Abstract

The need to update an enterprise quality management system (QMS) seems to be more urgent each time. Without adequate updating, the system may not be capable of responding to market changes, generating delivery delays and increasing customer costs and losses instead of allowing industries to improve product quality and services, reduce costs, and increase customer satisfaction. Thus, the present research deals with a case study of a Mexican metal mechanics industry certified to ISO 9001:2015 with the need to update its operating QMS. Due to reasons for growth, the industry has added new activities to the processes and modified others, working in the integration area to improve efficiency and efficacy. Therefore, an analysis of strengths, opportunities, weaknesses, and threats (SWOT) was performed. The status of the processes was evaluated, creating a document with new activities and updating those that showed non-compliance. The results of this investigation have the purpose of contributing to the importance of QMS empirical evidence in emerging countries and increasing quality studies in Mexican industries.

1. Introduction

Enterprises currently carry out their operations in a world characterized by global and competitive markets where clients demand better products and services. Due to this situation, organizations resort to implementing quality management systems (QMSs) with the purpose of increasing organizational performance and efficiency in processes and operations [1]. Thus, a QMS allows the organization to promote a culture oriented to quality and favor obtaining such results as behaviors, attitudes, activities, and processes that provide value by means of achieving the needs and expectations of the clients and stakeholders [2].

As part of the diverse standardized norms that establish the requirements and guidelines to implement a QMS, the ISO 9001:2015 norm is among the most widely recognized at the world level and applicable to any type of organization, regardless of its size and nature. This norm provides the infrastructure, procedures, processes, and necessary resources to help the organizations control and improve their yield and direct them towards efficiency, customer service, and product excellence [3]. The requirements for ISO 9001:2015 are generic and may be applied to any organization, regardless of its size, economic sector, products, and/or services provided [4].

Within the industrial economic sector, the metal mechanics industry is dedicated to manufacturing and transforming metals, machinery, and industrial equipment. According to México Industry [5], this manufacturing industry contributes close to 14% of the gross domestic product (GDP) in Mexico, where 305 metal mechanics economic units exist. The federal Mexican states that stand out with the largest number of metal mechanics manufacturing companies are Nuevo León (43), Mexico State (42), and Jalisco (32), while Sonora has six units. An important fact is that Sonora, jointly with Mexico City (CDMX) and Sinaloa, represents the greatest opportunity for developing this industry [6].

Additionally, Mexico Industry [7] points out that the negotiations established in the United States-Mexico-Canada Agreement (T-MEC, for its abbreviation in Spanish, Tratado Mexico-Estados Unidos-Canada) represent a great opportunity to develop the required technology in this country to perform the processes demanded by the metal mechanics industry. Consequently, tariffs, costs, and other competitive advantages are considered, which have an influence on increasing the capacities of Mexican industries.

It is important to mention that a Mexican metal mechanics enterprise established in the state of Sonora was selected as the object of study for this investigation and certified to the ISO 9001:2015 norm. However, a negotiation started with an international high-profile client who requested the production and delivery of new products—some of which form part of the enterprise integration area—that have experienced changes in their activities to comply with the specifications of the parts and components requested by the clients. Therefore, differences have been found between the documentation already performed and current processes; likewise, the need exists to establish markers that allow evaluation of the performance of the modified processes.

Due to the previous situation, updating the QMS was set up in the integration area of the organization in November 2021 with the purpose of identifying the processes that had added or modified activities. The documentation of such activities was performed by updating the organization chart of the integration area and assigning the responsible persons for the current processes as well as their markers to evaluate their performance. Updating the QMS facilitates improving process control, which also leads to reduced waste, decreased costs, and increased client satisfaction with their expectations, generating an increase in organization efficiency. National executives should be aware of the importance of quality management in processes, besides the fact that studies such as this one facilitate understanding the advantages generated by implementing QMS in the organizations of emerging countries.

