Abstract

Ultraviolet radiation (UVR) represents significant risks to both textile durability and human health. Natural dyes are gaining attention as eco-friendly alternatives to synthetic UV-blocking agents, offering aesthetic and functional benefits. This study explores the UV-protective properties of 100% cotton knit fabrics dyed with natural dyes—indigo, weld, and madder—using different mordanting processes, including materials with mordant abilities such as alum, pomegranate peel, and tannin extracted from quebracho. Twenty samples were evaluated, including undyed, individually treated, and combined dye-mordant formulations. UV protection was assessed through spectral transmittance and Ultraviolet Protection Factor (UPF) measurements before and after washing. The results showed that natural dyes significantly improved the UV resistance of cotton fabrics, particularly when combined with products like pomegranate and the tannin–alum mixture. Notably, some samples demonstrated improved UPF and became darker after washing, such as mordant combinations like tannin with alum. These findings suggest that natural dye, when combined with appropriate mordants, offers a sustainable and effective approach to producing UV-protective textiles. This is particularly valuable in children’s clothing, where chemical safety and sun protection are crucial. Future research should investigate the influence of pH on dye stability and UV-blocking performance to optimise formulations for industrial use and long-term functionality.

1. Introduction

Anti-ultraviolet (anti-UV) textiles, also known as UV-protective fabrics, are designed to block or absorb harmful UV radiation (UVR), protecting both the textile material and human health, especially the skin [1]. UVR is a form of electromagnetic radiation emitted by the sun and includes three main components: UVA (315–400 nanometres [nm]), UVB (280–315 nm), and UVC (100–280 nm). While UVC is mostly absorbed by the Earth’s atmosphere, UVA and UVB reach the surface and contribute to a range of harmful effects in humans [2], including pigmentation, skin cancer, premature aging, sunburn effects, and eye damage [1,3]. UVR also causes degradation in other areas, such as historic preservation or food storage [4]. As awareness of these risks grows, so does the demand for materials that can offer reliable sun protection [3,4].

In response to these needs, a wide range of UV-blocking materials has been developed across different fields. These materials function mainly by absorbing, scattering, or reflecting UV radiation and include inorganic compounds such as titanium dioxide and zinc oxide, organic absorbers like salicylic acid or benzophenone derivatives, and advanced polymer nanocomposites engineered for durability and transparency [4]. More recently, bio-based approaches incorporating natural compounds rich in flavonoids or tannins have emerged as renewable, non-toxic alternatives [5,6]. The versatility of these strategies has supported applications in sunscreens, coatings, packaging, and, gradually, in textiles [4]. Unlike sunscreens, which require regular reapplication, anti-UV fabrics provide consistent protection as long as they are worn and remain physically intact [7].

UV transmittance is a key parameter for assessing a textile’s UV-blocking ability. It refers to the proportion of UV light that passes through a material, indicating how much radiation penetrates the fabric. High transmittance values indicate poor protection, while low transmittance implies that the fabric effectively blocks UVR [8]. These measurements are typically taken across the UVA and UVB spectra and are used to calculate the Ultraviolet Protection Factor (UPF), a standardised metric that quantifies a fabric’s ability to prevent UVR from reaching the skin [9].

The UV resistance of a textile is influenced by various factors, including the type of fibre, fabric weave, thickness, colour, and the application of UV-absorbing treatments [3,10]. Synthetic fibres such as polyester and nylon generally offer better inherent UV protection compared to natural fibres, like cotton. Cotton is one of the most widely used natural fibres in the textile industry, especially in children’s clothing [11], appreciated for its comfort, breathability, and versatility. However, it presents certain limitations, particularly in terms of dye fixation and UV protection, which require improvement to meet modern performance standards [12]. Furthermore, during warmer seasons, when solar radiation levels and temperatures are higher, clothing is generally made from lighter and thinner fabrics. This reduction in fabric thickness and density can significantly diminish the garment’s ability to block UV radiation [3].

To improve UV resistance in textiles, synthetic finishing agents such as acids, phenyl salicylates, and benzophenones are commonly applied. However, these chemical treatments often raise environmental concerns due to their potential toxicity and persistence when released into water systems as industrial effluents [13]. In addition to these finishes, synthetic dyes used in textile colouration may also contain hazardous chemical substances, such as heavy metals and aromatic amines, representing risks not only to the environment but also to human health [14], especially to vulnerable populations [15,16]. Children, for instance, are particularly at risk, as their skin is thinner and more permeable and undergoes continuing physiological development [17]. This reduced epidermal barrier increases susceptibility to chemical penetration and to the harmful effects of UVR. Furthermore, children’s skin tends to be drier and more fragile than adults, which exacerbates their sensitivity to external agents [18]. Health disruptions during this critical growth phase can result in irreversible long-term effects [19]. Therefore, it is crucial to develop and promote safe and eco-friendly alternatives that effectively protect against UV rays without compromising human health.

In response to these concerns, interest in natural and eco-friendly alternatives for textile treatments has increased [10], particularly plant-based dyes. In contemporary industrial applications, natural dyes are primarily valued for their use in food products, but they are also being explored for broader applications in non-food sectors, including the textile industry [20]. These dyes are rich in bioactive compounds such as flavonoids, tannins, and anthraquinones, which impart colour and exhibit promising effective functional properties, including UV-blocking capabilities [6,21,22]. Despite these advantages, their adoption in textiles remains limited due to challenges such as a lack of raw material standardisation, high production costs, and generally low colour yield [23,24]. Compared to synthetic dyes, natural dyes generally offer lower colour performance; however, their ability to provide additional functionalities without the need for extra chemical finishes is attracting interest [1]. For successful commercialisation in the textile sector, it is essential that these dyes contribute not only to aesthetic appeal but also improve fabric functionality.

