Development and Characterization of Colored Lime–Gypsum Mortars for Heritage Building Restoration in Humid Environments

Abstract

1. Introduction

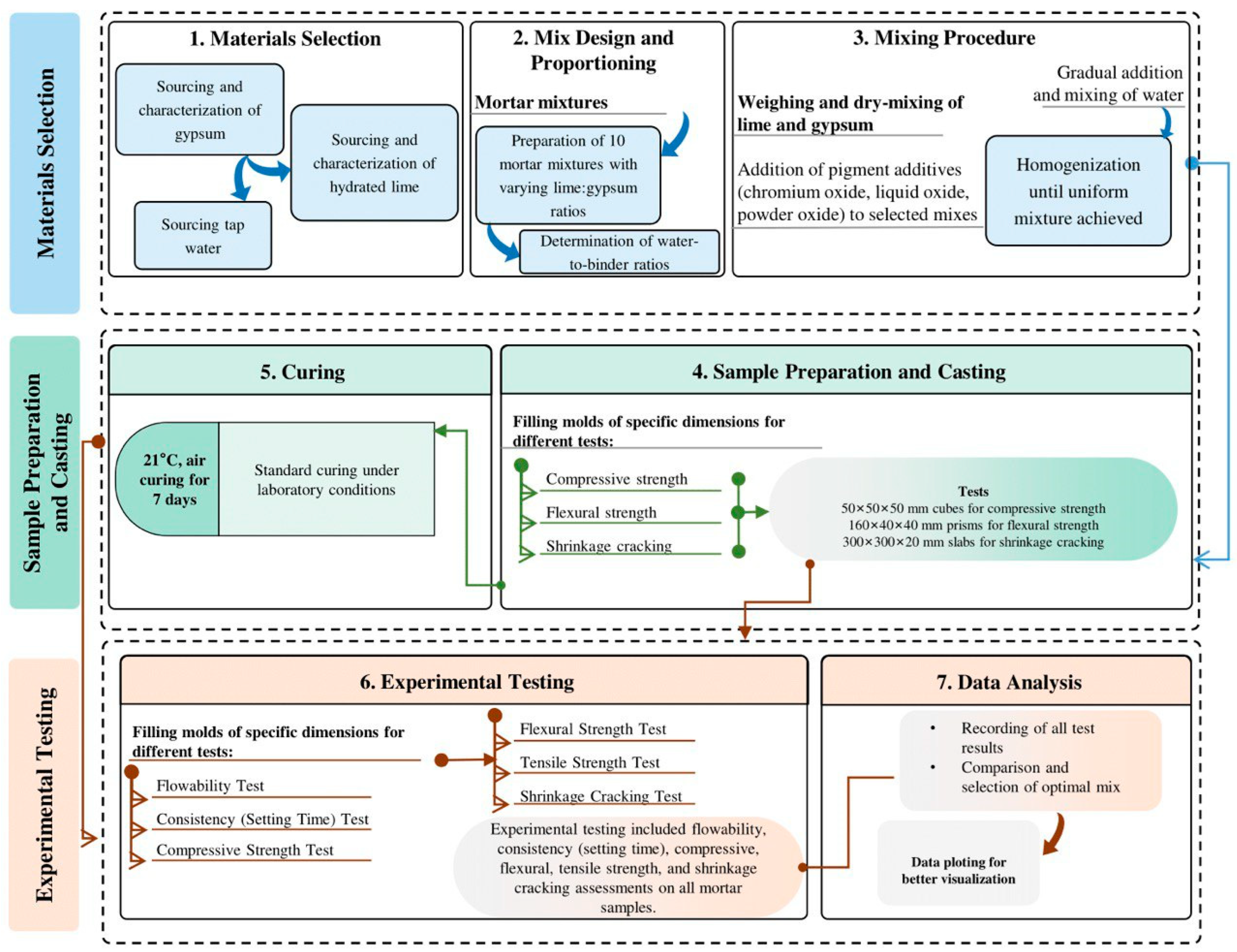

2. Materials and Methods

2.1. Materials

2.1.1. Gypsum

2.1.2. Lime

2.1.3. Tap Water

2.2. Experimental Procedures

2.2.1. Mix Proportions

2.2.2. Mixing Procedure

2.2.3. Sample Preparation and Curing

2.3. Test Procedure

2.3.1. Flow Test

2.3.2. Consistency Test

2.3.3. Compressive Strength Test

2.3.4. Flexural Strength Test

2.3.5. Shrinkage Cracking Test

3. Results

3.1. Flowability

3.2. Consistency Test (Setting Time)

3.3. Compressive Strength

3.4. Flexural Strength

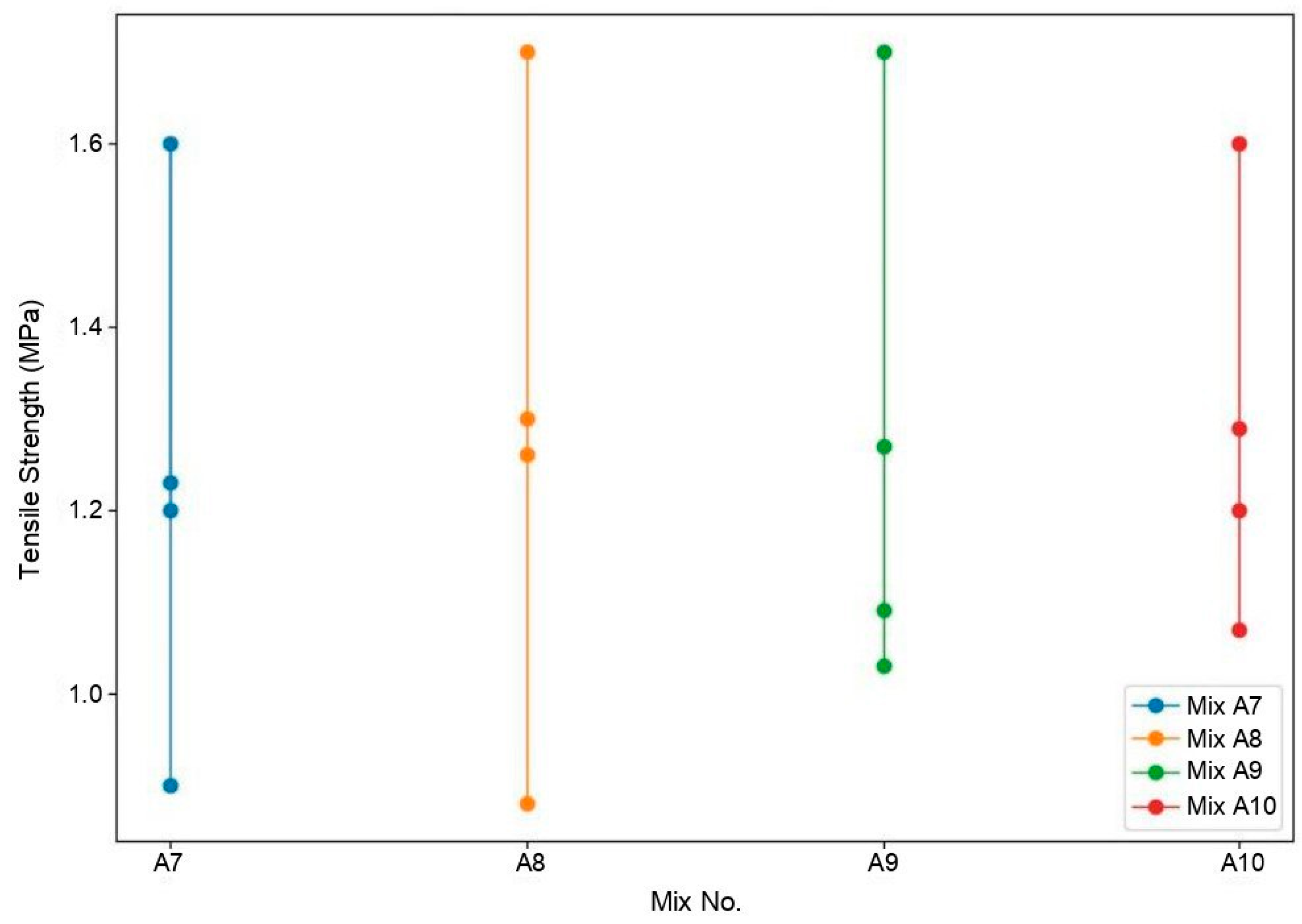

3.5. Tensile Strength

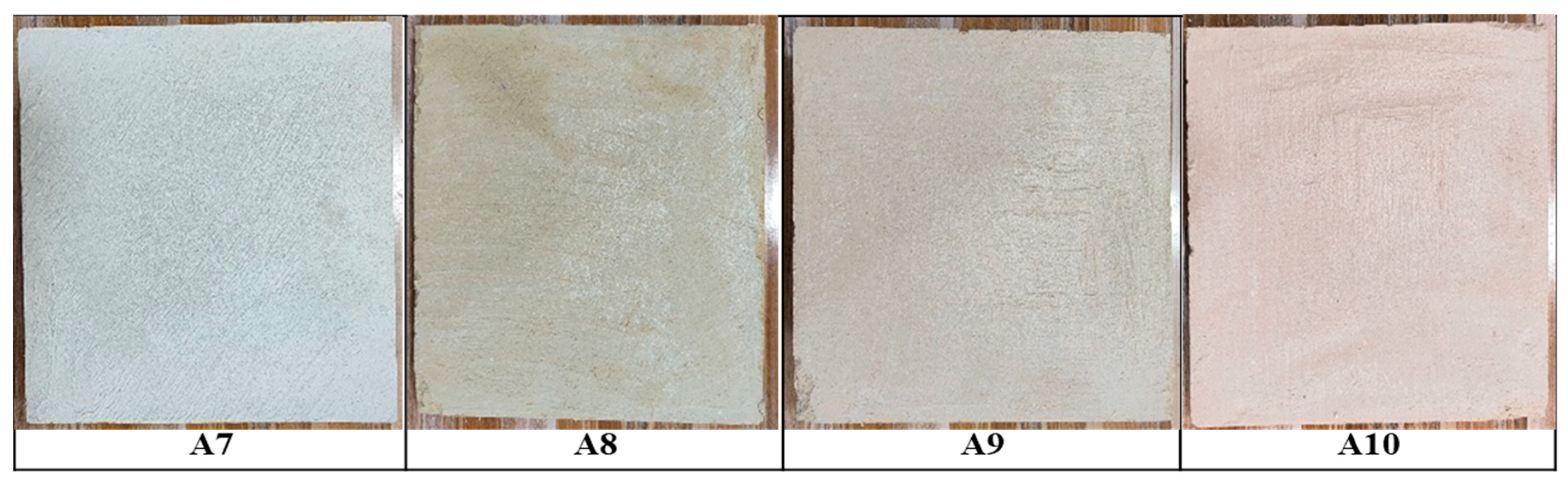

3.6. Shrinkage Cracking Test

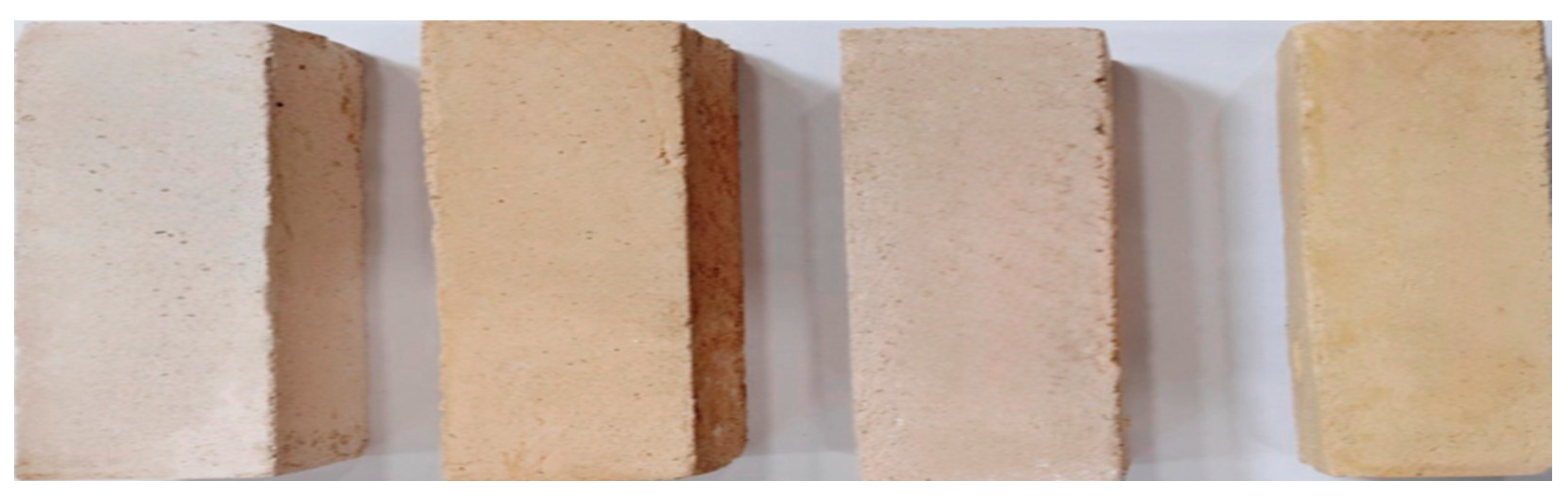

3.7. Visual Appearance and Esthetic Properties

4. Conclusions

5. Limitations and Suggestions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nursanty, E.; Rusmiatmoko, D.; Husni, M.F.D. From heritage to identity: The role of city authenticity in shaping local community