Lime Mortar, a Boon to the Environment: Characterization Case Study and Overview

Abstract

:1. Introduction

2. Characterization of Ancient Mortar—Overview

3. Lime with Bio-Additives

4. Characterization of Ancient Mortar—Case Study

4.1. Sample Collection Process

4.2. Material Analysis

- If, 0.30 < HI < 0.50—Weakly hydraulic

- 0.30 < HI < 0.70—Moderately hydraulic

- 0.30 < HI < 1.10—The higher the index, the greater the hydraulic properties

- 0.15 < CI—Air lime

- 0.15 < CI < 0.30—Sub-hydraulic lime

- 0.30 < CI < 0.50—Weakly hydraulic

- 0.50 < CI < 0.70—Moderately hydraulic

- 0.70 < CI < 1.10—The higher the index, the greater the hydraulic properties

| (a) Hydraulic Index Sample A (b) Cementation index Sample A | = (4.36 + 1.979 + 38.11)/(24.47 + 5.9) = 1.46 = (1.1 × 4.36 + 0.7 × 1.979 + 2.8 × 38.11)/(24.47 + 5.9) = 3.7 |

| (a) Hydraulic Index Sample B (b) Cementation index Sample C | = (1.58 + 1.372 + 16.63)/(13.79 + 1.9) = 1.24 = (1.2 × 1.58 + 0.7 × 1.372 + 2.8 × 16.63)/13.79 + 1.9) = 3.14 |

