1. Introduction

The industrial development of the next era would be represented by 3D printing in the construction industry. In addition to specialized materials and cutting-edge digital technologies, the shift from traditional to more automated procedures would call for a different degree of trained labor. The importance of 3D printing in the construction industry extends beyond the fact that, in comparison to other manufacturing applications, it is the sector that is adopting automation the slowest. Using 3D printing in construction offers the possibility of eliminating construction waste, reducing on-site accidents, and speeding up project completion, all of which would ultimately result in lower overall costs.

To enable large-scale implementation of 3D printing in construction, concrete—the world’s most widely used building material—must be carefully evaluated. The success of 3D concrete printing (3DCP) largely depends on the interplay between process parameters and the rheological properties of the fresh mixture, which govern its pumpability, extrudability, and buildability. In essence, rheology determines how the material behaves from extrusion through layer deposition to structural stability.

Among rheological parameters, yield stress and plastic viscosity are particularly critical. Static yield stress reflects the minimum stress required to initiate flow after rest and is closely tied to structuration and thixotropic rebuilding, while dynamic yield stress represents the stress needed to maintain flow. Their balance directly affects print quality and the interlayer bonding strength. The rate at which static yield stress evolves must align with the printing speed and layer deposition rate to ensure stability without premature stiffening, which results in cold-joint formation.

This property is associated with particle flocculation and the formation of early hydration products, leading to structural build-up when the material is at rest. As the microstructure stiffens, the static yield stress increases—a phenomenon known as thixotropy. It describes the reversible decrease in viscosity under shear and recovery when left undisturbed. The structural build-up rate (A

thix) is often used to quantify this time-dependent behavior [

1].

In 3D-printed concrete (3DCP), the static yield stress and its evolution rate reflect the mix’s resistance to deformation and its ability to retain shape after extrusion. The growth of static yield stress must align with the printing and extrusion rates to ensure proper buildability and interlayer bonding. Roussel [

2] described this behavior using Equation (1):

where τ = shear stress (Pa), τ

0 = static yield stress (Pa), A

thix = the rate for structuration of cement paste or concrete (Pa/s), and t = time (s)

A higher structuration rate indicates that, after the external force acting on the material is removed, the mix can quickly recover its yield stress. The overall build-up height attained increases with the rate of structuration. However, to prevent the production of cold joints or interlayer bond strength, the buildability rate must be controlled.

Figure 1 shows the same structure printed using the same print speed and extrusion rate while the static yield stress at the mixer was of different values for each mix. The figure illustrates how the initial static yield stress measured at the mixer is usually indicative of the mix’s rheological consistency throughout the printing process. The shear vane used at the mixer is the field shear vane illustrated in

Figure 2.

Globally, 3D printing is acknowledged as a sustainable method of automating the construction sector while reducing waste, accident rates, and the need for human intervention.

Because it preserves the essential components of conventional concrete, 3D-printable concrete has grown in popularity. By controlling its rheological characteristics, it transforms it into a printable version using the same ingredients as regular concrete mixes: cement, aggregates, sand, water, and a few proprietary chemical admixtures. In addition to studying printing parameters and the different kinds of printers that are available on the global market, researchers have spent years analyzing the layer-deposition technique and connecting it to material rheology.

2. Research Significance

Our knowledge of 3D printing in construction has greatly improved because of previous literary efforts. Nonetheless, attention has been directed into enhancing this technology’s sustainability even more. Since the manufacture of cement is responsible for about 8% of carbon dioxide (CO

2) gas emissions, the massive volumes of cement used in 3DCP cannot be regarded as an environmentally beneficial material [

3]. Various supplementary cementitious materials (SCMs) have been explored to replace cement and mitigate this limitation. Studies have shown that cement paste rheology is affected by the type of superplasticizer used in combination with silica fume as a replacement for cement. The study concluded that using an SNF plasticizer in combination with silica fume (SF) increased flow resistance (Pa/s), while addition of PA with SF decreased flow resistance. Although the study in [

4] investigated the combined effect of SF with different plasticizers, no attention was given to the structuration rate or static yield stress evolution rate within the open-time window of 3D-printable concrete since the study was intended for self-compacting concrete and tackled the flow resistance and gel strength at different time intervals.

The study presented in [

5] on metakaolin (MK) in 3D-printed cementitious composites provides useful trends in rheology and buildability, but its scope does not meet our objective of quantifying the coupled effect of SCM type × superplasticizer chemistry on time-dependent yield-stress evolution and printability. It evaluates only one SCM (MK at 5–10%) and does not vary the superplasticizer type, so SCM–admixture compatibility and interaction effects remain unresolved. While [

6] provides useful insight into early hydration and strength development as a function of temperature and PCE dosage, the work is conducted on neat cement pastes, so superplasticizer chemistry is limited to a single PCE system, and no SCMs are explored, so compatibility and interaction effects between SCM type and admixture chemistry are unresolved. Cement hydration is also tracked via electrical resistivity and related proxies rather than rheological metrics such as static/dynamic yield stress, the thixotropy/structuration rate (A

thix), and time-dependent yield-stress evolution. Ref. [

7] provides a useful framework for concrete mixture adjustment via superplasticizer dosing and workability control, offering insights that are conceptually relevant to managing fresh properties prior to placement. In relation to our study, however, two boundaries remain: (i) the analysis is anchored in slump-based workability for cast concrete, rather than time-resolved rheology (static/dynamic yield stress and thixotropy/structuration) tied to extrusion and buildability windows, and (ii) superplasticizer chemistry is not varied alongside supplementary cementitious materials (SCMs), so SCM × SP compatibility and interaction effects are not resolved.

The study in [

8] offers relevant insight into how PCE superplasticizer dosage influences water demand, strength, microstructure, and permeability in cemented paste fills (CPFs). Specifically, the study is framed around CPFs with silica tailings and a single PCE product (Master Glenium 7500, Master Builders-Admixtures, Beachwood, OH, USA), varying only the PCE dosage (0–5%) rather than SP chemistry.

While the study in [

9] usefully correlates SP dosage with fresh tests (slump-flow, V-funnel, and L-box) and rheometer outputs (yield stress and plastic viscosity) with compressive strength for SCC, its scope differs from extrusion-grade 3DCP. It evaluates a single PCE product with dosage variation in a fixed binder (CEM I + limestone filler, w/b = 0.37), without varying superplasticizer chemistry or the SCM type. Rheology is treated largely as instantaneous properties rather than a time-resolved structuration rate (A

thix). Consequently, the empirical strength–rheology correlations reported for cast SCC are informative background but are not directly translatable to the time-dependent yield-stress evolution in our study. The study in [

10] offers useful baseline trends on how the superplasticizer family and dosage influence yield stress and plastic viscosity in OPC–fly ash pastes, but its scope is bounded relative to our objective. The study is confined to paste-scale systems and reports largely instantaneous flow-curve metrics (30–65 s

−1, two-cycle sweeps) without time-resolved structuration (A

thix), open-time, or static yield-stress evolution rates. Although multiple SP families (PCE, SNF, SMF, and LS) and FA levels (15–35%) are compared, the work investigates only one type of SCM (FA) and does not factorially map SCM × SP chemistry interactions across dosage/compatibility. Furthermore, Ref. [

11] clarifies mechanisms of PCE–cement incompatibility (clinker porosity, C

3A polymorph) and mitigation via calcium sulfate additions; it is framed around OPC paste/mortar flow and hydration tracking (flow table, calorimetry, and in situ XRD) rather than time-resolved rheology parameters. Ref. [

12] rigorously explains cement–admixture “compatibility” via hydration and adsorption mechanisms, reporting paste-level fluidity/setting responses across several admixture families (LS, NS, MS/AS, and PCE) and addition timings. However, it is confined to paste systems and flow/setting indices, without quantifying time-resolved rheology (static/dynamic yield stress, thixotropy/A

thix) or aligning structuration with printing windows relevant to extrusion-based 3DCP. It does not factorially vary the SCM type × superplasticizer chemistry (e.g., metakaolin/silica fume/limestone/fly ash with different SP chemistries). Thus, while its mechanistic insights (e.g., alkali–sulfate effects on PCE adsorption; benefits/risks of delayed addition) are valuable background, the study does not resolve the coupled SCM × SP controls on the time-dependent yield-stress evolution rate.