identity and cultural preservation. J. Arch. Hum. Exp. 2023, 1, 131–150. Available online: https://www.researchgate.net/publication/379615167_From_Heritage_to_Identity_The_Role_of_City_Authenticity_in_Shaping_Local_Community_Identity_and_Cultural_Preservation (accessed on 1 July 2025). [CrossRef]

- Bond, S.; Worthing, D. Managing Built Heritage: The Role of Cultural Values and Significance; John Wiley & Sons: Hoboken, NJ, USA, 2016; Available online: https://www.wiley.com/en-us/Managing+Built+Heritage%3A+The+Role+of+Cultural+Values+and+Significance%2C+2nd+Edition-p-9781118298749 (accessed on 1 July 2025).

- Al-Jawadi, A.S.; Saleh, D.G.; Younis, A.A. Protection and management of the destroyed heritage in the Old City of Mosul, Northern Iraq. Iraqi Geol. J. 2022, 55, 224–233. Available online: https://www.researchgate.net/publication/366745587_Protection_and_Management_of_the_Destroyed_Heritage_in_the_Old_City_of_Mosul_Northern_Iraq (accessed on 1 July 2025). [CrossRef]

- Salman, M.D.; Alkinani, A.S. Preserving the past and building the future: A sustainable urban plan for mosul, Iraq. ISVS E-J. 2023, 10, 332–350. Available online: https://www.researchgate.net/publication/378108248_Preserving_the_Past_and_Building_the_Future_A_Sustainable_Urban_Plan_for_Mosul_Iraq (accessed on 1 July 2025).

- Yue, W.; Wang, B. Ceramic-added lime and cement mortars: A review of applications in building products. Sci. Prog. 2024, 107, 00368504241266559. Available online: https://journals.sagepub.com/doi/10.1177/00368504241266559 (accessed on 1 July 2025). [CrossRef] [PubMed]

- Manoharan, A.; Umarani, C. Lime mortar, a boon to the environment: Characterization case study and overview. Sustainability 2022, 14, 6481. Available online: https://www.mdpi.com/2071-1050/14/11/6481 (accessed on 1 July 2025). [CrossRef]

- Török, Á.; Szemerey-Kiss, B. Freeze-thaw durability of repair mortars and porous limestone: Compatibility issues. Prog. Earth Planet. Sci. 2019, 6, 1–12. Available online: https://www.researchgate.net/publication/333688124_Freeze-thaw_durability_of_repair_mortars_and_porous_limestone_compatibility_issues (accessed on 1 July 2025). [CrossRef]