4.3. Micro Characterization

4.3.1. XRF Analysis

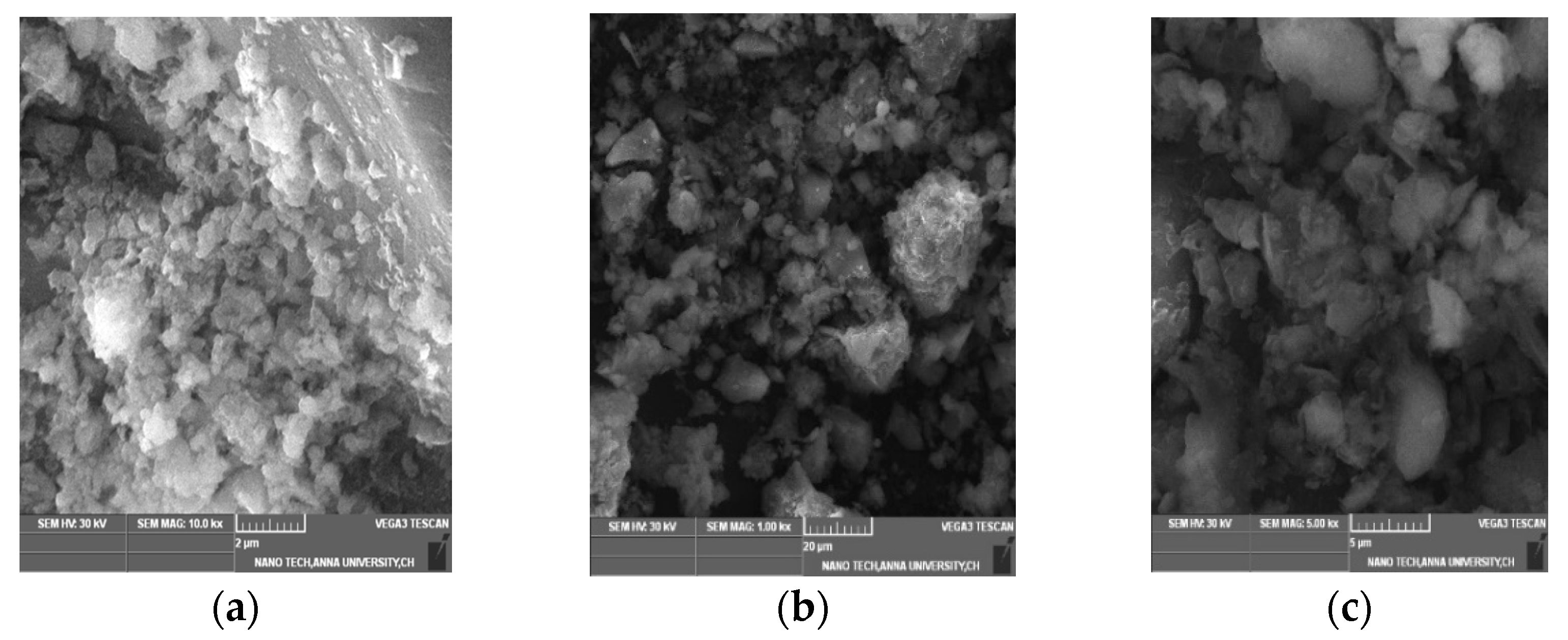

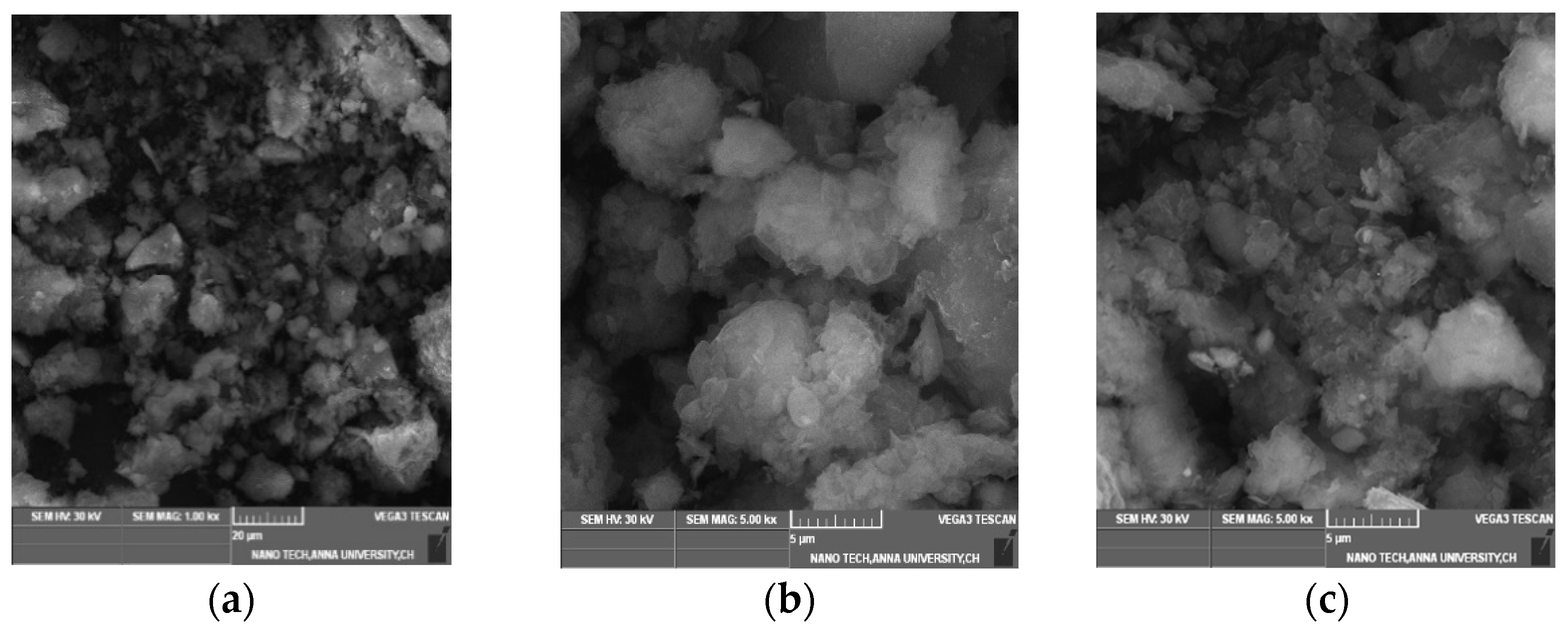

4.3.2. SEM Analysis

4.3.3. XRD Analysis

4.3.4. FT-IR Analysis

5. Summary and Conclusions

- -

- On visual inspection, the mortar material was very much cohesive, rigid, and bonded well to the ancient structures; external activities of birds/animals/humans have primarily caused external distress, necessitating periodical maintenance;

- -

- The SEM analysis showed the most homogeneous mixture of ancient lime mortar with stable self-healing calcium carbonate crystals with metastable polymorphs (vaterite);

- -

- The FTIR analysis confirmed the presence of organic protein additive materials (Amide group) used in ancient times that have improved the material binding properties and air-absorbing properties [37];

