1. Introduction

Textile and apparel products designed for extreme weather conditions or industrial applications require the integration of textile fabrics with insulation materials to ensure optimal protection. Typically, these components are assembled in a layered, sandwich-like structure, where the insulation material is enclosed between textile layers. One of the most widely used techniques for manufacturing such three-dimensional (3D) textile or nonwoven assemblies is the sewn-through method. In this construction, the textile layers serve as barriers against water and wind while also facilitating moisture management, whereas the 3D nonwoven core functions as the primary source of thermal insulation.

1.1. Development of Cold Spots

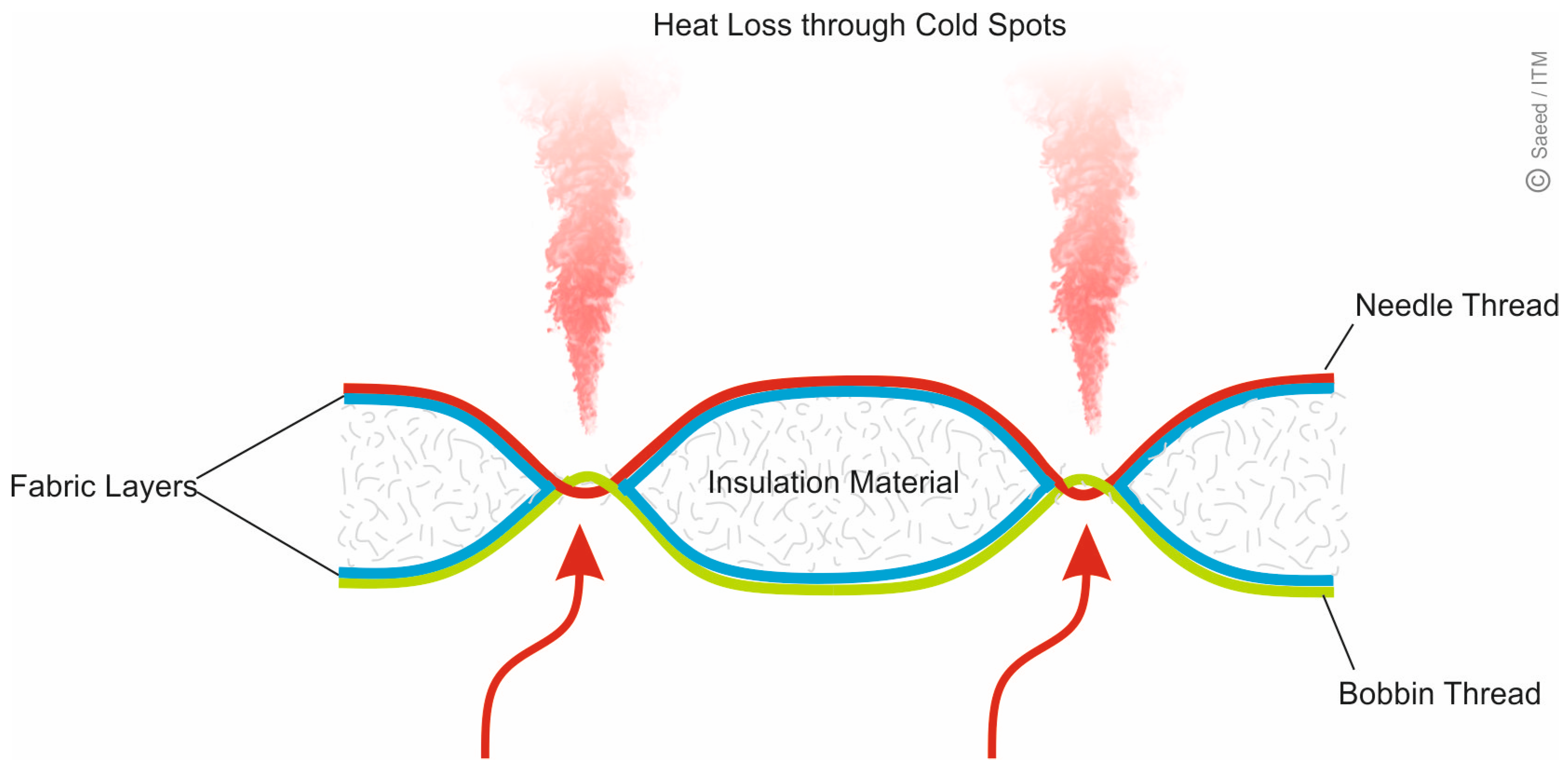

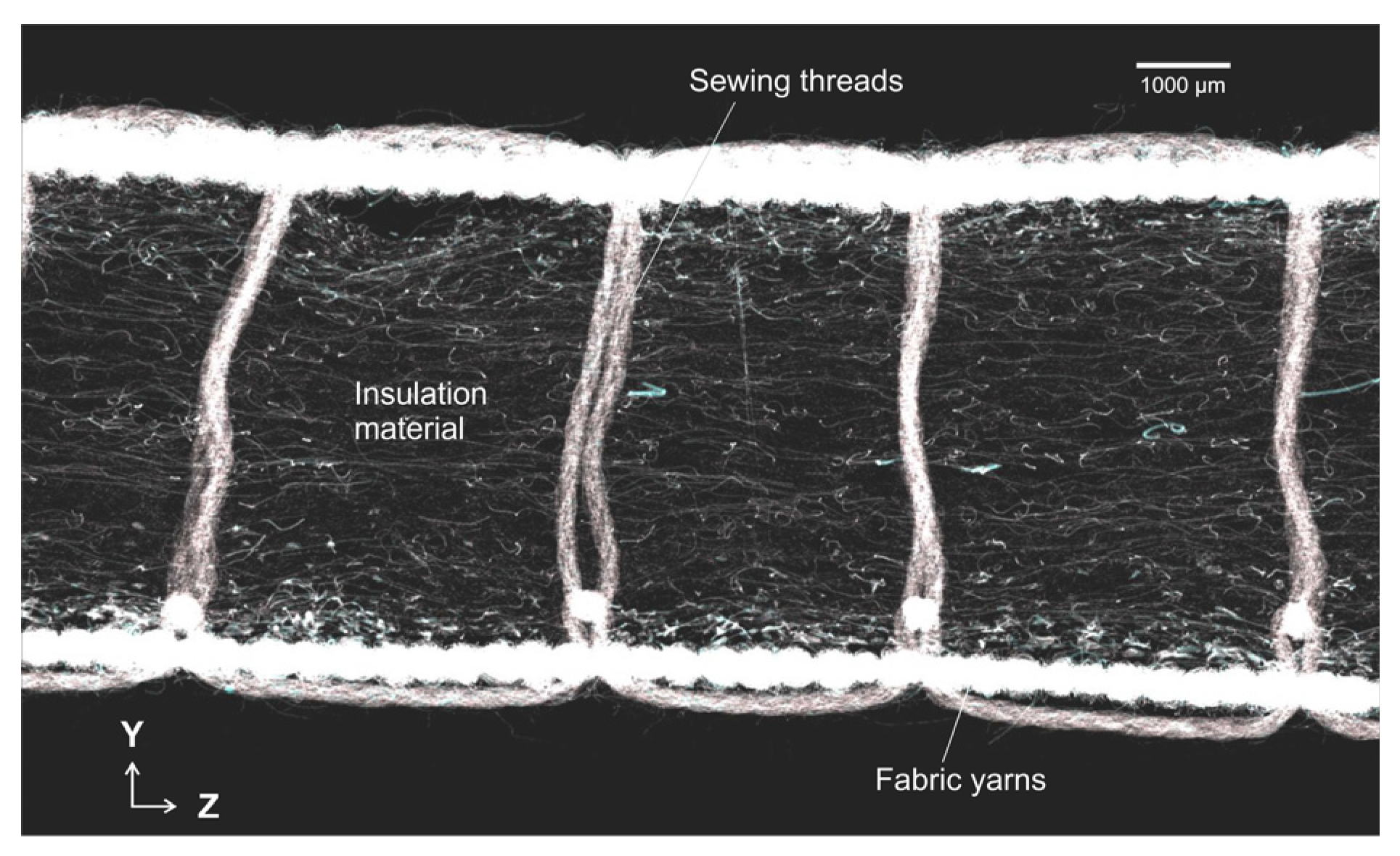

A significant drawback of the sewn-through method is the compression of the nonwoven insulation along the stitch lines due to the sewing thread systems. This compression disrupts the 3D structure, creating localized areas of reduced insulation known as cold spots, a concern widely recognized by garment technologists. As illustrated in

