Sustainable Concrete Using Porcelain and Clay Brick Waste as Partial Sand Replacement: Evaluation of Mechanical and Durability Properties

Abstract

1. Introduction

2. Experimental and Testing Program

2.1. Raw Materials

2.1.1. Cement

2.1.2. Natural Aggregates

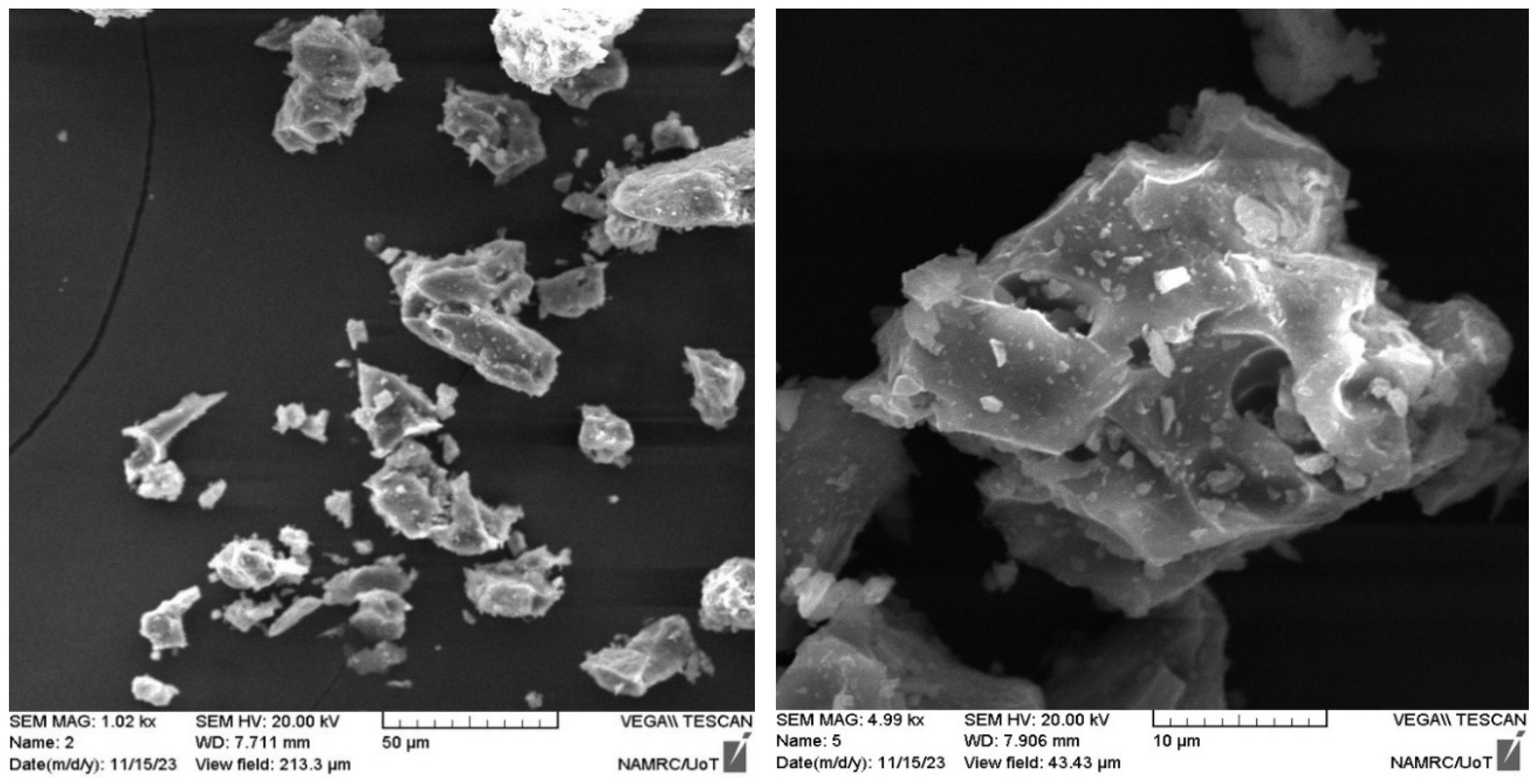

2.1.3. Waste Powder Materials (WPMs)

2.1.4. Polypropylene Fibers (PP.Fs)

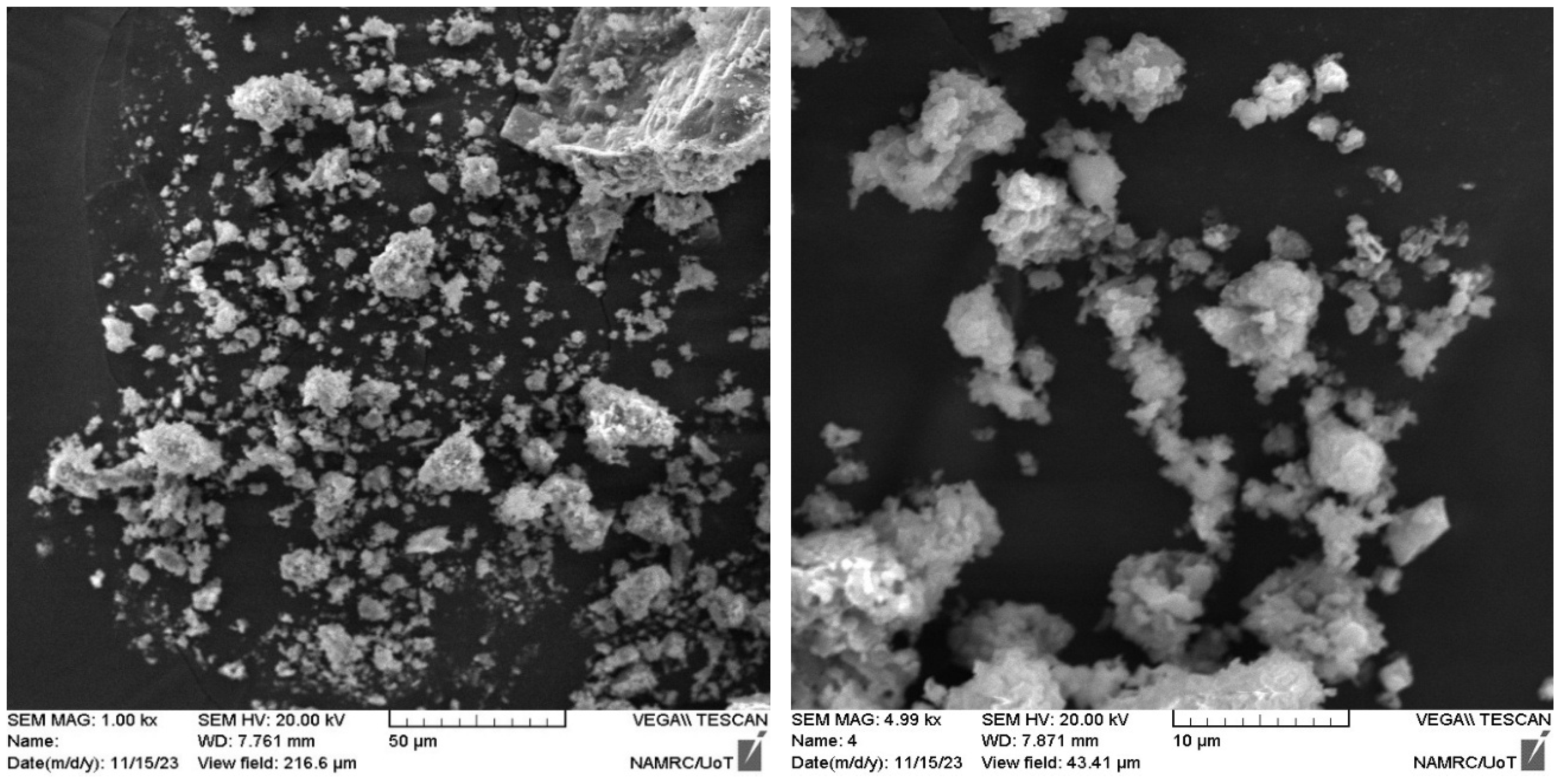

2.1.5. Zinc Oxide Nanoparticles (ZnO-NPs)

2.1.6. Chemical Admixture (S.P)

2.1.7. Water

2.2. Preparation of Concrete

Mixing Proportion

2.3. Mixing, Curing, and Preparation of Samples

2.4. Testing Program

2.4.1. Fresh Properties

2.4.2. Hardened Properties Testing

- A.

- Compressive Strength

- B.

- Flexural Strength

- C.

- Splitting Tensile Strength

- D.

- Dry Density, Porosity and Water Absorption Tests

2.4.3. Microstructural Analysis

- A.

- X-Ray Diffraction (XRD)

- B.