2. Updating Empirical Quality Management Systems

In the search for client satisfaction and other parties of interest, the companies implement quality management with the purpose of guaranteeing the adequate processes and quality improvement of the products or services offered [8]. Quality management is established as a key and essential element for institutional success since it allows satisfaction and maintains competitiveness in the environment where the organization develops [9].

Escutia [10] explains that in quality management, the environment and security are aspects that play a fundamental role in organizational success and reputation since they affect client satisfaction, legal compliance, and operational efficiency. On the one hand, Díaz [11] indicates that the QMS is the interaction between the parties to the organization focused on achieving quality objectives to satisfy the needs, expectations, and requirements of the interested parties.

On the other hand, León et al. [2] consider the QMS as a set of policies, objectives, processes, documents, and resources that lead to ensuring the organization’s quality as a whole, searching to comply with client needs and requirements. Murrieta et al. [12] explain that implementing a QMS allows companies in any business sector to go in depth to improve processes, including environmental and social aspects, to strengthen the organizational structure and trust perceived by the client when quality products are acquired.

Empirical studies that have implemented a QMS and have had the need to update it later on are available in specialized literature, such as Peña [13] in Colombia. This author demonstrated that the QMS evaluation of the current state of a laboratory evidenced the need for attending five procedures (effective communication, information security, risk identification, supplier selection and evaluation, and validation and testing method confirmation), which showed the need for creating and/or updating their documentation. The established markers were also evaluated, with the greatest fault located in the marker evaluating client continuity in sales.

The need for unifying institutional documents was pointed out by Zarama [14] in a work performed at a Colombian university, which conveyed optimizing the QMS and dealt with the requirements of the collaborators involved in the organization. New formats and registries were made and used to perform new documentation of the affected processes. Likewise, internal auditing quality was identified as the appropriate instrument to verify the correct functioning of the QMS.

Fernández [15] set out reviewing and updating the processes in a Colombian hospital due to the existence of problems, such as loss of documents and difficulties sharing information with other members or clients of the company, generating bad service. An initial diagnosis pointed out the need for updating 10 processes and identifying the documents that needed to be created or modified. Internal audits were recommended to detect failure modes and create a high level of conscience in the leaders of the processes for maintaining the QMS documents.

A study by Acosta et al. [16] showed a Colombian construction corporation that implemented a QMS according to ISO 9001:2008 [17] and set out updating ISO 9001:2015 [4] with the interest of being more competitive and obtaining adequate risk management and continuous improvement. An initial diagnosis was carried out with the intention of identifying the processes that needed to be updated and the documentation that had to be created or modified. This author recommended the participation of an external advisor as an active part of the QMS updating process.

Vizueta [18] analyzed a container company in Ecuador with the objective of improving the QMS yield of the administrative department. Firstly, the processes that should be updated were identified, which were internal control, human resources, accounting, import, and industrial security. Secondly, a training plan for the staff was recommended for socialization and integration of these new processes.

Zamorano [19] performed a study on a Mexican enterprise in the aerospace industry that had accelerated growth generated by an increment in sales. The company saw the need for implementing a QMS to have a formal process to verify their operations, fabrication processes, and documental procedures, facilitating follow-up on corrective actions for possible quality problems.

The studies previously mentioned set up the conditions favoring updating the QMS in an organization. For example, those that could be mentioned are the desire to achieve reaccreditation in a norm, obtain improvement in the processes and unify documents, have the intention of increasing enterprise competitiveness, and take advantage of its growth, among others.

3. Methods: Case study

The method used in the present research is a case study, in which Yin [20] points out that the capacity of studying cases in depth allows the possibility of investigating the causal complexity where various relevant factors may exist but with few observations. For Bernal [21], the objective of a case study is to analyze in depth or in detail a specific analysis, which may be a person, an institution or enterprise, a group, and so on. Likewise, Hernández et al. [22] set out that case studies “analyze a unit in depth to respond to a problem-solving approach, prove the hypothesis, and develop a theory”.

