A Brief Review of Mechanical Recycling of Textile Waste

Abstract

1. Introduction

2. Research Framework and Methodology

- Title screening to ensure relevance to mechanical recycling and fiber production;

- Abstract review to identify studies addressing technical aspects of fiber processing;

- Full-text analysis for final inclusion.

3. Overview and Challenges of Textile Mechanical Recycling

3.1. Different Approaches in Textile Recycling

3.2. Mechanical Recycling: Definitions

3.3. Process Steps and Material Suitability in Mechanical Recycling

4. Feedstock for Mechanical Recycling

4.1. Types and Sources of Textile Waste

4.2. Feedstock and Fiber Recovery

5. Pretreatment

6. Sorting

6.1. Advanced Sorting Technologies

6.2. Eco-Design Strategies and Digital Tagging

6.3. Polymer-Based Photonic Fibers

6.4. Challenges and Future Directions

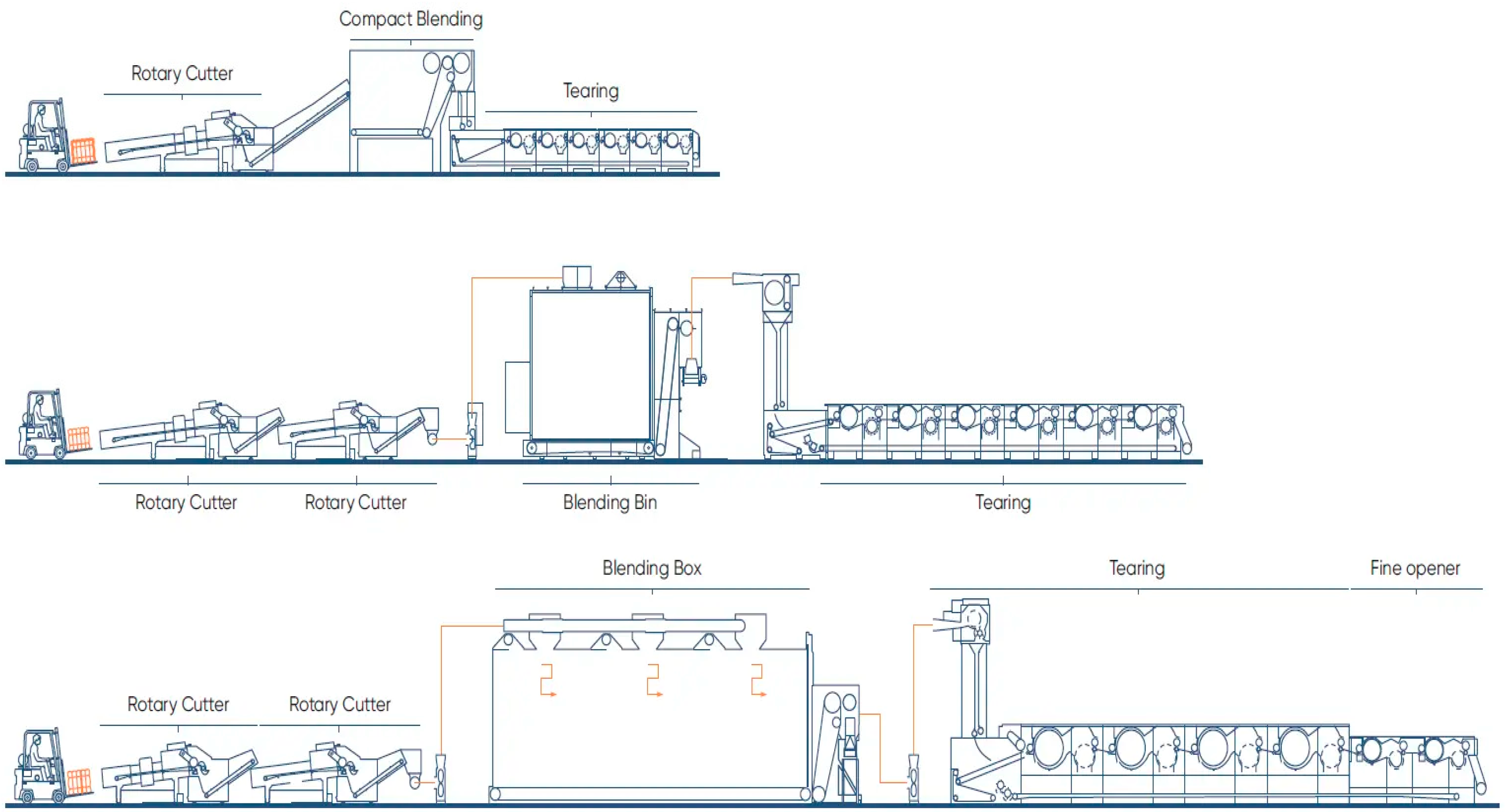

7. Shredding

7.1. Shredding Machines in Waste Processing

7.2. Operational Parameters and Process Optimization

8. Opening

8.1. Opening Machine in Fiber Recovery

8.2. Role of Fabric Wear and Atmospheric Conditions

8.3. Impact of Material Type and Structure on Fiber Recovery

9. Evaluation of Recycled Fiber Quality in Mechanical Recycling

9.1. Fiber Quality and Spinnability

9.2. Quantifying the Degree of Fiber Opening in Mechanical Recycling

10. Mechanical Textile Recycling: Circularity Pathways and Fiber Considerations

10.1. Open-Loop vs. Closed-Loop Recycling in Mechanical Textile Recovery

10.2. Fiber-Specific Considerations in Mechanical Textile Recycling

11. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Glossary

References

- Lindström, K.; Sjöblom, T.; Persson, A.; Kadi, N. Improving mechanical textile recycling by lubricant pre-treatment to mitigate length loss of fibers. Sustainability 2020, 12, 8706. [Google Scholar] [CrossRef]

- Textile Exchange Conference. 2024. Available online: https://textileexchange.org/ (accessed on 27 April 2025).

- Statista. 2025. Available online: https://www.statista.com/statistics/1250812/global-fiber-production-share-type/ (accessed on 22 July 2025).