Recent efforts have begun to explore SCM-admixture interactions in specific contexts, specifically in LC3 binder systems such as the study conducted by De Matos et al. [

13], which confirmed that the dispersion efficiency and workability retention of LC3 mixtures were strongly dependent on the binder chemistry and admixture-addition timing, evidencing a chemical coupling between calcined-clay surfaces and PCE adsorption behavior. Furthermore, in a related study, Chen et al. [

14] developed an inline two-component (2-K) extrusion setup where a pumpable LC3 mortar was dynamically mixed with a calcium nitrate accelerator immediately prior to deposition. This configuration demonstrated that the accelerator–LC3 interaction significantly enhanced dynamic yield stress and early buildability while maintaining adequate pumpability—highlighting binder-dependent accelerator performance in the 3D-printing context. Moreover, Yin et al. [

15] demonstrated that hydroxypropyl methylcellulose (HPMC), when used in slag-rich printable binders, markedly increased yield stress and thixotropy; however, excessive HPMC dosage impeded flow stability, confirming that VMA efficiency depends on the underlying SCM system. Nevertheless, Li, Wei, and Khayat [

16] optimized LC3-based mortars by adjusting PCE-to-VMA ratios, concluding that the printability window and build height were jointly governed by LC3 binder chemistry and the admixture balance.

The novelty of this research therefore lies in its systematic evaluation of both parameters in combination, demonstrating how certain SCM–superplasticizer pairings alter specific static yield stress evolution rates to guide practical extrudability, printability, and buildability through 3DCP open time windows (up to 45 min). By filling this gap, this study not only advances our rheological understanding of 3DCP but also provides process-relevant insights that can guide material selection and mix design for sustainable, high-performance printing applications. The static yield stress growth rate is measured experimentally using the stress-growth method with the help of the simple shear vane apparatus.

3. Methodology

3.1. Equipment Used in the Experimental Program

This work uses the shear vane apparatus (Wykeham Farrance Engineering Limited, Weston Road, Slough, England), which is commonly used in soil measurements, to determine the static yield stress evolution rate using the stress-growth method. The theory behind using the shear vane method is based on the similarity researchers have found between the 3DCP mixes in the fresh state and moist clay [

17]. The test was performed as in [

18,

19] following the standard ASTM D4648/D4648M test procedure [

20]. The involved shear vane apparatus is depicted in

Figure 3 and is also presented in [

21]. The single cell that is stocked with ready-made concrete mixes rotates at a steady speed. Batches of two liters of concrete were prepared by mechanical mixing. The temperature recorded at the time of the test was at 25–30 °C and 40–60% RH. Dry materials were premixed at low speed for 1 min, and 90% of the water content was added to the dry components; then mixing was presumed for 1 min at moderate speed. Finally, the remaining 10% of water content was mixed with the superplasticizer in the glass beaker before being dispersed onto the mixture. Subsequently, the mixing speed was shifted from low speed to high speed for 3 min to ensure mix homogeneity. The mixer (Hobart corporation, Troy, OH, USA) used here was a typical table-top mixer. For each mix design, three independent batches were prepared. Immediately after mixing (at t = 0), the material from each mixture was dispensed into 300 mL cylinders pre-assigned to the target time points (15, 30, and 45 min), with three cylinders per time point per mixture. At every time point, one insertion of the shear vane was performed per cylinder, since it is a destructive test when using a small specimen size, and shear was applied until the maximum torque value was recorded. For each time point, the readings from all cylinders (three batches reflecting the same mix design × three cylinders from each batch) were averaged into a single value, which is reported in the figures. Specimens were all left to rest for 2 min before applying shear.

The shear vane test was conducted at different concrete ages, measured relevant to the mixing stoppage age at time 0. The average maximum torque attained at each time point was used to derive the static yield stress value at that specific time by considering the shear surface area and the vane dimensions. To track the progressive yield stress evolution rate, tests were conducted at 15 min intervals; this was specifically inspired by the findings in [

22] during the different stages of static yield stress evolution of the cement paste mixes, where the first 30 min indicated the rapid linear growth of static yield stress, followed by the induction period within 30–60 min of the paste’s age The time point at 15 min was chosen to reflect the average layer time usually witnessed in a mid-sized 3D-printed structure. This study excluded any time after 45 min of age since 3D-printable concrete mixes are supposedly extrudable for only around 30–45 min at most.

By considering the shear surface area and the vane size, the static yield stress value at that moment was determined using the highest torque reached at the conclusion of the test period. Equations (2)–(4) were employed in the computation. Plotting the static yield stress values against time (t) shows how long the mix has aged since mixing stopped.

D = the measured diameter of the vane in mm; H = the measured height of the vane in mm.

T = torque (N · m); B = the slope of the calibration curve in (°/N · m); ∆ = deflection in degrees

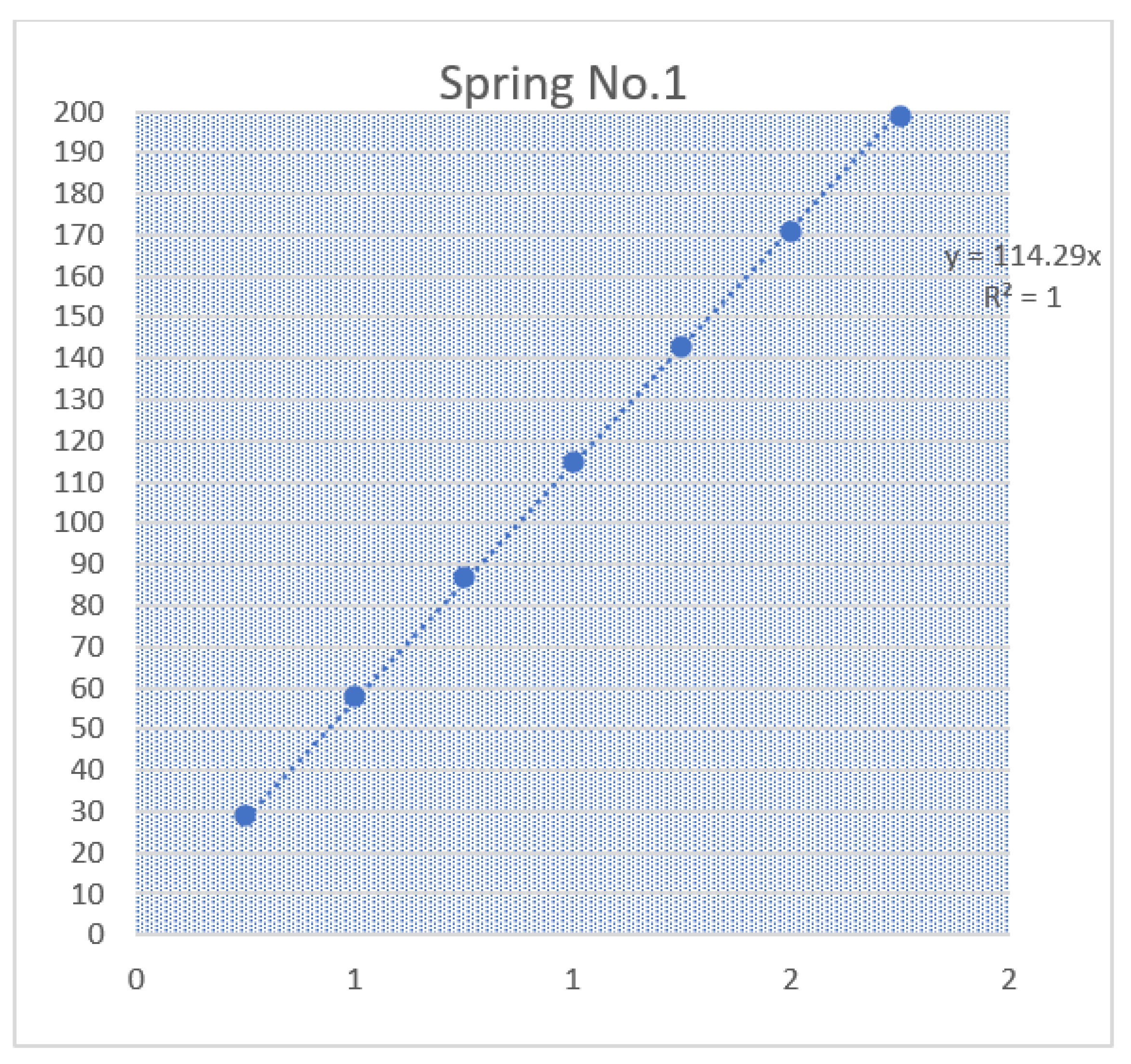

Figure 4, as presented in [

21], represents the slope of the calibration curve for the used spring. Spring No. 1 was used with the largest vane available in the lab, whose D = 25.4 mm and H = 25.4 mm, as presented in

Figure 3.