- Scanning Electron Microscope (SEM) and EDS

3. Results and Discussion

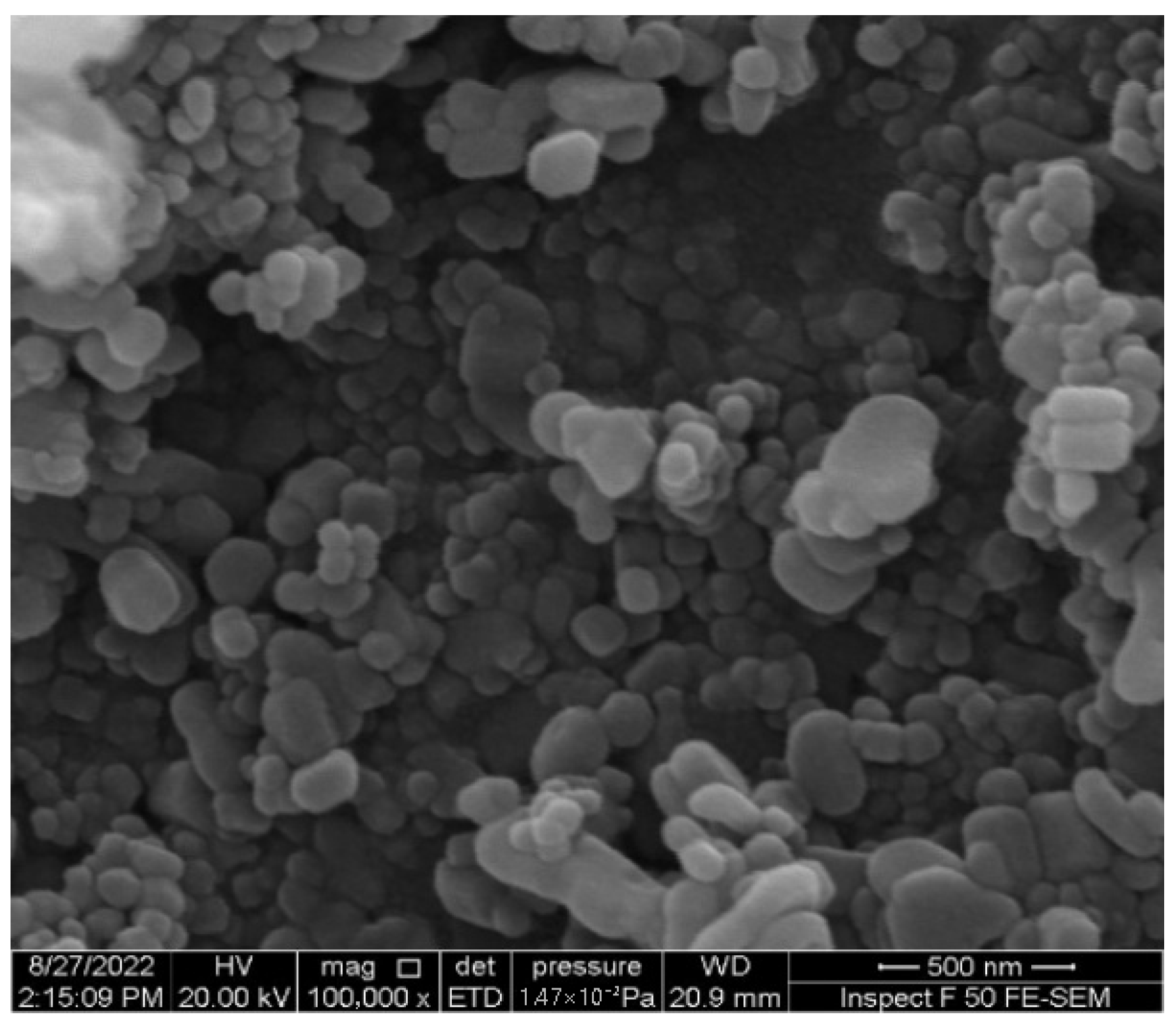

3.1. Slump Test

3.2. Compressive Strength

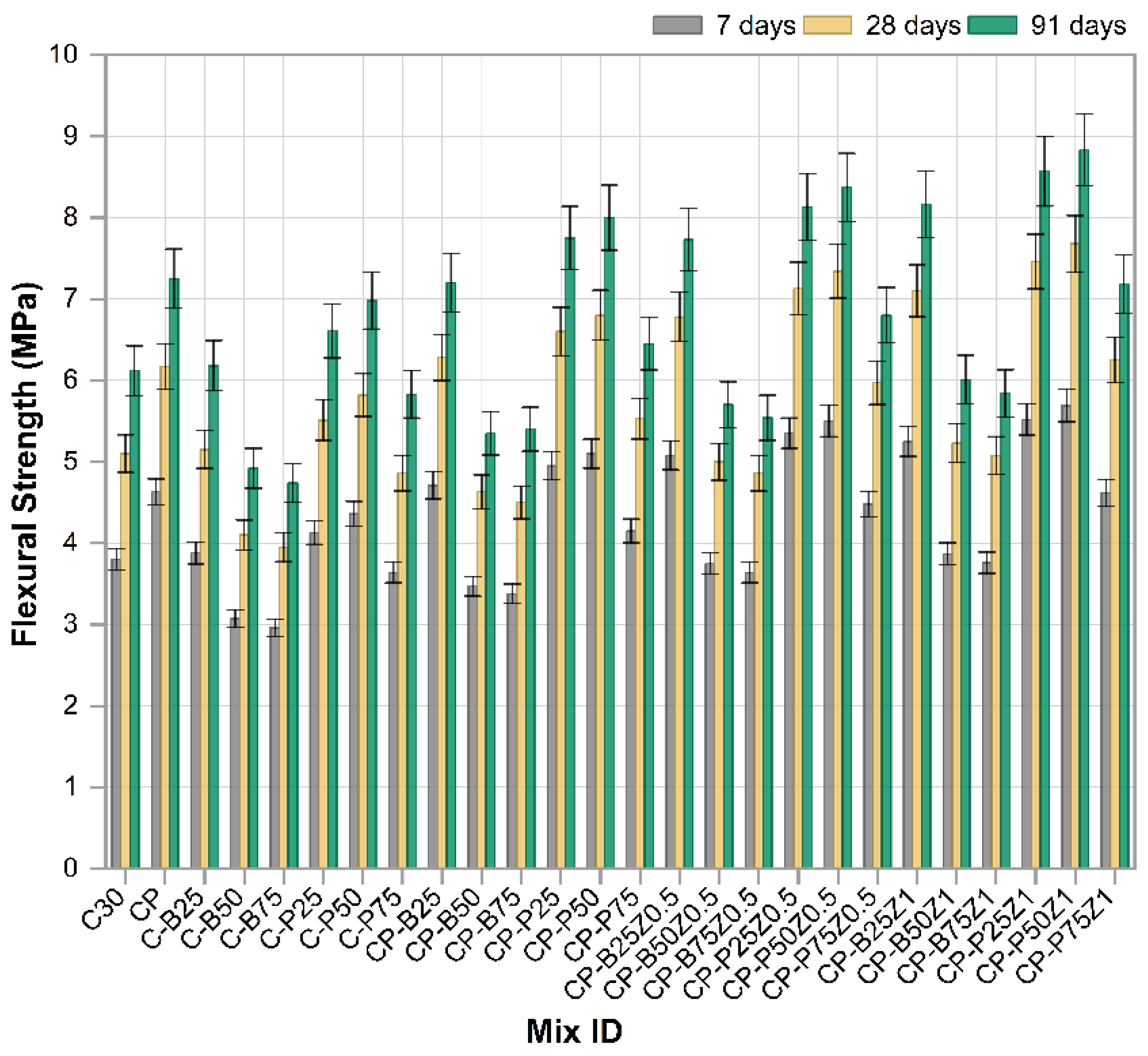

3.3. Flexural Strength

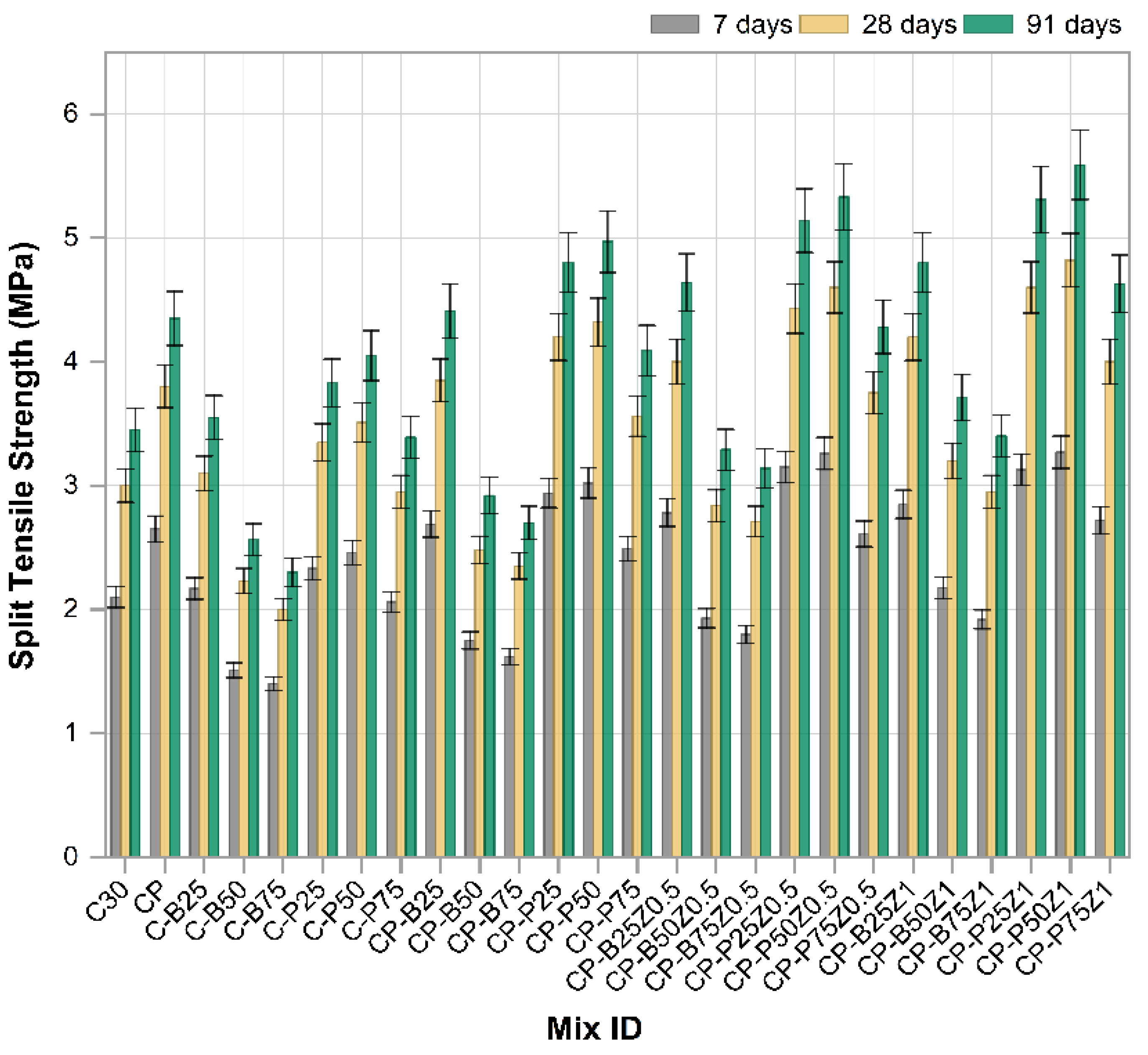

3.4. Splitting Tensile Strength

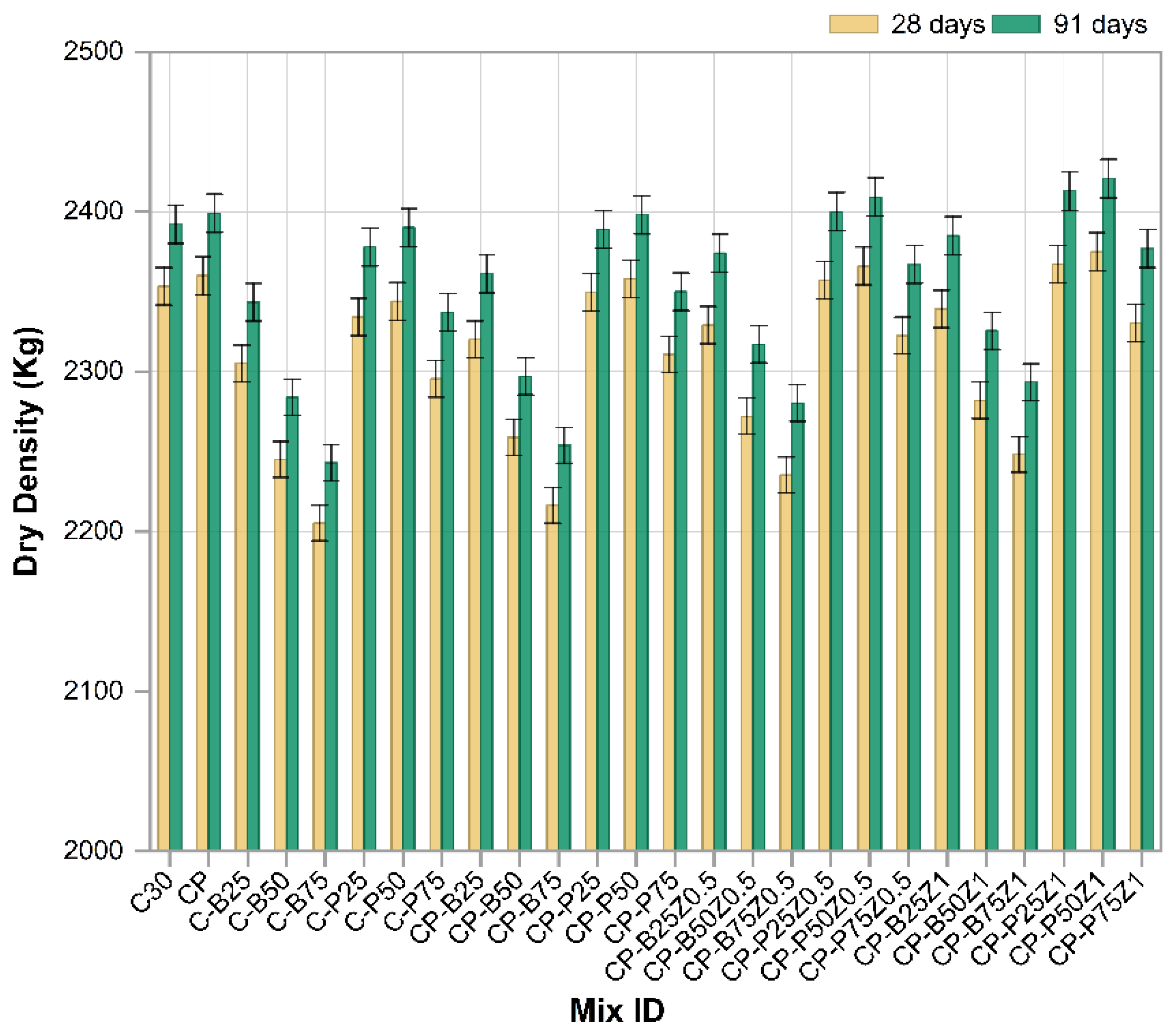

3.5. Dry Density

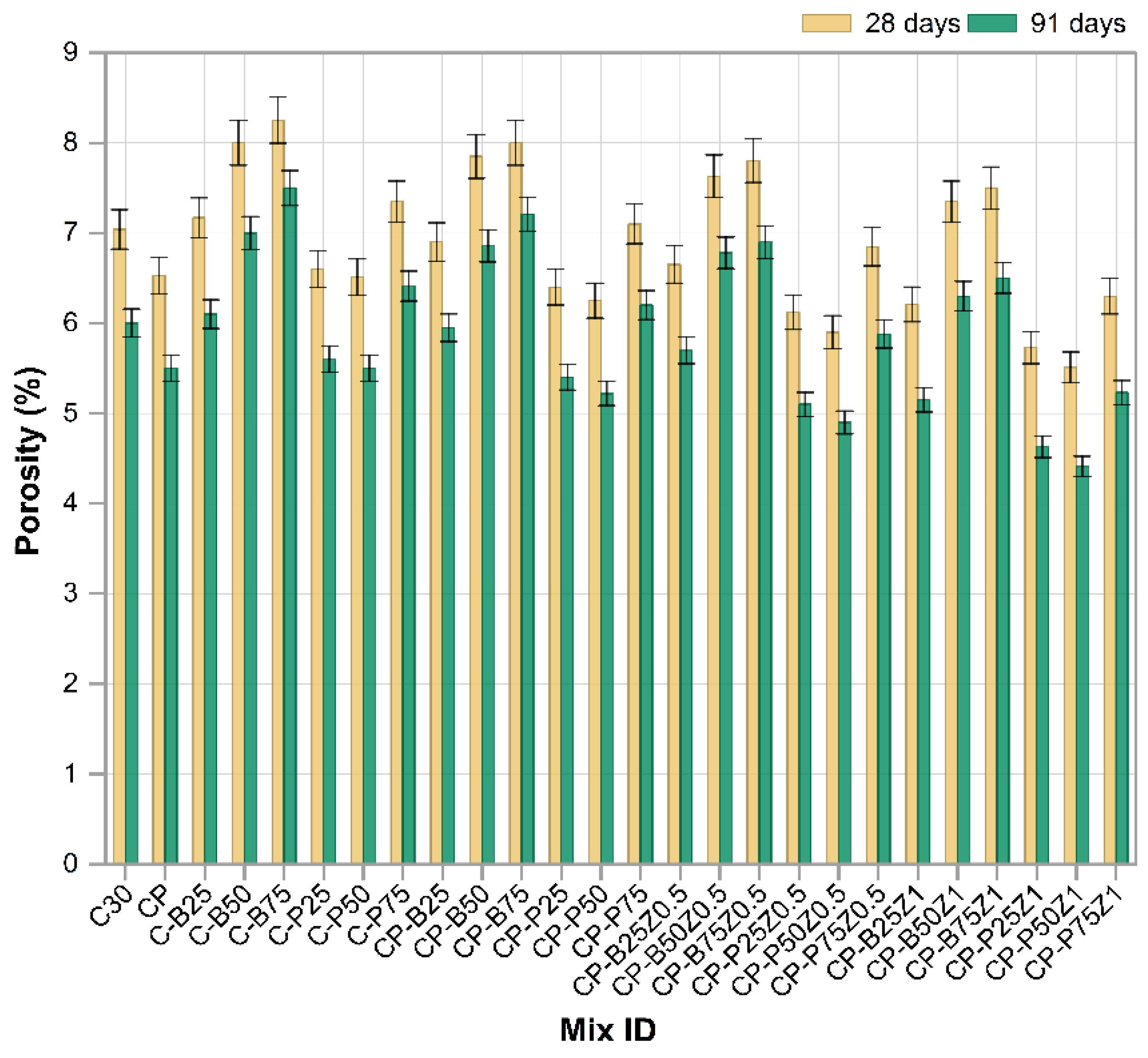

3.6. Porosity

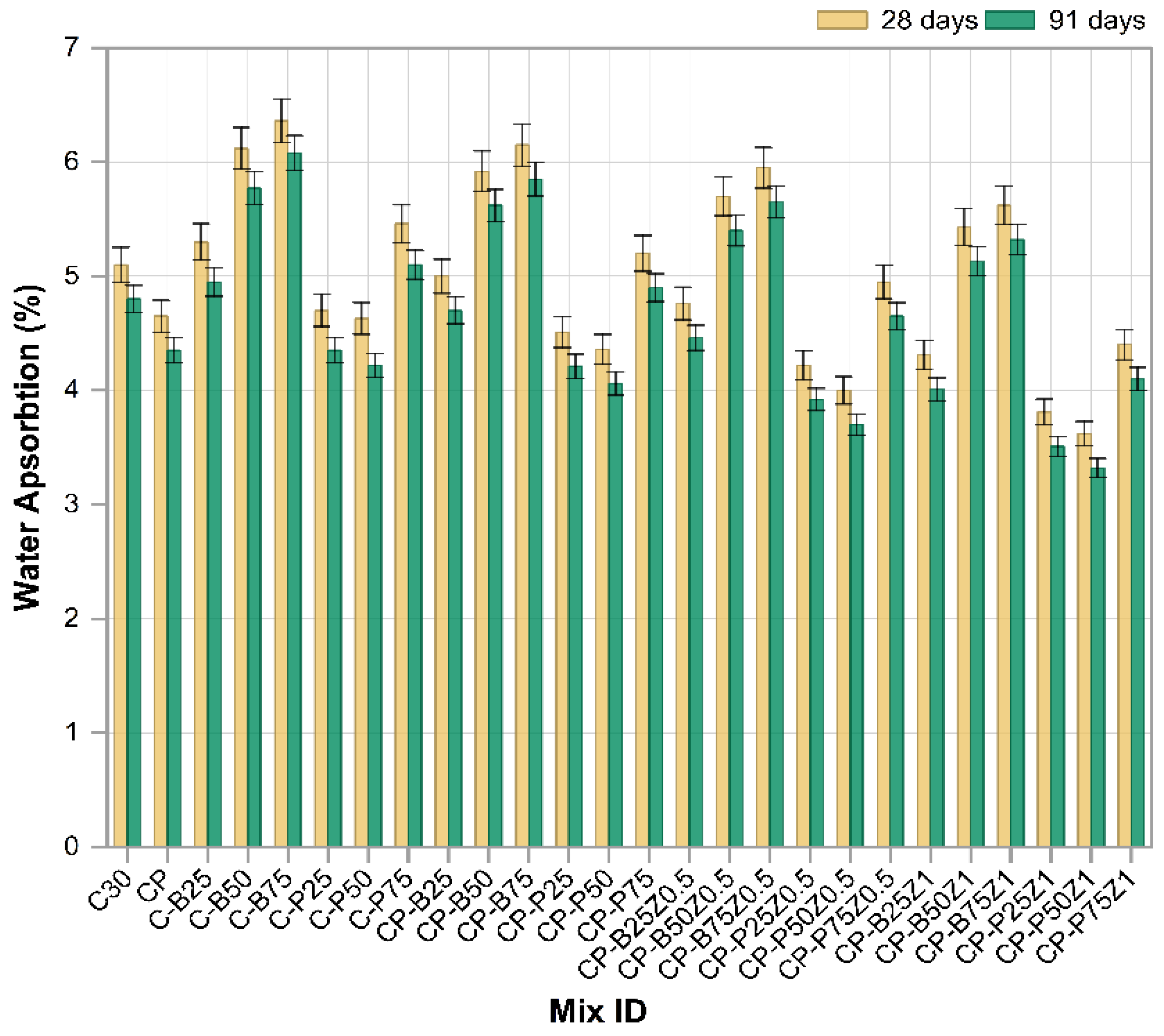

3.7. Water Absorption

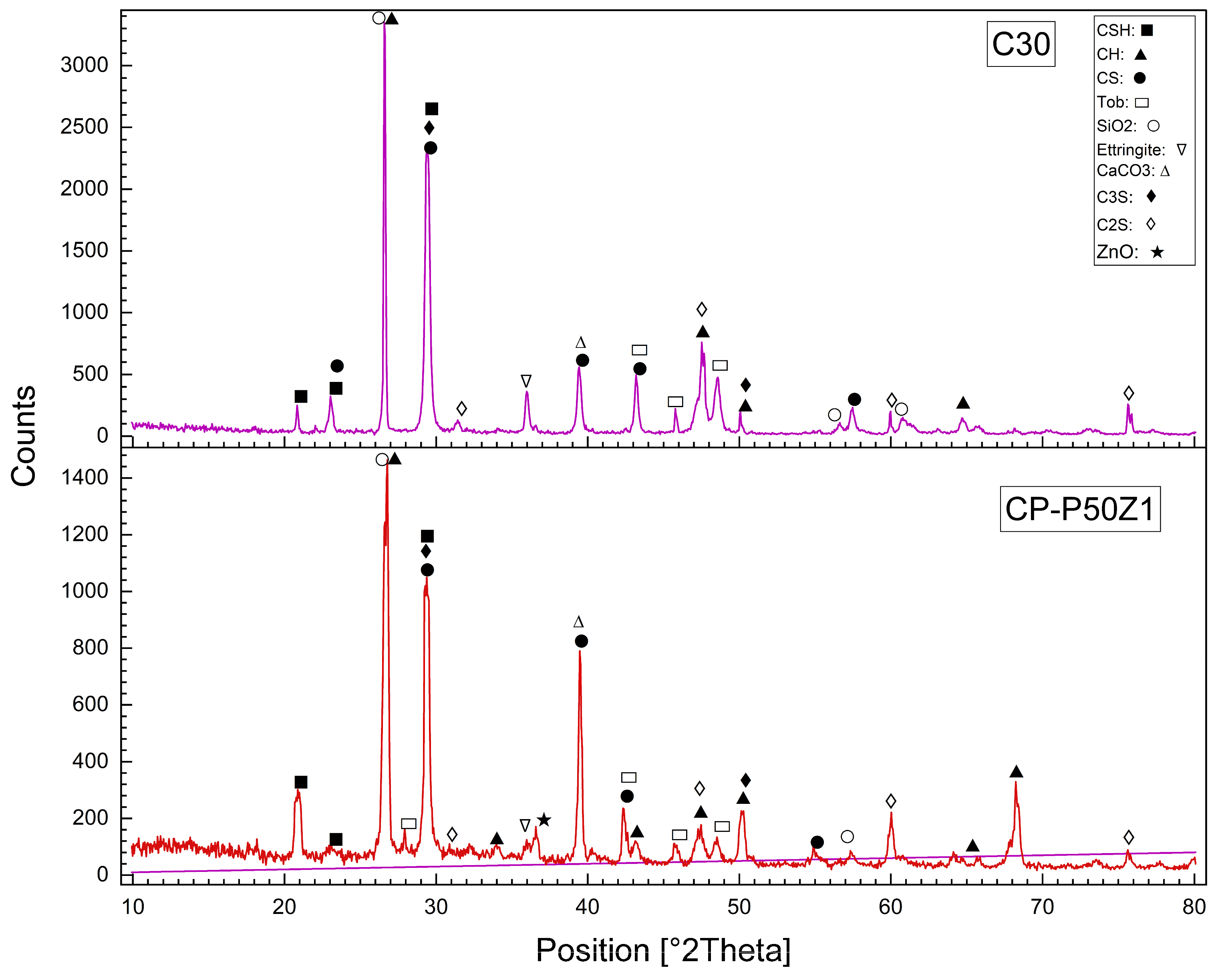

3.8. X-Ray Diffraction (XRD) of Reference and Modified Concrete Samples

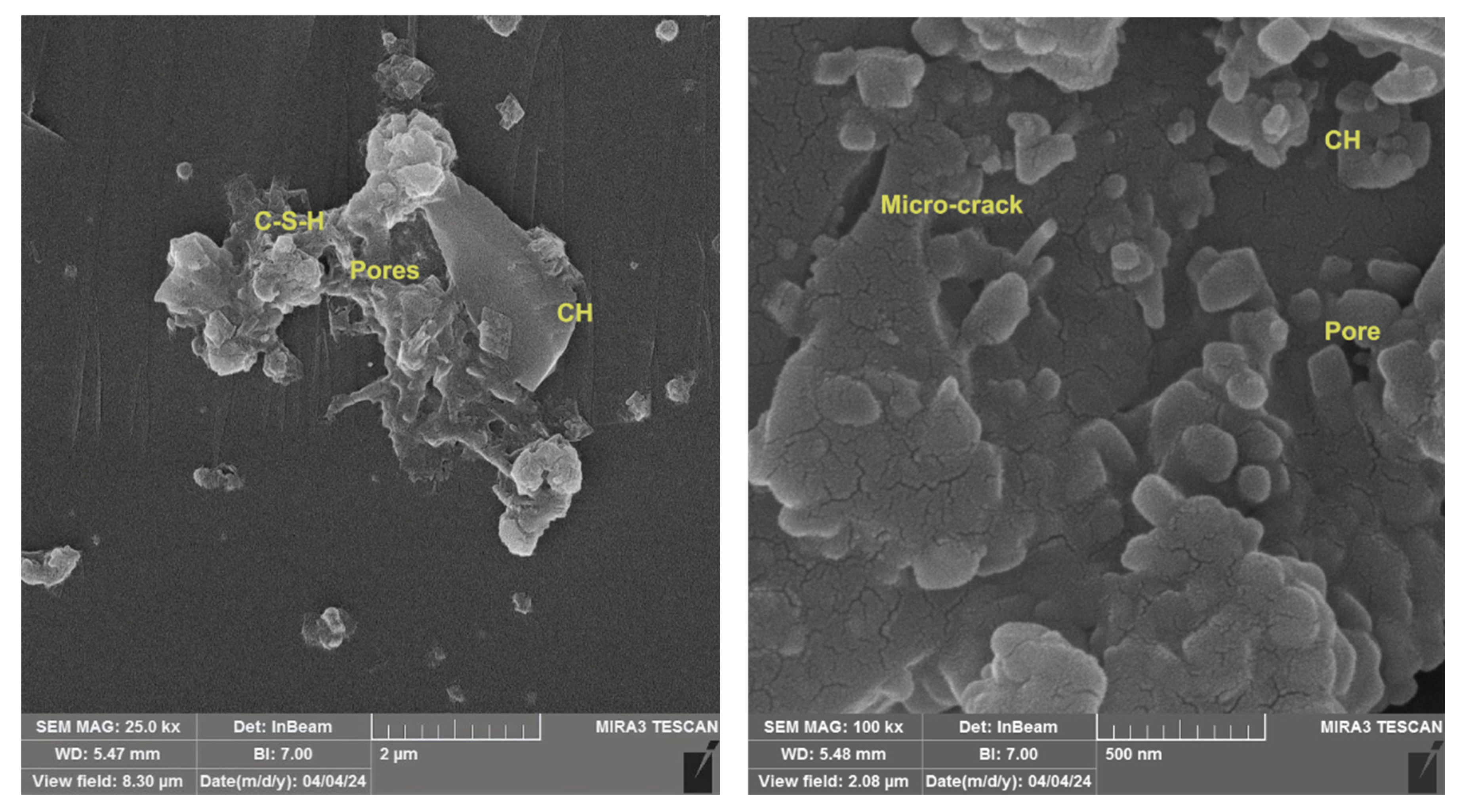

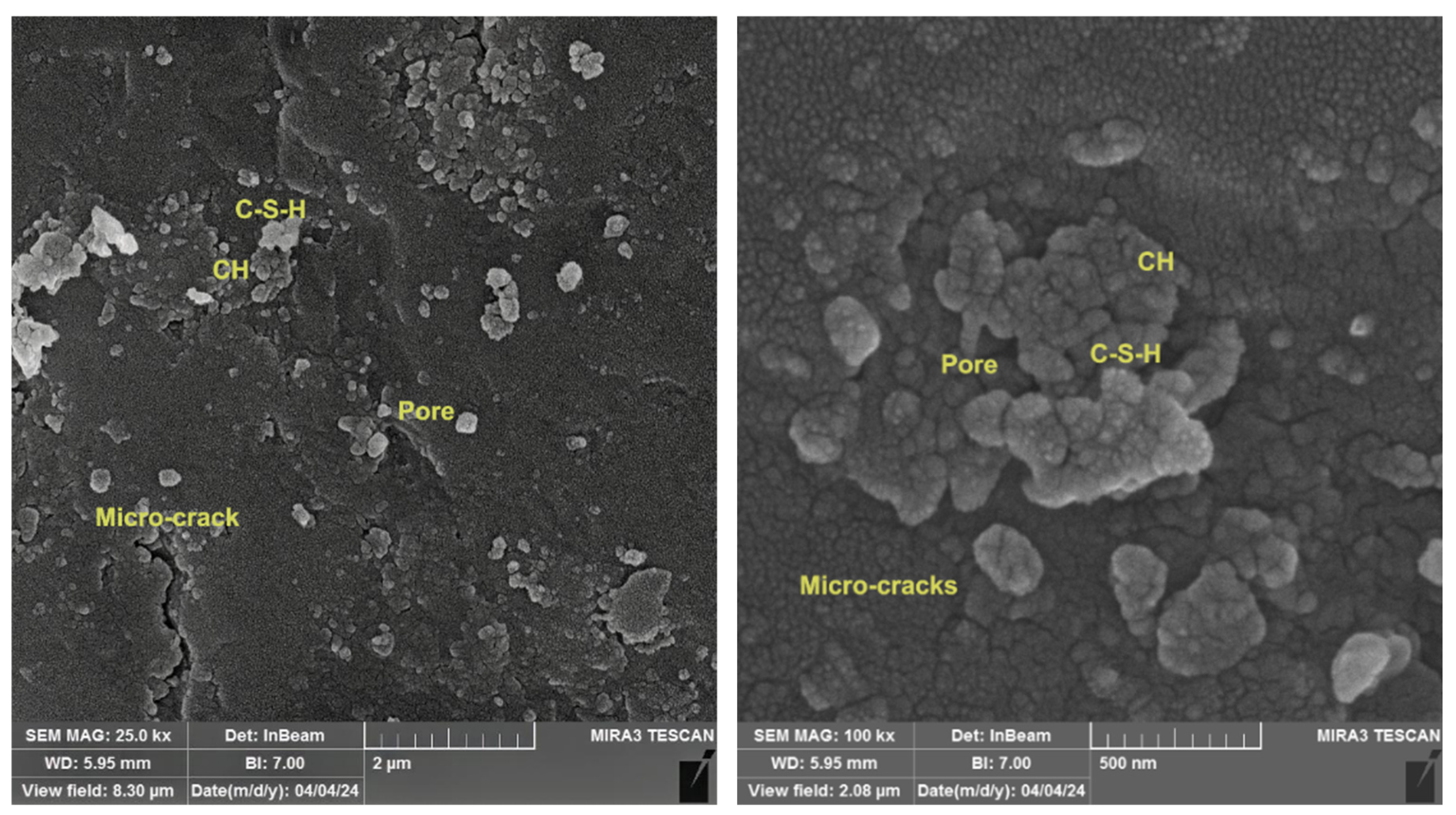

3.9. SEM Imaging of Reference and Modified Concrete Samples

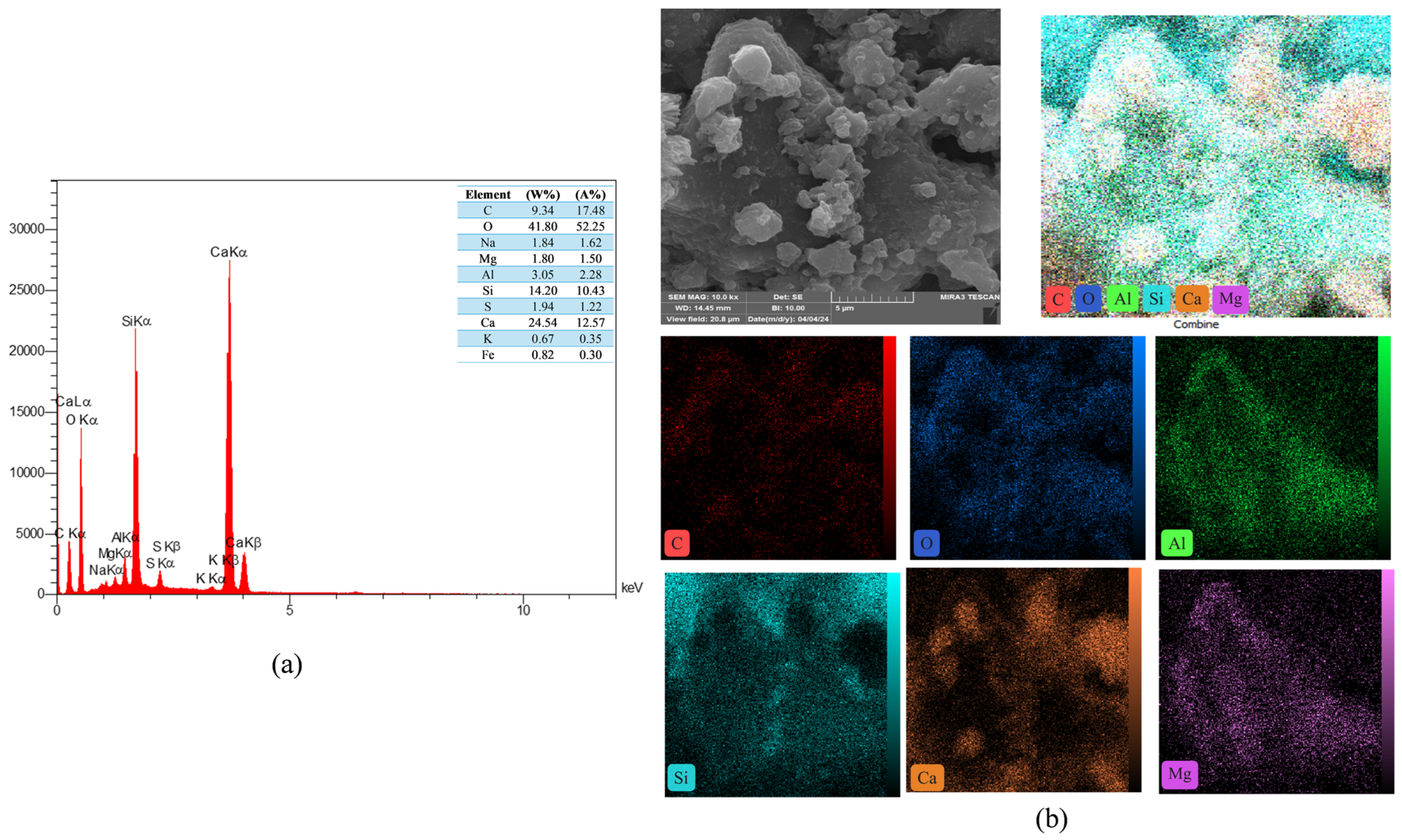

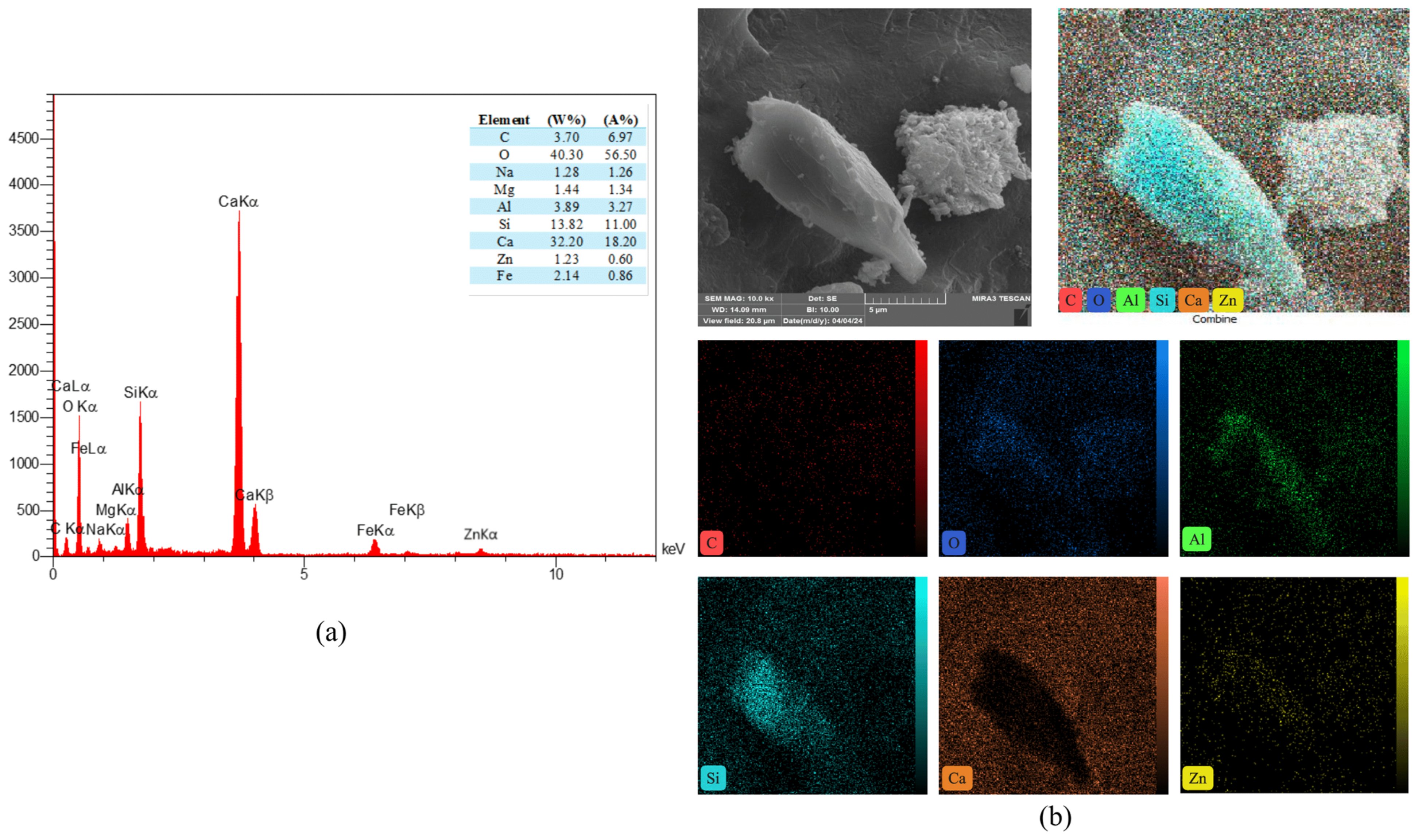

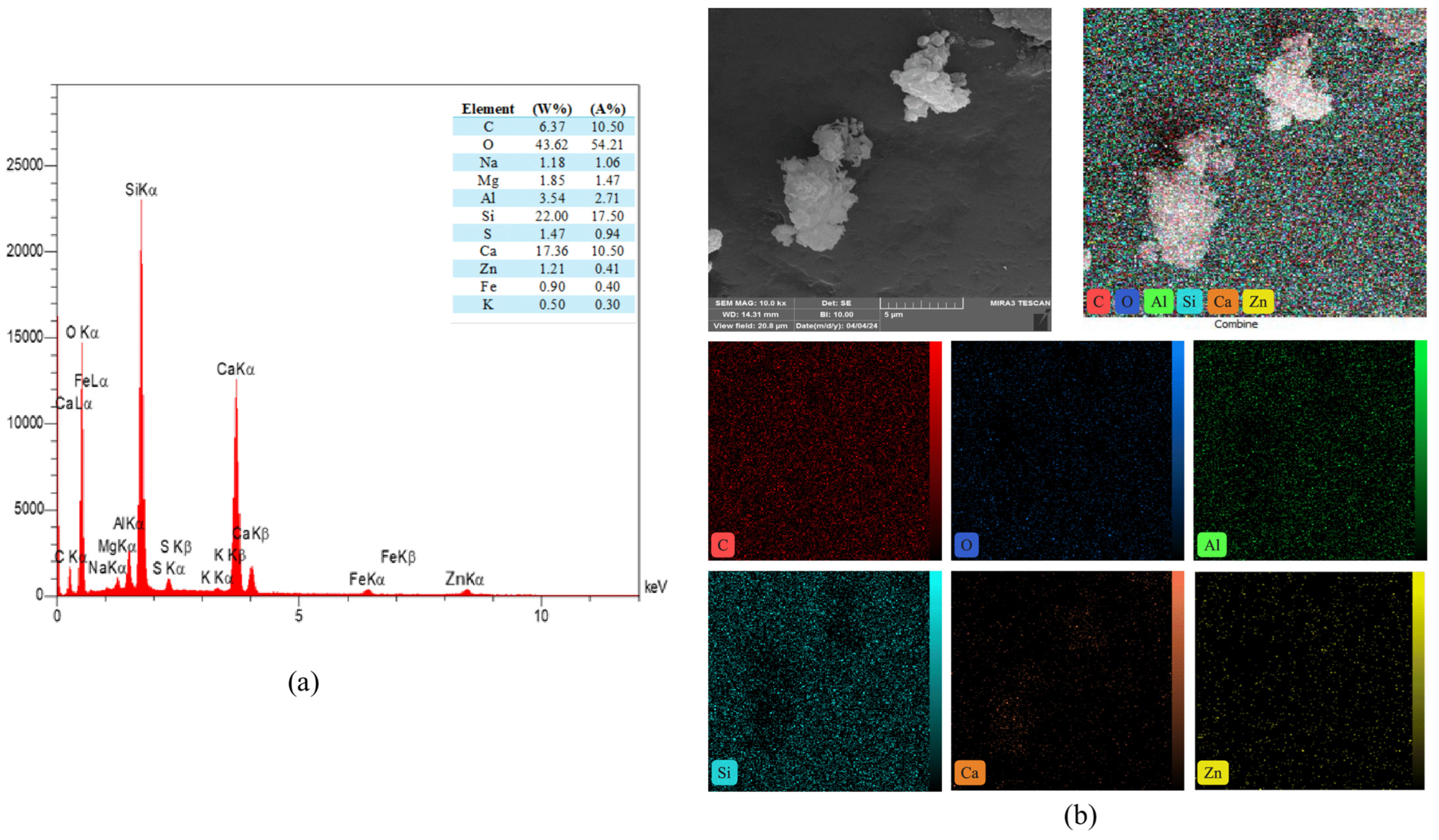

3.10. EDS Mapping of Reference and Modified Concrete Samples

3.11. Cost Evaluation of Natural Sand, Porcelain and Brick Waste Powders

3.12. Carbon Emissions Estimation

4. Conclusions

- SEM images of the powders revealed that porcelain exhibited irregular angular shapes with sharp angles. The brick particles exhibited a semi-elongated shape characterized by higher surface roughness and finer-grained agglomerates than porcelain particles.

- The mechanical test findings, including compressive strength, flexural strength, and splitting tensile strength of samples using waste powders, indicated that the optimal percentage for improving properties was 50% for PWP. The optimum amount for BWP was 25%. Conversely, increasing the proportion of natural sand substitution with waste powders to 75% resulted in a significant decline in mechanical characteristics.

- The dry density findings indicated that substituting sand with porcelain led to a slight reduction in concrete density. While it diminished further upon replacement with brick due to its higher porosity and water absorption.

