Innovative Composite Aggregates from Thermoplastic Waste for Circular Economy Mortars

Abstract

1. Introduction

- Alqahtani et al. [38] manufactured recycled plastic aggregates (RPAs) by mixing linear low-density polyethylene (LLDPE) with red sand, fly ash, quarry fines, or silica fumes.

- Liu et al. [39] demonstrated the feasibility of manufacturing lightweight aggregates by incorporating shredded automotive plastic waste into clay at 1200 °C.

- Ennahal et al. [40] prepared lightweight aggregates from marine sediments and recycled thermoplastic waste (PP/PS and PP/PE) at mixing temperatures of 200 to 230 °C.

- Del Rey Castillo et al. [21] developed a lightweight concrete using artificial aggregates made from plastic waste. Their mixture, with a 15% substitution rate, achieved a compressive strength of 20 MPa at 28 days and a density of 1800 kg/m3, demonstrating promising properties for this type of material.

- Gorak et al. [41] produced lightweight composite aggregates from waste, primarily recycled PET. Their study tested two different production technologies, using various synthesis mechanisms and temperatures to optimize the manufacturing of these aggregates, proving the feasibility of this approach.

- Erdogmus et al. [42] explored the use of expanded polystyrene (EPS) and waste rubber tire powder (WRTP) in fired clay bricks. They mixed different proportions of EPS and WRTP with clay and fired the mixtures at 1000 °C, aiming to create greener and cleaner constructions.

- Alahmad et al. [25] showed that adding 3–10% industrial rubber waste to an unsaturated polyester resin-based mortar improved ductility and reduced density and thermal conductivity. While mechanical strength decreased, durability remained comparable to the reference material and met repair standards.

- Owen et al. [43] reinforced PET matrices with epoxy-coated kenaf fibers (10% by weight). This approach improved the composite’s thermal stability to 409.4 °C and increased its melting peak to 252.8 °C, demonstrating the potential of these natural fibers for advanced applications.

- Webo et al. [24] designed a sustainable composite from recycled HDPE and denim fibers (0–20%). With 20% fiber content, the strength reached 30 MPa. Despite a reduction in thermal stability, the improved adhesion from MAPP confirms the utility of these composites for rigid structural applications that do not undergo high thermal stress.

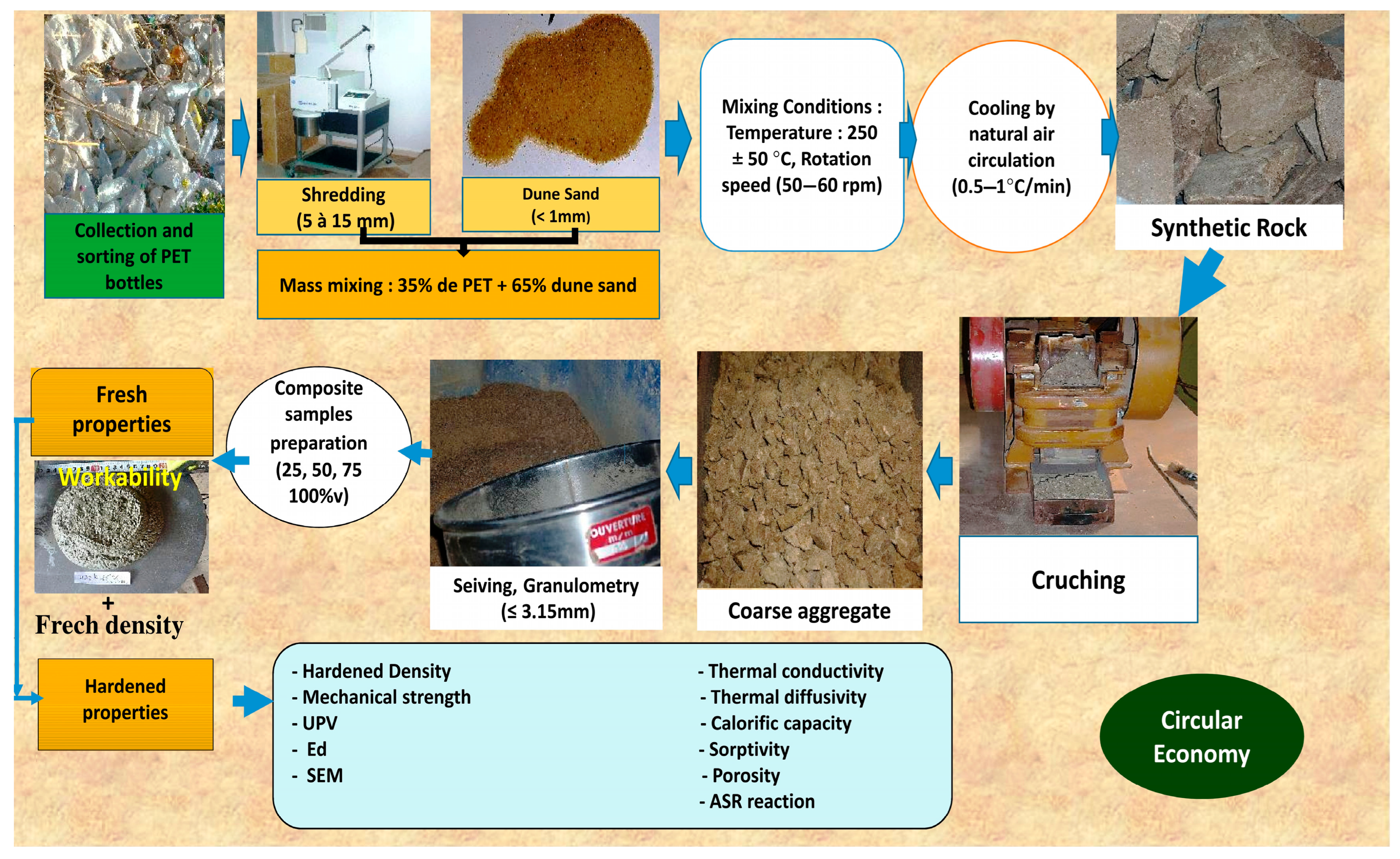

- The LSS manufacturing process ensures precise control of parameters (sand/PET ratio of 35:65, heating temperature of 250 ± 5 °C, and rotation speed of 50–60 rpm), with rigorous thermal selection for optimal fluidization without PET degradation.

- Controlled cooling at 0.5–1 °C/min allows for optimizing crystallization and minimizing stresses, resulting in a semi-crystalline PET matrix.

- The LSS is then crushed and sieved to obtain a specific particle size (≤3.15 mm), corresponding to construction sand standards.

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Lightweight Synthetic Sand (LSS)