To address this gap, the present study evaluates the UV-protective capacity of 100% cotton knit fabrics dyed with three natural dyes: indigo, weld, and madder, in combination with alum, pomegranate peel extract, and tannin (extracted from quebracho wood). It further investigates how these treatments respond to washing, with a focus on changes in both colour intensity and UV-blocking performance. By combining functional performance with environmental sustainability, this research contributes to the development of safer, bio-based alternatives for UV-protective textiles.

2. Materials and Methods

2.1. Materials

Three natural dyes were selected for their anti-UV and chromatic potential: indigo (extracted from Indigofera tinctoria plant), weld (extracted from Reseda luteola plant), and madder (extracted from Rubia tinctorum plant). In addition, three materials with mordant abilities were employed: tannin from quebracho wood (Schinopsis lorentzii) and pomegranate from Punica granatum peels used as bio-mordants and alum (aluminium-potassium sulphate dodecahydrate, AlK(SO4)2·12H2O), a conventional mordant.

All natural dyes, along with the quebracho tannin bio-mordant, were supplied by NIG Nahrungs-Ingenieurtechnik GmbH (Magdeburg, Germany). Pomegranate peel was provided by Aquitex (Porto, Portugal), and alum was obtained from Panreac Química SLU (Barcelona, Spain).

For the indigo dyeing process, fructose (used as a reducing agent) and calcium hydroxide (Ca(OH)2) (used as an alkaline agent) were used as dyeing auxiliaries. Both were purchased from Merck Millipore (Darmstadt, Germany). NGS Malhas company (Barcelos, Portugal) supplied 100% cotton knit fabrics with jersey structure and a mass per unit area of 145 g/m2.

2.2. Methods

2.2.1. Dyeing Processes

All dyeing processes were carried out using the exhaust dyeing method on IBELUS IL-720 equipment (Pregitzer & Ca., Lda, Guimarães, Portugal), with a bath ratio of 1:20. One-hundred per cent cotton knit samples were initially washed with 1 g/L of SDC-2408 ECE Non-Phosphate Detergent (A) to remove impurities. Prior to dyeing, the samples were pre-moistened to promote even colour uptake. A dye concentration of 4% (on the weight of fibre, WOF) was used for each dye (indigo, weld, and madder) while 15% WOF was used for pomegranate and alum mordants. For tannin, 8% WOF was applied. The 4% dye concentration ensures a visible and measurable colouration. The higher percentage of 15% for pomegranate and alum reflects the need for adequate fixation and mordanting efficiency, which is crucial to improve dye uptake and fastness properties. Tannin was used at a lower concentration (8%) due to its strong binding ability and high content of active compounds.

Dyeing processes that did not involve indigo were conducted at 80 °C for 60 min. For indigo dyeing, a vat dye process was applied. This required a modified formulation using twice the amount of calcium hydroxide and three times the amount of fructose relative to the indigo concentration. Indigo dyeing was carried out at a lower temperature of 60 °C for 60 min [25]. After dyeing, all samples were rinsed under running water at room temperature (approximately 18 °C). Indigo-dyed samples were then exposed to open air to allow natural oxidation of the dye, without the use of any auxiliary oxidising agents [26].

All materials were individually applied and tested on the fabrics. The selection of mordanting processes for each combination was based on prior chromatic studies, leading to the product combinations and procedures defined in Table 1.

Table 1.

Material combinations and mordanting processes used in the study.

In this study, a total of twenty different samples were analysed: one undyed control sample, six samples treated with individual products, and thirteen samples treated with product combinations. To ensure the reliability and reproducibility of the results, three replicates were prepared for each dyeing condition. The replicates were then evaluated in a standardised light chamber to qualitatively assess their chromatic appearance. Only dyeing conditions in which the three samples exhibited colour similarity were considered valid for further analysis.

2.2.2. Wash Fastness Tests

Wash fastness was determined on a Washtec-P according to NP EN ISO 105-C06, method A1S [27]. Tests were performed in a 150 mL liquor containing 4 g/L SDC-2408 ECE Non-Phosphate Detergent (A). Each dyed sample—stitched to a multifibre-adjacent fabric—was washed with 10 stainless-steel balls to provide mechanical action. The bath was agitated at 40 °C for 30 min. After washing, samples were carefully rinsed and dried at a controlled temperature of 25 °C before colour measurements were taken.

2.2.3. Colour Evaluations

Colour measurements before and after washing were evaluated using a Datacolor International SF600 Plus—CT spectrophotometer (Datacolor, Lucerne, Switzerland), operated through Datacolor TOOLS software (24.1.1 version). All measurements were conducted under standardised lighting and viewing conditions, employing the D65 illuminant to replicate natural daylight and a 10° standard observer to approximate human visual perception. Each sample was measured at three distinct locations to minimise the effect of localised colour irregularities, with particular care taken to ensure that measurements before and after washing were performed in the same area. The mean value of these readings was used for analysis, and results were considered valid only when the colour difference (ΔE*) between individual measurements did not exceed 1. The study specifically targeted colour change, excluding staining effects from evaluation. Changes in fabric appearance were quantified through CIELAB colour space metrics, focusing on ΔE* values to capture perceptual differences before and after washing [28,29]. To complement the instrumental data, wash fastness was also rated using the standard grey scale, where a score of 1 denotes severe colour change and 5 indicates excellent resistance to washing [28]. This dual approach ensured both objective and comparative insight into the dyeing performance under laundering conditions.