- The porosity ratio results of the concrete mixes containing PWP at 25% and 50% sand replacement ratio showed that porosity decreased. While mixes contain 25% BWP, porosity exhibited a modest rise. Increasing the sand replacement ratio with waste materials led to a notable increase in porosity, with the exception of porcelain, for which the optimal replacement ratio was 50%.

- The water absorption rate for mixes incorporating PWP at 25% and 50% sand replacement is diminished. However, the water absorption rate increases for mixes that incorporate 25% BWP sand replacement. Increasing the sand replacement ratio led to a notable increase in water absorption, but with the exception of porcelain, for which the optimal replacement ratio was 50%.

- Trials have demonstrated that incorporating polypropylene fibers into concrete mixes, alongside varying amounts of building wastes significantly enhances compressive, flexural, and tensile strength. The physical characteristics indicated a minor increase in density, accompanied by a decrease in absorption and porosity for the fiber-reinforced concretes.

- Experimental findings have demonstrated that partially substituting of cement with zinc oxide nanoparticles in fiber-reinforced concrete samples included PWP or BWP at different sand replacement ratios. It led to a marked enhancement in mechanical characteristics, density, reduced porosity and water absorption at all ages.

- XRD analysis indicated that samples reinforced with polypropylene fibers, PWP or BWP as a sand substitute and nano ZnO as a partial cement substitute exhibited an increase in hydration products. It characterized by a reduction in calcium hydroxide compounds and an elevation in CSH compounds.