Measurements of the vane size were taken using the vernier caliper tool (Mitutoyo Corporation, Kawasaki, Kanagawa, Japan).

In rheological measurements, vane geometry offers several significant advantages that enhance the accuracy and reliability of data collection, particularly for materials with complex flow behaviors [

20].

Enhanced Shear Uniformity: The vane geometry shears the material along a cylindrical surface, ensuring a more uniform distribution of shear stress across the sample compared to other geometries. This results in a consistent shear profile throughout the material, improving measurement accuracy.

Reduction in Slip Flow Effects: Slip flow, where the material fails to adhere properly to the measuring surface, is a common issue in rheological measurements that can lead to inaccurate results. The vane geometry addresses this by shearing the material internally rather than at the material–surface interface. This internal shearing, facilitated by the vane’s unique design, minimizes slip-related errors and ensures that the measurements more accurately reflect the material’s true rheological properties.

Minimal Sample Disturbance: The vane is gently inserted into the sample, causing minimal disruption to the material before measurements are taken. This is particularly important for thixotropic or shear-thinning materials, such as concrete mixtures, where any pre-shearing or disturbance can significantly alter the material’s behavior and lead to erroneous data.

Improved Consistency: The uniform shearing action provided by the vane geometry leads to more consistent results across multiple samples. This consistency is crucial for reliable rheological characterization, especially when studying materials like concrete, where interactions with the measurement apparatus can heavily influence outcomes.

In summary, the vane geometry provides a more accurate representation of a material’s rheological properties by reducing slip effects, minimizing sample disturbance, and ensuring a uniform shear distribution. This is particularly important for studying thixotropic suspensions, such as concrete, where measurement accuracy is critical. The enhanced precision and reliability of vane-based measurements contribute to a better understanding and characterization of material behavior under various conditions.

3.2. Materials Used in the Experimental Program

The materials used in this study include Ordinary Portland Cement (OPC), sand, aggregates, water, a superplasticizer, and three supplementary cementitious materials (SCMs): biochar, silica fume, and metakaolin.

Cement (Sinai Cement, Cairo, Egypt): CEM II 42.5 N-grade OPC was used as the base binder.

Biochar (BC): The biochar was produced via slow pyrolysis of tree-wood waste at 500–600 °C. It was sieved to a particle size of <75 µm to ensure homogeneity and compatibility with the cement matrix.

Silica fume (SF) (Sika Egypt, Cairo, Egypt): Obtained as a byproduct from silicon metal production, the silica fume had a median particle size of ~0.1 µm and a specific surface area exceeding 15,000 m2/kg.

Metakaolin (MK) (Arafa Ceramic Products, Aswan, Egypt): Produced from locally sourced kaolinitic clay from the Kalabsha region in Aswan, it was calcined at 750 °C and pulverized to pass through a 63 µm sieve.

Water and Superplasticizer: Potable tap water and two types of superplasticizers were used, a polycarboxylate-based superplasticizer (Sika Egypt, Cairo, Egypt) and a naphthalene-based superplasticizer (Sika Egypt, Cairo, Egypt) were used to achieve desired workability while maintaining a low water-to-binder ratio of 0.45.

The experimental approach adopted was intended to explore the effects of the SCM type and dosage on the rheological performance of 3D-printable concrete mixes. Mixtures shown in

Table 1 were formulated by varying replacement levels (10%, 20%, and 30%) of each SCM (by weight of binder) and maintaining a constant water-to-binder (w/b) ratio of 0.45 and a superplasticizer dosage within the acceptable range, as prescribed on the manufacturer’s technical data sheet. Two types of superplasticizers were used in the study: naphthalene-based (SNF-based) and PCE-based superplasticizers.

SCMs are byproducts from other industrial processes that possess cementitious properties. Their use as partial replacements for cement can significantly reduce the carbon footprint of concrete. In this context, biochar, a carbonaceous by-product of biomass pyrolysis, has attracted attention as both a functional additive in cementitious systems and a carbon sequestration medium. Biochar’s environmental appeal lies in its capacity to stably store carbon derived from atmospheric CO2 captured via photosynthesis. This carbon is rendered recalcitrant through pyrolysis and can persist in the built environment for hundreds of years when immobilized within cementitious matrices.

Silica fume (SF) and metakaolin (MK), owing to their fine particle sizes (typically < 1 µm) and pozzolanic reactivity, enhance the thixotropic behavior and early-age strength gain [

23]. However, their high surface area leads to elevated water demand and rapid slump loss, which can be detrimental to open time and may require the use of rheology-modifying admixtures and high-range water reducers.

Biochar (BC), by contrast, is characterized by a hierarchically porous morphology, with significant intraparticle porosity and surface hydroxyl functional groups. These properties facilitate internal curing, mitigating early-age shrinkage and sustaining printability over extended durations.

MK and SF are well-known for enhancing compressive and flexural strength through pozzolanic reactions, leading to the formation of additional C-S-H and densification of the microstructure. Metakaolin contributes to alumina availability, promoting the formation of additional alumino-silicate hydrates. Their benefits, however, are primarily long-term and contingent on adequate curing.

BC, while not pozzolanic, contributes to hardened properties via filler effects, crack-bridging, and microstructural refinement. Additionally, its surface chemistry can enhance interlayer bonding in 3DCP, a critical parameter where cold-joint formation is a known challenge.

Understanding the rheological evolution of 3D-printable cementitious materials is critical to achieving a balance between printability, extrudability, and buildability. This study is thus positioned to explore the interplay between different supplementary cementitious materials—BC, SF, and MK—on the structural build-up rate and the time-dependent increase in static yield stress of 3DCP mixtures. Each SCM contributes uniquely to thixotropic behavior and structuration kinetics due to its particle morphology, surface chemistry, and reactivity. SF and MK, owing to their ultrafine particle sizes and high pozzolanic reactivity, are expected to accelerate the build-up of internal structures through enhanced flocculation and particle–particle interactions. In contrast, BC, with its porous surface and inert nature, may influence structuration primarily through physical network reinforcement and water absorption, leading to delayed but sustained static yield stress development. Furthermore, the efficacy of superplasticizers is strongly modulated by the type of SCM used. SNF-based superplasticizers, which act predominantly via electrostatic repulsion, tend to lose efficiency in systems with high-surface-area SCMs such as SF and MK due to rapid adsorption and depletion from the pore solution. In contrast, PCE-based superplasticizers, which function via steric hindrance, are expected to maintain higher dispersion efficiency, especially in BC-rich systems where steric stabilization is crucial to prevent premature flocculation. Therefore, the interaction between the SCM type and SP chemistry is anticipated to significantly affect the rheological build-up behavior, with implications for open time, interlayer bonding, and print stability. This study aims to systematically quantify these effects to inform robust mix design strategies for high-performance 3D-printable concretes.

