1. Introduction

With a population of 180 million people living in a small area of 55,000 square miles, Bangladesh is one of the most densely populated countries in the world, holding the eighth position in the world rankings (

World Bank, 2024). In addition, this country has meager natural resources and is highly prone to various natural calamities. Despite these unfavorable factors, the country has maintained a remarkably high GDP growth rate of about 6% per year over the last several decades (

US Department of State, 2021;

BGMEA, 2020), lifting the country from a poor LDC (least developed country) since achieving independence in 1971 to a lower middle-income country in 2015. The country is expected to graduate to a middle-income country by 2026 and is aspiring to become an upper-middle-income country by 2031 (

The Daily Star, 2004).

Most of the growth in Bangladesh can be attributed to several areas, such as the export of readymade garments, remittances from expatriate Bangladeshi workers, agricultural sector growth, and a vibrant private sector that is allowed to flourish (

BGMEA, 2024;

EPB, 2024;

World Bank, 2024). In the garments sector, the focus of this study, Bangladesh has made remarkable progress in garment exports over the past several decades since the mid-1980s, when the industry took root in the country (

Rhee, 1990). The industry began its journey with almost no such exports during the early post-independence period. Such progress has led Bangladesh to be the second largest exporter in the global rankings in recent years, just after China (

Zaman, 2023). Around 2020, Bangladesh briefly lost its rank of second to Vietnam but has quickly regained its position in recent years.

In a pioneering, early paper,

Rhee (

1990) attributed this rapid progress to what is called a catalyst model of development. During that time,

A. Islam and Quddus (

1996) dubbed it a “miracle in the making”. As of today, it is quite evident, as will be demonstrated in this paper, that Bangladesh has really achieved a miracle. This progress is indeed a miracle if one considers the fact that the country does not have some of the critical inputs for garment making, such as cotton, fibers, export quality fabric, and machinery, among others.

Rhee (

1990) and

A. Islam and Quddus (

1996,

2008,

2011) give more details about the situation of the industry during the early years and the weaknesses thereof, how the industry pioneers were able to overcome major weaknesses during the early years for the formation of this industry, which factors helped in overcoming them, and how such remarkable progress was made by becoming a major global player in the highly competitive apparel market in a short period of time. Over time, the industry in Bangladesh has achieved strong global market access and global recognition.

As the industry has expanded, matured, and received global recognition, the industry also received global attention from various global actors and entities, raising various concerns and criticisms leveled against the industry. These external global actors include the governments of the country’s major export partners, trade unions, environment groups, and human rights organizations, including prominent international organizations such as the ILO, the UN, UNICEF, and the WTO, to name a few. In addition to the concerns from external sources, concerns were also raised internally by domestic labor unitions, civil society organizations, local NGOs, think tanks, the press, and intellectual groups, among others.

As such, the industry is now facing many social compliance challenges coming from abroad. The challenges from overseas come in the form of pressure to improve various social compliance aspects of the industry. These issues can be considered challenges regarding the industry’s longer-term viability and sustainability, arising from external sources that may threaten the further progress of the industry on the global stage if corrective actions are not satisfactorily addressed. This paper aims to understand the long-term trend in the growth and development of the industry, as well as the role and significance of garment exports to total exports, along with the sensitivity (elasticity) of total exports to garment exports. The above will be followed by critical discussions on some selected social sustainability issues and challenges facing the industry. In particular, this paper will focus on specific aspects of social sustainability issues, such as the highly controversial child labor issue, low wages and benefits, the workplace safety of the workers, workers’ rights, and the workers’ health and working environment, among others. This paper also discusses what progress, if any, has been made in these areas, and what the agenda is going forward. Addressing these issues has become critical for the medium- to long-term viability of the industry.

2. Global Garment Industry: An Overview

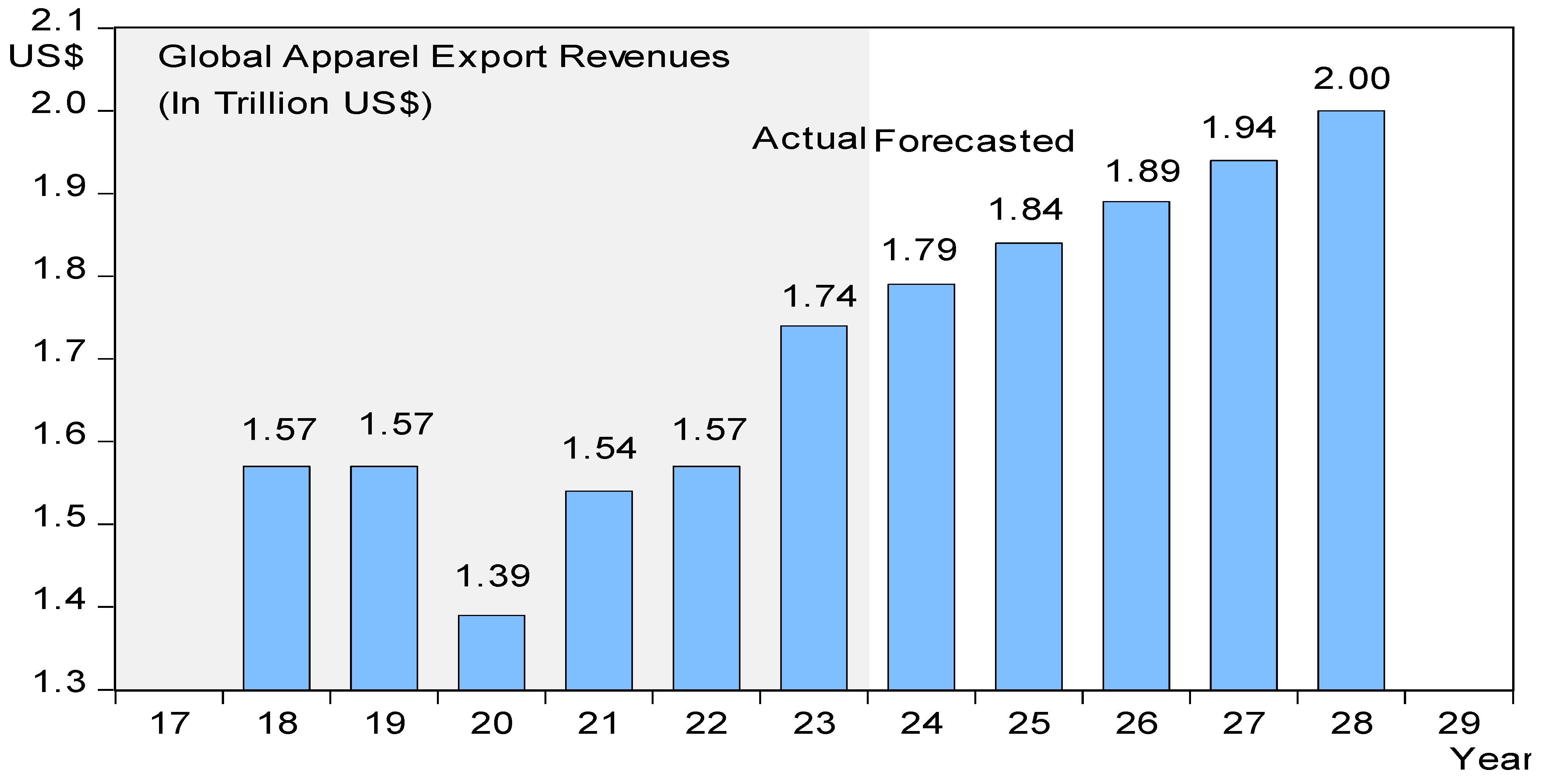

The global apparel market is quite large, with annual revenues of about USD 1.78 trillion, and it is projected to grow to about USD 2.0 trillion by 2028 (

Statista Research Department, 2024).

