Optimization of Kaolin Clay Composition for Enhanced Mechanical Properties in 3D-Printed Structures

Abstract

1. Introduction

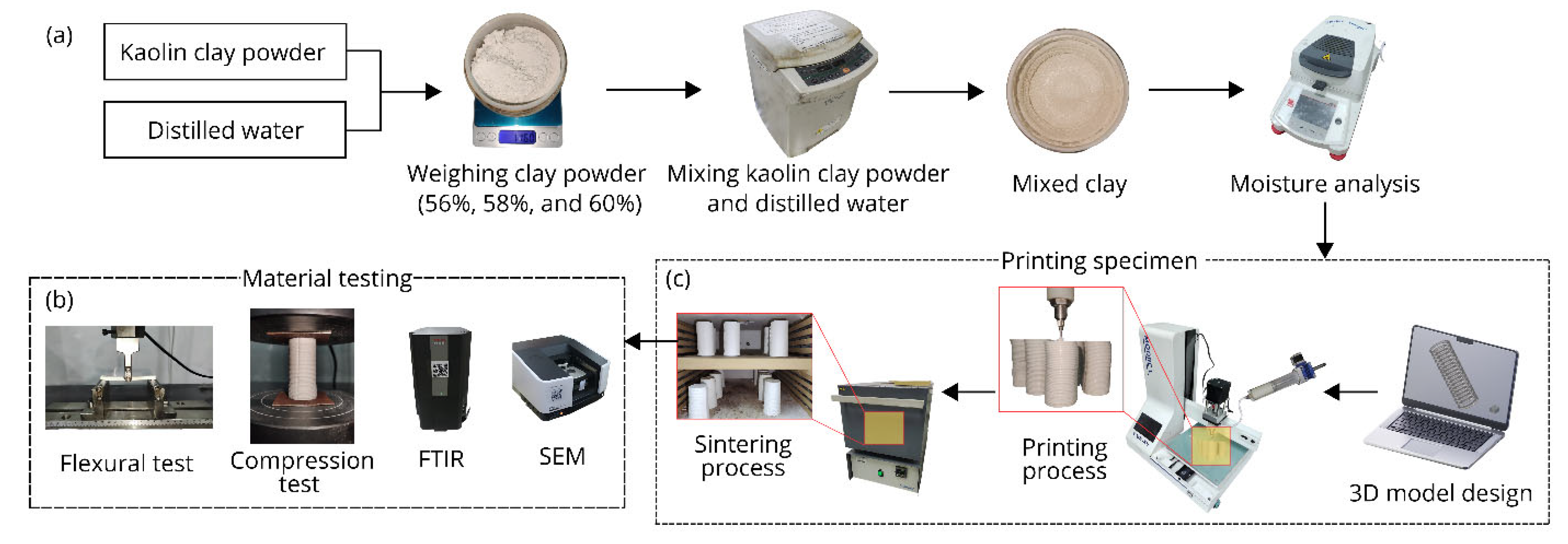

2. Materials and Methods

2.1. Materials Preparation

2.2. Mixing of Clay Mixture

2.3. Moisture Content Analysis

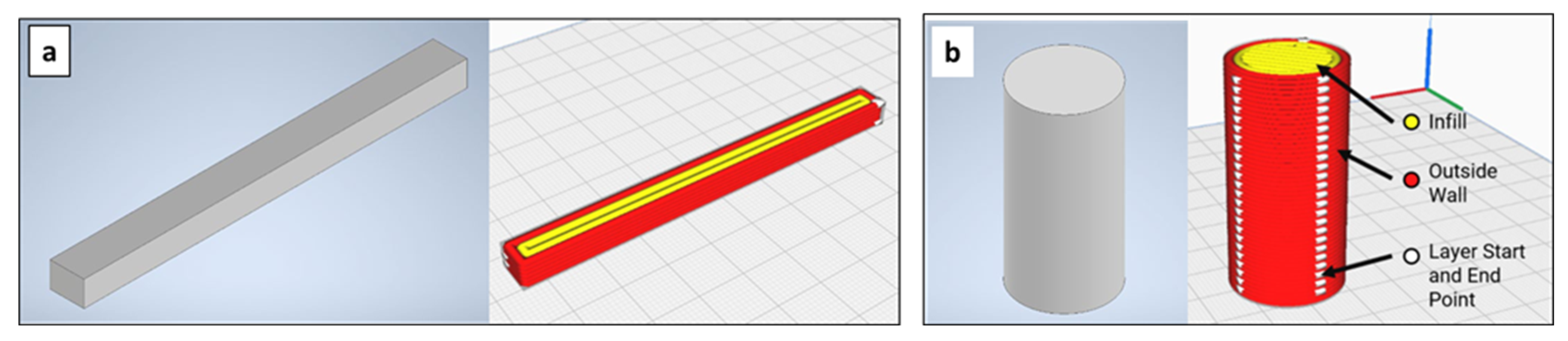

2.4. Three-Dimensional Modeling and Slicing of Specimen

2.5. Printing Process

2.6. Sintering

2.7. SEM and FTIR

2.8. Flexural Testing

2.9. Compression Testing

3. Results and Discussion

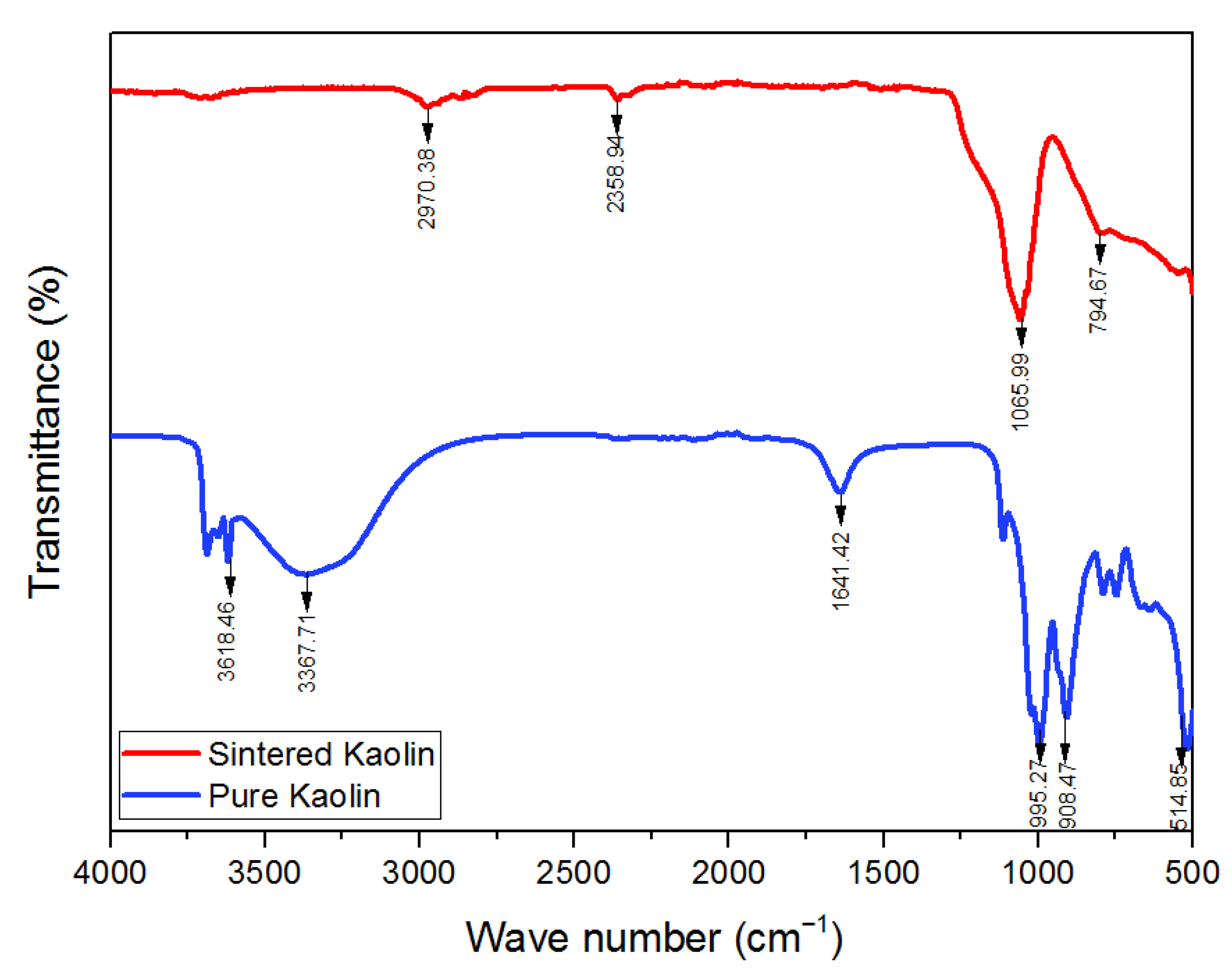

3.1. FTIR Spectroscopy

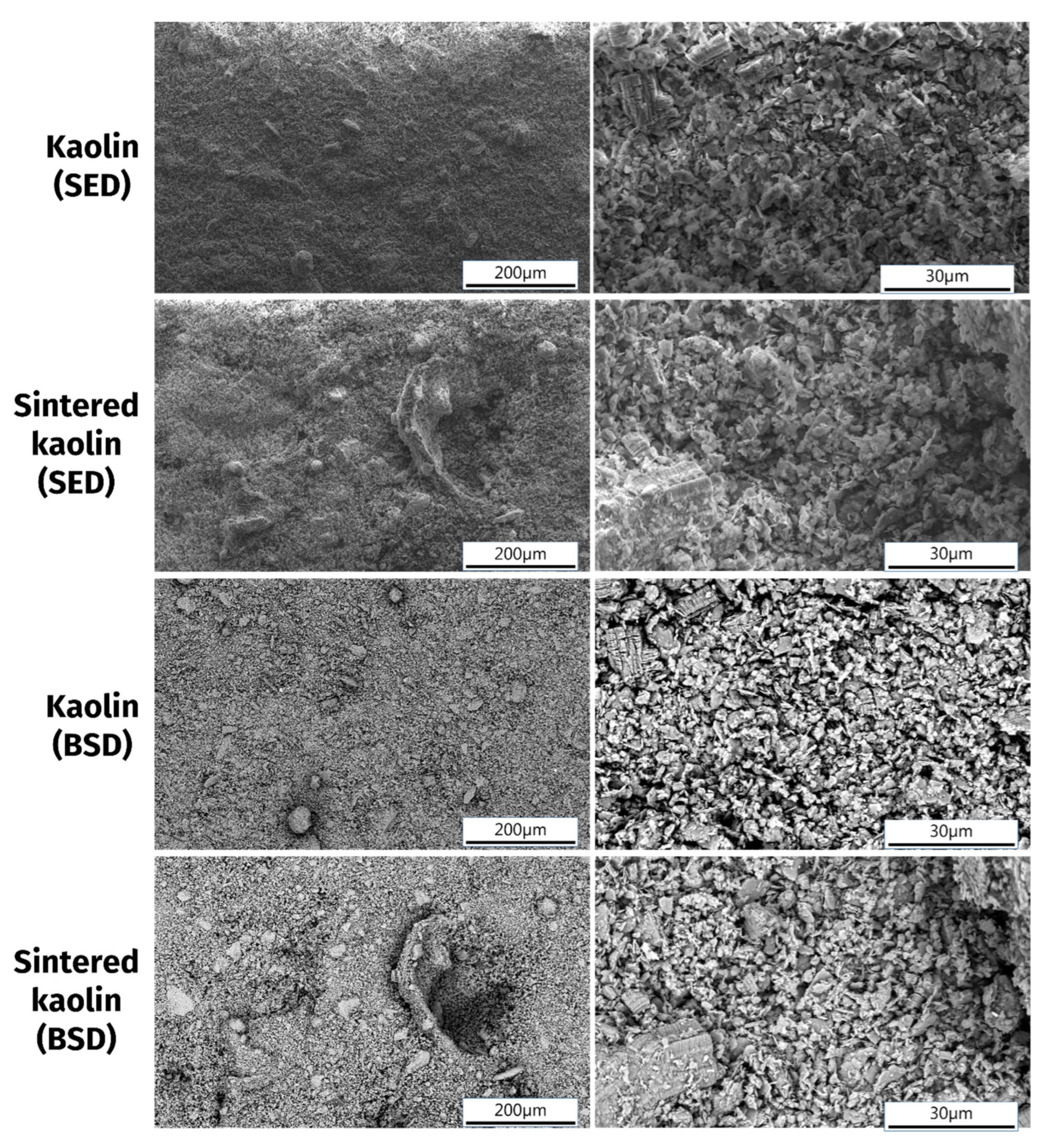

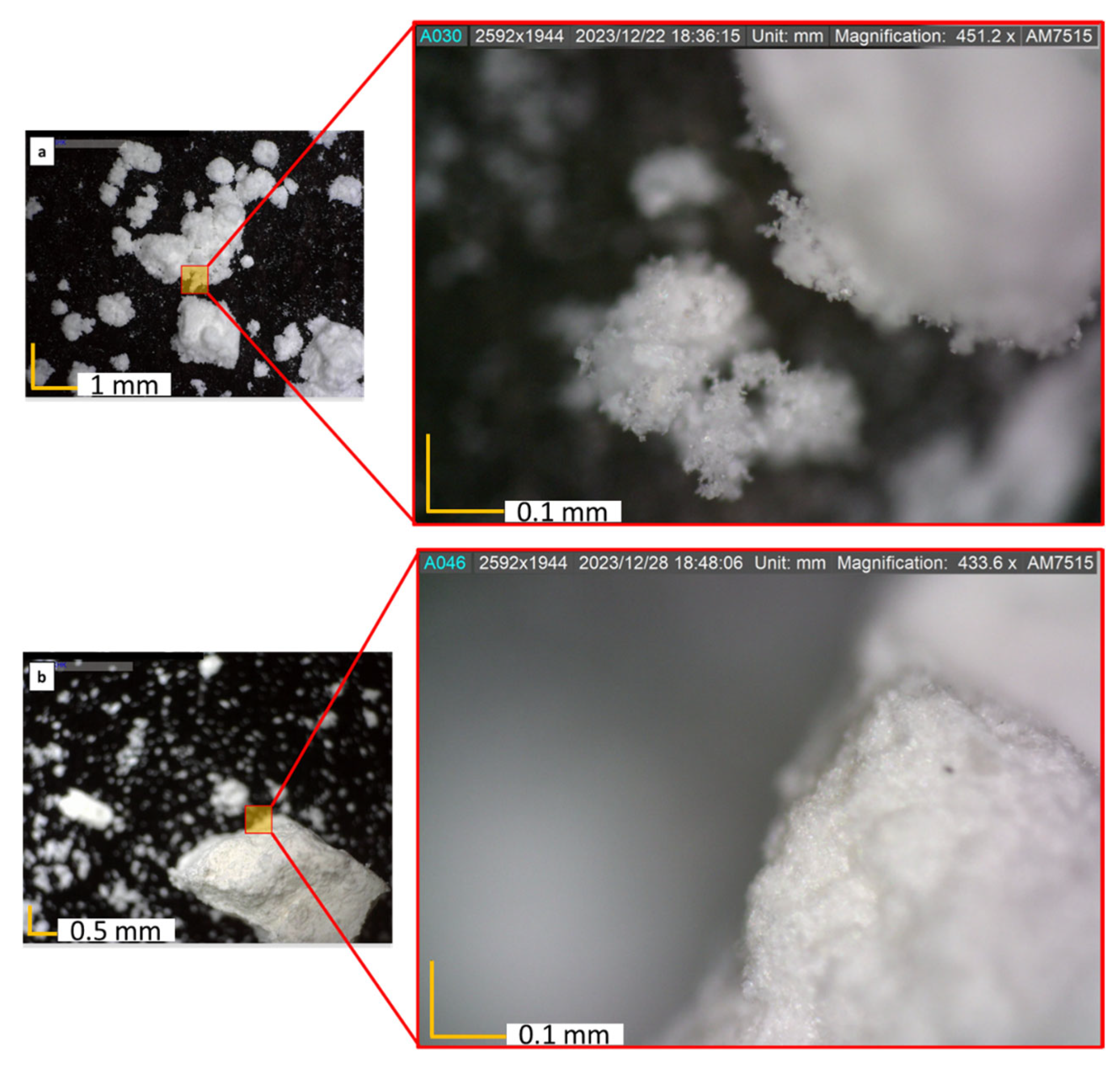

3.2. SEM Analysis

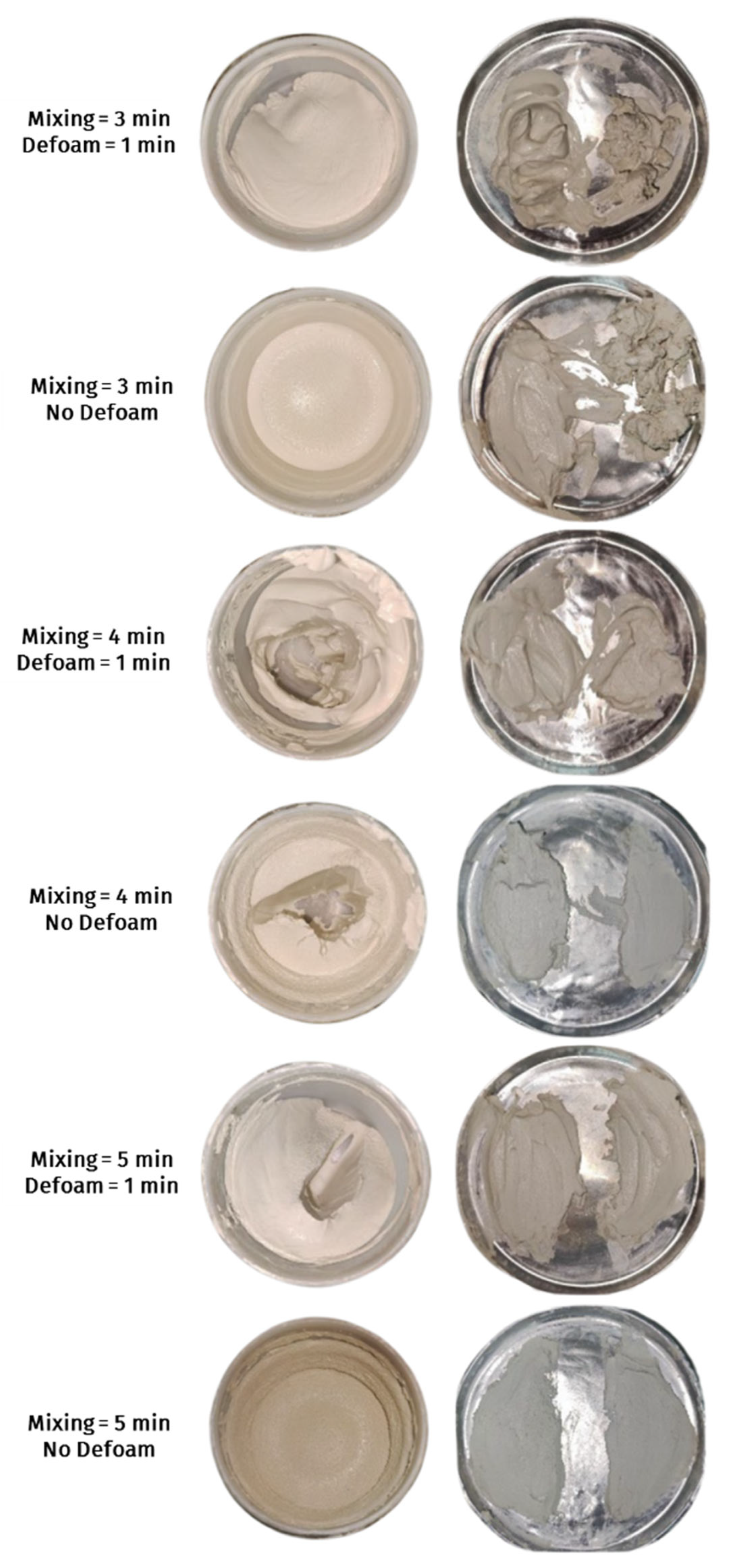

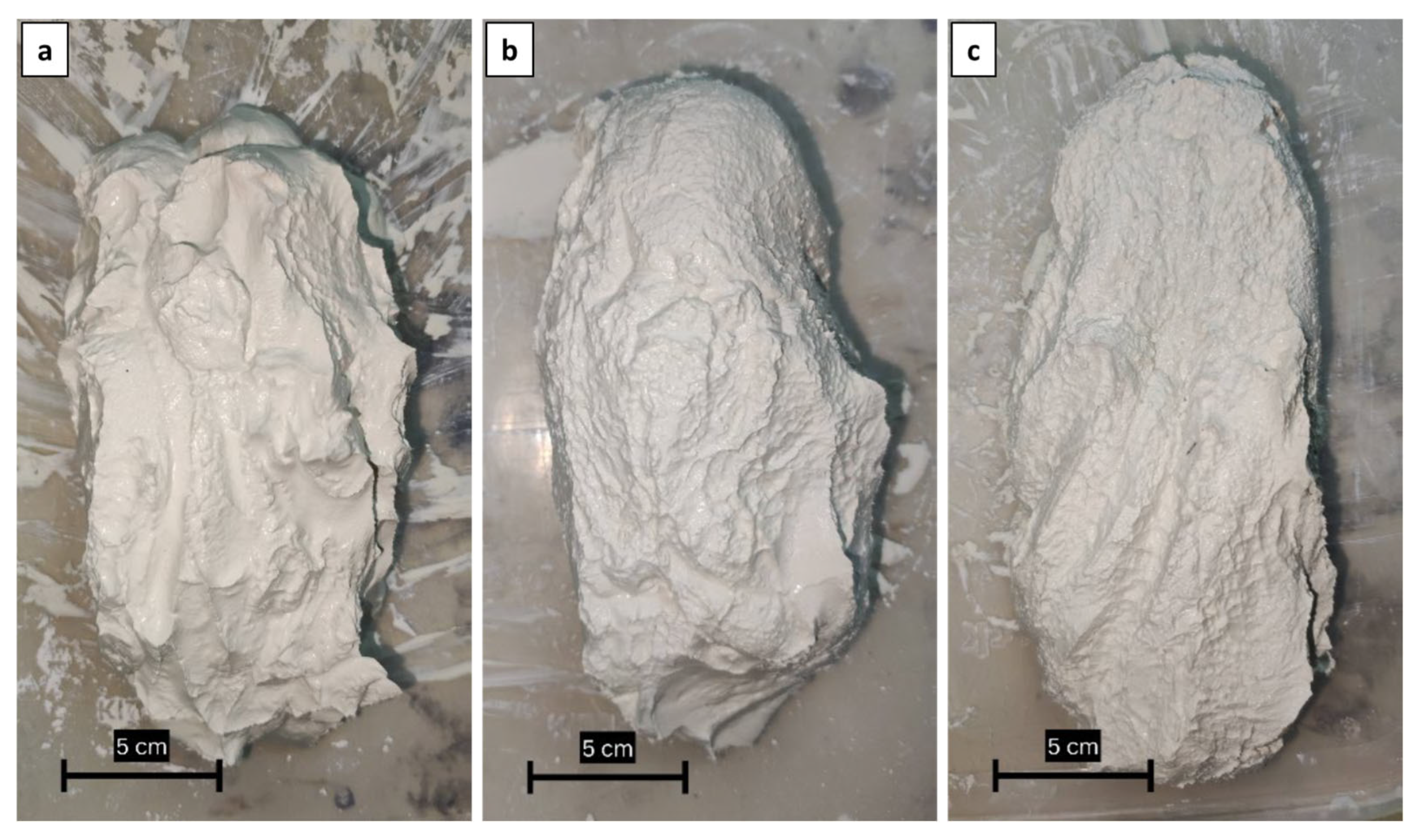

3.3. Clay Mixture Uniformity

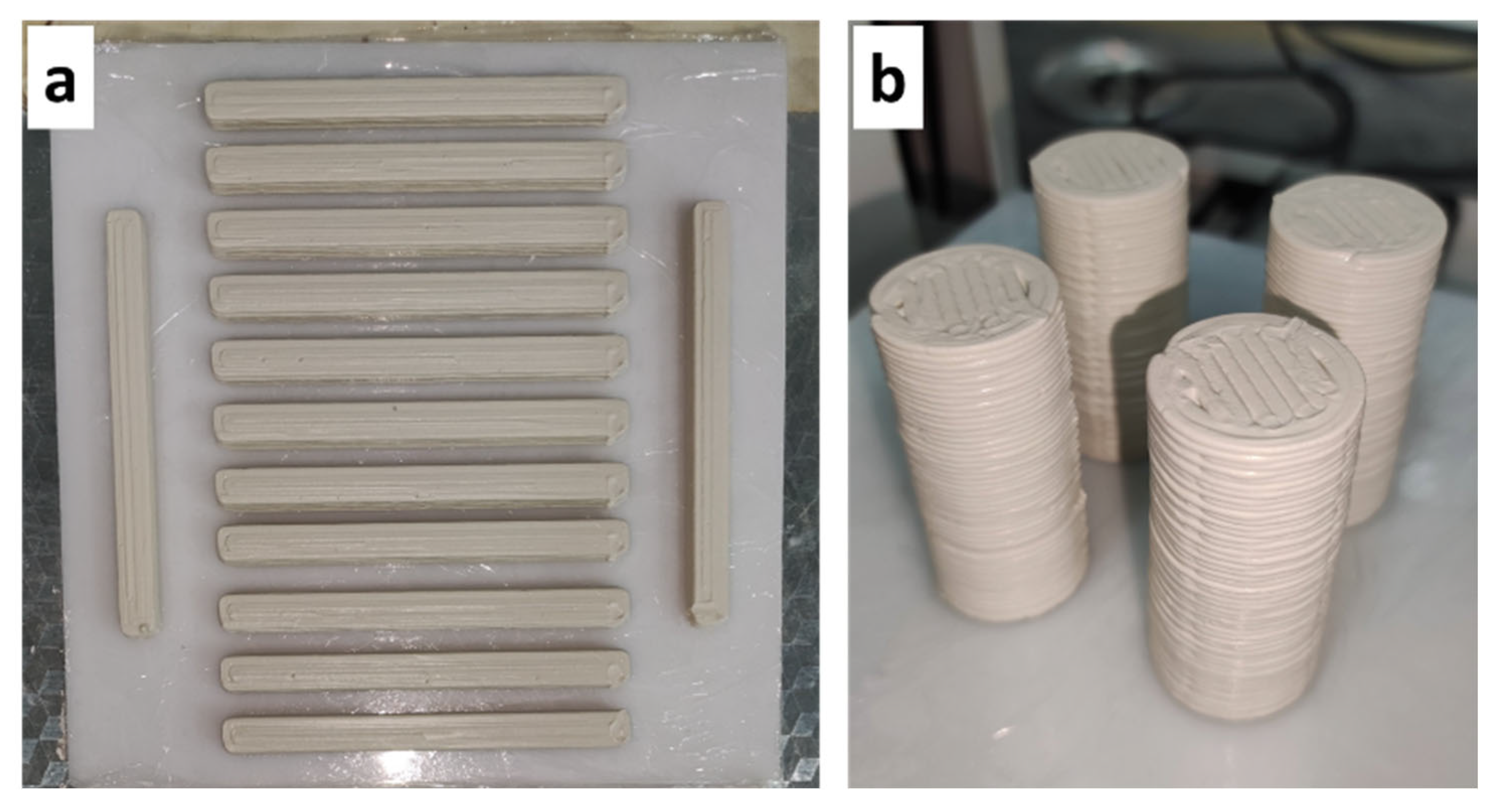

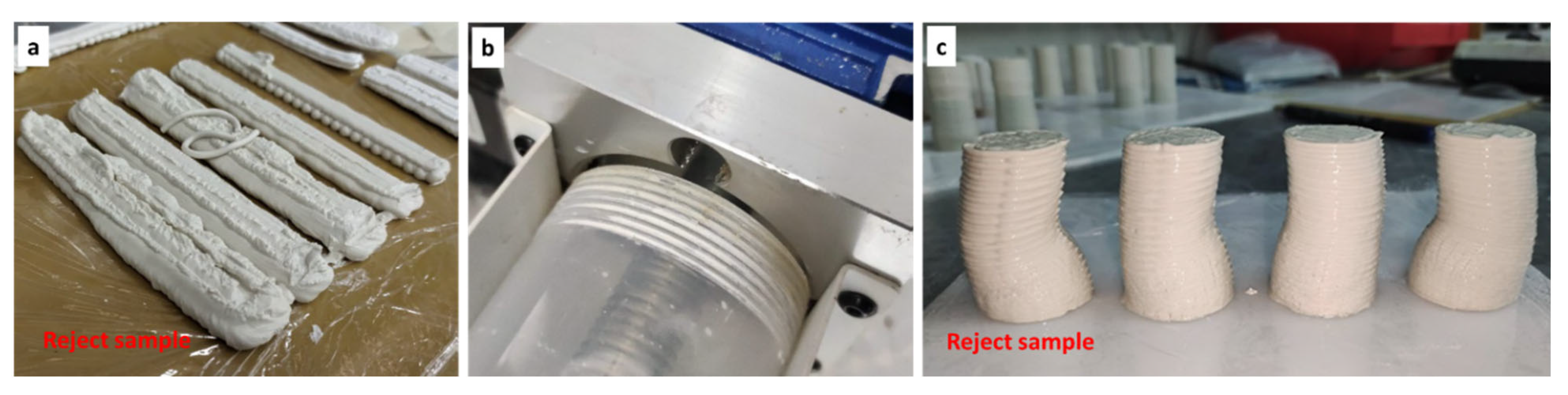

3.4. 3D Printing of Clay