- McLoughlin, J.; Hayes, S.; Paul, R. Cotton fibre for denim manufacturer. In Denim Manufacture, Finishing and Applications; Woodhead Publishing: Sawston, UK, 2015; pp. 15–36. [Google Scholar] [CrossRef]

- Textile Waste: Federal Entities Should Collaborate on Reduction and Recycling Efforts. Available online: https://files.gao.gov/reports/GAO-25-107165/index.html?_gl=1*b1u6h9*_ga*MjkyODI3MzUuMTczNzIyMDk1N (accessed on 27 April 2025).

- EPA. Textiles: Material-Specific Data. 2022. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/textiles-material-specific-data (accessed on 27 April 2025).

- U.S. Environmental Protection Agency. Available online: https://www.epa.gov/sites/default/files/2020-11/documents/2018_ff_fact_sheet.pdf (accessed on 27 April 2025).

- What Really Happens to Unwanted Clothes? Green America. Available online: https://www.greenamerica.org/unraveling-fashion-industry/what-really-happens-unwanted-clothes (accessed on 27 April 2025).

- Gan, S.; Xiao, S.; Liu, T.; Wang, C.; Li, S.; Sun, Y.; Tang, Y. Recycle waste PET yarn on site by feeding waste yarn as grinded powder to improve product quality, increase energy efficiency and reduce environmental impact. J. Eng. Fibers Fabr. 2024, 19, 15589250241242009. [Google Scholar] [CrossRef]

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.S. Possibility routes for textile recycling technology. Polymers 2021, 13, 3834. [Google Scholar] [CrossRef] [PubMed]

- Celep, G.; Tetik, G.D.; Yilmaz, F. Limitations of textile recycling: The reason behind the development of alternative sustainable fibers. In Next-Generation Textiles; IntechOpen: London, UK, 2022. [Google Scholar]

- Huang, X.; Tan, Y.; Huang, J.; Zhu, G.; Yin, R.; Tao, X.; Tian, X. Industrialization of open-and closed-loop waste textile recycling towards sustainability: A review. J. Clean. Prod. 2024, 436, 140676. [Google Scholar] [CrossRef]

- Yousef, S.; Tatariants, M.; Tichonovas, M.; Kliucininkas, L.; Lukošiūtė, S.; Yan, L. Sustainable green technology for recovery of cotton fibers and polyester from textile waste. J. Clean. Prod. 2020, 254, 120078. [Google Scholar] [CrossRef]

- Raluca, B.R.A.D. Circular economy and recycling in the textile industry. Ann. Univ. Oradea. Fascicle Text. Leatherwork 2023, 24, 17–26. [Google Scholar]