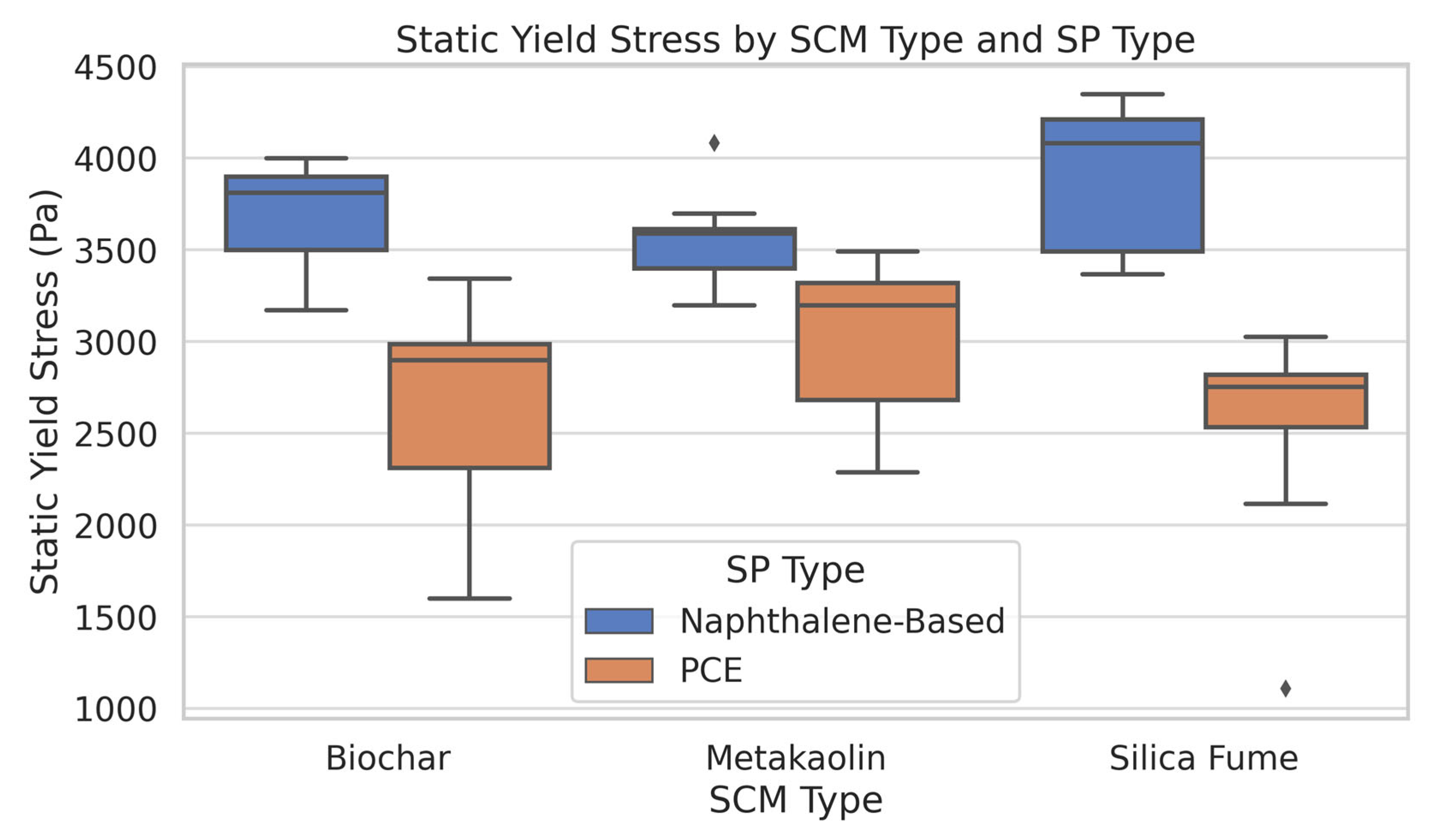

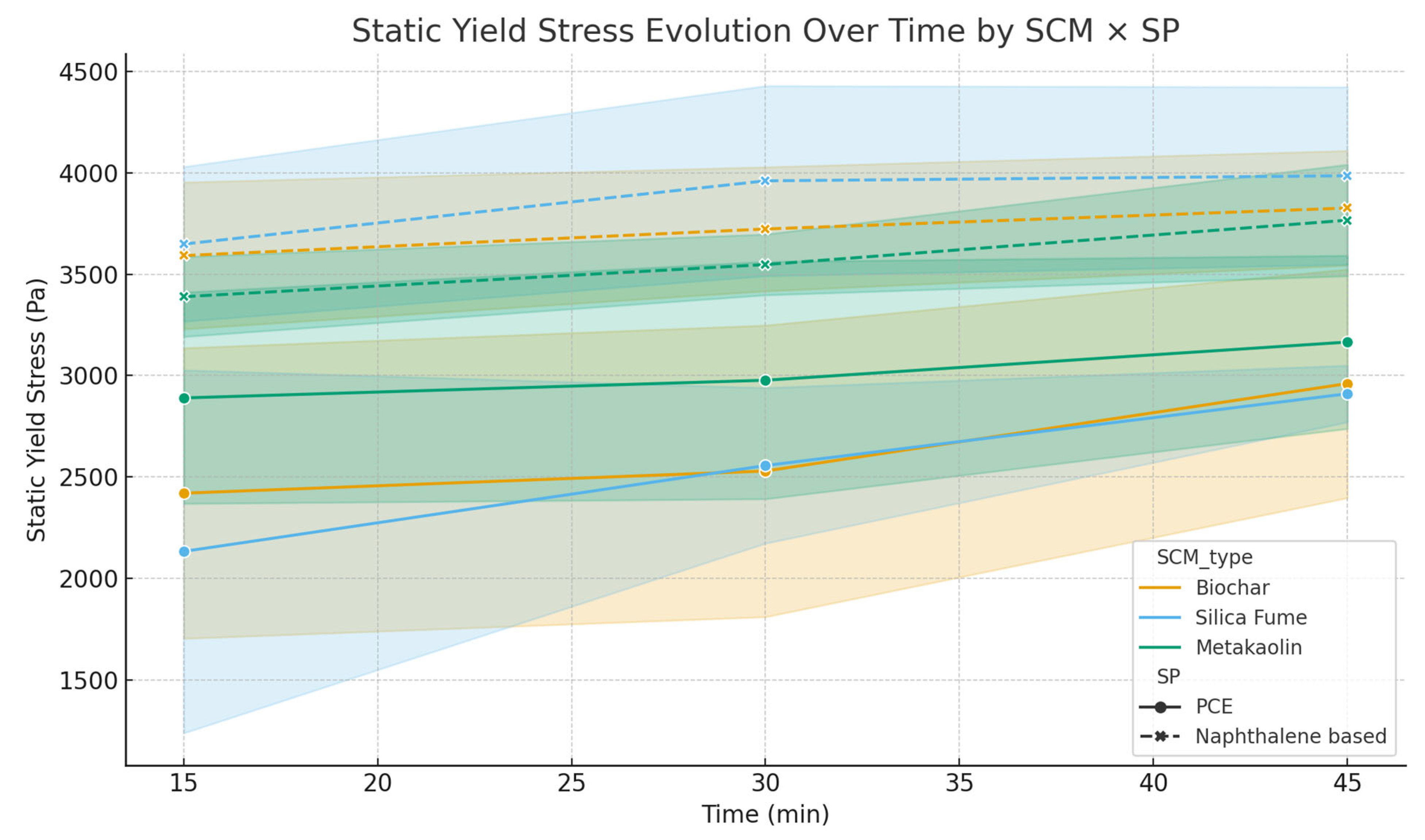

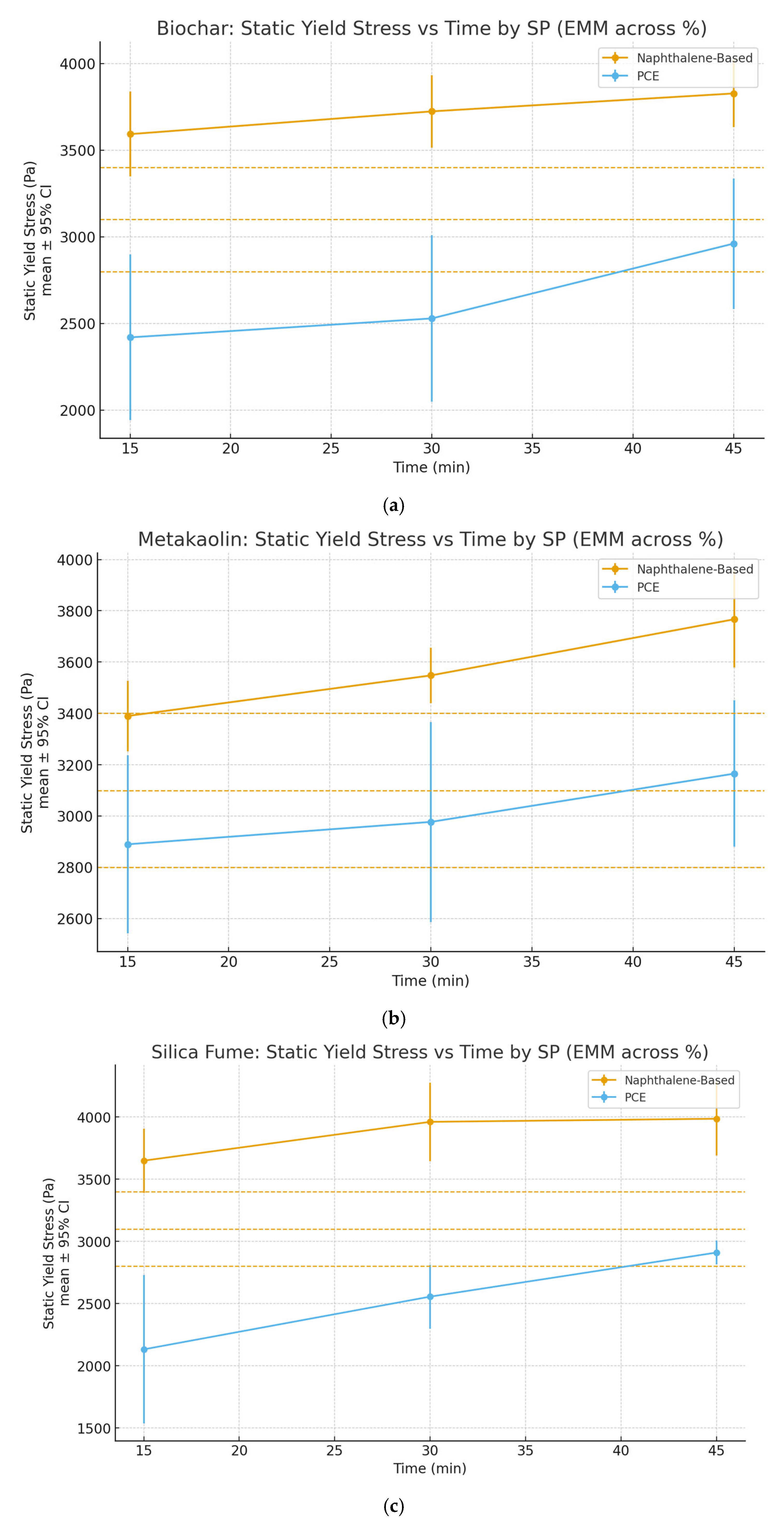

5. Discussion

Static yield stress τ

s (time) remains the most practical proxy for buildability and interlayer adhesion in extrusion-based 3DCP [