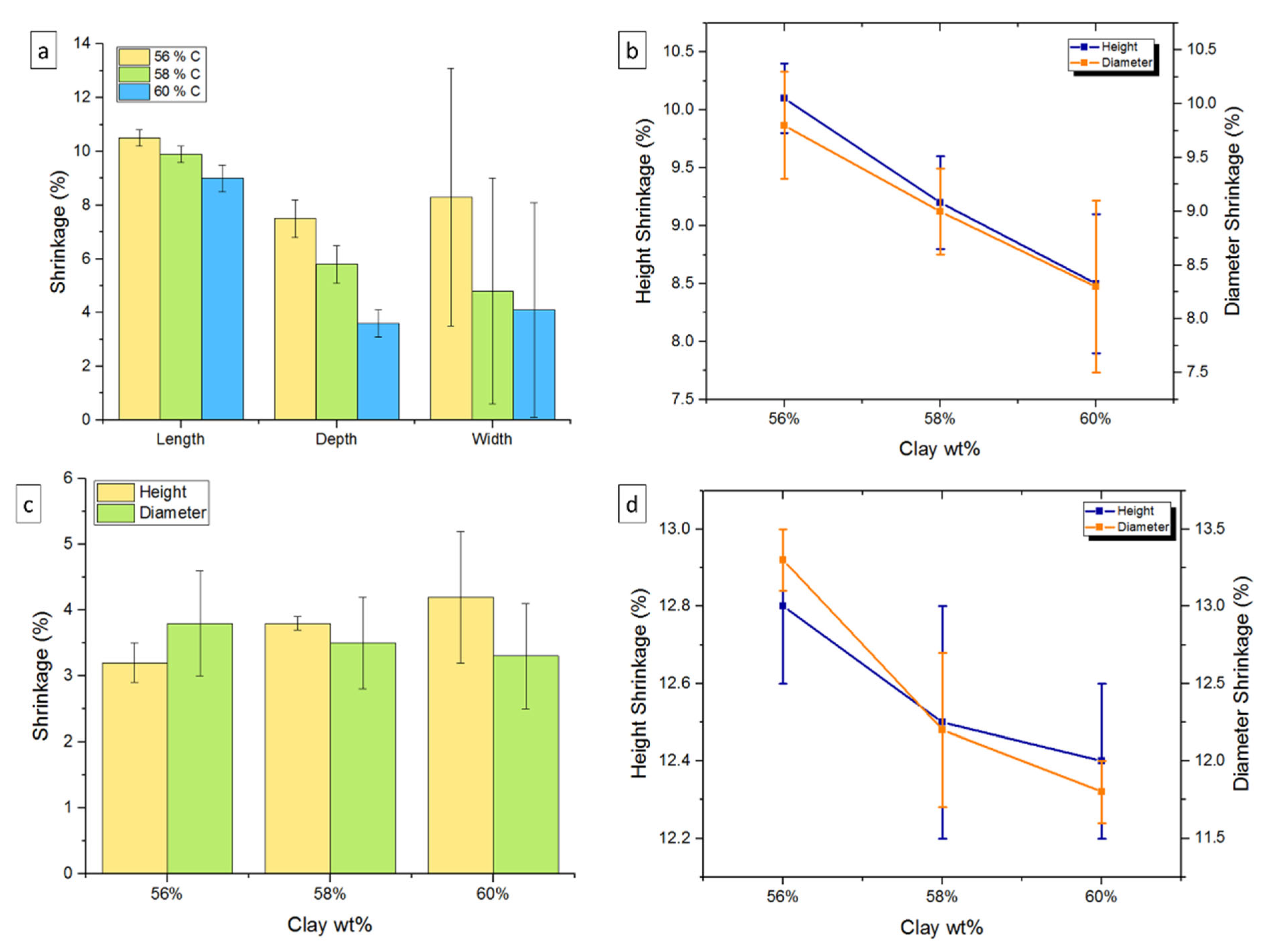

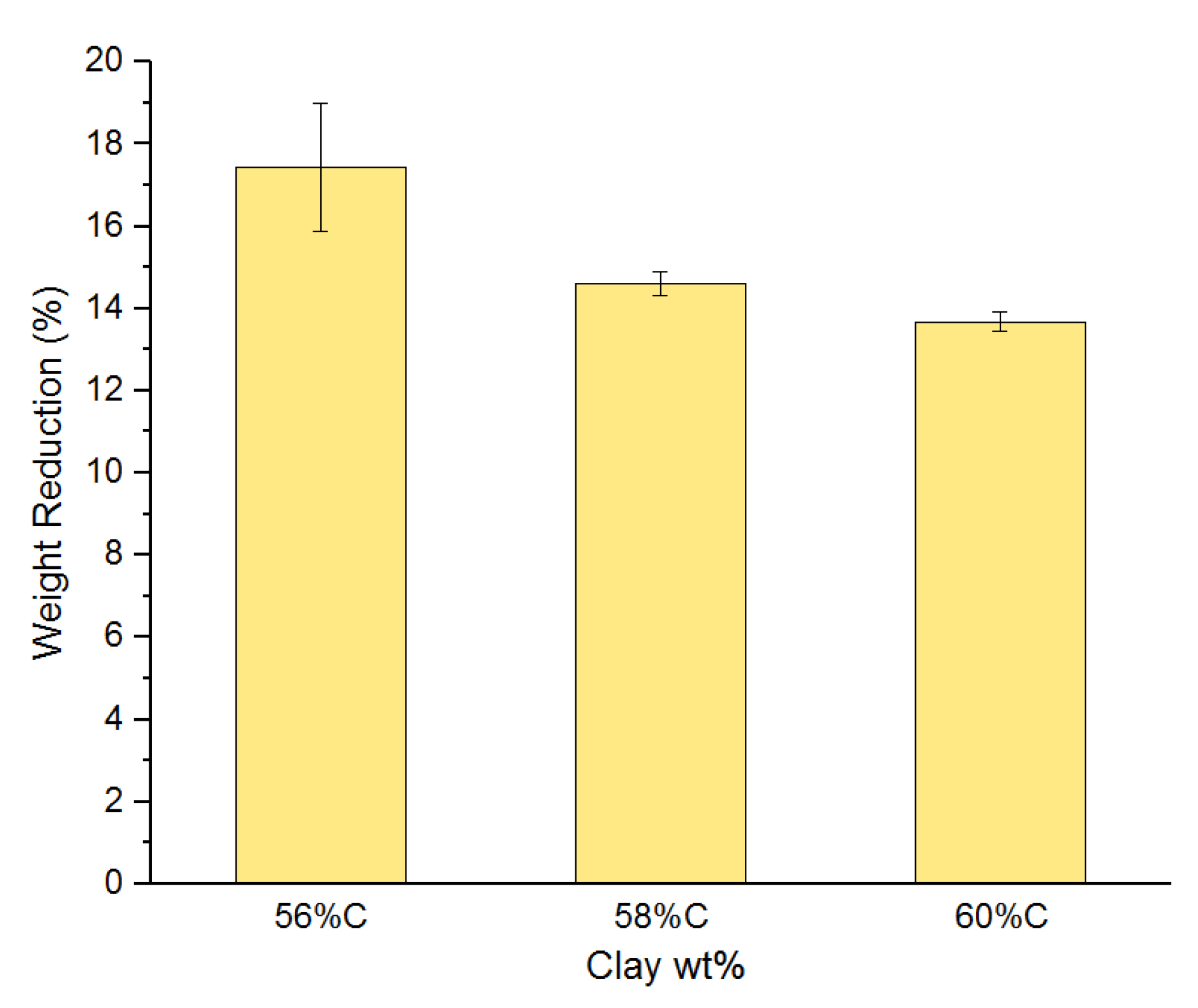

3.5. Effects of Drying and Sintering on Printed Clay

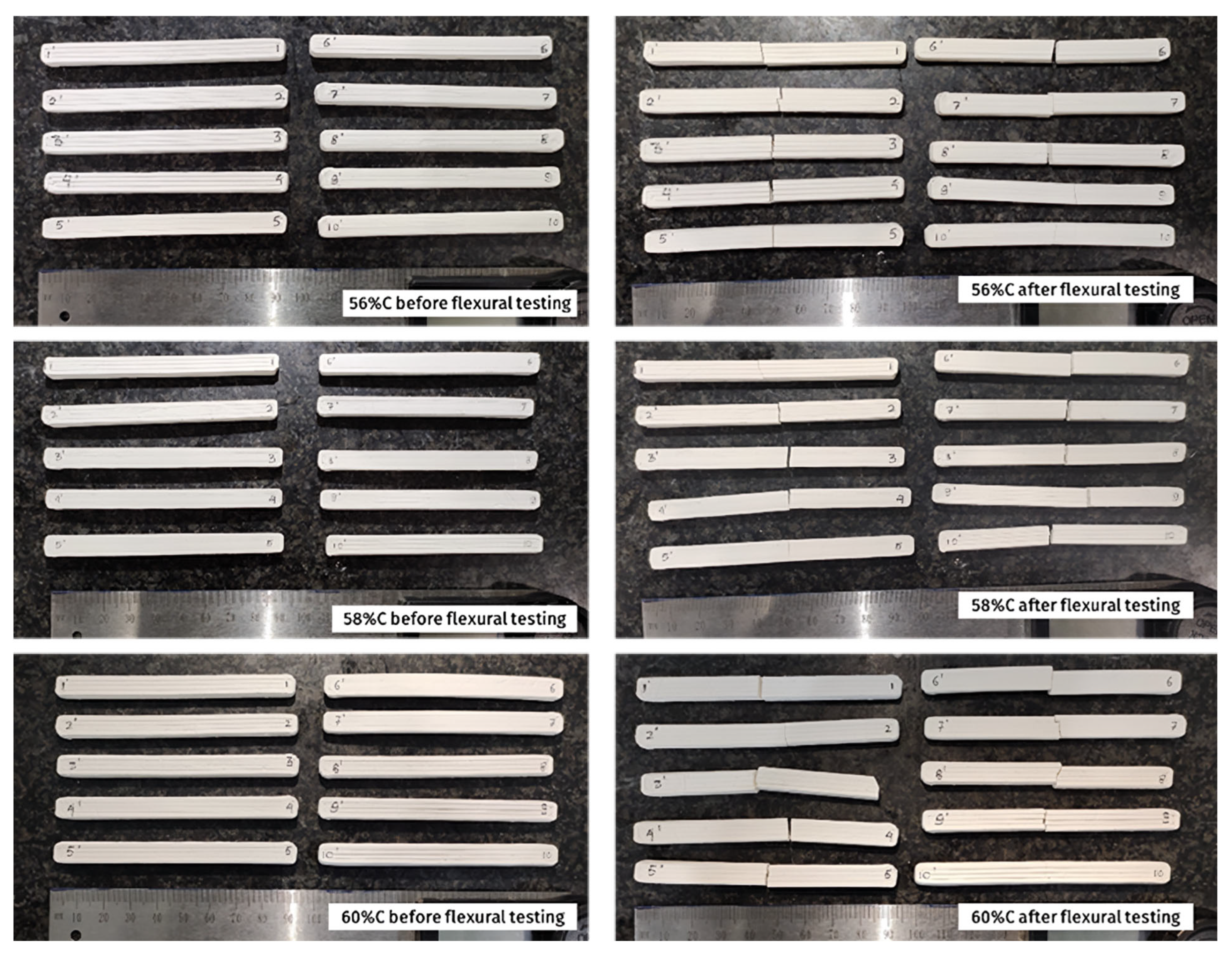

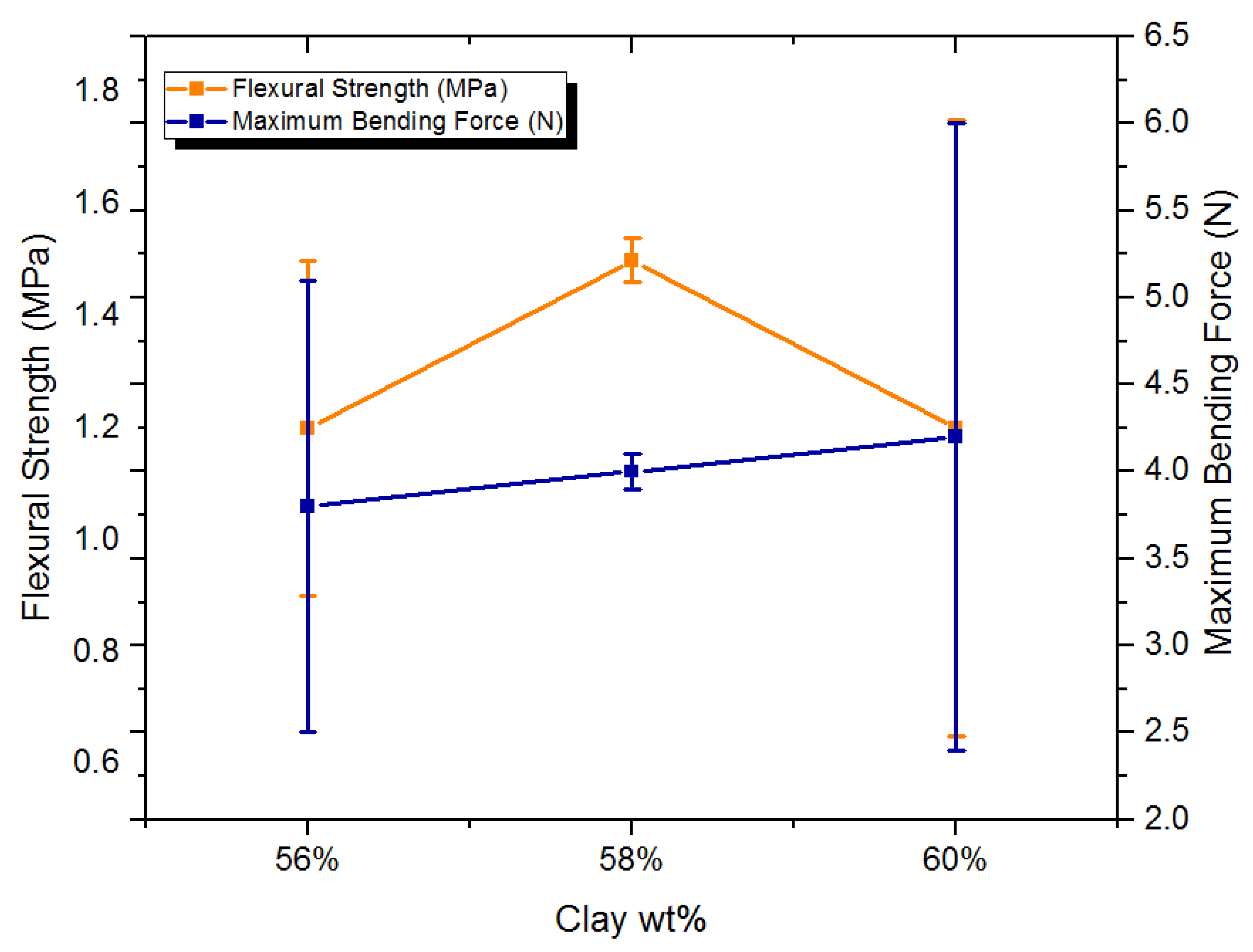

3.6. Flexural Strength Testing

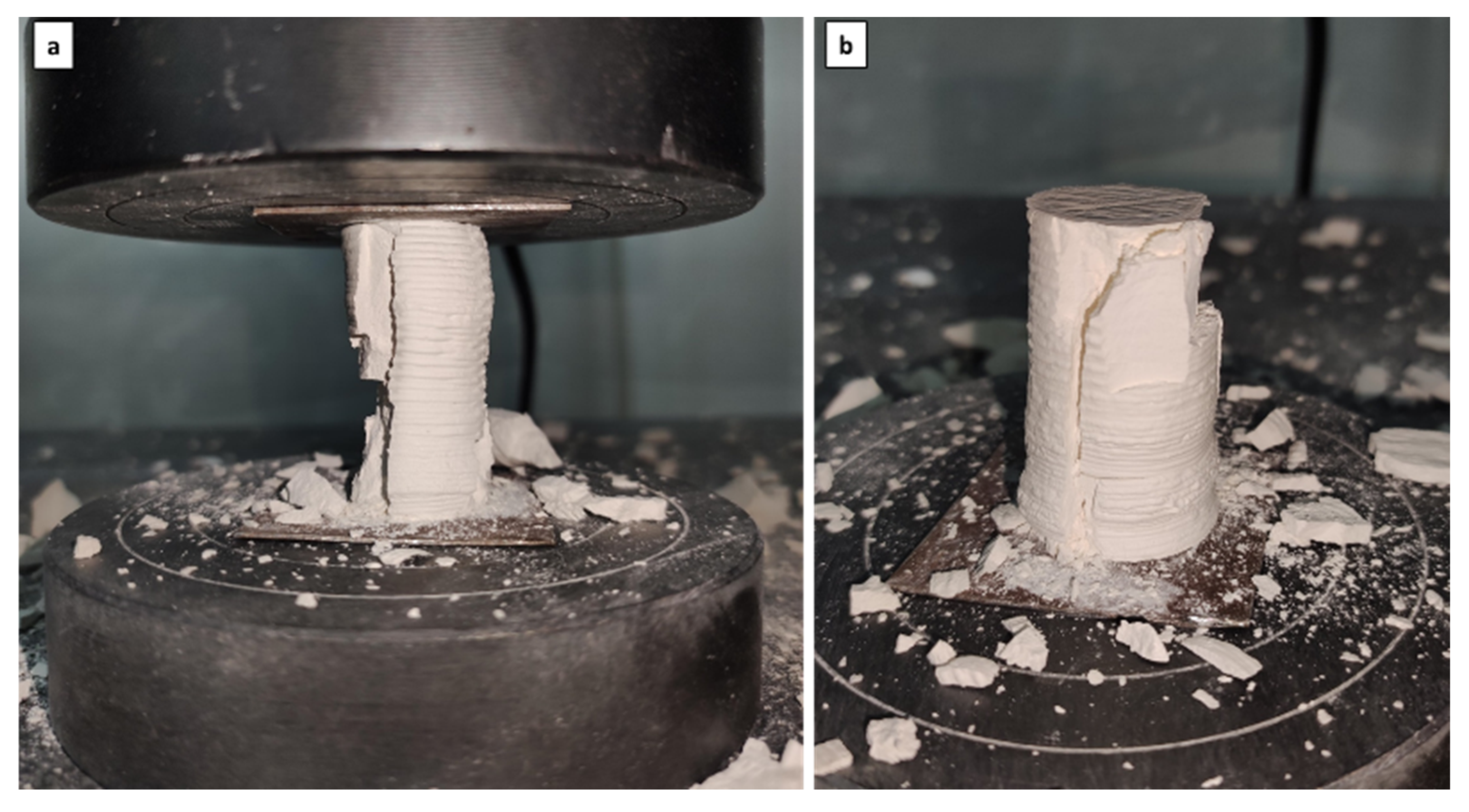

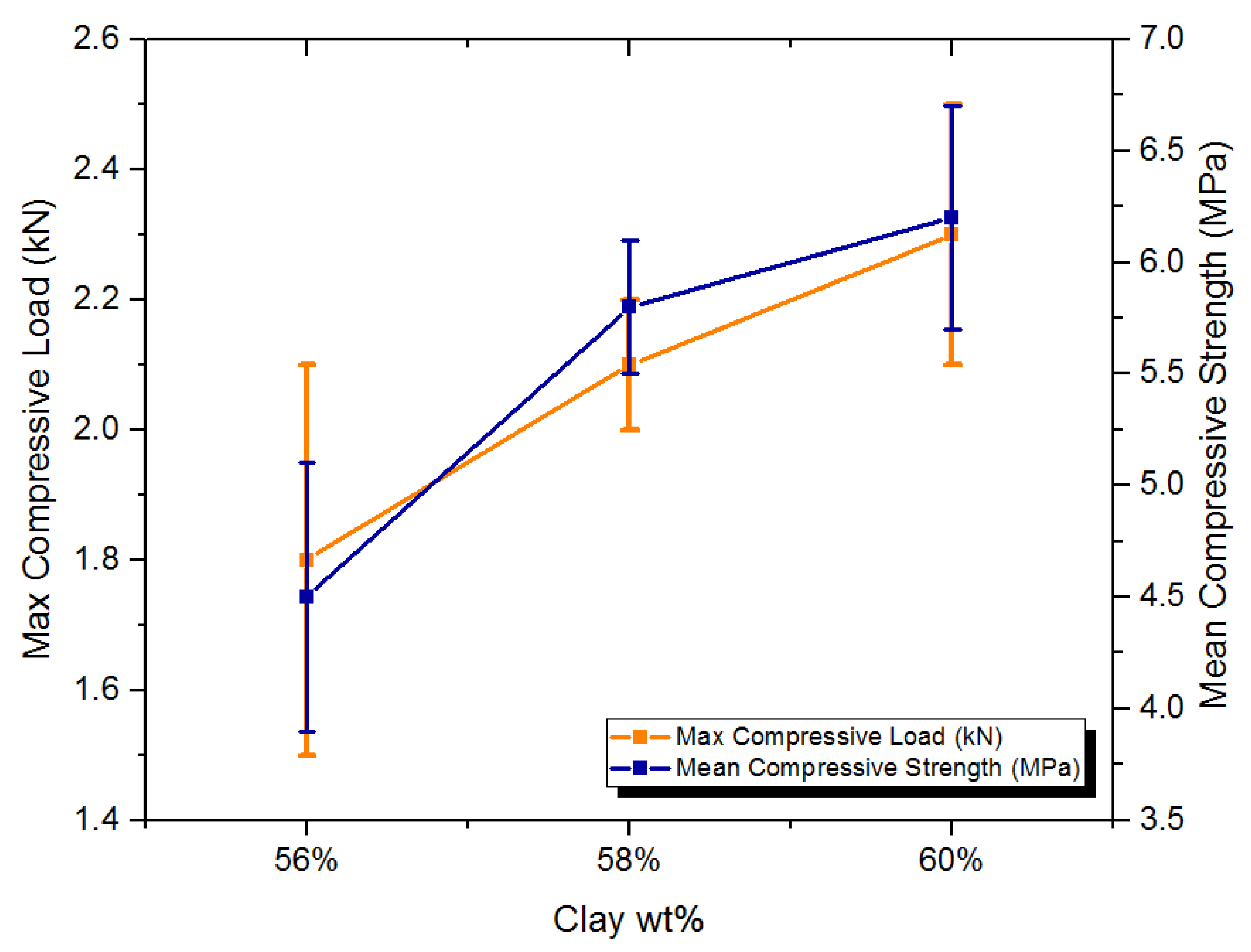

3.7. Compressive Strength Testing

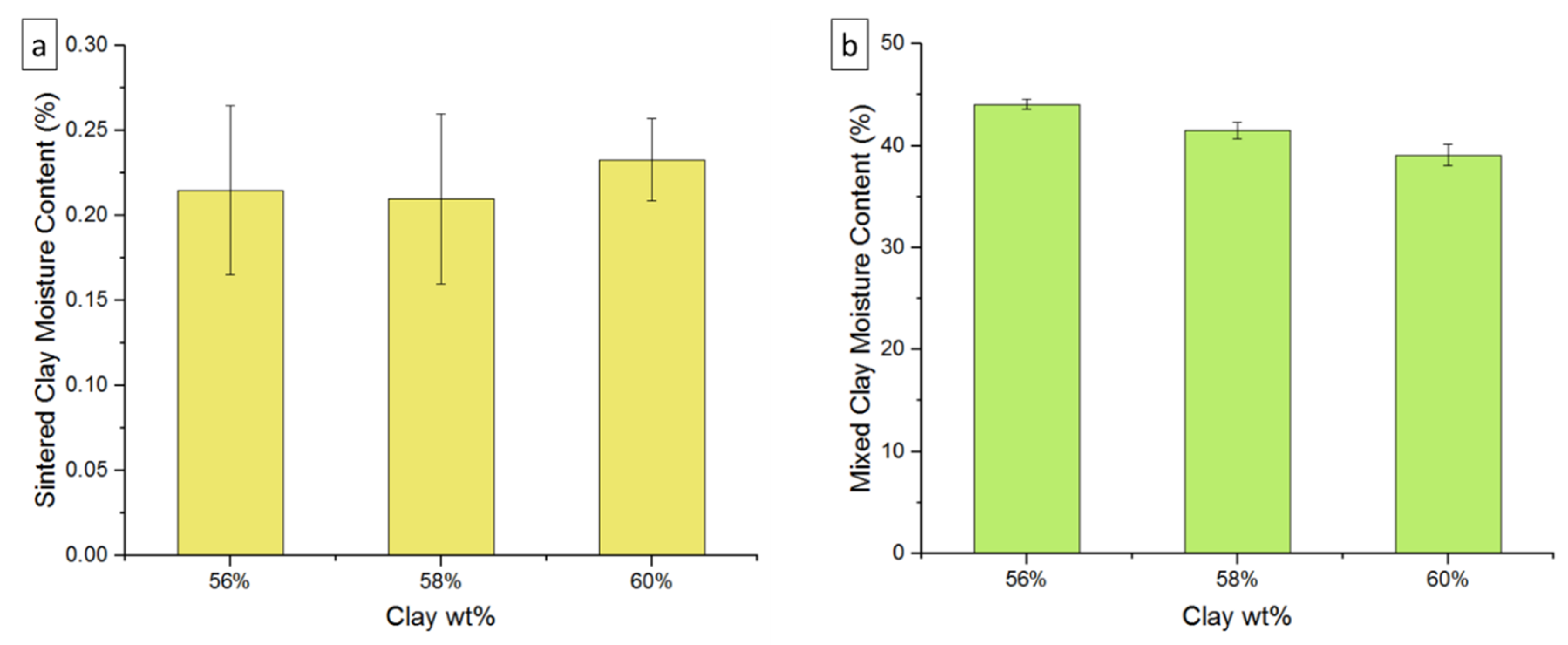

3.8. Moisture Analysis

3.9. Visual and Physical Examination

3.10. Imperfection During the Manufacturing Process

3.11. Discussion

4. Conclusions

- 1.

- The ideal clay mixture consists of 60% clay and 40% water, striking the best balance between structural strength, printability, and ease of handling. This composition ensures a smooth extrusion process while maintaining the shape stability of the printed objects.

- 2.

