Experimental Investigation of Low Carbon Concrete Using Ground Seashell Powder as Filler and Partial Cement Replacement

Abstract

1. Introduction

- The outer layer, which is composed of a protein matrix, provides strength and protection.

- The middle layer, made of calcite, a crystalline form of calcium carbonate, contributes to the shell’s shape and stiffness.

- The inner layer is characterised by a highly ordered arrangement of calcium carbonate crystals.

2. Research Aim and Outline

3. Literature Review

4. Materials and Methods

4.1. Raw Materials

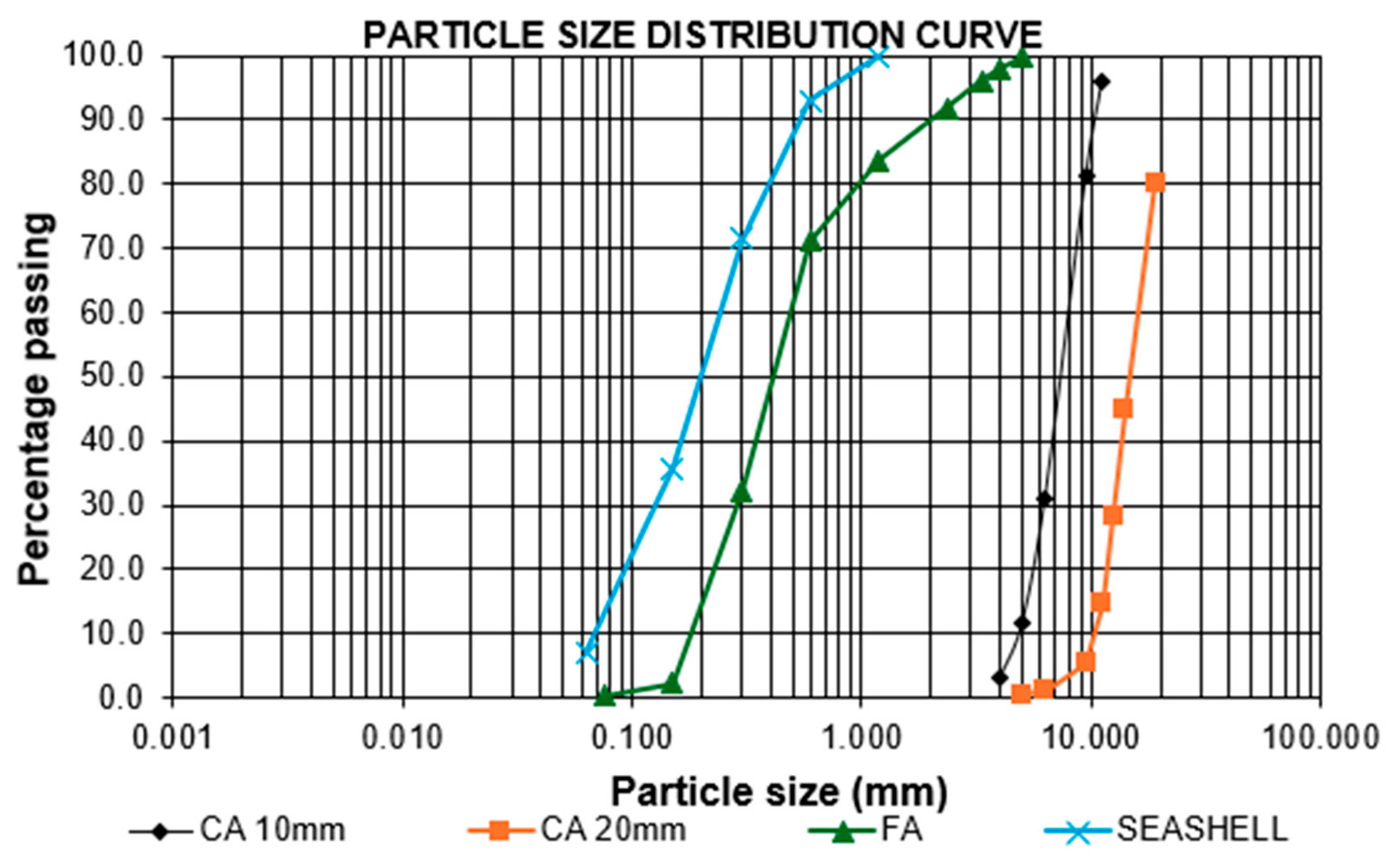

4.2. Particle Size Distribution (PSD)

4.3. Mix Design and Specimen Preparation

4.4. Calculation of Carbon Emission

5. Results and Discussions

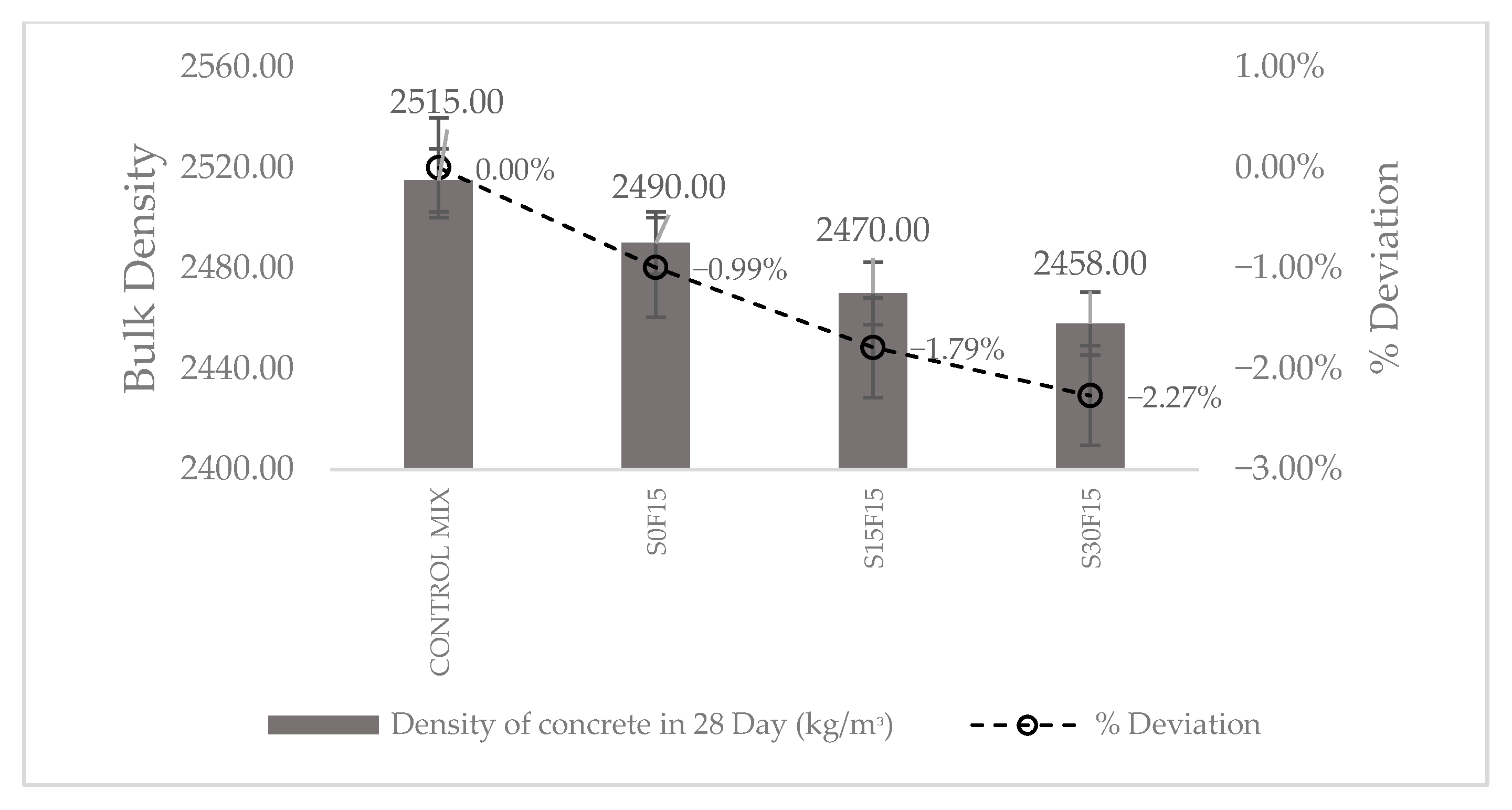

5.1. Density of Concrete

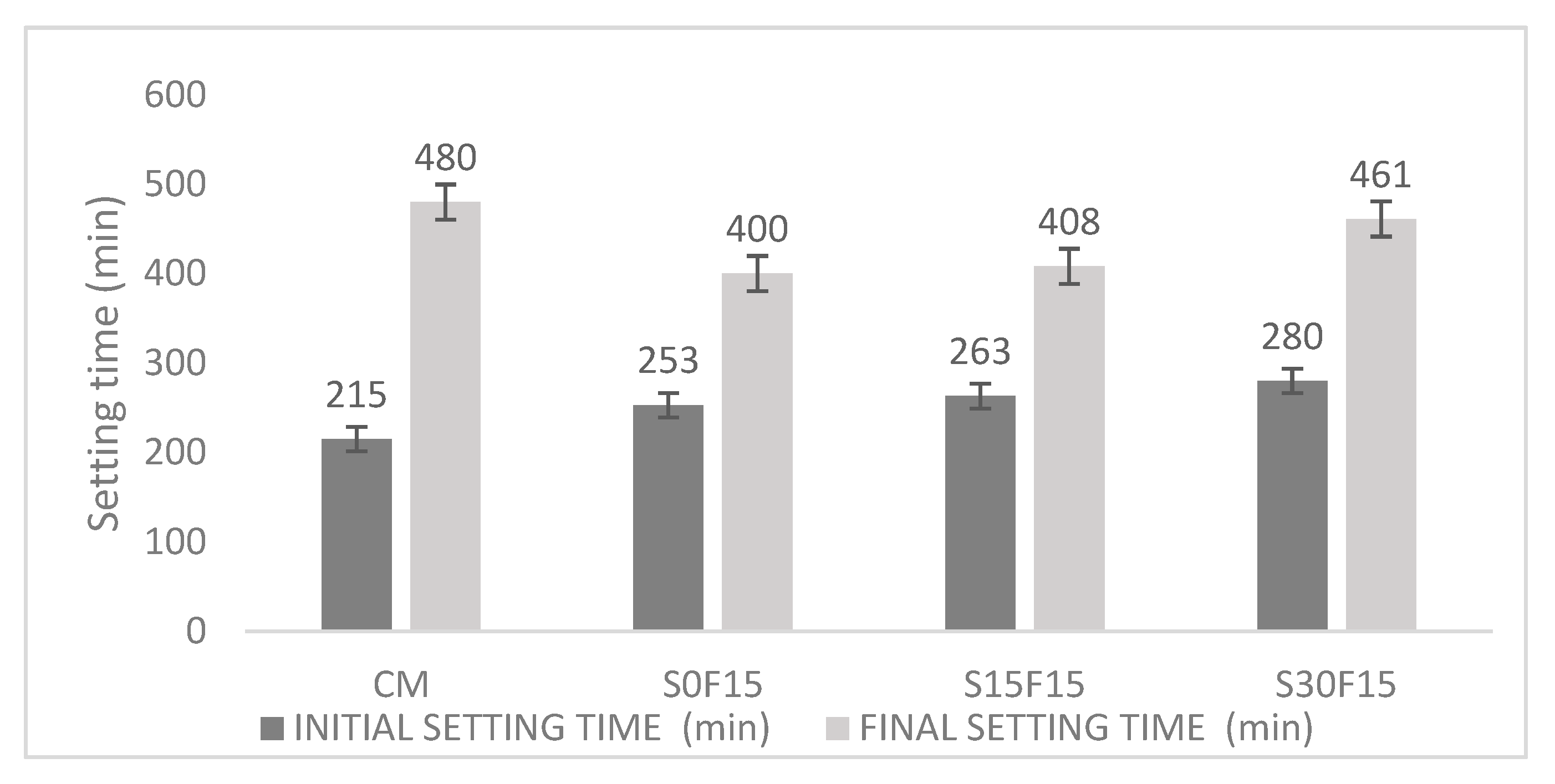

5.2. Initial and Final Setting Time of Concrete Mixes

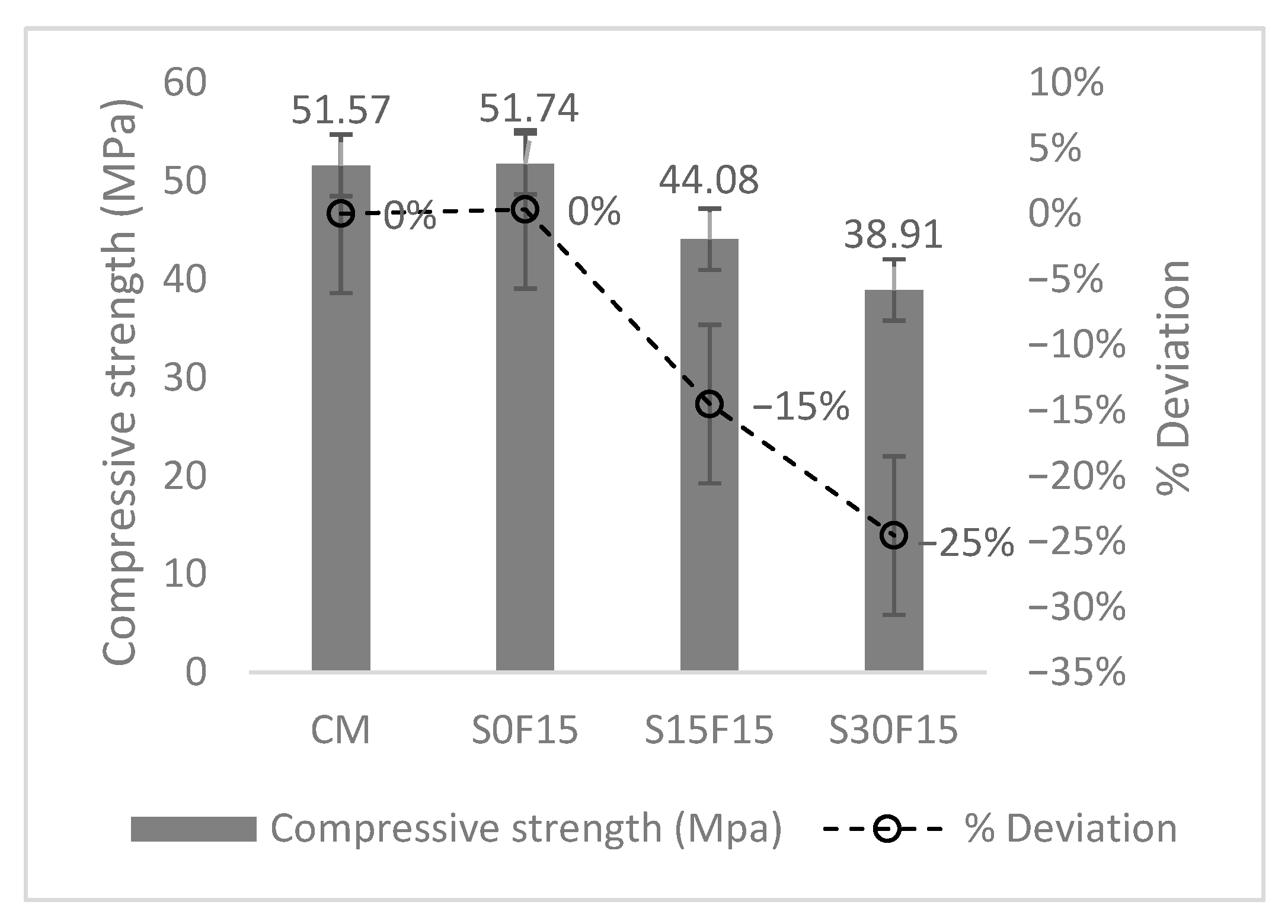

5.3. Compressive Strength Test

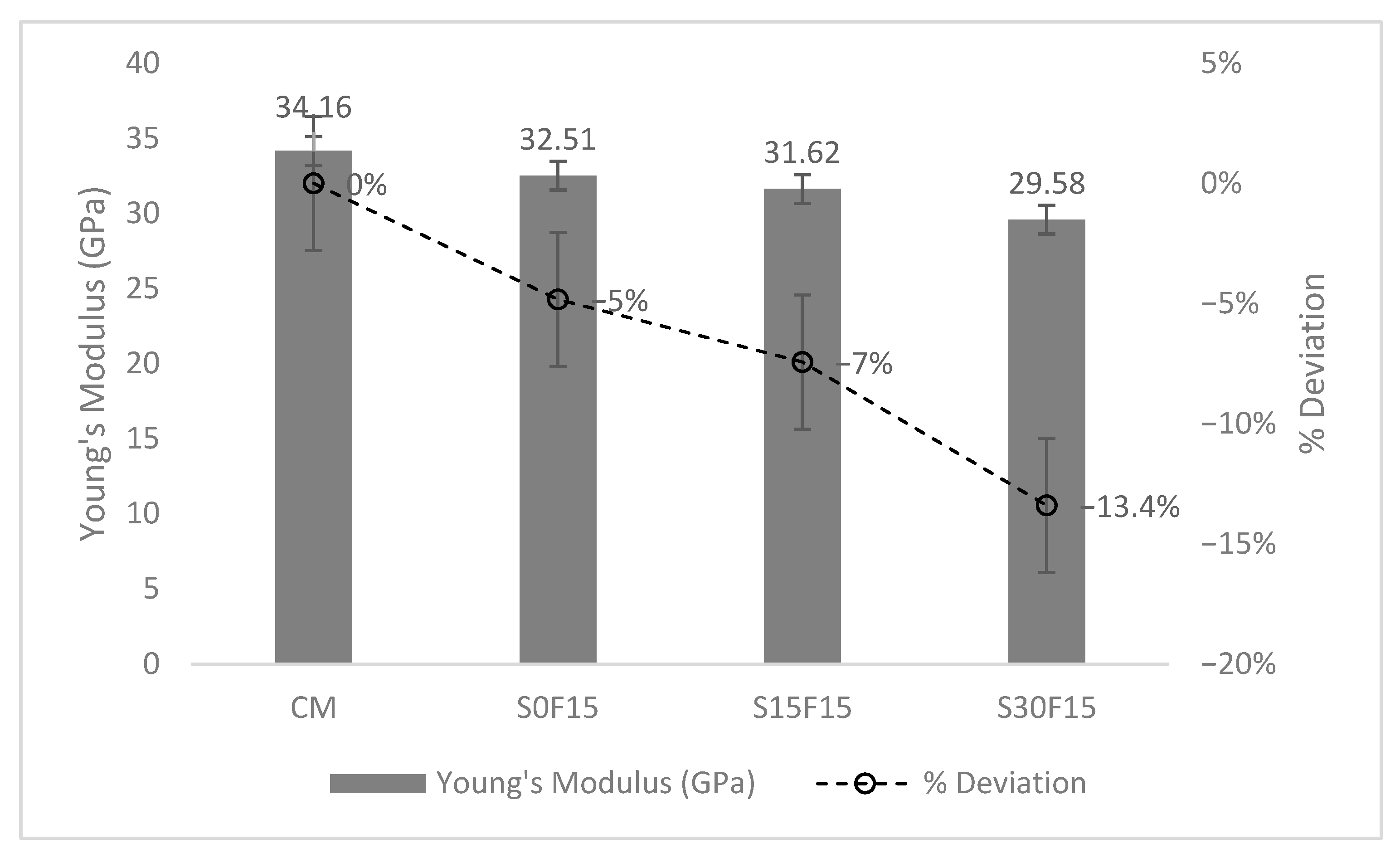