- Esan, M.T. Review of gypsum reinforced composites as building materials. Discov. Civ. Eng. 2024, 1, 5. Available online: https://link.springer.com/article/10.1007/s44290-024-00005-x (accessed on 1 July 2025). [CrossRef]

- Doğruyol, M.; Gönül, A.; Başboğa, M. Comparative Analysis of Cement-Based and Historic Gypsum-Based Mortars for Historical Restoration: Implications on Mechanical and Thermal Compatibility. J. Build. Eng. 2025, 109, 112982. Available online: https://www.sciencedirect.com/science/article/abs/pii/S2352710225012197 (accessed on 1 July 2025). [CrossRef]

- Abed, D.M.; Al-Saffar, Z.H. Review Article on the Use of Lime Mortar in Heritage Buildings. NTU J. Eng. Technol. 2023, 2. [Google Scholar] [CrossRef]

- Warren, J. Conservation of Earth Structures. Butterworth-Heinemann. Traditional Materials in the Middle East. 1999. Available online: https://openlibrary.org/books/OL124417M/Conservation_of_earth_structures (accessed on 1 July 2025).

- Çikiş, D.T. The Evolution and Change of Building Facades: A Research for Developing Alternative Composite Surface Materials. 2007, Mühendislik ve Fen Bilimleri Enstitüsü. Available online: https://core.ac.uk/download/pdf/324141224.pdf (accessed on 1 July 2025).

