Abstract

There has been an interest in understanding the relationship between textile cotton fiber strength (or tenacity) and structure for better fiber quality measurement and enhancement. This study utilized coupled Stelometer and high volume instrument (HVI) measurements with attenuated total reflection Fourier transform infrared spectroscopy methods to relate fiber strength and associated properties (Stelometer elongation and HVI micronaire) with structure properties on six Upland (as A, B, C, D, E, and F) and one Pima cultivar. Although Stelometer tenacity agreed with HVI strength in general, the Upland D cultivar (immature) was observed to show the lowest HVI strength value, while the Upland F cultivar (larger infrared crystallinity index) was found to possess the smallest Stelometer tenacity value. A few strong and significant correlations were noted, for example, between infrared crystallinity and Stelometer elongation for the Upland A fibers, between infrared maturity and Stelometer tenacity for the Upland C fibers, and between infrared maturity and HVI strength for the Upland D fibers. Furthermore, there were apparent distinctions in regressions and statistics of examined correlations between each Upland cultivar and their combined fiber set, addressing the challenge of understanding the unique response between fiber physical and structure properties from different measurements even within one cotton cultivar.

1. Introduction

Strength is one of the essential physical properties of textile cotton fibers. Its measurement can be categorized into a single fiber test or a bundle fiber test. The methods for a single fiber strength measurement involve the Mantis single-fiber tester [1,2], the Instron tensile tester [3], and the Favimat single-fiber tester [4,5], whereas the techniques for a bundle fiber strength measurement include the Stelometer bundle tester [6], Fibrotest [7], and the high volume instrument (HVI) [8]. Researchers have attempted to relate one strength test to another [2,4,7]. For example, Thibodeaux et al. [2] examined the relationship between the single-fiber strength from the Mantis test and bundle fiber strength from the Stelometer and HVI and observed that both the Stelometer and HVI bundle strength were linearly proportional to the ratio of the average Mantis breaking load to the square of the average fiber ribbon width. Delhom et al. [4] found that the single-fiber test produced higher mean values than the bundle test on the basis of the single-fiber test from the Favimat and bundle fiber measurements from the Stelometer and HVI. Cui et al. [7] studied the relationship between Fibrotest and HVI strengths on 12 cotton samples with different micronaire (MIC) values and noted an insignificant effect of the MIC value on the strength difference between the two measurements. Also, they observed low Fibrotest strengths compared to the Stelometer strength for the three international calibration cottons that had standard Stelometer strength values.

From the perspective of cotton research for better fiber quality measurement and enhancement, there is still an interest in how cotton fiber strength relates to fiber structure. Given the complexity of both fiber strength measurement and structure determination, researchers have taken different strategies. For example, Benedict et al. [9] reported a correlation of 0.94 between the average length of the cellulose chains in the crystalline cellulose and the HVI bundle fiber strength after analyzing the crystalline microfibrillar fragments by 13C-nuclear magnetic resonance (NMR) spectroscopy. Hsieh’s group [1,3,10] developed the ‘‘XRAY’’ X-ray diffraction (XRD) analysis program to assess the crystallite size and crystallinity parameters of dried developing cotton fibers from the wide-angle XRD pattern and further correlated the crystallite size and crystallinity with fiber-breaking force and tenacity (or strength) that were measured from a Mantis single fiber tester or an Instron tensile tester. The results indicated that the single fiber breaking forces were positively related to both crystallite size and crystallinity, and the breaking force and tenacity increase appeared to be related more to crystallite size than to crystallinity. In addition, the pattern of single-fiber breaking tenacities against fiber crystallinity differed between cotton fibers from two genotypes of SJ-2 and Maxxa. They found that other structural parameters than the crystallite sizes and crystallinity, such as fibril orientation and residual stress, may play important roles in impacting the single fiber strength of cotton fibers. Using a different approach, Liu et al. [11] estimated the fiber infrared maturity (MIR) and infrared crystallinity (CIIR) of Upland and Pima cotton fibers from attenuated total reflection Fourier transform infrared (ATR FT-IR) spectroscopy in an effort to relate both MIR and CIIR values to Stelometer tenacity (STEten) and elongation (STEelo) properties. The uniqueness of this work was the capability of the ATR FT-IR method to scan tiny Stelometer breakage specimens (2~5 mg), which cannot be readily analyzed by a conventional XRD measurement or by chemical extraction and identification analysis. Compared to an increase in fiber STEten with either MIR or CIIR for Pima fibers, there was an unclear trend between the two for the combined Upland fiber set from the U.S. (two varieties) and outside of the U.S. (14 varieties from 2 Asian and 2 African countries). Based on comprehensive measurements from HVI, cross-sectional image analysis, Cottonscope, and Favimat, Kim et al. [12] investigated the effect of fiber maturity on the bundle and single fiber strength of Upland cotton constructed from a genetic approach. They showed significant and positive correlations between MIC and HVI bundle fiber strength or elongation value, and also between MIC or maturity ratio value and single fiber breaking force rather than with single fiber strength. Overall, making a direct comparison between these studies is challenging because of differences in bundle/single fiber strength measurement methods (Stelometer, HVI, Instron tensile tester, and Favimat), fiber crystallinity/maturity determination methods (XRD, 13C NMR, ATR FT-IR, HVI, cross-sectional image analysis, and Cottonscope), and fiber sources (field-grown or greenhouse-grown).