24,

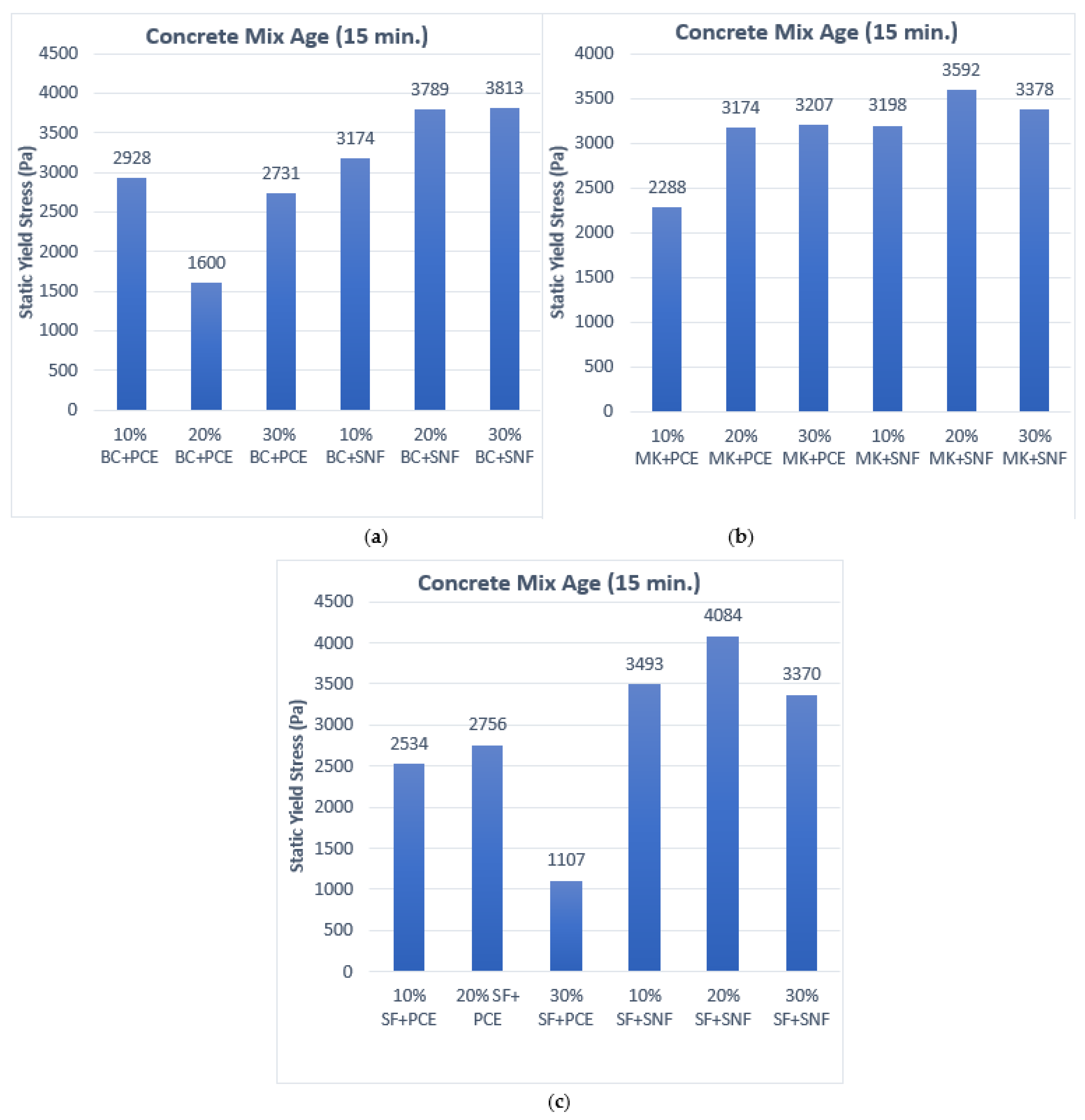

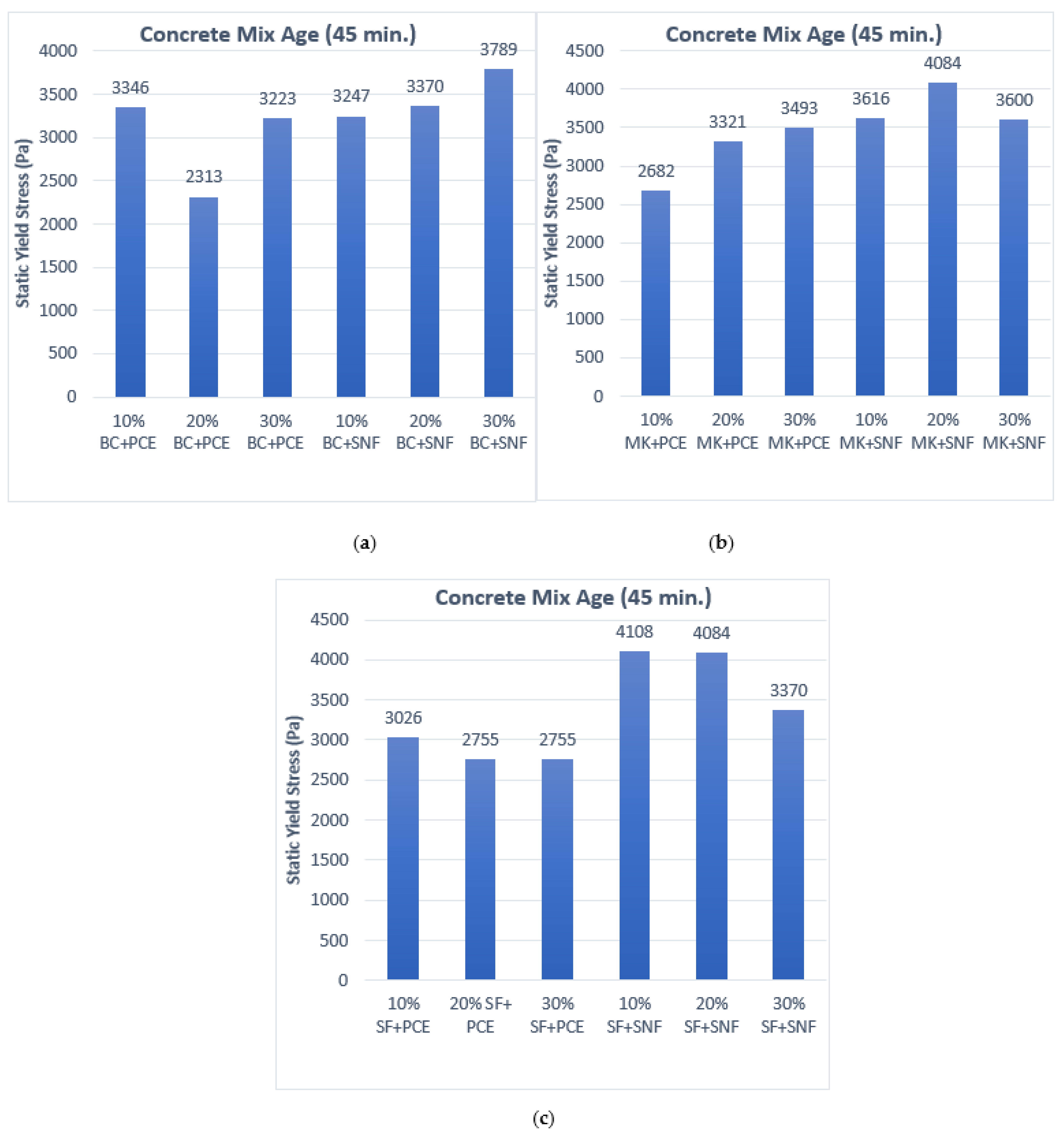

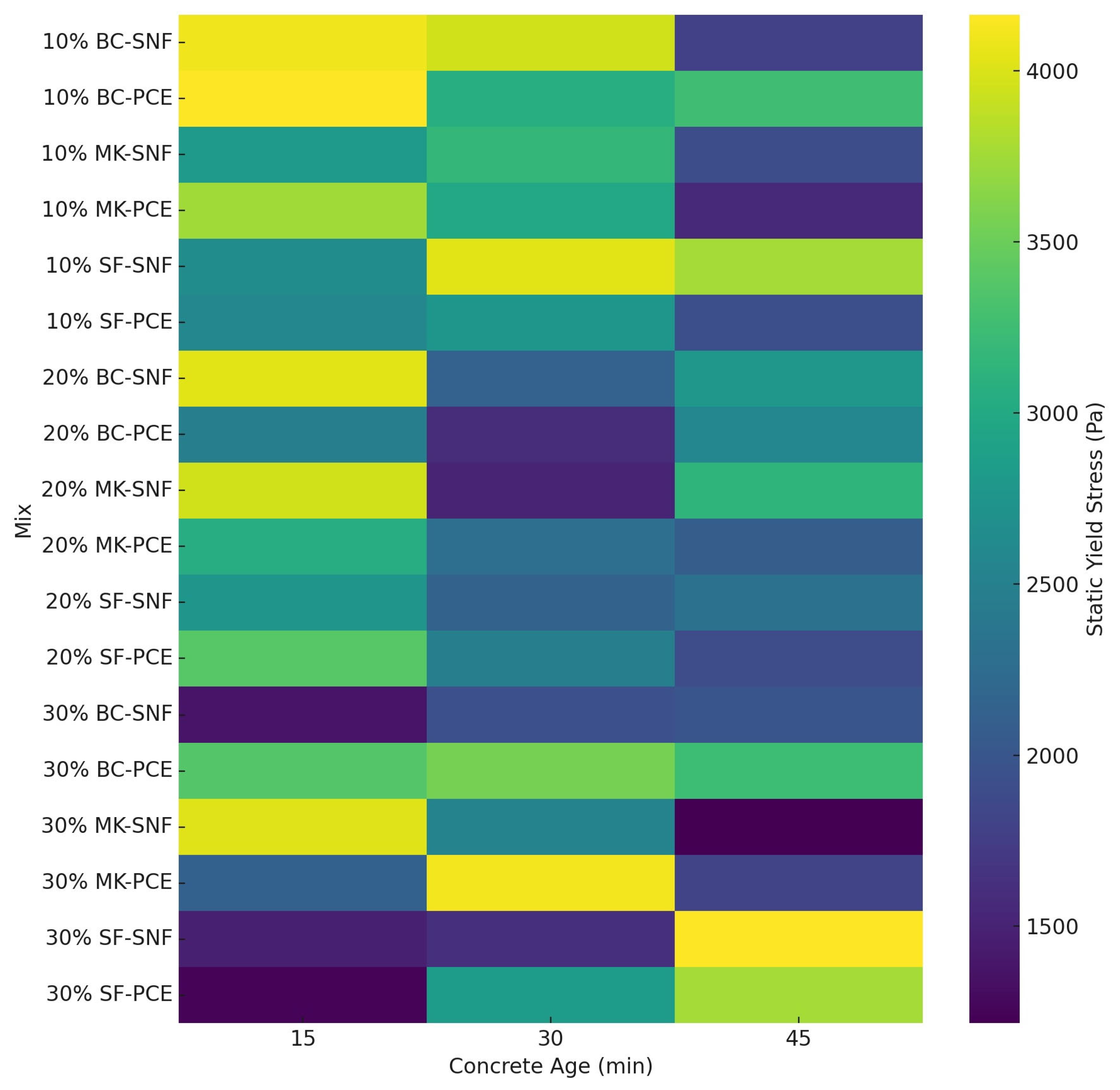

25]. Across 15–45 min, all mixes show monotonic structuration with clear SCM × superplasticizer (SP) dependencies (

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10). Across

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10, the time-dependent structuration rate is clearly combination-specific. Averaged by the SCM–SP pairing, SF+ PCE shows the strongest cumulative growth in static yield stress—+18.6% from 15→30 min and +16.6% from 30→45 min, totaling +38.5% over 15→45 min—while silica fume + SNF rises to +11.7% and +2.1% in the same windows, totaling up to +14.1% over 15→45 min. MK + PCE increases by +5.0% and +7.2% (+12.7% total), and MK +SNF gains +7.5% and +6.3% (+14.3% total). BC mixtures evolve more modestly: BC + PCE gains +7.1% from 15→30 min then +12.7% from 30→45 min, showing a total increase of +20.7% over 15→45 min, whereas BC + SNF rises by only +3.5% from 15→30 min and +2.6% from 30→45 min, showing a total increase of +6.2% over 15→45 min. Within each SCM family, the SP comparison indicates that PCE starts and stays with lower static yield stress values than SNF in this dataset: for SF, PCE is lower by 28.0% (15 min), 28.7% (30 min), and 22.2% (45 min); for Metakaolin, it is lower by 10.8%, 8.7%, and 7.6%; and for BC, it is lower by 19.1%, 16.6%, 10.7%. These quantitative outcomes also align with the known roles of MK, SF, and BC and the PCE vs. naphthalene dispersion mechanisms [

26,

27,

28,

29,

30,

31,

32,

33,

34,

35] while extending prior work by explicitly mapping SCM × SP effects to time-specific extrudability/pumpability (15 min), printability/open time (30 min), and buildability (45 min) targets.