2.2.4. Ultraviolet Protection Evaluations

The UV-protective performance of the dyed fabric samples was evaluated in accordance with AATCC Test Method 183-2020 [30], which determines the Ultraviolet Protection Factor (UPF) of textiles. Spectral transmittance measurements were performed using a Shimadzu UV-2600 spectrophotometer (Shimadzu Corporation, Tokyo, Japan) equipped with an integrating sphere, allowing for accurate assessment of both direct and diffuse UV transmittance.

Measurements were taken across the 280–400 nm wavelength range, covering both UVB (280–315 nm) and UVA (315–400 nm) regions. Data acquisition and UPF calculations were carried out using UVProbe software. Each sample was tested under controlled conditions, and the resulting UPF values were used to determine the level of UV protection (UVR protection category). A higher UPF value indicates greater UV-blocking capability. According to established classification criteria, fabrics with a UPF below 15 are considered to offer low or insufficient protection. Values between 15 and 24 are classified as good, 25 to 39 as very good, and 40 or higher as providing excellent UV protection. UPF was calculated according to Equation (1):

where Eλ represents the relative erythemal spectral effectiveness, Sλ is the solar spectral irradiance, Tλ is the spectral transmittance of each fabric, and Δλ is the wavelength interval in nm [30,31].

3. Results and Discussion

3.1. Colour Measurement and Wash Fastness

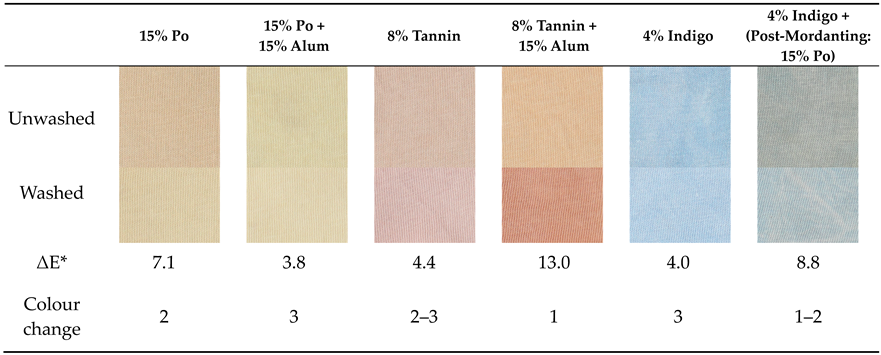

Table 1, Table 2 and Table 3 present the wash fastness results of knit cotton samples dyed with indigo, weld, and madder dyes, and different mordant combinations. This was measured by the greyscale rating and the ΔE* between unwashed and washed samples. The results showed that, among the samples dyed with mordants that also produce colour, the combination of 15% pomegranate + 15% alum exhibited the best wash fastness, with a ΔE* of 3.8 and a rating of 3 (see Table 2). The combination of 8% tannin + 15% alum showed the poorest wash fastness, with a ΔE* of 13.0 and a greyscale rating of 1, indicating a very high level of colour change after washing. However, this does not necessarily indicate a loss of colour during washing; in this case, it suggests a change in hue and lightness, as can be observed in Table 2. The colour before washing appears more yellowish, while after washing it becomes darker with an orange tone. This shift toward a more intense colour can be observed in all samples mordanted with tannin and alum, in both dyeing processes with weld (see Table 3) and with madder (see Table 4). This phenomenon is related to the pH sensitivity of the products used. The detergent applied during the wash fastness test has a slightly alkaline pH, which can interact with the dye compounds fixed on the fabric surface. Many natural dyes are sensitive to changes in pH, and exposure to an alkaline environment during washing can alter their molecular structure or bonding characteristics, resulting in a noticeable change in colour [32]. In addition to pH effects, studies have shown that the type of water and washing temperature significantly influence colour change and fabric behaviour [5,33]. A study conducted by Aliei et al. [33] reported that cotton fabrics dyed with natural dyes demonstrated greater fibre shrinkage and more pronounced colour shifts at elevated temperatures, particularly a decrease in luminosity, resulting in darker tones after washing. Although distilled water was used in the present study, thus avoiding the mineral content found in hard water, the temperature and pH of the washing medium could still contribute to structural and optical modifications in the dyed fabric.

Table 2.

Wash fastness and colour change in dyed samples with different mordants and indigo.

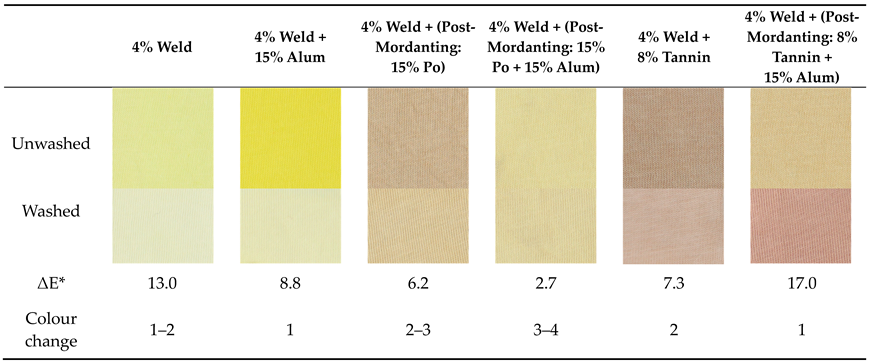

Table 3.