- The highest flexural strength recorded was 1.3125 MPa, achieved with the 60% clay mixture, highlighting the positive correlation between higher clay content and mechanical strength. In contrast, the lowest flexural strength was observed in the 56% clay mixture, showing a decrease of approximately 10.5% compared to the optimal composition.

- 3.

- The highest compressive strength was 6.14 MPa, also obtained with the 60% clay mixture, making it 35% stronger than the 56% clay composition. This improvement is attributed to the enhanced particle bonding and reduced porosity in the sintered specimens with a higher clay ratio.

- 4.

- Shrinkage analysis revealed that specimens with higher water content experienced up to 10% volumetric shrinkage and 14% weight reduction during drying and sintering. This underscores the importance of precisely controlling the clay-water ratio to minimize deformation and dimensional inaccuracies in the final product.

- 5.

- Proper moisture control is essential throughout the printing, drying, and sintering processes. Excess water increases shrinkage, deformation, and the risk of cracks, while insufficient water can hinder extrusion, resulting in poor layer adhesion and nozzle clogging.

- 6.

- The manufacturing process must account for the inherent shrinkage of kaolin-based materials by adjusting the initial design dimensions accordingly. This is crucial to achieving accurate final product dimensions after sintering.

- 7.

- From an optimization perspective, the 60% clay mixture represents an optimum within the tested range (56–60%). Although a higher clay fraction might further enhance mechanical performance, it could also make the slurry too viscous or dry for smooth extrusion. Increasing clay content beyond 60% may lead to processing challenges such as nozzle clogging, irregular deposition, or poor interlayer bonding. Therefore, the present results define a practical balance between strength and printability within the studied parameters.