Figure 1 displays the time trend and growth of the global apparel sales revenue from 2018 to 2024 and the forecasted value to 2028. With the rising world population and world income, the demand for apparel is expected to grow further with time. The figure also shows the industry by major segments such as children’s apparel, men’s apparel, and women’s apparel. It is evident from this figure that women’s apparel dominates in the export market followed by men’s apparel and, next, by children’s apparel. The overall growth of the global apparel market will be beneficial for the apparel-exporting countries in the world including Bangladesh, the second-largest garment exporter in the world (

Zaman, 2023).

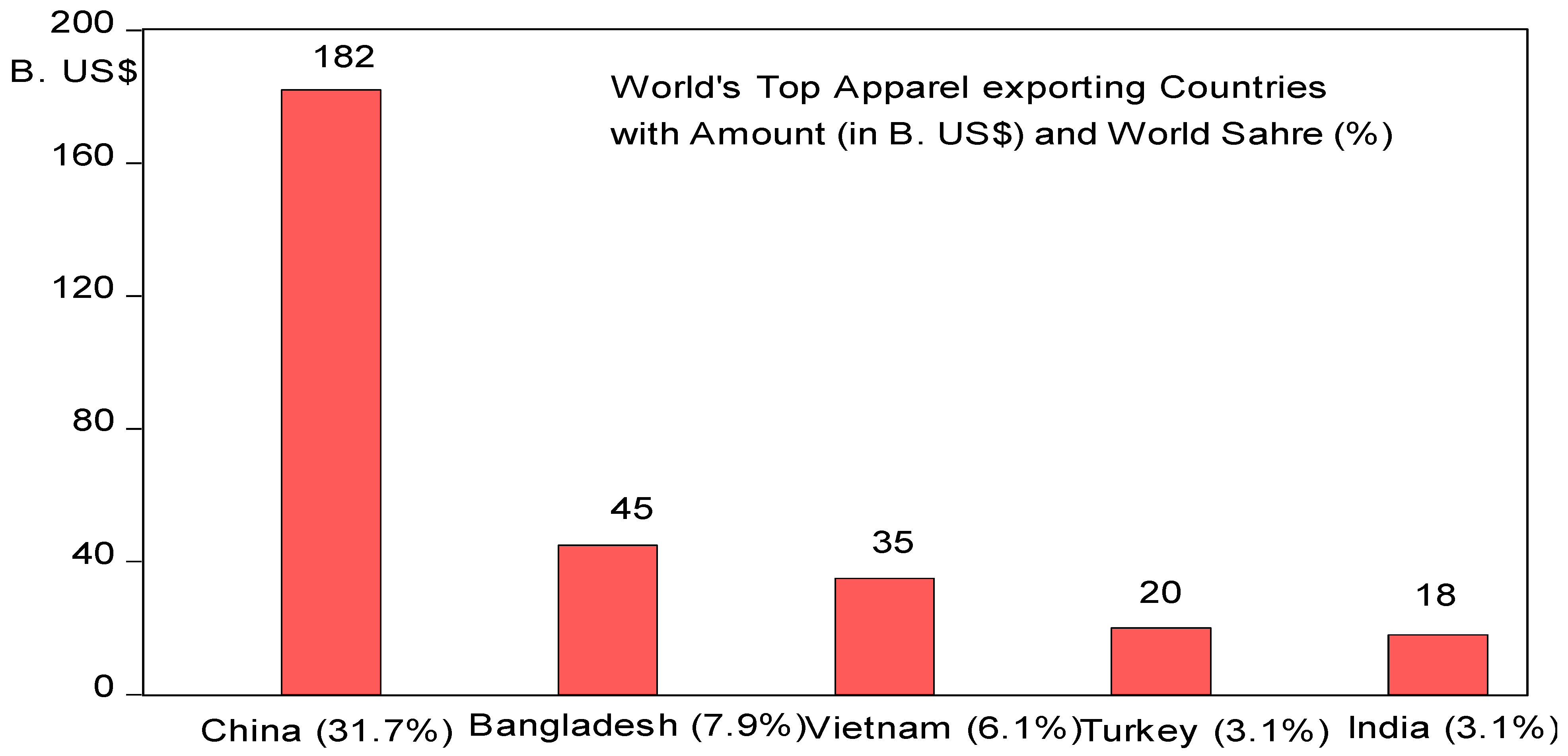

Historically, the apparel market used to be dominated by Western countries, but, gradually, with increased globalization and a more open trading environment, the countries in Asia have gained significance. The Western countries lost the edge because garment production is highly labor-intensive in the production process and labor is abundant and cheap in the Asian countries. As such, the apparel market is dominated by Asian countries in modern times, such as China, Bangladesh, Vietnam, India, Pakistan, Indonesia, Cambodia, Hong Kong, and Thailand, among others.

Figure 2 shows that the topmost of these countries is China, with the largest market share, followed by Bangladesh with the second largest, and Vietnam with the third largest.

3. Literature Review

This section reviews some articles that are related to the growth and development of the export garment industry in Bangladesh. Some articles also discuss the economic, social, and human aspects of this industry. From the social perspective, the issues covered include topics such as worker rights, wages and income, gender bias, child labor issues, worker safety, and several other social issues, among others.

In an early but pioneering paper,

Rhee (

1990) identifies the major elements that have contributed to Bangladesh’s astounding success with garment exports and sketches a catalyst model of development with an outward orientation to explain the success of this industry. The outward orientation is referred to as catalysis from home in collaboration with foreign catalysts, in this case, Daewoo Corporation from South Korea and Desh Garments from Bangladesh, as well as abroad (South Korea).

Rhee (

1990) noted that Bangladesh exported a meager USD 3.9 million in 1980–1981 (0.5% of the country’s total exports) during the initial phase of the industry that grew rapidly to about USD 300 million (28.2% of total exports) by 1986–1987, with a demonstrated annual average growth rate of 106% per annum over this short period of time. At that time, the paper reported that the female workforce constituted about 90% of the garment industry employment. The paper then discusses the historical evolution of the industry, and how the success of Desh Garments was replicated throughout the country by the entry of other catalysts internally. Finally, the paper discusses any lessons that other low-income countries can learn from this experience.

In a subsequent early paper,

A. Islam and Quddus (

1996) discussed the evolution and rapid growth of this industry and various contributions it made to the country’s employment, particularly women’s employment and empowerment, exports, foreign exchange earnings, gross domestic product, and the development of various backward, parallel, and forward linkage industries. The paper also discussed various weaknesses of this industry at that time such as lack of critical ingredients within the country, such as lack of cotton, fibers, quality fabric, financing, etc. In addition, the paper talked about the external challenges facing the industry at that time such as the potential abolition of the quota regime under the Multi-Fiber Agreement (MFA) and the resulting more intense competition from other established and evolving garment-exporting countries in Asia (China, Vietnam, Cambodia, Thailand).

Paul-Majumder and Begum (

2000) discuss women’s employment and disparity in the export-oriented garment industry versus other export-oriented industries and non-export-oriented industries. The study uses survey data for 1990, 1993, and 1997 to evaluate how the employment of women in export-oriented industries exploits the “comparative advantages of their disadvantages.” It evaluates gender differences in conditions of employment and the work environment. The authors recommend policy measures for eliminating the gender imbalances arising from women’s employment in export-oriented garment industries.

