R.I., and A.S.; validation, M.A. and K.J.; formal analysis, R.I. and A.S.; investigation, writing, and editing. I.A.K., T.N., and A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no specific grant from any funding agency in the public, private, or not-for-profit sectors.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ibrahim, M.; Ahmad, S.F.; Shahid, M.K.; Asif, M. Factors Influencing the Performance of Supply Chain Management in Manufacturing Industry of Pakistan. Ind. Eng. Lett. 2015, 5, 34–41. [Google Scholar]

- Poonkuzhali, S. Effective Cost Analysis Model For Apparel Industry. Int. J. Appl. Eng. Res. 2015, 10, 20263–20276. [Google Scholar]

- Hussain, D.; Figueiredo, M.; Ferreira, F. SWOT Analysis of Pakistan Textile Supply Chain. In Proceedings of the IX. Congreso Galego de Estatística e Investigación de Operacións, Orense, España, 12–14 November 2009. [Google Scholar]

- Waddell, G. How Fashion Works: Couture, Ready-to-Wear and Mass Production; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Subhashini, R.; Varghese, N. Methods of Improving Productivity in Apparel Industry. Int. J. Res. Eng. Sci. Manag. 2021, 4, 130–141. [Google Scholar] [CrossRef]

- Raza, M.; Frooghi, R.; Aziz, A. Determinants of compulsive buying behaviour in apparel industry of Pakistan. Int. J. Innov. Creat. Change 2020, 11, 172–189. [Google Scholar]

- Memon, N.A. Readymade garment manufacturers face energy shortage and high cost of production. Pak. Text. J. 2012, 61, 1. Available online: https://books.apple.com/us/book/readymade-garment-manufacturers-face-high-cost-of/id482375136 (accessed on 2 October 2025).

- Hoque, A.; Rasiah, R.; Furuoka, F.; Kumar, S. Technology adoption in the apparel industry: Insight from literature review and research directions. Res. J. Text. Appar. 2021, 25, 292–307. [Google Scholar] [CrossRef]

- Janarthanan, M.; Nithinmanighanden, R.T.; Muralidharan, L.; Prasanth, R. Reduction of Fabric Consumption, by Increasing Fabric Utilization & Minimizing Wastage in Garment Sector. Int. Res. J. Eng. Technol. 2020, 7, 889–905. [Google Scholar]

- Naveed, T.; Hussain, A.; Babar, A.A.; Naeem, A.; Mussana, H.; Xin, W.; Duan, L.; Zhong, Y. A Comparative Study on Fabric Efficiencies for Different Human Body Shapes in the Apparel Industry. Autex Res. J. 2018, 19, 104–118. [Google Scholar] [CrossRef]

- Taifa, I.W.; Twaha, I.; A Mwakibambo, M. Critical analysis of material consumption and cost reduction techniques for the apparel cutting processes. Tanzan. J. Sci. 2021, 47, 1689–1700. [Google Scholar] [CrossRef]

- Enes, E.; Kipöz, Ş. The Role of Fabric Usage For Minimization of Cut-and-Sew Waste Within the Apparel Production Line: Case Of A Summer Dress. J. Clean. Prod. 2019, 248, 119221. [Google Scholar] [CrossRef]

- Collier, B.J.; Collier, J.R. CAD/CAM in the Textile and Apparel Industry. Cloth. Text. Res. J. 1990, 8, 7–13. [Google Scholar] [CrossRef]

- Patnaik, S.; Patnaik, A. Advancements in production planning and control. In Automation in Garment Manufacturing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 291–309. [Google Scholar]

- Jhanji, Y. Computer-aided design—Garment designing and patternmaking. In Automation in Garment Manufacturing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 253–290. [Google Scholar]

- Haque, M.M.; Islam, M.Z.; Khan, A.M. Comparative Study on Advantages of Using CAD/CAM and Manual Cutting System in the Apparel Industries in Bangladesh. Autex Res. J. 2013, 13, 235–249. [Google Scholar]

- Chaudhary, S.; Kumar, P.; Johri, P. Maximizing performance of apparel manufacturing industry through CAD adoption. Int. J. Eng. Bus. Manag. 2020, 12, 184797902097552. [Google Scholar] [CrossRef]

- Špelic, I. The current status on 3D scanning and CAD/CAM applications in textile research. Int. J. Cloth. Sci. Technol. 2020, 32, 891–907. [Google Scholar]

- Chen, C. Analysis of the Influence of Fashion Design on Clothing Structure and Garment Management. In Recent Trends in Decision Science and Management: Proceedings of ICDSM 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 39–44. [Google Scholar]

- Ho, S. Salwar Kameez. Singapore Infopedia. Available online: https://www.nlb.gov.sg/main/article-detail?cmsuuid=ce2a4b6a-6aea-46d3-917f-81fe0f1b1d56 (accessed on 1 October 2025).

- Kumar, M.; Walia, A. Elucidation of the Indian salwar kameez. IJASOS-Int. E J. Adv. Soc. Sci. 2016, 2, 753–761. [Google Scholar]

- Bilal, A.; Nadeem, A.; Chishti, I.H. Female Fashion Trends in Lahore. J. Punjab Univ. Hist. Soc. 2021, 34, 237–252. [Google Scholar]

- Kumar, M.; Walia, A. Traditional Arabic Costume and Indian Salwar Kameez: A Reciprocal Correlation. In Proceedings of the 10th International Conference on Language, Humanities, Education and Social Sciences (ICLHESS-18), Bali, Indonesia, 12–13 January 2018; ISBN 978-93-86878-09-0. [Google Scholar] [CrossRef]

- Liu, C.; Kennon, R. Improving The Compromise Between Clothing Style and Dynamic Comfort from Sleeve Construction. Res. J. Text. Appar. 2005, 9, 34–39. [Google Scholar] [CrossRef]

- Kazlacheva, Z.; Dineva, P.; Ilieva, J. An investigation of fashion design and pattern making of ladies’ jackets with different types of sleeves. ARTTE Appl. Res. Tech. Technol. Educ. 2016, 4, 253–261. [Google Scholar] [CrossRef]

- Venkatasamy, N. Fashion trends and their impact on the society. In Proceedings of the International Conference on Apparels and Fashion, Talminadu, India, April 2015. [Google Scholar]

- Rasheed, A. Textile Engineering: An Introduction; Nawab, Y., Shaker, K., Eds.; Walter de Gruyter GmbH & Co KG: De Gruyter Oldenbourg, Germany, 2023; pp. 137–158. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).