- 8.

- Future research is recommended to explore higher clay contents (e.g., 62–64%) and to investigate their effects on rheology, extrusion pressure, and nozzle design optimization. Such studies could provide insights into the trade-offs between improved mechanical strength and printability limitations, ultimately expanding the printable range for clay-rich formulations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Noaimat, Y.A.; Chougan, M.; Al-kheetan, M.J.; Al-Mandhari, O.; Al-Saidi, W.; Al-Maqbali, M.; Al-Hosni, H.; Ghaffar, S.H. 3D printing of limestone-calcined clay cement: A review of its potential implementation in the construction industry. Results Eng. 2023, 18, 101115. [Google Scholar] [CrossRef]

- Portoacă, A.I.; Ripeanu, R.G.; Diniță, A.; Tănase, M. Optimization of 3D Printing Parameters for Enhanced Surface Quality and Wear Resistance. Polymers 2023, 15, 3419. [Google Scholar] [CrossRef] [PubMed]

- Del Rosario, M.D.L.A.O.; Medina, M.; Duque, R.; Ortega, A.A.J.; Castillero, L. Advancing Sustainable Construction: Insights into Clay-Based Additive Manufacturing for Architecture, Engineering, and Construction. In Developments in Clay Science and Construction Techniques; Almusaed, A., Almssad, A., Yitmen, I., Eds.; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Shi, D.; Xu, K.; Chao, Z.; Cui, P. Experimental study on mechanical properties of triaxial geogrid reinforced marine coral sand-clay mixture based on 3D printing technology. Front. Mar. Sci. 2025, 12, 1660611. [Google Scholar] [CrossRef]

- Giwa, I.; Game, D.; Ahmed, H.; Noorvand, H.; Arce, G.; Hassan, M.; Kazemian, A. Performance and macrostructural characterization of 3D printed steel fiber reinforced cementitious materials. Constr. Build. Mater. 2023, 369, 130593. [Google Scholar] [CrossRef]