Wash fastness colour differences of samples dyed with weld or weld combined with different mordants.

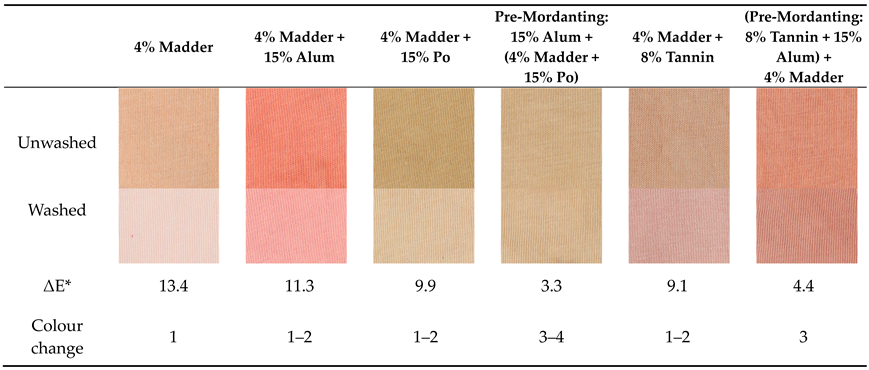

Table 4.

Wash fastness colour differences of samples dyed with madder or madder combined with different mordants.

For the indigo-dyed fabrics, 4% indigo alone revealed good wash resistance (ΔE* = 4.0, greyscale rating 3). However, when combined with 15% pomegranate as a post-mordant, the colour changed to grey-green, and the wash fastness significantly declined (ΔE* = 8.8, greyscale rating 1–2), suggesting that post-mordanting with pomegranate adversely affects the durability of indigo-dyed fabrics (see Table 2).

In the dyeing processes using weld and madder, the best wash fastness results were observed when pomegranate was combined with alum during mordanting (see Table 3 and Table 4).

However, as the mordanting processes differ, only the individual products are being analysed, which may influence the results. Regardless of the dye used, all samples showed an improvement in colour intensity when any mordant was applied. Furthermore, the results clearly demonstrated that the choice of mordant significantly influences the final hue and tone of the dyed fabrics, as also reported in the literature [33,34].

3.2. Transmittance Measurement of Dyed Samples

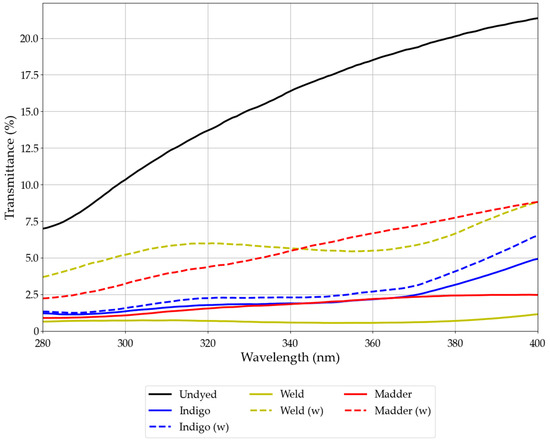

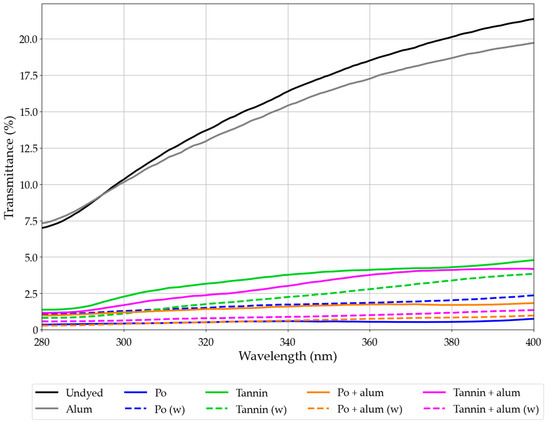

Figure 1 demonstrates the UV transmittance (%) of samples undyed and dyed with indigo, weld, or madder-dyed knit cotton fabrics in the 280–400 nm wavelength range. It highlights their effectiveness in UV protection both before and after washing. These results are consistent with different studies that demonstrated this functionality in natural dyes [35,36,37].

Figure 1.

Transmittance spectra of samples dyed with indigo, weld, or madder before and after (w) washing.

In Figure 1, the undyed fabric showed the highest UV transmittance, gradually increasing from approximately 7% at 280 nm to over 20% at 400 nm. This indicates poor UV protection. In contrast, all fabrics dyed with 4% natural dyes—indigo, weld, and madder—demonstrated significantly reduced transmittance, with values generally between 1.5% and 4%, indicating substantial improvement in UV blocking. Among the dyed samples, 4% indigo showed slightly higher transmittance than weld and madder at longer wavelengths but remained consistently protective throughout the spectrum. Weld and madder exhibited nearly identical performance with strong UV-blocking capability.