Figure 1, these compressed zones extend along the entire stitch line, forcing the trapped air within the insulation to escape, ultimately diminishing its thermal efficiency. Consequently, the stitch lines act as thermal bridges, allowing heat to escape and reducing overall insulation performance. This thermal compromise is an inherent limitation of conventional sewn-through sewing techniques and remains an unresolved challenge in current garment manufacturing processes.

Heat transfer in textiles is a multifaceted phenomenon, involving the simultaneous interaction of conduction, convection, and radiation [

1]. When considering stitched three-dimensional (3D) textile insulation materials, conduction plays a dominant role, particularly along the compressed stitch lines, where the insulating structure is altered due to sewing-induced deformation. In fibre-based insulation materials, thermal conductivity is primarily influenced by the conductive properties of both the fibre polymers and the entrapped air. Since air has significantly lower thermal conductivity compared to textile fibres, it is the fibrous component that contributes more prominently to overall heat transfer [

2]. Thus, preserving the integrity of the insulation structure and maximizing air entrapment are crucial for enhancing thermal resistance.

Additionally, textile and insulation materials possess an intrinsically porous structure, which allows for air circulation and potential convective heat loss. Various heat transfer mechanisms operate simultaneously, impacting the thermal behaviour of textile assemblies. However, a critical aspect of thermal inefficiency in sewn textile structures arises from needle penetration points, which introduce unimpeded pathways for heat dissipation. These needle holes disrupt the insulation barrier, creating localized thermal bridges that significantly reduce the overall insulating performance of the assembly. A number of studies have been performed to measure the clothing comfort using thermal manikins [

3,

4] and to assess various seam types in terms of thermal properties [

5], but no studies are found on the impact of compressions along stitch lines.

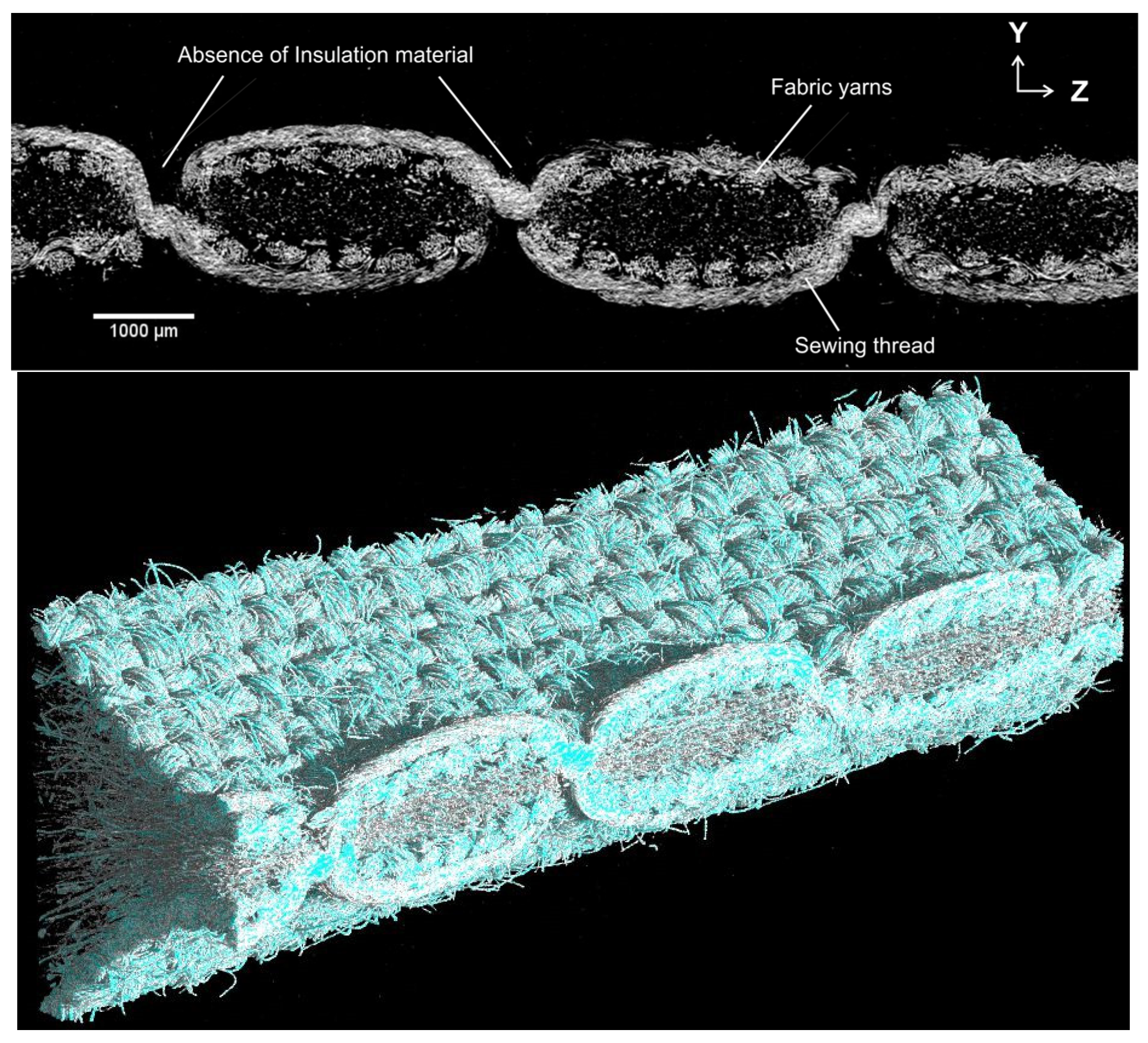

At each stitch point, where the two-thread system interlaces, the insulation material is absent, as illustrated in

Figure 2.

This advanced X-ray tomography imaging method provides visualization of how the sewing process affects the insulation material at a microscopic level.

Figure 2 (bottom panel) presents an isometric view of a sewn-through insulation system, consisting of two fabric layers with an insulating material sandwiched between them. Additionally, the two-dimensional cross-sectional image in

Figure 2 (top panel) offers deeper insight into the effects of stitching on insulation integrity at its cross-section. The tomography analysis demonstrates that at the thread interlacing points, only the two-thread system is present, while the insulating material is displaced from these areas. This occurs because the mechanical force exerted by the sewing machine needle and thread tension pushes the insulation fibres aside, leaving voids at the stitch lines. Furthermore, the insulation material between two consecutive needle insertions undergoes severe compression, with maximum densification observed close to the needle penetration points. This compression significantly reduces the loft of the insulation, thereby diminishing its ability to trap air, which is a key factor in thermal resistance. The combined effect of material displacement, compression, and the formation of needle holes leads to substantial localized heat loss, particularly along the stitch lines.