2.2. Experimental Procedure

2.3. Testing Methods

2.3.1. Workability

2.3.2. Fresh and Dry Densities

2.3.3. Mechanical Strength

2.3.4. Ultrasonic Pulse Velocity Test

2.3.5. Dynamic Elasticity Modulus (Ed)

2.3.6. Thermal Proprieties

2.3.7. Scanning Electron Microscopy

2.3.8. Alkali–Silica Reaction

2.3.9. Porosity Accessible to Water

2.3.10. Water Absorption

3. Results and Discussion

3.1. Density in the Fresh and Hardened State

3.2. Compressive Strength

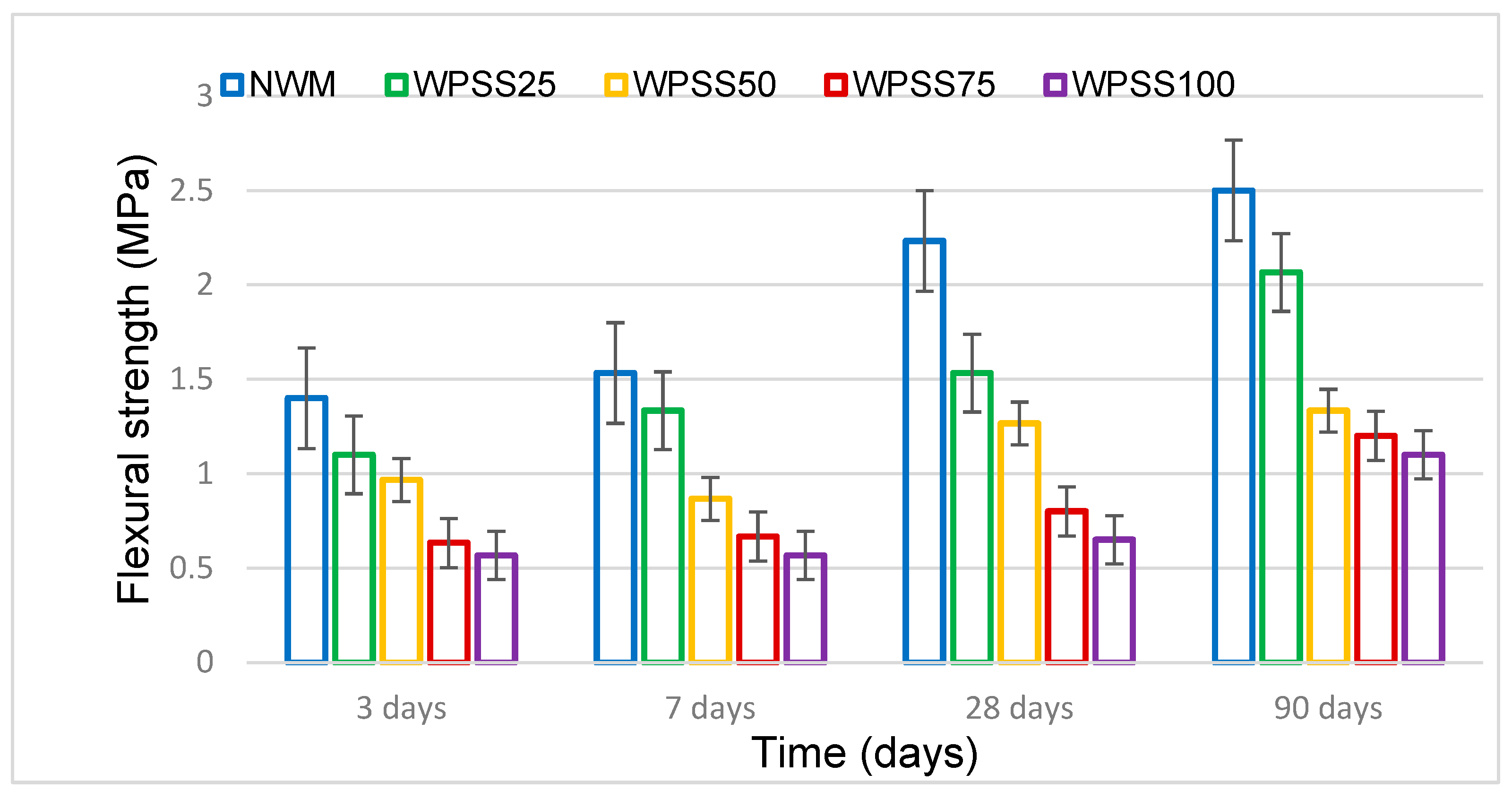

3.3. Flexural Strength

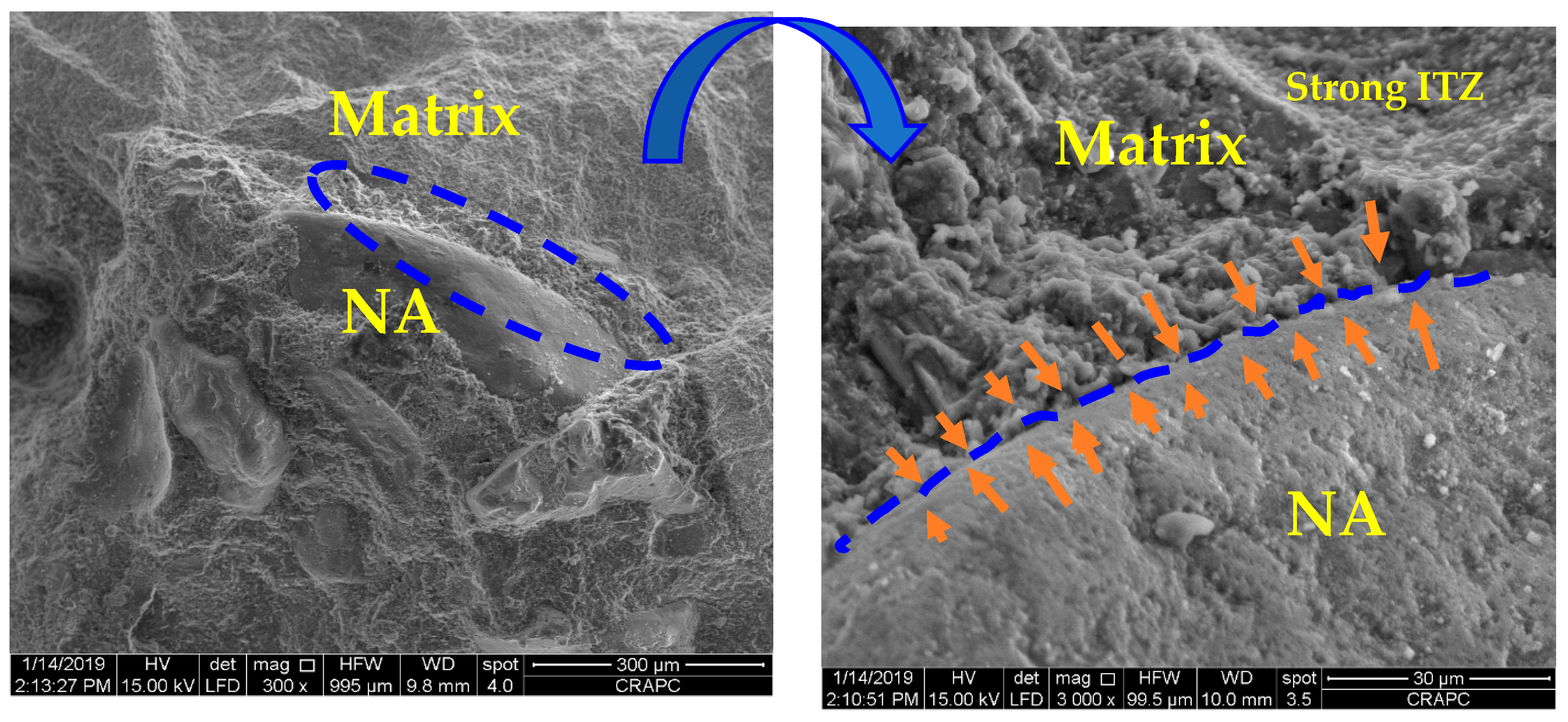

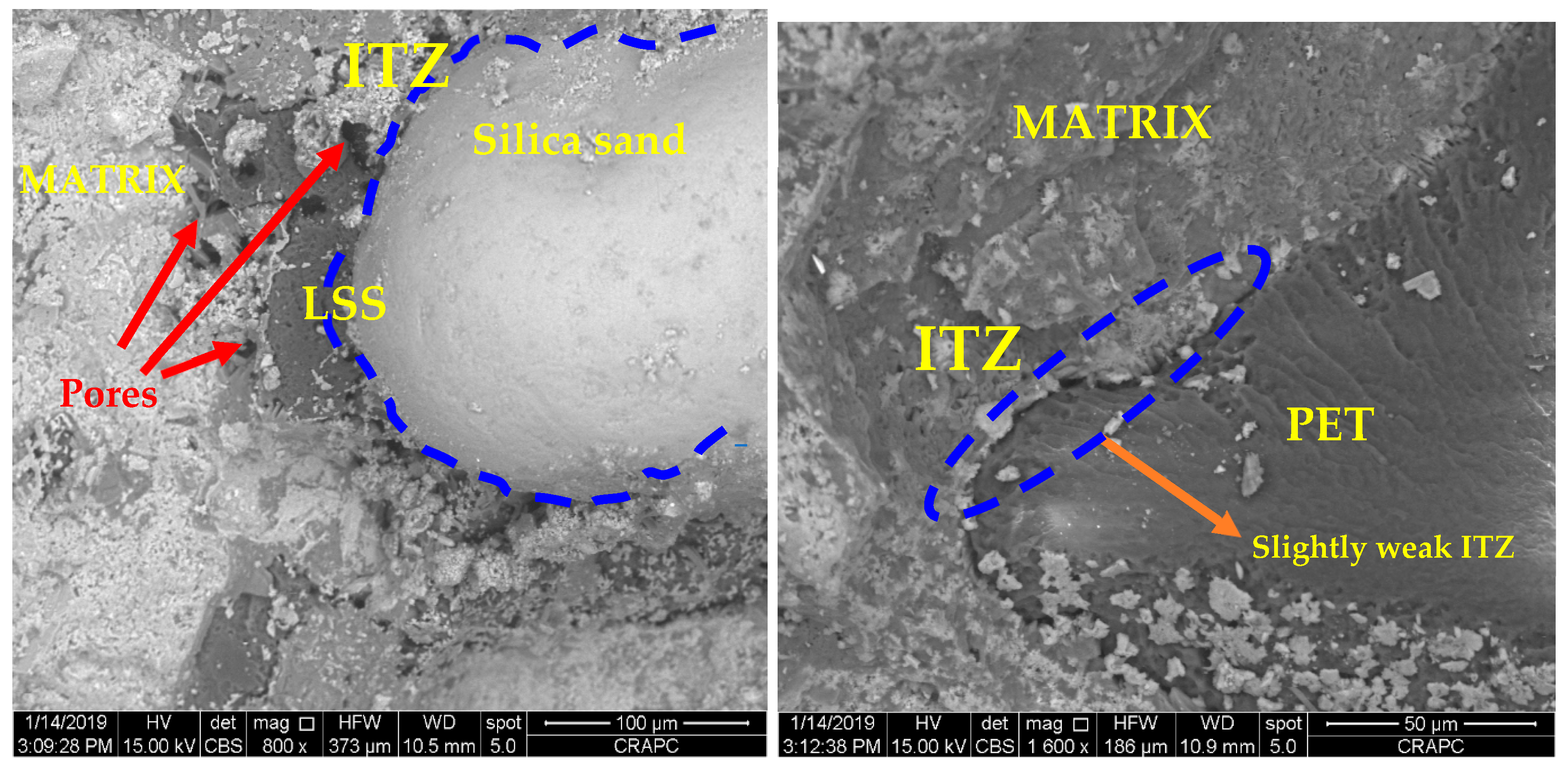

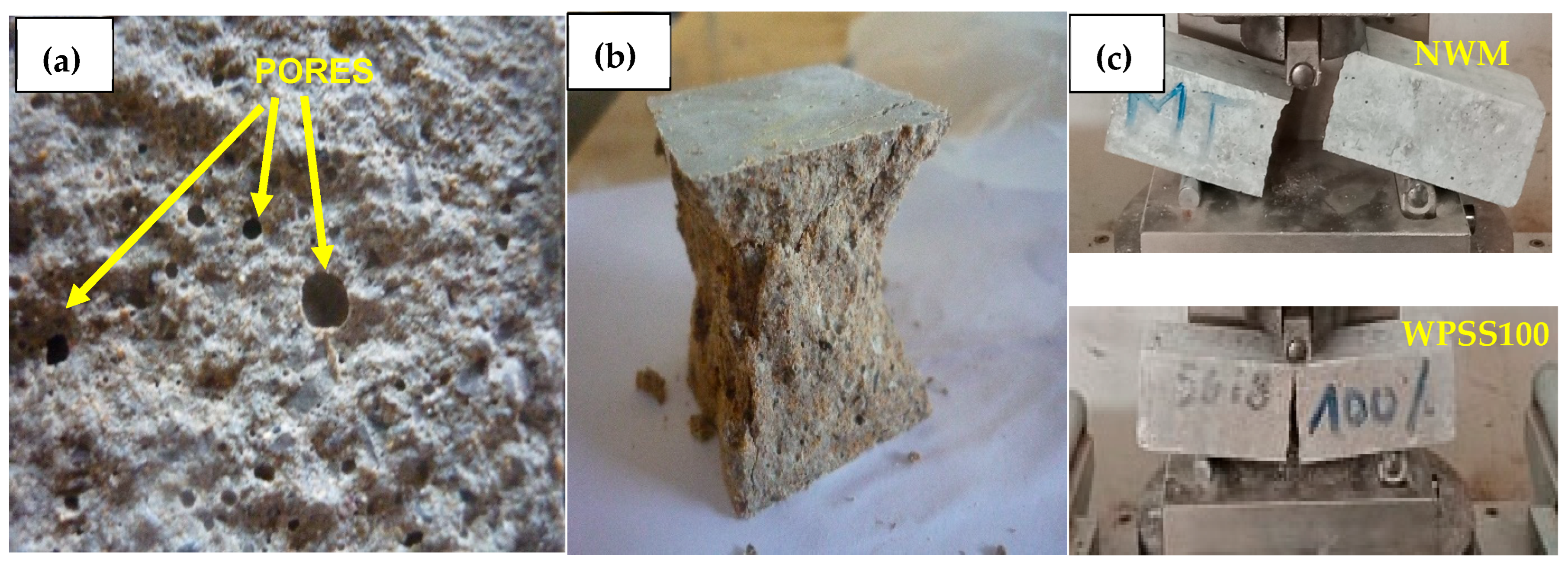

3.4. Scanning Electron Microscopy (SEM) Analysis

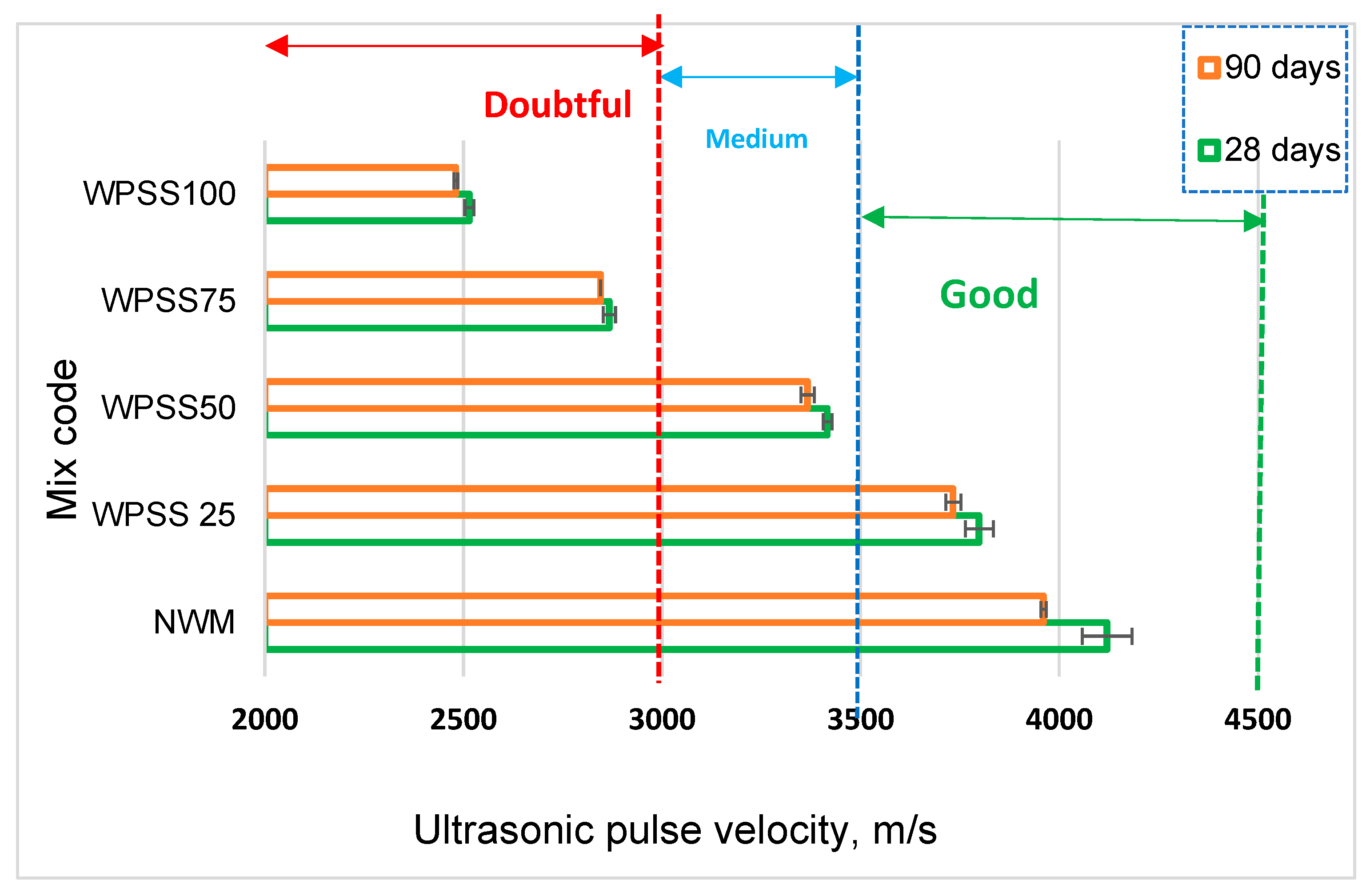

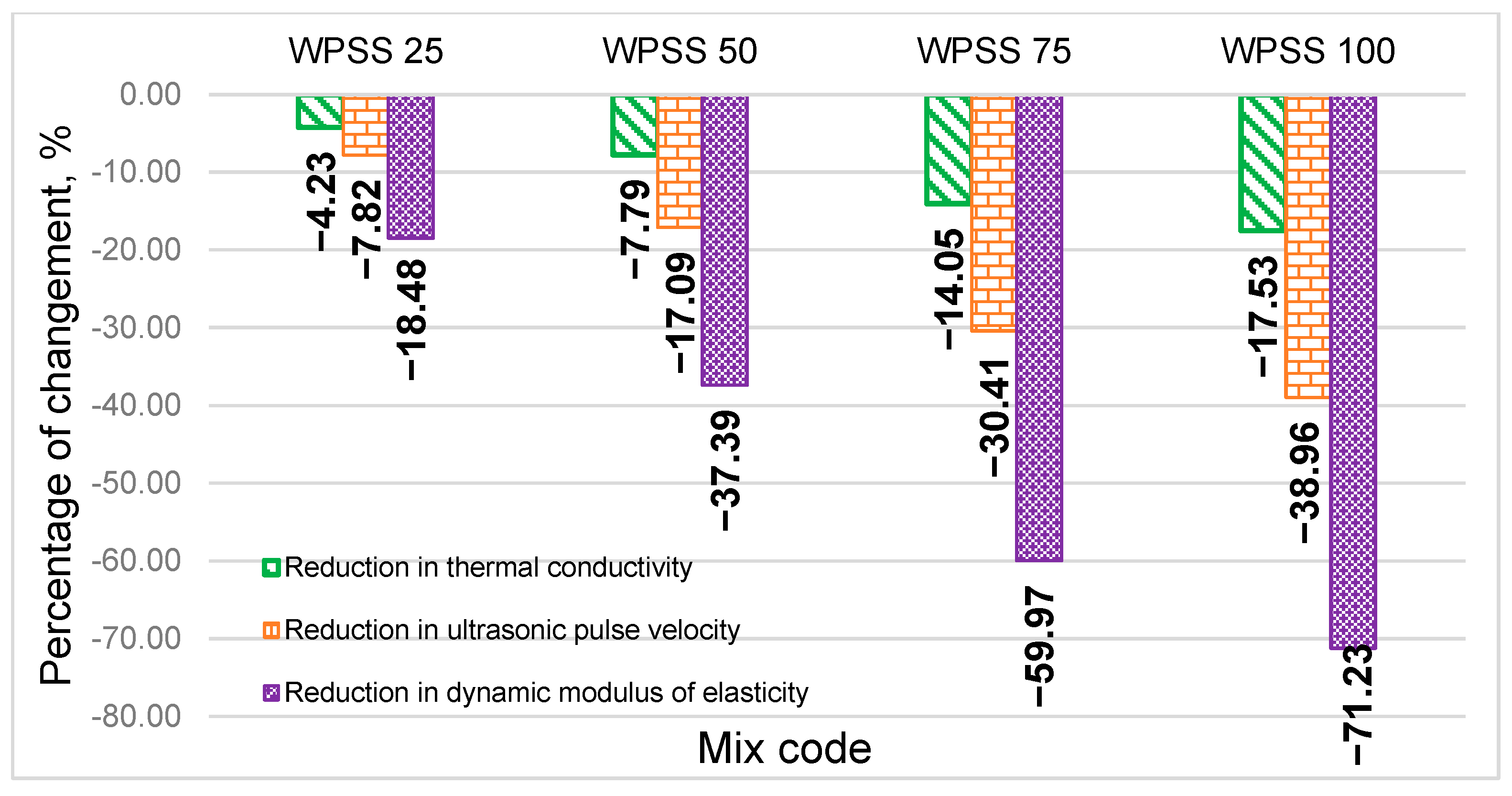