- SEM images indicated that the concrete mixes reinforced with fibers, PWP or BWP as a sand substitute and nano ZnO as a partial cement substitute exhibited more cohesiveness and reduced porosity compared to the reference sample. This is attributable to the filling effect of the fine particles and the role of nano ZnO in filling the micro-voids within the structure.

- EDS analysis revealed that the concrete mixes reinforced with polypropylene fibers, PWP or BWP sand substitutes and nano ZnO as a partial cement substitute exhibited an increase in hydration products. This is due to porcelain and brick wastes have high amounts of silica and alumina. Furthermore, nano zinc oxide promoted the pozzolanic reaction.

- In general, the concrete mix including sand replacement with 50% of PWP showed the best performance compared to the other mixes, whether or not additives were used including polypropylene fibers and zinc oxide nanoparticles. This substitution enhanced microstructure and diminished porosity, hence improving the concrete’s resistance to cracking.

- The production cost for one ton from porcelain or brick wastes as fine aggregate is lower than for sand.

5. Recommendations for Future Research

- Utilizing a composite of (porcelain and brick) wastes to examine their combined influence on the performance of the resulting concrete.

- Investigating the impact of higher PP.Fs percentages on the performance of concrete containing various amounts of waste materials.

- Utilizing of higher dosages of ZnO-NPs and investigating their impact on the characteristics of mixes exclusively composed of fibers without of waste materials.

- Investigating the influence of several additives or replacements on the characteristics like resistance to corrosion, wear resistance and impact resistance.

- Assessment of long-term performance regarding shrinkage, contraction and water permeability.