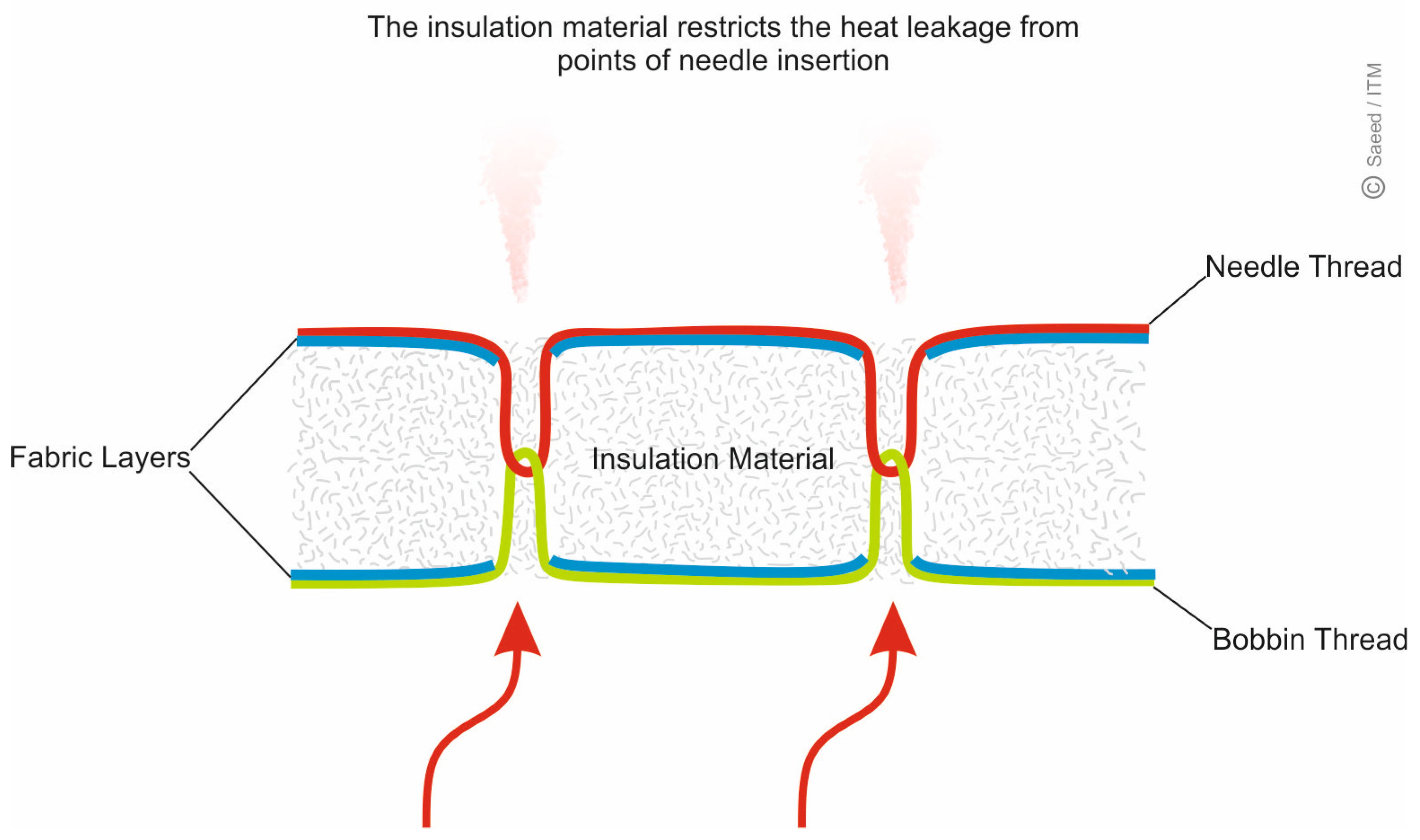

Despite advancements in sewing machine technology, no existing method has successfully eliminated this issue. Consequently, garment technologists, product designers, and technical apparel developers are compelled to explore alternative stitching techniques and innovative design modifications to mitigate the negative effects of cold spots and enhance the thermal performance of insulated textile products. The patents shown in

Figure 3 are an example that how technical product developers tried to overcome the compression along stitch lines problem with the help of complex material handling methods due to the absence of a machine-based technological solution. The main aim remains to preserve and restrict the heat from escaping from the insulation system [

7,

8,

9,

10,

11].

1.2. Development of Spacer Stitching

An innovative sewing technique, known as spacer stitching, has been developed to address the issue of compression along stitch lines in insulated textile assemblies. The technology has also been awarded patents [

12,

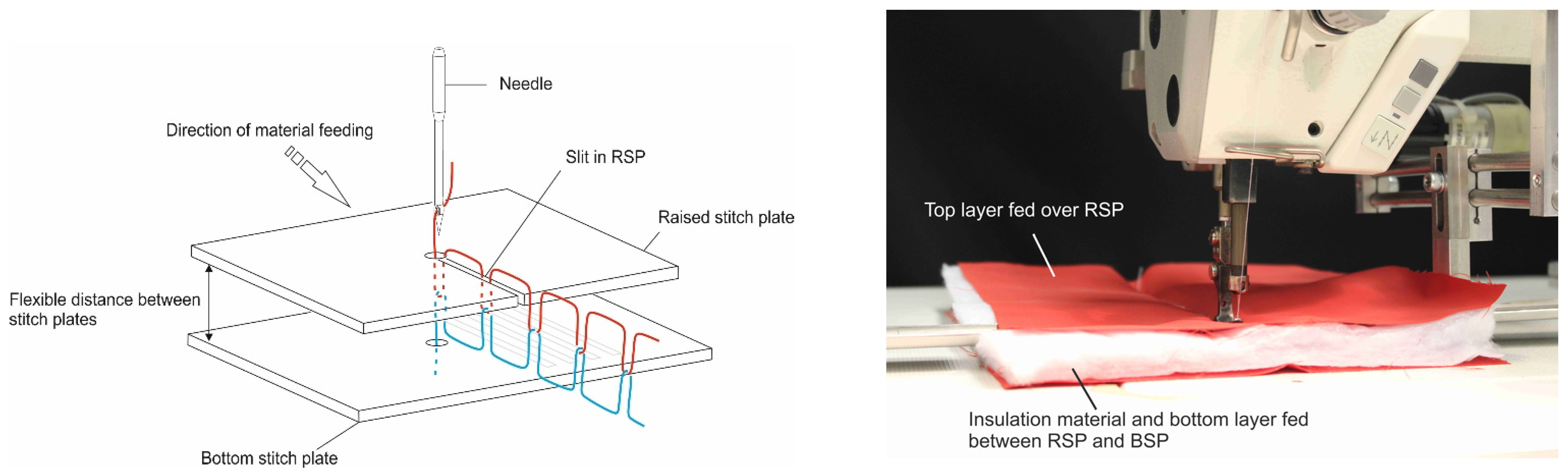

13]. The three-dimensional stitch formation illustration is shown in

Figure 4. The core mechanism of spacer stitching is based on a specialized thread interlacing technique that creates a rectangular-shaped stitch formation. It optimally redistributes stitching forces, preventing the compression of insulating fibres along stitch lines. Unlike conventional sewn-through methods, which compromise insulation by flattening the material at needle penetration points, spacer stitching preserves the three-dimensional (3D) loft of the insulation layer. This reduction in localized mechanical compression effectively eliminates cold spots and prevents heat from escaping.