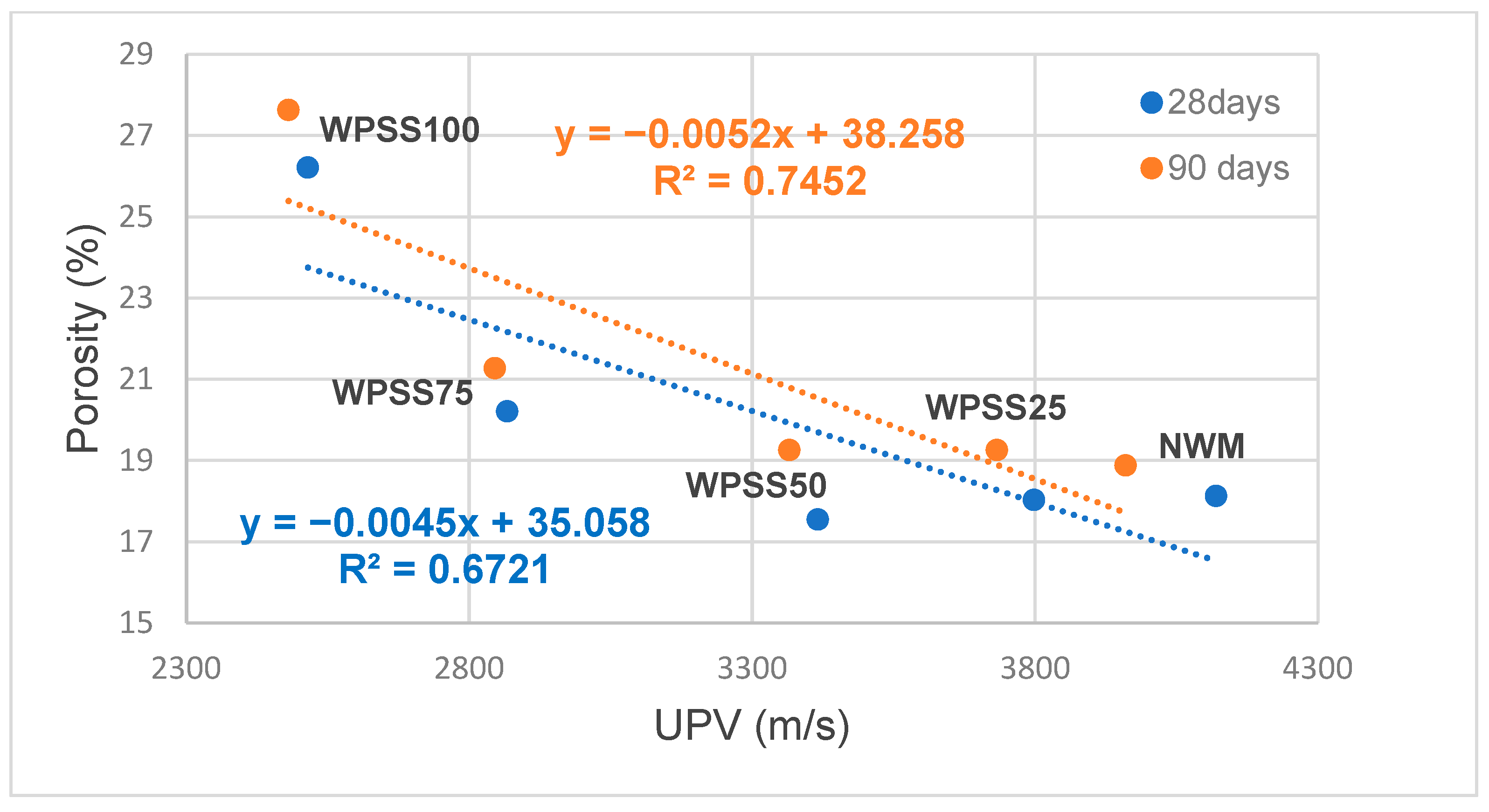

3.5. Ultrasonic Pulse Velocity (UPV) Test

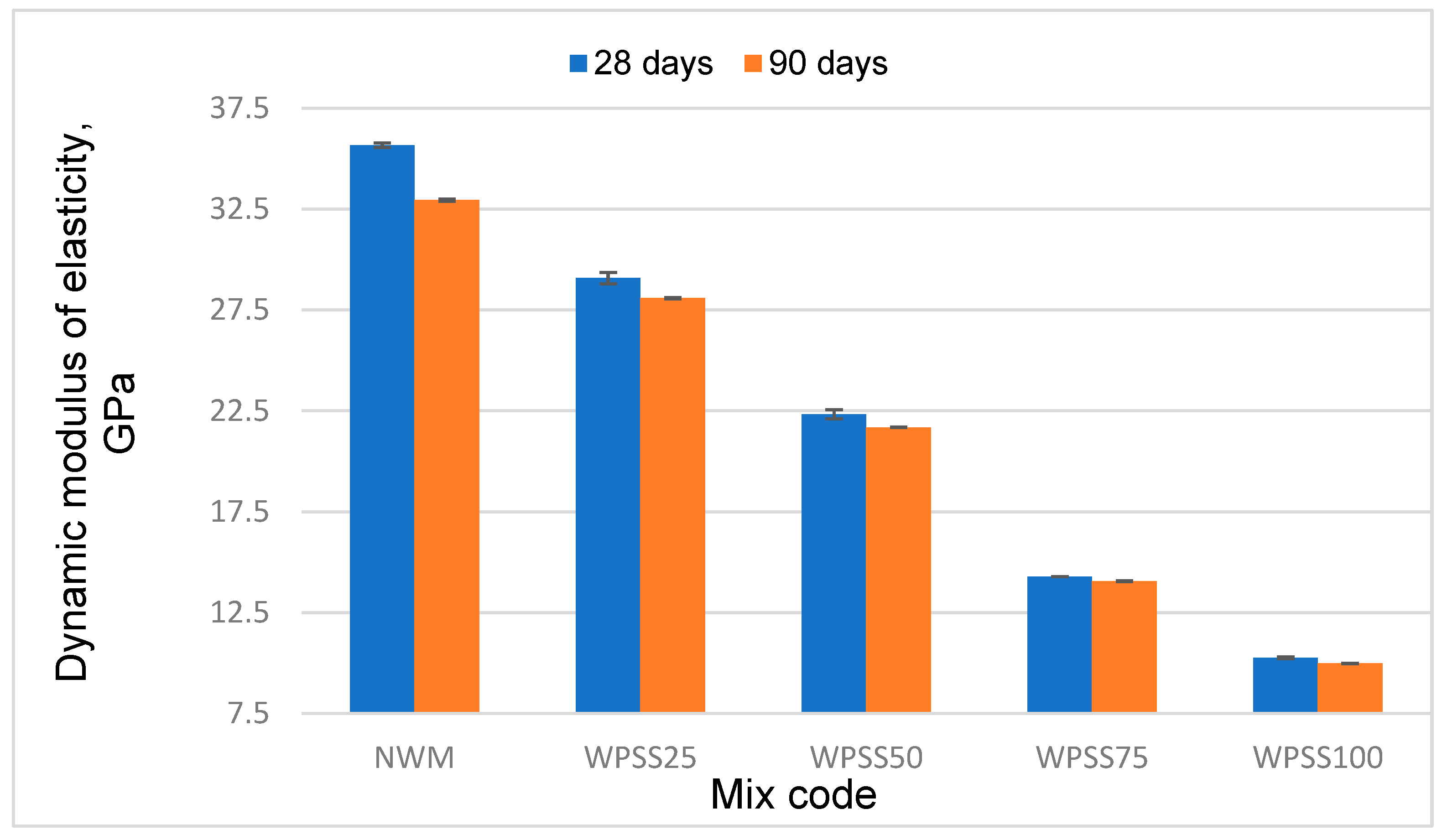

3.6. Dynamic Modulus of Elasticity

3.7. Thermal Properties

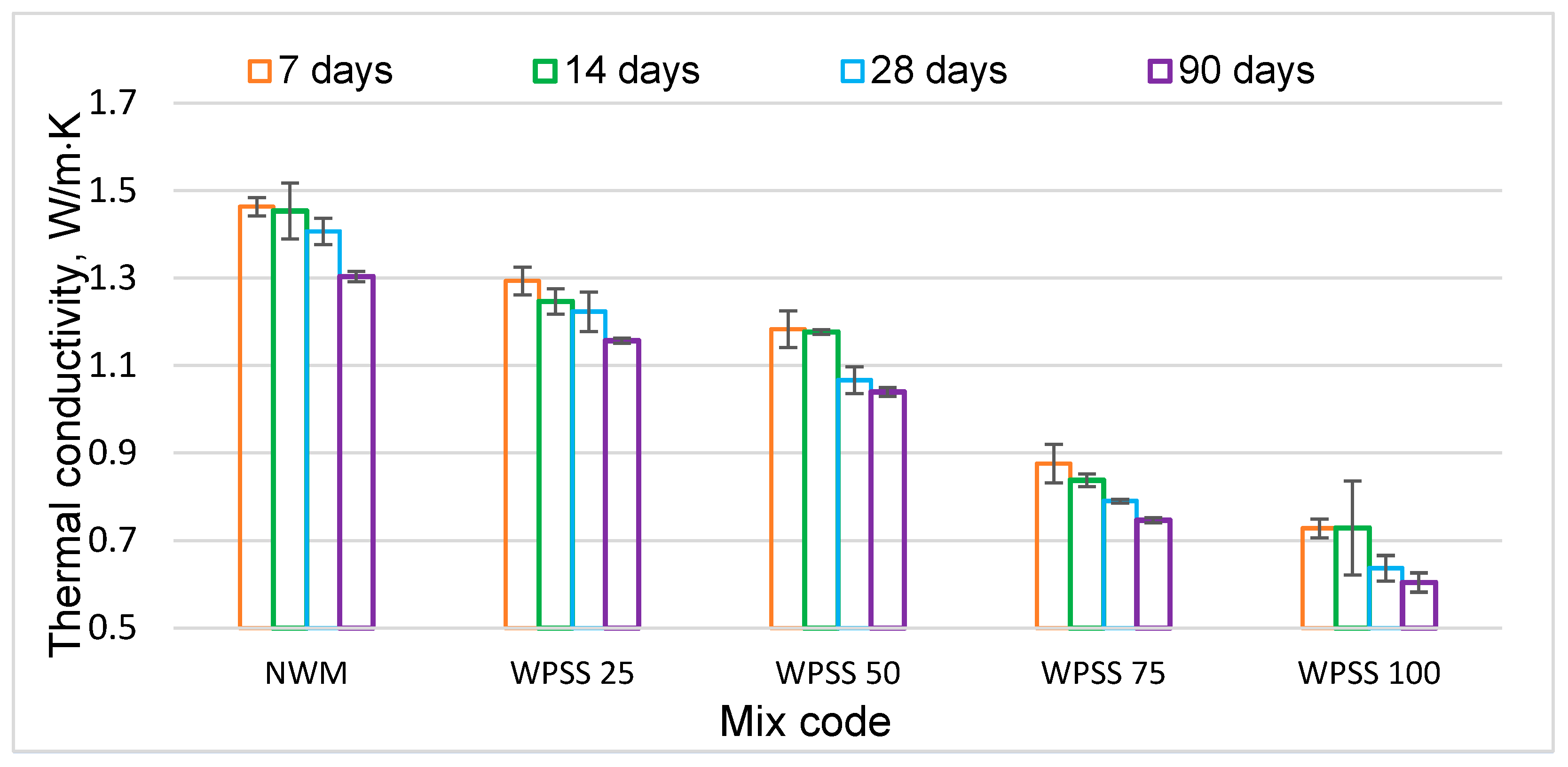

3.7.1. Thermal Conductivity of WPSS Composite Mortars

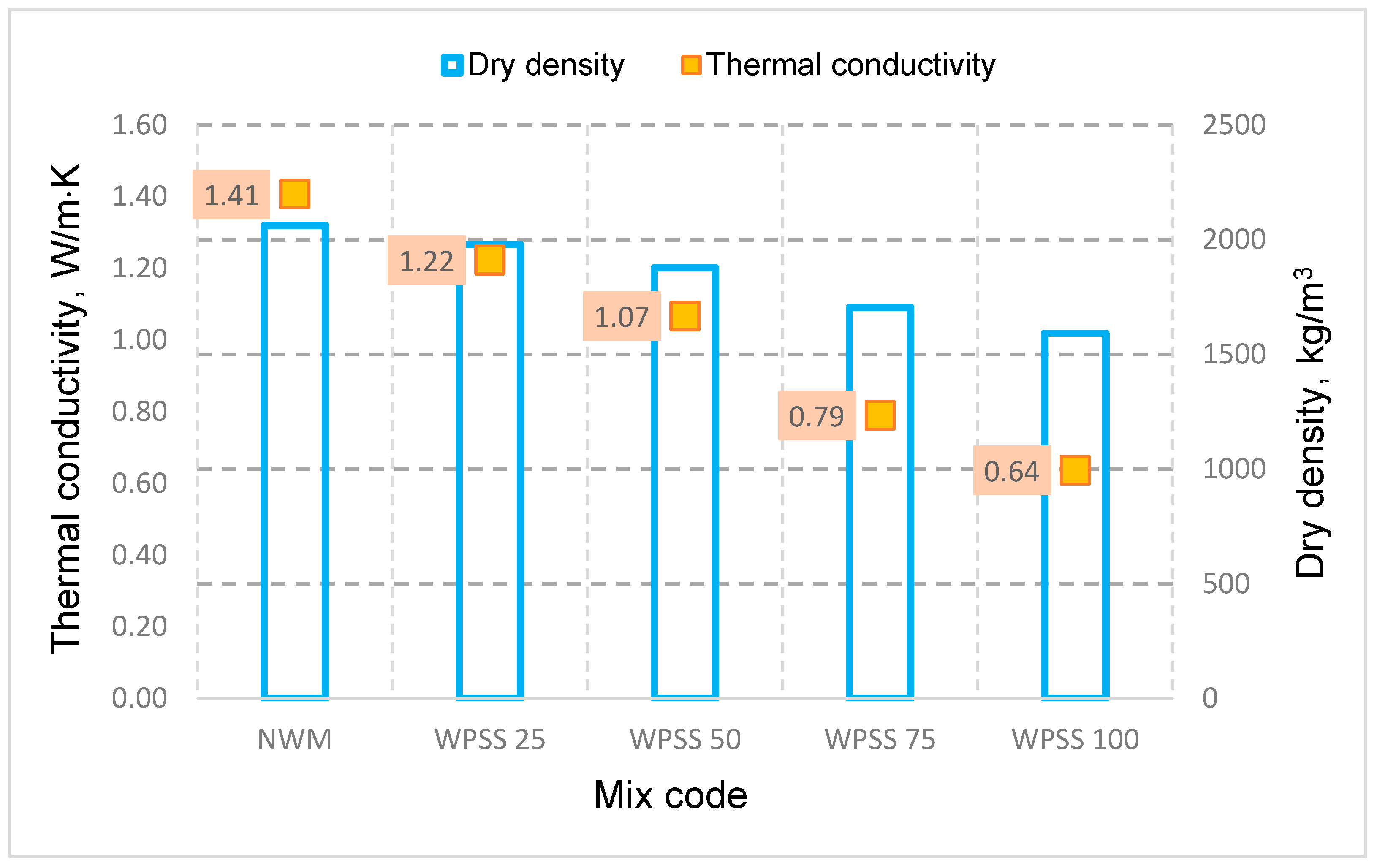

3.7.2. Thermal Conductivity–Density Relationship

3.7.3. Calorific Capacity

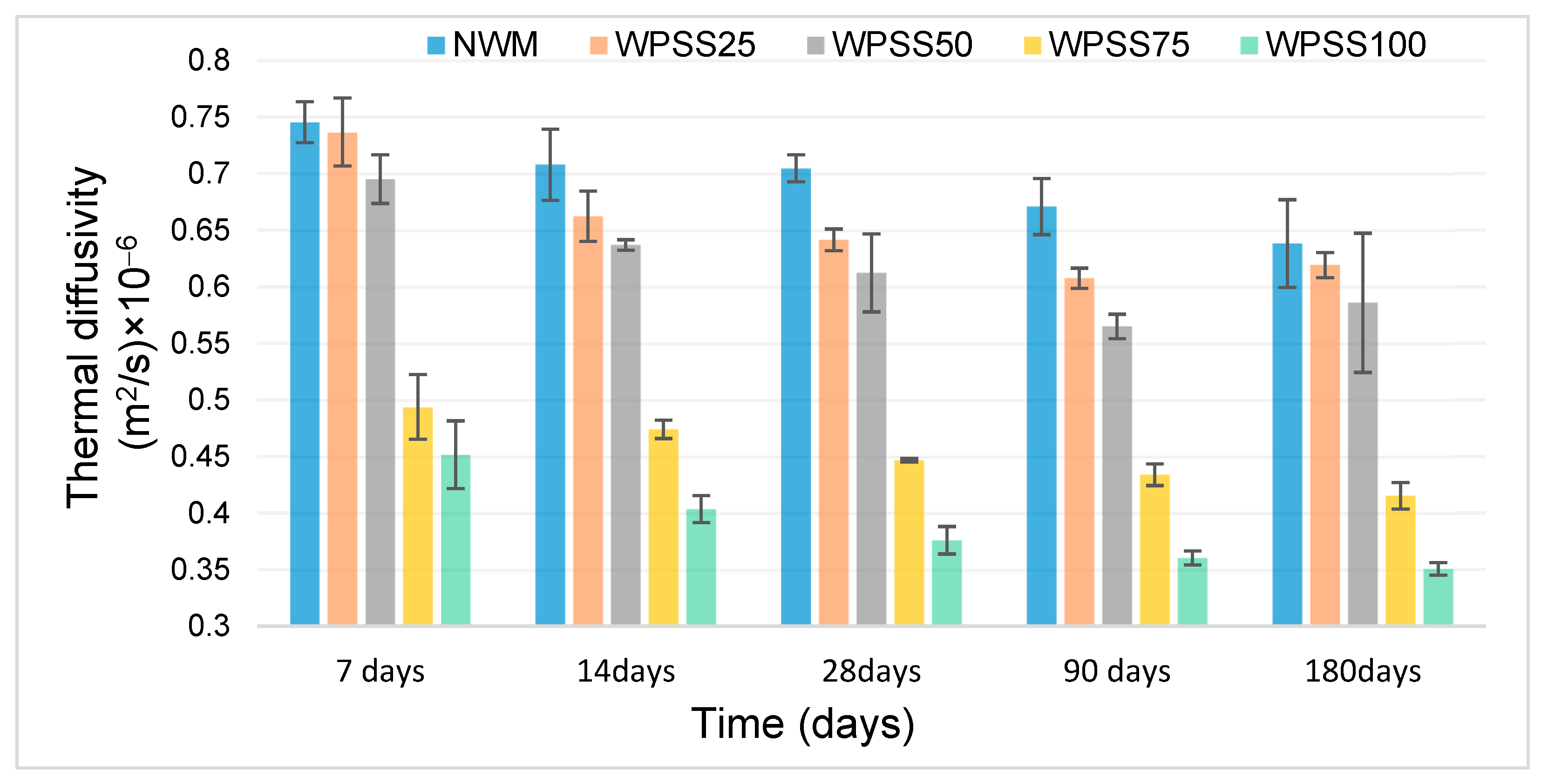

