1. Introduction

The construction industry is one of the largest contributors to global environmental degradation, with cement production alone responsible for approximately 8% of anthropogenic CO

2 emissions [

1]. While cement mortars remain integral to modern masonry, rendering, and repair applications, their inherent brittleness, low tensile strength, and limited crack resistance necessitate performance enhancement strategies [

2]. One of the most widely adopted solutions has been fiber reinforcement, which improves crack control, post-cracking toughness, and overall mechanical behavior of cementitious matrices [

3,

4,

5,

6,

7,

8,

9].

Synthetic fibers like polypropylene or steel offer mechanical benefits but raise sustainability concerns due to their high carbon footprint and lack of biodegradability. In contrast, natural fibers such as coconut coir present an eco-friendly alternative with favorable mechanical and thermal properties, wide availability in tropical regions, and compatibility with cementitious matrices [

10,

11]. Coir fibers also exhibit high lignin content and resilience to microbial attack, which contributes to their durability in alkaline environments [

12,

13].

Recent studies have further highlighted the benefits of coconut coir fiber inclusion in cementitious materials. For instance, Nawab et al. (2023) demonstrated that adding untreated coir fibers in combination with supplementary cementitious materials, such as silica fume and metakaolin, can significantly improve the mechanical strength and durability of mortars [

14]. Similarly, Vélez et al. (2022) reported that optimized coconut fiber content enhanced both tensile and flexural performance in concrete, with improvements linked to effective crack bridging and energy absorption mechanisms [

15]. Martinelli et al. (2023) provided a comprehensive review confirming that coir fibers offer an optimal balance of mechanical enhancement, cost-effectiveness, and environmental benefits when incorporated at moderate dosages [

16]. However, higher dosages may lead to fiber agglomeration, poor dispersion, and increased porosity, which can reduce compressive strength and workability [

14,

17]. Moreover, untreated coir fibers, while cost-effective, may degrade over time due to cement alkalinity and moisture fluctuations if not properly optimized [

13,

18].

From a sustainability perspective, Al-Naghi et al. (2025) investigated hybrid systems combining coconut fibers with other waste-based additives, showing synergistic gains in strength and durability while reducing the carbon footprint of recycled aggregate concrete [

19]. These findings support the role of coconut fibers in advancing circular economy principles by diverting agricultural waste from landfills and lowering reliance on synthetic fibers. Such approaches align with the United Nations Sustainable Development Goals (SDGs), particularly those focused on sustainable cities, responsible consumption, and climate action.

Despite growing interest, several research gaps remain. Few studies systematically examine the combined effect of fiber length and content, particularly in mortar systems subjected to both mechanical and durability testing.

This study investigates sixteen mortar mixes reinforced with untreated coconut fibers, varying in fiber content (0.5–2.0%) and length (10–25 mm). Key performance indicators include compressive and flexural strength, water absorption, and microstructure analysis. The findings aim to identify optimal reinforcement parameters while supporting sustainable and regionally accessible material innovations in cement-based construction.

2. Materials and Methods

This study investigates the physical and mechanical properties of structural cement mortars reinforced with coconut coir fibers. A total of 16 different mixes were cast in order to assess the effect of the fibers’ length and content on the performance of mortars. The main goal is to optimize these two variables in order to achieve the best flexural and compressive strengths. The Scanning Electron Microscopy (SEM) analysis was also performed to observe the fiber–matrix interaction. The preparation, testing procedures, and analysis methods are presented below.

2.1. Cement and Sand

Type I Ordinary Portland Cement was used as the primary binder. It was obtained from the Kuwait Cement Company in Kuwait. The manufacturer’s technical datasheet properties include its compressive strength class (CEM I 42.5R, ≥42.5 MPa at 28 days), initial and final setting times (90 min and 210 min, respectively), and Blaine fineness (340 m2/kg).

Natural river sand was used as the fine aggregate. It was clean, dry, and free from organic impurities. A sieve analysis was conducted in accordance with ASTM C136-19 to determine the particle size distribution of the sand [

20]. The mass retained on each sieve was recorded, and the cumulative percentage passing was calculated. The results were then plotted to generate the particle size distribution curve presented in

Figure 1. The analysis confirmed a well-graded profile, with the majority of particles ranging between 0.15 mm and 0.6 mm, which is optimal for ensuring good packing, minimal voids, and workable mortar.

2.2. Coconut Coir Fibers

Coconut coir fibers were extracted from the husk of mature coconuts, a renewable and abundant agricultural byproduct. After soaking, cleaning, and natural drying, they were manually cut into various lengths. The fibers’ characteristic properties, determined separately, include 85% water absorption and a 180 MPa tensile strength.

2.3. Mix Design and Mortar Preparation

A total of 57 specimens were cast, comprising 16 fiber-reinforced mixes, each with varying fiber volume fractions (0.5%, 1.0%, 1.5%, and 2.0%) and fiber lengths (10 mm, 15 mm, 20 mm, and 25 mm), as well as 9 control samples without fiber. The mix design is summarized in

Table 1. The cement-to-sand ratio was fixed at 1:3 by weight. Each mix was designated as “MCxFy” where x indicates fiber content (%), and y indicates fiber length (mm). For example, MC1F15 refers to a mix with 1% fiber at a length of 15 mm.

The mortar was then cast into 40 mm × 40 mm × 160 mm three-gang molds. After casting, the specimens were covered and cured at 20 ± 2 °C and 95% relative humidity for 24 h before demolding. They were then water-cured for 28 days prior to testing.

2.4. Test Methods

The experimental program involved testing all 56 mortar specimens for water absorption and mechanical strength. Additionally, selected samples were subjected to SEM to investigate the microstructure and fiber–matrix interaction.