A critical factor governing thermal insulation efficiency is the volume of entrapped air within the insulating material. Since air has a thermal conductivity 10 to 20 times lower than textile fibres, maximizing its retention within the insulation structure significantly enhances thermal resistance [

14]. By maintaining the integrity of the insulation layer, spacer stitching optimizes air entrapment, thereby improving the overall thermal performance of the garment and reducing heat loss to the external environment.

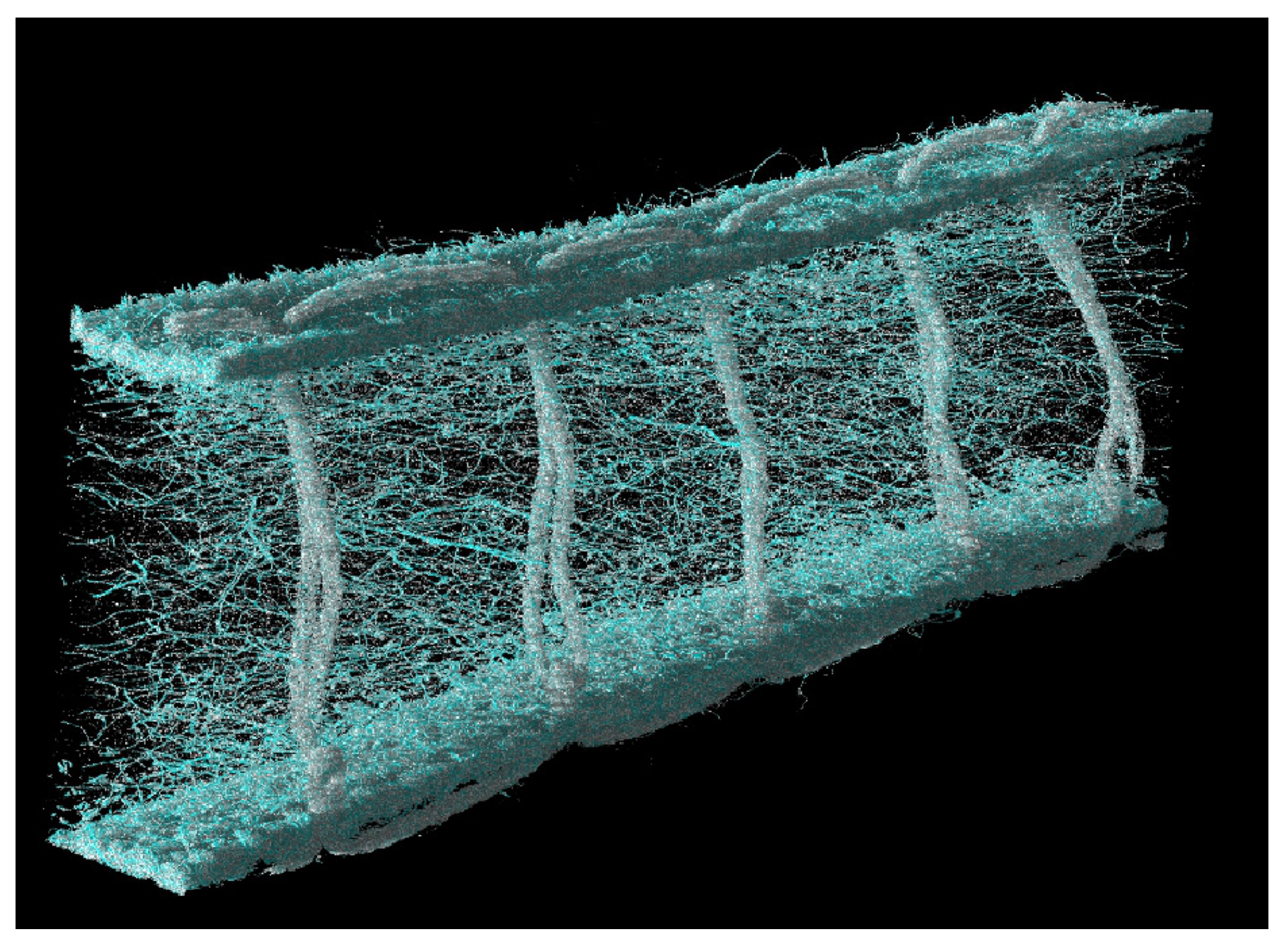

Figure 5 presents the results of an advanced X-ray tomography analysis, providing a comprehensive understanding of the internal structural behaviour at stitch lines in sewn-through insulation systems utilizing spacer stitching technology. The isometric view in

Figure 5 (bottom panel) illustrates the layered structure of the insulation system, comprising two fabric layers with an insulating material sandwiched between them. Meanwhile, the two-dimensional cross-sectional image in

Figure 5 (top panel) highlights the differences in material compression and air retention compared to

Figure 2.

A key observation from the tomography results is that, at the needle insertion points in spacer stitching, the insulation remains in a significantly more relaxed and voluminous state compared to the highly compressed regions seen in

Figure 2 (top panel), where conventional sewing was used. Unlike traditional sewing, which forces insulation fibres aside and flattens them at stitch lines, spacer stitching preserves the loft of the insulation material, ensuring that air pockets remain [

1,

6] intact even at needle penetration points. The presence of air within the insulation structure is a crucial factor in enhancing thermal resistance, as air has a much lower thermal conductivity compared to textile fibres.

By mitigating the formation of cold spots and maintaining a more consistent insulation thickness, spacer stitching effectively reduces conductive heat loss through stitch lines. Several publications show its advantage over the conventional sewn-through sewing method [

6,

15,

16]. The combination of increased air retention, reduced localized compression, and improved fabric separation results in superior thermal performance, making this technique highly advantageous for garments and insulation products designed for extreme environmental conditions. These findings highlight the potential of spacer stitching technology as an innovative solution to enhance thermal efficiency in high-performance outerwear and technical textile applications.

The initial patented design for spacer stitching introduced a dual-level fabric feeding mechanism, utilizing two stitch plates. The additional stitch plate, termed the “raised stitch plate” (RSP), is positioned above the standard stitch plate found in traditional sewing machines. For clarity, the original stitch plate is referred to as the “bottom stitch plate” (BSP). In the construction of a 3D nonwoven structure, consisting of two fabric layers with an insulating core in between, the top fabric is directed over the RSP, while the lower fabric and insulation are fed through the gap between the RSP and BSP, where the stitching process takes place [

12]. A schematic of the spacer stitch mechanism from the initial patent, along with a prototype integrated into a lockstitch machine, is illustrated in

Figure 4. The maximum distance of stitch plates possible in the initial prototype machine was limited to 12 mm. The stitch height was also customizable.

As research progressed, the limitations identified in the initial spacer stitching patent, such as stitch crossover and restriction to straight-line stitching, were addressed, leading to an expanded scope of application for the technology. Consequently, a new patent was filed, introducing a novel presser-foot mechanism [

17]. A working prototype was developed and tested on a standard Class 300 lockstitch sewing machine (

Figure 6 (right)). Due to the ongoing patent filing process, detailed descriptions of the mechanism’s functionality and the core principles behind the updated spacer stitching technique are deliberately excluded. However, the resulting product from the newly patented spacer stitching method retains the characteristic three-dimensional stitch structure found in the original design, as shown in

Figure 4 and

Figure 5. The maximum uncompressed thickness possible for the insulation material is 12 mm and the stitch height is customizable.