- -

- The characterization study develops in-depth knowledge of the materials used during the historical period; thus, trials can be performed and compatible repair material produced for contemporary maintenance. Every study provides new knowledge concerning these materials and opens up huge opportunities for further research to determine the various other stable ingredients used by our ancestors that have resulted in time-resistant and climate-resistant structures;

- -

- Tamil Nadu is rich in cultural heritage, with thousands of ancient structures in the form of temples, mosques, and palaces that need proper maintenance and preservation. These experimental methods researched here (SEM, XRD, FTIR, XRF, and the chemical dissolution test) were performed to determine compatible repair materials for the preservation of magnificent historical structures;

- -

- The research on bio-additives added to ancient lime mortar reveals a considerable gap in the literature in terms of characterizing old lime mortar, which should be studied in-depth, and whether it can be replaced with artificial inorganic toxic additives to the construction materials in the future.

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frankeová, D.; Koudelková, V. Influence of aging conditions on the mineralogical micro-character of natural hydraulic lime mortars. Constr. Build. Mater. 2020, 264, 120205. [Google Scholar] [CrossRef]

- Sun, G.; Li, X.; Wu, Y. Impacts of climate change on biological dynamics. Discret. Dyn. Nat. Soc. 2016, 2016, 9046107. [Google Scholar] [CrossRef] [Green Version]

- Pintea, A.O.; Manea, D.L. New types of mortars obtained by adding traditional mortars with natural polymers to increase physic mechanical performances. Procedia Manuf. 2019, 32, 201–207. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A.; Candeias, A. Effects of natural and accelerated carbonation on the properties of lime-based materials. J. CO2 Util. 2021, 49, 101552. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Rehan, R.; Nehdi, M. Carbon dioxide emissions and climate change: Policy implications for the cement industry. Environ. Sci. Policy 2005, 8, 105–114. [Google Scholar] [CrossRef]

- de Almendra Freitas, J., Jr.; Marienne do Rocio de Mello Maron da Costa, M.; Valduga Artigas, L.; Martins, L.; Roberto Sanquetta, C. Assessment of the impact of binders in the evolution of carbonation in mortars. Constr. Build. Mater. 2019, 225, 496–501. [Google Scholar] [CrossRef]

- van Hees, R.P.J.; Binda, L.; Papayianni, I.; Toumbakari, E. RILEM TC 167-COM: ‘Characterisation of old mortars with respect to their repair’Characterisation and damage analysis of old mortars. Mater. Struct. 2004, 37, 644–648. [Google Scholar] [CrossRef]

- TC 203-RHM (Jan Erik Lindqvist). Rilem TC 203-RHM: Repair mortars for historic masonry. Testing of hardened mortars, a process of questioning and interpreting. Mater. Struct. 2009, 42, 853–865. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Moropoulou, A. Physico-chemical study of Cretan ancient mortars. Cem. Concr. Res. 2003, 33, 651–661. [Google Scholar] [CrossRef]

- Borsoi, G.; Silva, A.S.; Menezes, P.; Candeias, A.; Mirão, J. Analytical characterization of ancient mortars from the archaeological roman site of Pisões. Constr. Build. Mater. 2019, 204, 597–608. [Google Scholar] [CrossRef] [Green Version]

- Degryse, P.; Elsen, J.; Waelkens, M. Study of ancient mortars from Sagalassos (Turkey) in view of their conservation. Cem. Concr. Res. 2002, 32, 1457–1463. [Google Scholar] [CrossRef]

- Haneefa, K.M.; Rani, S.D.; Ramasamy, R.; Santhanam, M. Microstructure and geochemistry of lime plaster mortar from a heritage structure. Constr. Build. Mater. 2019, 225, 538–554. [Google Scholar] [CrossRef]

- Leone, G.; de Vita, A.; Magnani, A.; Rossi, C. Characterization of archaeological mortars from Herculaneum. Thermochim. Acta 2016, 624, 86–94. [Google Scholar] [CrossRef]

- Ayat, A.; Bouzerd, H.; Ali-Boucetta, T.; Navarro, A.; Benmalek, M.L. Valorisation of waste glass powder and brick dust in air-lime mortars for restoration of historical buildings: Case study theatre of Skikda (Northern Algeria). Constr. Build. Mater. 2022, 315, 125681. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Konstantinidis, A.; Koltsou, P.; Papadopoulos, S. Use of Posidonia oceanica fibres in lime mortars. Constr. Build. Mater. 2021, 298, 123881. [Google Scholar] [CrossRef]