- Gliozzo, E.; Pizzo, A.; La Russa, M.F. Mortars, plasters and pigments—Research questions and sampling criteria. Archaeol. Anthropol. Sci. 2021, 13, 193. Available online: https://link.springer.com/article/10.1007/s12520-021-01393-2 (accessed on 1 July 2025). [CrossRef]

- Akbulut, Z.F.; Guler, S.; Osmanoğlu, F.; Kıvanç, M.R.; Khan, M. Evaluating sustainable colored mortars reinforced with fly ash: A comprehensive study on physical and mechanical properties under high-temperature exposure. Buildings 2024, 14, 453. Available online: https://www.mdpi.com/2075-5309/14/2/453 (accessed on 1 July 2025). [CrossRef]

- IQS 28-2010; Materials Specification & Construction Works. Iraqi Standard, IQS 28-2010, in Gypsum For Buildings. National Center for Construction Laboratories & Research: Alachua, FL, USA, 2004. Available online: https://www.scribd.com/document/395467049/Iraqi-Standard-Materials-Specification-Construction-Works (accessed on 1 July 2025).

- IQS 548; Iraqi Standard (Materials Specification & Construction Works), Lime Used in Buildings. National Center for Construction Laboratories & Research: Alachua, FL, USA, 2004. Available online: https://www.scribd.com/document/395467049/Iraqi-Standard-Materials-Specification-Construction-Works (accessed on 1 July 2025).

- ASTM C110-20; Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone. ASTM: West Conshohocken, PA, USA, 2003. Available online: https://dl.azmanco.com/standards/ASTM-C/ASTM-C-Series-Full/C/C110.pdf (accessed on 1 July 2025).

- ASTM C1437-07; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM: West Conshohocken, PA, USA, 2001. Available online: https://standards.iteh.ai/catalog/standards/astm/eb043b44-4318-4588-9399-0db781ab3ec3/astm-c1437-07?srsltid=AfmBOoos7uVOkNUNN_GAlundgWcAuLXyxKB05ZJxbmvXZ85FwpTR5vCN (accessed on 1 July 2025).

- ASTM, C511; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM: West Conshohocken, PA, USA, 2008.

- EN 1015–11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 1999.

- Branco, F.G.; Belgas, M.d.L.; Mendes, C.; Pereira, L.; Ortega, J.M. Mechanical performance of lime mortar coatings for rehabilitation of masonry elements in old and historical buildings. Sustainability 2021, 13, 3281. [Google Scholar] [CrossRef]

- Snow, J.; Torney, C. Lime Mortars in Traditional Buildings; Historic Scotland: Edinburgh, UK, 2014.

- de Sande, V.T.; Sadique, M.; Bras, A.; Pineda, P. Activated sugarcane bagasse ash as efficient admixture in cement-based mortars: Mechanical and durability improvements. J. Build. Eng. 2022, 59, 105082. [Google Scholar] [CrossRef]

- Silva, B.; Pinto, A.F.; Gomes, A.; Candeias, A. Short-and long-term properties of lime mortars with water-reducers and a viscosity-modifier. J. Build. Eng. 2021, 43, 103086. [Google Scholar] [CrossRef]

- Lanzón, M.; García-Ruiz, P. Effect of citric acid on setting inhibition and mechanical properties of gypsum building plasters. Constr. Build. Mater. 2012, 28, 506–511. [Google Scholar] [CrossRef]

- Westgate, P.; Paine, K.; Ball, R.J. Physical and mechanical properties of plasters incorporating aerogel granules and polypropylene monofilament fibres. Constr. Build. Mater. 2018, 158, 472–480. [Google Scholar] [CrossRef]

- National Lime Association. Lime Terminology, Standards & Properties. Fact Sheet: Properties of Lime. 2007. Available online: https://www.studocu.com/row/document/universidad-de-concepcion/fisica-de-los-materiales/lime-terminology-standards-properties/100284534 (accessed on 1 July 2025).