5.4. Modulus of Elasticity

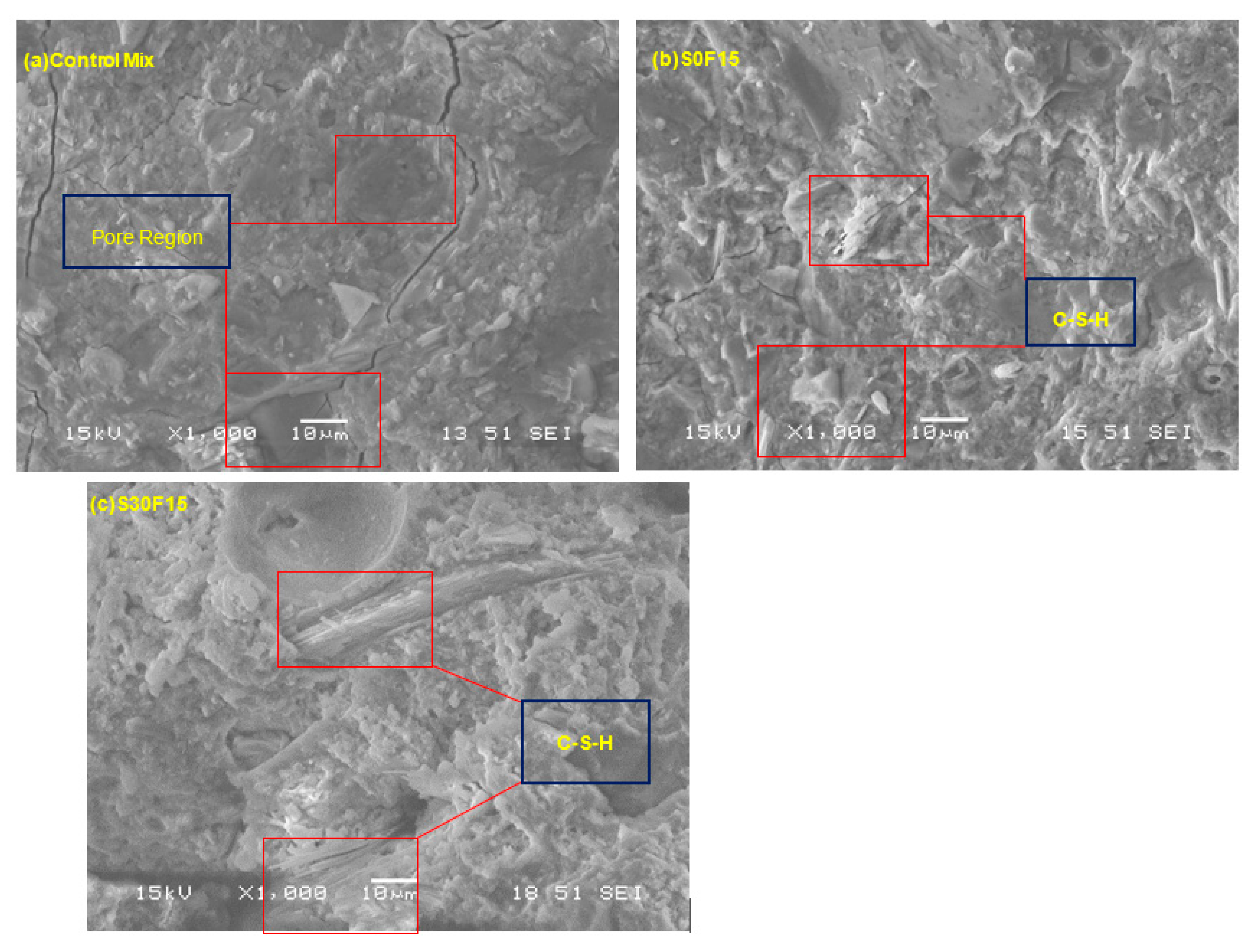

5.5. Scanning Electron Microscopy (SEM)

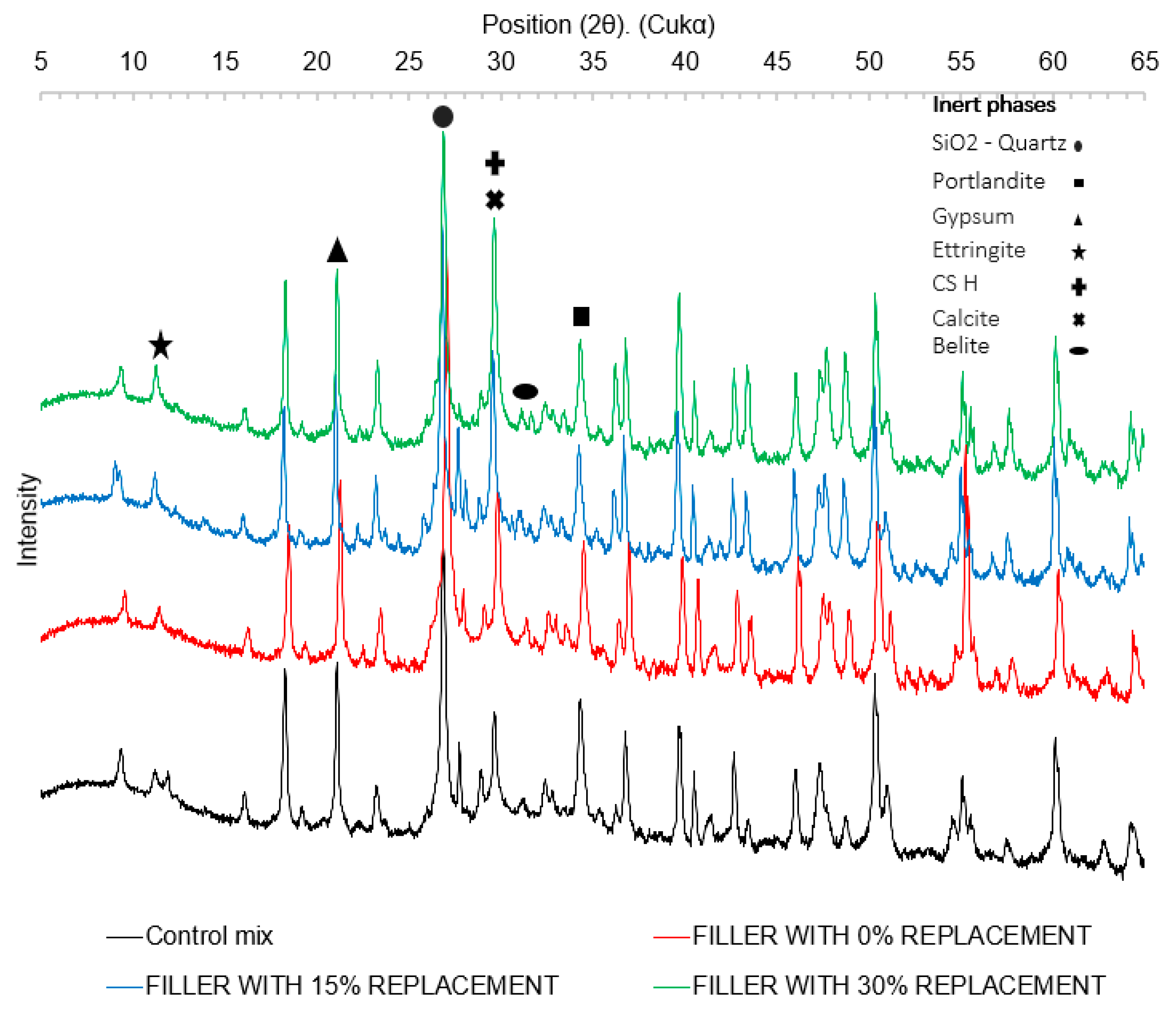

5.6. X-Ray Diffraction (XRD)

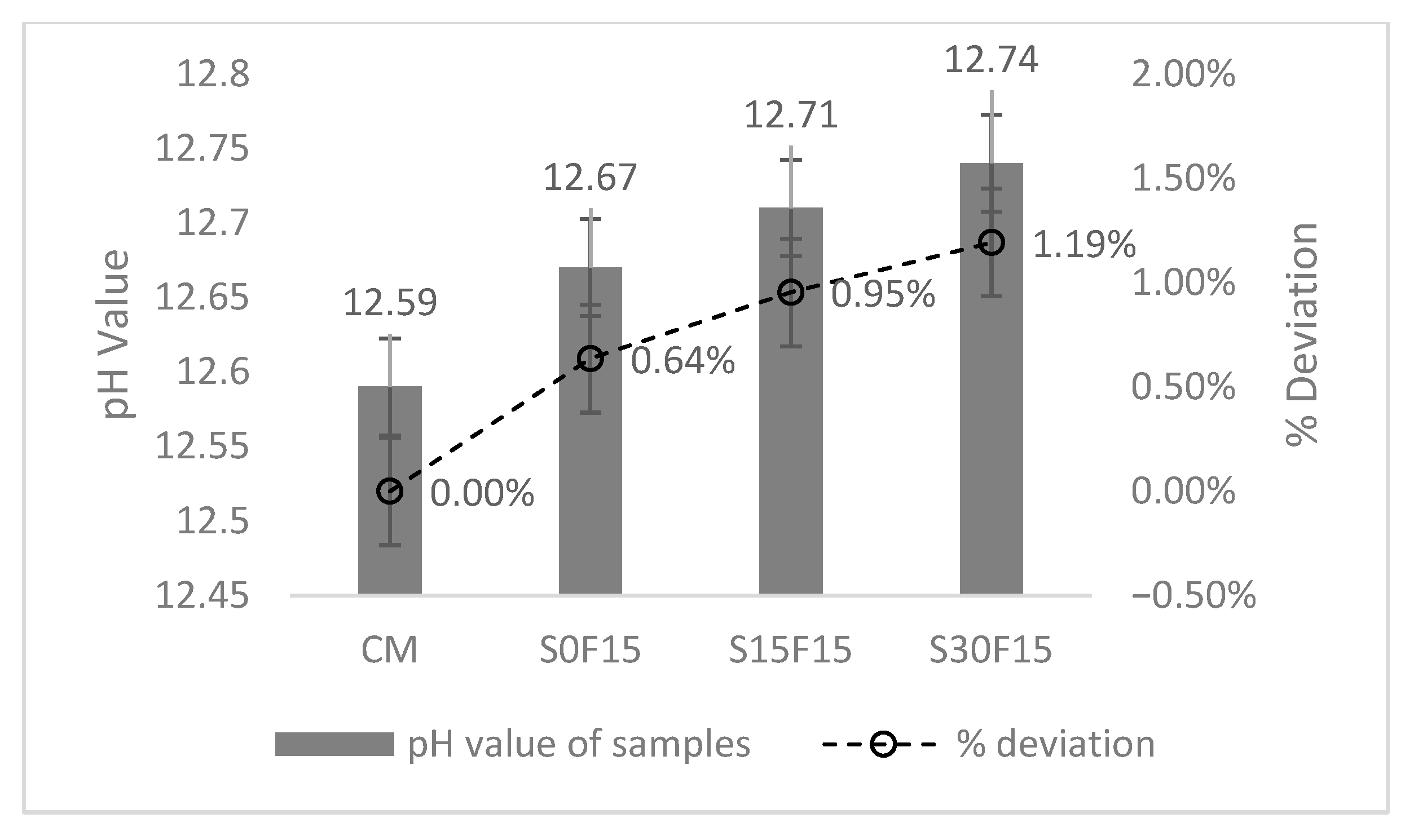

5.7. Alkalinity Test

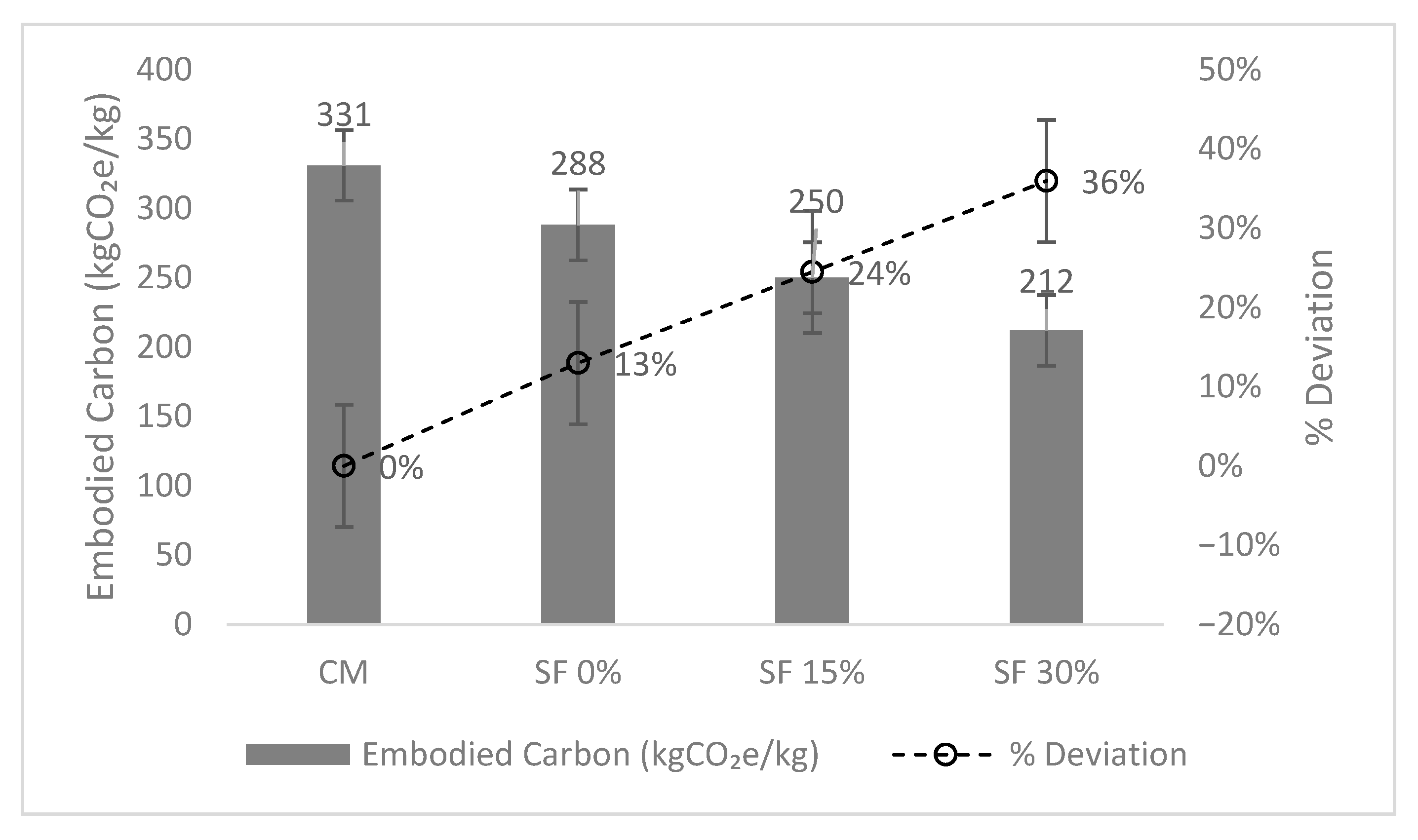

5.8. Carbon Emissions

6. Conclusions

- The seashells were initially ground to a powder form, within the size range of 63–125 microns, which can be used as filler and 0–63 microns used as cement replacement material in conventional concrete. The key benefit is to utilise this recycled waste to reduce the carbon emissions of concrete without negatively affecting its performance. The cement was reduced by 15%, 30% and 45% (with seashell powder utilised as 15% filler, 15% filler + 15% cement replacement, and 15% filler + 30% cement replacement, respectively).

- Utilising waste seashells facilitates the production of environmentally friendly concrete. Specifically, when compared to conventional concrete, incorporating