- As already reported, it is better to investigate in depth one type of each modified concrete. Long term studies need to know preliminary results on each modified concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Papamichael, I.; Voukkali, I.; Loizia, P.; Zorpas, A.A. Construction and demolition waste framework of circular economy: A mini review. Waste Manag. Res. J. A Sustain. Circ. Econ. 2023, 41, 1728–1740. [Google Scholar] [CrossRef]

- Sahmi, N.; Sayhood, E.; Mohammed, N. Impact of recycled aggregate on bond behavior between concrete and steel bars: A systematic review. Eng. Technol. J. 2025, 43, 308–325. [Google Scholar] [CrossRef]

- Azeez, A.; Hassan, M.; Atiyah, A. Evaluation of the Performance of Steel Slag and Waste Glass as a Cement Replacement. Eng. Technol. J. 2023, 41, 1568–1587. [Google Scholar] [CrossRef]

- Ray, S.; Haque, M.; Sakib, M.N.; Mita, A.F.; Rahman, M.M.; Tanmoy, B.B. Use of ceramic wastes as aggregates in concrete production: A review. J. Build. Eng. 2021, 43, 102567. [Google Scholar] [CrossRef]

- Ngayakamo, B.H. Sustainable concrete production: The role of ceramic waste as a partial coarse aggregate substitute. Discov. Civ. Eng. 2025, 2, 32. [Google Scholar] [CrossRef]

- Hashim, A.A.; Anaee, R.A.; Nasr, M.S. Durability, Mechanical, and Corrosion Characteristics of Recycled Aggregate Concrete Utilizing Locally Sourced Waste and Ultrafine Cerium Oxide. J. Appl. Sci. Nanotechnol. 2025, 5, 24–38. [Google Scholar] [CrossRef]

- Besklubova, S.; Kravchenko, E.; Tan, B.Q.; Zhong, R.Y. A feasibility analysis of waste concrete powder recycling market establishment: Hong Kong case. Environ. Impact Assess. Rev. 2023, 103, 107225. [Google Scholar] [CrossRef]

- Patra, I.; Al-Awsi, G.R.L.; Hasan, Y.M.; Almotlaq, S.S.K. Mechanical properties of concrete containing recycled aggregate from construction waste. Sustain. Energy Technol. Assess. 2022, 53, 102722. [Google Scholar] [CrossRef]

- Belebchouche, C.; Temami, O.; Khouadjia, M.L.K.; Hamlaoui, S.; Berkouche, A.; Chouadra, T. Recycling of Brick and Road Demolition Waste in the Production of Concrete. Sci. Eng. Technol. 2024, 4, 14–23. [Google Scholar] [CrossRef]