The effect of washing is also presented in Figure 1. Weld-dyed fabrics showed a denoted increase in transmittance after washing, rising to over 7% at higher wavelengths. This suggests a significant loss of UV protection due to dye removal. Madder-dyed fabrics also showed a moderate increase in transmittance, particularly after 340 nm, indicating a partial reduction in UV-blocking effectiveness. In contrast, indigo-dyed fabrics retained their UV-protective properties relatively well after washing, with only a slight increase in transmittance, confirming good wash fastness and durable UV protection. These findings are consistent with the results observed in the wash fastness colour tests, where indigo demonstrated the least loss of colour intensity among the three dyes. Since colour is one of the factors that determine a fabric’s UV protection [33,38], the loss of dye during washing is expected to result in a reduction of UV-blocking properties. This is due not only to the decrease in colour intensity but also to the inherent anti-UV properties of natural dyes themselves [6].

Regarding the mordants used, the fabric mordanted solely with alum exhibited the highest transmittance across the spectrum, indicating minimal UV protection, similar to the undyed control sample. In contrast, all other mordanted samples demonstrated significantly lower transmittance values, confirming that mordanting improves the fabric’s UV-blocking capacity (see Figure 2). Among these, the pomegranate-mordanted sample showed the lowest transmittance percentages, indicating strong UV protection, which aligns with findings in the literature [35]. However, when pomegranate is combined with alum, transmittance levels increased slightly, suggesting a reduction in UV protection compared to pomegranate used on its own.

Figure 2.

Transmittance spectra of samples mordanted with alum, pomegranate, and tannin, before and after (w) washing.

When the samples were mordanted with pomegranate peel, tannin, or alum (or a combination of these) and subjected to washing, only the sample treated solely with pomegranate showed an increase in transmittance percentage, as illustrated in Figure 2. Characteristically, washing results in dye loss and, consequently, a decrease in functionality, particularly in terms of UV protection. However, in this case, all other samples exhibited a decrease in transmittance, indicating an improvement or retention of UV-blocking properties after washing.

When comparing these findings with the wash fastness results shown in Table 1, an interesting correlation appears. The sample mordanted with tannin and alum exhibited improved UV protection after washing, likely due to the resulting darker colour caused by pH changes. This aligns with several studies that confirm a correlation between darker shades and improved UV-blocking effectiveness [5,34]. In contrast, the samples treated with pomegranate + alum or tannin alone exhibited some colour fading after washing; however, the transmittance percentage decreased, indicating an improvement in UV protection. This finding suggests that washing does not necessarily compromise the functional properties of naturally dyed fabrics. In some cases, it may even improve it, possibly due to structural or molecular changes in the dye–fibre interaction. These results underscore the importance of further research to clarify the mechanisms by which washing influences such structural and molecular changes.

The UPF and UVR protection category results showed that undyed cotton samples exhibited low UV protection (UPF = 8), as depicted in Table 5. This confirms the necessity of dyeing or mordanting to improve functionality, as fabrics must achieve at least a UPF rating of 30 to meet the minimum protection requirements [39]. As the sample treated with alum alone exhibited a very low UPF value, it was excluded from the washing tests.

Table 5.

UPF values and UVR protection category of samples mordanted, before and after washing.

Among the unwashed samples, pomegranate alone attained the highest UPF value of 213. However, this value decreased to 70 after washing. Considering the results after washing, higher values were achieved with samples that combine alum with other mordants, either with pomegranate or tannin. These results suggest that such combinations improve the effectiveness of UV-blocking and its durability after washing. All mordants showed excellent UV protection both before and after washing, except for tannin, which presented very good protection. The UPF value of the sample mordanted with tannin was improved to the excellent category after washing.

Indigo-dyed fabrics demonstrated excellent UV protection both before and after washing, with only a small reduction in UPF from 61 to 50. Interestingly, when post-mordanted with pomegranate, the UPF slightly improved after washing (from 65 to 67), showing strong wash fastness and stable UV protection, aligning with previous observations regarding indigo’s durability (see Table 6).

Table 6.

UPF values and UVR protection category of samples dyed with indigo, before and after washing.

Samples dyed with weld alone or with weld combined with alum initially exhibited high UV protection, with UPF values of 140 and 65, respectively. However, these values decreased significantly after washing, dropping to 18 and 21, respectively. In the weld + alum combination, although the dyed fabric exhibits a much stronger colour, its UPF value is lower than that of the fabric dyed with weld alone. Typically, higher colour saturation and darker shades are associated with increased UPF, as they tend to absorb more UV radiation. However, these findings align with those of Maqbool [40], who reported that some cotton fabrics with lower colour strength still achieved high mean UPF values and fell within the excellent category of UV protection. This suggests that UPF is not solely dependent on colour properties but is also significantly influenced by the chemical composition of the dye molecules and the primary constituents present in the dye mixture [6].

The use of mordants such as alum in combination with pomegranate contributed to improved UV protection. However, the most notable result was observed in the sample dyed with weld and mordanted with tannin + alum, which showed a remarkable increase in UPF after washing, from 36 to 132 (see Table 7). This aligns with the chromatic changes observed, as the fabric became more orange and darker post-wash.

Table 7.

UPF values and UVR protection category of samples dyed with weld, before and after washing.