- Tripathi, M.; Sharma, M.; Bala, S.; Thakur, V.K.; Singh, A.; Dashora, K.; Hart, P.; Gupta, V.K. Recent technologies for transforming textile waste into value-added products: A review. Curr. Res. Biotechnol. 2024, 7, 100225. [Google Scholar] [CrossRef]

- Yatvitskiy, M.; Ludwig, K.; Gupman, S.; Cobb, K.; Cao, H.; Clarke-Sather, A. Innovative methods for secondary material development in mechanical textile recycling. In Proceedings of the International Textile and Apparel Association Annual Conference Proceedings, Shanghai, China, 11–13 October 2025; Iowa State University Digital Press: Ames, IA, USA, 2025; Volume 81. [Google Scholar]

- Lindström, K.; van der Holst, F.; Berglin, L.; Persson, A.; Kadi, N. Mechanical textile recycling efficiency: Sample configuration, treatment effects and fibre opening assessment. Results Eng. 2024, 24, 103252. [Google Scholar] [CrossRef]

- Teixeira França Alves, P.H.; Clarke-Sather, A.; Carlson, S.; Martini, A. Theoretical Method for Characterizing Textile Failure Mechanics in Mechanical Recycling with Carded Drums. In Proceedings of the International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, New Brunswick, NJ, USA, 12–16 June 2023; p. 87233. [Google Scholar] [CrossRef]

- Nemeša, I.; Pešić, M.; Bozoki, V. Mechanical recycling of textile waste. Tekst. Ind. 2024, 72, 24–28. [Google Scholar]

- Harmsen, P.; Bos, H. Textiles for Circular Fashion: Part 1: Fibre Resources and Recycling Options; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2020. [Google Scholar]

- ISO 5157:2023; Textiles Vocabulary—Part 13: Recycling, Reuse and Regenerated Fibres. International Organization for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/82145.html (accessed on 12 August 2025).

- Hinzmann, M.; Hirschnitz-Garbers, M.; Sachdeva, A.; Duhoux, T.; Maes, E.; Peeters, K.; Colignon, P. Study on the technical, regulatory, economic and environmental effectiveness of textile fibres recycling. Eur. Comm. 2021, 24, 205. [Google Scholar]

- Andritz. Available online: https://www.andritz.com/products-en/annual-report/nonwoven-textile/textile-recycling-overview-nonwoven-and-textile#and-anchor2 (accessed on 18 July 2025).

- Sustainability Directory. Why Are Synthetic Fibers Difficult to Recycle? Available online: https://pollution.sustainability-directory.com/question/why-are-synthetic-fibers-difficult-to-recycle/ (accessed on 20 August 2025).

- Utebay, B.; Celik, P.; Cay, A. Valorization of fabric wastes through production of recycled cotton yarns by compact ring and open-end rotor spinning. J. Clean. Prod. 2023, 409, 137135. [Google Scholar] [CrossRef]

- Koszewska, M. Circular economy—Challenges for the textile and clothing industry. Autex Res. J. 2018, 18, 337–347. [Google Scholar] [CrossRef]

- Textile Exchange. Guide to Recycled Materials. Available online: https://2d73cea0.delivery.rocketcdn.me/app/uploads/2021/09/GRS-202-V2.0-Guide-to-Recycled-Materials.pdf (accessed on 20 August 2025).

- Lindström, K.; Sjöblom, T.; Persson, A.; Kadi, N. Decreasing inter-fiber friction with lubricants for efficient mechanical recycling of textiles. In Proceedings of the 19th World Textile Conference-Autex 2019, Ghent, Belgium, 12–16 June 2019. [Google Scholar]

- Valmet Forward. Available online: https://www.valmet.com/more-industries/textiles/technologies-textile-recycling/mechanical-recycling/ (accessed on 18 July 2025).

- Gun, A.D.; Oner, E. Investigation of the quality properties of open-end spun recycled yarns made from blends of recycled fabric scrap wastes and virgin polyester fibre. J. Text. Inst. 2019, 110, 1569–1579. [Google Scholar] [CrossRef]

- de Oliveira Neto, G.C.; Teixeira, M.M.; Souza, G.L.V.; Arns, V.D.; Tucci, H.N.P.; Amorim, M. Assessment of the Eco-Efficiency of the Circular Economy in the Recovery of Cellulose from the Shredding of Textile Waste. Polymers 2022, 14, 1317. [Google Scholar] [CrossRef] [PubMed]

- Aronsson, J.; Persson, A. Tearing of post-consumer cotton T-shirts and jeans of varying degree of wear. J. Eng. Fibers Fabr. 2020, 15, 1558925020901322. [Google Scholar] [CrossRef]

- Refashion. Mechanical Recycling Process. Available online: https://recycle.refashion.fr/wp-content/uploads/2025/04/REFASHION_Mechanical-recycling-of-textiles.pdf (accessed on 5 July 2025).