In a different paper,

Kabeer and Mahmud (

2004) discuss the growth and evolution of this industry from a historical perspective. In addition, the paper touches upon gender disparity issues facing female workers in the industry, particularly focusing on job contracts and their terms and conditions, and their rights. They reported widespread gender disparity in the industry.

Observing the phenomenal growth of the garment industry in Bangladesh,

A. Islam and Quddus (

2008) dubbed this industry as a “Miracle in the making”. The paper analyzed and reviewed the export garment industry data and trends in the early years such as the number of factories, employment including women’s employment, exports, and market structure, among others. The study also discussed the impact of the industry on the economy, along with some discussion on social compliance issues such as worker rights, child labor, and the role of trade unions. It also discusses some policy implications for improving the industry for the benefit of the country.

In a follow-up and a more updated book chapter,

A. Islam and Quddus (

2011) argued that the readymade garment industry has served as an “engine of economic growth” for the economy of Bangladesh for more than two decades. This study analyzes and reviews the most recent industry trends and achievements. In particular, it presents trends in industry variables such as the number of factories, employment including women’s employment, exports, and market structure, among others. In addition, this paper addresses several issues, such as the anticipated impact of the readymade garment industry on the economy in the next decade, policies to strengthen forward and backward linkages, and various risks and challenges that lie ahead—social compliance issues such as worker rights and the role of unions, child labor, and the impact of protectionist policies in major markets.

Akhter et al. (

2010) discuss the success achieved by the garment industry in capturing a position in the global value chain quite successfully that helped the social and economic development of the country. The paper also discusses some weaknesses and challenges facing the industry, particularly with respect to female workers, focusing on such issues as workers’ residential environment, working conditions, age, health conditions including access to hospital and medical services, and frequency of factory fire accidents.

Furthermore,

Akhter and Rahman (

2018) analyze the gender dynamics within the Bangladesh garment industry, focusing on issues such as female labor force participation, gender wage gap, sexual harassment, and empowerment initiatives.

S. Islam and Bailkis (

2018) focus on the aftermath of the Rana Plaza building collapse in 2013, and the steps taken by the Bangladesh garment industry to improve safety standards and protect workers’ rights.

In a different article,

Paul-Majumder and Begum (

2000) discuss the gender imbalance in the export garment industries in Bangladesh using survey data from 1990, 1993, and 1997. The paper evaluates gender differences in both conditions of employment and the work environment itself and examines the differences among the export-oriented garment industry, other export industries, and non-export industries. They find a prevalence of wide gender differences within the garment industry, as well as between the garment industry and other non-garment industries, and recommend policy measures for eliminating the gender gap arising from women’s employment in export-oriented garment industries.

Ahmed and Alam (

2020) discuss the sustainability issues faced by the Bangladesh garment industry, including labor rights, safety concerns, and environmental impact. It also explores potential solutions and opportunities for improvement. On the other hand,

Rahman and Haque (

2020) explore how innovation is driving growth in the Bangladesh garment industry, from technological advancements in production processes to the adoption of sustainable practices.

Siddiqui and Vita (

2021) discuss the comparative analysis of the impact of logistics performance on trade with respect to the garment sector in Cambodia, Bangladesh, and India. The article employs panel data analysis to assess the impact of logistics performance on trade across the three countries of Cambodia, Bangladesh, and India over the time period ranging from 2001 to 2016 for the garment sector. The results obtained through empirical analysis indicate the causes and impacts of logistics performance on trade in the case of the garment sector. Logistics performance has been denoted by the Logistics Performance Index (LPI) and the adoption of e-clearance mechanisms. The study suggests that government should promote private and foreign investment in infrastructure development projects. In a more recent study,

Florido-Benitez (

2024) explores the sustainable future of e-commerce companies through a digital marketing and logistics context. However, these logistic and global supply chain issues fall beyond the social sustainability focus of our paper and, hence, these are not explored further in this paper.

While the literature review above shows that the export garment industry has achieved remarkable success, some studies have also noted some social compliance issues facing the industry. However, many of these studies are now quite dated and some studies did not pay adequate and serious attention to some burning social compliance and social sustainability issues. This paper, therefore, attempts to meet some of these weaknesses by providing updates on the growth and development of the industry, along with updates on the social compliance and social sustainability issues facing the industry today.

4. Methodology

This article will rely heavily on data and information collected mainly from secondary sources. Internal data sources include Government of Bangladesh (GOB) publications, Bangladesh Bank (BB) publications, BGMEA publications, newspaper articles, and academic journal publications. External data sources include publications from the WTO, the World Bank, the IMF, Statista, and the fashion world, among others.

Most analyses will be performed using various quantitative tools, such as regression analysis and elasticity analysis, as well as those based on tabular, descriptive, graphical, and trend analysis). For quantitative analysis, growth estimation and elasticity analysis utilize some regression methods with correction for autocorrelation. The simple linear regression analysis would be used to estimate time trend regression as well as causal regression to test for a few simple hypotheses. Additional analyses were performed using descriptive analysis, tabular analysis, and graphical analysis. Annual time-series data covering the period from 1984 to 2022 (reflecting 39 annual observations) were used for trend analysis and regression analysis.

5. Growth and Development of the Export Garment Industry in Bangladesh

The garment industry is the most prominent industry in the manufacturing sector and the export sector of Bangladesh (

BGMEA, 2024;

EPB, 2024;

A. Islam & Quddus, 2011). The industry has grown very rapidly over the years and now assumes the place of the second-largest exporting nation in the global apparel market (

EPB, 2024). Bangladesh lost its second position briefly in 2020 to Vietnam, but quickly regained its position since 2021. Recently, more than four million people (

BGMEA, 2020) have been working in this sector, spread over more than 4000 garment factories (

PressXpress, 2024). Citing the ILO,

Paton (

2021) reports that there were 4500 garment factories employing 4.5 million workers in Bangladesh in recent years. Female workers constitute about 58% of workers in this industry (

PressXpress, 2024). The percentage of female workers was about 90% of the garment workers in the early years of the industry development (

Rhee, 1990). The garment industry is the largest export earner with about USD 47.39 billion in 2023. This represents about 82% of the total exports of this country, about 7.9% of the global apparel market, and about 9.25% of the country’s GDP (

PressXpress, 2024). The country’s garment exports are primarily destined for the U.S. and EU countries.