Madder-dyed samples revealed excellent UV protection, and certain combinations of mordants further improved this. For instance, pre-mordanting with alum followed by a dye bath containing madder and pomegranate resulted in a UPF of 174 for unwashed samples and 97 for washed samples—both still falling within the excellent category after washing. While there was a decrease in the UPF value in all madder-dyed samples after washing, they all remained in the excellent category, except for the sample dyed solely with madder, which dropped to the good category (see Table 8).

Table 8.

UPF values and UVR protection category of samples dyed with madder, before and after washing.

In general, the best wash-fast UV protection was seen in indigo and certain samples treated with mordant combinations (e.g., weld with post-mordanting of pomegranate + alum). The combination of mordants, particularly tannin with alum, appears to improve the UPF after washing. This improvement is observed not only in samples that become more saturated after washing but also in some cases where there is a loss of colour, like in the sample dyed with 4% weld and post-mordanted with 15% pomegranate. However, most samples showed a decrease in UPF rating after washing, which aligns with the literature indicating that darker and more saturated colours generally absorb more UVR than lighter shades, resulting in higher UPF values [33,38]. Despite this small reduction in values, in most cases the UVR protection category remains excellent.

Further research is required to improve the chromatic properties of the dyes after washing. Nevertheless, the present findings confirmed the potential of these dyes for use in UV protection purposes. As Mamun [34] reported, the use of natural dyes in the textile industry has increased significantly over the past decade, accompanied by growing interest in their functional properties. To advance this potential toward real-world adoption, it is necessary to optimise and validate results under industrial conditions, considering both equipment and large-scale processes. Equally important is the evaluation of dyed textile materials in focus groups, particularly within fashion products for children, to assess usability and wash durability in practice. Functional clothing has become an increasingly popular trend in children’s apparel [41], highlighting the importance of testing these textiles directly with end users. Therefore, continued investigation is crucial to ensure both technical performance and consumer acceptance in industrial applications.

4. Conclusions

Natural dyes, when applied with thoughtful mordant strategies, can significantly improve the UV-protective properties of knit cotton fabrics. The performance after washing varies depending on the dye and mordant used, but combinations involving pomegranate peel, tannin, or alum showed the most promising and durable results. These findings support the viability of natural dye systems for aesthetic and functional textile applications like UV protection.

The integration of natural dyes in textile applications offers a non-toxic alternative to conventional synthetic dyes and chemical treatments. Their ability to confer functional properties, such as UV resistance, allows the replacement of both synthetic colourants and additional finishing agents that may present risks to human health and the environment. This is especially important in the context of children’s apparel, as children are more physiologically vulnerable to chemical exposure and more susceptible to the harmful effects of UVR. Ensuring effective, safe, and long-lasting sun protection through textiles dyed with natural resources contributes to their health and wellbeing and minimises the negative effects on the environment caused by products used in conventional finishing processes.

Although this study confirms the potential of these dyes for UV-protective purposes, further research is needed to improve their chromatic performance, particularly after washing. Improving colourfastness remains an important challenge for industrial adoption. Future research should also explore the influence of pH on the stability and UV-blocking effectiveness, as pH changes can influence dye–fibre interactions and overall effectiveness.

As research in this area advances, anti-UV textiles dyed with natural colourants present an innovative solution that combines health protection, environmental responsibility, and aesthetic appeal, contributing to the future of the textile and fashion industry.

Author Contributions

Conceptualisation, D.S.; methodology, D.S.; validation, D.S., J.C., and I.C.; formal analysis, D.S.; investigation, D.S.; resources, D.S.; data curation, D.S.; writing—original draft preparation, D.S.; writing—review and editing, D.S., J.C., P.M., and I.C.; funding acquisition, P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Regional Development Fund through the Operational Competitiveness Program and the National Foundation for Science and Technology of Portugal (FCT) under the projects UID/CTM/00264/2020 of Centre for Textile Science and Technology (2C2T) on its component base (https://doi.org/10.54499/UIDB/00264/2020) and programme (https://doi.org/10.54499/UIDP/00264/2020). D.S. and I.C. also acknowledge FCT for a PhD scholarship (https://doi.org/10.54499/2021.06351.BD) and junior researcher contract (https://doi.org/10.54499/2022.08710.CEECIND/CP1718/CT0031), respectively.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zannat, A.; Uddin, M.N.; Mahmud, S.T.; Mia, R.; Ahmed, T. Natural Dyes and Pigments in Functional Finishing. In Renewable Dyes and Pigments; Islam, S.U., Ed.; Elsevier: Davis, CA, USA, 2024; pp. 271–287. [Google Scholar]

- Axelson, G.E.; Constanza, J.; Rezaee, R.; Axelson, A.; Cenci, A.; Khan, A.; Weimann, R.; Ilyas, E.N. Evaluation of UV-A and UV-B Transmission through the Windows of Gas, Hybrid, and Electric Vehicles. Arch. Dermatol. Res. 2025, 294, 317. [Google Scholar] [CrossRef] [PubMed]

- Klinkhammer, K.; Weskott, P.; Ratovo, K.; Krieg, M.; Bendt, E.; Mahltig, B. Transmission Reduction for UV and IR Radiation with Dyed Lyocell Knitted Textiles. Appl. Sci. 2023, 13, 5432. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, X.; Liu, C.; Liu, Z.; Liu, L.; Feng, C.; Ju, J.; Yao, X. Ultraviolet-Blocking Polymers and Composites: Recent Advances and Future Perspectives. J. Mater. Chem. A Mater. 2024, 12, 32638–32664. [Google Scholar] [CrossRef]