Both fiber STEten and HVI strength (HVIstr) reflect the external force-induced breaking of cotton bundle fibers, but the values have been calculated differently. Unlike the Stelometer test, which uses the weight of a broken bundle beard to normalize the breaking force for assessing the STEten, the HVI test uses a fiber MIC as the mass substitute for HVIstr. Other factors such as fiber sample size, fiber bundle orientation, pre-tension, speed of the break, and clamp placement influence the STEten and HVIstr values [13]. In an earlier investigation, Liu et al. [11] examined the relationship between the STEten or STEelo property and the MIR or CIIR index on a combined Upland fiber set, including two U.S. varieties. Taking a similar approach, this study related STEten and STEelo properties as well as HVI MIC and HVIstr properties to MIR or CIIR values on six U.S. Upland cultivars. The main objectives of this study were: (1) to evaluate the bundle strength agreement between HVIstr and STEten measurements on six Upland cotton cultivars and (2) to correlate the STEten and STEelo properties as well as HVI MIC and HVIstr properties with MIR and CIIR indices from ATR FT-IR measurements on Stelometer fiber breakage specimens of these fibers. As a comparison to Upland cultivars, Pima cottons were included in the analysis.

2. Materials and Methods

2.1. Cotton Lint Samples

A total of 31 Upland lot samples representing 6 Upland cotton cultivars and 18 Pima fiber samples from 1 Pima cultivar were collected randomly. These cotton fibers were grown in the U.S., but their specific geographic origins and crop years were not available. There were 4, 5, 6, 5, 3, and 8 fiber lots in respective Upland A, B, C, D, E, and F cultivars, and samples in a cultivar were replicated field lots from the same location. They were well conditioned at a constant relative humidity of 65 ± 2% and a temperature of 21 ± 1 °C for at least 48 h prior to routine HVI and Stelometer testing as well as the ATR FT-IR spectral acquisition.

2.2. Fiber HVI and Stelometer Property Measurement

Average HVIstr and MIC properties were obtained from five replicates on each sample by an Uster HVI 900A system (Zellweger Uster Inc., Knoxville, TN, USA). Mean STEten and STEelo values were determined from three replicates on individual samples by the use of a Stelometer flat bundle tester (Spinlab, Knoxville, TN, USA) with 1/8 inch (3.2 mm) clamp spacing as detailed previously [11]. All broken bundles free of any impurities (or non-lint materials) were retained for subsequent ATR FT-IR spectral scans.

2.3. Fiber MIR and CIIR Calculation

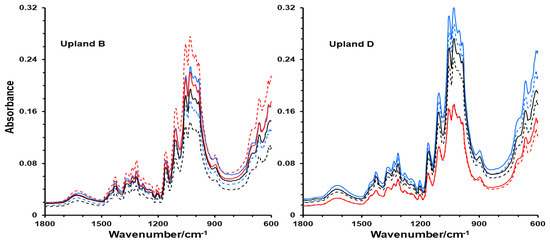

Fiber MIR and CIIR values were estimated by applying simple algorithmic analysis to the ATR FT-IR spectra, as shown in Figure 1, with the proposed procedure [14]. Briefly, after the spectra were exported into Microsoft Excel, the first algorithmic R1 equation below was used to calculate the R1 value:

where I1500, I1032, and I956 are each a three-point intensity average at respective wavenumbers. The I1032 characterized the large and positive intensity variation, while the I956 represented the large and negative intensity variation in the difference spectrum between immature and mature cotton. The I1500 was used to offset two readings because of its minimum absorbance.

R1 = (I956 − I1500)/(I1032 − I1500)

Figure 1.

Representative six raw ATR FT-IR spectra (2 spectra/bundle shown in solid and dotted lines × 3 bundles given in black, red, and blue colors) in the 1800–600 cm−1 region from one Upland B sample (MIC = 4.70) or one Upland D sample (MIC = 2.96). MIR or CIIR values for each sample were the averages of MIR or CIIR values from six raw ATR FT-IR spectral measurements.

Next, the second algorithm, MIR, was used to convert the R1 value into the MIR index:

in which R1, R1,lr, and R1,sm are the R1 values for the unknown sample, the largest R1, and the smallest R1, respectively. The R1,sm and R1,lr values were determined to be 0.14 and 0.59.