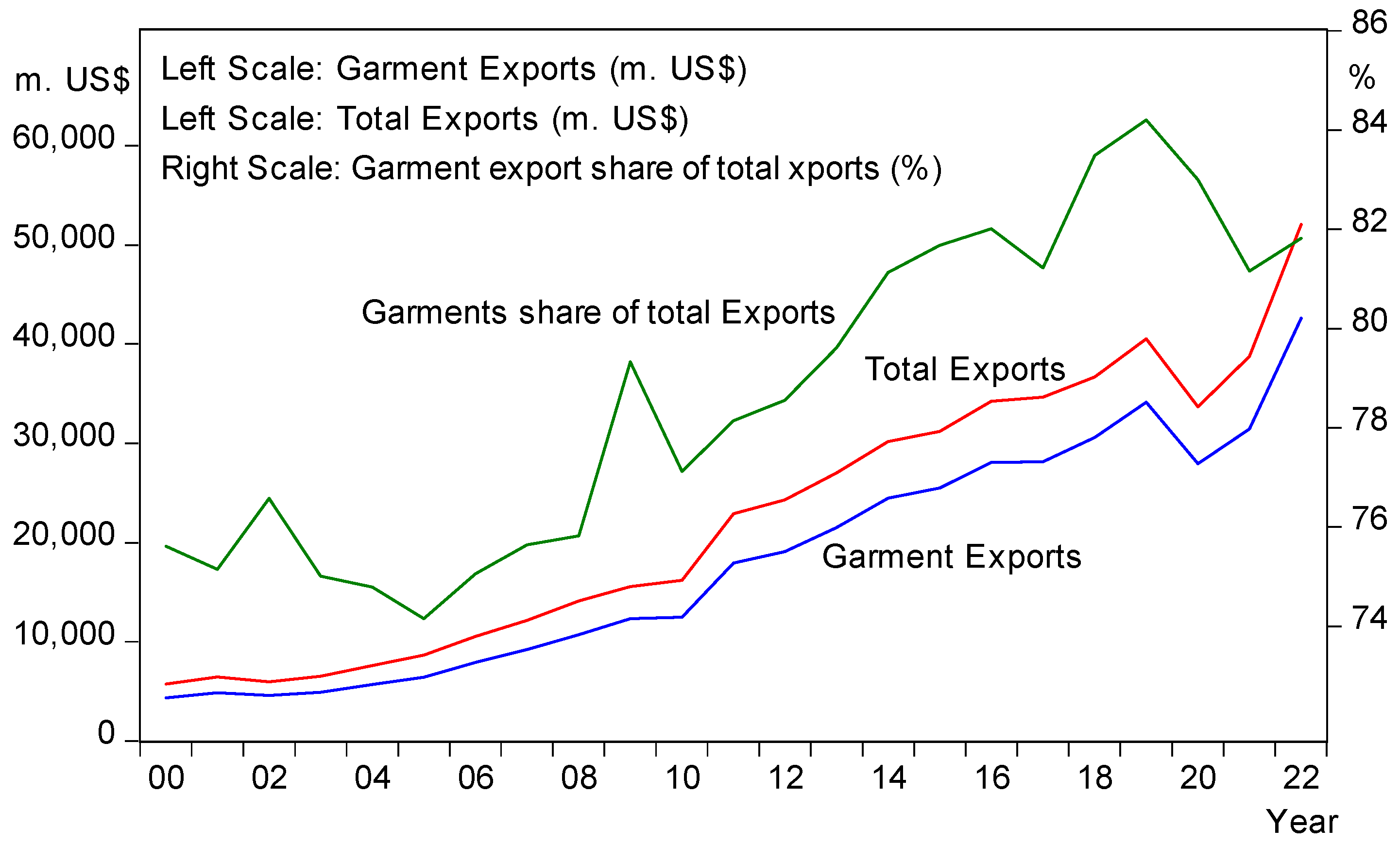

Table 1 reports some data on the yearly trend of garment exports and total exports from Bangladesh to the rest of the world for a recent 10-year period from FY 2011-12 to FY 2020-2, along with the share (%) of garment exports to the total exports. Both variables have grown steadily and rapidly over this time, with a small dip during the COVID-19 pandemic, but that is only for a brief period. In addition, it is observed that garment exports constitute a very high proportion of total exports during each year with a peak of 84.21% in 2018–2019 and 81.16% in 2020–2021.

The previous discussion based on

Table 1 is further corroborated by the associated

Figure 3 that follows. In this diagram, the time trend of exports is shown in terms of a time-series graph for a longer period from 2000 to 2022. The graph shows that there was a small dip in exports during the 2007–2009 global recession known as the Great Recession (

A. Islam & Quddus, 2011). This article also demonstrated that the overall economy of Bangladesh showed remarkable resilience during the 2007–2009 Great Recession. However, during the COVID-19 pandemic, there was another but bigger dip in both total exports and garment exports, as the world economy was shattered due to shutdowns, lockdowns, and other restrictions on the economy and people.

Paton (

2021) reports that garment exports were down 17% due to the pandemic. This dip in exports is not surprising and was caused by the COVID-19 pandemic, but exports recovered very quickly, again showing fast recovery and strong resilience. Having said that, the overall trend has been upward in both total and garment exports, except for those two major global crisis periods. Observing the rapid growth of the industry in Bangladesh,

Rhee (

1990), in an early study, explained this growth as the catalyst model of development. In another early study, this growth has been dubbed as a “miracle in the making” (

A. Islam & Quddus, 1996). Today, the industry has matured and gained second place in the global apparel market, simply an astounding success, and surely a miracle.

As the industry evolved, it has expanded its exports to many countries in the world now, notably in the advanced country markets such as the U.S. and the EU countries.

Table 2 below gives the major export destination countries for Bangladesh. This table shows the dollar amount (in million USD) of garment exports from Bangladesh to its top ten trading partners along with the share for each country for three recent years: 2020–2021 to 2022–0223. It is quite clear from this table that the U.S. is the largest export destination country for Bangladesh, with a market share of 19.0% in 2022–2023, up from 18% in 2020–2021 (

Bangladesh Bank, 2024). Focusing on 2022–2023, the U.S. is followed by Germany with about a 13% share, the U.K. with about a 10% share, and Spain with about an 8% share. The other top countries are, respectively, in that order: France (6%), Italy (4%), India (3.9%), the Netherlands (3.8%), Poland (3.4%), and Canada (3.2%). Together, these top ten countries import about 73% of Bangladesh’s total garment exports in 2022–2023. The remaining other countries receive about 27% of the total garment exports from Bangladesh.

Figure 2, as discussed in a previous section, gives the export share of Bangladesh vis à vis several other major garment-exporting countries in the global apparel market. It is very clear from this figure that China is the most dominant player in the global apparel market, exporting about USD 182 billion worth of garments to the rest of the world in 2022, which constitutes about 31.7% of global exports (

Zaman, 2023). China is distantly followed by the second largest player Bangladesh with only about USD 45 billion of exports that constitute about 7.9% of the global share, but it is only about 1/4th of China’s exports in both volume and market share. It is to be noted that Vietnam in Asia is the closest competitor of Bangladesh with exports of 35 billion and a share of 6.1%. In fact, Bangladesh briefly lost its second position to Vietnam in 2020, but quickly regained its second position in 2021. The other close competitors of Bangladesh on the global stage are Turkey (3.1%) and India (3.1%) (

Zaman, 2023).

6. Estimation of Trend Growth and Elasticity Analysis of the Bangladesh Garment Industry

In this section, regression analysis is performed for two purposes: (a) calculation of constant annual average growth rate; this calculation is performed using both nominal variable (before adjusting for inflation) and real variable (after adjusting for inflation); and (b) conduct a hypothesis test to examine the sensitivity (or response) of total exports with respect to changes in garment exports. This sensitivity test is performed for both nominal data and real (inflation-adjusted) data.

6.1. Regression Analysis to Calculate Long-Term Trend Growth Rate

In this sub-section, we attempt to calculate the average annual growth rate of the Bangladesh garment industry using the following regression methodology. Noting x(t) as garment exports in time t (t = 1, 2, 3, … n, where n = 39 annual observations) and assuming x(t) grows at a constant rate of ‘g’ per year, the growth process can be modeled as follows:

Taking natural log (ln) on both sides:

Writing the intercept term a = ln x(0) and the slope coefficient b = ln(1 + g), Equation (2) can be rewritten as follows:

Adding a random error term u with assumed usual i.i.d. properties to Equation (3) gives Equation (4) as the estimable semi-logarithmic equation, as follows:

Equation (4) is used to estimate ‘a’ and ‘b’ coefficients. From the estimated ‘b’ coefficient, and since b = ln (1 + g), the constant average growth rate ‘g’ can be obtained as follows:

Using (5), g can be calculated as follows:

and from (6), ‘g’ in percentage form is estimated by (7) below:

Following the above methodology, the long-term average growth rate “g” is estimated and reported in

Table 3 for four export-related variables: (i) total exports (nominal); (ii) total exports (real); (iii) garment exports (nominal); and (iv) garment exports (real). Four regression equations were estimated using the four variables as dependent variables against time. Note that the regression equations are not presented here to save space, but the estimated percentage growth rates are reported here in the table below. The nominal variables (before adjusting for inflation) were converted to real variables (after adjusting for inflation) using the GDP deflator.