- Pavia, S.; Caro, S. An investigation of Roman mortar technology through the petrographic analysis of archaeological material. Constr. Build. Mater. 2008, 22, 1807–1811. [Google Scholar] [CrossRef]

| Property | IQS No. 28-2010 Limits |

|---|---|

| Fineness (%) | ≤8% |

| Standard consistency % | - |

| Setting time (min.) | 8–25 |

| Compressive strength (MPa) | ≥3 |

| Flexural strength (MPa) | - |

| Mix No. | Gypsum | Lime | Chromium Oxide (g) | Liquid Oxide (mL) | Powder Oxide (g) | Water w/b Ratio (%) |

|---|---|---|---|---|---|---|

| A1 | 1 | 0 | - | - | - | 0.6 |

| A2 | 0 | 1 | - | - | - | 0.7 |

| A3 | 1 | 1 | - | - | - | 0.6 |

| A4 | 1 | 1.5 | - | - | - | 0.6 |

| A5 | 1 | 2 | - | - | - | 0.6 |

| A6 | 1 | 2.5 | - | - | - | 0.6 |

| A7 | 1 | 1 | - | - | - | 0.6 |

| A8 | 1 | 1 | 0.5 | - | 4 | 0.6 |

| A9 | 1 | 1 | - | 0.2 | 4 | 0.6 |

| A10 | 1 | 1 | 0.5 | 0.2 | 0.5 | 0.6 |

| Mix No. | Gypsum | Lime | Water (%) | Initial Setting (min.) | Final Setting (min.) |

|---|---|---|---|---|---|

| A1 | 1 | 0 | 0.55 | 7 | 60 |

| 0.60 | 8 | >60 | |||

| A2 | 0 | 1 | 0.65 | 8 | 23 |

| 0.70 | 8 | 25 | |||

| A3 | 1 | 1 | 0.55 | 8 | 26 |

| 0.60 | 12 | 35 | |||

| A4 | 1 | 1.5 | 0.55 | 7 | 25 |

| 0.60 | 8 | 25 | |||

| A5 | 1 | 2 | 0.55 | 7 | 21 |

| 0.60 | 8 | 24 | |||

| A6 | 1 | 2.5 | 0.55 | 7 | 17 |

| 0.60 | 7 | 27 |

| Mix No. | Gypsum | Lime | Additives | Water (%) | ||

|---|---|---|---|---|---|---|

| Chromium Oxide (g) | Liquid Oxide (mL) | Powder Oxide (g) | ||||

| A7 | 1 | 1 | - | - | - | 0.6 |

| A8 | 1 | 1 | 0.5 | - | 4 | 0.6 |

| A9 | 1 | 1 | - | 0.2 | 4 | 0.6 |

| A10 | 1 | 1 | 0.5 | 0.2 | 0.5 | 0.6 |

| Mix No. | Gypsum | Lime | Additives | Water (%) | ||

|---|---|---|---|---|---|---|

| Chromium Oxide (g) | Liquid Oxide (mL) | Powder Oxide (g) | ||||

| A7 | 1 | 1 | - | - | - | 0.6 |

| A8 | 1 | 1 | 0.5 | - | 4 | 0.6 |

| A9 | 1 | 1 | - | 0.2 | 4 | 0.6 |

| A10 | 1 | 1 | 0.5 | 0.2 | 0.5 | 0.6 |

| Mix No. | Gypsum | Lime | Additives | Water (%) | ||

|---|---|---|---|---|---|---|

| Chromium Oxide(g) | Liquid Oxide (mL) | Powder Oxide (g) | ||||

| A7 | 1 | 1 | - | - | - | 0.6 |

| A8 | 1 | 1 | 0.5 | - | 4 | 0.6 |

| A9 | 1 | 1 | - | 0.2 | 4 | 0.6 |

| A10 | 1 | 1 | 0.5 | 0.2 | 0.5 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thyab, F.J.; Al-Saffar, Z.H.; Ibrahim, A.G.; Faris, H. Development and Characterization of Colored Lime–Gypsum Mortars for Heritage Building Restoration in Humid Environments. Constr. Mater. 2025, 5, 65. https://doi.org/10.3390/constrmater5030065

Thyab FJ, Al-Saffar ZH, Ibrahim AG, Faris H. Development and Characterization of Colored Lime–Gypsum Mortars for Heritage Building Restoration in Humid Environments. Construction Materials. 2025; 5(3):65. https://doi.org/10.3390/constrmater5030065

Chicago/Turabian StyleThyab, Faris J., Zaid Hazim Al-Saffar, Anas Ghaiath Ibrahim, and Helen Faris. 2025. "Development and Characterization of Colored Lime–Gypsum Mortars for Heritage Building Restoration in Humid Environments" Construction Materials 5, no. 3: 65. https://doi.org/10.3390/constrmater5030065

APA StyleThyab, F. J., Al-Saffar, Z. H., Ibrahim, A. G., & Faris, H. (2025). Development and Characterization of Colored Lime–Gypsum Mortars for Heritage Building Restoration in Humid Environments. Construction Materials, 5(3), 65. https://doi.org/10.3390/constrmater5030065