Therefore, the purpose of the present research is to analyze the case of a manufacturing company that has required updating its QMS as a consequence of taking advantage of growth opportunities in the market. In this manner, the company improves the processes, minimizing waste of any type (waiting, transport, rework, defects, among others) and, in consequence, increasing organizational efficiency.

Study Objectives and Procedures

The present case study was performed in a metal mechanics manufacturing company located in Northwestern Mexico and focused particularly on the integration area since it is the last link in the production process. Additionally, the area is in charge of performing deliveries to the clients. The directors expressed that the request for new pieces and components provoked the addition and modification of activities in some processes. Therefore, the project has as its objective to update the QMS within this area to enable consistency in improving processes and greater organizational efficiency.

The steps performed for developing the company QMS update were the following: (1) identifying the processes that constitute the integration area; (2) evaluating the current status of the QMS of the integration area; (3) evaluating the current processes against the QMS current documentation; (4) updating the documentation of the processes and defining the markers for the processes, which are described as follows:

Firstly, the processes and activities that impact the integration area were defined by elaborating on the proposal of an updated organization chart. A SWOT (strengths, weaknesses, opportunities, and threats, FODA in Spanish) analysis was performed to establish the current state of the area, since the ISO 9001:2015 norm indicates that the organization should determine the internal and external matters that are pertinent for its purpose and strategic direction, which affect its capacity to achieve the results foreseen by the QMS.

The QMS degree of compliance within the integration area was identified with respect to that established in the ISO norm, comparing the content of the current documentation with the verification list that determines the compliance of the ISO 9001:2015 norm numbers. Subsequently, the status of the current processes was evaluated against the previous documentation within the QMS, highlighting two possible results of the evaluation: new activity or lack of updating.

The documentation of the activities added to the processes was also performed by updating those that resulted in incompliance; key opportunity areas were identified for the marker allocation proposal to know the level of efficiency in the integration area. A traffic light scheme was proposed to detect promptly when the expected results are not obtained.

4. Results and Discussion

4.1. Identifying Processes and SWOT Analyses

The processes and their activities—currently constituting the integration area—were determined; and the responsible persons for each process were identified (see Table 1):

Table 1.

Processes and activities of the integration area.

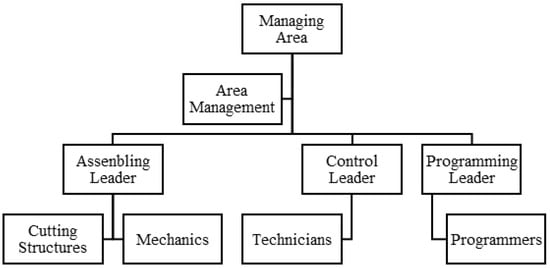

An organization chart of the area was proposed since it was operating with a non-official hierarchy, generating conflicts occasionally at the moment of decision-making (see Figure 1).

Figure 1.

An organization chart proposed for the Integration Area.

The organization chart should allow assigning new responsibilities and tasks to the staff area with the objective of involving the flow of information and decision-making in the new processes to update and execute them in an optimum manner. Source: Authors’ own production.

Table 2 deals with the results of the SWOT analysis developed for the integration area.

Table 2.

Analysis of strengths, weaknesses, opportunities, and threats (SWOT).

The previous SWOT shows similarities with the research performed by Castro et al. [23], Freire [24], and Alva et al. [25] in metal mechanics companies, who found that this type of company has a high technical capacity and commitment to their working teams. However, they also point out that in these companies, areas of opportunity are identified due to deficiencies in quality management.

Jointly with the previous SWOT results, the need for updating the QMS is established since the company was asked to produce new parts that required modifying the activities of the processes in the integration area. This situation represented an incorrect adjustment in the current QMS with respect to its respective documentation and markers for the processes, thus placing them at risk both in complying with the requirements of the demanded products and the expected satisfaction of the client.