Table 3 shows that the nominal total exports of Bangladesh grew at the constant annual average rate of 11.88% per annum over the entire 39-year period from 1984 to 2022, whereas the real total exports grew only at 5.03 percent per annum over the same period. In contrast, the nominal garment exports grew at 16.31% per annum, whereas real garment exports grew at 9.12% per annum over the same 39-year period. Thus, it is obvious that the nominal growth rate was higher than the real growth rate for both total exports and garment exports. This is not surprising given that the nominal growth rate includes an inflation component that biases the nominal growth rate. Furthermore, it is evident from this table that the growth rate for garment exports, both in nominal and real terms exceeded the growth rate of total exports in both nominal and real terms. The real growth rate of garments at a constant average of 9.12 percent per annum has truly been remarkable for the country and made the country a major player in the highly competitive global apparel market.

6.2. Elasticity of Total Real Exports to Real Garment Exports

In this sub-section, we will examine the elasticity of total real exports to real garment exports. The relevant nominal (before adjusting for inflation) variables were converted to real (inflation-adjusted) variables by deflating with the country’s GDP deflator. To examine the sensitivity of total real exports to changes in real garment exports, we specify a non-linear exponential equation of the following form:

where

xrtot = real (inflation-adjusted) value of total exports (m. USD)

xrgar = real (inflation-adjusted) value of garment exports (m. USD)

a = intercept

b = coefficient of xrgar

v = random error term with assumed usual i.i.d. properties.

Taking logarithm on both sides converts (8) into the log-linear form equation as follows:

which can be rewritten as follows:

where lxrtot = ln xrtot, m = ln a, lxgrar = ln (xgar), and v’ = ln v.

In this log-linear transformation, ‘m’ is the intercept term, and ‘k’ is the coefficient representing the effect of lxgar (real garment exports) on lxrtot (real total exports). Our main interest is in the coefficient ‘k’, which will measure how real total exports respond to changes in real garment exports.

In Equation (10), we specify the null and alternative hypotheses for testing as follows:

H0: k = 0 (real total exports do not respond to real garment exports).

H1: k > 0 (total real exports respond positively responds to real garment exports).

Since the alternative hypothesis is a unidirectional (positive direction), a one-tailed t-test needs to be applied. If the estimated t-statistic exceeds the tabulated t-statistic at a given level of significance (say 5%) with (n − 2) = (39 − 2) = 37 degrees of freedom, we will reject H0 in favor of H1.

Table 4 reports the regression result after controlling for autocorrelation by the AR(1) process. In this table, the Durbin Statistic of 1.82 is close to 2.0, and the errors seem to be free of autocorrelation. With an F-value of 280.46 and a

p-value of 0.000, the overall regression equation is statistically significant at a level better than 1%. The adjusted R

2 value of 0.95 explains 95% of the variation in real total exports by real garment exports. The slope coefficient of lxgar (real garment exports) has a t-value of 4.82 and the

p-value of 0.00 is statistically significant at better than 1% level of significance. The coefficient is positive as expected, which helps reject H

0 and supports the alternative hypothesis that real garment exports have a strong positive effect on real total exports. With the coefficient value being 0.28, the response of real total exports seems to be relatively inelastic rather than elastic. This implies that every 1% change in real garment exports tends to change total exports by 0.28%. This inelastic response can be good news in the sense that if the garment industry falters for any reason (domestic or external), the total exports will not decline as much. However, it is not so good news in the sense that as the garment exports increase, it does not increase total exports proportionately or better.

7. Selected Social Compliance Challenges Facing the Industry

As mentioned earlier, with the growth and development of the RMG industry in Bangladesh and its ascendence to one of the top global players in the world, the country has drawn the attention of various agencies and organizations both inside and outside the country. Addressing these concerns raised by the organizations outside the country is critical for the long-run survival and sustainability of this global industry for Bangladesh. Such organizations may include consumer groups, other civil society groups, labor unions, human rights organizations, environmental groups, garment-importing countries, and international organizations such as the UN, the ILO, the World Bank, and the IMF, among others. Some of these organizations surely intend well for the country and this industry, but others may have not-so-good intentions (such as protectionist forces). Those with good intentions provide feedback, constructive suggestions, and financial and material support for the improvement of the industry, particularly with respect to the industry’s long-term viability and sustainability issues, so that it can stay as a responsible partner and player on the global stage.

Turning to sustainability, this issue has drawn serious global attention in recent decades. The UN itself has initiated goals and action plans to achieve sustainability in terms of the UN’s Millennium Development Goals (MDGs), followed by, at its expiration, the 2030 Agenda for Sustainable Development, launched on 1 January 2016 (

UN, 2015). This agenda has 17 Sustainable Development Goals (SDGs) in total. During these times, ESG (Environmental, Social, and Governance) has drawn the strong attention of researchers and policy makers. The SDGs and action plans and the ESG strategies focus on various aspects of sustainability and governance. Sustainability is a very broad concept that has many aspects and dimensions, such as economic sustainability, financial sustainability, social sustainability, demographic sustainability, and political sustainability, to name a few major ones. Sustainability can be understood or examined from a national perspective, a regional perspective, or a local perspective. Furthermore, sustainability can be understood and examined at the individual company or organization level, industry level, or country level.

Given the broadness of the sustainability issue, we focused in this paper on some social sustainability issues, which is one aspect of sustainability, among others. However, even social sustainability can have different sub-dimensions, such as environmental sustainability, or sustainability related to child labor issues, workplace safety, the gender gap, and the working environment, among others. Of the 17 SDGs mentioned above, some of them are related to social sustainability directly or indirectly. Of these 17 goals, 4 goals are related to social sustainability. These are Goal #1 (End Poverty For All), Goal #3 (Ensure Healthy Lives), Goal #5 (Achieve Gender Equality), and Goal #8 (Promote Sustained, Inclusive, and Sustainable Economic Growth, Full and Productive Employment, and Decent Work). To ensure that the scope of this paper is manageable, this paper will focus only on those selected major social sustainability aspects. There are other social issues that will not be addressed in this paper to keep focus on the above issues.

7.1. Child Labor Issue

Child labor issue is not new in the world, and it is found in most emerging and developing economies in the world. Child labor was utilized in the past in today’s advanced economies during their time of industrialization. Bangladesh is not unique in this respect. In this country, it is estimated that about 4.7 million underage children (5–14 years of age) are employed in 2022–2023 (

Wikipedia, 2024). Many of these are employed in rural areas (83%) such as in agriculture as well as in urban areas (17%) such as in domestic help, street vending, break breaking, various manufacturing industries (such as garment industry, leather and shoe industry, selling illicit products, begging, and some your girls may be trafficked into prostitution.

In the garment industry, there was a substantial number of underage employment during the initial growth phase of the growth of the industry in Bangladesh, especially during the 1980s and 1990s. During those periods, Bangladesh was exporting about 50% of its cheaper low value-added garments to the U.S. alone (

BGMEA, 2004). So, the U.S. market was very critical for this growing industry.