- Miriello, D.; Bloise, A.; Crisci, G.M.; de Luca, R.; de Nigris, B.; Martellone, A.; Osanna, M.; Pace, R.; Pecci, A.; Ruggieri, N. New compositional data on ancient mortars and plasters from Pompeii (Campania–Southern Italy): Archaeometric results and considerationsabout their time evolution. Mater. Charact. 2018, 146, 189–203. [Google Scholar] [CrossRef]

- Lezzerini, M.; Ramacciotti, M.; Cantini, F.; Fatighenti, B.; Antonelli, F.; Pecchioni, E.; Fratini, F.; Cantisani, E.; Giamello, M. Archaeometric study of natural hydraulic mortars: The case of the Late Roman Villa dell’Oratorio (Florence, Italy). Archaeol. Anthropol. Sci. 2017, 9, 603–615. [Google Scholar] [CrossRef]

- Santhanam, K.; Shanmugavel, D.; Ramadoss, R.; Arakatavemula, V. Characterisation on ancient mortar of Chettinadu house at Kanadukathan, Karaikudi, Tamil Nadu, India. Mater. Today Proc. 2021, 43, 1147–1153. [Google Scholar] [CrossRef]

- Franzini, M.; Leoni, L.; Lezzerini, M. A procedure for determining the chemical composition ofbinder and aggregate in ancient mortars: Its application tomortars from some medieval buildings in Pisa. J. Cult. Herit. 2000, 1, 365–373. [Google Scholar] [CrossRef]

- Papayianni, I.; Pachta, V.; Stefanidou, M. Analysis of ancient mortars and design of compatible repair mortars: The case study of Odeion of the archaeological site of Dion. Constr. Build. Mater. 2013, 40, 84–92. [Google Scholar] [CrossRef]

- Izzo, F.; Arizzi, A.; Cappelletti, P.; Cultrone, G.; de Bonis, A.; Germinario, C.; Graziano, S.F.; Grifa, C.; Guarino, V.; Mercurio, M.; et al. The art of building in the Roman period (89 B.C.–79 A.D.): Mortars, plasters and mosaic floors from ancient Stabiae (Naples, Italy). Constr. Build. Mater. 2016, 117, 129–143. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Li, B.; Yu, G.; Li, L. Experimental study on factors affecting the physical and mechanical properties of shell lime mortar. Constr. Build. Mater. 2019, 228, 116726. [Google Scholar] [CrossRef]

- Loureiro, A.M.S.; da Paz, S.P.A.; Veiga, M.d.R.; Angélic, R.S. Investigation of historical mortars from Belém do Pará, Northern Brazil. Constr. Build. Mater. 2020, 233, 117284. [Google Scholar] [CrossRef]

- Izzo, F.; Furno, A.; Cilenti, F.; Germinario, C.; Gorrasi, M.; Mercurio, M.; Langella, A.; Grifa, C. Thedomus domini imperatoris Apiciibuilt by Frederick II along the Ancient Via Appia (southern Italy): An example of damage diagnosis for a Medieval monument in rural environment. Constr. Build. Mater. 2020, 259, 119718. [Google Scholar] [CrossRef]

- Fort, R.; Ergenç, D.; Aly, N.; de Buergo, M.A.; Hemeda, S. Implications of new mineral phases in the isotopic composition of Roman lime mortars at the Kom el-Dikka archaeological site in Egypt. Constr. Build. Mater. 2021, 268, 121085. [Google Scholar] [CrossRef]

- Kuckova, S.; Rambouskova, G.; Junkova, P.; Santrucek, J.; Cejnar, P.; Smirnova, T.A.; Novotny, O.; Hynek, R. Analysis of protein additives degradation in aged mortars using mass spectrometry and principal component analysis. Constr. Build. Mater. 2021, 288, 123124. [Google Scholar] [CrossRef]

- Qian, K.; Song, Y.; Lai, J.; Qian, X.; Zhang, Z.; Liang, Y.; Ruan, S. Characterization of historical mortar from ancient city walls of Xindeng in Fuyang, China. Constr. Build. Mater. 2022, 315, 125780. [Google Scholar] [CrossRef]