4.2. Evaluation of the Current QMS Status within the Integration Area

An assessment was made with the minimum requirements from Chapter 4 to 10 of the norm ISO 9001:2015 with the purpose of evaluating the current integration area QMS status. This instrument was made taking as reference the one used by Ruiz [26] and sent by electronic mail to the integration area manager and the responsible persons for assembling, control, programming, and management processes; one week was considered for their response, and they were asked to send it back by electronic mail (see Table 3):

Table 3.

Instrument used to evaluate the current quality management system (QMS).

For the headings considered not applicable within the area, “N.A.” was applied and not contemplated for evaluation. Table 4 points out the results of each chapter of the norm evaluated.

Table 4.

Current quality management system requires diagnostic evaluation.

The QMS evaluation studies of the metal mechanics industry were performed by Torres and Carriel [27], Arce [28], and Fernández [29]. The low compliance levels in headings such as planning, performance evaluation, improvement, organization, and leadership context are derived from QMS organization incompliance. This incompliance urged the industries to update the QMS to improve process and product performance, besides complying with quality objectives.

4.3. Evaluation of the Current Processes in the Area Against the Existing QMS Documentation

The processes that are currently developed in the integration area were evaluated to collate them against the existing QMS initial documentation and identify the changes suffered by the processes and activities since the initial documentation for the ISO 9001:2015 certification. Three criteria were applied here: updated, lack of updating, or new process (see Table 5).

Table 5.

Evaluation of the current processes against the current quality management system (QMS) documentation.

The studies of Millán and Lache [30] and Duarte [31] show the convenience of reviewing the documentation of the processes to verify the needs of using and/or possible opportunities for improving and thus debugging the QMS documentation. Furthermore, the documentation allows defining the scope and a clear definition of the posts within the organization, which allows better identification of the responsible persons and authorities of the processes developed.

4.4. Updating the Process Documentation That Impacts the Integration Area

Table 6 lists the processes and working instructions that suffered modifications or were documented as new processes. Additionally, the identification code was added according to the QMS currently used by the investigated organization.

Table 6.

Quality management system (QMS) currently updated.

Table 7 shows the current processes in the integration area and their corresponding activities.

Table 7.

Updated processes in the integration area.

As an example, Table 8 shows part of the format used for updating the assembly process documentation.

Table 8.

Format for assembling documentation.

4.5. Definition of Markers for the Integration Area Processes

The following markers were proposed to evaluate if the integration area is efficiently developing its activities:

- Client satisfaction: The integration area is in charge of delivering the product to the client and, thus, has an optimum position to evaluate the project developed.

- Adding components to the project: This marker intends to evaluate the purchasing area and warehouse, which have the responsible staff to provide all the supplies (components) to carry out the project. Commonly, many components exceed or, even worse, are lacking; thus, in both cases, waste happens.

- Parts received with late delivery: This marker intends to evaluate delivery dates from the machining area to the integration area compared to the date met for the total delivery of the parts per project. Thus, delays in the final delivery date are evident.

- Reworks: Allows identifying the percentage of reworks performed per project and also its responsible process.

Table 9 shows the design of the integration area markers, including the name of the marker, the formula to calculate it, and the evaluation metrics.

Table 9.

Markers for the integration area.

Some research works on proposals for metal mechanics industry markers are those performed by Castelblanco [32], Fuentes and Pinto [33], and Sánchez et al. [34], which show similarities in proposing markers such as client satisfaction, non-conformance products, and delivery time compliance, which denotes the importance for the enterprise of monitoring and evaluating these factors to reach optimum organization quality management.

4.6. Discussion

Updating the QMS of the company of interest provides formality to the changes performed in the affected processes due to the request to make new products. In the same manner, in the study by Zamorano [19], updating is performed because the company needs a formal medium to verify the processes and their activities and write the corresponding documentation to avoid problems in quality management that could generate increments in costs and decrease client satisfaction.

The results obtained in the present study also contribute to facilitating the possibility of renewing the ISO 9001:2015 norm certification that the company currently owns. For example, in the studies of Peña [13] and Acosta et al. [16], updating the QMS was performed with the purpose of obtaining the recertification of the NTC-ISO/IEC 17025 and ISO 9001:2015 norms, respectively.