The lower and slower rise in τ

s for BC mixtures over 15–45 min could be explained with two concurrent effects: First, early water uptake into BC’s macro-mesoporous network temporarily reduces the free mixing water available to lubricate particle contacts. However, much of that water is not immediately active at the interface within the first 45 min. Instead, the trapped water behaves as delayed internal curing, defeating the expected higher τ

s value because of the actual lower effective w/b ratio. The reduced static yield stress and water reservoir action, accompanied by the addition of BC, have been confirmed in [

36,

37,

38]. Second, preferential adsorption of PCE onto carbonaceous surfaces reduces the concentration of effective dispersant around cement/SCM grains. Rather than yielding a denser flocculated particles network, this depletion suppresses particle flocculation at early times. The net result is relaxed extrudability and printability due to low τ

s(15) and modest τ

s(30) and a shortfall at 45 min relative to the buildability limit. When SNF is used with BC, since BC competes for the added admixture and no steric hindrance is imposed, effective dispersion is weaker, typically raising the apparent absolute τ

s values, but it can push τ

s(30) closer to (or above) the printability ceiling.

MK’s alumina-rich, highly reactive surface supplies abundant nucleation sites for early C-(A)-S-H, increases solid volume fraction, and elevates ionic strength, which together accelerate the structuration rate. This is directly aligned with reports stating that metakaolin acts as a thixotropic/nucleation-rich pozzolan, increasing yield stress and the build-up rate at early ages [

39,

40]. With PCE, strong carboxylate–aluminate anchorage and side-chain steric hindrance effects create compact but mobile agglomerates at 15 min, often keeping τ

s(15) near the extrudability limit while still allowing manageable τ

s(30). With SNF, weaker steric stabilization and higher van der Waals attractions favor earlier interparticle bridging, so τ

s(15) and τ

s(30) rise further; by 45 min, MK–SNF mixtures comfortably exceed the buildability target.

SF provides a moderate kinetic pathway because of its very high surface area, which increases adsorption capacity, but its predominantly siliceous surface imparts comparatively weaker affinity for PCE anchoring than MK’s aluminate sites. The outcome with PCE is a stable dispersion at 15–30 min, with measured, monotonic growth in τ

s: extrudability and printability are typically satisfied, and the 45 min value lies just below the buildability limit. With SNF, steric hindrance is reduced; early flocculation and bridging intensify, producing higher absolute τ

s from 30 to 45 min at the cost of tighter interlayer timing. This is consistent with studies in [

41,

42], showing that silica fume increases yield stress through the monotonic build-up rate emphasized by its dispersion quality.

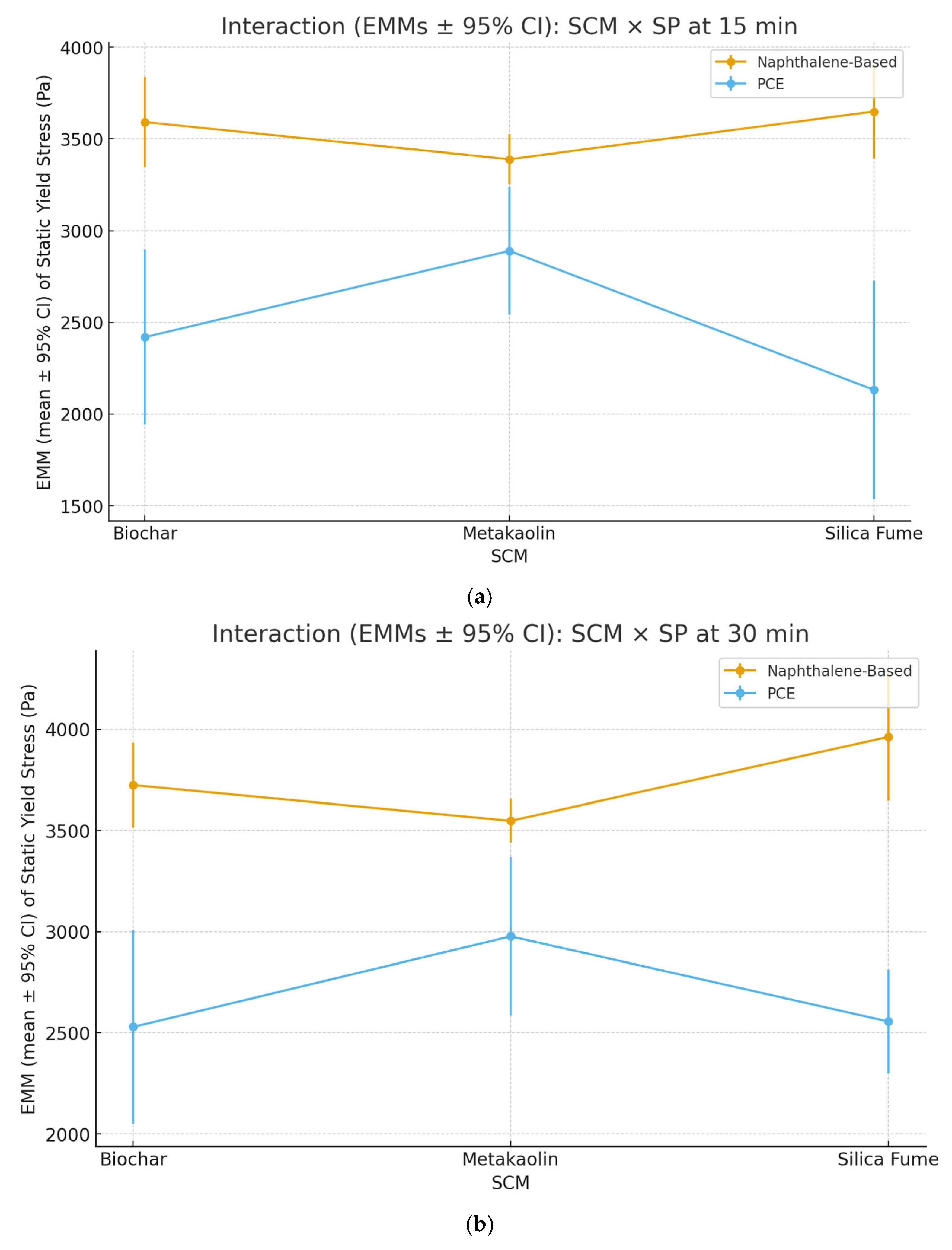

To translate the results into field selection, we evaluate each SCM–SP family against sequential gates based on static yield stress—Gate 1 (extrudability at 15 min): τ

s(15) ≤ 2.8 kPa; Gate 2 (printability/open time at 30 min): τ

s(30) ≤ 3.1 kPa; and Gate 3 (buildability at 45 min): τ

s(45) ≥ 3.4 kPa. Within this framework, SF + PCE consistently passes Gates 1–2 and sits just below Gate 3 by ~0.30–0.45 kPa, while BC + PCE also passes Gates 1–2 and is closest to Gate 3, typically short by only ~0.05–0.10 kPa at 45 min. Both are therefore desirable SCM-SP combinations for 3DCP mixtures: they are printable with comfortable open time and can either be used directly for prints with considerably long layer times or could use minor tuning by adding moderate-type accelerators for prints with shorter layer times. By contrast, MK/SF + SNF mixtures deliver high τ

s(45) and readily meet Gate 3 but could frequently breach Gate 1 and/or Gate 2. While MK/SF+ SNF mixtures could allow for relatively short layer times and faster layer deposition rates without needing an accelerator, they reflect stiffer 3DCP mixtures at the start, where minor tuning of the w/b ratio or SP dosage could help lower the initial static yield stress values, specifically when used with less-tolerant pumping and extrusion systems. In short, when the target is balanced printability with reliable buildability, practitioners could begin with SF (10–15%) + PCE. If the project prioritizes maximum open time with long paths, extended layer times, and hot climate conditions, BC + PCE mixtures are preferable by adding a mild accelerator dosage to meet the 45 min buildability gate. If fast-layer deposition dominates, MK/SF + SNF mixtures are viable provided Gate 1–2 limits are brought into compliance. This gate-based mapping turns the measured trends into actionable mix choices and clarifies why each SCM-SP combination is desirable for specific printing project objectives. To further reinforce the results, two-way ANOVA with interaction terms was run to include both categorical variables, the SP type and the SC Type, along with two continuous co-variates, the SCM dosage percentage and the concrete age.

Table 2 illustrates the key findings.

