Cost-Effective Perspective of Fiber-Reinforced Geopolymer Concrete Under Different Curing Regimes

Abstract

1. Introduction

2. Experimental Program

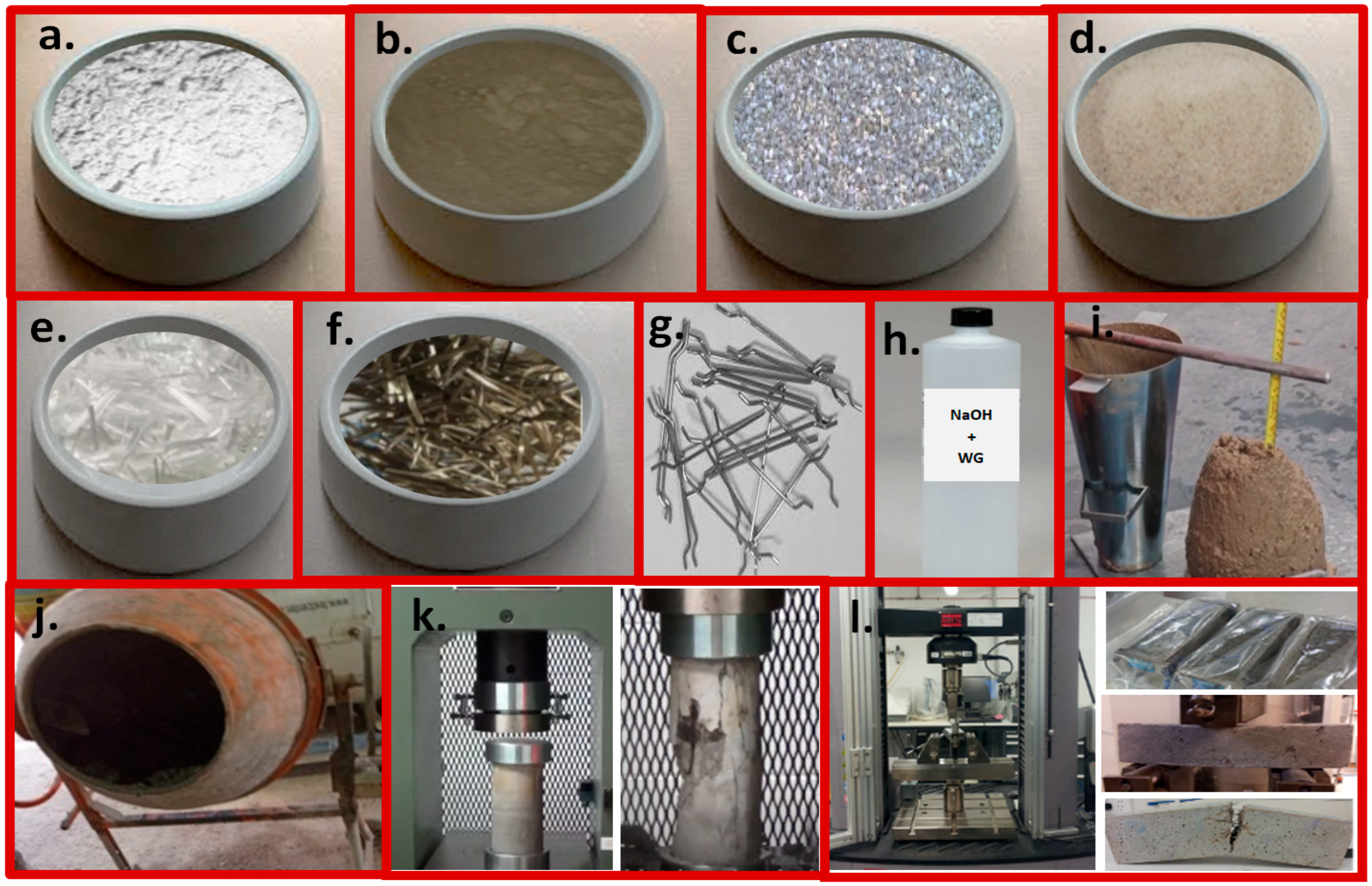

2.1. Materials

2.2. Mix Proportions

2.3. Specimen Preparation and Testing Procedure

3. Results and Discussion

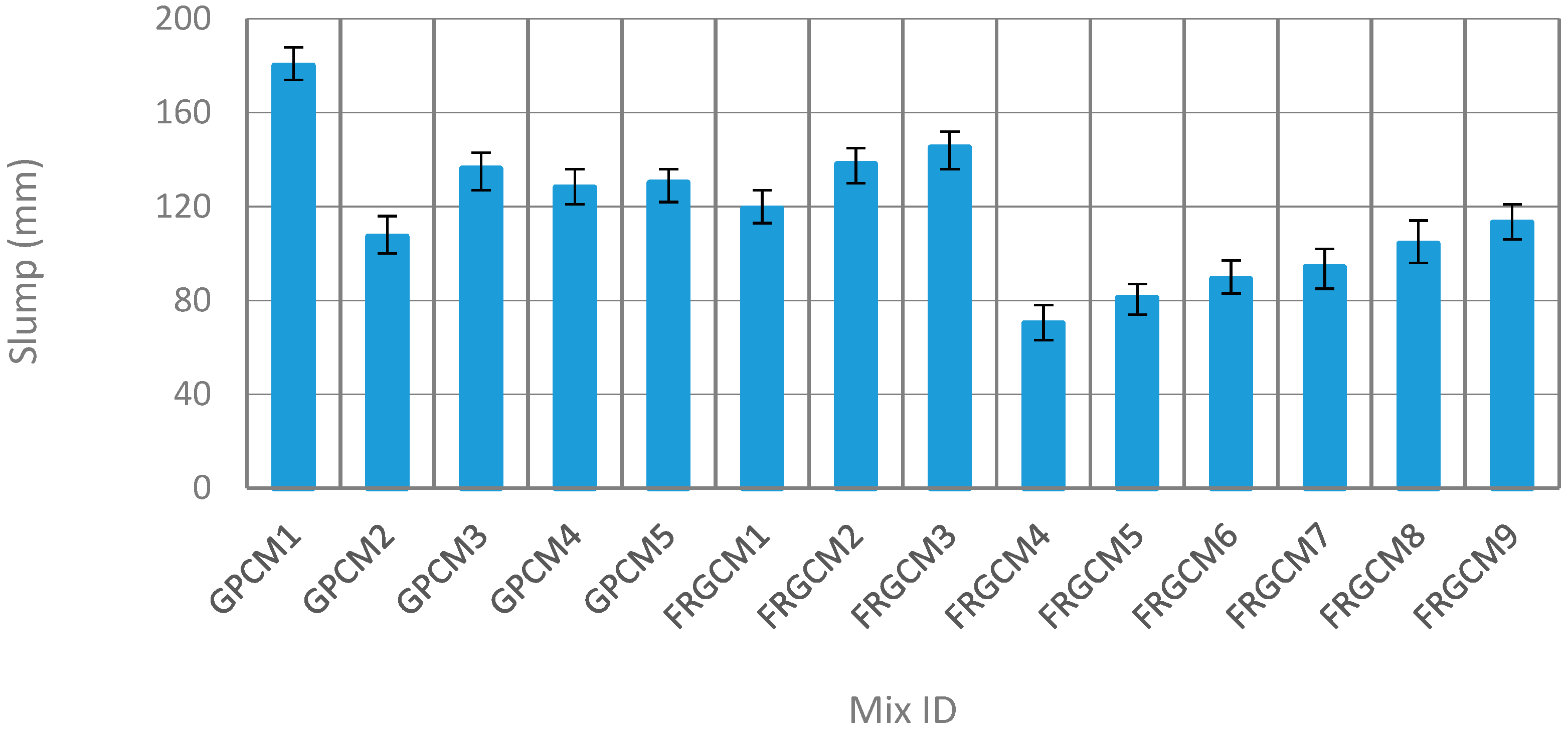

3.1. Fresh Properties

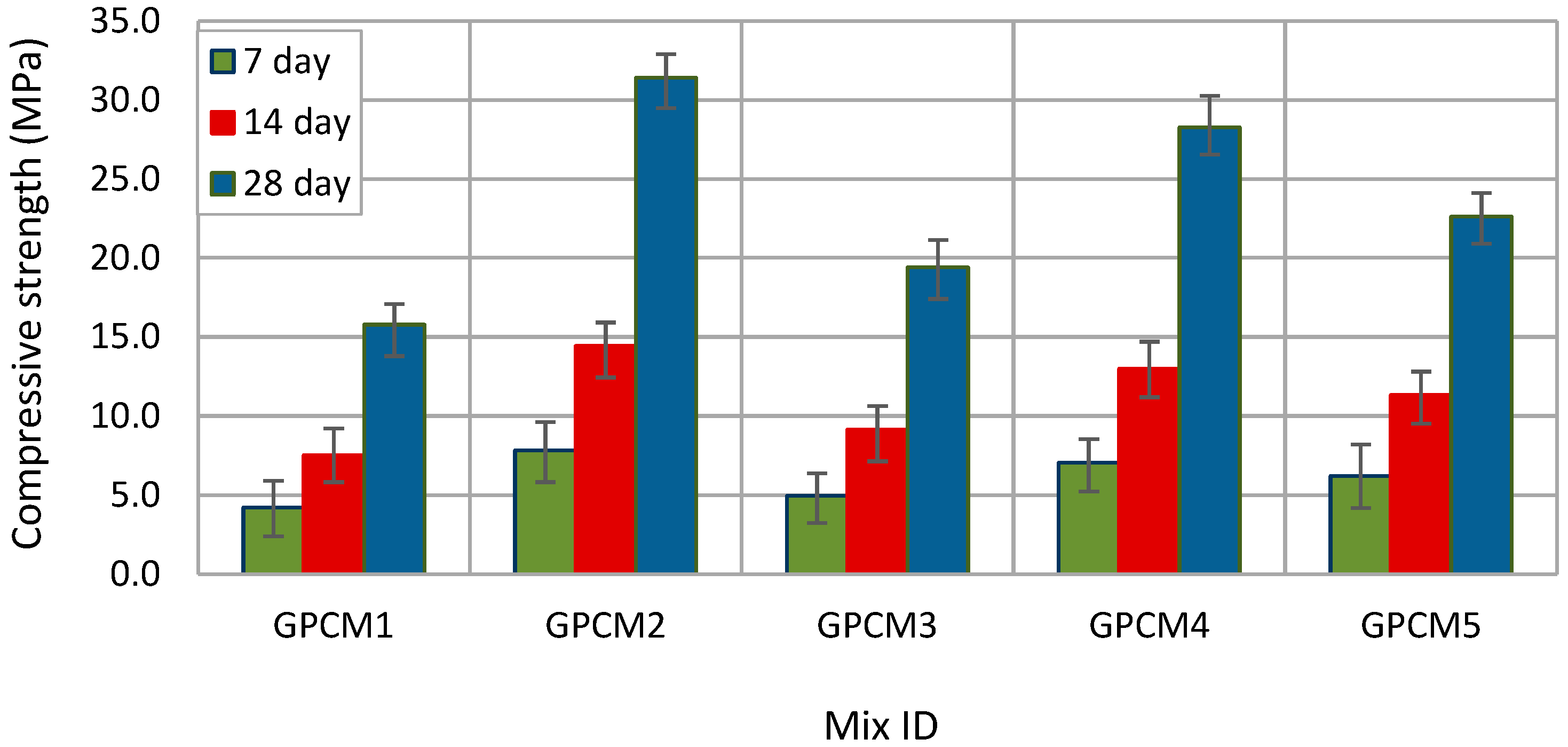

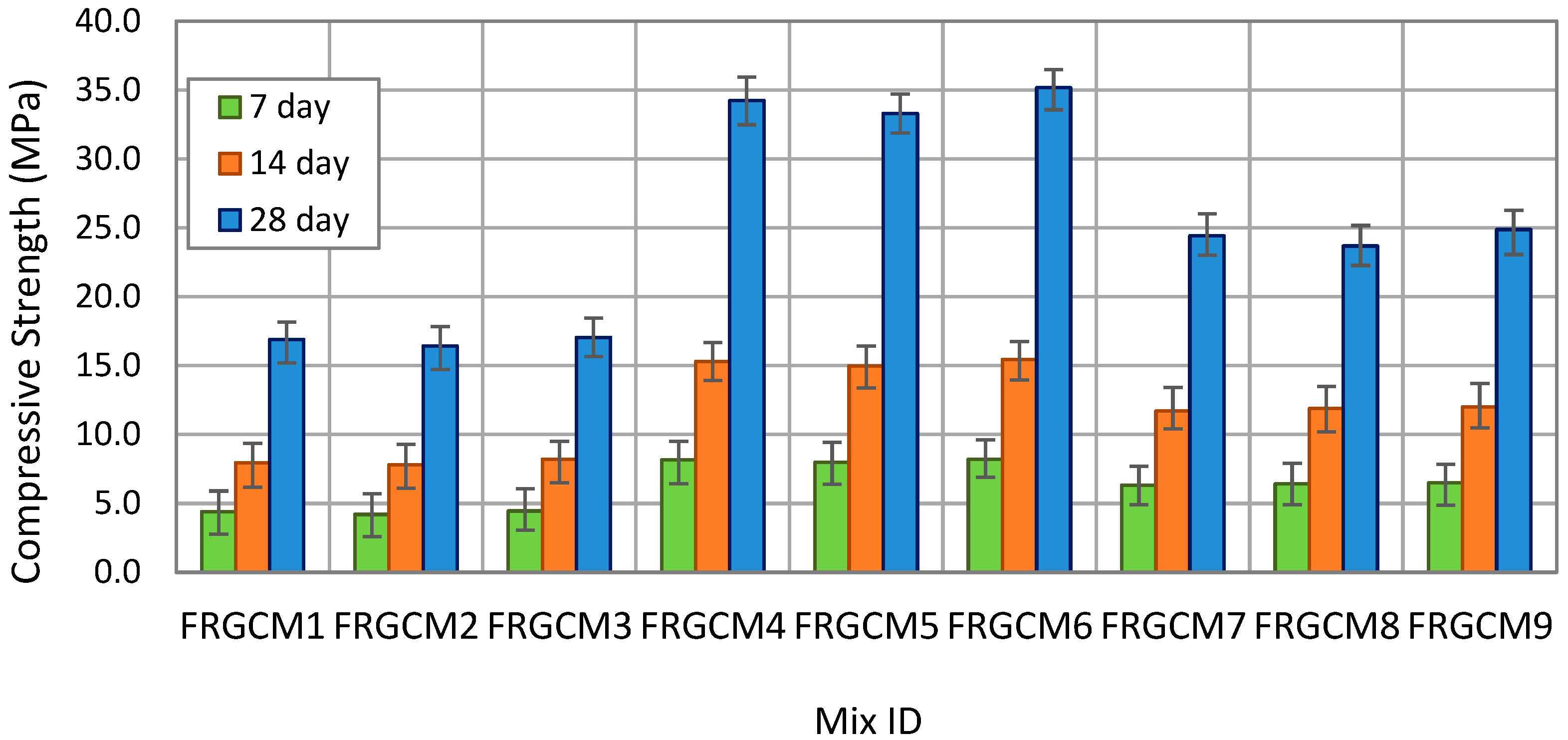

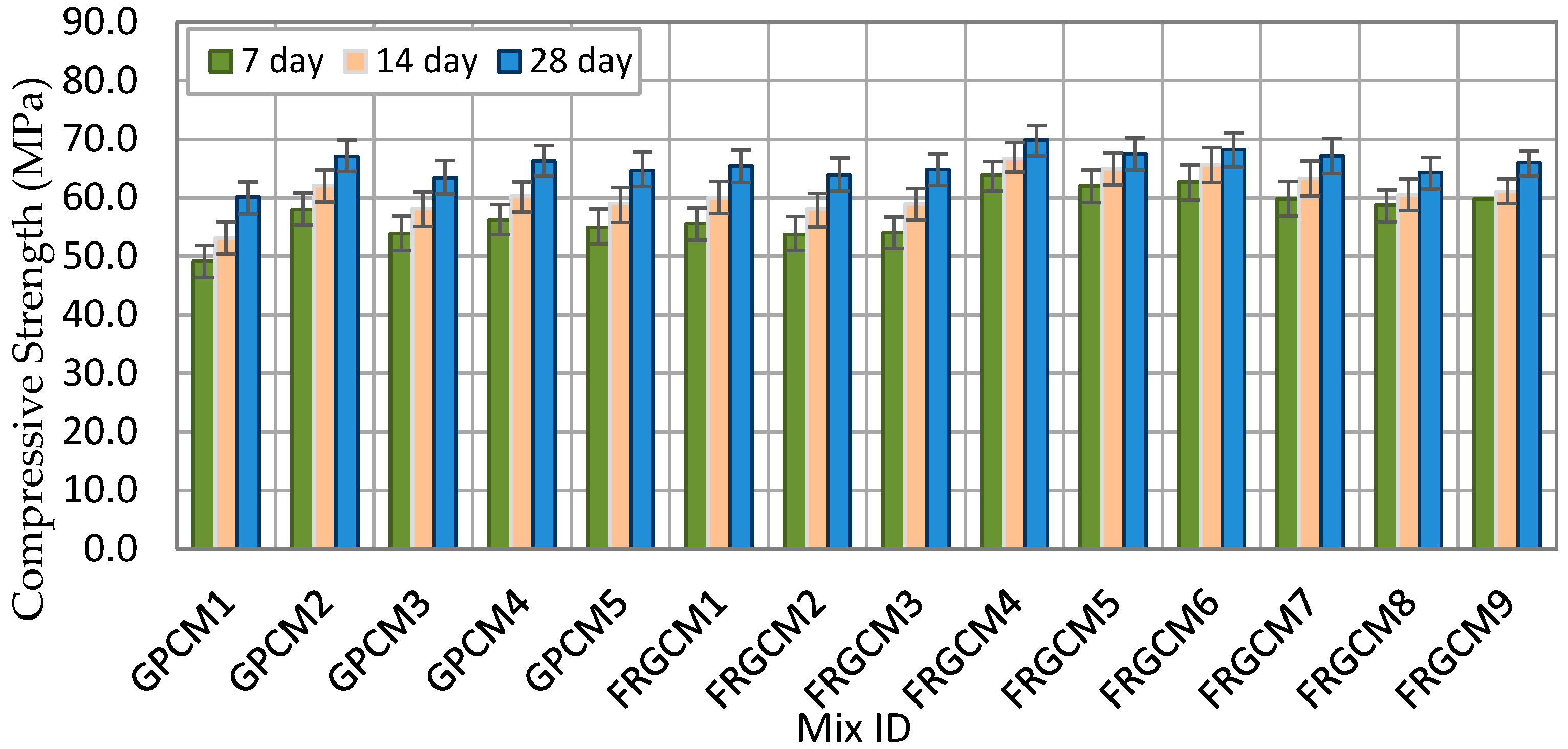

3.2. Compressive Strength

3.2.1. Effect of Geopolymer-Based Materials

3.2.2. Effect of Imbedded Fibers

3.2.3. Effect of Different Curing Regimes

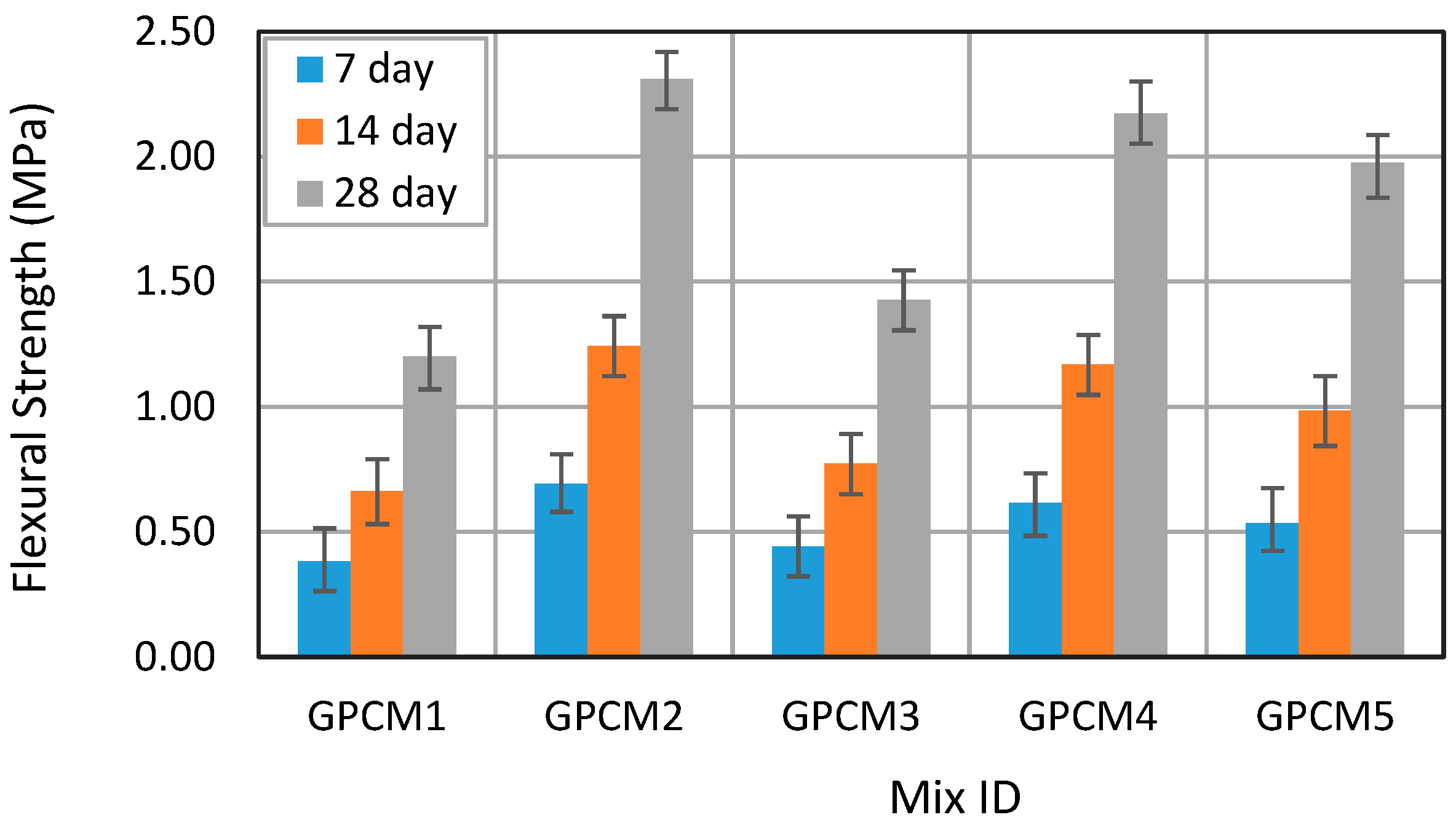

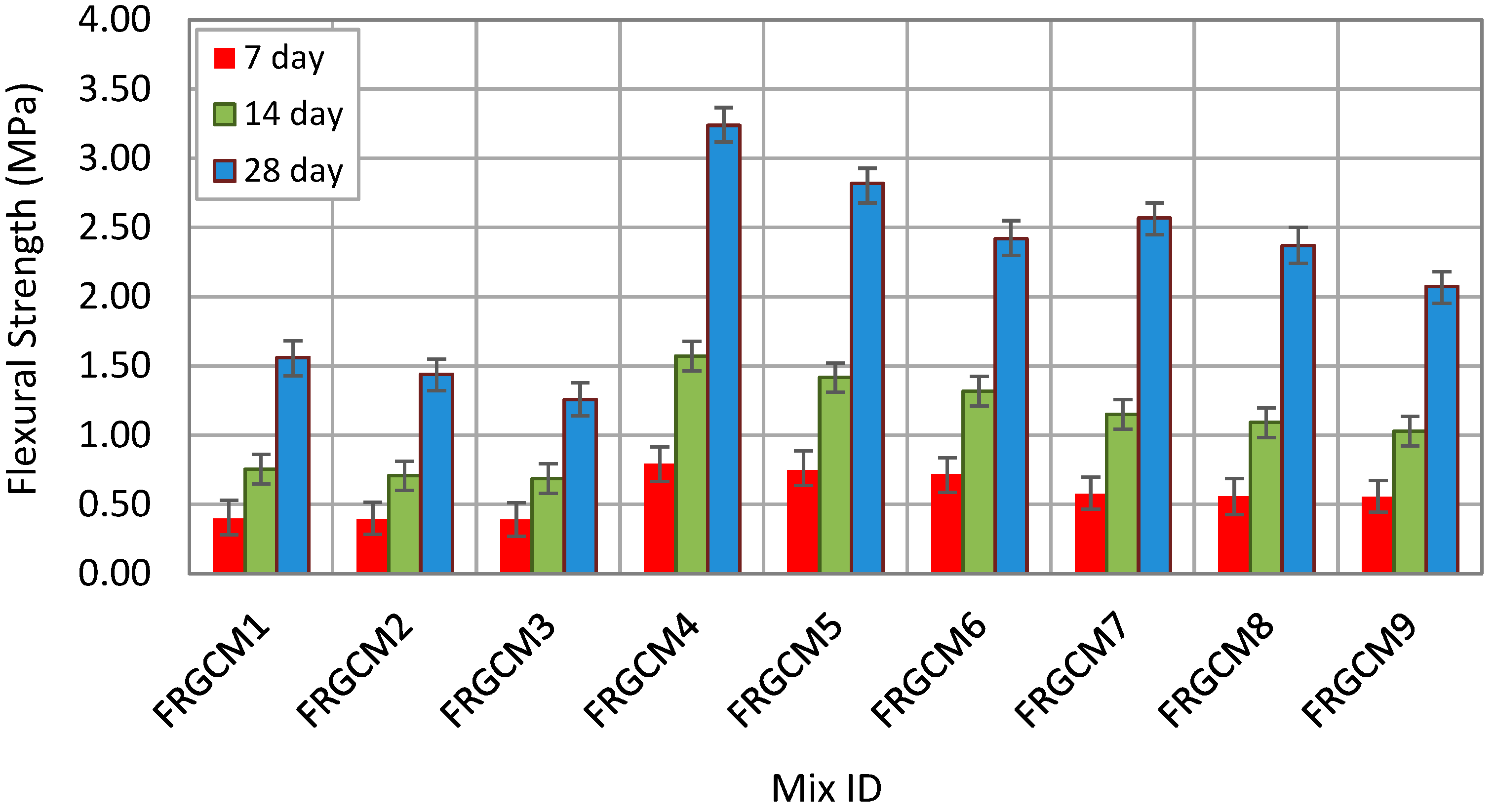

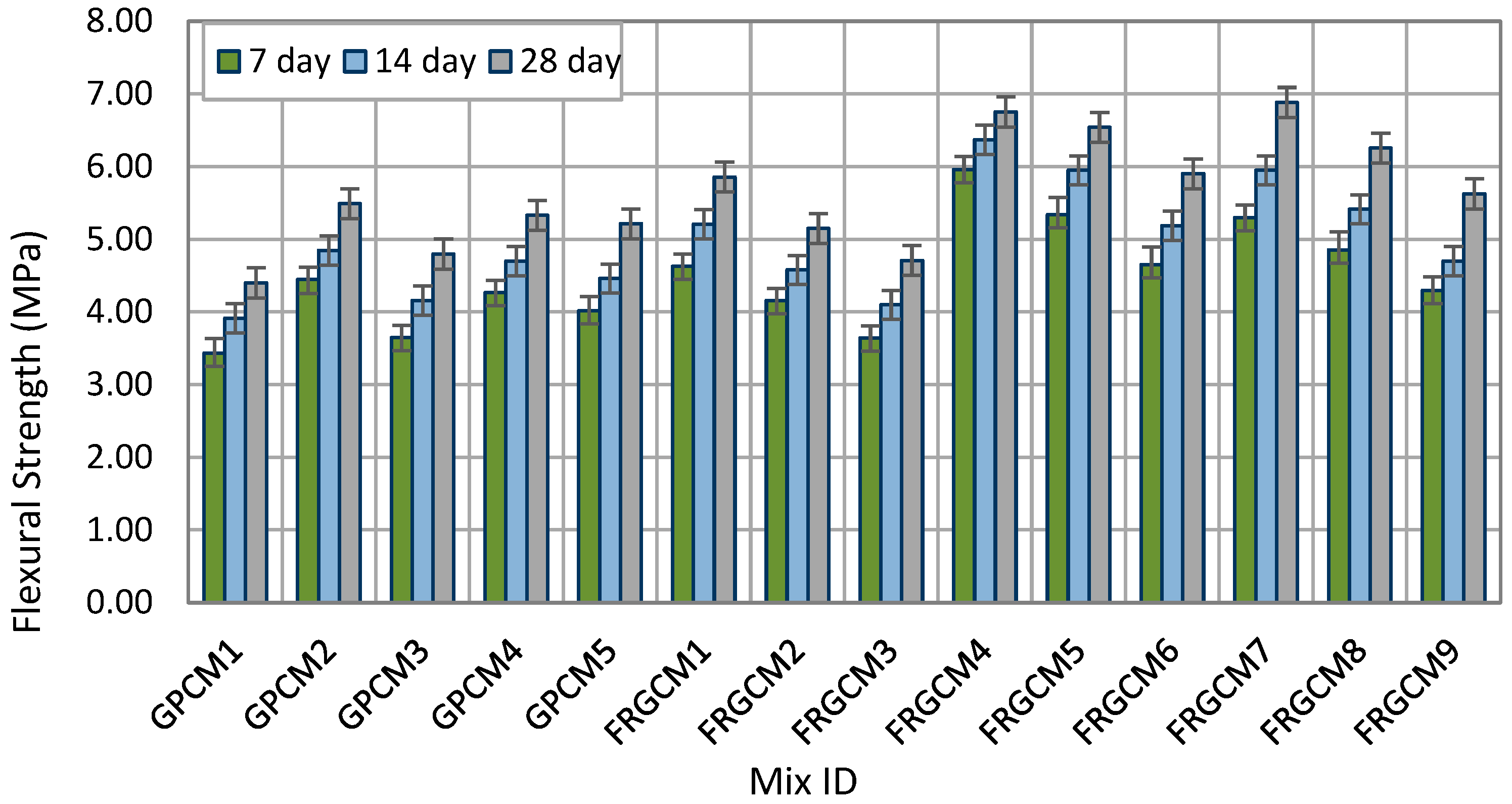

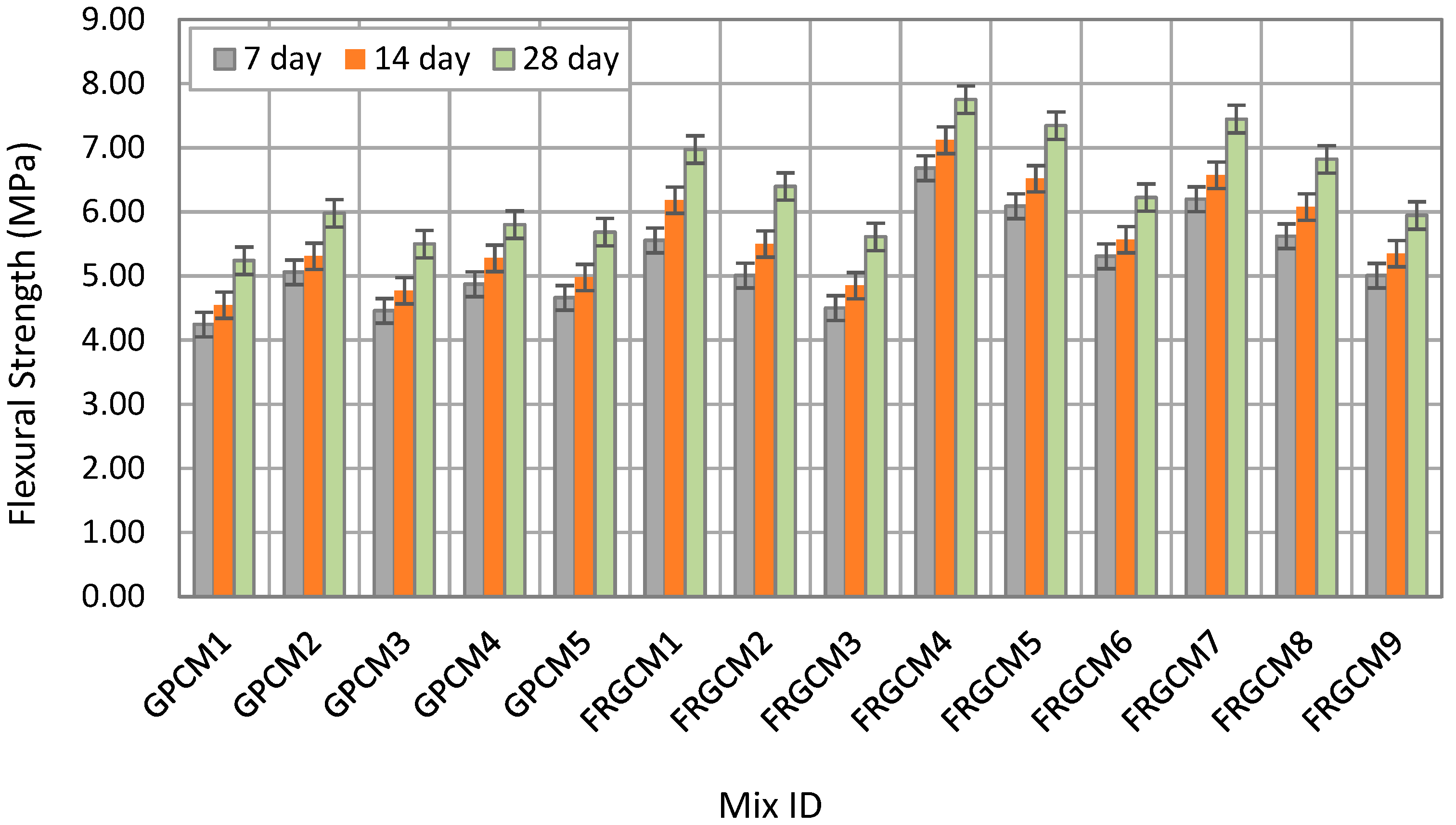

3.3. Flexural Strength

3.3.1. The Effect of Geopolymer-Based Materials

3.3.2. The Effect of Imbedded Fibers

3.3.3. Effect of Different Curing Regimes

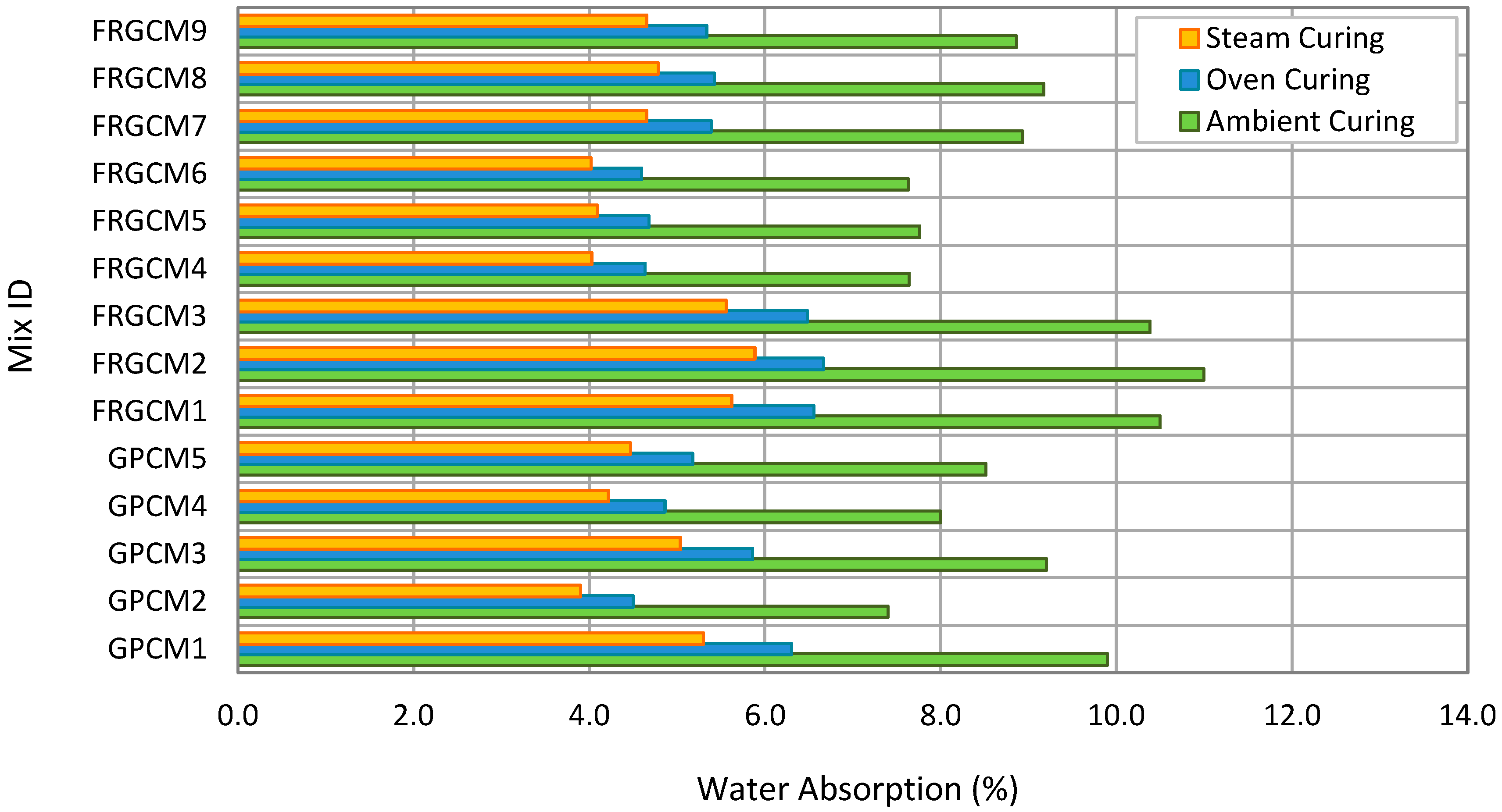