2.4.1. Water Absorption

Water absorption was tested to evaluate the porosity and permeability characteristics of the mortar specimens. The procedure followed the guidelines of ASTM C1403-15 [

21]. Each specimen was oven-dried at (100–110 °C) for a minimum of 24 h, then cooled in air (preferably in a desiccator) to room temperature (20–25 °C). The rate of water absorption was then calculated using Equation (1):

where

W1 is the oven-dry mass (g), and

W2 is the saturated surface-dry mass (g).

2.4.2. Flexural Strength Test

The flexural strength of the mortar specimens was evaluated to assess their resistance to bending and the effect of fiber incorporation on tensile behavior under flexure. The procedure followed EN 1015-11 [

22], which specifies dimensions, loading configuration, and calculation methods for determining flexural performance.

The flexural strength

was calculated using Equation (2).

where

F is the maximum applied load (N);

L is the span length between supports (mm), 100 mm;

b is the specimen width (mm), 40 mm, and

d is the specimen depth (mm), 40 mm.

2.4.3. Compressive Strength Test

Compressive strength was measured on the two broken halves of each specimen as per EN 1015-11 [

22].

The compressive strength,

, was calculated using Equation (3).

where

is the compressive strength (MPa);

F is the maximum load at failure (N);

A is the loaded area of the specimen face (mm

2).

3. Results and Discussion

This section presents the experimental results for all tested mortar specimens. The findings are organized into five key categories: water absorption, mechanical properties (flexural and compressive strength), failure modes, microstructural characteristics, and the combined effects of fiber content and length. In addition, regression analysis was conducted to derive predictive equations based on the experimental data. Each result is analyzed comparatively, with the performance of fiber-reinforced mixes evaluated against that of the control specimens.

3.1. Water Absorption

The water absorption behavior across the mortar mixes showed significant variation, influenced by both fiber content and fiber length. The control mix exhibited an absorption rate of 9.43%. Several compositions of fiber-reinforced mortars demonstrated an improved resistance to water ingress. For example, MC1F15 achieved the lowest water absorption at 8.38%, followed closely by MC0.5F20 at 8.81%. The results in

Figure 2 indicate that both fiber content and fiber length influenced the water absorption behavior of the mortars. Mixes with moderate fiber contents (0.5–1.0 %) generally exhibited lower water absorption than the control, particularly when combined with intermediate fiber lengths (15 mm and 20 mm). This suggests that well-dispersed fibers of sufficient length can bridge microcracks and refine the pore structure, thereby reducing permeability. In contrast, shorter fibers (10 mm) showed less consistent benefits, and higher dosages (1.5–2.0 %) tended to increase water absorption in some cases, likely due to fiber agglomeration and entrapped voids. These trends highlight the importance of balancing fiber dosage and geometry to achieve optimal densification of the mortar matrix while minimizing pathways for moisture ingress.

These findings are consistent with prior studies in [

23,

24], who reported that moderate dosages of coconut coir could improve mortar density by bridging microcracks and promoting a denser matrix. This behavior is attributed to the physical interaction between well-dispersed fibers and the surrounding cement paste, which limits pore connectivity.