- Dai, M.; Peng, M.; Liu, C.; Wang, H.; Ali, J.; Naz, I. Analysis and imitation of organic Sanhetu concrete discovered in an ancient Chinese tomb of Qing Dynasty. J. Archaeol. Sci. Rep. 2019, 26, 101918. [Google Scholar] [CrossRef]

- Bertolini, L.; Carsana, M.; Gastaldi, M.; Lollini, F.; Redaelli, E. Binder characterisation of mortars used at different ages in the San Lorenzo church in Milan. Mater. Charact. 2013, 80, 9–20. [Google Scholar] [CrossRef]

- Donaisa, M.K.; Alraisa, M.; Konomia, K.; George, D.; Ramundt, W.H.; Smith, E. Energy dispersive Xray fluorescence spectrometry characterization of wall mortars with principal component analysis: Phasing and exit u versus in situ sampling. J. Cult. Herit. 2020, 43, 90–97. [Google Scholar] [CrossRef]

- Singh, M.R.; Ganaraj, K.; Sable, P.D. Surface mediated Ca-phosphate biomineralization and characterization of the historic lime mortar, Janjira Sea Fort, India. J. Cult. Herit. 2020, 44, 110–119. [Google Scholar] [CrossRef]

- Morricone, A.; Macchia, A.; Campanella, L.; David, M.; de Togni, S.; Turci, M.; Maras, A.; Meucci, C.; Ronc, S. Archeometrical analysis for the characterization of mortars from Ostia Antica. Procedia Chem. 2013, 8, 231–238. [Google Scholar] [CrossRef] [Green Version]

- Degloorkar, N.K.; Pancharathi, R.K. Characterization of ancient mortar for sustainability of an 800-year oldheritage site in India. Mater. Today Proc. 2020, 32, 734–739. [Google Scholar] [CrossRef]

- Rodriguez-Juareza, M.E.; Perez-Diaza, E.; Lopez-Domingueza, G.I.; Picazoa, V.L.; Valencia-Cruzb, D.; Millan-Maloc, B.M.; Rodriguez-Garcia, M.E. Development and characterization of lime-based stucco for modern construction and restoration applications based on ancient stuccoes from the “El Cerrito” pyramid, Quer étaro, Mexico. Case Stud. Constr. Mater. 2022, 16, e00875. [Google Scholar] [CrossRef]

- Ventolà, L.; Vendrell, M.; Giraldez, L.P. Traditional organic additives improve lime mortars: New old materials for restoration and building natural stone fabrics. Merino Construct. Build. Mater. 2011, 25, 3313–3318. [Google Scholar] [CrossRef]

- Jasiczak, J.; Zielinski, K. Effect of protein additive on properties of mortar. Cem. Concr. Compos. 2006, 28, 451–457. [Google Scholar] [CrossRef]

- Thirumalini, S.; Ravi, R.; Rajesh, M. Experimental investigation on physical and mechanical properties of lime mortar: Effect of organic addition. J. Cult. Herit. 2018, 31, 97–104. [Google Scholar] [CrossRef]

- Li, W.; Dobraszczyk, B.J.; Dias, A.; Gil, A.M. Polymer Conformation Structure of Wheat Proteins and Gluten Subfractions Revealed by ATR-FTIR. Cereal Chem. 2006, 83, 407–410. [Google Scholar] [CrossRef]

- Luxbn, M.P.; Dorrego, F. Ancient xvi century mortar from the Dominican republic: Its characteristics, microstructure and additives. Cem. Concr. Res. 1996, 26, 841–849. [Google Scholar]

- Marini, L. (Ed.) Chapter 5—The Product Solid Phases. In Developments in Geo-Chemistry; Elsevier: Amsterdam, The Netherlands, 2007; Volume 11, pp. 79–167. [Google Scholar]

- Biernat, M.; Jaegermann, Z.; Tymowicz-Grzyb, P.; Konopka, G. Influence of low-temperature reaction time on morphology and phase composition of short calcium phosphate whiskers. Process. Appl. Ceram. 2019, 13, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Kulpetchdara, K.; Limpichaipanit, A.; Randorn, C.; Rujijanagul, G.; Tunkasiri, T.; Chokethawai, K. Microstructure-property relations of biphasic calcium phosphate obtained by hot pressing process. Process. Appl. Ceram. 2019, 13, 300–309. [Google Scholar] [CrossRef]