MIR = (R1 − R1,sm)/(R1,lr − R1,sm)

Similarly, CIIR was computed using two algorithms, with the first algorithm R2 utilizing three respective IR intensities at 800, 730, and 708 cm−1, and the second algorithm CIIR (%) changing the R2 values into fiber CIIR.

R2 = (I708 − I800)/(I730 − I800)

CIIR (%) = ((R2 − 1.4)/2.0) × 100

To collect the spectra, an FTS 3000MX Fourier transform IR spectrometer (Varian Instruments, Randolph, MA, USA) equipped with a ceramic source, KBr beam splitter, deuterated triglycine sulfate (DTGS) detector, and an ATR attachment was used. Two spectra in the absorbance unit were collected for each broken bundle over the range of 4000–600 cm−1 at 4 cm−1 with 32 co-added scans, and the mean spectra for each sample were exported into Microsoft Excel 2016 to assess fiber CIIR and MIR indices.

The sampling depth of the ATR device is from 2 to 15 μm, depending on the ATR crystal materials and wavenumber range [15,16], while the thickness of the secondary cell wall (SCW) in mature cotton fibers varies from 2 to 7 μm [17]. Therefore, the ATR FT-IR method is capable of representing the information inside mature cotton fibers by the use of both a low refractive index crystal (ZnSe or diamond) and a low spectral region (1100 to 600 cm−1). Overall, the use of the ATR device greatly facilitates the sampling procedure and is also time-efficient for a large number of sample analyses.

2.4. Mathematical and Statistical Analysis

Mathematical and statistical analyses were conducted using Microsoft Excel 2016. For mathematical analysis, Pearson correlation coefficient (r), slope, and coefficient of determination (R2) were acquired from the relationships among fiber Stelometer, HVI, and spectral values by fitting the data into a linear regression trendline option. When the ׀r׀ value is less than 0.3, between 0.3 and 0.7, or greater than 0.7, a weak, moderate, or strong (either positive or negative) linear correlation exists between the two variables [18]. For statistical analysis, p-values among a pair of fibers’ physical and structural properties were calculated using the Excel regression function under Data Analysis. The p-value cutoff for significance was 0.05, with three levels at 0.05~0.01 (*), 0.01~0.001 (**), and <0.001 (***).

3. Results and Discussion

3.1. Fiber STEten vs. STEelo from Stelometer Measurement

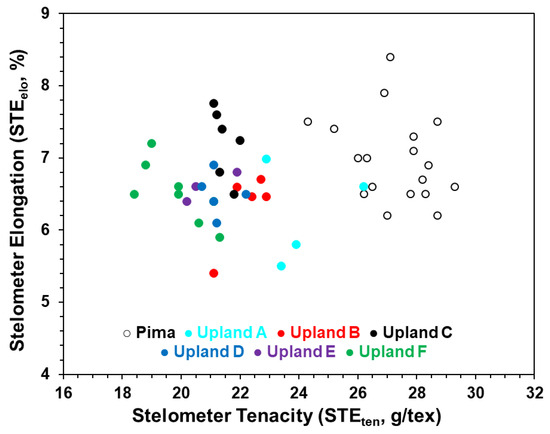

The relationships between fiber STEten and STEelo for Upland and Pima cultivars are depicted in Figure 2. As expected, the Pima cultivar exhibited a significantly higher STEten (24.3–29.3 g/tex) than the six Upland cultivars (18.4–26.2 g/tex) (p-value < 0.001), and the six Upland cultivars showed apparent differences in STEten among them. Average STEten values summarized in Table 1 for the Pima cultivar as well as Upland A, B, C, D, E, and F cultivars were 27.3, 24.1, 22.2, 21.5, 21.3, 20.9, and 19.9 g/tex, respectively. Meanwhile, the Pima cultivar showed a statistical difference in STEelo from six Upland cultivars (p-value = 0.02), and six Upland cultivars showed a little difference among them (Figure 2). Respective mean STEelo values were 7.0, 6.2, 6.3, 7.2, 6.5, 6.6, and 6.5% for the Pima cultivar as well as Upland A, B, C, D, E, and F cultivars (Table 1).

Figure 2.

Plot of STEelo vs. STEten for six Upland cultivars (A, B, C, D, E, and F) and one Pima cultivar.

Table 1.

Comparison of mean and range of STEten, STEelo, HVIstr, HVI MIC, MIR, and CIIR values for six Upland and one Pima cultivar.

As summarized in Table 2, fiber elongation was correlated with tenacity weakly for all Upland datasets (r = −0.17) or Pima fibers (r = −0.30). Throughout this work, a negative r value means that as one variable increases, the other decreases in the dataset, and vice versa. Despite a limited number of fiber samples within each Upland cultivar, Table 2 revealed a complicated scenario between STEelo and STEten among six Upland cultivars. Three Upland cultivars (C, D, and F) showed an increase in STEten with decreasing STEelo (r = −0.74 to −0.14), whereas the other three cultivars (A, B, and E) were in an opposite pattern (r = 0.14 to 0.94). Only Upland F fibers showed a strong and significant negative relationship between STEelo and STEten (r = −0.74, p-value = 0.04). The difference in genotype and growth environment and their interactions within Upland or Pima cultivars are probably responsible for the observation in Table 2, and more studies might be necessary to look into why cultivars acted differently when relating fiber tenacity to elongation as well as other properties discussed below.