3.7.4. Thermal Diffusivity

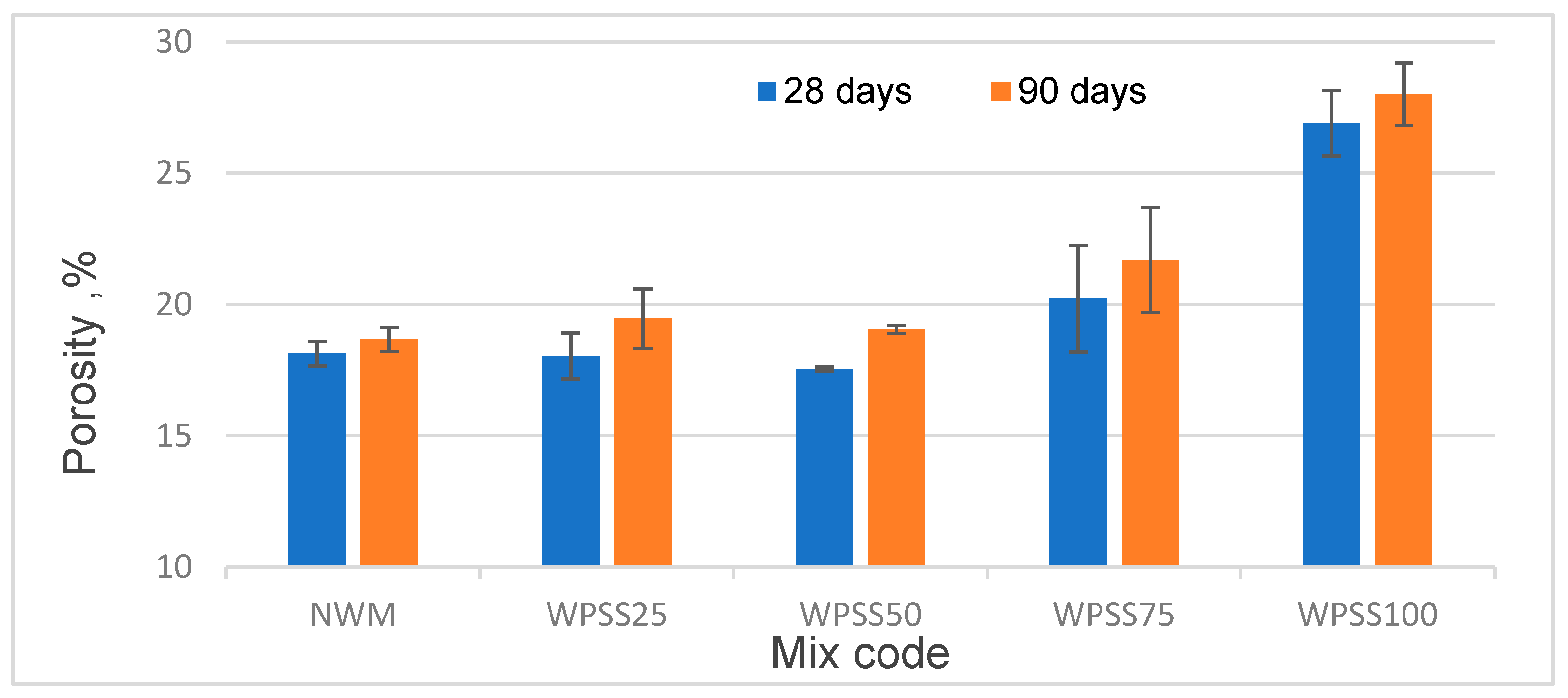

3.8. Open Porosity

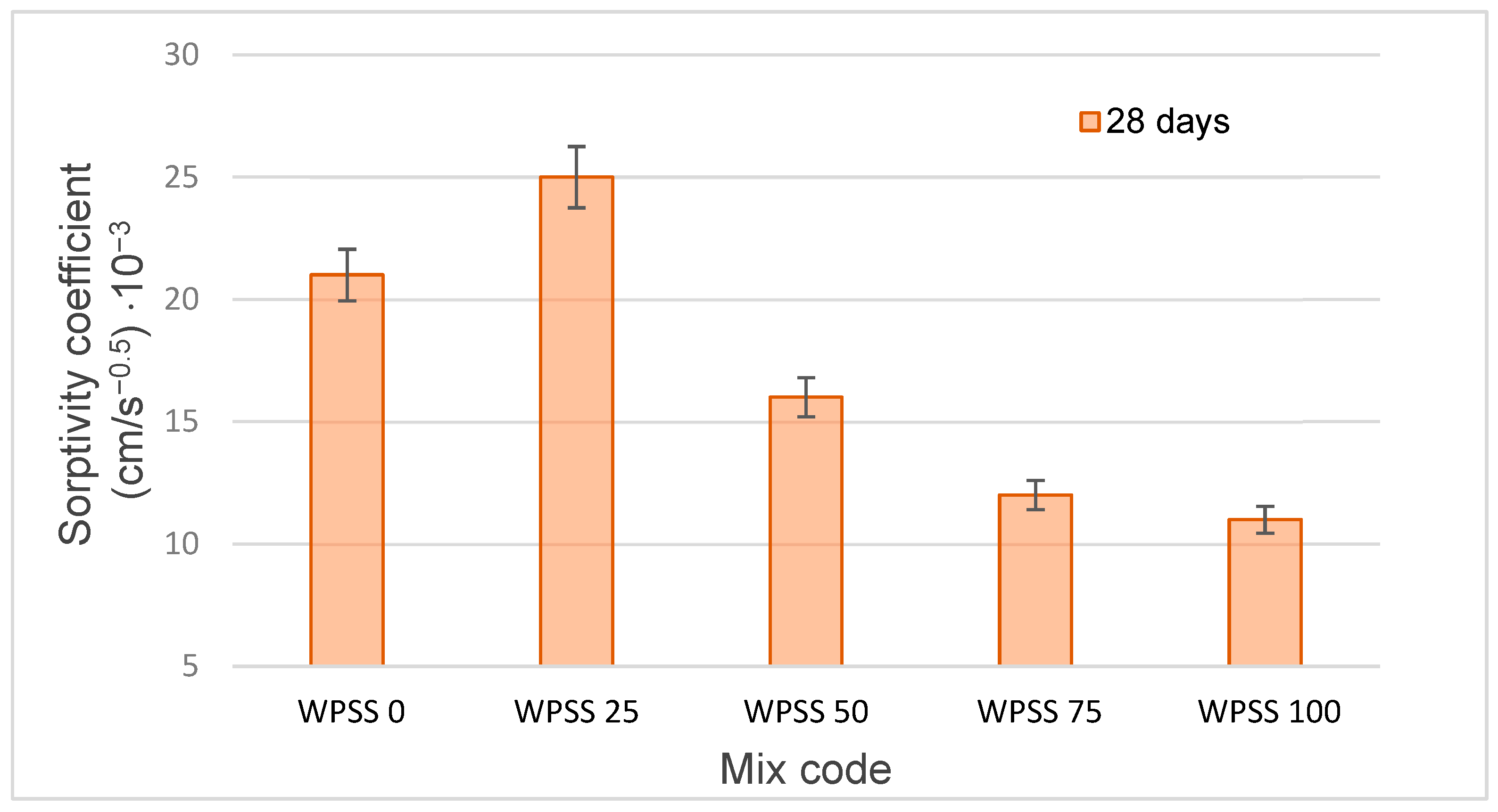

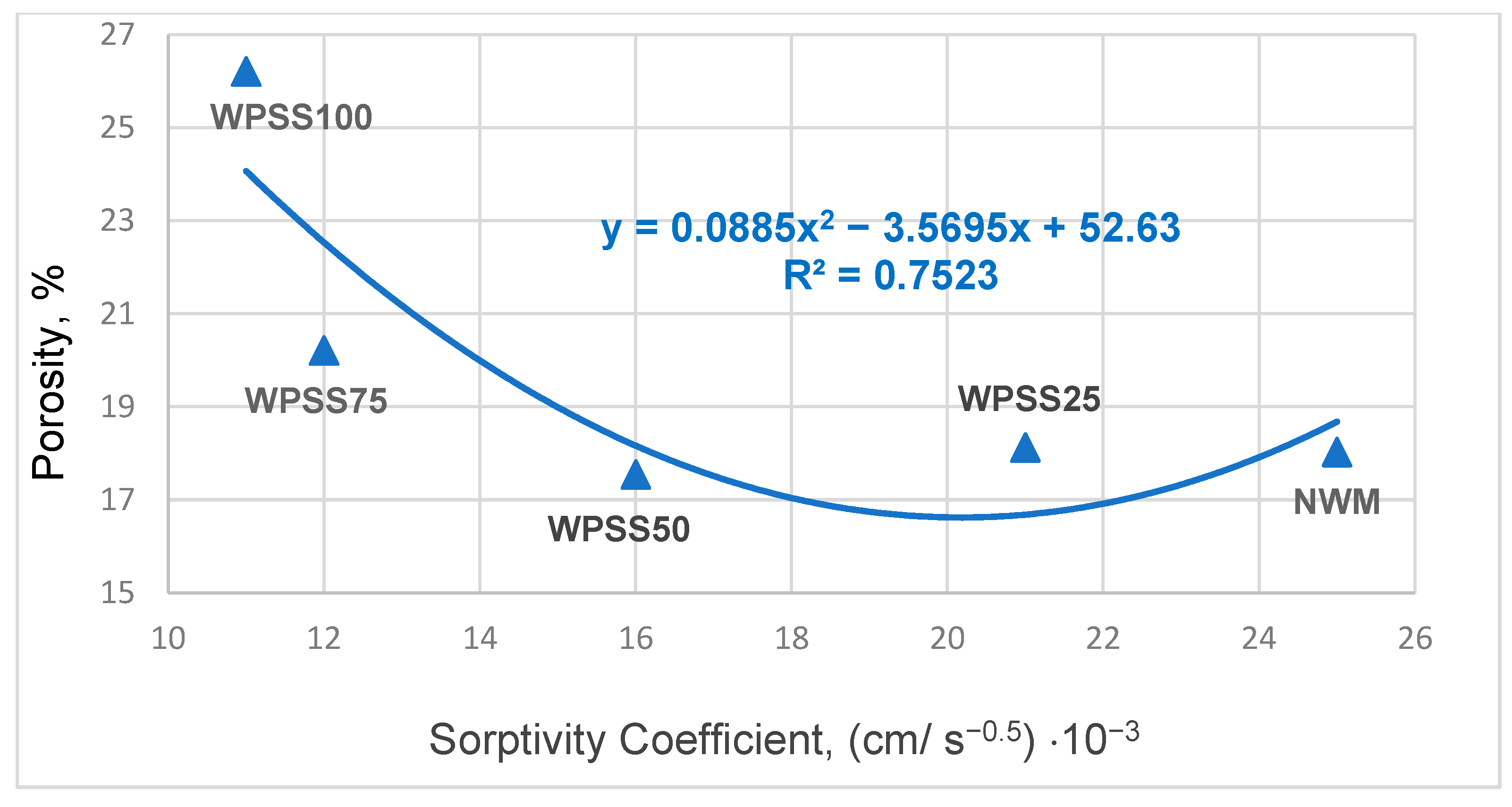

3.9. Sorptivity

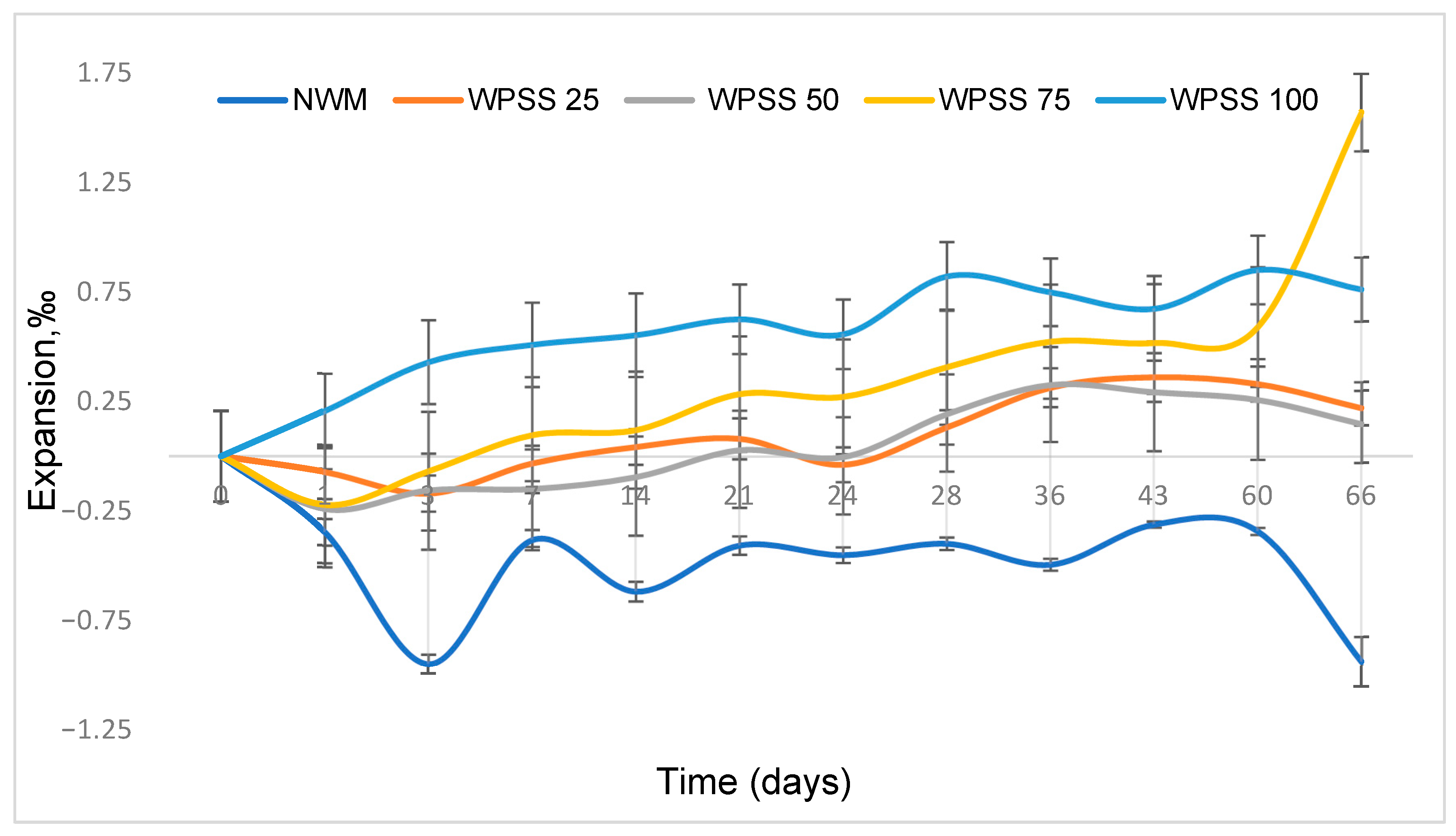

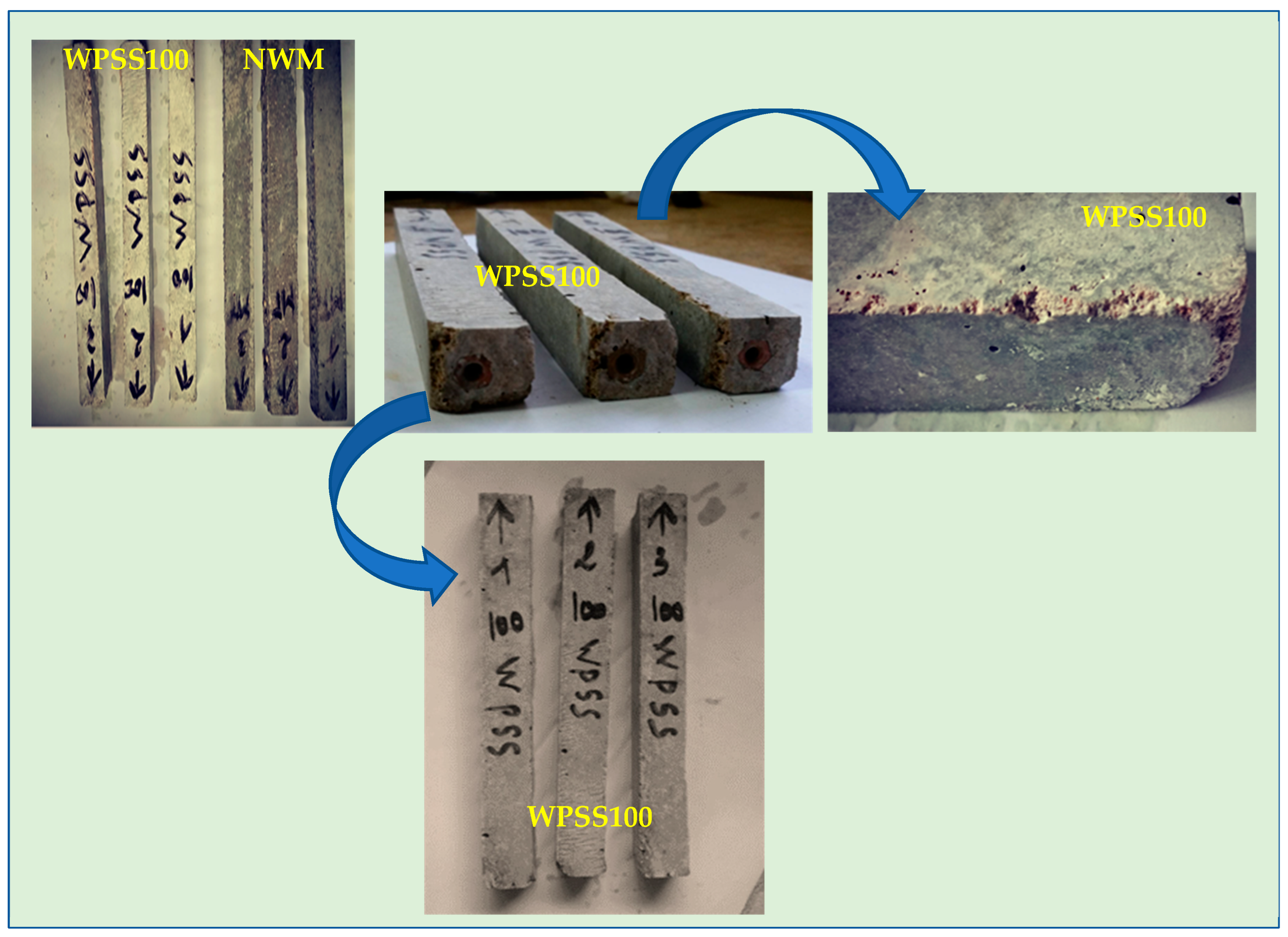

3.10. The Alkali–Silica Reaction

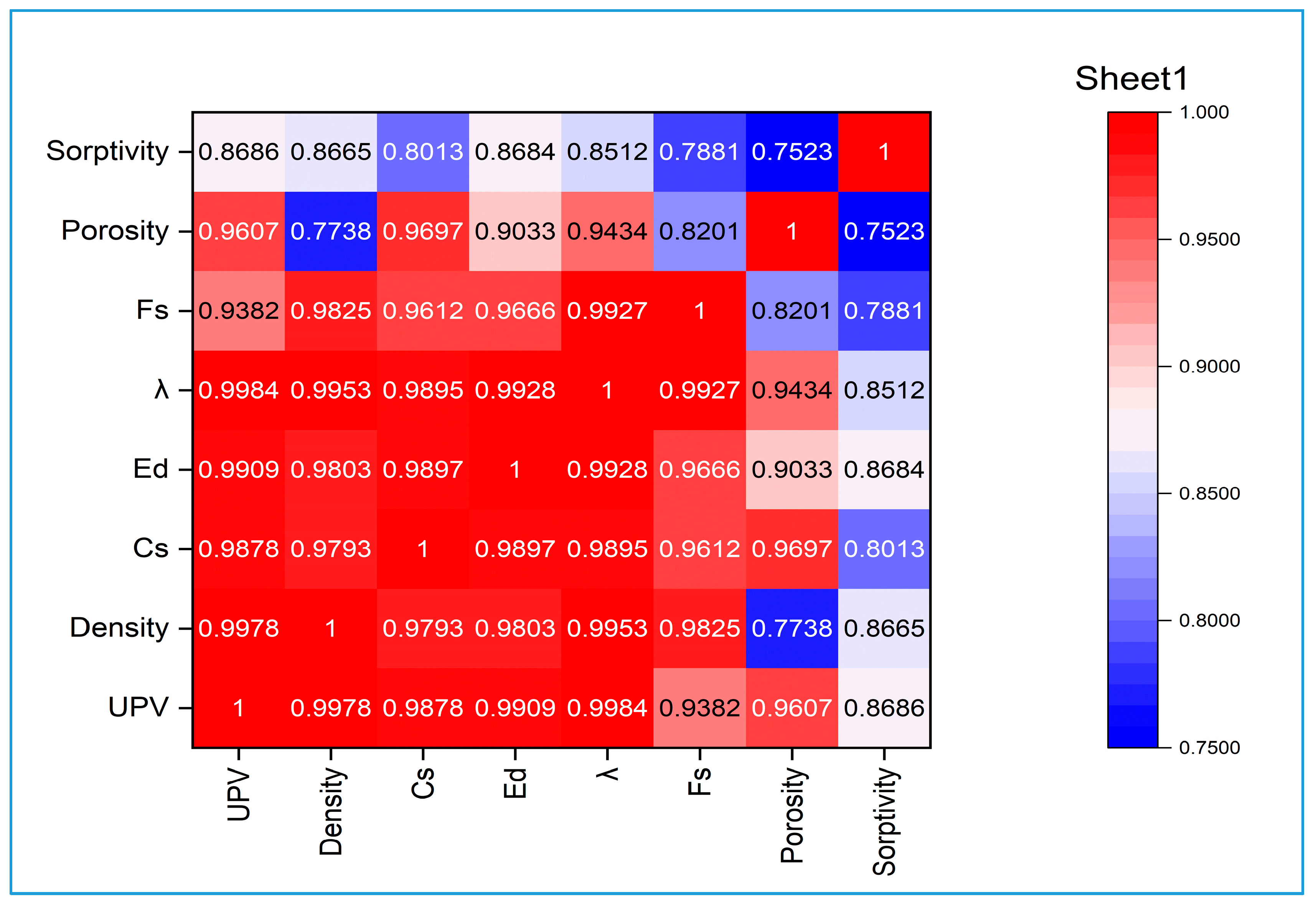

3.11. Benefits of LSS Aggregate Incorporation in Mortar