3.4. Durability Properties

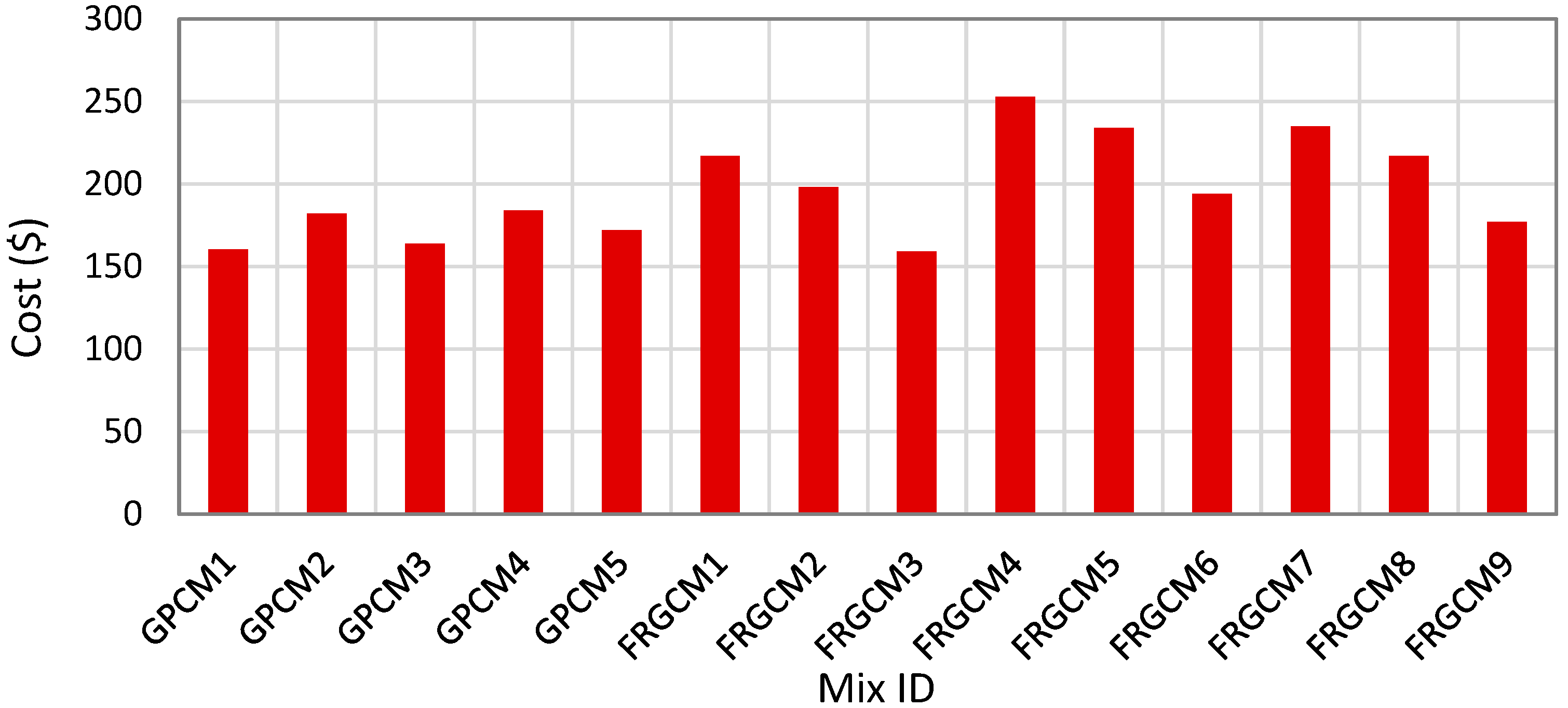

3.5. Cost Analysis

3.5.1. Materials Cost Analysis

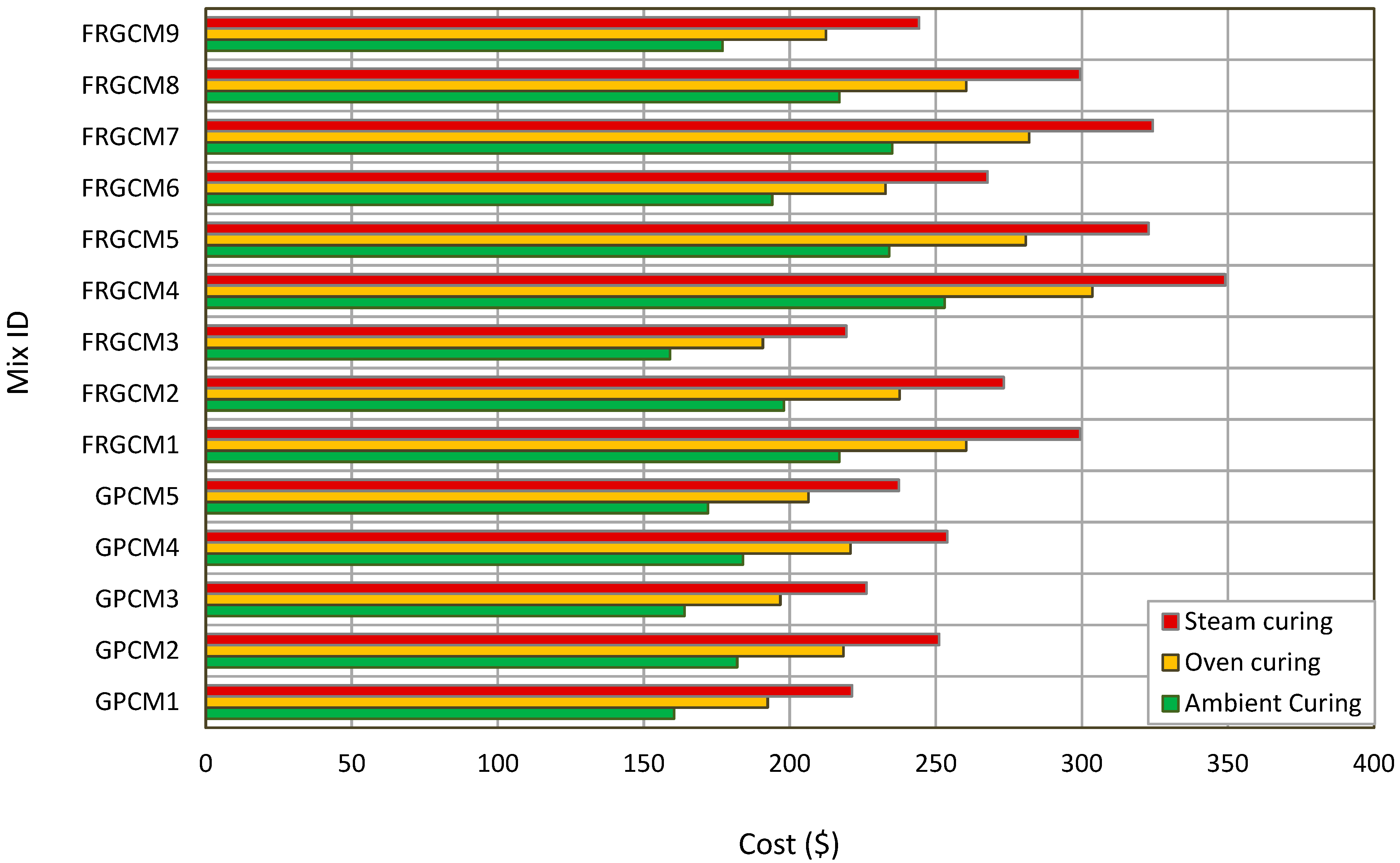

3.5.2. Cost Analysis for Different Curing Regimes

3.5.3. Feasibility Evaluation for Strength and Durability Under Different Curing Regimes

4. Conclusions

- The compressive and flexural strength developments of GPC under ambient curing conditions are significantly influenced by the type and proportion of aluminosilicate binder materials. Thus, mixes including 100% FA offer limited early strength under ambient curing conditions due to FA’s low calcium content and the inherently slow geopolymerization kinetics at room temperature. The GPCMs produced with 100% or 75% of GGBS showed satisfied development under ambient curing conditions due to GGBS’s high calcium oxide content, which facilitates faster matrix formation.