Table 2.

Comparison of r and significance (significant *, p-value = 0.05~0.01) between STEelo and STEten for individual Upland cultivars, all Upland datasets, and one Pima cultivar.

3.2. Fiber HVIstr vs. MIC from HVI Measurement

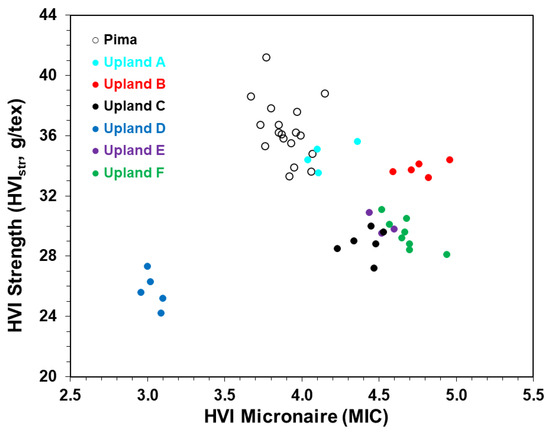

Similar to STEten in Figure 2, the Pima cultivar in Figure 3 showed a greater HVIstr than six Upland cultivars (p-value < 0.001), and six Upland cultivars had obvious differences in HVIstr within them. Average HVIstr values for the Pima cultivar as well as Upland A, B, C, D, E, and F cultivars were 36.3, 34.6, 33.8, 28.8, 25.7, 30.1, and 29.5 g/tex, respectively (Table 1). There was an unclear separation in MIC between the Pima cultivar and six Upland cultivars, but there were some differences in MIC among the six Upland cultivars. Average MIC values for the Pima cultivar as well as Upland A, B, C, D, E, and F cultivars were 3.90, 4.15, 4.77, 4.42, 3.03, 4.52, and 4.68, respectively (Table 1). Clearly, Upland D fibers were immature due to their quite low MIC (=3.03) as well as MIR (=0.64) and MIR (=58.4%) in Table 1. HVI elongation property on these fibers was measured with HVIstr and MIC simultaneously at the time. Since the HVI elongation measurement was not calibrated at that time, this study neither discussed HVI elongations nor compared them to STEelo. Recently, McCormick et al. [19] developed cotton elongation standards from two commercial bales (with low and high HVI elongation) and used these potential standards to correct HVI against Stelometer elongation measurements. Their result showed that the corrected HVI elongations were at least as good as the Stelometer elongations.

Figure 3.

Plot of HVIstr vs. MIC for six Upland cultivars (A, B, C, D, E, F) and one Pima cultivar.

Table 3 suggested that, unlike Pima fibers that had a tendency to decrease in fiber HVIstr with elevating MIC insignificantly (r = −0.35, p-value > 0.05), all Upland datasets showed an increase in fiber HVIstr with MIC moderately and significantly (r = 0.55, p-value = 0.001). This observation resembled a significant but weak correlation between MIC and HVIstr on 168 Upland kinds of cotton, covering a broad range of maturity and strength [12]. Further examination indicated that three Upland cultivars (A, B, and C) increased in fiber HVIstr along with MIC (r = 0.49 to 0.65), whereas the remaining three cultivars (D, E, and F) decreased in fiber HVIstr with MIC (r = −0.79 to −0.62). Among them, only Upland F fibers showed a strong and significant negative relationship between fiber HVIstr and MIC (r = −0.79, p-value = 0.02), likely due to a higher CIIR index for Upland F fibers (Table 1). Hence, caution should be taken when compiling two or more Upland cultivars into one dataset to study the specific relationships as given in Table 2. This caution might be applied to the same cultivar in different geographic locations and crop years.

Table 3.

Comparison of r and significance (significant *, p-value = 0.05~0.01; very significant **, p-value = 0.01~0.001) between HVIstr and MIC for individual Upland cultivars, all Upland datasets, and one Pima cultivar.