This paper discusses a comparative evaluation of sewn-through baffled jackets using a dynamic thermal manikin, contrasting the conventional lockstitch sewing method with the advanced spacer stitching technique. The new method of spacer stitching integrates the innovative presser-foot system to facilitate 3D stitch formation. The findings emphasize the structural and thermal performance improvements offered by this approach over traditional stitching technologies.

2. Materials and Methods

2.1. Materials

The sewing material used was a commercially available sewing material used for baffled jacket manufacturing. The material was 100% virgin polyester, with 50 denier yarn, and had an area weight (GSM) of 65 g/m2. The sewing thread was made of 100% polyester for both needle and bobbin threads.

The insulation material was provided by G-Loft from its Eco Plus insulation technology [

18]. The insulation material is made of thermobond and spray-bonded random-fibre 100% recycled polyester nonwoven for specific use as heat-barrier, bulk elastic, and easy-care insulation. The insulation material uses the blended ratio of 3 different polyester fibres (i.e., hollow fibre, micro fibre, and thermobond fibre) tailored to the required biophysical parameters and the washing behaviour of insulation material. The specifications of insulation material as provided by the insulation material manufacturer are mentioned in

Table 1.

2.2. Sewing Methods

The sewn-through sewing method was used for the manufacturing of jackets using both conventional sewing and spacer stitching technology based on Stitch Class 300 (lockstitch). The sewn-through sewing method is one of the most commonly used techniques for constructing insulated jackets, offering a simple and cost-effective approach to keeping insulation material in place. This method involves stitching through the outer and inner fabric layers while securing the insulation in between. As a result, quilted compartments, or baffles, are created to prevent the insulation from shifting, ensuring even warmth distribution throughout the garment. It is a very lightweight construction compared to other manufacturing techniques; additionally, this method is very cost-effective because it consumes optimal textile and insulation material and does not require complex additional construction steps, making it an economical choice for mass production.

For the sewing methods used in this study, the lockstitch sewing principle was employed. Lockstitch is classified under Stitch Class 300 [

22]. Due to its strong and stable stitch formation, lockstitch is commonly utilized in the production of sewn-through insulated jackets, ensuring that the insulation material remains evenly distributed within the fabric layers.

To evaluate the impact of different stitching techniques on thermal performance, two identical jackets were fabricated using the same material and construction specifications, with the only variable being the sewing method. The two sewing techniques assessed in this study were as follows:

Conventional Sewing Technology—A traditional sewn-through method where the stitching compresses the insulation material at stitch lines, potentially creating cold spots and heat loss pathways.

Spacer Stitching Technology—An innovative sewing technique designed to minimize compression at stitch points, maintaining the loft and structural integrity of the insulation material to enhance thermal performance.

Both jackets were constructed using identical sewing machine parameters, ensuring consistency in stitch density, thread tension, and other mechanical settings across both techniques. This standardization allowed for a direct comparison of the thermal insulation properties of conventional and spacer-stitched jackets, highlighting the effectiveness of each method in maintaining warmth and reducing heat loss through stitch lines. The sewing machine parameters shown in

Table 2 were adopted for jackets sewn both with the conventional and the spacer stitching technology.

Each jacket was composed of two layers of textile material, and in between the insulation material was sandwiched and fixed using the sewn-through sewing method. Both jackets were constructed using the same cut pattern, tailored specifically to fit a thermal manikin, “Sonny” (Thermetrics, Seattle, DC, USA), modelled after the body dimensions of a Western male child aged eight years. The pattern was consistently applied to ensure identical sizing for both garments.

Figure 7 shows two jackets prepared with spacer stitching (left) and with conventional sewing (right).

Although both jackets were made from the same template, the spacer-stitched jacket, benefiting from its three-dimensional stitch formation, allows the fabric and insulation layers to rest more naturally and evenly on a flat surface compared to the jacket sewn with conventional sewing, which can be noticed in

Figure 7. Critical parameters, such as the spacing between stitch lines, their placement, stitch density, and overall dimensions, were precisely maintained across both samples. The only differing factor was the stitching technique itself, enabling a fair and accurate performance comparison. Both garments successfully covered all thermal sensors positioned on the thermal manikin.

2.3. Thermal Manikin

Both jackets were tested using a dynamic thermal manikin to evaluate their thermal insulation performance under realistic conditions. The thermal manikin used in this study, named “Sonny”, was developed by Thermetrics and is specifically designed to replicate the average body dimensions of an 8-year-old Western male child model [

23]. This advanced research tool allows scientists and testing laboratories to assess the thermal properties of children’s clothing, accessories, and environmental conditions using the same standardized protocols applied in adult garment evaluations. It allows testing in accordance with ASTM F1291, ASTM F1720, EN 13537, EN 342, and ISO/DIS 15831 international standards [

24,

25,

26,

27,

28].

“Sonny” shares the same technological capabilities as the well-known adult thermal manikins “Newton” and “Liz”, making it a highly reliable instrument for thermal testing. It features a 16-zone thermal heating architecture, enabling a detailed analysis of heat transfer and insulation effectiveness across different body regions (

Figure 8). Additionally, it can be equipped with specialized options such as a sweating skin system, which simulates perspiration, and a walking motion stand, which allows for dynamic movement simulations.

With a maximum power output of 700 W/m

2, “Sonny” is capable of mimicking the metabolic heat generation of a real human body. It operates within an extensive temperature range of −20 °C to 50 °C, making it suitable for evaluating garments designed for both extreme cold and hot climates. By utilizing this sophisticated manikin in dynamic conditions, this study ensures a realistic assessment of how both conventional and spacer-stitched jackets perform under movement, taking into account factors such as airflow, pumping effects, and heat retention during wear [

23,

29].

In this study, thermal manikin testing was conducted following EN 342 [

27]. The environmental conditions during the measurements were controlled at a temperature of 20 ± 0.5 °C, a relative humidity of 50 ± 5%, and an air velocity of less than 1 m/s. Before testing, both the laboratory environment and the garment samples were conditioned for a minimum of 12 h to ensure thermal equilibrium.

2.4. Measurement of Dry Thermal Resistance and Clo Value

The thermal resistance (Rct), the ability of the fabric to resist the heat flow of test samples, is determined during dry tests by measuring the heat flux through the garment after steady-state conditions have been achieved. The ThermDAC control software provides precision control to maintain the manikin at any temperature setting within the system’s range. ThermDAC (Thermetrics, Seattle, DC, USA) monitors the power required to maintain the manikin temperature and automatically calculates the Rct of the garment ensemble.

The dry thermal resistance is calculated by using the following formula for each zone independently [

29].

where

The Clo values are calculated according to the following equation.

where

The Clo values which are suitable for winter conditions are subjective to human beings living in those conditions and the combination of clothing systems to achieve the desired comfort level [

30]. In a study performed on Korean women, the comfortable ambient temperature for a clothing insulation of 1clo was approximately 27 °C while for Western countries it is 21 °C [

31].