- Meejoo, S.; Maneeprakorn, W.; Winotai, P. Phase and thermal stability of nanocrystalline hydroxyapatite prepared via microwave heating. Thermochim. Acta 2006, 447, 115–120. [Google Scholar] [CrossRef]

- Shanmugavel, D.; KumarYadav, P.; Ramadoss, M.A.K.R. Experimental analysis on the performance of egg albumen as a sustainable bio admixture in natural hydraulic lime mortars. J. Clean. Prod. 2021, 320, 128736. [Google Scholar] [CrossRef]

| Ref. No | Author | Location of Ancient Structure | Characterization | Ingredients | Research Findings |

|---|---|---|---|---|---|

| [10] | [1] | Minoan civilization | Petrographical and mineralogical characterization, calorimetry, XRD, TGA, FTIR, and chemical analysis | Hydraulic lime, with crushed brick, with pozzolan | The level of hydraulicity and compatible repair material suggestion |

| [11] | [2] | Beja, Portugal | Petrography, XRD, TGA, SEM-EDS, potentiometry and combustion analysis | Calcitic air lime | The compatible repair materials and water-proofing properties and higher mechanical strength |

| [12] | [3] | Turkey | Optical microscopy and XRD | Lime, volcanic tuff, and ceramic waste | High freeze-thaw resistance |

| [13] | [4] | Indian lime mortars | SEM–EDS | Hydraulic lime | The polymorphic changes and the presence of portlandite, anhydrite, and gypsum were confirmed along with minor traces of ettringite and thaumasite; the chloride and sulfate phases are explained |

| [14] | [5] | Herculaneum, Italy | XRF, petrography, and TGA | Slaked lime and ground brick dust | The importance of the maintenance of structures |

| [15] | [6] | Skikda in Algeria | Mechanical properties—compression and flexural strength, fresh state–flow table test, durability, Water absorption, and carbonation tests | Air lime, brick dust, and glass powder | Reuse of waste products with lime |

| [16] | [7] | Greece | SEM, compression, and flexure | Lime and marine plant fibers | Fiber-reinforced lime mortar and low carbon emissions |

| [17] | [8] | Campania–Southern Italy | Optical microscopy (OM), X-ray powder diffraction (XRPD), X-ray fluorescence (XRF), electron probe microanalysis (EPMA), and Raman spectroscopy | Lime | Identifying various ancient mortar mix |

| [18] | [9] | Florence, Italy | Archaeometry study, XRD, SEM, and XRF | Hydraulic lime | Prevailing calcite and hydraulic compounds |

| [19] | [10] | Karaikudi, Tamil Nadu | Acid loss analysis, XRD, XRF, SEM and FTIR | Powdered brick, animal fur (especially goat), volcanic pozzolanic material, egg white, jaggery, and fenugreek seeds | Confirmation for Ingredients in the mortar sample |

| [20] | [11] | Pisa | EDAX, XRF, the chemical composition of the binder, petrographical and mineralogical determinations | Lime and fine aggregates | The presence of carbonate crystalline fraction and an amorphous carbonate-free fraction |

| [21] | [12] | Roman Odeion | Physio-mechanical, Microstructural Chemical properties | Lime, clay, pozzolan, gypsum, brick dust, and different types of aggregates | The compatible repair material selection and preservation of ancient monuments |

| [22] | [13] | Villa San Marco | Digital video microscopy, optical microscopy, digital image analysis, SEM-EDS analysis, and quantitative powder X-ray diffraction | Lime and volcanic sand as aggregate | Reference for the research of ancient structures and selection of materials |

| [23] | [14] | China | Water/lime ratio, sand/lime ratio and curing ages | Shell lime and glutinous rice | The improved properties of structures using shell lime compared with rock lime |

| [24] | [15] | Belém do Pará, Northern Brazil | XRF, SEM, DSC | Shell lime | The types of layered coating and resistance of the ancient mortar to various climates because of the homogenous selection and development of the binder material |

| [25] | [16] | Southern Italy | Photogrammetric survey, damage diagnosis, petrography and FTIR | Geomaterials, limestone, yellow tuff, grey tuff and brick | The damage categories and indices and decision making for restoration |