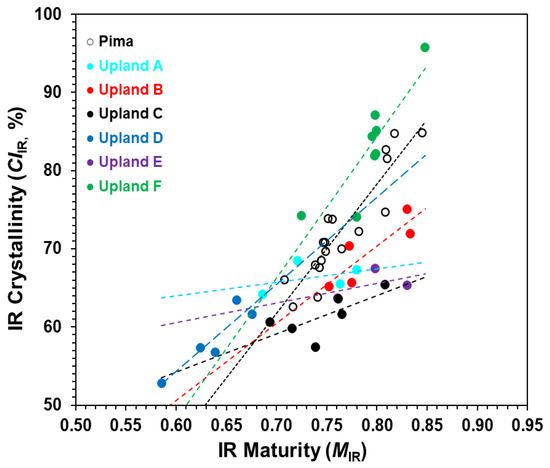

3.3. Fiber MIR vs. CIIR Index from ATR FT-IR Measurement

Relating CIIR to MIR in Figure 4 and also the statistics in Table 4 showed an increase in fiber CIIR with MIR moderately to greatly and significantly for both all Upland datasets (r = 0.69, p-value < 0.001) and Pima fibers (r = 0.92, p-value < 0.001). Apparently, there were differences in synchronous fiber MIR and CIIR developments between Upland and Pima cultivars, as well as among six Upland cultivars. For example, more fiber CIIR production than MIR accumulation was observed for Upland F fibers (regression slope = 181.3), followed by Upland D fibers (slope = 111.6), Upland B fibers (slope = 99.1), Upland C fibers (slope = 49.0), Upland E fibers (slope = 25.3), and Upland A fibers (slope = 17.2). Upland D and F cultivars showed strong and significant relationships between fiber CIIR and MIR (r = 0.87 to 0.92, p-value = 0.03).

Figure 4.

Plot of CIIR vs. MIR for six Upland cultivars (A, B, C, D, E, and F) and one Pima cultivar.

Table 4.

Comparison of r and significance (significant *, p-value = 0.05~0.01; very significant *** at p < 0.001, p < 0.001) between CIIR and MIR for individual Upland cultivars, all Upland datasets, and one Pima cultivar.

Relative to Upland D fibers in Table 1 that had the smallest MIR index (0.64 on average) and CIIR index (58.4%), other Upland cultivars showed larger MIR values (0.74 to 0.80) with varying CIIR readings (61.4 to 83.1%). Obviously, the MIR and CIIR values of Pima fibers (MIR = 0.77 and CIIR = 72.6%) were within those of the Upland cultivars. The observation suggested that the ATR FT-IR spectral measurement could be applied to compare cotton fiber chemical and structural differences induced by cotton varieties and growth environments, but it could not be used to distinguish the Pima fibers from the Upland ones on the basis of MIR and CIIR values.

3.4. Relationship between Fiber STEten and HVIstr

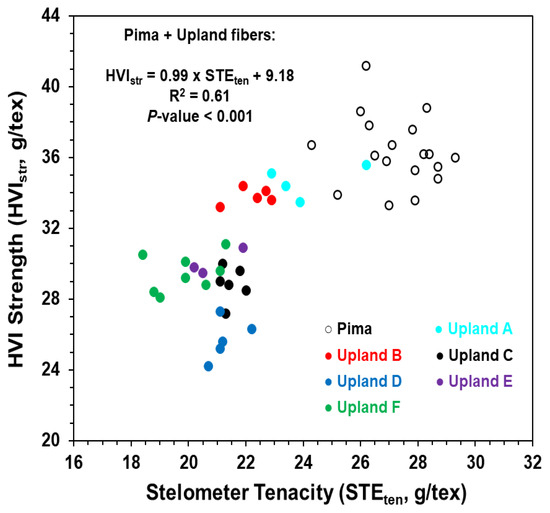

The plot of HVIstr against STEten in Figure 5 revealed a reasonable agreement between two measurements but with a scattered pattern. This indicated that the fiber strength testing mechanism is complicated and the measurement could be influenced by a number of factors, such as fiber elongation, elastic properties, cross-sectional area, length, crystallite size, fibril orientation, residual stress, strength uniformity, as well as the operator’s experience [3,11,13,19,20]. STEten decreased in the order of Pima (27.3), Upland A (24.1), Upland B (22.2), Upland C (21.5), Upland D (21.3), Upland E (20.9), and Upland F (19.9). In contrast, HVIstr decreased in the sequence of Pima (36.3), Upland A (34.6), Upland B (33.8), Upland E (30.1), Upland F (29.5), Upland C (28.8), and Upland D (25.7). Notably, the Upland D cultivar, immature with the smallest MIC, MIR, and CIIR values among six Upland cultivars, showed the lowest HVIstr value (25.7) but relatively larger STEten value (21.3), while the Upland F cultivar, having the greater CIIR index than other Upland cultivars, showed the smallest STEten value (19.9) but relatively larger HVIstr value (29.5).

Figure 5.

Plot of HVIstr vs. STEten for six Upland cultivars (A, B, C, D, E, and F) and one Pima cultivar.