- Bhutto, M.A.; Sudheer, M. Effect of recycled porcelain-ceramic aggregates on concrete: A review. In Proceedings of the International Conference on Sustainable Development in Civil Engineering, Jamshoro, Pakistan, 16–18 February 2023. [Google Scholar]

- Roig-Flores, M.; Reig, L.; Albero, V.; Hernández-Figueirido, D.; Melchor-Eixea, A.; Pitarch, Á.M.; Piquer, A. Utilisation of ceramic stoneware tile waste as recycled aggregate in concrete. Buildings 2023, 13, 1968. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Wu, H.; Wang, W.; Wang, L.; Yao, C.; Wu, J. Research progress on recycled clay brick waste as an alternative to cement for sustainable construction materials. Constr. Build. Mater. 2021, 274, 122113. [Google Scholar] [CrossRef]

- Tawfik, T.A.; Sičáková, A.; Kuzielová, E.; Kušnír, Š.; Eštoková, A.; Bálintová, M.; Junáková, N. Sustainable reuse of waste ceramic tiles powder and waste brick powder as a replacement for cement on green high strength concrete properties. Innov. Infrastruct. Solut. 2024, 9, 166. [Google Scholar] [CrossRef]

- Simon, J.; Beushausen, H.; Alexander, M. The Use of Recycled Construction and Demolition Waste in Low-Strength Concrete Brick and Block Production: A South African Perspective. In Proceedings of the 1st International Conference on Net-Zero Built Environment, Cape Town, South Africa, 5–7 November 2025; Kioumarsi, M., Shafei, B., Eds.; Springer Nature: Basel, Switzerland, 2025; pp. 279–291. [Google Scholar] [CrossRef]

- Li, Q.; Liu, P.; Wang, M.; Xia, H. Effects of elevated temperature on the mechanical properties of concrete with aggregate of waste porcelain tile. J. Build. Eng. 2023, 64, 105585. [Google Scholar]

- Şenol, A.F.; Karakurt, C. High-strength self-compacting concrete produced with recycled clay brick powders: Rheological, mechanical and microstructural properties. J. Build. Eng. 2024, 88, 109175. [Google Scholar] [CrossRef]