- Tsai, P.F.; Yuan, S.M. Using Infrared Raman Spectroscopy with Machine Learning and Deep Learning as an Automatic Textile-Sorting Technology for Waste Textiles. Sensors 2025, 25, 57. [Google Scholar] [CrossRef] [PubMed]

- Faghih, E.; Saki, Z.; Moore, M. A Systematic Literature Review—AI-Enabled Textile Waste Sorting. Sustainability 2025, 17, 4264. [Google Scholar] [CrossRef]

- Sasikumar, U.; Mundkur, S.; Athalye, A. Strategies for Separating and Recycling Textile Blends. Adv. Environ. Waste Manag. Recycl. 2023, 6, 443–450. [Google Scholar]

- Halvorsen, T.S.; Tyapin, I.; Jha, A. Autonomous textile sorting facility and digital twin utilizing an AI-reinforced collaborative robot. Electronics 2025, 14, 2706. [Google Scholar] [CrossRef]

- Puchowicz, D.; Cieslak, M. Raman spectroscopy in the analysis of textile structures. In Recent Developments in Atomic Force Microscopy and Raman Spectroscopy for Materials Characterization; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Stipanovic, H.; Koinig, G.; Fink, T.; Schimper, C.B.; Lilek, D.; Egan, J.; Tischberger-Aldrian, A. Quantifying cotton content in post-consumer polyester/cotton blend textiles via NIR spectroscopy: Current attainable outcomes and challenges in practice. Recycling 2025, 10, 152. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The Jeans Redesign—Insights from the First Two Years, 2019–2021. 2021. Available online: https://content.ellenmacarthurfoundation.org/m/68b1aa5ebfef9d4/original/The-Jeans-Redesign-Insights-from-the-first-two-years.pdf (accessed on 19 July 2025).

- Iezzi, B.; Shtein, M.; Wang, T.; Rothschild, M. Fiber and Fabric-Integrated Tracing Technologies for Textile Sorting and Recycling: A Review. In Technology Innovation for the Circular Economy: Recycling, Remanufacturing, Design, Systems Analysis and Logistics; Scrivener Publishing LLC: Beverly, MA, USA, 2024; pp. 223–237. [Google Scholar]

- Textile Shredders for Textile Recycling. Shred Trucks, Industrial Shredders, Slow-Speed Shredders, Shred-Tech. Available online: https://shred-tech.com/textile-shredder/ (accessed on 19 July 2025).

- Textile Shredders. Amos Mfg., Inc. Available online: https://www.amos-mfg.com/shredding-applications/textile-shredders/ (accessed on 19 July 2025).

- Shredders for Textile Recycling. Schutte Hammermill. Schutte Hammermill. Available online: https://www.hammermills.com/recycling/textiles/ (accessed on 19 July 2025).

- Single Shaft Industrial Shredders. Vecoplan, LLC—Industrial Shredder Manufacturer. Available online: https://www.vecoplanllc.com/size-reduction-equipment/industrial-shredders/single-shaft-shredders?material=28 (accessed on 19 July 2025).

- Margasa. Textile Recycling Lines. Available online: https://exhibitorsearch.messefrankfurt.com/images/original/document_downloads/10000008202401/345410/1708430551717_3662456617.pdf (accessed on 5 July 2025).

- Expertise Areas. Available online: https://www.ri.se/en/expertise-areas/expertises/tearing-and-processing-of-textile-materi (accessed on 5 July 2025).