- Thermal curing regimes (oven curing or steam curing) have a substantial influence on the compressive and flexural strength developments of GPC, especially for GPC mixes involving high FA content. Thermal curing demonstrates significant enhancement in 7-day compressive strength compared to their peers under ambient curing. GPC mixes including high percentages of GGBS respond less dramatically to thermal curing relative to 100% FA mixes.

- The incorporation of HESF, BSFs, or PPFs into GPCM results in slight initial compressive strength developments, especially under ambient curing conditions. The inclusion of 0.75% HESF leads to the highest flexural strength enhancement in all curing regimes and all utilized binder materials. The addition of 0.75% BSFs into GPCMs also improves the flexural performance but is less effective than HESFs due to the differences in physical and mechanical properties. Conversely, the incorporation of 0.5% PPFs results in more modest gains, as their low modulus limits their ability to resist flexural stresses.

- The application of low fiber proportions and heat-assisted curing systems into GPC significantly improves the water absorption performance of geopolymer concretes, particularly with FFA and hybrid systems, highlighting the importance of optimizing both fiber content and curing regimes for durability enhancement.

- The most affordable option is GPCM1 (100% FA without fibers), but it demonstrates low compressive and flexural strengths under ambient curing conditions. RGCM4 (100% GGBS and 0.75% HESF) can be considered the best strength and durability option, as it provides the highest strength performance but results in higher material costs. RGCM7 (50% FA, 50% GGBS, and 0.75% HSF) can be regarded as a balanced option since it offers satisfied flexural strength, compressive strength, and durability performance with moderate cost compared to other options.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CGPC | Composite Geopolymer Concrete |

| GPC | Geopolymer Concrete |

| FA | Fly Ash |

| GGBS | Ground Granulated Blast-Furnace Slag |

| HESFs | Hooked-End Steel Fibers |