Analysis of the pattern in Figure 5 suggested that (i) the Pima cultivar showed a clear cut in STEten values from all but one Upland A sample (p-value < 0.001), whereas five Pima samples were overlapped in HVIstr with two Upland cultivars, although the difference (Pima vs. Upland A and B) was significant (p-value = 0.004); (ii) Upland A cultivar differed in STEten from the Upland B cultivar (p-value = 0.037), but their HVIstr values were not statistically different (p-value > 0.05); (iii) three Upland cultivars (C, E, and F) showed a clear difference in STEten (p-value = 0.003); however, they had an insignificant difference in HVIstr (p-value > 0.05); and (iv) four Upland cultivars (B, C, D, and E) exhibited an insignificant difference in STEten values (p-value > 0.05), but they showed significant differences in HVIstr values (p-value < 0.001).

In general, there was a strong and significant correlation between STEten and HVIstr for combined Pima and Upland fibers (r = 0.78, p-value < 0.001) in Figure 5, and also a moderate and significant correlation for all Upland datasets (r = 0.57, p-value < 0.001) in Table 5. Opposed to the Upland C fibers and Pima fibers that showed a weak correlation between HVIstr and TEten (r = −0.17 to −0.01) in Table 5, five of six Upland cultivars (A, B, D, E, and F) indicated a moderate to strong correlation insignificantly (r = 0.35 to 0.93, p-value > 0.05).

Table 5.

Comparison of r and significance (very significant *** at p < 0.001, p < 0.001) between STEten and HVIstr for individual Upland cultivars, all Upland datasets, and one Pima cultivar.

In the aspect of consistent and good agreement between two strength measurements, the six Upland cultivars were grouped into three fiber sets according to mean MIR values. The first set consisted of three Upland cultivars (B, E, and F) with respective mean MIR values of 0.79, 0.80, and 0.79 (or mean MIC values of 4.77, 4.52, and 4.68); the second set included two Upland cultivars (A and C) with respective mean MIR values of 0.74 and 0.75 (or mean MIC values of 4.15 and 4.42); and the third set consisted of one Upland cultivar (D) with a mean MIR value of 0.64 (or a mean MIC value of 3.03). As anticipated, there were improved correlations between STEten and HVIstr for the first set (r = 0.79) and the second set (r = 0.84), compared to a r value of 0.57 for all Upland datasets in Table 5.

3.5. Relationships between Fiber MIR or CIIR and MIC or HVIstr

For all Upland datasets in Table 6, there was a stronger correlation between MIR and MIC (r = 0.81, p-value < 0.001) than between CIIR and MIC (r = 0.57, p-value = 0.001). It was consistent with a previous report that the MIC values of 16 crossed-Upland kinds of cotton were significantly correlated with fiber maturity and linear densities determined by Cottonscope and image analysis methods [12]. Further analysis revealed that MIC increased insignificantly with fiber MIR for Upland A and D fibers (r = 0.66 to 0.80) and decreased with fiber MIR for the remaining four Upland cultivars (r = −0.99 to −0.26), in which only Upland E fibers possessed a strong and significant correlation (r = −0.99, p-value = 0.03). Similarly, MIC increased with fiber CIIR for Upland A and D cultivars, but none of the six Upland cultivars showed any significant correlations between fiber CIIR and MIC. For Pima fibers, there existed weak and insignificant correlations either between MIR and MIC (r = 0.10, p-value > 0.05) or between CIIR and MIC (r = 0.10, p-value > 0.05).

Table 6.

Comparison of r and significance (significant *, p-value = 0.05~0.01; very significant **, p-value = 0.01~0.001; very significant *** at p < 0.001, p < 0.001) between MIR or CIIR and MIC or HVIstr for individual Upland cultivars, all Upland datasets, and one Pima cultivar.

Compared to a weak correlation between fiber CIIR and HVIstr for all Upland datasets (r = 0.20, p-value > 0.05) in Table 6, there was a moderate and significant relationship between fiber MIR and HVIstr (r = 0.46, p-value = 0.008). Four Upland cultivars (A, B, E, and F) showed an increase in HVIstr with MIR (r = 0.01 to 0.71), and the other two cultivars (C and D) indicated a decrease in HVIstr with MIR (r = −0.98 to −0.39), of which only Upland D fibers (immature) had a strong and significant correlation (r = −0.98, p-value = 0.002). Two of the six Upland cultivars (A and F) suggested an HVIstr increase with fiber CIIR (r = 0.46 to 0.66); however, none of the six Upland cultivars showed any significant correlation between fiber CIIR and HVIstr. Within Pima fibers, weak and insignificant correlations were observed between either MIR and HVIstr (r = 0.10, p-value > 0.05) or CIIR and HVIstr (r = 0.26, p-value > 0.05).