During the early 1990s, concerns were raised in the U.S. about cheaper garment imports that used child labor. A coalition was formed in the U.S. involving labor unions, some environmental groups, and consumer groups to start lobbying with the U.S. administration and the U.S. Congress, such as the Harkin Law named after Senator Harkin (although never passed), to ban cheaper garment imports from Bangladesh, citing the issue of child labor (

BGMEA, 2004). Most likely, their intention was not the welfare of the children in Bangladesh, but primarily to protect the U.S. domestic industry from cheaper imports from Bangladesh.

Given the above development in the U.S., the most important market for the country, the apex industry association of garment owners, the BGMEA (the Bangladesh Garment Manufacturers and Exporters Association) along with export companies became very worried about losing the most important market. To protect Bangladesh’s continued ability to export to the U.S. market, the BGMEA and the garment manufacturers became proactive and immediately started to take dramatic action to remove child labor from the garment industry. During this time, about 10% of the workers were underage children, numbering from 40 to 50 thousand child workers, mostly girls (

BGMEA, 2004).

The

BGMEA (

2004) and the manufacturers went into action to summarily dismiss thousands of underage children from the factories beginning in 1993, without giving any alternative option, such as schooling. This resulted in a serious adverse social consequence in the country in terms of poor families losing income, and the dismissed children, having no other alternative (such as schooling, which their families could not afford in the first place), were forced onto the streets to engage in activities such as street begging, working for street vendors, break breaking, domestic help (servants), and even dangerous work such as selling illicit products, and it is alleged that some young girls were trafficked into prostitution (

BGMEA, 2004). These adverse consequences raised serious social concerns in the country such as the civil society organizations, think tanks, the press, the government, and some international organizations such as UNICEF and the ILO.

In this situation, a solution started to evolve with initiatives from UNICEF (United Nations International Children’s Emergency Fund) and the ILO (the International Labor Organization), along with the BGMEA representing the garment manufacturers and with the blessings of the government. There was a MOU (Memorandum of Understanding) reached and signed among the above parties in 1995 to provide schooling and some income supplement to poor families for the displaced and dismissed children (

BGMEA, 2024). The UNICEF took the responsibility to provide non-formal schooling, and the ILO took the responsibility for verification and monitoring. This program became very successful in eliminating child labor from the industry.

However,

Reza (

2017) conducted a study of the issue of child labor in the garment industry in Bangladesh. The study focused on two Memorandums of Understanding (MoUs) to eliminate child labor from the garment industry and enroll those children in schooling programs. The first MoU was signed in 1995, and the second MoU was signed in 2000. This study reports that the industry did an outstanding job of removing under-aged children from formal garment factories and incorporating them into schooling. However, the study finds that some child labor is still employed in both formal and informal garment factories, but more so in the informal garment sector (

Reza, 2017). For the country as a whole, the attempts to eliminate child labor have made marginal progress at best, considering all sectors of the economy, including agriculture and informal sectors (

ILO, 2016).

Even though there may be remnants of child labor that still prevail, as per

Reza (

2017), it can still be concluded that Bangladesh’s garment industry has achieved remarkable progress in eliminating child labor from the industry. As a result, the Bangladeshi example is now considered by many as a model to replicate in other export-oriented industries in the country, such as leather and shoes, and, eventually, to other non-export-oriented manufacturing industries, informal service sectors, and the agricultural sectors. In addition, it is also considered a model for other countries to follow. The BGMEA now claims that the child labor issue has been successfully tackled and that Western concerns about the issue, particularly for the Bangladesh export garment industry, need to be put to rest. This big achievement in the child labor front is fully consistent with the social sustainability goals of both the SDGs (Goal #3 and Goal #8) and the social aspects of ESG.

However, it is important to note that child labor is not unique to the export garment industry in Bangladesh, but also in other sectors of the country, as well as in many other countries such as Vietnam, India, Pakistan, China, etc. It remains a global problem and needs attention to eliminate child labor from all different sectors in different countries in the world (

ILO, 2016;

US Department of State, 2021).

7.2. Low Wages and Income in the Bangladesh Garment Industry

Consistent with the goals of both the SDGs and ESG, low wages, income, and benefits are some of the major social sustainability challenges facing the garment industry in Bangladesh. There are also external concerns raised about the very low wages of garment workers. Unions in the also demand higher wages. The government of Bangladesh (henceforth, GOB) sets minimum wages for various categories of workers. According to the Minimum Wage Ordinance 1994, apprentices and helpers are to receive BDT 500 and BDT 930 per month, respectively. Often female helpers are discriminated against in terms of wage levels, and these wages are also often fixed far below the minimum wage rate. A survey conducted in 1998 showed that 73% of female helpers, as opposed to 15% of their male counterparts, did not receive even the minimum wage.

Table 5 reports the monthly wage of garment sector workers for ten Asian countries that are competitors to each other. The top monthly wage is reported for China at USD 491, which is distantly followed by Thailand at USD 228. Bangladesh ranks 6th from the top with an average wage of USD 163 per month and the lowest wage is for Lao PDR and Pakistan. In terms of distributional properties among the ten countries, the median wage is USD 172.5, which divides the distribution into two equal parts, with half of the countries above the median and half below. Bangladesh is below the median monthly wage. The distribution has wide variation across countries, as shown by a large standard deviation of 108.69.

The relatively low worker income in Bangladesh, accompanied by international concerns, has posed a major dilemma for the garment industry of the country. Low wage is a major source of competitive and comparative advantage for the industry in the highly competitive global apparel market. In addition, worker productivity in the garment industry is also lower than in other Asian countries. Hence, raising wages in a country with low productivity is likely to raise unit labor costs (wages divided by worker productivity), which may adversely affect their competitive advantage in the industry. On the other hand, low wages may cause worker unhappiness, low morale, high turnover, worker demonstrations, strikes, and shutdowns in demanding higher pay and benefits. These factors, directly and indirectly, may cause productivity to be reduced further in an already low-productivity environment.

Historically, the monthly wages in the Bangladesh garment sector have been very low. In 1990, it was only BDT 627, which gradually rose over time, as shown in

Figure 4. Lower wages and benefits have triggered significant labor unrest in different years to demand higher wages, benefits, factory safety, and working conditions. To mitigate the most recent labor unrest and to respond to international pressure, Bangladesh’s government moved to raise the monthly minimum wage for garment workers to BDT 8000 (USD 96), up from the previous BDT 5300 (USD 63) in September of 2018 (

PressXpress, 2024). In 2023, the government raised the minimum wage further by 56.25% from BDT 8000 in 2018 to BDT 12,500 in 2023 (about USD 115 at BDT 119 to USD exchange rate at that time) (

PressXpress, 2024). This is still considered low by the worker unions and the international community, but a move in the right direction, and it needs further adjustments upward in the future. Even though further progress is needed in improving income and wages, the progress made as of now could be described as achieving at least partial gains in the social sustainability goal of both SDGs (Goal #1 (Reduce Poverty), Goal #3 (Healthy Lives), and Goal #8 (Decent Work)) and ESG (Social Aspects). However, more progress needs to be achieved in this area.