3.2. Flexural Strength

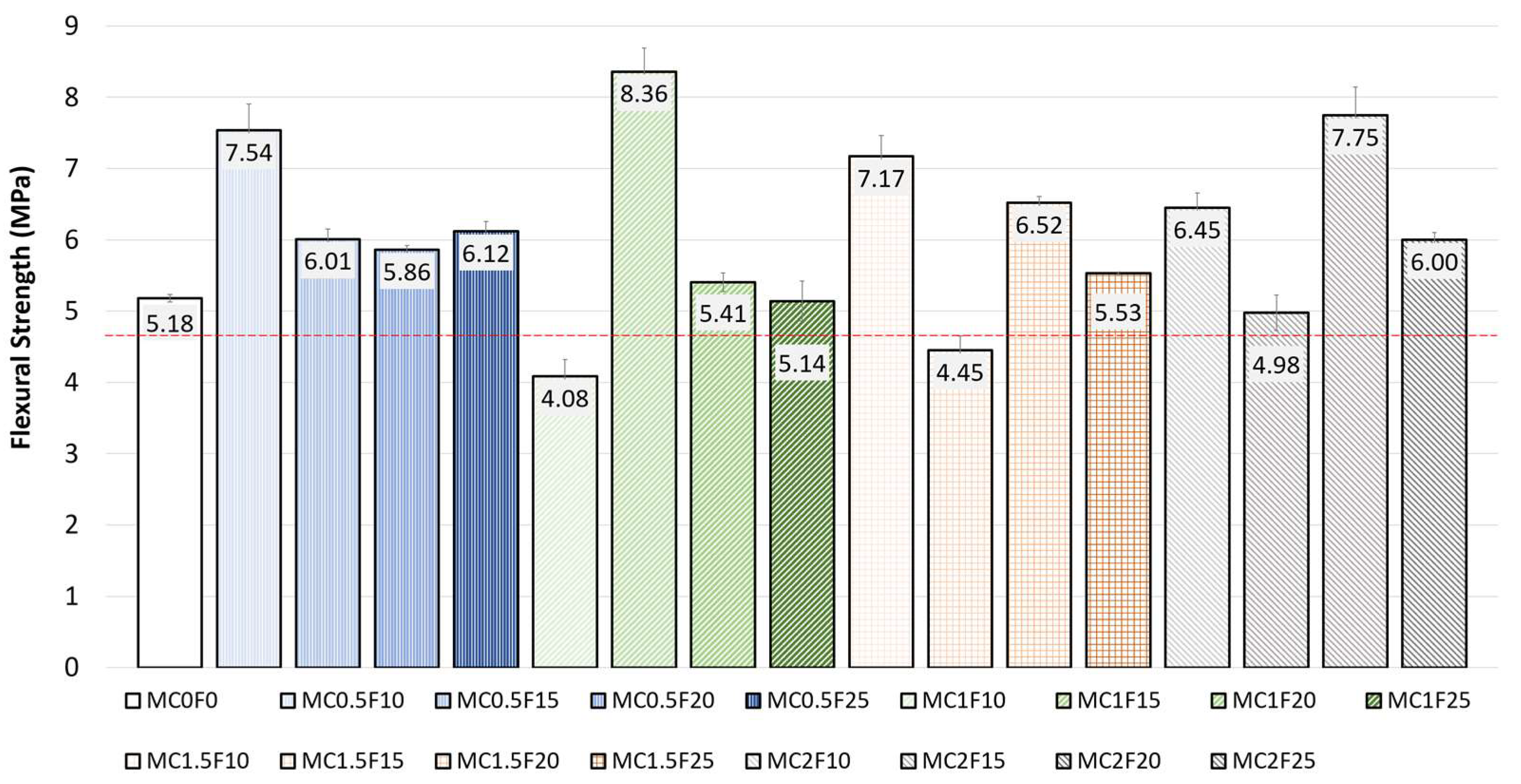

The flexural strength results of all the mixes are presented in

Figure 3. The control mix recorded an average flexural strength of 5.18 MPa. The incorporation of coir fibers significantly improved this performance across several mixes, most notably in MC1F15, which achieved a peak value of 8.36 MPa, representing a 61% increase relative to the control. This performance enhancement is attributed to the fiber’s ability to bridge microcracks, delay crack propagation, and distribute tensile stresses throughout the matrix. Similar improvements were reported by [

4], who observed that short coconut fibers significantly improved post-crack behavior and energy absorption in mortar composites. Similarly, ref. [

13] highlighted the role of alkali-resistant natural fibers in enhancing crack resistance and flexural ductility, especially at moderate dosages.

Other mixes, such as MC2F20 and MC0.5F10, also performed well, recording flexural strengths of 7.75 MPa and 7.54 MPa, respectively. These results indicate that both lower and higher fiber volumes can yield positive outcomes when appropriately paired with effective fiber lengths. Notably, the 10 mm fibers in MC0.5F10 may have offered sufficient crack-bridging at low content without compromising dispersion.

On the other hand, MC1F10 exhibited the lowest flexural strength among fiber-reinforced mixes, at 4.08 MPa, 21.2% below the control. This underperformance likely stems from the insufficient length of the fibers to engage in effective stress transfer at higher content, as well as possible agglomeration effects. This outcome is consistent with findings by [

18], who reported that short natural fibers, when overused, can lead to ineffective bridging and dispersion issues.

The results emphasize that flexural performance is governed not just by fiber dosage but by the interaction between fiber length, volume, and dispersion quality. While MC1F15 yielded the most optimal combination of strength and fiber utilization, other high-performing mixes, such as MC2F20, suggest that even higher dosages can be effective when matrix cohesion is preserved.