3. Discussion of Results

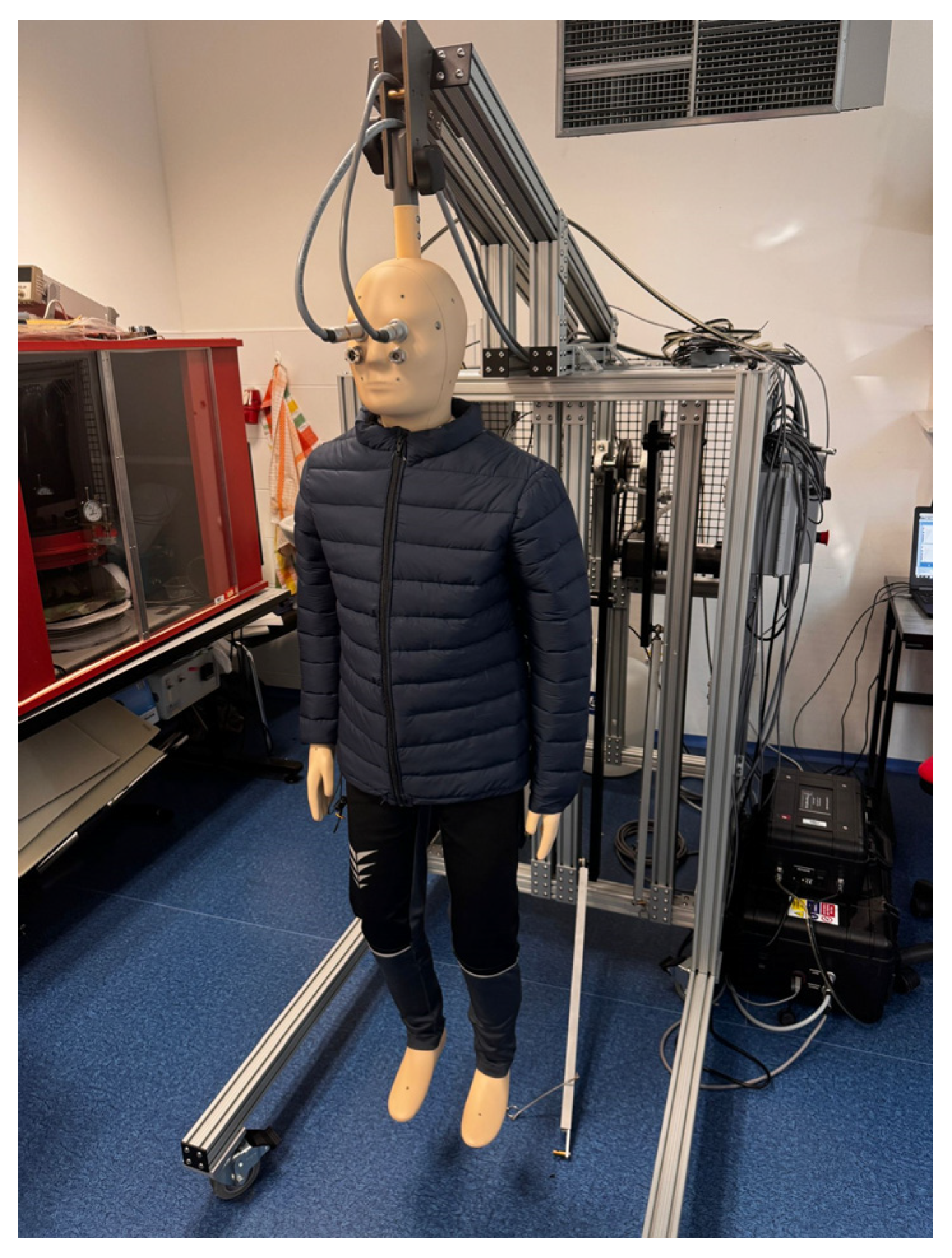

The thermal manikin, designed to replicate human body heat through a network of integrated temperature sensors, was outfitted with jackets and subjected to a 30 min dynamic testing cycle under walking conditions.

Figure 9 shows the jacket being worn by the thermal manikin on the motorized walking stand. This experiment provides an in-depth comparative study of the thermal resistance properties between the jacket constructed with the novel spacer stitching technology and that made using the traditional sewn-through method, utilizing advanced thermal manikin analysis in a real-life walking scenario.

The results are depicted as time-dependent thermal resistance profiles over the 30 min testing period for each jacket type, capturing both the stabilization and steady-state phases of thermal behaviour. Each jacket configuration was tested three times, and the results were averaged to ensure accuracy. This approach offers a thorough insight into how spacer stitching enhances thermal insulation performance compared to conventional techniques, and how both construction methods respond dynamically during real-life walking scenarios. Measurements were collected across the body zones covered by the jacket, i.e., the chest, back, upper arms, and forearms, providing a detailed assessment of regional thermal resistance (Rct).