| BFs | Basalt Fibers |

| PPFs | Polypropylene fibers |

| OPC | Ordinary Portland Cement |

References

- Alnkaa, A.A.; Alnkaa, A.A.; Danish, A.; Yaprak, H.; Memiş, S.; Gencel, O.; Amran, M.; Ozbakkaloglu, T. Performance evaluation and cost analysis of ternary blended geopolymers for sustainable built environment under different curing regimes. Constr. Build. Mater. 2023, 409, 133842. [Google Scholar] [CrossRef]

- Chelluri, S.; Hossiney, N. Performance evaluation of ternary blended geopolymer binders comprising of slag, fly ash and brick kiln rice husk ash. Case Stud. Constr. Mater. 2024, 20, e02918. [Google Scholar] [CrossRef]

- Wu, T.; Ng, S.T.; Chen, J. Incorporating carbon capture and storage in decarbonizing China’s cement sector. Renew. Sustain. Energy Rev. 2025, 209, 115098. [Google Scholar] [CrossRef]

- Wu, S.; Shao, Z.; Andrew, R.M.; Bing, L.; Wang, J.; Niu, L.; Liu, Z.; Xi, F. Global CO2 uptake by cement materials accounts 1930–2023. Sci. Data 2024, 11, 1409. [Google Scholar] [CrossRef] [PubMed]

- Al-Qutaifi, S.; Hanan, A.K.; Hamza, A.J. The Influence of Molarity Activity on the Green and Mechanical Properties of Geopolymer Concrete. Constr. Mater. 2025, 5, 16. [Google Scholar] [CrossRef]

- Abdelaal, A.; Youssef, A. Experimental investigation on corroded and non-corroded RC tunnels under different loading conditions. J. Eng. Appl. Sci. 2023, 70, 146. [Google Scholar] [CrossRef]

- Elena, C.; Chiara, P.; Gianni, B.; Alessandra, M. Corrosion attack in existing reinforced concrete structures: In-field investigation and analysis of naturally corroded bars. Mater. Struct. 2024, 57, 243. [Google Scholar] [CrossRef]

- Al-Qutaifi, S.; Ethaib, S.; Awei, Y.R. Evaluating the impact of inclusion Metakaolin and silica fume on the green and mechanical properties of low calcium fly ash concrete. In Annales de Chimie. Science des Materiaux; International Information and Engineering Technology Association (IIETA): Edmonton, AB, Canada, 2022; Volume 46, p. 323. [Google Scholar]