seashells into the mix with 15% and 30% seashell powder content as cement replacement (plus 15% cement replaced with the powder acting as a filler in both cases), resulted in a notably lower carbon emission by about one quarter to one third, respectively.

- The compressive strength of concrete with seashells was reduced as the fraction of seashell replacement increased. The compressive strength of different mix combinations displayed a moderate descending trend. The highest strength was observed in a mix without any partial replacement of cement with seashells, but with the inclusion of 15% seashell filler. This is almost the same value as that of the control mix. On the other hand, the mix featuring 30% partial replacement demonstrated ~25% reduction in strength over the control mix.

- Experimental results from the tested concrete cylinders revealed that the Young’s modulus of elasticity of the seashell-powder-containing concrete mixes was moderately lower than the control mix counterpart. The reductions were about 5%, 7% and 13% for mixes S0F15, S15F15 and S30F15, respectively, compared to the control mix CM. These results suggest that the inclusion of seashells up to an optimum level does not drastically affect the stiffness properties of the resulting concrete material.

- The bulk density of concrete reduces as the proportion of seashell insertion increases. This tendency shows that because seashells have a lower density than typical aggregates, they diminish the total density of the concrete. However, the decrease is very small, ranging from 0.99% to 2.27% of the control mix (as the percentage of partial replacement of cement and the filler effect of seashells increases).

- The initial setting time showed a 30% increase compared to the control mix when seashells were added at a 30% partial replacement, while the final setting time decreased by about 12%. This is mainly due to the porous nature of seashells, which can absorb water and retards the hydration process in the early stage.