| [26] | [17] | Egypt | Polarized optical microscopy (POM), scanning electron microscopy (SEM–EDS), X-ray diffraction (XRD), thermogravimetry (TG), X-ray fluorescence (XRF), ion chromatography (IC) and petrological techniques | Lime, soil and airborne particles | Self-healing capacity of mortar and changes in isotopic fractions by time |

| [27] | [18] | Swedish church | Mass spectrometry principal component analysis, liquid chromatography and electrospray ionization quadrupole time-of-flight mass spectrometry | Lime, animal glue, blood, egg and milk | Method of protein analysis and the presence of protein was identified by mass spectrometric techniques |

| [28] | [19] | China | Visual inspection, apparent density, compressive strength and chemical composition | Hydrated lime, sand, clay and blue bricks | Characterization study to determine aggregate binder ratio and strength |

| [29] | [20] | China | XRD, SEM, FTIR and TGA | Lime, sticky rice, sand and clay | Encouraging the use of organic additives |

| [30] | [21] | San Lorenzo Church, Milan | XRD, SEM, TGAand visual observation | Lime and sand | The presence of silico-aluminate |

| [31] | [22] | Corsiglia, CastelViscardo | XRF | Lime | For the preservation of cultural heritage, compatible repair materials production and identification |

| [32] | [23] | Janjira Sea Fort, India | XRD, SEM, FTIR, NMR and MIP | Lime | Formation of apatite and the presence of phosphate-solubilizing bacteria |

| [33] | [24] | Ostia Antica | Mineral–petrographic composition, XRD and FTIR | Lime | The presence of calcitic hydraulic materials and flying lime and dolomite aggregate with impurities of metamorphic quartz typical of a filler |

| [34] | [25] | India | SEM-EDS, XRD, FTIR, TGA-DT and acid-dissolutionanalysis | Lime | The presence of organic content and formation of crystal morphology of calcite and quartz is identified |

| [35] | [26] | Pyramid, Queretaro, Mexico | SEM, stucco elemental composition by ICP-OES, EDS, XRD, and particle size analysis | Quicklime, pozzolan/organic ashes, additives, and aggregates such as sand and fibers | Characterization by experimentation |

| Sample. Name | Sample Location | Sample | Binder | Aggregate |

|---|---|---|---|---|

| A | Beam-Column Joint | Vedapureeswarar Temple | 1 | 3 |

| B | Beam-Column Joint | Lakshmi Narashimar Temple | 1 | 2 |

| Wave Number | Indication | Constituent | Reference | Ref No |

|---|---|---|---|---|

| Around 472 cm−1 | Hydroxyapatite | [23] | [32] | |

| (960−962 cm−1) | Phosphate group | Apatite | [27,28,29] | [43,44,45] |

| Around 1000 cm−1 | Quartz | |||

| 1250 cm−1 to 1550 cm−1 | Carbonate ions | Calcite | ||

| Around 1650 cm−1 | Amide group | [23] | [32] | |

| Around 880 cm−1 | Microbial activity | |||

| Formula | Components | Sample A | Sample B |

|---|---|---|---|

| Mgo | Magnesium oxide | 5.9 | 1.9 |

| SiO2 | Silica oxide | 38.11 | 16.63 |

| CaO | Calcium oxide | 24.47 | 13.79 |

| Al2O3 | Aluminum oxide | 4.36 | 1.58 |

| Fe2O3 | Iron oxide | 1.979 | 1.372 |

| SO2 | Sulphur oxide | 0.09 | 0.10 |

| K2O | Potassium oxide | 0.56 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manoharan, A.; Umarani, C. Lime Mortar, a Boon to the Environment: Characterization Case Study and Overview. Sustainability 2022, 14, 6481. https://doi.org/10.3390/su14116481

Manoharan A, Umarani C. Lime Mortar, a Boon to the Environment: Characterization Case Study and Overview. Sustainability. 2022; 14(11):6481. https://doi.org/10.3390/su14116481

Chicago/Turabian StyleManoharan, Abirami, and C. Umarani. 2022. "Lime Mortar, a Boon to the Environment: Characterization Case Study and Overview" Sustainability 14, no. 11: 6481. https://doi.org/10.3390/su14116481

APA StyleManoharan, A., & Umarani, C. (2022). Lime Mortar, a Boon to the Environment: Characterization Case Study and Overview. Sustainability, 14(11), 6481. https://doi.org/10.3390/su14116481