- Hosen, K.; Bărbulescu, A. Sustainable Concrete Using Ceramic Tile Waste as a Substitute for Brick Aggregate. Materials 2025, 18, 3093. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Zhu, Z.; Guo, Q.; Wu, X.; Zhao, R. Research on different types of fiber reinforced concrete in recent years: An overview. Constr. Build. Mater. 2023, 365, 130075. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Chapoñan Inoñan, J.J.; Delgado Fernández, E.; Muñoz Pérez, S.P.; Garcia Chumacero, J.M.; Sánchez Diaz, E.; Diaz Ortiz, E.A.; Rodriguez Laffite, E.D.; Villena Zapata, L.I.; Malpartida Iturregui, J.D.D. Influence of polypropylene fibers on the microstructure and physical and mechanical properties of concrete. Innov. Infrastruct. Solut. 2024, 9, 488. [Google Scholar] [CrossRef]

- Tan, C.T.; Yew, M.K.; Yew, M.C.; Lee, F.W.; Lim, S.K.; Beh, J.H.; Lee, J.C.; Lim, J.H. Mechanical property enhancement in concrete composites with hybrid polypropylene fibre reinforcement. Sci. Rep. 2025, 15, 24986. [Google Scholar] [CrossRef] [PubMed]

- Gopalakrishnan, R.; Nithiyanantham, S. Effect of ZnO nanoparticles on cement mortar for enhancing the physico-chemical, mechanical and related properties. Adv. Sci. Eng. Med. 2020, 12, 348–355. [Google Scholar] [CrossRef]

- Patil, H.; Dwivedi, A. Impact of nano ZnO particles on the characteristics of the cement mortar. Innov. Infrastruct. Solut. 2021, 6, 222. [Google Scholar] [CrossRef]

- Garg, R.; Garg, R. Effect of zinc oxide nanoparticles on mechanical properties of silica fume-based cement composites. Mater. Today: Proc. 2021, 43, 778–783. [Google Scholar] [CrossRef]

- IQS 5/1984; Portland Cement. Iraqi Standard Specifications: Baghdad, Iraq, 1984.

- ASTM C150-04; Standard Specification for Portland Cement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- IQS 45/1984; Aggregates from Natural Sources for Concrete and Building Construction. Iraqi Standard Specifications: Baghdad, Iraq, 1984.

- ASTM C33; Method for Standard Specification for Concrete Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- Alotaibi, J.G.; Alajmi, A.E.; Alsaeed, T.; Khalaf, J.A.; Yousif, B.F. On the incorporation of waste ceramic powder into concrete. Front. Mech. Eng. 2024, 10, 1469727. [Google Scholar] [CrossRef]

- Dang, J.; Xiao, J.; Duan, Z. Effect of pore structure and morphological characteristics of recycled fine aggregates from clay bricks on mechanical properties of concrete. Constr. Build. Mater. 2022, 358, 129455. [Google Scholar] [CrossRef]

- ASTM C1116; Standard Specification for Fiber-Reinforced Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- BS EN 934-2:2001; Admixtures for Concrete, Mortar and Grout, Concrete Admixtures, Definitions, Requirements, Conformity, Marking and Labeling. British Standard Institution: London, UK, 2001.

- BS EN 5328-2; Concrete-Part 2, Methods for Specifying Concrete Mixes. British Standard Institution: London, UK, 1997.

- Baranov, A.N.; Sokolov, P.S.; Solozhenko, V.L. ZnO under pressure: From nanoparticles to single crystals. Crystals 2022, 12, 744. [Google Scholar] [CrossRef]

- ASTM C143/C143M; Standard Test Method for Slump of Hydraulic-Cement Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- BS 1881-116; Testing Concrete. Method for Determination of Compressive Strength of Concrete Cubes. British Standard Institution: London, UK, 1983.

- ASTM C293; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). American Society for Testing and Materials: West Conshohocken, PA, USA, 2008.

- ASTM C496; Standard Test Method for Splitting Tensile of Cylindrical Concrete Specimens. American Society for Testing and Materials: West Conshohocken, PA, USA, 2006.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2006.

- ASTM C856; Standard Practice for Petrographic Examination of Hardened Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- ASTM C1723; Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- Elaqra, H.A.; Haloub, M.A.A.; Rustom, R.N. Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Constr. Build. Mater. 2019, 203, 75–82. [Google Scholar] [CrossRef]

- Shadbad, K.R.; Foroughi-Asl, A.; Talatahari, S.; Mohasseb, S. The effects of nanoparticle additives on thermophysical properties of concrete mixtures. Open J. Civ. Eng. 2022, 12, 587–614. [Google Scholar] [CrossRef]

- Wang, Y.; Nejati, F.; Edalatpanah, S.A.; Goudarzi Karim, R. Experimental study to compare the strength of concrete with different amounts of polypropylene fibers at high temperatures. Sci. Rep. 2024, 14, 8566. [Google Scholar] [CrossRef] [PubMed]

- Keshavarz, Z.; Mostofinejad, D. Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete. Constr. Build. Mater. 2019, 195, 218–230. [Google Scholar] [CrossRef]

- Raini, I.; Jabrane, R.; Mesrar, L.; Akdim, M. Evaluation of mortar properties by combining concrete and brick wastes as fine aggregate. Case Stud. Constr. Mater. 2020, 13, e00434. [Google Scholar] [CrossRef]

- Latifi, M.R.; Biricik, Ö.; Mardani Aghabaglou, A. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Wang, X.; Dong, S.; Ashour, A.; Zhang, W.; Han, B. Effect and mechanisms of nanomaterials on interface between aggregates and cement mortars. Constr. Build. Mater. 2020, 240, 117942. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Pang, S.D.; Zhao, S. Durability and microstructural properties of concrete with recycled brick as fine aggregates. Constr. Build. Mater. 2020, 262, 120032. [Google Scholar] [CrossRef]

- Hou, L.; Wen, B.; Huang, W.; Zhang, X.; Zhang, X. Mechanical Properties and Microstructure of Polypropylene–Glass-Fiber-Reinforced Desert Sand Concrete. Polymers 2023, 15, 4675. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Bansal, M.; Garg, R. An overview of beneficiary aspects of zinc oxide nanoparticles on performance of cement composites. Mater. Today Proc. 2021, 43, 892–898. [Google Scholar] [CrossRef]

- Esmaeili, J.; AL-Mwanes, A.O. Performance Evaluation of Eco-Friendly Ultra-High-Performance Concrete Incorporated with Waste Glass-A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012030. [Google Scholar] [CrossRef]

- Abdul Rahim Zai, A.; Salhotra, S. Effect of waste foundry sand and glass fiber on mechanical properties and fire resistance of high-strength concrete. Mater. Today Proc. 2020, 33, 1733–1740. [Google Scholar] [CrossRef]

- Gorji Azandariani, M.; Vajdian, M.; Asghari, K.; Mehrabi, S. Mechanical properties of polyolefin and polypropylene fibers-reinforced concrete—An experimental study. Compos. Part C Open Access 2023, 12, 100410. [Google Scholar] [CrossRef]

- Al-Rbaihat, R.; Al-Marafi, M.N.I. Combined Effect of Silicon Dioxide and Titanium Dioxide Nanoparticles on Concrete Properties. J. Ecol. Eng. 2023, 24, 319–335. Available online: https://www.jeeng.net/Combined-Effect-of-Silicon-Dioxide-and-Titanium-Dioxide-Nanoparticles-on-Concrete,173210,0,2.html (accessed on 27 September 2025). [CrossRef]

- Mora-Ortiz, R.S.; Díaz, S.A.; Del Angel-Meraz, E.; Magaña-Hernández, F. Recycled Fine Aggregates from Mortar Debris and Red Clay Brick to Fabricate Masonry Mortars: Mechanical Analysis. Materials 2022, 15, 7707. [Google Scholar] [CrossRef]

- Tanash, A.O.; Muthusamy, K.; Budiea, A.M.A.; Fauzi, M.A.; Jokhio, G.; Jose, R. A review on the utilization of ceramic tile waste as cement and aggregates replacement in cement based composite and a bibliometric assessment. Clean. Eng. Technol. 2023, 17, 100699. [Google Scholar] [CrossRef]

- Burgos Cotrina, J.A.; Cubas Benavides, E.A.; Garcia Chumacero, J.M. Analysis of the combination of glass and polypropylene fibers on the mechanical properties of mortar. J. Build. Pathol. Rehabil. 2025, 10, 22. [Google Scholar] [CrossRef]

- Thangapandi, K.; Anuradha, R.; Archana, N.; Muthuraman, P.; Awoyera Paul, O.; Gobinath, R. Experimental Study on Performance of Hardened Concrete Using Nano Materials. KSCE J. Civ. Eng. 2020, 24, 596–602. [Google Scholar] [CrossRef]

- Zhang, Z.; Ji, Y.; Wang, D. Research Progress on Fiber-Reinforced Recycled Brick Aggregate Concrete: A Review. Polymers 2023, 15, 2316. [Google Scholar] [CrossRef]

- Elemam, W.E.; Agwa, I.S.; Tahwia, A.M. Reusing Ceramic Waste as a Fine Aggregate and Supplemental Cementitious Material in the Manufacture of Sustainable Concrete. Buildings 2023, 13, 2726. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. An experimental investigation on the integral waterproofing capacity of polypropylene fiber concrete with fly ash and slag powder. Constr. Build. Mater. 2019, 212, 675–686. [Google Scholar] [CrossRef]

- Klak, F.S.; Saleh, H.; Tais, A.S. Recycling of crushed clay bricks as fine aggregate in concrete and cement mortar. Aust. J. Struct. Eng. 2023, 24, 67–76. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Cao, K.; Sun, L. Review on the Durability of Polypropylene Fibre-Reinforced Concrete. Adv. Civ. Eng. 2021, 2021, 6652077. [Google Scholar] [CrossRef]

- Amor, F.; Baudys, M.; Racova, Z.; Scheinherrová, L.; Ingrisova, L.; Hajek, P. Contribution of TiO2 and ZnO nanoparticles to the hydration of Portland cement and photocatalytic properties of High Performance Concrete. Case Stud. Constr. Mater. 2022, 16, e00965. [Google Scholar] [CrossRef]

- Gonçalves, B.; Exposito, C.; Toshimi Ishikawa, T.; Yuuki Koga, G. X-ray diffraction study of the early hydration of Portland cements containing calcium carbonate by in-situ and ex-situ approaches. Constr. Build. Mater. 2023, 365, 129947. [Google Scholar] [CrossRef]

- Liu, Q.; Li, B.; Xiao, J.; Singh, A. Utilization potential of aerated concrete block powder and clay brick powder from C&D waste. Constr. Build. Mater. 2020, 238, 117721. [Google Scholar] [CrossRef]