- Chen, Y.; Jansen, K.; Zhang, H.; Rodriguez, C.R.; Gan, Y.; Çopuroğlu, O.; Schlangen, E. Effect of printing parameters on interlayer bond strength of 3D printed limestone-calcined clay-based cementitious materials: An experimental and numerical study. Constr. Build. Mater. 2020, 262, 120094. [Google Scholar] [CrossRef]

- Bell, F.; Mcclure, E.; Friedman-Gerlicz, C.; Ta, R.; Buechley, L. Shape-Changing Clay-Dough: Taking a Material-Oriented Approach to 3D Printing Ceramic Forms. In Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems, New York, NY, USA, 11–16 May 2024; Association for Computing Machinery: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, T.; Huang, G. State-of-the-art research progress and challenge of the printing techniques, potential applications for advanced ceramic materials 3D printing. Mater. Today Commun. 2024, 40, 110001. [Google Scholar] [CrossRef]

- Kumar, R.; Mehdi, H.; Bhati, S.S.; Arunkumar, M.; Mishra, S.; Lohumi, M.K. A comprehensive review of advancements in additive manufacturing for 3D printed medical components using diverse materials. Discov. Mater. 2025, 5, 152. [Google Scholar] [CrossRef]

- Motamedi, M.; Mesnil, R.; Tang, A.-M.; Pereira, J.-M.; Baverel, O. Structural build-up of 3D printed earth by drying. Addit. Manuf. 2024, 95, 104492. [Google Scholar] [CrossRef]

- Andersson, H.; Örtegren, J.; Zhang, R.; Grauers, M.; Olin, H. Variable low-density polylactic acid and microsphere composite material for additive manufacturing. Addit. Manuf. 2021, 40, 101925. [Google Scholar] [CrossRef]

- Liu, G.; Lu, X.; Zhang, X.; Zhao, Y.; Yi, S.; Xu, J.; Zhan, Y.; Yin, J.; Feng, C.; Zhou, Z.; et al. 3D/4D additive–subtractive manufacturing of heterogeneous ceramics. J. Mater. Sci. Technol. 2024, 201, 210–221. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Nematollahi, B.; Sikora, P.; Dorn, T.; Stephan, D.; Albar, A.; Al-Kheetan, M.J. Effect of natural and calcined halloysite clay minerals as low-cost additives on the performance of 3D-printed alkali-activated materials. Mater. Des. 2022, 223, 111183. [Google Scholar] [CrossRef]

- Li, Y.; Chen, A.; Su, J.; Li, Y.; Zhang, Y.; Li, Z.; Zhou, S.; He, J.; Cao, Z.; Shi, Y.; et al. An overview on ceramic multi-material additive manufacturing: Progress and challenges. Int. J. Extrem. Manuf. 2025, 7, 42005. [Google Scholar] [CrossRef]

- Prabhakar, M.N.; Cabo, M.C.; Yu, R.; Weldemhret, T.G.; Woo, L.D.; Jung-il, S. Surface flame retardancy of clay mineral powder infused onto the top of the layer of vinyl ester/bamboo composites through a modified VARTM process. Polym. Test. 2024, 132, 108367. [Google Scholar] [CrossRef]

- Altheoy, F.; Zaid, O.; Ahmed, B.; Elhadi, K.M. Impact of double hooked steel fibers and nano-kaolin clay on fresh properties of 3D-Printable ultra-high-performance fiber-reinforced concrete. J. Build. Eng. 2024, 97, 110917. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M. Evaluating the printability of concretes containing lightweight coarse aggregates. Cem. Concr. Compos. 2020, 109, 103570. [Google Scholar] [CrossRef]

- Ayeni, O.; Onwualu, A.P.; Boakye, E. Characterization and mechanical performance of metakaolin-based geopolymer for sustainable building applications. Constr. Build. Mater. 2021, 272, 121938. [Google Scholar] [CrossRef]

- Afridi, A.; Al Rashid, A.; Koç, M. Recent advances in the development of stereolithography-based additive manufacturing processes: A review of applications and challenges. Bioprinting 2024, 43, e00360. [Google Scholar] [CrossRef]

- Tabakova, V.; Klug, C.; Schmitz, T.H. Injection 3D Printing of Doubly Curved Ceramic Shells in Non-Synthetic Particle Suspensions. Materials 2024, 17, 3955. [Google Scholar] [CrossRef] [PubMed]

- Abeykoon, C.; Sri-Amphorn, P.; Fernando, A. Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int. J. Lightweight Mater. Manuf. 2020, 3, 284–297. [Google Scholar] [CrossRef]

- Godec, D.; Cano, S.; Holzer, C.; Gonzalez-Gutierrez, J. Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel. Materials 2020, 13, 774. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Z.; Ma, G.; Zhang, M. Interlayer bonding improvement of 3D printed concrete with polymer modified mortar: Experiments and molecular dynamics studies. Cem. Concr. Compos. 2020, 110, 103571. [Google Scholar] [CrossRef]

- Chang, S.-M.; Hur, S.; Park, J.; Lee, D.-G.; Shin, J.; Kim, H.S.; Song, S.E.; Baik, J.M.; Kim, M.; Song, H.-C.; et al. Optimization of piezoelectric polymer composites and 3D printing parameters for flexible tactile sensors. Addit. Manuf. 2023, 67, 103470. [Google Scholar] [CrossRef]

- Ting, G.H.A.; Quah, T.K.N.; Lim, J.H.; Tay, Y.W.D.; Tan, M.J. Extrudable region parametrical study of 3D printable concrete using recycled glass concrete. J. Build. Eng. 2022, 50, 104091. [Google Scholar] [CrossRef]

- Worasith, N.; Goodman, B.A. Clay mineral products for improving environmental quality. Appl. Clay Sci. 2023, 242, 106980. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Keerthana, K.; Anukiruthika, T.; Moses, J.A.; Anandharamakrishnan, C. Development of fiber-enriched 3D printed snacks from alternative foods: A study on button mushroom. J. Food. Eng. 2020, 287, 110116. [Google Scholar] [CrossRef]

- Wu, Y.; Lan, J.; Wu, M.; Zhou, W.; Zhou, S.; Yang, H.; Zhang, M.; Li, Y. Rheology and Printability of a Porcelain Clay Paste for DIW 3D Printing of Ceramics with Complex Geometric Structures. ACS Omega 2024, 9, 26450–26457. [Google Scholar] [CrossRef] [PubMed]

- Rozbroj, J.; Žurovec, D.; Hlosta, J.; Topinková, M.; Ovčačíková, H.; Diviš, J.; Pokorná, K.; Nečas, J.; Zegzulka, J. Rheological characterization of clay–refractory waste composites for direct ink writing of ceramic structures. Open Ceram. 2025, 24, 100850. [Google Scholar] [CrossRef]

- Marquez, C.; Mata, J.J.; Renteria, A.; Gonzalez, D.; Gomez, S.G.; Lopez, A.; Baca, A.N.; Nuñez, A.; Hassan, M.S.; Burke, V.; et al. Direct Ink-Write Printing of Ceramic Clay with an Embedded Wireless Temperature and Relative Humidity Sensor. Sensors 2023, 23, 3352. [Google Scholar] [CrossRef]

- Nair, S.A.O.; Panda, S.; Santhanam, M.; Sant, G.; Neithalath, N. A critical examination of the influence of material characteristics and extruder geometry on 3D printing of cementitious binders. Cem. Concr. Compos. 2020, 112, 103671. [Google Scholar] [CrossRef]

- Percoco, G.; Arleo, L.; Stano, G.; Bottiglione, F. Analytical model to predict the extrusion force as a function of the layer height, in extrusion based 3D printing. Addit. Manuf. 2021, 38, 101791. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Ham, H.; Sonh, J.; Gunbayar, M.; Jeffy, R.; Nagarajan, R.; Khatun, M.R.; Noh, I. 3D bioprinting of complex tissue scaffolds with in situ homogeneously mixed alginate-chitosan-kaolin bioink using advanced portable biopen. Carbohydr. Polym. 2023, 317, 121046. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. High-performance concrete incorporating calcined kaolin clay and limestone as cement substitute. Constr. Build. Mater. 2020, 264, 120152. [Google Scholar] [CrossRef]

- Ordoñez, E.; Monteiro, S.N.; Colorado, H.A. Valorization of a hazardous waste with 3D-printing: Combination of kaolin clay and electric arc furnace dust from the steel making industry. Mater. Des. 2022, 217, 110617. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, W.; Zheng, J.; Li, Y. Effect of methane hydrate dissociation and reformation on the permeability of clayey sediments. Appl. Energy 2020, 261, 114479. [Google Scholar] [CrossRef]

- Chen, Y.; Figueiredo, S.C.; Li, Z.; Chang, Z.; Jansen, K.; Çopuroğlu, O.; Schlangen, E. Improving printability of limestone-calcined clay-based cementitious materials by using viscosity-modifying admixture. Cem. Concr. Res. 2020, 132, 106040. [Google Scholar] [CrossRef]

- Yang, L.; Sepasgozar, S.M.E.; Shirowzhan, S.; Kashani, A.; Edwards, D. Nozzle criteria for enhancing extrudability, buildability and interlayer bonding in 3D printing concrete. Autom. Constr. 2023, 146, 104671. [Google Scholar] [CrossRef]

- Lin, T.; Zhao, Z.; Wang, T.; Pan, Y.-T. Three-Dimensional Printing of Large Ceramic Products and Process Simulation. Materials 2023, 16, 3815. [Google Scholar] [CrossRef]

- Lacelle, T.; Sampson, K.L.; Sarvestani, H.Y.; Rahimizadeh, A.; Robles, J.B.; Mirkhalaf, M.; Rafiee, M.; Jakubinek, M.B.; Paquet, C.; Ashrafi, B. Additive manufacturing of polymer derived ceramics: Materials, methods, and applications. APL Mater. 2023, 11, 70602. [Google Scholar] [CrossRef]