The selection of the proposed markers was the result of working jointly with the senior management staff of the integration area and the respective responsible persons for the assembly, control, programming, and management processes. In this manner, the staff, from their own experience in their duties, expressed that evaluating the client is the means by which the areas needing improvement are identified. Furthermore, the components added to the project can be evaluated to avoid or decrease waste; the parts received out of time allow for delays in deliveries, and assessing reworks provides evidence on the corrections needed to be performed and avoids low productivity.

5. Conclusions

Today, world trends urge quality management in organizations of all commercial sectors and sizes to increase their possibilities of competing successfully in the market. However, few Mexican companies have had the capacity to confront first-level organizations. One of the roots of this problem has its origin in a lack of quality discipline and culture, which delays efficient improvement of processes, products, and services.

Therefore, the organizations should focus their efforts on adequate quality management—an essential task to survive in the current global markets. For this purpose, implementing a QMS reinforces the organization structure and allows the staff to understand the quality implications for the optimum compliance of client requirements and those of other interested parties. Nevertheless, the QMS are not static; in other words, they may not have the need to be updated as a consequence of factors such as the application of new requirements by the clients or performing improvements to the organization’s processes, among others.

The present research analyzes the case of a Mexican metal mechanics industry that exploited growth opportunities and the consequent need to increase its product supply. For this purpose, new activities were added to the processes and others were modified, which started to operate without documental reference or indicators assigned, causing reworks and delays in the organization’s integration.

To solve this situation, the proposal to update the QMS was accepted in the area to avoid implementing empirical measurements that could generate resource waste for the company. Initially, a new organization chart was made to determine lines of authority in the area, working with four processes. The assembling process was updated, adding three activities; the control process was updated, and three activities were added; the programming process was updated, and two activities were added. On the one hand, the management process required new documentation. Additionally, four markers were proposed to evaluate the efficiency of the integration area operation: (1) Client satisfaction; (2) Added components; (3) Parts received out of time; and (4) Number of reworks; these markers facilitate identifying the areas that may improve, as well as avoiding waste, delays in deliveries, the number of reworks, and low productivity.

It is convenient to mention that for updating the QMS, the work was conducted jointly with the manager of the integration area and the responsible persons from the assembly, control, programming, and management processes, who checked every added or modified process and activity and provided their authorization and validation according to their experience and what is expected by the corresponding norm.

The results obtained show similarities with diverse studies discussed in this research study, since our intention is to assist the organization (objective of the study) in performing the production of the new products requested to comply with the client’s requirements. Likewise, the intentions are to encourage quality management in Mexican enterprises of any sector that has the need to update their QMS. In this manner, the companies may obtain reaccreditation of any norm or deal or increment their capabilities to comply with the clients, who are each time more demanding in quality, time delivery of the products, and high-performance services.

The present research study showed that, as a limiting factor, working only with the integration area processes, future works should update the QMS of the other areas that conform to the studied metal mechanics company since a global evaluation of the level of compliance of such systems could be performed, and consequently, the areas of opportunity that may arise could be addressed.

Author Contributions

Conceptualization, J.C.L.-F. and E.A.L.-L.; methodology, J.C.L.-F. and E.A.L.-L.; formal analysis, J.C.L.-F. and A.B.-S.; writing—original draft preparation, J.C.L.-F. and R.D.F.-R.; writing—review and editing, J.C.L.-F., E.A.L.-L., R.D.F.-R. and A.B.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable

Informed Consent Statement

Not applicable

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sansalvador, M.; Brotons, J. Quality Cost Analysis: A Case Study of a Spanish Organization. Total Qual. Manag. Bus. Excell. 2013, 24, 378–396. [Google Scholar] [CrossRef]

- León, C.; Menéndez, A.; Rodríguez, I.; López, B.; García, M.; Fernández, S. Importancia de un sistema de gestión de la calidad en la Universidad de Ciencias Médicas. Rev. Arch. Méd. Camagüey 2018, 22, 843–857. [Google Scholar]

- Parra, G.; de la Ossa, J.; del Carmen, S. Diagnóstico de la Situación Actual de una Empresa de Servicios de Alimentación con Respecto al Cumplimiento de los Requisitos de la Norma ISO 9001:2015 para un Sistema de Gestión de la Calidad. SIGNOS, Investigación en Sistemas de Gestión. 2019. Available online: https://revistas.usantotomas.edu.co/index.php/signos/article/view/4937/pdf (accessed on 1 November 2023).