- Lambrecht, L.; Capablanca, L.; Bou-Belda, E.; Montava, I.; Díaz-García, P.; Gisbert-Payá, J. Enhancing Polyphenols and Tannins Concentration on Cotton Dyed with Red Tea. Sustainability 2023, 15, 3062. [Google Scholar] [CrossRef]

- Santiago, D.; Cunha, J.; Cabral, I. Chromatic and Medicinal Properties of Six Natural Textile Dyes: A Review of Eucalyptus, Weld, Madder, Annatto, Indigo and Woad. Heliyon 2023, 9, e22013. [Google Scholar] [CrossRef] [PubMed]

- Harrison, S.L.; Buettner, P.G.; Nowak, M.J. Sun-Protective Clothing Worn Regularly during Early Childhood Reduces the Number of New Melanocytic Nevi: The North Queensland Sun-Safe Clothing Cluster Randomized Controlled Trial. Cancers 2023, 15, 1762. [Google Scholar] [CrossRef]

- Licari, J.J.; Swanson, D.W. Test and Inspection Methods. In Adhesives Technology for Electronic Applications; William Andrew: Amsterdam, The Netherlands, 2011; pp. 345–377. ISBN 978-1-4377-7889-2. [Google Scholar]

- Saha, B.; Saha, A.; Das, P.; Kakati, A.; Banerjee, A.; Chattopadhyay, P. A Comprehensive Review of Ultraviolet Radiation and Functionally Modified Textile Fabric with Special Emphasis on UV Protection. Heliyon 2024, 10, e40027. [Google Scholar] [CrossRef]

- Li, K.; Li, X.; Li, Y.; Wu, C. Dyeing and UV Protective Properties of Chitosan-Modified Cotton Fabric Treated with Black Rice Extract. J. Nat. Fibers 2023, 20, 2163448. [Google Scholar] [CrossRef]

- Santiago, D.; Cabral, I.; Cunha, J. Children’s Functional Clothing: Design Challenges and Opportunities. Appl. Sci. 2024, 14, 4472. [Google Scholar] [CrossRef]

- Neeta; Arya, N.; Grover, A. Vaishali Utilizing Henna and Babool Bark for Antibacterial and UV-Protective Cellulosic Fiber (Cotton) Treatment. Polym. Bull. 2025, 82, 3191–3206. [Google Scholar] [CrossRef]

- Che, J.; Yang, X. A Recent (2009–2021) Perspective on Sustainable Color and Textile Coloration Using Natural Plant Resources. Heliyon 2022, 8, e10979. [Google Scholar] [CrossRef] [PubMed]

- Islam, T.; Repon, M.R.; Islam, T.; Sarwar, Z.; Rahman, M.M. Impact of Textile Dyes on Health and Ecosystem: A Review of Structure, Causes, and Potential Solutions. Environ. Sci. Pollut. Res. 2023, 30, 9207–9242. [Google Scholar] [CrossRef]

- Tang, A.Y.L.; Lo, C.K.Y.; Kan, C. wai Textile Dyes and Human Health: A Systematic and Citation Network Analysis Review. Color. Technol. 2018, 134, 245–257. [Google Scholar] [CrossRef]

- Svedman, C.; Engfeldt, M.; Malinauskiene, L. Textile Contact Dermatitis: How Fabrics Can Induce Dermatitis. Curr. Treat. Options Allergy 2019, 6, 103–111. [Google Scholar] [CrossRef]

- Etzel, R.A. The Special Vulnerability of Children. Int. J. Hyg. Environ. Health 2020, 227, 113516. [Google Scholar] [CrossRef]

- Brod, B.A.; Treat, J.R.; Rothe, M.J.; Jacob, S.E. Allergic Contact Dermatitis: Kids Are Not Just Little People. Clin. Dermatol. 2015, 33, 605–612. [Google Scholar] [CrossRef] [PubMed]

- Shittu, E.; Lakhanpaul, M.; Vigurs, C.; Sarkar, K.; Koch, M.; Parikh, P.; Campos, L.C. A Rapid Systematic Scoping Review of Research on the Impacts of Water Contaminated by Chemicals on Very Young Children. Sci. Total Environ. 2023, 891, 164604. [Google Scholar] [CrossRef]

- Shahid-ul-Islam; Rather, L.J.; Mohammad, F. Phytochemistry, Biological Activities and Potential of Annatto in Natural Colorant Production for Industrial Applications—A Review. J. Adv. Res. 2016, 7, 499–514. [Google Scholar] [CrossRef] [PubMed]

- Do, K.L.; Su, M.; Mushtaq, A.; Zhao, F. Dyeing of Silk with Natural Lac Dye from Laccifer Lacca Kerr. and Evaluation of Antibacterial and UV-Protective Properties. Fibers Polym. 2023, 24, 2773–2783. [Google Scholar] [CrossRef]

- Xu, H.; Yang, C.; Song, H.Y. Eco-Friendly Dyeing and Functional Finishing of Organic Cotton Using Optimized Oolong Tea Stems (Agricultural Waste) Through Response Surface Methodology. Molecules 2025, 30, 509. [Google Scholar] [CrossRef]