- The microstructural analysis using the SEM analysis revealed denser microstructures with fewer microcracks and enhanced C–S–H gel formation in seashell-modified concretes, particularly in the S30F15 mix, indicating improved matrix densification and hydration. XRD analysis confirmed an increase in calcite and a reduction in portlandite content with higher seashell levels, signifying beneficial filler and secondary reaction effects that enhance structural compactness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eziefula, U.G.; Ezeh, J.C.; Eziefula, B.I. Properties of seashell aggregate concrete: A review. Constr. Build. Mater. 2018, 192, 287–300. [Google Scholar] [CrossRef]

- Borrachero, M.V.; Payá, J.; Brito, S.; Segura, Y.P.; Soriano, L.; Tashima, M.M.; Monzó, J.M. Reusing Construction and DemolitionWaste to Prepare Alkali-Activated Cement. Materials 2022, 15, 3437. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A.; Gobinath, R. Role of recycling fine materials as filler for improving the performance of concrete—A review. Aust. J. Civ. Eng. 2019, 17, 85–95. [Google Scholar] [CrossRef]

- Kanavaris, F.; Gibbons, F.; Walport, E.; Shearer, E.; Abbas, A.A.; Orr, J.; Marsh, B. Reducing embodied carbon dioxide of structural concrete with lightweight aggregate. Proc. Inst. Civ. Eng. Eng. Sustain. 2022, 175, 75–83. [Google Scholar] [CrossRef]

- Abbas, A.; Mahadevan, M.; Prajapati, S.; Ayati, B.; Kanavaris, F. Development of low-carbon lightweight concrete using pumice as aggregate and cement replacement. In Proceedings of the RILEM International Conference on Synergising Expertise Towards Sustainability and Robustness of Cement-based Materials and Concrete Structures (SynerCrete’23), Milos, Greece, 14–16 June 2023; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Nasaeng, P.; Wongsa, A.; Cheerarot, R.; Sata, V.; Chindaprasirt, P. Strength enhancement of pumice-based geopolymer paste by incorporating recycled concrete and calcined oyster shell powders. Case Stud. Constr. Mater. 2022, 17, e01307. [Google Scholar] [CrossRef]