- ISO 9001:2015; Sistemas de Gestión de Calidad: Requisitos. ISO Publishing: Geneve, Switzerland, 2015. Available online: https://www.iso.org/obp/ui/#iso:std:iso:9001:ed-5:v1:es (accessed on 29 October 2023).

- Mexico Industry. Metalmecánica, Eje de la Cadena Productiva. 2022. Available online: https://mexicoindustry.com/noticia/metalmecanica-eje-de-la-cadena-productiva (accessed on 1 October 2023).

- Gobierno de México. Fabricación de Maquinaria y Equipo para la Industria Metalmecánica. 2023. Available online: https://www.economia.gob.mx/datamexico/es/profile/industry/metalworking-machinery-manufacturing?optionsSelector1=Economic%20Unit (accessed on 23 September 2023).

- México Industry. El T-MEC, Gran Oportunidad para la Industria Metalmecánica en México. 2021. Available online: https://mexicoindustry.com/noticia/el-t-mec-gran-oportunidad-para-la-industria-metalmecanica-en-mexico (accessed on 1 October 2023).

- Meza, E. Gestión de Calidad de los Servicios de Salud Ofertados por el Centro de Salud Tipo a Cotacachi del Instituto Ecuatoriano de Seguridad Social (IESS). 2022. Available online: https://repositorio.pucese.edu.ec/bitstream/123456789/3273/1/Meza%20Echeverr%c3%ada%20Eduardo%20Sebasti%c3%a1n.pdf (accessed on 20 September 2023).

- Naranjo, R. La Calidad del Servicio y Satisfacción de los Usuarios en el Instituto Ecuatoriano de Seguridad Social IESS. 2020. Available online: https://repositorio.uta.edu.ec/jspui/bitstream/123456789/31521/1/04%20ADP.pdf (accessed on 22 September 2023).

- Escutia, L. Diseño e Implementación del Sistema de Gestión de Calidad, Medio Ambiente y Seguridad y Salud Conforme a las Normas ISO 9.001, ISO 14.001 e ISO 45.001 en una Empresa Especializada en Instalaciones de Telecomunicaciones. 2023. Available online: https://riunet.upv.es/bitstream/handle/10251/196608/Escutia%20-%20Diseno%20e%20implementacion%20del%20sistema%20de%20gestion%20de%20calidad%20medio%20ambiente%20y%20seguridad%20y%20....pdf?sequence=1&isAllowed=y (accessed on 20 September 2023).

- Díaz, J. El Primer Libro: Guía Para Implementar un Sistema de Gestión de Calidad. Gandhi Pública. 2018. Available online: https://books.google.com.ec/books?id=PGhRDwAAQBAJ&printsec=frontcover&source#v=onepage&q&f=false (accessed on 2 October 2023).

- Murrieta, Y.; Ochoa, E.; Carballo, B. Reflexión Crítica de los Sistemas de Gestión de Calidad: Ventajas y Desventajas. Rev. En-Contexto 2020, 8, 115–132. [Google Scholar] [CrossRef]

- Peña, P. Actualización del Sistema de Gestión de Calidad en MASCOLAB SAS Sede Medellín Conforme a los Requisitos de la NTC-ISO/IEC 17025: 2017. 2019. Available online: https://repositorio.ucundinamarca.edu.co/bitstream/handle/20.500.12558/2839/ACTUALIZACI%C3%93N%20DEL%20SISTEMA%20DE%20GESTI%C3%93N%20DE%20CALIDAD%20EN%20MASCOLAB%20S.A.S%20SEDE%20MEDELL%C3%ADN%20CONFORME%20A%20LOS%20REQUISIT.pdf?sequence=1 (accessed on 11 September 2023).