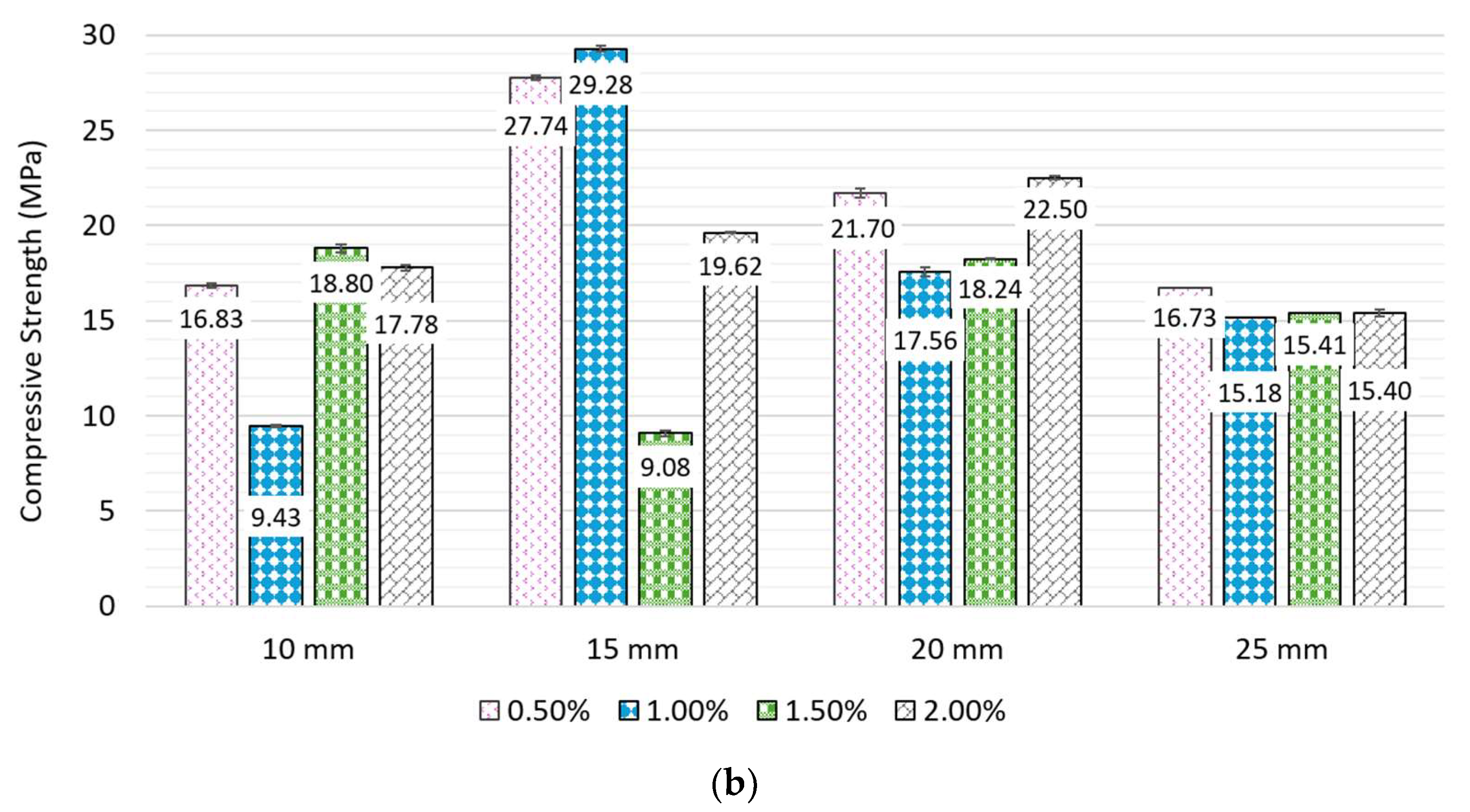

3.3. Compressive Strength

The compressive strength of the mortar mixes was strongly influenced by both the content and length of the coconut coir fibers. The control mix exhibited a compressive strength of 12.65 MPa. The incorporation of coir fibers led to substantial improvements in several compositions, with MC1F15 achieving the highest strength at 29.28 MPa, more than double that of the control. MC0.5F20 and MC2F25 also surpassed 20 MPa, indicating that both moderate and high fiber dosages can enhance compressive behavior under certain conditions. Interestingly, MC0.5F15 reached 27.74 MPa, nearly matching the best-performing mix despite using 50% less fiber, indicating a strong balance between efficiency and performance (

Figure 4).

These results align with findings by [

10,

18], who observed that coir fiber inclusion can enhance compressive strength by improving crack resistance, internal confinement, and energy absorption, especially when fiber dispersion is well controlled. Ref. [

13] further emphasized the role of fiber–matrix bonding in restricting crack propagation and delaying failure under compression.

However, the performance was not universally improved across all fiber combinations. For instance, MC1F10 and MC1.5F15, despite having similar fiber contents, recorded relatively lower compressive strengths of 9.43 MPa and 11.32 MPa, respectively. This decline suggests that inadequate fiber length or excessive fiber content may have caused agglomeration or introduced voids during mixing. These observations are consistent with those of [

14], who reported that poorly dispersed fibers tend to create weak zones in the matrix, thereby compromising compressive integrity.

Overall, the results confirm that coir fibers can significantly enhance compressive strength, provided that fiber content and length are optimized to avoid negative effects on workability and compaction. As summarized in

Table 2, mixes such as MC1F15 and MC2F20 exhibit a strong balance between reinforcement efficiency and matrix integrity.

The improvement in each property was evaluated relative to the control specimen. The outstanding performance of MC1F15, 1.61 times higher in flexural strength and 2.31 times higher in compressive strength, demonstrates the importance of achieving a balance between adequate reinforcement and cohesive packing. A similar balance has also been reported in blended cement systems by [

25,

26]. This reinforces the notion that natural fiber-reinforced mortars can be engineered to exceed conventional strength benchmarks when properly designed.

3.4. Failure Mode and Durability

The failure mode after flexural testing revealed significant variations in failure patterns across different fiber dosages and lengths (

Figure 5a–s). The control mix exhibited a brittle fracture, splitting cleanly into two parts with minimal post-cracking resistance. In contrast, fiber-reinforced specimens exhibited a more ductile behavior, with clear evidence of crack bridging and fiber pull-out, particularly in MC1F15 (

Figure 5i) and MC2F25 (

Figure 5s).

As shown in

Figure 5, these mixes exhibited partial cohesion even after peak loading, indicative of effective energy absorption and fiber anchoring within the matrix. The presence of visible fibers spanning the cracked sections suggests strong fiber–matrix bonding and an ability to redistribute stress after matrix cracking. These observations are consistent with findings by [

3,

18], who noted improved crack control and delayed failure in mortars reinforced with coir and sisal fibers, respectively.

The increased ductility and improved fracture resistance observed in the current study reflect the capacity of coconut coir fibers to transform a brittle material into a quasi-ductile system. The failure mode of specimens such as MC1.5F25 (

Figure 5c) and MC2F25 (

Figure 6), which exhibited fiber bridging and gradual opening of cracks, highlights the importance of optimized fiber dimensions in achieving controlled post-peak behavior.

From a durability perspective, the improved cohesion and delayed crack propagation suggest that coir-reinforced mortars are less likely to experience premature degradation in service. Crack width control, in particular, plays a crucial role in limiting moisture ingress and slowing down deterioration processes such as freeze–thaw damage and carbonation. While long-term durability tests were beyond the scope of this study, the observed performance aligns with expectations for enhanced service life, as previously suggested by [

13,

23].