- Abbas, A.; Jabr, E. Experimental investigation of bio-concrete using eggshells as supplementary cementitious material. In Proceedings of the Concrete Solutions 2025—9th International Conference on Concrete Repair, Durability & Technology, MATEC Web of Conferences, Lisbon, Portugal, 16–18 June 2025; Volume 409, p. 13007. [Google Scholar] [CrossRef]

- Chen, J.J.; Ng, P.L.; Li, B.H.; Kwan, A.K.H. Concurrent paste replacement and aggregate replacement strategy for producing eco-efficient and low-carbon concrete. Clean. Technol. Environ. Policy 2022, 24, 2459–2477. [Google Scholar] [CrossRef]

- Kang, S.H.; Hong, S.G.; Moon, J. The use of rice husk ash as reactive filler in ultra-high performance concrete. Cem. Concr. Res. 2019, 115, 389–400. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, D.; Yu, X.; Liu, R.; Liao, Y. Properties of Cementitious Materials Utilizing Seashells as Aggregate or Cement: Prospects and Challenges. Materials 2024, 17, 1222. [Google Scholar] [CrossRef]

- Ephraim, M.E.; ThankGod, O.; Gbinu, K.S. Performance of high Strength Concrete Using Oyster Shell Ash as Partial Replacement for Cement. SSRG Int. J. Civ. Eng. 2019, 6, 33–38. [Google Scholar] [CrossRef]

- González-Caro, Á.; Merino-Lechuga, A.M.; Fernández-Ledesma, E.; Fernández-Rodríguez, J.M.; Jiménez, J.R.; Suescum-Morales, D. The Effect of Acanthocardia tuberculata Shell Powder as Filler on the Performance of Self-Compacting Mortar. Materials 2023, 16, 1734. [Google Scholar] [CrossRef]

- Magnabosco, G.; Giuri, D.; Di Bisceglie, A.P.; Scarpino, F.; Fermani, S.; Tomasini, C.; Falini, G. New material perspective for waste seashells by covalent functionalization. ACS Sustain. Chem. Eng. 2021, 9, 6203–6208. [Google Scholar] [CrossRef]

- Joseph, O.O. Evaluation of the properties of lightweight concrete using periwinkle shells as a partial replacement for coarse aggregate. J. Appl. Sci. Environ. Manag. 2016, 20, 497–505. [Google Scholar] [CrossRef]

- Orangun, C.O. The suitability of periwinkle shells as coarse aggregate for structural concrete. Mater. Constr. 1974, 7, 341–346. [Google Scholar] [CrossRef]

- Liao, Y.; Fan, J.; Li, R.; Da, B.; Chen, D.; Zhang, Y. Influence of the usage of waste oyster shell powder on mechanical properties and durability of mortar. Adv. Powder Technol. 2020, 23, 103503. [Google Scholar] [CrossRef]

- Silva, A.L.d.; Kohlman Rabbani, E.R.; Shakouri, M. Seashell Powder as a Sustainable Alternative in Cement-Based Materials: A Systematic Literature Review. Sustainability 2025, 17, 592. [Google Scholar] [CrossRef]

- Jasni, S.A.; Muthusamy, K.; Ruslan, H.N.; Hamada, H.M.; Ab Wahab, E.S. Use of Seashell as Cement Replacement in Construction Material: A Review. Construction 2024, 4, 7–20. [Google Scholar] [CrossRef]

- Hasan, K.; Karim, A.; Islam, M.T.; Ali, M.B.; Rahman, M.T.; Rahman, M.M.; Yahaya, F.M. A review of the mechanical properties and durability of concrete containing recycled seashells as a partial cement replacement. J. Mater. Cycles Waste Manag. 2023, 25, 3192–3216. [Google Scholar] [CrossRef]

- Abbas, A.; Abdalla, K.; Saji, G. Experimental investigation of seashell concrete with anti-corrosion agent enhancement. In Proceedings of the Concrete Solutions 2025—9th International Conference on Concrete Repair, Durability & Technology, MATEC Web of Conferences, Lisbon, Portugal, 16–18 June 2025; Volume 409, p. 14003. [Google Scholar] [CrossRef]

- Abbas, A.; Abdalla, K.; Sidgel, A. Self-healing of concrete incorporating seashells as partial cement replacement. In Proceedings of the Concrete Solutions 2025—9th International Conference on Concrete Repair, Durability & Technology, MATEC Web of Conferences, Lisbon, Portugal, 16–18 June 2025; Volume 409, p. 14004. [Google Scholar] [CrossRef]

- Bamigboye, G.; Enabulele, D.; Odetoyan, A.O.; Kareem, M.A.; Nworgu, A.; Bassey, D. Mechanical and durability assessment of concrete containing seashells: A review. Cogent Eng. 2021, 8, 1883830. [Google Scholar] [CrossRef]

- Nukah, P.D.; Abbey, S.J.; Booth, C.A.; Nounu, G. Optimisation of embodied carbon and compressive strength in low-carbon concrete. Materials 2022, 15, 8673. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Nworgu, A.T.; Odetoyan, A.O.; Kareem, M.; Enabulele, D.O.; Bassey, D.E. Sustainable use of seashells as binder in concrete production: Prospect and challenges. J. Build. Eng. 2021, 34, 101864. [Google Scholar] [CrossRef]

- Leman, A.S.; Shahidan, S.; Nasir, A.J.; Senin, M.S.; Mohd Zuki, S.S.; Wan Ibrahim, M.H.; Deraman, R.; Khalid, F.S.; Azhar, A.T.S. Properties of concrete containing coconut shell powder (CSP) as a filler. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012006. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E.; Li, L. Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J. Clean. Prod. 2019, 220, 235–252. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Okechukwu, U.E.; Olukanni, D.O.; Bassey, D.E.; Okorie, U.E.; Adebesin, J.; Jolayemi, K.J. An effective economic combination of waste seashell and river sand as fine aggregate in green concrete. Sustainability 2022, 14, 12822. [Google Scholar] [CrossRef]

- Othman, N.H.; Bakar, B.H.A.; Don, M.M.; Johari, M.A.M. Cockle shell ash replacement for cement and filler in concrete. Malays. J. Civ. Eng. 2013, 25, 201–211. [Google Scholar] [CrossRef]