- Zarama, O. Propuesta para la Unificación de Documentos Institucionales: Estrategia Clave para Optimizar, Actualizar y Asegurar el Sistema de Gestión de Calidad Nacional (SGC) SIAC en Línea-USTA Colombia, Universidad Santo Tomás. 2019. Available online: https://repository.usta.edu.co/bitstream/handle/11634/19224/2019OscarZarama.pdf?sequence=11&isAllowed=y (accessed on 13 September 2023).

- Fernández, S. Ajuste de la Documentación del SGC en los Procesos Misionales del Hospital Nuestra Señora de los Santos de la Victoria Valle de Acuerdo a la Norma ISO 9001: 2015. 2019. Available online: https://bibliotecadigital.univalle.edu.co/server/api/core/bitstreams/cfa7aaaa-6a24-450a-a1fa-ee4e08b1e5c3/content (accessed on 19 September 2023).

- Acosta, Á.; Cerón, J.; Morales, C.; Torres, D. Formulación de un Plan Para la Actualización del Sistema de Gestión de la Concepción Pacifico Tres SAS, Según la Norma ISO 9001: 2015. 2020. Available online: https://repositorio.ucm.edu.co/bitstream/10839/3065/1/%c3%81NGELA%20MAR%c3%8dA%20ACOSTA%20CASTRO.pdf (accessed on 19 September 2023).

- ISO 9001:2008; Sistemas de Gestión de Calidad: Requisitos. ISO Publishing: Geneve, Switzerland, 2008. Available online: https://www.iso.org/obp/ui/#iso:std:iso:9001:ed-4:v2:es (accessed on 29 January 2024).

- Vizueta, A. Actualización del Sistema de Gestión de Calidad Basado en la Norma ISO 9001: 2015 de una Empresa de Servicio de Mantenimiento y Reparación de Contenedores para la Mejora del Desempeño Laboral del Área Administrativa en la Ciudad de Guayaquil. 2021. Available online: https://dspace.ups.edu.ec/bitstream/123456789/20756/1/UPS-GT003340.pdf (accessed on 14 September 2023).

- Zamorano, M.; Anaya, M. Desarrollo de una Metodología para un Sistema de Gestión de Calidad en Base a la Norma ISO 9001 en los Procesos Clave de la Empresa SELLUS PRECISION. 2023. Available online: https://investigadores.unison.mx/es/studentTheses/desarrollo-de-una-metodolog%C3%ADa-para-un-sistema-de-gesti%C3%B3n-de-calid (accessed on 12 September 2023).

- Yin, R. Case Study Research: Design and Methods, 4th ed.; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Bernal, C. Metodología de la Investigación, 4th ed.; PEARSON: Bogotá, Colombia, 2016. [Google Scholar]

- Hernández, R.; Fernández, C.; Baptista, P. Metodología de la Investigación, 5th ed.; McGraw-Hill/Interamericana Editores, S.A. de C.V.: Ciudad de México, Mexico, 2010. [Google Scholar]

- Castro, C.; Gamarra, J.; Rojas, A.; Villena, L. Planeamiento Estratégico Agregado Para la Empresa: Corporación Comercial Jerusalén. 2015. Available online: https://tesis.pucp.edu.pe/repositorio/bitstream/handle/20.500.12404/14312/CASTRO_GAMARRA_PLANEAMIENTO_JERUSALEN.pdf?sequence=1&isAllowed=y (accessed on 16 October 2023).

- Freire, J. La Competitividad de la Industria Metalmecánica de la Provincia del Guayas y su Incidencia en las Exportaciones del Ecuador Hacia la Comunidad Andina de Naciones (CAN): Una Propuesta de Gestión de Desarrollo Estratégico del Sector. 2019. Available online: https://cybertesis.unmsm.edu.pe/bitstream/handle/20.500.12672/10699/Freire_mj.pdf?sequence=1&isAllowed=y (accessed on 15 October 2023).