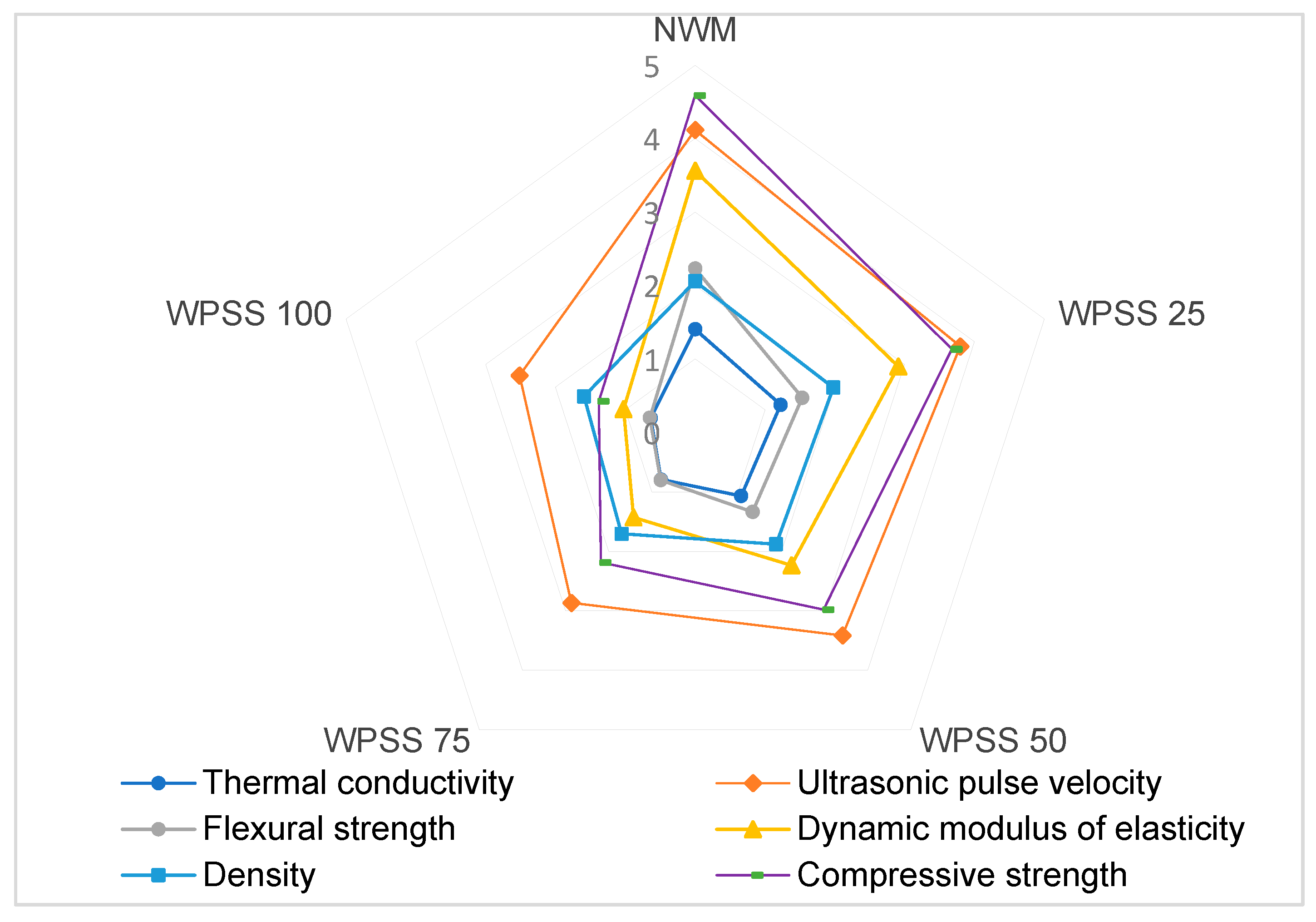

3.12. WPSS Performance Based on Radar Chart Analysis

4. Conclusions

- The innovative LSS manufacturing process is distinguished by precise parameter control (sand/PET ratio of 35:65, heating temperature of 250 ± 5 °C, and rotation speed of 50–60 rpm), rigorous thermal selection, controlled cooling at 0.5–1 °C/min to optimize crystallization