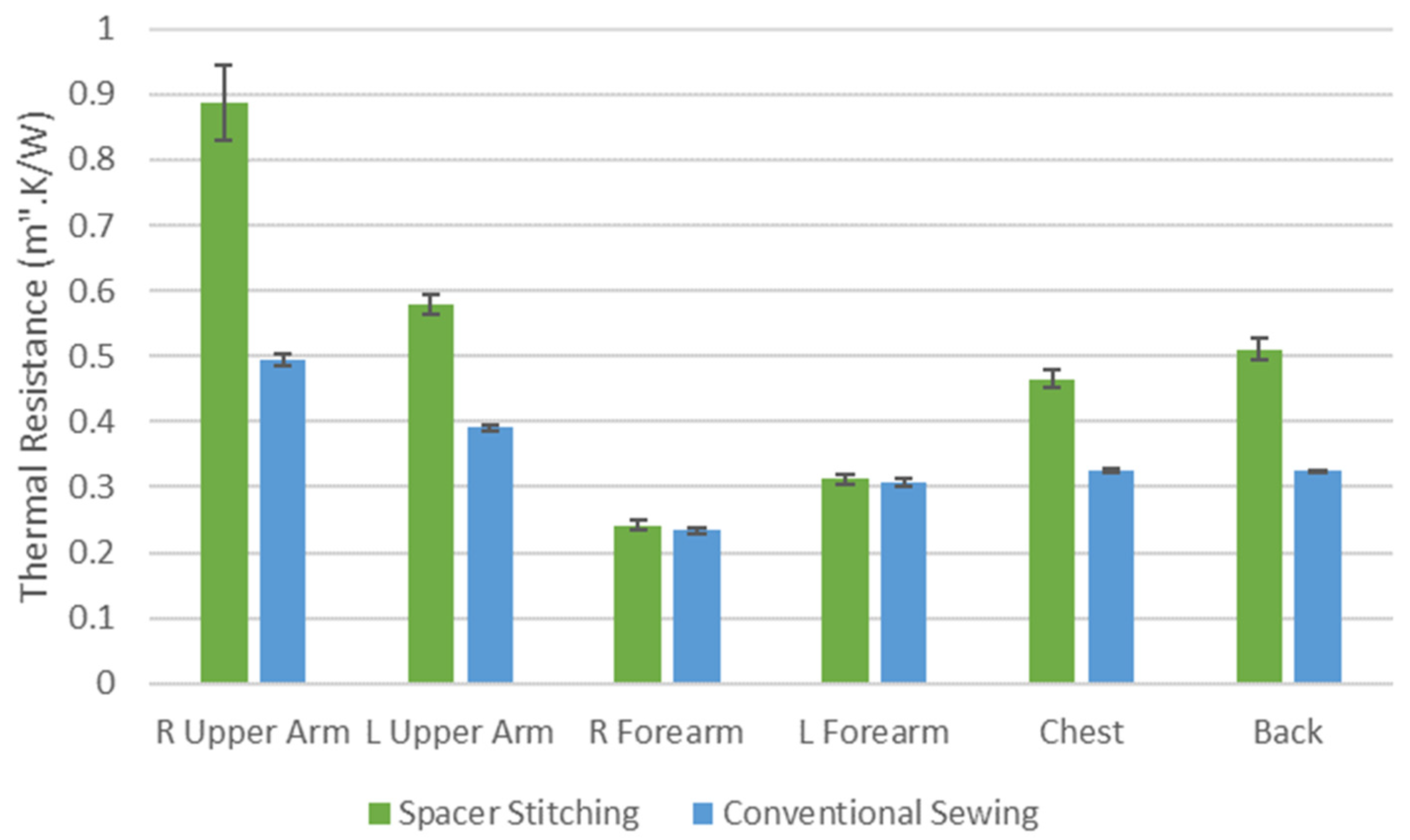

The results for the average thermal resistance of the two jackets are shown in

Figure 10. The bar graph illustrates a comparative analysis of the average

Rct values across six body zones for jackets constructed using spacer stitching and conventional sewing methods.

In all measured zones, spacer stitching consistently exhibits higher thermal resistance values than conventional sewing, indicating superior insulation performance. The chest and back regions are particular areas of key interest, as they protect vital organs and are crucial for maintaining physiological stability in extreme environmental conditions. The results show that the chest region demonstrated a 43% increase in thermal resistance with spacer stitching compared to conventional methods, while the back region exhibited up to a 58% improvement. The front chest area, incorporating a central zipper, likely experienced increased heat loss, resulting in slightly lower thermal resistance compared to the back section.

Notably, the right upper arm zone demonstrated substantially higher thermal resistance compared to the left upper arm in the spacer stitching sample, which may be attributed to manufacturing inconsistencies or pattern asymmetry, as no physiological explanation justifies such a discrepancy. In the forearm zones, the differences between the two construction methods are relatively smaller, although spacer stitching still maintained a slight advantage. The lower thermal resistance observed in the forearm regions can be explained by the open cuffs and arm movements, which may have caused a “pumping” effect, facilitating air exchange and heat loss through cuff openings. The overall trend demonstrates that spacer stitching provides enhanced thermal protection across almost all body regions.

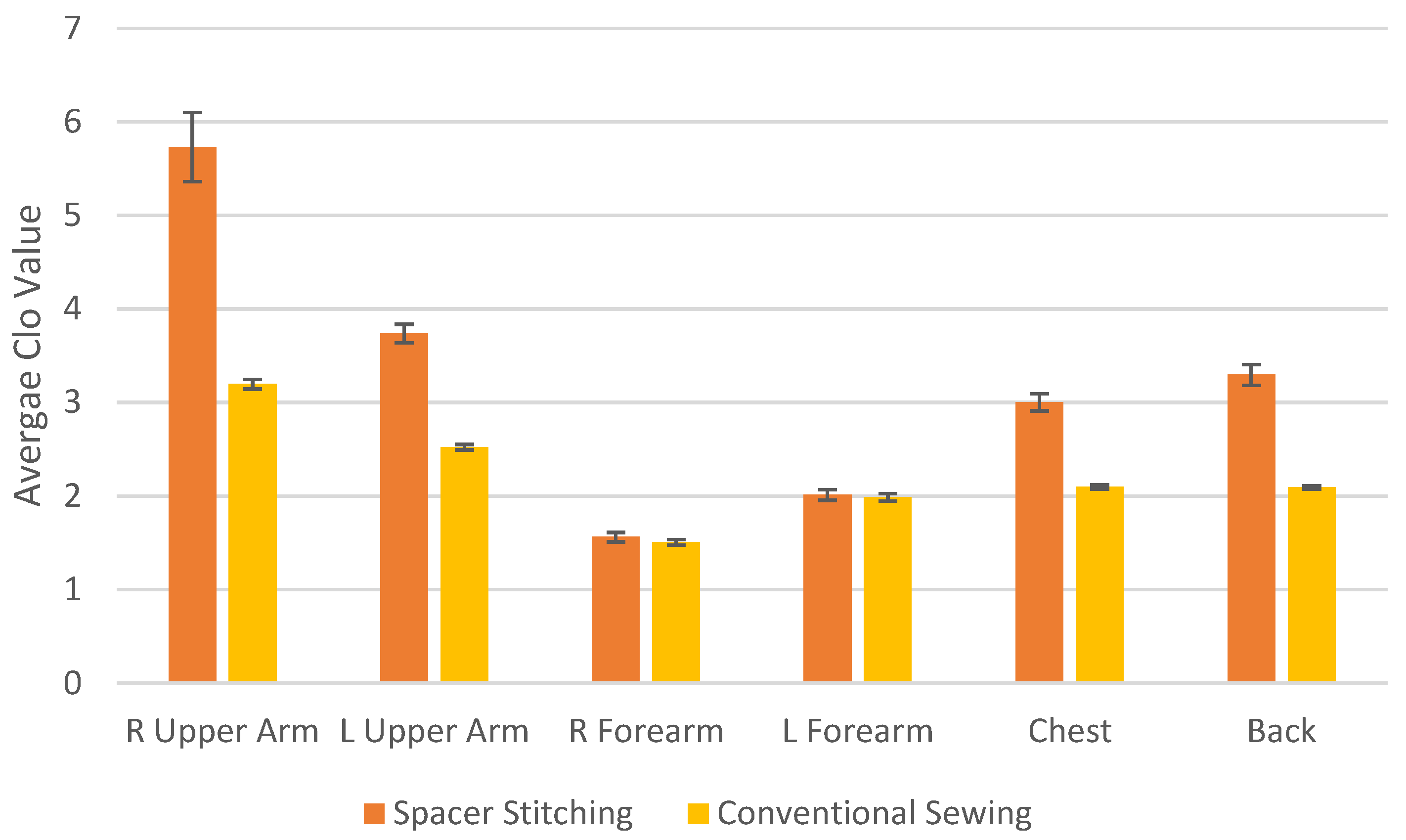

The Clo value is another unit of measurement used to quantify the thermal insulation of clothing. It represents how well a fabric or garment can retain body heat, which directly affects how warm or cool one feels while wearing it. The results for the Clo value of both jackets are shown in

Figure 11. The graph illustrates the average thermal insulation, measured in Clo units, across various body regions for the two distinct sewing techniques: spacer stitching and conventional sewing.

A clear trend emerges from the data, with spacer stitching consistently outperforming conventional sewing in thermal insulation for all examined body regions. This suggests that spacer stitching enhances heat retention, likely due to its ability to trap air more effectively and the fact that it does not compress the insulation materials, unlike during conventional sewing, thus improving thermal properties. The chest and back regions are areas of key interest, as they protect vital organs and are crucial for maintaining physiological stability in extreme environmental conditions. While the Clo value for the jacket sewn with the conventional method remains around 2 in this area, which is the thermal insulation required for a casual outdoor winter jacket, the Clo value for the spacer stitching-sewn jacket goes above 3 for critical areas like the chest and back section. The upper right arm Clo value seems out of proportion with its counterpart left side. It may be attributed to manufacturing inconsistencies or pattern asymmetry, as no physiological explanation justifies such a discrepancy. The lower Clo values in the forearm regions can be explained by the open cuffs and arm movements, which may have caused a “pumping” effect, facilitating air exchange and heat loss through cuff openings.