- Kottasamy, A.; Samykano, M.; Kadirgama, K.; Rahman, M.; Noor, M.M. Experimental investigation and prediction model for mechanical properties of copper-reinforced polylactic acid composites (Cu-PLA) using FDM-based 3D printing technique. Int. J. Adv. Manuf. Technol. 2022, 119, 5211–5232. [Google Scholar] [CrossRef]

- Mahesh, V.; Joseph, A.S.; Mahesh, V.; Harursampath, D.; VN, C. Investigation on the mechanical properties of additively manufactured PETG composites reinforced with OMMT nanoclay and carbon fibers. Polym. Compos. 2021, 42, 2380–2395. [Google Scholar] [CrossRef]

- Bhattacherjee, S.; Basavaraj, A.S.; Rahul, A.V.; Santhanam, M.; Gettu, R.; Panda, B.; Schlangen, E.; Chen, Y.; Copuroglu, O.; Ma, G.; et al. Sustainable materials for 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104156. [Google Scholar] [CrossRef]

- Suiker, A.S.J.; Wolfs, R.J.M.; Lucas, S.M.; Salet, T.A.M. Elastic buckling and plastic collapse during 3D concrete printing. Cem. Concr. Res. 2020, 135, 106016. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Wang, Y. Hardened properties of layered 3D printed concrete with recycled sand. Cem. Concr. Compos. 2020, 113, 103724. [Google Scholar] [CrossRef]

- Barnabas, A.A.; Balogun, O.A.; Akinwande, A.A.; Ogbodo, J.F.; Ademati, A.O.; Dongo, E.I.; Romanovski, V. Reuse of walnut shell waste in the development of fired ceramic bricks. Environ. Sci. Pollut. Res. 2023, 30, 11823–11837. [Google Scholar] [CrossRef]

- Ketov, A.; Rudakova, L.; Vaisman, I.; Ketov, I.; Haritonovs, V.; Sahmenko, G. Recycling of rice husks ash for the preparation of resistant, lightweight and environment-friendly fired bricks. Constr. Build. Mater. 2021, 302, 124385. [Google Scholar] [CrossRef]

- Akbari, S.; Kostov, K.; Brinkfeldt, K.; Adolfsson, E.; Lim, J.-K.; Andersson, D.; Bakowski, M.; Wang, Q.; Salter, M. Ceramic Additive Manufacturing Potential for Power Electronics Packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1857–1866. [Google Scholar] [CrossRef]

- Vakalova, T.V.; Revva, I.B. Use of zeolite rocks for ceramic bricks based on brick clays and clay loams with high drying sensitivity. Constr. Build. Mater. 2020, 255, 119324. [Google Scholar] [CrossRef]

- Jawad, A.H.; Abdulhameed, A.S.; Kashi, E.; Yaseen, Z.M.; ALOthman, Z.A.; Khan, M.R. Cross-Linked Chitosan-Glyoxal/Kaolin Clay Composite: Parametric Optimization for Color Removal and COD Reduction of Remazol Brilliant Blue R Dye. J. Polym. Environ. 2022, 30, 164–178. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jäger, H.; Ahmadi, S.J.; Lacroix, M. Electron beam crosslinking of alginate/nanoclay ink to improve functional properties of 3D printed hydrogel for removing heavy metal ions. Carbohydr. Polym. 2020, 240, 116211. [Google Scholar] [CrossRef]

- Yue, Y.; Guo, X.; Liu, T.; Liu, H.; Wang, T.; Yuan, P.; Zhu, H.; Bai, Z.; Bao, X. Template free synthesis of hierarchical porous zeolite Beta with natural kaolin clay as alumina source. Microporous Mesoporous Mater. 2020, 293, 109772. [Google Scholar] [CrossRef]

- Lao, X.; Xu, X.; Jiang, W.; Liang, J.; Miao, L.; Wu, Q. Influences of impurities and mineralogical structure of different kaolin minerals on thermal properties of cordierite ceramics for high-temperature thermal storage. Appl. Clay Sci. 2020, 187, 105485. [Google Scholar] [CrossRef]

- Şahin, O.; İlcan, H.; Ateşli, A.T.; Kul, A.; Yıldırım, G.; Şahmaran, M. Construction and demolition waste-based geopolymers suited for use in 3-dimensional additive manufacturing. Cem. Concr. Compos. 2021, 121, 104088. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D printing of polymer and associated composite: A review on mechanical properties, defects and treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Chen, Y.; Çopuroğlu, O.; Rodriguez, C.R.; de Mendonca Filho, F.F.; Schlangen, E. Characterization of air-void systems in 3D printed cementitious materials using optical image scanning and X-ray computed tomography. Mater. Charact. 2021, 173, 110948. [Google Scholar] [CrossRef]

- Zaheer, M.D.; Dauksevicius, R.; Zia, Q.; Tabassum, M. Solvent-free manufacturing and 3D printing of ceramic-rich biopolymeric PHA-based piezocomposite for eco-friendly mechanical sensors. J. Phys. D Appl. Phys. 2025, 58, 475501. [Google Scholar] [CrossRef]

- Miao, W.-J.; Wang, S.-Q.; Wang, Z.-H.; Wu, F.-B.; Zhang, Y.-Z.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants 2025, 13, 112. [Google Scholar] [CrossRef]

- Kawashima, S.; Wang, K.; Ferron, R.D.; Kim, J.H.; Tregger, N.; Shah, S. A review of the effect of nanoclays on the fresh and hardened properties of cement-based materials. Cem. Concr. Res. 2021, 147, 106502. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Lu, X.; Zhao, Y.; Zhou, Z.; Xu, J.; Yin, J.; Tang, T.; Wang, P.; Yi, S.; et al. 4D Additive–Subtractive Manufacturing of Shape Memory Ceramics. Adv. Mater. 2023, 35, 2302108. [Google Scholar] [CrossRef] [PubMed]

- Dadkhah, M.; Tulliani, J.-M.; Saboori, A.; Iuliano, L. Additive manufacturing of ceramics: Advances, challenges, and outlook. J. Eur. Ceram. Soc. 2023, 43, 6635–6664. [Google Scholar] [CrossRef]

- Mobaraki, M.; Ghaffari, M.; Yazdanpanah, A.; Luo, Y.; Mills, D.K. Bioinks and bioprinting: A focused review. Bioprinting 2020, 18, e00080. [Google Scholar] [CrossRef]

- Bose, S.; Akdogan, E.K.; Balla, V.K.; Ciliveri, S.; Colombo, P.; Franchin, G.; Ku, N.; Kushram, P.; Niu, F.; Pelz, J.; et al. 3D printing of ceramics: Advantages, challenges, applications, and perspectives. J. Am. Ceram. Soc. 2024, 107, 7879–7920. [Google Scholar] [CrossRef]

- Elsersawy, R.; Donyadari, R.; Khondoker, M.A.H. Extrusion 3D-Printed Kaolinite Ceramic Filters for Water Applications. J. Manuf. Mater. Process. 2025, 9, 278. [Google Scholar] [CrossRef]

- Chen, R.; Cai, G.; Dong, X.; Pu, S.; Dai, X.; Duan, W. Green utilization of modified biomass by-product rice husk ash: A novel eco-friendly binder for stabilizing waste clay as road material. J. Clean. Prod. 2022, 376, 134303. [Google Scholar] [CrossRef]

- Abdelkader, M.; Petrik, S.; Nestler, D.; Fijalkowski, M. Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market. Ceramics 2024, 7, 68–85. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Koç, M. Parameter tuning for sustainable 3D Printing(3DP) of clay structures. J. Eng. Res. 2025, 13, 1826–1842. [Google Scholar] [CrossRef]

- Yu, H.; Chen, E.; Chen, Y.; Qi, Z. The Model of Ceramic Surface Image Based on 3D Printing Technology. Mob. Inf. Syst. 2022, 2022, 5850967. [Google Scholar] [CrossRef]

| Al2O3 | CaO | MgO | MnO2 | Cr2O3 | Na2O | K2O | SiO2 | TiO2 |

|---|---|---|---|---|---|---|---|---|

| 33–39 | 0.01–0.07 | 0.01–0.10 | <0.01–0.05 | <0.01–0.05 | 0.01–0.17 | 0.25–0.80 | 45–47 | 0.25–0.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nuryanta, M.I.; Nurhary, M.A.; Firmansyah, H.N.; Joshua, D.; Hajad, M.; Widodo, R.D.; Widodo, T.D.; Kusni, M.; Wiranata, A.; Kusumawanto, A.; et al. Optimization of Kaolin Clay Composition for Enhanced Mechanical Properties in 3D-Printed Structures. Constr. Mater. 2025, 5, 83. https://doi.org/10.3390/constrmater5040083

Nuryanta MI, Nurhary MA, Firmansyah HN, Joshua D, Hajad M, Widodo RD, Widodo TD, Kusni M, Wiranata A, Kusumawanto A, et al. Optimization of Kaolin Clay Composition for Enhanced Mechanical Properties in 3D-Printed Structures. Construction Materials. 2025; 5(4):83. https://doi.org/10.3390/constrmater5040083

Chicago/Turabian StyleNuryanta, Muhammad Irfan, Muhammad Afif Nurhary, Hendrix Noviyanto Firmansyah, Dicke Joshua, Makbul Hajad, Rahmat Doni Widodo, Teguh Dwi Widodo, Muhammad Kusni, Ardi Wiranata, Arif Kusumawanto, and et al. 2025. "Optimization of Kaolin Clay Composition for Enhanced Mechanical Properties in 3D-Printed Structures" Construction Materials 5, no. 4: 83. https://doi.org/10.3390/constrmater5040083

APA StyleNuryanta, M. I., Nurhary, M. A., Firmansyah, H. N., Joshua, D., Hajad, M., Widodo, R. D., Widodo, T. D., Kusni, M., Wiranata, A., Kusumawanto, A., & Muflikhun, M. A. (2025). Optimization of Kaolin Clay Composition for Enhanced Mechanical Properties in 3D-Printed Structures. Construction Materials, 5(4), 83. https://doi.org/10.3390/constrmater5040083