3.5. Microstructural Analysis

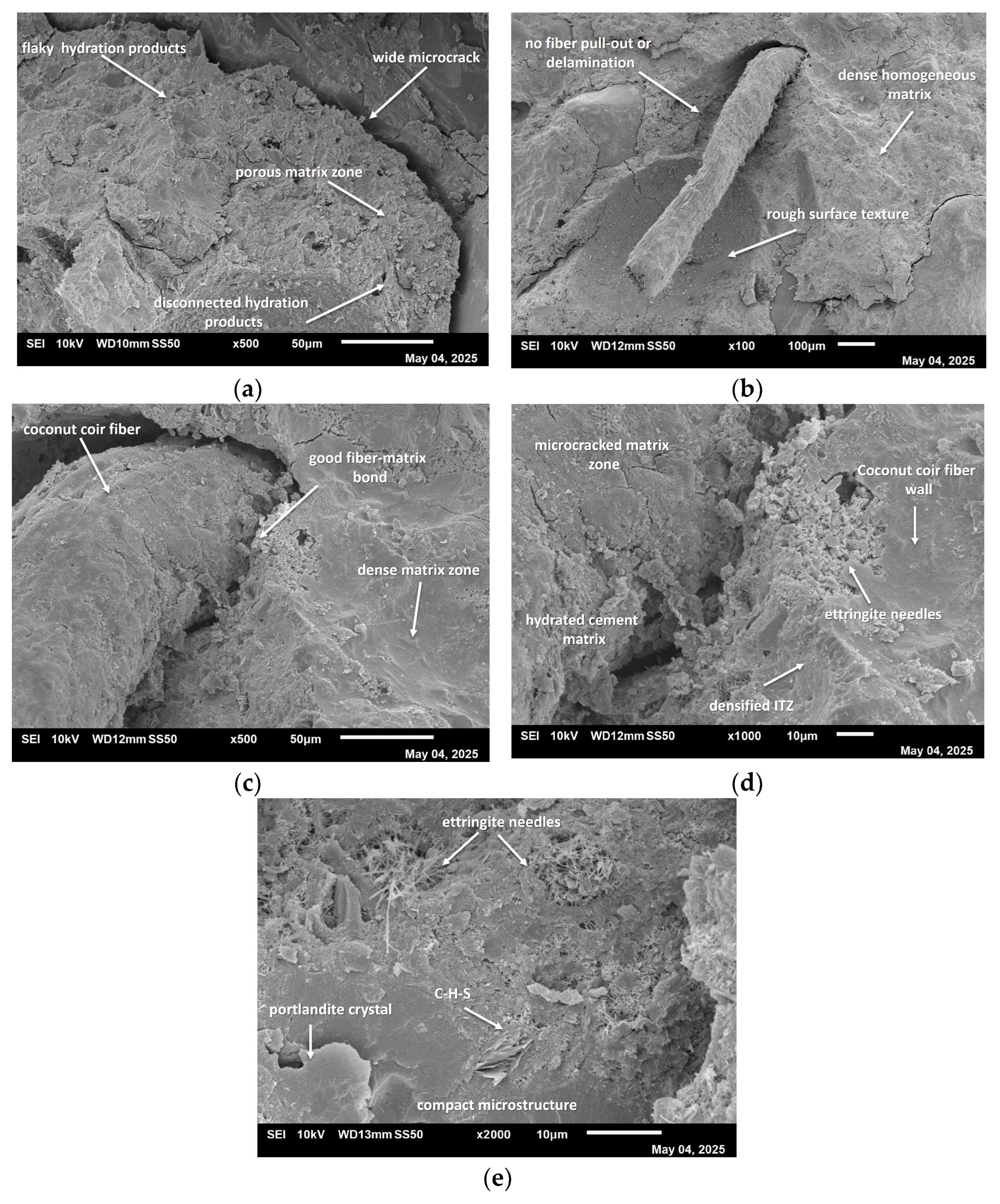

Scanning Electron Microscopy (SEM) was conducted to investigate the microstructural features of both the control mortar and the mortar reinforced with untreated coconut fibers. SEM micrographs were captured at magnifications ranging from ×500 to ×1000 to examine matrix morphology, interfacial transition zones (ITZ), and hydration behavior.

In the control specimen, a relatively porous matrix was observed, with minor cracks and disconnected hydration products (

Figure 7a). The scattered voids also suggest a porous and brittle matrix structure that corresponds to the higher water absorption (9.43%) and lower flexural strength (5.18 MPa) observed in the experimental results. The presence of flaky hydration products indicates incomplete cement hydration and a discontinuous matrix network.

In contrast, the fiber-reinforced mortar showed significantly improved microstructural integrity. At ×100 magnification (

Figure 7b), a coconut coir fiber is visibly embedded in the matrix, with clear evidence of physical interlock due to the fiber’s rough surface texture. No significant fiber pull-out or delamination was detected, suggesting effective stress transfer at the fiber–matrix interface. The surrounding matrix appeared denser and more homogeneous than that of the control sample.

Higher magnification (×500 and ×1000;

Figure 7c,d) revealed a well-developed interfacial transition zone (ITZ) characterized by densely packed hydration products and minimal porosity. The absence of visible microcracks and the compact morphology near the fiber suggest effective microstructural densification, likely attributed to the mechanical restraint imposed by the embedded fiber. This confinement appears to enhance the local packing and growth of hydration products, contributing to improved matrix cohesion.

At ×2000 magnification (

Figure 7e), distinct hydration products were identified in greater detail. A dense cluster of needle-like ettringite crystals was observed, indicating early-stage hydration reactions between aluminates and sulfates. Nearby, a large portlandite crystal exhibiting characteristic plate-like morphology confirmed calcium hydroxide precipitation from silicate hydration. Adjacent to this, a tightly packed formation of calcium silicate hydrate (C–S–H) gel was visible, representing the primary strength-contributing phase of the matrix. These microstructural observations reflect the localized densification and heterogeneity induced by fiber inclusion, supporting improved mechanical performance and durability.

The improved matrix continuity and interfacial quality help explain the enhanced flexural performance (8.36 MPa) and reduced water absorption (8.38%) recorded for the optimized fiber-reinforced mix (MC1F15). These features are in line with SEM-based observations [

13], which demonstrated that coir fibers embedded within a compact matrix enhance crack-bridging capabilities and improve post-cracking energy dissipation.

Overall, the SEM analysis confirms that coconut fiber reinforcement contributes not only to mechanical enhancement but also to microstructural densification and improved durability. The observed differences in interfacial bonding and matrix continuity validate the role of coir fibers in promoting crack resistance and limiting moisture ingress in cement mortars.