- Anagnostopoulos, N.; Sideris, K.K.; Georgiadis, A. Mechanical characteristics of self-compacting concretes with different filler materials, exposed to elevated temperatures. Mater. Struct. 2009, 42, 1393–1405. [Google Scholar] [CrossRef]

- Galan, I.; Briendl, L.; Thumann, M.; Steindl, F.; Röck, R.; Kusterle, W.; Mittermayr, F. Filler effect in shotcrete. Materials 2019, 12, 3221. [Google Scholar] [CrossRef]

- Liao, Y.; Shi, H.; Zhang, S.; Da, B.; Chen, D. Particle size effect of oyster shell on mortar: Experimental investigation and modelling. Materials 2021, 14, 6813. [Google Scholar] [CrossRef]

- BS EN 206:2013+A2:2021; Concrete. Specification, Performance, Production and Conformity. British Standards Institution: London, UK, 2021. [CrossRef]

- Teychenné, D.C.; Franklin, R.E.; Erntroy, H.C. Design of Normal Concrete Mixes, 2nd ed.; BRE Report BR 331; Building Research Establishment (BRE): Garston, Watford, UK, 1997; ISBN 978-1-86081-172-2. [Google Scholar]

- BS EN 12350-2:2019; Testing Fresh Concrete—Slump Test. British Standards Institution: London, UK, 2019. [CrossRef]

- Nowtricity. Current Emissions in the United Kingdom. CO2 Emissions per kWh in United Kingdom—Nowtricity. Available online: https://www.nowtricity.com/country/united-kingdom/ (accessed on 13 March 2025).

- Gibbons, O.P.; Orr, J.J.; Archer-Jones, C.; Arnold, W.; Green, C. How to Calculate Embodied Carbon, 2nd ed.; Institution of Structural Engineers (IStructE): London, UK, 2022. [Google Scholar]

- Kim, J.; Cha, I.; Jo, B.; Lee, H. Evaluation of compressive strength of eco-friendly cementitious composites incorporating waste oyster shells under sodium chloride solution exposure. Case Stud. Constr. Mater. 2025, 23, e04944. [Google Scholar] [CrossRef]

- BS EN 197-1:2011; Cement—Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2019.

- Eisa, M.S.; Basiouny, M.E.; Youssef, A.M. Effect of using various waste materials as mineral filler on the properties of the asphalt mix. Innov. Infrastruct. Solut. 2018, 3, 29. [Google Scholar] [CrossRef]

- BS EN 12390-13:2021; Testing Hardened Concrete—Determination of Secant Modulus of Elasticity in Compression. British Standards Institution: London, UK, 2021. [CrossRef]

- Nduka, D.O.; Akanbi, E.T.; Ojo, D.O.; Babayemi, T.E.; Jolayemi, K.J. Investigation of the mechanical and microstructural properties of masonry mortar made with seashell particles. Materials 2023, 16, 2471. [Google Scholar] [CrossRef]

- Zhou, M.; Chen, J.; Huang, W.; Chao, H.; Yu, L.; Ma, X.; Ouyang, X. Multiscale study on the effect of Seashell powder on rheology, hydration and strength development of cement paste. Constr. Build. Mater. 2024, 456, 139257. [Google Scholar] [CrossRef]

- Chung, S.Y.; Oh, S.E.; Jo, S.S.; Lehmann, C.; Won, J.; Elrahman, M.A. Microstructural investigation of mortars incorporating cockle shell and waste fishing net. Case Stud. Constr. Mater. 2023, 18, e01719. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Professional: New York, NY, USA, 2014; ISBN 9780071797870. [Google Scholar]

| Type of Material | Specific Gravity | Water Absorption (%) |

|---|---|---|

| Fine Aggregate | 2.37 | 7.06 |

| Coarse Aggregate (5–10 mm) | 3.00 | 0.68 |

| Coarse Aggregate (10–20 mm) | 2.56 | 0.53 |

| Seashell Powder | 2.38 | 1.42 |

| Materials | Control Mix | S0F15 | S15F15 | S30F15 |

|---|---|---|---|---|

| Cement Content * | 350 | 300 | 255 | 210 |

| Seashell-Cement Replacement | 0 | 0 | 45 (15%) | 90 (30%) |

| Seashell-Filler | 0 | 50 (15%) | 50 (15%) | 50 (15%) |

| Water Content | 160 | 160.75 | 161.43 | 162.10 |

| Coarse Aggregate (10–20 mm) | 925 | 925 | 925 | 925 |

| Coarse Aggregate (5–10 mm) | 465 | 465 | 465 | 465 |

| Fine Aggregate (<5 mm) | 510 | 510 | 510 | 510 |

| Type of Material | Emission Factor |

|---|---|

| Cement | 0.91 [36] |

| Water | 0.000344 [36] |

| Fine Aggregate | 0.004 [36] |

| Coarse Aggregate | 0.00747 [36] |

| Seashell Powder | 0.059 (new proposed value) |

| Phase | Control Mix | S0F15 | S15F15 | S30F15 |

|---|---|---|---|---|

| Quartz | 60.6 | 68.0 | 57.9 | 58.1 |

| Portlandite | 9.8 | 6.1 | 6.3 | 5.4 |

| Gypsum | 7.6 | 4.4 | 2.9 | 2.8 |

| Ettringite | 10.4 | 5.7 | 5.7 | 6.9 |

| C-S-H | 2.6 | 2.7 | 1.0 | 1.3 |

| Calcite | 5.8 | 10.6 | 18.2 | 25.0 |

| Belite | 0.8 | 0.5 | 1.1 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, A.; Kudukkan, A. Experimental Investigation of Low Carbon Concrete Using Ground Seashell Powder as Filler and Partial Cement Replacement. Constr. Mater. 2025, 5, 82. https://doi.org/10.3390/constrmater5040082

Abbas A, Kudukkan A. Experimental Investigation of Low Carbon Concrete Using Ground Seashell Powder as Filler and Partial Cement Replacement. Construction Materials. 2025; 5(4):82. https://doi.org/10.3390/constrmater5040082

Chicago/Turabian StyleAbbas, Ali, and Anjana Kudukkan. 2025. "Experimental Investigation of Low Carbon Concrete Using Ground Seashell Powder as Filler and Partial Cement Replacement" Construction Materials 5, no. 4: 82. https://doi.org/10.3390/constrmater5040082

APA StyleAbbas, A., & Kudukkan, A. (2025). Experimental Investigation of Low Carbon Concrete Using Ground Seashell Powder as Filler and Partial Cement Replacement. Construction Materials, 5(4), 82. https://doi.org/10.3390/constrmater5040082