7.3. Factory Accidents and Workplace Safety Issues

The manufacturing sector in Bangladesh in general and the garment industry in particular have been prone to various deadly industrial accidents over the years. Consistent with both the SDGs and the ESG strategy, these issues have become some of the major social compliance and sustainability issues facing the garment industry in Bangladesh. The most devastating industrial accident happened in 2013 with the collapse of the multistory Rana Plaza commercial building that housed several garment factories making and supplying Western brands. The collapse apparently happened due to structural failures, resulting in the death of more than 1100 workers and injuring many, and was one of the deadliest in the country’s history (

Paton, 2021). Just before this accident, another major industrial accident happened in 2012 with a fire in the garment factory named Tazreen Fashion factory that killed 112 workers and injured more than 200.

These back-to-back two major accidents caused uproar both at home and abroad. Many global apparel sourcing companies were also blamed for their system of contracting and subcontracting, which made it difficult to identify the sourcing companies whose products these factories are catering to. In addition, there were much delay in accountability and to give compensation to the victims or their surviving family members. In a paper published before these accidents,

Akhter et al. (

2010) provided some details of the frequency, severity, and some of the possible causes of industrial accidents in garment factories in Bangladesh, as shown in

Table 6 below.

This table indicates that these accidents have resulted in deaths (listed in column 3) and injuries (listed in column 4) to many workers. Some of the major causes listed in this table include inadequate fire exit doors, fire exit doors being locked or blocked by boxes and materials, and suffocation from smoke inhalation, among others (

Akhter et al., 2010).

The two back-to-back major deadly accidents raised serious awareness and concerns both nationally and internationally. In the past, Western brands would not care much or take any responsibility for worker rights and worker safety in the factories from which they sourced their products. After these high-profile and deadly recent accidents, there has been a lot of criticism in the press and public, both in the country and internationally. There was an urge to take responsibility and take action to ensure worker rights and worker safety at the workplace.

Since then, there have been mitigation efforts to increase building inspections and make buildings safer across the garment factories in Bangladesh. The BGMEA, the government, the press, and the public became engaged in addressing the issue. The international community also became engaged. The latter came forward and cooperated with the BGMEA, factory owners, and the government. All of these groups may be motivated by self-interest in addressing worker rights, occupational hazards, and worker and factory safety issues.

The brand owners generally do not own factories; instead, they just outsource to local factories and companies to obtain their needed supplies. However, in response to domestic and global outrage and criticisms, European Western brands such as Inditex, H&M, and Primark, labor unions, and factory owners (about 200 of the brands) came with a pioneering and landmark legally binding agreement signed in 2013. This agreement is known as the “Alliance” on fire and building safety for the industry to conduct independent inspections of the factories that supplied their products. The agreement required brands to collectively contribute funding for safety training and factory improvements where structural and other deficiencies are found. In addition, any company that the ILO found had violated the terms could be fined or expelled from the group (

Paton, 2021). A second but parallel initiative also emerged, known as the “Alliance for Bangladesh Worker Safety”, signed by American brands such as Walmart, Gap, and Target, that began in the same year. This agreement was less binding and less restrictive than the Accord agreement.

Both groups worked on improving building safety and making other building improvements, such as installing fire exits and fire extinguishers and improving fire safety from faulty electric connections and devices, just to name a few, as well as drastic measures, such as factory closures. For example, because of the Accord, 38,000 inspections were conducted and more than 120,000 fire, building, and electrical hazards were fixed in the country (

Paton, 2021). However, nearly 200 factories lost their contracts, with two million workers losing their jobs as an unintended consequence of the operations. It is to be noted that the efforts by both the Accord and Alliance contributed significantly to improving building safety and structural integrity in many factories in the garment industry and their efforts also led to the shutting down of many seriously deficient factories, according to

Paton (

2021) and

PressXpress (

2024). This, however, led to the dismissal of and ensuing joblessness of thousands of garment workers, as mentioned above. However, these agreements might be near expiration and cause serious concerns about the future of workers and building safety (

Paton, 2021). It is also to be noted that the BGMEA and the government cooperated with these initiatives. The government also conducted factory inspections and took corrective measures in many other factories. In addition, Bangladesh passed the Labor Act in 2006, which was later amended in 2018 to update the country’s labor laws with the contemporary world. The Labor Laws amended Act makes it mandatory to form a Safety Committee and an Elected Participation Committee in every factory. Subsequent amendments have set the groundwork for safeguarding workers’ rights, ensuring fair wages, reasonable working hours, and improved safety standards (

PressXpress, 2024). In 2022, Bangladesh’s Ministry of Labor and Employment launched a pilot program for an employment injury scheme in collaboration with the ILO for ready-made garment (RMG) workers.

With the expiration of the Accord and Alliance, a new body was formed, named the Ready-made Garments Sustainability Council to be overseen by the BGMEA and the expiring Accord (

Paton, 2021). The Board of this council will consist of 18 seats equally split between labor groups, global brand representatives, and factory owners (

Paton, 2021). This body, along with the government, must continue to carry the work forward with oversight, inspections, training, and remediation efforts and thereby contribute to improving building and worker safety going forward to mitigate this social compliance and sustainability challenge, as several thousand more factories remain unsafe for workers in the industry. The Accord and the Alliance provided a unique cooperative model or precedent for promoting factory safety that many other industries within Bangladesh and other emerging economies may try to replicate in their countries with international cooperation. Although more work needs to be completed, the achievements made so far moved the country forward towards achieving the social sustainability aspects of both the SDGs, Goal #3 Healthy Lives and Goal #8 Decent Work, and the social aspects of the ESG strategy. Further progress is surely needed in this area.

8. Worker Health Issues and Poor Working Environment

Other social sustainability issues would be health issues and work environment issues. These could be related to each other; in particular, the poor work environment may contribute to worker health issues. Many factories may be cramped with workers in very congested and overcrowded facilities with poor ventilation, inadequate fire exits, and poor sanitary conditions. Many garment factories in Bangladesh often compromise on the health and safety of workers because of the pressure from ordering companies to observe strict deadlines. Managers and supervisors of these garment factories will often push workers to make sure an order is met on a timely basis. In addition,

Paul-Majumder and Begum (

2000) found that workers, particularly female workers, face a variety of occupational health risks in their workplace such as poor health benefits, lack of health facilities inside the factories, lack of insurance against accidents and/or sickness and disease, poorly ventilated and congested workplace, inadequate ventilation in the rooms, dust and toxic materials floating in the air, and inadequate fire exists, among others, that adversely affect their health. In addition, there is very little support for providing medical and mental health support.

Paul-Majumder and Begum (

2000) examine the validity of the assumption that the export-oriented industry is supposed to maintain working conditions that are comparable to international standards because the industry produces for the international market. Therefore, export-oriented industrialization is supposed to have a positive impact on working conditions. However, the study reports that in most cases, the export-oriented industry is based on sub-standard working conditions. They also argued that the sub-standard working conditions in the garment industry affect men and women differently because they hold different job positions. Women suffer the worst because they hold low-skilled jobs where occupational hazards are greater. As such, the garment factories not only failed to meet international standards, but they even grossly violated the Factory Act of 1965 and the Factory Rules of 1979, which specify that every factory must have adequate staff amenities. In all garment factories surveyed, staff amenities are grossly insufficient. For example, on average, the study finds that there was only 1 latrine per 61 female workers, compared with 1 for every 31 male workers. In addition, garment workers suffer from the absence of a lunchroom, a lack of pure drinking water, and a lack of canteen facilities and/or breakroom.

The above creates a serious social compliance problem because there are few ways for workers in general and female workers in particular to file complaints against management. Almost none of the factories have any kind of human resources department and local officials often turn a blind eye to violations in garment sectors. Moreover, most of these workers are uneducated poor women. As such, many workers, especially female workers, either do not have the knowledge, courage, or ability to speak out against an unjust work environment. In addition, the fear of losing jobs would prevent them from lodging complaints. As such, the poor working conditions prevail in many factories.