- Wanassi, B.; Azzouz, B.; Hassen, M.B. Value-added waste cotton yarn: Optimization of recycling process and spinning of reclaimed fibers. Ind. Crops Prod. 2016, 87, 27–32. [Google Scholar] [CrossRef]

- Kanan, M.; Wannassi, B.; Azouz, B.; Hassen, M.B.; Assaf, R.; Barham, A.S. Cotton recycling: An experimental study of the mechanical preparation process. Case Stud. Chem. Environ. Eng. 2024, 10, 100849. [Google Scholar] [CrossRef]

- Dias, T.; Delkumburewatte, G.B. Changing porosity of knitted structures by changing tightness. Fibers Polym. 2008, 9, 76–79. [Google Scholar] [CrossRef]

- Gong, H.; Ozgen, B. Fabric structures: Woven, knitted, or nonwoven. In Engineering of High-Performance Textiles; Woodhead Publishing: Sawston, UK, 2018; pp. 107–131. [Google Scholar] [CrossRef]

- Béchir, W.; Béchir, A.; Mohamed, B.H. Industrial cotton waste: Recycling, reclaimed fiber behavior and quality prediction of its blend. Text. Appar. 2018, 28, 14–20. [Google Scholar]

- Payne, A. Open-and closed-loop recycling of textile and apparel products. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Woodhead Publishing: Sawston, UK, 2015; pp. 103–123. [Google Scholar]

- SOEX. IZ Circular Textiles GmbH. Available online: https://www.soex.de/en/ (accessed on 11 July 2025).

- Patagonia, Mechanical Recycling. Available online: https://www.patagonia.com/our-footprint/mechanical-recycling.html (accessed on 11 July 2025).

| Waste | Textile Waste Types | Source of Waste |

|---|---|---|

| Post-industrial, Pre-consumer | Blending, carding, dropping wastage, sliver, draw and ring frame waste | Spinning |

| Weaving, sizing, knotting, beam residual, auxiliary selvage wastage | Weaving | |

| Samples, fabrics with stains, barre marks, stripes, hole, thick, thin yarns | Knitting | |

| Shade variation, crease | Dyeing | |

| Cutting, sewing, finishing, printing, embroidery waste | Garmenting | |

| Post-consumer | Garments, home textiles, technical textiles, nonwoven | Final consumer |

| Type of Fiber | Type of Feedstock | Output Fiber Length (mm) |

|---|---|---|

| Cotton | Pre-consumer garment cutting waste | 6 to 21 |

| Pre-consumer yarn hard waste | 6 to 26 | |

| Pre-consumer yarn hard, woven selvage waste | 6 to 21 | |

| Post-consumer denim/jeans waste | 6 to 18 | |

| Wool | Post-consumer garment cutting waste | 20–50 |

| Pre-consumer fabric cutting waste | 20–60 | |

| Pre-consumer woven selvage, yarn hard waste | 20–60 |

| Technology | Principle | Advantages | Limitations |

|---|---|---|---|

| NIR Spectroscopy | Based on vibrational absorption in the NIR region (780–2526 nm); sensitive to changes in dipole moments [34,38]. | Accuracy in textile classification can be enhanced with machine learning (ML) and deep learning (DL) approaches [35]. | Limited ability to classify blended fabrics (e.g., polyester/cotton); performance affected by textile structure, treatment, alkaline treatment, and dark-colored materials [35,36,39]. |

| Raman Spectroscopy | Probes vibrational states via inelastic scattering; sensitive to changes in molecular polarizability [34,38]. | Enables nanoparticle detection; non-destructive; requires minimal sample; improved with ML/DL methods [35,38]. | Fluorescence interference can suppress Raman signals [38]. |

| RGB Imaging | Sorting based on red, green, and blue (RGB) visual channels, using surface features such as color, texture, and shape [35]. | Effective in differentiating textiles based on surface pattern and color distribution [35]. | Cannot distinguish materials with similar appearance but different chemical composition; affected by image quality, fabric deformation, and rigid classification schemes [35]. |

| Hyperspectral Imaging | Combines spectral and spatial data to distinguish fiber compositions [35]. | High-throughput, non-destructive method for fiber identification [35]. | Requires large datasets and intensive calibration [35]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.M.; Yin, R.; West, A. A Brief Review of Mechanical Recycling of Textile Waste. Textiles 2025, 5, 41. https://doi.org/10.3390/textiles5040041

Islam MM, Yin R, West A. A Brief Review of Mechanical Recycling of Textile Waste. Textiles. 2025; 5(4):41. https://doi.org/10.3390/textiles5040041

Chicago/Turabian StyleIslam, Md Mayedul, Rong Yin, and Andre West. 2025. "A Brief Review of Mechanical Recycling of Textile Waste" Textiles 5, no. 4: 41. https://doi.org/10.3390/textiles5040041

APA StyleIslam, M. M., Yin, R., & West, A. (2025). A Brief Review of Mechanical Recycling of Textile Waste. Textiles, 5(4), 41. https://doi.org/10.3390/textiles5040041