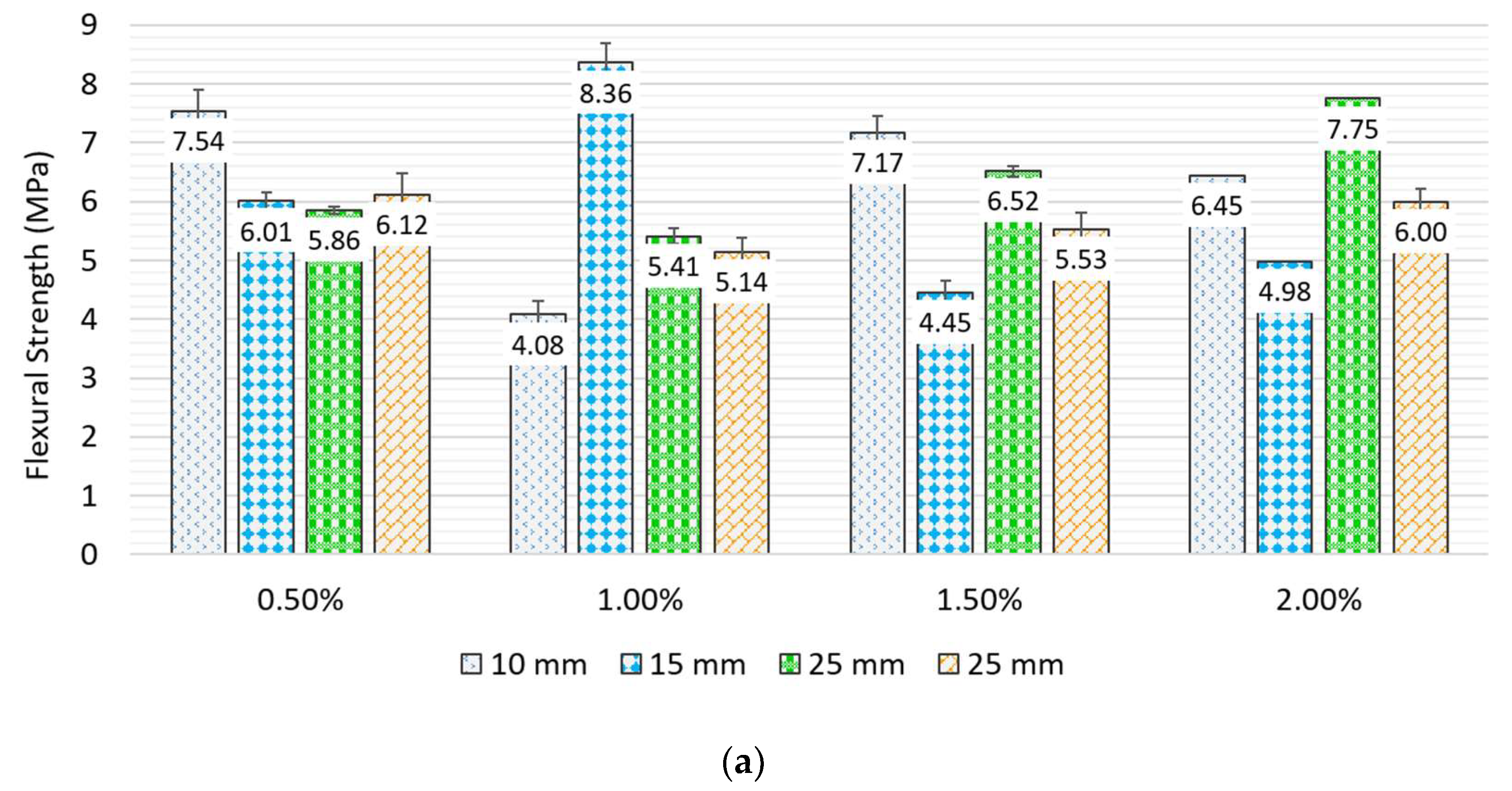

3.6. Influence of Fiber Length

The length of coconut coir fibers had a substantial impact on both flexural and compressive strength. As depicted in

Figure 8, intermediate fiber lengths, particularly 15 mm and 20 mm, consistently produced superior mechanical performance across all tested mixes.

The highest flexural strength of 8.36 MPa was recorded for MC1F15, while the highest compressive strength of 29.28 MPa was achieved with the same mix, confirming the optimal interaction between fiber geometry and matrix performance at this length.

This trend is supported by the findings of [

13], who reported that 15–25 mm coir fibers provided a good balance between crack-bridging effectiveness and fiber distribution in cementitious composites.

3.7. Influence of Fiber Content

The influence of fiber content on the mechanical behavior of mortar was nonlinear, with performance peaking at moderate dosages and declining at higher concentrations. As illustrated in

Figure 9, both flexural and compressive strengths reached their maximum at a fiber content of 1.0%, particularly for the MC1F15 mix. Increasing the fiber content to 1.5% and 2.0% did not result in further improvement and, in some cases, led to reductions in mechanical properties.

This performance pattern is consistent with the findings of [

18], who reported that optimal fiber dosages for natural fiber-reinforced mortars typically fall within the 0.5% to 1.5% range by volume. At these levels, fibers are sufficiently dispersed to bridge cracks and redistribute stress, while avoiding agglomeration and loss of matrix cohesion. In contrast, excessive fiber content increases the likelihood of clustering and entrapped air, leading to porosity, poor workability, and compromised mechanical integrity.

The current study demonstrated that while MC2F20 (2.0% fiber, 20 mm) achieved a high compressive strength of 27.85 MPa, its flexural performance (7.75 MPa) was slightly lower than that of MC1F15. This suggests that although higher fiber contents may still contribute to compressive confinement, they do not necessarily enhance tensile or flexural behavior proportionally. Ref. [

14] similarly cautioned against high dosages of untreated natural fibers, citing inconsistent fiber distribution and increased internal voids as major drawbacks.