Although the situation has been improving, many health-related problems persist and may contribute to low employee morale, high turnover, and low productivity. These workers bring good profit to the factory owners and the country’s development, but their health issues are not properly taken care of. It is recommended that factory owners should pay more attention and provide more financial, medical, and mental health support to affected workers. The extra costs would be worth investing in because it is expected to be paid off by higher morale, less absenteeism, less turnover, and higher productivity of workers. Consistent with both the SDGs (Goal #3 (Healthy Lives) and Goal #8 (Decent Work)) and the social aspects of the ESG strategy, the improvements made are encouraging but partial, and, hence, more needs to be accomplished in this area as well.

8.1. Long Working Hours

Workers in the garment factories are reported to work very long hours and with low wages. From a worker’s perspective, as wages are low, some may voluntarily work long hours to make ends meet to support their poor families. Many may also work long hours to meet production and delivery quotas and deadlines for international orders facing the companies. The RMG factories claim to operate one eight-hour shift six days a week. However, available information shows that women are virtually compelled to work more hours and sometimes work late into the evening; sometimes they work until 3 o’clock in the morning and report back to start work again five hours later at 8 o’clock in the morning. They are asked to work whole months at a time, violating the Factory Act, which stipulates that no employee should work more than ten days consecutively without a break. The articles by

Paul-Majumder and Begum (

2000) and

Kabeer and Mahmud (

2004), among others, have discussed these issues in their respective papers. Consistent with the SDGs (Goal #3 (Healthy Lives) and Goal #8 (Decent Work)) and ESG strategy, significantly more progress needs to be made in reducing long working hours.

8.2. Gender Disparity

Most garment workers come from rural areas who do not have much education and skills, are generally young and unmarried, come from very poor and desperate families, generally have no experience in factory work (

Paul-Majumder & Begum, 2000), and are eager to have some employment opportunities to help their needy families. There is a big supply of such women in Bangladesh. As they venture to move to cities to find work in the export garment industry, they are happy that they have a job and earn some income to maintain their families. In fact, the garment industry has opened doors for female employment at a large scale for the rural mostly uneducated (or less educated) women. These opportunities have led to the improvement of family income and family status, a boost of self-confidence and self-esteem, the empowerment of women in family decision-making in a mostly male-dominated society, poverty reduction, and the overall socio-economic upliftment of millions of these workers who would not have any better alternatives. In this sense, the export garment industry made a remarkable contribution to the female labor force in the country. The study by

Paul-Majumder and Begum (

2000) seems to have found these positive improvements in the garment sector employment.

However, it is noted that many female workers face gender disparity in work, employment conditions, allocation of positions, work environment, and wages and benefits. In the garment industry, most tasks are allocated largely based on gender. This determines worker compensation and benefits. In these factories, many different tasks need to be performed by workers such as cutting, sewing, inserting buttons, making buttonholes, checking, cleaning the threads, ironing, folding, packing, training, quality control, and supervising, all the way up to managing. It is not surprising that the pay structure for these tasks is not the same.

The study by

Paul-Majumder and Begum (

2000) examined the validity of the assumption that the terms and conditions of employment in the export-oriented garment industry are gender-differentiated. They found that the earnings based on data from surveys of 1990 and 1993, a female garment worker earns only 58 percent of a male worker’s earnings compared to non-export industries, where females earn 60 percent of male earnings. In terms of pay increases, it was found that female employees fared worse than their male counterparts. In addition, the study found pay increases were more pronounced in higher-level jobs than the lower-level ones. The higher-level jobs such as supervisory work, quality control work, and managerial positions were assigned more to male workers than to female workers, and female workers were more likely assigned to unskilled and temporary jobs, generally, in sewing and finishing work, where wages are lower. These factors also contributed significantly to exaggerating the gender gap. The surveys reveal gender differences in earnings in every job category in the garment industry. It thus seems clear that the garment industry in Bangladesh needs to make significant progress in reducing gender disparity in the workplace to achieve the SDGs (Goal #5: achieve gender equality) and the social aspects of the ESG strategy.

9. Summary, Conclusions, and Limitations

This study focused on two critical aspects of the export garment industry in Bangladesh: firstly, the growth and development of the industry over time and, secondly, to discuss some selected social compliance and social sustainability issues facing the industry. For the first issue, this paper used more elaborate, longer, and more up-to-date data to analyze the growth and development of industry including the sensitivity of total exports of the country to changes in garment exports, both variables measured in real (inflation-adjusted) terms. The study found continued strong trend growth over the years, and this growth was very resilient to changes in global economic crises and the COVID-19 pandemic. The study also found that garment exports contribute more than 80% of total exports and employ millions of workers, the majority of whom are female workers, and about 12% of the country’s GDP. In addition, the study found, based on the regression analysis, that the country’s total real exports were sensitive to real garment exports, but the elasticity was found to be less than unity. The implication is that both total exports and garment exports move together, and both seem to be generally stable over time, with some risk of instability in cases of serious disruptions, such as the 2019 pandemic (see

Figure 3) and the discussion there.

On the second issue related to sustainability, the paper examined some serious social compliance issues, namely child labor, worker wages and income, worker safety at the workplace, gender disparity, long working hours, and poor working conditions. The child labor issue has been successfully tackled with the help and cooperation of the BGMEA, the ILO, UNICEF, and the government and factory owners. This has become a model for other industries in the country, as well as other countries, to follow. As such, this can be considered a success story.

On other social compliance issues as per the UN’s SDGs and ESG (focusing on social aspects) strategies and practices, such as worker safety at the workplace, wages and income, gender gaps, and working environment, there is a serious deficiency still prevailing in the industry in terms of complying with the country’s labor laws, as well as international standards and external concerns and expectations. It is to be noted, however, that the BGMEA, the factory owners, and the government are aware of the social compliance issues discussed in this paper, they understand their significance for the survival of the industry in the global context and have acted upon these issues over time for improvements (

BGMEA, 2020). There have been substantial improvements over the years due to these efforts; however, much more remains to be completed to make the industry more socially compliant in line with social and industry norms, international expectations and standards, and the overall sustainability of the industry for years to come. It is highly recommended that the government act wisely and effectively in collaboration with the BGMEA, factory owners, and international partners (the ILO, UNICEF) to improve compliance with various social compliance regulations, agreements, and practices in the industry. Many of these regulations and agreements should not be only on paper but, rather, more seriously enforced. The allegations of widespread corruption, lack of political will, political interference, and other factors may lead to non-enforcement and/or poor enforcement that may delay or hinder needed improvements. These changes must happen to ensure the long-term viability and sustainability of the industry and thereby preserve its place in the global marketplace.

This paper has some limitations. First, the addresses only selected major aspects of social sustainability. As such, some other social aspects of sustainability are not discussed. Secondly, various economic and environmental sustainability issues were not addressed either. Thirdly, while very important, issues such as global supply chain and logistics issues facing Bangladesh’s garment trade (see

Florido-Benitez, 2024;

Siddiqui & Vita, 2021) across nations were not addressed. This and the other two issues mentioned here fall far beyond the social sustainability focus of this paper. Future studies may address these issues.

Finally, it should be mentioned that the lessons learned from this paper for Bangladesh’s export garment industry will have implications for similar other Asian, African, Caribbean, and Latin American countries. In addition, any comparative study of similar countries across different regions will shed further light on the social sustainability issues facing them.