- Alva, R.; Durán, D.; Guzmán, G. Plan Estratégico de la Empresa Corporación de Ingeniería Metálica S.R.L. 2017. Available online: https://repositorio.up.edu.pe/bitstream/handle/11354/2062/Rocio_Tesis_Maestria_2017.pdf?sequence=1&isAllowed=y (accessed on 12 September 2023).

- Ruiz, N. Diagnóstico Inicial para la Implementación de la Norma ISO 9001:2015 en Remarq S.A.S. 2017. Available online: http://hdl.handle.net/10654/17269 (accessed on 27 December 2023).

- Torres, C.; Carriel, J. Propuesta de Mejora Continua para la Calidad del Servicio en una Empresa Metalmecánica de la Ciudad de Guayaquil Basada en la Norma ISO 9001:2015. 2023. Available online: https://dspace.ups.edu.ec/bitstream/123456789/24848/4/UPS-GT004333.pdf (accessed on 22 September 2023).

- Arce, C. Diseño del Sistema Integrado de Gestión en una Empresa Metalmecánica y de Servicios de Salud. 2018. Available online: https://red.uao.edu.co/bitstream/handle/10614/10466/T08134.pdf;jsessionid=A234BD22B9A63E4C41676E9CA7573165?sequence=5 (accessed on 25 September 2023).

- Fernández, N. Migración de un Sistema de Gestión de Calidad Basado en la Norma ISO 9001:2008 a la Norma ISO 9001:2015 en una Empresa Metalmecánica. 2020. Available online: https://cybertesis.unmsm.edu.pe/bitstream/handle/20.500.12672/11621/Fernandez_tn.pdf?sequence=1&isAllowed=y (accessed on 23 September 2023).

- Millán, J.; Lache, A. Rediseño del Sistema de Gestión de la Calidad a Través de Metodologías de Mejora de Procesos para Incrementar la Productividad en una Empresa Metalmecánica de Bogotá. 2018. Available online: https://repository.usergioarboleda.edu.co/bitstream/handle/11232/1164/Redise%C3%B1o%20del%20Sistema%20de%20Gesti%C3%B3n%20de%20la%20Calidad%20a%20trav%C3%A9s%20de%20metodolog%C3%ADas%20de%20mejora.%20Metalmec%C3%A1nica%20de%20Bogot%C3%A1.pdf?sequence=1&isAllowed=y (accessed on 22 September 2023).

- Duarte, P. Propuesta de Desarrollo de un Sistema de Gestión de Calidad para una Empresa Metalmecánica Pequeña, Basado en la Norma ISO 9001:2015. 2019. Available online: https://repositorio.uchile.cl/bitstream/handle/2250/170637/Propuesta-de-desarrollo-de-un-sistema-de-gesti%C3%B3n-de-calidad-para-una-empresa.pdf (accessed on 19 September 2023).

- Castelblanco, K. Indicadores de Gestión de Calidad en Empresas del Sector Manufactura. 2016. Available online: https://repository.uamerica.edu.co/bitstream/20.500.11839/6999/1/07061509389-2016-II-GC.pdf (accessed on 25 September 2023).

- Fuentes, T.; Pinto, E. Diseño de un Sistema de Indicadores de Gestión en una Empresa Metalmecánica. 2009. Available online: https://laccei.org/LACCEI2009-Venezuela/p145.pdf (accessed on 23 September 2023).

- Sánchez, N.; Velosa, J.; Ramírez, J. Planificación y Estructuración de Sistema de Gestión de Calidad para la Empresa Diseño e Ingeniería Metalmecánica S.A.S. bajo los Lineamientos de la Norma NTC ISO 9001:2015. 2018. Available online: https://repository.usta.edu.co/bitstream/handle/11634/15379/2018javiervelosa.pdf?sequence=8 (accessed on 17 September 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).