- Li, Z.; Ding, S.; Yu, X.; Han, B.; Ou, J. Multifunctional cementitious composites modified with nano titanium dioxide: A review. Compos. Part A Appl. Sci. Manuf. 2018, 111, 115–137. [Google Scholar] [CrossRef]

- Islam, M.J. Comparative Study of Concrete with Polypropylene and Polyethylene Terephthalate Waste Plastic as Partial Replacement of Coarse Aggregate. Adv. Civ. Eng. 2022, 2022, 4928065. [Google Scholar] [CrossRef]

- Asghari, Y.; Mohammadyan-Yasouj, S.E. Utilization of Porcelain Polishing Residues and Metakaolin in Self-Consolidating Concrete. Constr. Build. Mater. 2024, 420, 135588. [Google Scholar] [CrossRef]

- Boulghebar, K.; Sadok, A.H.; Brahma, A. Effect of recycled brick sand on mechanical and transfer properties of roller compacted concrete “RCC” used for dams. Matéria 2025, 30, 20240703. [Google Scholar] [CrossRef]

- Kunther, W.; Ferreiro, S.; Skibsted, J. Influence of the Ca/Si ratio on the compressive strength of cementitious calcium–silicate–hydrate binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar] [CrossRef]

- Hu, C. Microstructure and mechanical properties of fly ash blended cement pastes. Constr. Build. Mater. 2014, 73, 618–625. [Google Scholar] [CrossRef]

- Sevim, O.; Alakara, E.H.; Guzelkucuk, S. Fresh and Hardened Properties of Cementitious Composites Incorporating Firebrick Powder from Construction and Demolition Waste. Buildings 2023, 13, 45. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, D.; Cheng, S.; Xu, X.; Zhao, C.; Wang, X.; Wu, Q.; Bai, X. Sustainable reuse of ceramic waste powder as a supplementary cementitious material in recycled aggregate concrete: Mechanical properties, durability and microstructure assessment. J. Build. Eng. 2022, 52, 104418. [Google Scholar] [CrossRef]

- Bampanis, I.; Vasilatos, C. Recycling Concrete to Aggregates, Implications on CO2 Footprint. Mater. Proc. 2023, 15, 28. [Google Scholar] [CrossRef]

- Lei, B.; Yu, L.; Chen, Z.; Yang, W.; Deng, C.; Tang, Z. Carbon Emission Evaluation of Recycled Fine Aggregate Concrete Based on Life Cycle Assessment. Sustainability 2022, 14, 14448. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | Fe2O3 | Al2O3 | CaO | MgO | SO3 | Na2O, K2O | Insoluble Residue | L.O. I |

|---|---|---|---|---|---|---|---|---|---|

| Percent (%) | 20.14 | 3.25 | 5.84 | 63.26 | 2.38 | 1.27 | 0.62 | 0.71 | 1.94 |

| Testing | Result | Limitations IQS: No. (5)/1984 |

|---|---|---|

| Initial time setting, min | 97 | Minium 45 min |

| Final time setting, h: min | 6:47 | Maximum 10 h |

| Compressive strength at 3 days, MPa | 21.24 | Minium 15 MPa |

| Compressive strength at 28 days, MPa | 43.42 | - |

| Fineness (sieve no. 200) | 3.78 | Maximum 10 |

| Physical Property | Standard Specification | Result | Limitations of IQS: No. 45/1984 |

|---|---|---|---|

| Specific gravity | ASTM:C128-1988 | 2.641 | - |

| Absorption (%) | ASTM:C128-1998 | 0.775 | - |

| Unit weight for dry loose (kg/m3) | ASTM:C29-89 | 1591 | - |

| Sulfate percentage (%) | IQS: No. 45/1984 | 0.0922 | ≤0.5 |

| Substance less than 75 μm (%) | IQS: No. 45/1984 | 3.93 | ≤5 |

| Oxide (%) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | TiO2 | MnO | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| PWP | 67.82 | 18.51 | 2.31 | 3.26 | 1.53 | 2.72 | 2.28 | 0.67 | 0.02 | 0.07 |

| BWP | 55.73 | 20.74 | 5.00 | 11.27 | 3.25 | 0.94 | 1.15 | 0.45 | 0.08 | 0.13 |

| Feature | Fiber Length | Fiber Diameter | Elastic Modulus | Tensile Strength | Density |

|---|---|---|---|---|---|

| Value | 12 mm | 0.032 mm | 3000–3500 MPa | 600–700 MPa | 0.910 g/cm3 |

| Feature | Appearance | Average Particle Size | Density | Purity | Color |

|---|---|---|---|---|---|

| Details | Powder | 30 ± 10 nm | 5.60 g/cm3 | 99.8% | white to light yellow |

| Mixture Name | Cement (kg) | FA (kg) | CA (kg) | Water (kg) | PP. Fs (kg) | S.P (kg) | ZnO-NPs (kg) | WPMs (kg) |

|---|---|---|---|---|---|---|---|---|

| C30 | 360 | 691.2 | 1036.8 | 180 | 0 | 0 | 0 | 0 |

| CP | 360 | 691.2 | 1036.8 | 180 | 4.55 | 3.6 | 0 | 0 |

| C-P25 | 360 | 518.4 | 1036.8 | 180 | 0 | 3.6 | 0 | 172.8 |

| C-P50 | 360 | 345.6 | 1036.8 | 180 | 0 | 3.6 | 0 | 345.6 |

| C-P75 | 360 | 172.8 | 1036.8 | 180 | 0 | 3.6 | 0 | 518.4 |

| C-B25 | 360 | 518.4 | 1036.8 | 180 | 0 | 3.6 | 0 | 172.8 |

| C-B50 | 360 | 345.6 | 1036.8 | 180 | 0 | 3.6 | 0 | 345.6 |

| C-B75 | 360 | 172.8 | 1036.8 | 180 | 0 | 3.6 | 0 | 518.4 |

| CP-P25 | 360 | 518.4 | 1036.8 | 180 | 4.55 | 3.6 | 0 | 172.8 |

| CP-P50 | 360 | 345.6 | 1036.8 | 180 | 4.55 | 3.6 | 0 | 345.6 |

| CP-P75 | 360 | 172.8 | 1036.8 | 180 | 4.55 | 3.6 | 0 | 518.4 |

| CP-B25 | 360 | 518.4 | 1036.8 | 180 | 4.55 | 3.6 | 0 | 172.8 |

| CP-B50 | 360 | 345.6 | 1036.8 | 180 | 4.55 | 3.6 | 0 | 345.6 |

| CP-B75 | 360 | 172.8 | 1036.8 | 180 | 4.55 | 3.6 | 0 | 518.4 |

| CP-P25Z0.5 | 358.2 | 518.4 | 1036.8 | 180 | 4.55 | 3.6 | 1.8 | 172.8 |

| CP-P50Z0.5 | 358.2 | 345.6 | 1036.8 | 180 | 4.55 | 3.6 | 1.8 | 345.6 |

| CP-P75Z0.5 | 358.2 | 172.8 | 1036.8 | 180 | 4.55 | 3.6 | 1.8 | 518.4 |

| CP-B25Z0.5 | 358.2 | 518.4 | 1036.8 | 180 | 4.55 | 3.6 | 1.8 | 172.8 |

| CP-B50Z0.5 | 358.2 | 345.6 | 1036.8 | 180 | 4.55 | 3.6 | 1.8 | 345.6 |

| CP-B75Z0.5 | 358.2 | 172.8 | 1036.8 | 180 | 4.55 | 3.6 | 1.8 | 518.4 |

| CP-P25Z1 | 356.4 | 518.4 | 1036.8 | 180 | 4.55 | 3.6 | 3.6 | 172.8 |

| CP-P50Z1 | 356.4 | 345.6 | 1036.8 | 180 | 4.55 | 3.6 | 3.6 | 345.6 |

| CP-P75Z1 | 356.4 | 172.8 | 1036.8 | 180 | 4.55 | 3.6 | 3.6 | 518.4 |

| CP-B25Z1 | 356.4 | 518.4 | 1036.8 | 180 | 4.55 | 3.6 | 3.6 | 172.8 |

| CP-B50Z1 | 356.4 | 345.6 | 1036.8 | 180 | 4.55 | 3.6 | 3.6 | 345.6 |

| CP-B75Z1 | 356.4 | 172.8 | 1036.8 | 180 | 4.55 | 3.6 | 3.6 | 518.4 |

| No. | Phase | Chemical Formula | Crystallized | JCPDS |

|---|---|---|---|---|

| 1 | Ettringite | Ca6Al2(SO4)3(OH)12·26H2O | Hexagonal | (41-1451) |

| 2 | Portlandite | Ca(OH)2 | Hexagonal | (04-0733) |

| 3 | Tobermorite | Ca5Si6(O,OH,F)18·5H2O | Orthorhombic | (45-1480) |

| 4 | C-S-H | CaO·SiO2·H2O | Poor crystallized | (09-0212) |

| 5 | Wollastonite CS | CaSiO3 | Monoclinic | (43-1460) |

| 6 | Quartz | SiO2 | Hexagonal | (033-1161) |

| 7 | Calcite | CaCO3 | Hexagonal | (005-0586) |

| 8 | Zinc Oxide | ZnO | Hexagonal | (36-1451) |

| Material | Price per 1 Ton |

|---|---|

| Sand | 20$ |

| Porcelain waste powder | 14 ± 3$ |

| Brick waste powder | 10 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, M.T.; Abdul-Hamead, A.A.; Othman, F.M. Sustainable Concrete Using Porcelain and Clay Brick Waste as Partial Sand Replacement: Evaluation of Mechanical and Durability Properties. Constr. Mater. 2025, 5, 78. https://doi.org/10.3390/constrmater5040078

Hasan MT, Abdul-Hamead AA, Othman FM. Sustainable Concrete Using Porcelain and Clay Brick Waste as Partial Sand Replacement: Evaluation of Mechanical and Durability Properties. Construction Materials. 2025; 5(4):78. https://doi.org/10.3390/constrmater5040078

Chicago/Turabian StyleHasan, Mustafa Thaer, Alaa A. Abdul-Hamead, and Farhad M. Othman. 2025. "Sustainable Concrete Using Porcelain and Clay Brick Waste as Partial Sand Replacement: Evaluation of Mechanical and Durability Properties" Construction Materials 5, no. 4: 78. https://doi.org/10.3390/constrmater5040078

APA StyleHasan, M. T., Abdul-Hamead, A. A., & Othman, F. M. (2025). Sustainable Concrete Using Porcelain and Clay Brick Waste as Partial Sand Replacement: Evaluation of Mechanical and Durability Properties. Construction Materials, 5(4), 78. https://doi.org/10.3390/constrmater5040078