On the lower end, 0.5% fiber content was effective in enhancing performance, particularly when combined with optimal lengths. For example, MC0.5F10 achieved a flexural strength of 7.54 MPa and compressive strength of 25.73 MPa, which are both significantly above the control mix. These results confirm that even low fiber volumes can yield substantial improvements when properly proportioned and distributed.

In summary, the results affirm that 1.0% fiber content offers the best balance of strength enhancement and workability, in line with several previous studies [

10,

13]. The declining trend beyond this point supports the need for content optimization to avoid diminishing returns and processing challenges in fiber-reinforced mortar applications.

3.8. Regression Modeling of Strength Properties

To predict the mechanical performance of coconut fiber-reinforced mortars, a polynomial regression analysis was conducted using the experimental dataset comprising 16 distinct mix compositions. The independent variables considered were fiber content (% by volume) and fiber length (mm), with the aim of estimating both flexural strength and compressive strength.

The analysis yielded a third-degree polynomial regression model that provided a meaningful balance between prediction accuracy, physical interpretability, and mathematical simplicity, making it suitable for practical applications. The resulting regression equations are

where

and

are the predicted flexural and compressive strengths (in MPa),

is the fiber content (%), and

is the fiber length (mm).

Model performance was evaluated using standard regression metrics. The coefficient of determination (R2) was 0.63 for flexural strength and 0.62 for compressive strength, with respective Root Mean Squared Errors (RMSE) of 0.68 MPa and 3.88 MPa. These values confirm the model’s ability to generalize across the tested parameter range.

This model provides a practical framework for estimating strength performance in coir-reinforced mortars and can aid in preliminary mix design decisions or parametric studies in similar materials research.

While the proposed regression models demonstrated good predictive capacity within the tested parameter range, their accuracy has not yet been validated using an independent set of specimens. Future work will include such validation to confirm model robustness under different mix conditions. In addition, a sensitivity analysis is recommended to quantify the relative influence of each input parameter, fiber content, and fiber length, on the predicted mechanical properties. This would provide a clearer understanding of parameter significance and assist in prioritizing mix design adjustments for specific performance targets.

4. Conclusions

This study evaluated the effectiveness of untreated coconut coir fibers as a sustainable reinforcement in cement mortars, focusing on the combined effects of fiber content and length on mechanical strength and water absorption. Sixteen fiber-reinforced mortar mixes were developed and tested in accordance with EN and ASTM standards. Results demonstrated that moderate fiber inclusion significantly improved both flexural and compressive strengths while reducing water absorption.

The mix containing 1.0% coir fibers at 15 mm length (MC1F15) consistently outperformed all other configurations, achieving a flexural strength of 8.36 MPa and a compressive strength of 29.28 MPa, representing increases of 61% and 131%, respectively, compared to the control. The lowest water absorption (8.38%) was also recorded for this mix, confirming its durability advantage. Conversely, higher fiber dosages (1.5% and 2.0%) resulted in reduced strength in some mixes due to fiber agglomeration and reduced workability. SEM analysis confirmed enhanced microstructural cohesion in well-performing mixes.

A regression analysis was also conducted to model the influence of fiber content and length on strength properties. The resulting polynomial equations showed strong predictive capacity and may serve as useful tools for preliminary mix optimization.

While the study focused on short-term performance using untreated fibers under controlled conditions, future research should address long-term durability under freeze–thaw cycles, sulfate exposure, and carbonation. Further investigation into fiber surface treatments, hybrid reinforcement strategies, and large-scale implementation is also recommended.

Importantly, this research supports broader sustainability objectives by encouraging the use of agricultural waste as a renewable construction material. Coconut coir is abundant, biodegradable, and widely available across tropical and subtropical regions, including South and Southeast Asia, Africa, and the Middle East, making it a regionally appropriate alternative to synthetic reinforcements. Its incorporation in mortar production reduces landfill burden, supports circular economy practices, and contributes to the decarbonization of the construction sector.

The findings directly contribute to several United Nations Sustainable Development Goals (SDGs), including SDG 11 (Sustainable Cities and Communities), SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action), and SDG 9 (Industry, Innovation and Infrastructure). By valorizing locally available waste fibers, this study advances the development of greener, more resource-efficient construction materials tailored to regional needs and global sustainability targets.

Author Contributions

Conceptualization, E.M.; methodology, validation, D.M. and R.A.; formal analysis, investigation, resources, D.A., D.M., F.A., M.S. and R.A.; data curation, D.A. and D.M.; Project administration, E.M. and D.A.; writing—original draft preparation, D.A. and D.M.; writing—review and editing, E.M.; visualization, D.A. and D.M.; supervision, project administration, E.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data supporting the findings of this study are contained within the article.

Acknowledgments

The authors would like to express their gratitude to the Kuwait Institute for Scientific Research for providing the necessary facilities for the SEM analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Boesch, M.E.; Hellweg, S. Identifying Improvement Potentials in Cement Production with Life Cycle Assessment. Environ. Sci. Technol. 2010, 44, 9143–9149. [Google Scholar] [CrossRef]

- Guruswamy, K.P.; Thambiannan, S.; Anthonysamy, A.; Jalgaonkar, K.; Dukare, A.S.; Pandiselvam, R.; Jha, N. Coir Fibre-Reinforced Concrete for Enhanced Compressive Strength and Sustainability in Construction Applications. Heliyon 2024, 10, e39773. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and Dynamic Properties of Coconut Fibre Reinforced Concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsieh, Y.-C. Effects of Short Coconut Fiber on the Mechanical Properties, Plastic Cracking Behavior, and Impact Resistance of Cementitious Composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Alhabib, W.; Alhawal, J.; AlRashidi, B.; AlAbdulqader, S.; AlSayegh, Z.; Mustafaraj, E. The Impact of Recycled Material Reinforcement on the Performance of Mortars. Eng. Technol. Appl. Sci. Res. 2024, 14, 17214–17221. [Google Scholar] [CrossRef]