These findings underscore the significance of sewing techniques in optimizing thermal comfort in garment design. Spacer stitching, in particular, shows promise for applications requiring superior insulation, such as performance sportswear or protective clothing.

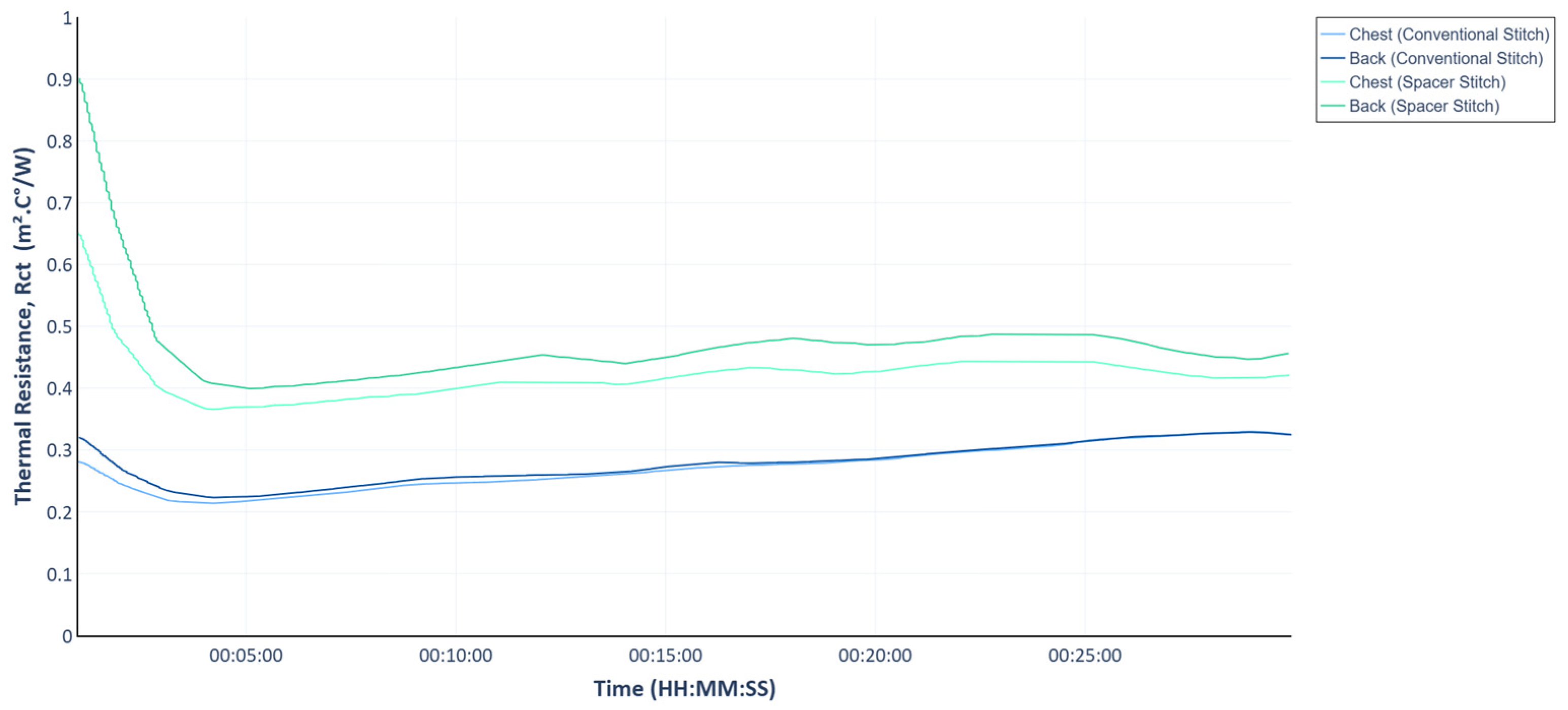

The graph in

Figure 12 illustrates the dynamic thermal resistance (

Rct) profiles over a 30 min testing time for jackets sewn with two different techniques, i.e., conventional stitching and spacer stitching. The data focuses on two critical body zones, namely, the chest and back, both of which play a vital role in maintaining core body temperature. Across the entire duration of the test, the jacket constructed using the spacer stitching method consistently demonstrates higher thermal resistance values in both the chest and back regions when compared to that made with conventional sewing. This indicates that spacer stitching provides superior insulation performance.

After approximately 10 min of test start, when the thermal equilibrium is achieved, the thermal values begin to stabilize, offering a reliable comparison of steady-state performance. The back region, in both sewing methods, shows higher Rct values than the chest, likely due to the presence of a front zipper, which can act as a localized point for heat loss.

Importantly, the spacer-stitched jacket maintains a more stable and elevated thermal resistance throughout the test. This improvement is attributed to the three-dimensional structure of spacer stitching, which reduces compression along stitch lines and preserves the insulating loft. In contrast, the conventional lockstitch method tends to compress the insulation material, creating thermal bridges that facilitate heat escape. Overall, the graph effectively demonstrates that spacer stitching is a significantly more effective technique for retaining body heat in cold-weather clothing.

The results for thermal resistance, the Clo values, and the comparison over the whole duration of testing demonstrate that spacer stitching significantly preserves the insulation loft, leading to consistently higher thermal resistance values across the garment. In contrast, conventional sewing compresses the insulation material along the stitch lines, creating thermal bridges that facilitate increased heat loss through the seams. Collectively, these results indicate that spacer stitching offers enhanced thermal insulation performance by maintaining structural integrity and minimizing compression, establishing it as a more effective construction method for cold-weather clothing compared to traditional lockstitch techniques.

4. Conclusions

The dynamic thermal manikin experiments conducted in this study demonstrate the critical impact of stitch line compression on the thermal performance of insulated jackets. Conventional sewing methods inherently compress the insulation material at the stitch lines. This compression disrupts the uniform distribution of the insulating layer, creating zones of reduced insulation thickness, commonly referred to as thermal bridges, through which heat easily escapes. As a result, the garment manufactured with conventional sewn-through techniques exhibited lower overall thermal resistance, particularly in vital regions such as the chest and back, which are essential for maintaining core body temperature in extreme conditions.

In contrast, the jacket manufactured using the innovative spacer stitching technique showed visible improvements in thermal insulation performance. Spacer stitching employs a three-dimensional stitch formation that minimizes compression at the points of needle insertion. By preserving the loft and structural integrity of the insulation material, spacer stitching significantly reduces the formation of thermal bridges. Consequently, jackets constructed with this method maintain higher levels of trapped air within the insulation, leading to consistently higher thermal resistance across all critical body zones, even during dynamic conditions such as simulated walking movements.

The chest and back sections, which protect key functional organs, particularly benefited from spacer stitching, with improvements in thermal resistance of approximately 43% and 58%, respectively, compared to conventional methods. These enhancements underline the importance of maintaining the insulation loft and preventing stitch-line compression to optimize the thermal performance of cold-weather apparel. Moreover, this study shows that even though some variability exists due to garment construction nuances, the overall trend remains clear: spacer stitching effectively blocks heat loss along stitch lines and ensures a more consistent thermal barrier.

In conclusion, spacer stitching represents a significant technological advancement in the design and manufacturing of insulated garments. By addressing the longstanding issue of stitch-line compression, it offers a promising pathway to enhance wearer comfort, safety, and protection in cold and extreme environmental conditions. Future applications of this technique could lead to the development of even more efficient thermal clothing for outdoor professionals, athletes, military personnel, and others exposed to harsh climates.