3.6. Relationships between Fiber MIR or CIIR and STEten or STEelo

Contrary to a moderate and significant positive relationship between fiber MIR and HVIstr (r = 0.46, p-value = 0.008) or a weak and insignificant positive correlation between fiber CIIR and HVIstr (r = 0.20, p-value > 0.05) for all Upland datasets in Table 6, Table 7 implied a weak and insignificant negative correlation between fiber MIR and STEten (r = −0.01, p-value > 0.05) or a negative moderate but significant correlation between fiber CIIR and STEten (r = −0.40, p-value = 0.02). The differing STEten and HVIstr responses to MIR or CIIR indices could be due to differences in the way of normalizing the breaking force, as the Stelometer test uses the weight of a broken bundle while the HVI test uses a MIC. MIC was positively and significantly related to fiber maturity, represented by MIR for all Upland datasets in general (Table 6), or by fiber maturity and linear density reported earlier [12].

Table 7.

Comparison of r and significance (significant *, p-value = 0.05~0.01) between MIR or CIIR and STEten or STEelo for individual Upland cultivars, all Upland datasets, and one Pima cultivar.

As shown in Table 7, four Upland cultivars (A, B, C, and E) suggested an STEten increase with MIR (r = 0.47 to 0.92), while the other two cultivars (D and F) indicated an opposite direction (r = −0.37 to −0.01), but only Upland C fibers had a strong and significant correlation (r = 0.90, p-value = 0.01). The same trend was observed for these six Upland cultivars when relating STEten to fiber CIIR; however, none of them showed significant correlations between fiber CIIR and STEten. Relative to a moderate and insignificant correlation between MIR and STEten (r = 0.45, p-value > 0.05) for Pima fibers, there existed a moderate and significant correlation between CIIR and STEten (r = 0.58, p-value = 0.01).

Statistically, MIR was related more to HVIstr (r = 0.46, p-value = 0.008) than to STEten (r = −0.01, p-value > 0.05) for all Upland datasets, echoing a previous inconclusive observation between STEten and MIR on combined Upland fibers from the U.S. and four foreign countries [11]. A recent investigation reported that both MIC and maturity values were positively and significantly correlated with single fiber breaking force but negatively with single fiber strength on a set of Upland kinds of cotton constructed from a genetic approach [12]. Meanwhile, fiber CIIR was related less to HVIstr (r = 0.20) than to STEten (r = −0.40) for this Upland dataset. The observation agreed with a previous study that single fiber breaking tenacities against fiber XRD crystallinity differed between developing SJ-2 and Maxxa cotton fibers [3].

Notably, in Table 7, there was a weak correlation between either MIR and STEelo (r = −0.01, p-value > 0.05) or between CIIR and STEelo (r = −0.22, p-value > 0.05) for all Upland datasets and also for Pima fibers (r = 0.10 and −0.14, respectively). In general, three of six Upland cultivars (A, B, and E) showed an increase in STEelo with MIR (r = 0.33 to 0.99), whereas the other three cultivars indicated the opposite change (r = −0.62 to −0.49); however, only Upland E fibers had a strong and significant correlation between the two (r = 0.99, p-value = 0.03). Unlike Upland B, C, D, and F cultivars, Upland A and E fibers were found to increase in STEelo with fiber CIIR (r = 0.41 to 0.99), in which only Upland A cultivar was to have a strong and significant correlation (r = 0.99, p-value = 0.01) among six Upland cultivars.

4. Conclusions

This study linked fiber Stelometer and HVI properties to fiber crystallinity and maturity indices determined by analyzing ATR FT-IR spectra of tiny Stelometer breakage specimens, aiming to examine the relationships between fiber physical and structure properties among six Upland and one Pima cotton cultivar. Although the plot of STEten against HVIstr implied a reasonable agreement between two strength measurements (r = 0.57 ***), the Upland D cultivar (immature with the smallest MIC, MIR, and CIIR values) was observed to show the lowest HVIstr value (=25.7) but a relatively larger STEten value (=21.3). In contrast, the Upland F cultivar (having the greater CIIR index) showed the smallest STEten value (=19.9) but a relatively larger HVIstr value (=29.5).

A comprehensive examination of multiple relationships on individual Upland cultivars suggested strong and significant correlations between CIIR and STEelo for the Upland A fibers (r = 0.99 *), between MIR and STEten for the Upland C fibers (r = 0.90 *), between MIR and HVIstr for the Upland D fibers (r = 0.98 **), and also between MIR and MIC (r = 0.99*), as well as between MIR and STEelo (r = 0.99 *) for the Upland E fibers. Relatively, there existed a moderate and significant correlation between CIIR and STEten for Pima fibers (r = 0.58 *). Different responses underscored the importance of experimental design and data analysis in understanding the unique response among any pair of fiber MIC, HVIstr, STEten, STEelo, MIR, and CIIR values, even within one cultivar. Beyond the approach reported here, other strategies might be explored with the ultimate purpose of improving fiber strength or elongation measurement, unraveling fiber strength or elongation’s response to fiber structure, and enhancing fiber utilization and processing efficiency.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The author sincerely thanks J. Linda and N. Carroll of ARS USDA for their technical assistance in conducting the Stelometer measurement. Mention of a product or specific equipment does not constitute a guarantee or warranty by the U.S. Department of Agriculture and does not imply its approval to the exclusion of other products that may also be suitable.