- Yang, X.; Tian, D.; Jiang, H.; Gao, Z.; Wang, Y.; Tang, Z.; Lu, S. Effect of Coconut Fibers with Interfacial Improvement on the Dynamic Performance of Cement Mortar. J. Build. Eng. 2024, 98, 111524. [Google Scholar] [CrossRef]

- Muñoz, S.; Villena, L.; Tesen, F.; Coronel, Y.; Garcia, J.; Brast, C. Influence of Coconut Fiber on Mortar Properties in Masonry Walls. Electron. J. Struct. Eng. 2023, 23, 52–58. [Google Scholar] [CrossRef]

- Sathiparan, N.; Rupasinghe, M.N.; Pavithra, B.H.M. Performance of Coconut Coir Reinforced Hydraulic Cement Mortar for Surface Plastering Application. Constr. Build. Mater. 2017, 142, 23–30. [Google Scholar] [CrossRef]

- AlMuhanna, M.; AlSenan, R.; Mustafaraj, E.; Luga, E.; Corradi, M. Fibre Reinforcement of Cement Mortars for Reinforcement of Masonry Buildings: An Experimental Investigation. J. Build. Pathol. Rehabil. 2024, 9, 142. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Charoenvai, S.; Zeghmati, B.; Shin, U.C. Development of Coconut Coir-Based Lightweight Cement Board. Constr. Build. Mater. 2007, 21, 277–288. [Google Scholar] [CrossRef]

- Indumathi, M.; Nakkeeran, G.; Kiran, G.U.; Roy, D.; Al-Fakih, A. Mechanical and Sustainability Performance of Concrete Incorporated Limestone Powder, Recycled Ceramic Aggregates, and Coconut Fibers. Innov. Infrastruct. Solut. 2025, 10, 197. [Google Scholar] [CrossRef]

- Andiç-Çakir, Ö.; Sarikanat, M.; Tüfekçi, H.B.; Demirci, C.; Erdoǧan, Ü.H. Physical and Mechanical Properties of Randomly Oriented Coir Fiber-Cementitious Composites. Compos. Part B Eng. 2014, 61, 49–54. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Huang, L.; Kasal, B. Effect of Alkali Treatment on Microstructure and Mechanical Properties of Coir Fibres, Coir Fibre Reinforced-Polymer Composites and Reinforced-Cementitious Composites. Constr. Build. Mater. 2016, 112, 168–182. [Google Scholar] [CrossRef]

- Nawab, M.S.; Ali, T.; Qureshi, M.Z.; Zaid, O.; Kahla, N.B.; Sun, Y.; Anwar, N.; Ajwad, A. A Study on Improving the Performance of Cement-Based Mortar with Silica Fume, Metakaolin, and Coconut Fibers. Case Stud. Constr. Mater. 2023, 19, e02480. [Google Scholar] [CrossRef]

- Vélez, E.; Rodríguez, R.; Yanchapanta Gómez, N.B.; Mora, E.D.; Hernández, L.; Albuja-Sánchez, J.; Calvo, M.I. Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits. Fibers 2022, 10, 96. [Google Scholar] [CrossRef]

- Martinelli, F.R.B.; Ribeiro, F.R.C.; Marvila, M.T.; Monteiro, S.N.; Filho, F.d.C.G.; Azevedo, A.R.G.d. A Review of the Use of Coconut Fiber in Cement Composites. Polymers 2023, 15, 1309. [Google Scholar] [CrossRef] [PubMed]

- Awoyera, P.O.; Odutuga, O.L.; Effiong, J.U.; Sarmiento, A.D.J.S.; Mortazavi, S.J.; Hu, J.W. Development of Fibre-Reinforced Cementitious Mortar with Mineral Wool and Coconut Fibre. Materials 2022, 15, 4520. [Google Scholar] [CrossRef]

- Silva, L.M.E.; Christoforo, A.L.; Carvalho, R.C. Calibration of Concrete Damaged Plasticity Model Parameters for Shear Walls. Matéria 2021, 26, e12944. [Google Scholar] [CrossRef]

- Al-Naghi, A.A.A.; Ali, T.; Inam, I.; Qureshi, M.Z.; Ben Kahla, N.; Ghazouani, N.; Ahmed, H. Sustainable Concrete: Investigating the Synergistic Effects of Coconut Fiber, Wheat Straw Ash, and Silica Fume on RAC Strength and Durability. Sci. Rep. 2025, 15, 24542. [Google Scholar] [CrossRef]

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C1403-15; Standard Test Method for Rate of Water Absorption of Masonry Mortars. ASTM International ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- EN 1015-11:1999; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. CEN CEN—European Committee for Standardization: Brussels, Belgium, 1999.

- Santos, A.P.; do Nascimento, M.R.P.; Barboza, C.S.; Omido, A.R. Behavior of Cement Mortar with the Addition of Coconut Fibers. Rev. De Gest. Soc. E Ambient. 2023, 17, 1–19. [Google Scholar] [CrossRef]

- Savastano Jr, H.; Warden, P.G.; Coutts, R.S.P. Mechanically Pulped Sisal as Reinforcement in Cementitious Matrices. Cem. Concr. Compos. 2003, 25, 311–319. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, Y.; Wang, J.; Jiao, M.; Ling, Y. Fracture Models and Effect of Fibers on Fracture Properties of Cementitious Composites—A Review. Materials 2020, 13, 5495. [Google Scholar] [CrossRef] [PubMed]

- Bui, H.; Levacher, D.; Boutouil, M.; Sebaibi, N. Effects of Wetting and Drying Cycles on Microstructure Change and Mechanical Properties of Coconut Fibre-Reinforced Mortar. J. Compos. Sci. 2022, 6, 102. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).