- Imtiaz, L.; Rehman, S.K.; Memon, S.A.; Khan, M.K.; Javed, M.F. A review of recent developments and advances in eco-friendly geopolymer concrete. Appl. Sci. 2020, 10, 7838. [Google Scholar] [CrossRef]

- Danish, A.; Ozbakkaloglu, T.; Mosaberpanah, M.A.; Salim, M.U.; Bayram, M.; Yeon, J.H.; Jafar, K. Sustainability benefits and commercialization challenges and strategies of geopolymer concrete: A review. J. Build. Eng. 2022, 58, 105005. [Google Scholar] [CrossRef]

- Marathe, S.; Sadowski, Ł. Developments in biochar incorporated geopolymers and alkali activated materials: A systematic literature review. J. Clean. Prod. 2024, 469, 143136. [Google Scholar] [CrossRef]

- Neupane, K. Evaluation of environmental sustainability of one-part geopolymer binder concrete. Clean. Mater. 2022, 6, 100138. [Google Scholar] [CrossRef]

- Odeh, A.; Al-Fakih, A.; Alghannam, M.; Al-Ainya, M.; Khalid, H.; Al-Shugaa, M.A.; Thomas, B.S.; Aswin, M. Recent progress in geopolymer concrete technology: A review. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 48, 3285–3308. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Lubloy, E. Behavioural studies on binary blended high strength self compacting geopolymer concrete exposed to standard fire temperature. Ain Shams Eng. J. 2024, 15, 102394. [Google Scholar] [CrossRef]

- MG, G.; Shetty, K.K.; Nayak, G.; Kamath, K. Evaluation of Mechanical, Ecological, Economical, and Thermal Characteristics of Geopolymer Concrete Containing Processed Slag Sand. Sustainability 2024, 16, 7402. [Google Scholar] [CrossRef]

- Sharma, V.; Dash, S.; Gupta, P. Comprehensive review of fly ash: Environmental impact and applications. Environ. Qual. Manag. 2024, 34, e22338. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, H.; Wu, J. Study of the impact of policy interventions on the sustainable development of fly ash recycling industry in western China via dynamic business model. Waste Manag. 2025, 200, 114780. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef] [PubMed]

- Sbahieh, S.; McKay, G.; Al-Ghamdi, S.G. Comprehensive analysis of geopolymer materials: Properties, environmental impacts, and applications. Materials 2023, 16, 7363. [Google Scholar] [CrossRef]

- Al-Qutaifi, S.; Bagheri, A. Evaluating Fresh and Hardened Properties of High-Strength Concrete Including Closed Steel Fibres. Open Civ. Eng. J. 2021, 15, 104–114. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628. [Google Scholar] [CrossRef]

- Demir, İ.; Korkmaz, S. Effect of Molarity, Curing Time and Curing Temperature on Perlite Powder-Containing Slag-Based Geopolymers. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 48, 763–778. [Google Scholar] [CrossRef]

- Verma, M.; Meena, R.K.; Singh, I.; Gupta, N.; Saxena, K.K.; Reddy, M.M.; Salem, K.H.; Salmaan, U. Investigation on the impact of elevated temperature on sustainable geopolymer composite. Adv. Mech. Eng. 2023, 15, 16878132231196402. [Google Scholar] [CrossRef]

- Gultekin, A. Effect of Fiber Type and Length on Strength, Fracture Energy, and Durability Properties of Microwave-Cured Fiber-Reinforced Geopolymer Mortars. Buildings 2024, 14, 3723. [Google Scholar] [CrossRef]

- Al-Qutaifi, S.; Nazari, A.; Bagheri, A. Mechanical properties of layered geopolymer structures applicable in concrete 3D-printing. Constr. Build. Mater. 2018, 176, 690–699. [Google Scholar] [CrossRef]

- ASTM C143/C143M-15; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C39/C39M-14; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C1609/C1609M-12; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- Ram, A.K.; Mohanty, S. State of the art review on physiochemical and engineering characteristics of fly ash and its applications. Int. J. Coal Sci. Technol. 2022, 9, 9. [Google Scholar] [CrossRef]

- Thapa, S.; Debnath, S.; Kulkarni, S.; Solanki, H.; Nath, S. Mechanical properties of geopolymer concrete incorporating supplementary cementitious materials as binding agents. Discov. Civ. Eng. 2024, 1, 62. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, W.; Liu, M. Setting time and mechanical properties of chemical admixtures modified FA/GGBS-based engineered geopolymer composites. Constr. Build. Mater. 2024, 431, 136473. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Klyuev, S.; Gholampour, A. Fly ash-based eco-efficient concretes: A comprehensive review of the short-term properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef]

- Qu, C.; Qin, Y.; Wang, T. From cement to geopolymers: Performances and sustainability advantages of ambient curing. J. Build. Eng. 2024, 91, 109555. [Google Scholar] [CrossRef]

- Kan, L.; Lv, L.; Chen, H.; Wen, B.; Ma, X.; Wang, F. High-temperature resistance of engineered geopolymer composite: Isolating the effects of key components. Constr. Build. Mater. 2025, 481, 141664. [Google Scholar] [CrossRef]

- Shi, X.; Shi, Y.; Chen, X.; Wang, W. Effect of Polypropylene and Straw Fiber Materials on the Unconfined Compressive Strength of Tailings and Wasted Stone Mixed Backfill. Materials 2025, 18, 392. [Google Scholar] [CrossRef]

- Disu, A.A.; Kolay, P.; Puri, V.; Kumar, S. Effect of Polypropylene Fiber and Curing on the Unconfined Compressive Strength of Geopolymer Stabilized Kaolin Clay. In Geo-Congress 2022; ASCE: Reston, VA, USA, 2022; pp. 148–156. [Google Scholar]

- Diab, M.A. Enhancing class F fly ash geopolymer concrete performance using lime and steam curing. J. Eng. Appl. Sci. 2022, 69, 59. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Irum, S.; Shabbir, F. Performance of fly ash/GGBFS based geopolymer concrete with recycled fine and coarse aggregates at hot and ambient curing. J. Build. Eng. 2024, 95, 110148. [Google Scholar] [CrossRef]

- Laxmi, G.; Patil, S.; Hossiney, N.; Thejas, H.K. Effect of hooked end steel fibers on strength and durability properties of ambient cured geopolymer concrete. Case Stud. Constr. Mater. 2023, 18, e02122. [Google Scholar] [CrossRef]

- Ayawanna, J.; Poowancum, A. Enhancing flexural strength of metakaolin-based geopolymer reinforced with different types of fibers. Sustain. Chem. Pharm. 2024, 37, 101439. [Google Scholar] [CrossRef]

- Abdellatief, M.; Hamouda, H.; Palou, M.T.; Tawfik, T.A. Synergistic effects of basalt fiber and volcanic pumice powder in high-strength geopolymer concrete. Sci. Rep. 2025, 15, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Çelik, A.I. Influence of slag, silica fume and waste tire wire on high-strength characteristics of geopolymer concrete cured under ambient and oven conditions. Int. J. Civ. Eng. 2024, 22, 1565–1585. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.; Meikle, S. Development of geopolymer mortar under ambient temperature for in situ applications. Constr. Build. Mater. 2016, 120, 198–211. [Google Scholar] [CrossRef]

- Vatin, N.I.; Hematibahar, M.; Gebre, T.H. Impact of basalt fiber reinforced concrete in protected buildings: A review. Front. Built Environ. 2024, 10, 1407327. [Google Scholar] [CrossRef]

- Adamu, M.; Doshi, T.D.; Khed, V.C.; Ibrahim, Y.E. Effect of steel fibres on the mechanical strengths of fly ash/GGBS based geopolymer concrete under ambient curing condition. Adv. Top. Mech. Mater. Struct. Constr. 2023, 31, 398–407. [Google Scholar]

- Mohamed, O.; Zuaiter, H. Fresh properties, strength, and durability of fiber-reinforced geopolymer and conventional concrete: A review. Polymers 2024, 16, 141. [Google Scholar] [CrossRef]

- Saludung, A.; Azeyanagi, T.; Ogawa, Y.; Kawai, K. Mechanical and microstructural evolutions of fly ash/slag-based geopolymer at high temperatures: Effect of curing conditions. Ceram. Int. 2023, 49, 2091–2101. [Google Scholar] [CrossRef]

- Yang, Z.; Xie, Y.; He, J.; Wang, F.; Zeng, X.; Ma, K.; Long, G. A comparative study on the mechanical properties and microstructure of cement-based materials by direct electric curing and steam curing. Materials 2021, 14, 7407. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Shen, Z.; Zhang, M.; Wang, Z.; Li, J. Mechanical properties and microstructure of cement-based materials by different high-temperature curing methods: A review. J. Build. Eng. 2024, 96, 110464. [Google Scholar] [CrossRef]