Conflicts of Interest

The author declares no conflicts of interest. Although the author is employed by the funding organization, the funders had no role in the design of the study, in the collection, analysis, or interpretation of data, or in the writing of the manuscript but approved the decision to publish the results.

References

- Hsieh, Y.-L.; Hu, X.-P.; Wang, A. Single fiber strength variations of developing cotton fibers-strength and structure of G. Hirsutum and G. barbedense. Text. Res. J. 2000, 70, 682–690. [Google Scholar] [CrossRef]

- Thibodeaux, D.; Hebert, J.; El-Gawad, N.; Moraitis, J. Relating bundle strength to Mantis single fiber strength measurements. J. Cotton Sci. 1998, 2, 62–67. [Google Scholar]

- Hsieh, Y.-L.; Hu, X.-P.; Nguyen, A. Strength and crystalline structure of developing Acala cotton. Text. Res. J. 1997, 67, 529–536. [Google Scholar] [CrossRef]

- Delhom, C.; Cui, X.; Thibodeaux, D. Single fiber testing via Favimat. In Proceeding of the 2010 Beltwide Cotton Conferences, New Orleans, LA, USA, 5–7 January 2010; pp. 1405–1410. [Google Scholar]

- Hequet, E.; Abidi, N. Examination of the relationships between individual fibers tensile properties and bundle tensile properties. In Proceeding of the 2010 Beltwide Cotton Conferences, New Orleans, LA, USA, 5–7 January 2010; p. 1391. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard test method for breaking strength and elongation of cotton fibers (flat bundle method) (D1445). In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Cui, X.; Cai, Y.; Delhom, C.; Rodgers, J.; Martin, V.; Watson, M. Experience of the Fibrotest for measuring cotton fiber length and strength properties. In Proceeding of the 2013 Beltwide Cotton Conferences, San Antonio, TX, USA, 7–10 January 2013; pp. 799–802. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard test method for measurement of physical properties of cotton fibers by high volume instruments (D5867). In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Benedict, C.; Kohel, R.; Jividen, G. Crystalline cellulose and cotton fiber strength. Crop Sci. 1994, 34, 147–151. [Google Scholar] [CrossRef]

- Hu, X.-P.; Hsieh, Y.-L. Crystalline structure developing cotton fibers. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1451–1459. [Google Scholar] [CrossRef]

- Liu, Y.; Thibodeaux, D.; Gamble, G.; Rodgers, J. Preliminary study of relating cotton fiber tenacity and elongation with crystallinity. Text. Res. J. 2014, 84, 1829–1839. [Google Scholar] [CrossRef]

- Kim, H.J.; Delhom, C.D.; Rodgers, J.E.; Jones, D.C. Effect of fiber maturity on bundle and single-fiber strength of upland cotton. Crop Sci. 2019, 59, 115–124. [Google Scholar] [CrossRef]

- Naylor, G.R.; Delhom, C.D.; Cui, X.; Gourlot, J.P.; Rodgers, J.E. Understanding the influence of fiber length on the High Volume Instrument™ measurement of cotton fiber strength. Text. Res. J. 2014, 84, 979–988. [Google Scholar] [CrossRef]

- Liu, Y.; Delhom, C.D. Investigation of fiber maturity and crystallinity information in Upland seed cottons by Fourier Transform infrared spectroscopy. Text. Res. J. 2023, 93, 2507–2519. [Google Scholar] [CrossRef]

- Averett, L.A.; Griffiths, P.A.; Nishikida, K. Effective path length in attenuated total reflection spectroscopy. Anal. Chem. 2008, 80, 3045–3049. [Google Scholar] [CrossRef] [PubMed]

- Larkin, P. Principles and spectral Interpretation. In Infrared and Raman Spectroscopy; Elsevier: Waltham, MA, USA, 2011; pp. 27–54. [Google Scholar]

- Van der Sluijs, M.H.J. Cotton appearance. In Cotton Fibers: Characteristics, Uses and Performance; Nova Science Publishers, Inc.: New York, NY, USA, 2017; pp. 135–158. [Google Scholar]

- Ratner, B. The correlation coefficient: Its values range between +1/−1, or do they? J. Target. Meas. Anal. Mark. 2009, 17, 139–142. [Google Scholar] [CrossRef]

- McCormick, K.M.; Morais, J.P.S.; Hequet, E.; Kelly, B. Development of the correction procedure for High Volume Instrument elongation measurement. Text. Res. J. 2019, 89, 4095–4103. [Google Scholar] [CrossRef]

- Yang, S.; Gordon, S. Accurate prediction of cotton ring-spun yarn quality from high-volume instrument and mill processing data. Text. Res. J. 2017, 87, 1025–1039. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).