- Rather, L.J.; Zhou, Q.; Ali, A.; Haque, Q.M.R.; Li, Q. Valorization of Agro-Industrial Waste from Peanuts for Sustainable Natural Dye Production: Focus on Adsorption Mechanisms, Ultraviolet Protection, and Antimicrobial Properties of Dyed Wool Fabric. ACS Food Sci. Technol. 2021, 1, 427–442. [Google Scholar] [CrossRef]

- Mia, R.; Bakar, M.A.; Islam, M.R.; Ahmed, T. Eco-Friendly Coloration from Mahogany Wood Waste for Sustainable Dyeing of Organic Nonwoven Cotton Fabric. Results Eng. 2023, 17, 101032. [Google Scholar] [CrossRef]

- Santiago, D.; Cunha, J.; Cabral, I. Textile Dyeing with Indigofera Tinctoria-Derived Dye: Exploring Eco-Friendly Processes and Expanding the Colour Spectrum. Color. Technol. 2025, 2025, 1–12. [Google Scholar] [CrossRef]

- Boutrup, J.; Ellis, C. The Art and Science of Natural Dyes: Principles, Experiments, and Results, 1st ed.; Schiffer Publishing, Ltd.: Atglen, PA, USA, 2019; ISBN 978-0-7643-5633-9. [Google Scholar]

- ISO 105-C06:2010; Textiles—Tests for Colour Fastness—Part C06: Colour Fastness to Domestic and Commercial Laundering. International Organization for Standardization: Geneva, Switzerland, 2010.

- Wardman, R.H. An Introduction to Textile Coloration: Principles and Practice; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 978-1-119-12156-5. [Google Scholar]

- Berns, R.S. Billmeyer and Saltzman’s: Principles of Color Technology, 4th ed.; Wiley: Hoboken, NJ, USA, 2019; ISBN 9781119367314. [Google Scholar]

- AATCC 183-2020; Transmittance or Blocking of Erythemally Weighted Ultraviolet Radiation Through Fabrics. American Association of Textile Chemists and Colorists: Durham, NC, USA, 2020.

- Gambichler, T. Ultraviolet Protection of Clothing. In Functional Textiles for Improved Performance, Protection and Health; Pan, N., Sun, G., Eds.; Woodhead Publishing: Cambridge, UK, 2011; pp. 45–63. ISBN 9781845697235. [Google Scholar]

- Rashad, H.G.; El Khatib, H.S.; Shokry, G.M.; EL-Zawahry, M.M. Fabrication of PH-Sensitive Silk and Wool Fabrics Treated with Pectin for Multichromic Sensor Dyes with Biochromic Butterfly Pea Flowers (Clitoria ternatea L.) Extract. Int. J. Biol. Macromol. 2025, 311, 143972. [Google Scholar] [CrossRef]

- Aliei, H.; Carrera-Gallissa, E.; Cayuela, D. Evaluating the Impact of Washing Conditions on the Color Changes of Naturally Colored Cotton Fabrics: A Focus on Detergents, Water Types, and Temperature. Materials 2024, 17, 5777. [Google Scholar] [CrossRef]

- Al Mamun, M.A.; Haji, A.; Mahmud, M.H.; Repon, M.R.; Islam, M.T. Bibliometric Evidence on the Trend and Future Direction of the Research on Textile Coloration with Natural Sources. Coatings 2023, 13, 413. [Google Scholar] [CrossRef]

- Agnhage, T.; Zhou, Y.; Guan, J.; Chen, G.; Perwuelz, A.; Behary, N.; Nierstrasz, V. Bioactive and Multifunctional Textile Using Plant-Based Madder Dye: Characterization of UV Protection Ability and Antibacterial Activity. Fibers Polym. 2017, 18, 2170–2175. [Google Scholar] [CrossRef]

- Pargai, D.; Jahan, S.; Gahlot, M. Functional Properties of Natural Dyed Textiles. In Chemistry and Technology of Natural and Synthetic Dyes and Pigments; Samanta, A.K., Awwad, N., Algarni, H.M., Eds.; IntechOpen: London, UK, 2020; pp. 207–226. [Google Scholar]

- Mansour, R.; Dhouib, S.; Sakli, F. UV Protection and Dyeing Properties of Wool Fabrics Dyed with Aqueous Extracts of Madder Roots, Chamomiles, Pomegranate Peels, and Apple Tree Branches Barks. J. Nat. Fibers 2022, 19, 610–620. [Google Scholar] [CrossRef]

- Schmidt-Przewozna, K.; Zajaczek, K. Influence of Flavonoid Dyes on the Color and Pro-Health Benefits of Linen Fabrics. J. Nat. Fibers 2022, 19, 11165–11180. [Google Scholar] [CrossRef]

- Lu, J.T.; Ilyas, E. An Overview of Ultraviolet-Protective Clothing. Cureus 2022, 14, e27333. [Google Scholar] [CrossRef]

- Maqbool, M.; Ali, S.; Hussain, M.T.; Khan, A.; Majeed, S. Comparison of Dyeing and Functionalization Potential of Some Selected Plant Extracts Applied on Cotton Fabric. J. Nat. Fibers 2019, 18, 42–50. [Google Scholar] [CrossRef]

- Santiago, D.; Januário, V.; Cunha, J. Sustainable Fashion—Positioning a Baby Clothing Brand. In Advances in Fashion and Design Research; Broega, A.C., Cunha, J., Carvalho, H., Providência, B., Eds.; Springer International Publishing: Guimarães, Portugal, 2023; pp. 675–687. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).