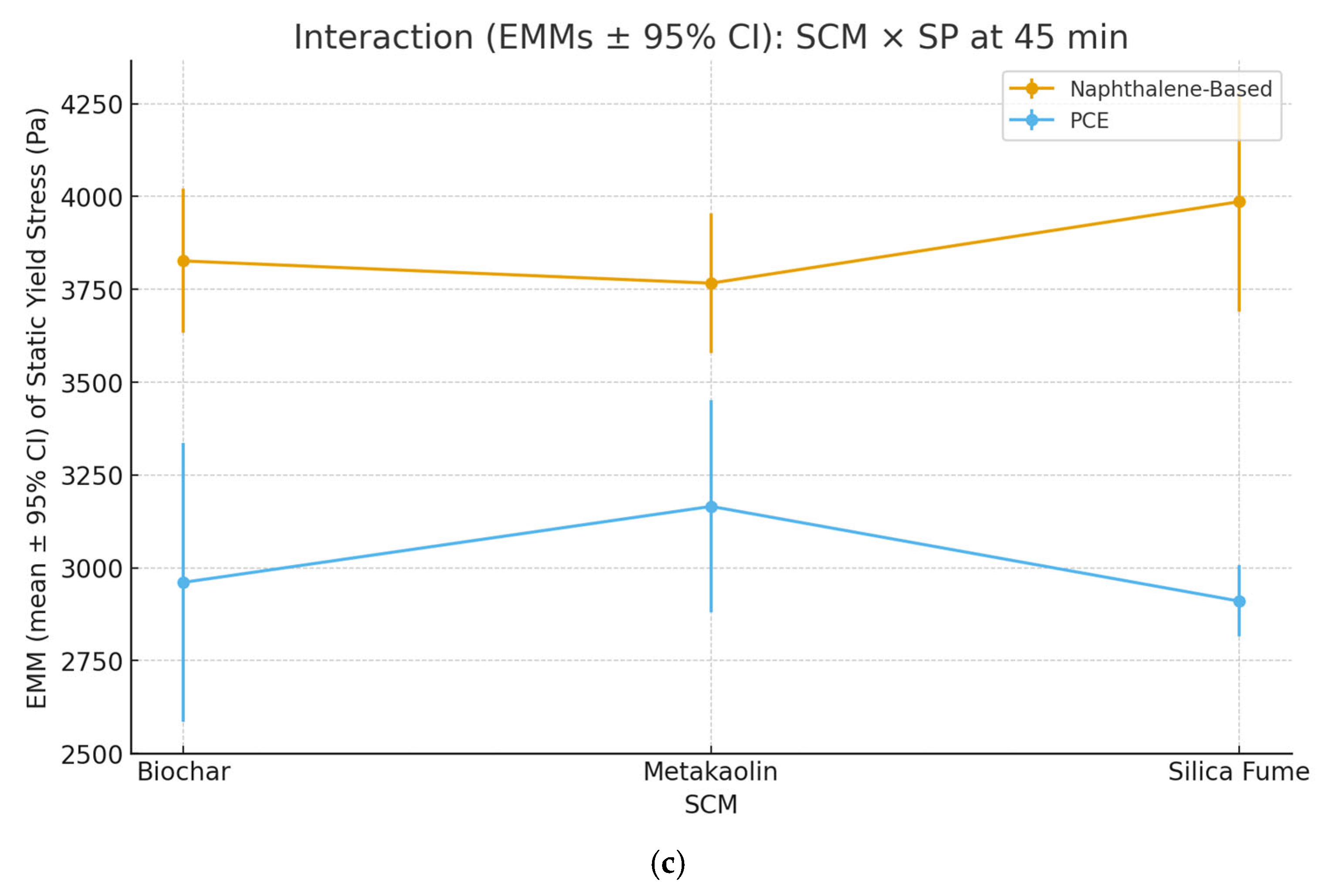

The statistical analysis revealed that superplasticizer (SP) chemistry exerted the strongest influence on static yield stress. Two-way ANOVA confirmed a highly significant main effect of SP type (

p < 0.001), with SNF-based admixtures consistently producing higher yield stresses compared to PCE. Time was also significant (

p = 0.005), highlighting the progressive structuration of the mixtures over the testing period. Although SCM type alone did not exhibit a significant effect (

p = 0.709), the interaction between SCM and SP was significant (

p = 0.031), indicating that the influence of SP chemistry varies depending on the supplementary cementitious material. Uncertainty is reported as the mean ± 95% CI for every condition, and SD vs. time curves document repeatability. Across conditions,

Figure 11 and

Figure 12 show that CIs are narrow (≈1–4% of the mean) and SDs remain small (CV ≈ 1–2% for PCE; ≈1.5–3% for naphthalene), indicating robust measurement precision. In the mean ± 95% CI line plots (per SCM, lines for SP), the separation between PCE and naphthalene trajectories typically exceeds the CI half-widths, visually reinforcing the strong SP main effect; when the PCE–naphthalene gap varies by SCM, the non-parallelism of the lines makes the SCM × SP interaction apparent. Horizontal reference lines at 2.8 kPa (15 min extrudability/pumpability ceiling), 3.1 kPa (30 min open time/printability ceiling), and 3.4 kPa (45 min buildability floor) allow for the direct assessment of practical performance windows. The SD vs. time plots remain low and largely flat, confirming good repeatability rather than noise-driven trends. Finally, the EMM interaction plots in

Figure 13 (SCM × SP at each time, ±95% CI; pooled across % replacement) display clear non-parallel profiles, providing an intuitive visual corroboration of the significant interaction identified by ANOVA and aligning the inferential results with the practical thresholds for extrudability, open time, and buildability.

6. Concluding Remarks and Recommendations

The current study confirms the following key findings:

The superplasticizer (SP) type exerts the strongest influence on static yield stress. SNF-based admixtures consistently produced higher yield stresses than PCE, enhancing buildability but reducing open time, whereas PCE promoted smoother structuration and longer workability.

The progressive structuration rate was observed over time; static yield stress increased monotonically within the 15–45 min testing window.

The influence of SCM on rheology of 3DCP mixtures depends heavily on the super-plasticizer type used.

Higher SCM dosages intensified flocculation under naphthalene admixtures, particularly with metakaolin and silica fume, while PCE largely neutralized this effect. Biochar showed weaker dosage sensitivity due to its unique porous morphology and internal curing effect.

In 3DCP, mix performance is system-dependent (pump, hose length, nozzle, ambient T/RH, path speed, and dwell time), so all recipes need project-specific tuning. However, this study presents a framework to minimize print failures, ensure mix consistency across various batches, and reduce the need for mix parameters’ tuning to a minimal level during operation.

Practical recommendations are based on the following key findings:

SF + PCE mixtures would be nearest to reaching a balanced default between printability and extrudability.

SF + NSF or MK + NSF mixtures would be the most desirable for short layer times, short print paths, and high buildability rates.

To optimize open-time windows and have relaxed layer time for longer print paths or hot climate conditions, BC + PCE mixtures could be used.

Future recommendations to be considered for further development are listed below:

Evaluate other SCMs such as fly ash, GGBS, and nano-silica.

Conduct factorial studies on SCM dosage thresholds to identify safe operating ranges where buildability and open time are both satisfied.

Transition from laboratory rheological tests to full-scale 3D printing trials to validate whether observed trends in static yield stress translate into practical improvements in buildability, interlayer adhesion, and deposited layer quality.

Explore predictive modeling of yield stress evolution using machine learning, incorporating factors such as SCM type, SP chemistry, dosage, and environmental conditions.

Assess the long-term mechanical and durability properties of printed elements influenced by early-age structuration (e.g., compressive strength, shrinkage, and permeability).

In conclusion, this study establishes that the synergistic interaction between SCM type and superplasticizer chemistry is the primary determinant of rheological performance and buildability in 3D-printable concrete. By elucidating these interdependencies, this work provides a clear framework for designing mixes that combine robust structural stability with sufficient open time for continuous printing and smooth operation in large-scale on-site 3D printing. The outcomes not only bridge the gap between laboratory optimization and field-scale implementation but also underscore the strategic role of SCMs combined with tailored admixture systems in advancing sustainable 3D concrete printing.

Ultimately, the insights gained here lay the groundwork for scalable, low-carbon 3DCP technologies capable of transforming the contribution of the construction industry toward a more efficient and environmentally responsible built environment.