- Zhang, B. Durability of Low-carbon Geopolymer Concrete: A Critical Review. Sustain. Mater. Technol. 2024, 40, e00882. [Google Scholar] [CrossRef]

| Compound | FFA | GGBS |

|---|---|---|

| SiO2 | 6.80% | 38.6% |

| Al2O3 | 0.32% | 21.3% |

| Fe2O3 | 14.63% | 2.0% |

| CaO | 0.96% | 39.8% |

| SO3 | 12.53% | 2.7% |

| MgO | 0.11% | 14.2% |

| K2O | 0.19% | 0.36% |

| TiO2 | 0.22% | 0.57% |

| LOI | 41.1% | <1% |

| Property | Sand | Gravel |

|---|---|---|

| Max Particle Size | 4 mm | 20 mm |

| Specific Gravity | 2.62 | 2.64 |

| Bulk Density | 1550 kg/m3 | 1630 kg/m3 |

| Water Absorption | 2.3% | 1.7% |

| Physical Properties | |||

|---|---|---|---|

| Property | HESF | PPF | BF |

| Length | 30 mm | 20 mm | 20 mm |

| Diameter | 0.5 mm | 0.5 mm | 0.02 mm |

| Aspect Ratio (L/D) | 60 | 40 | 1000 |

| Density | 7850 kg/m3 | 900 kg/m3 | 2700 kg/m3 |

| Mechanical properties | |||

| Property | HESF | PPF | BF |

| Tensile Strength | 1800 MPa | 650 MPa | 470 MPa |

| Modulus of Elasticity | 200 GPa | 5 GPa | 110 GPa |

| Mix No. | Mix ID | FFA Kg/m3 | GGBS Kg/m3 | Utilized Fibers | V% | AAS Kg/m3 | SP Kg/m3 |

|---|---|---|---|---|---|---|---|

| 1 | GPCM1 | 600 | 0 | 0 | 0 | 210 | 3.7 |

| 2 | GPCM2 | 0 | 600 | 0 | 0 | 210 | 8.5 |

| 3 | GPCM3 | 450 | 250 | 0 | 0 | 210 | 5.7 |

| 4 | GPCM4 | 250 | 450 | 0 | 0 | 210 | 7.7 |

| 5 | GPCM5 | 300 | 300 | 0 | 0 | 210 | 7 |

| 6 | FRGCM1 | 600 | 0 | HSF | 0.75% | 210 | 7.5 |

| 7 | FRGCM2 | 600 | 0 | BF | 0.75% | 210 | 8.3 |

| 8 | FRGCM3 | 600 | 0 | PPF | 0.5% | 210 | 5.5 |

| 9 | FRGCM4 | 0 | 600 | HSF | 0.75% | 210 | 12.7 |

| 10 | FRGCM5 | 0 | 600 | BF | 0.75% | 210 | 13.7 |

| 11 | FRGCM6 | 0 | 600 | PPF | 0.5% | 210 | 11.2 |

| 12 | FRGCM7 | 300 | 300 | HSF | 0.75% | 210 | 9.9 |

| 13 | FRGCM8 | 300 | 600 | BF | 0.75% | 210 | 10.7 |

| 14 | FRGCM9 | 300 | 600 | PPF | 0.5% | 210 | 8.8 |

| Mix No. | Mix ID | FA Cost (USD/m3) | GGBS Cost (USD/m3) | Fiber Cost (USD/m3) | AAS Cost (USD/m3) | Sand Cost (USD/m3) | Gravel Cost (USD/m3) | SP Cost (USD/m3) | Total Cost (USD/m3) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | GPCM1 | 42 | 0 | 0 | 82.5 | 15 | 13.5 | 7.4 | 160.4 |

| 2 | GPCM2 | 0 | 72 | 0 | 82.5 | 15 | 13.5 | 17 | 182 |

| 3 | GPCM3 | 31.5 | 30 | 0 | 82.5 | 15 | 13.5 | 11.4 | 164 |

| 4 | GPCM4 | 17.5 | 54 | 0 | 82.5 | 15 | 13.5 | 15.4 | 184 |

| 5 | GPCM5 | 21 | 36 | 0 | 82.5 | 15 | 13.5 | 14 | 172 |

| 6 | FRGCM1 | 42 | 0 | 70.88 | 82.5 | 15 | 13.5 | 15 | 217 |

| 7 | FRGCM2 | 42 | 0 | 53.25 | 82.5 | 15 | 13.5 | 16.6 | 198 |

| 8 | FRGCM3 | 42 | 0 | 12.75 | 82.5 | 15 | 13.5 | 11 | 159 |

| 9 | FRGCM4 | 0 | 72 | 70.88 | 82.5 | 15 | 13.5 | 25.4 | 253 |

| 10 | FRGCM5 | 0 | 72 | 53.25 | 82.5 | 15 | 13.5 | 27.4 | 234 |

| 11 | FRGCM6 | 0 | 72 | 12.75 | 82.5 | 15 | 13.5 | 22.4 | 194 |

| 12 | FRGCM7 | 21 | 36 | 70.88 | 82.5 | 15 | 13.5 | 19.8 | 235 |

| 13 | FRGCM8 | 21 | 36 | 53.25 | 82.5 | 15 | 13.5 | 21.4 | 217 |

| 14 | FRGCM9 | 21 | 36 | 12.75 | 82.5 | 15 | 13.5 | 17.6 | 177 |

| Mix ID | Compressive Strength | Flexural Strength | Water Absorption | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ambient Curing | Oven Curing | Steam Curing | Ambient Curing | Oven Curing | Steam Curing | Ambient Curing | Oven Curing | Steam Curing | |

| GPCM1 | Poor | Good | Very Good | Poor | Fair | Fair | Poor | Good | Very Good |

| GPCM2 | Good | Excellent | Excellent | Fair | Good | Good | Good | Excellent | Excellent |

| GPCM3 | Poor | Good | Very Good | Poor | Fair | Fair | Poor | Good | Excellent |

| GPCM4 | Good | Excellent | Excellent | Fair | Good | Good | Good | Excellent | Excellent |

| GPCM5 | Good | very Good | Excellent | Poor | Fair | Good | Fair | Very Good | Excellent |

| FRGCM1 | Poor | Good | Very Good | Poor | Very Good | Excellent | Poor | Good | Very Good |

| FRGCM2 | Poor | Good | Very Good | Poor | Good | Very Good | Poor | Good | Very Good |

| FRGCM3 | Poor | Good | Very Good | Poor | Fair | Fair | Poor | Good | Very Good |

| FRGCM4 | Good | Excellent | Excellent | Fair | Excellent | Excellent | Good | Excellent | Excellent |

| FRGCM5 | Good | Excellent | Excellent | Fair | Very Good | Very Good | Good | Excellent | Excellent |

| FRGCM6 | Good | Excellent | Excellent | Fair | Good | Good | Good | Excellent | Excellent |

| FRGCM7 | Good | Very Good | Excellent | Poor | Very Good | Excellent | Fair | Very Good | Excellent |

| FRGCM8 | Good | Very Good | Excellent | Poor | Very Good | Excellent | Fair | Very Good | Excellent |

| FRGCM9 | Good | Very Good | Excellent | Poor | Good | Good | Fair | Very Good | Excellent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Qutaifi, S.; Rashid, R.M.; Kawoosh, A.S. Cost-Effective Perspective of Fiber-Reinforced Geopolymer Concrete Under Different Curing Regimes. Constr. Mater. 2025, 5, 81. https://doi.org/10.3390/constrmater5040081

Al-Qutaifi S, Rashid RM, Kawoosh AS. Cost-Effective Perspective of Fiber-Reinforced Geopolymer Concrete Under Different Curing Regimes. Construction Materials. 2025; 5(4):81. https://doi.org/10.3390/constrmater5040081

Chicago/Turabian StyleAl-Qutaifi, Sarah, Rusul M. Rashid, and Atared Salah Kawoosh. 2025. "Cost-Effective Perspective of Fiber-Reinforced Geopolymer Concrete Under Different Curing Regimes" Construction Materials 5, no. 4: 81. https://doi.org/10.3390/constrmater5040081

APA StyleAl-Qutaifi, S., Rashid, R. M., & Kawoosh, A. S. (2025). Cost-Effective Perspective of Fiber-Reinforced Geopolymer Concrete Under Different Curing Regimes. Construction Materials, 5(4), 81. https://doi.org/10.3390/constrmater5040081