and the semi-crystalline PET matrix, and targeted crushing/sieving to obtain a specific particle size (≤3.15 mm) conforming to standards.

- Through our research, we have developed a novel thermal treatment protocol that significantly enhances the interfacial transition zone (ITZ) between plastic aggregates and cement matrix, achieving a notable improvement in bonding strength compared with untreated alternatives.

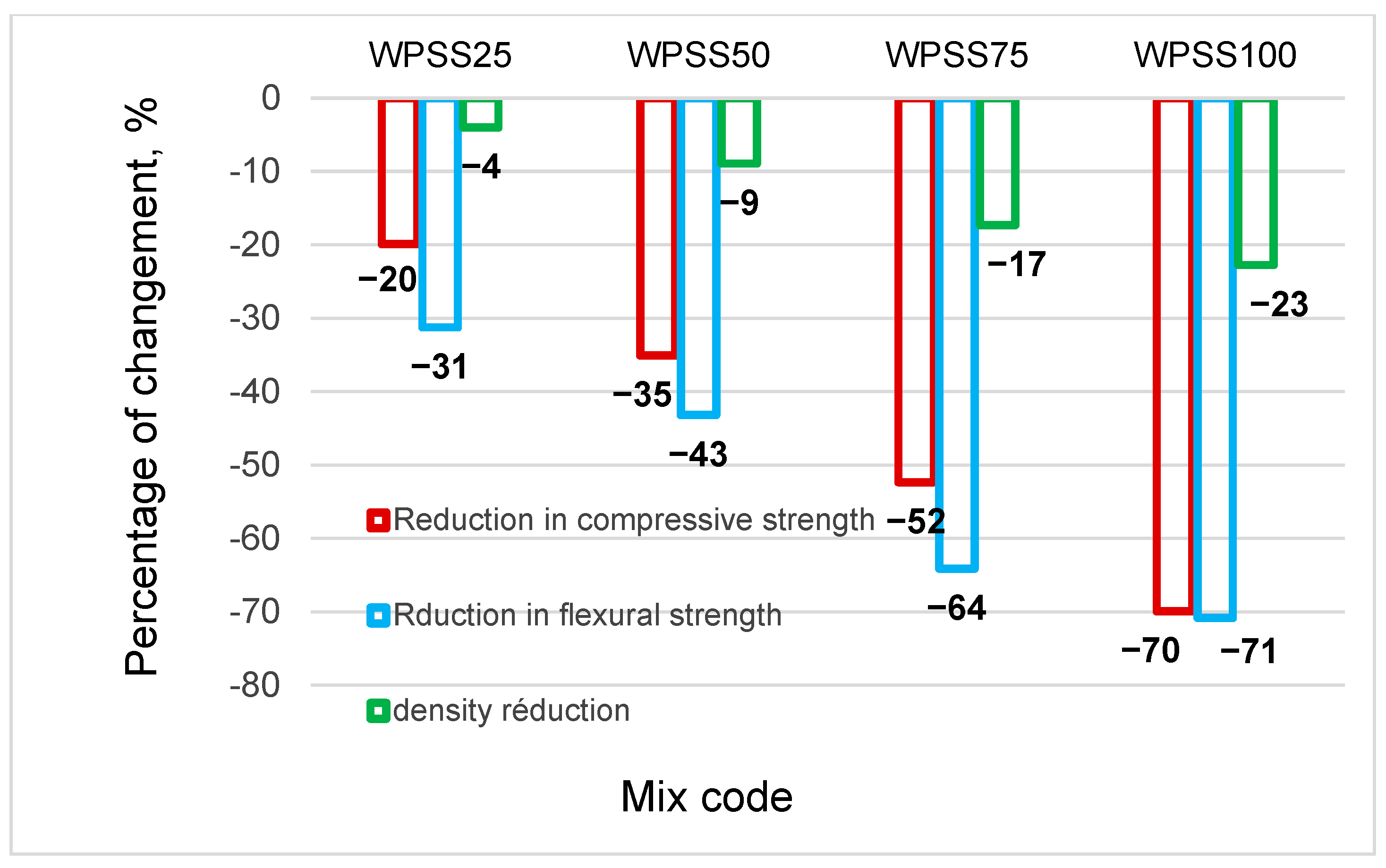

- The incorporation of LSS into composite mortars reduces the density by 4, 9, 17 and 23% for WPSS25, WPSS50, WPSS75 and WPSS100 mortars, respectively, as compared with that of the control mortar (NWM). Therefore, lightweight eco-composites reduce the size of construction elements, thereby lowering material, logistics, and overall building costs.

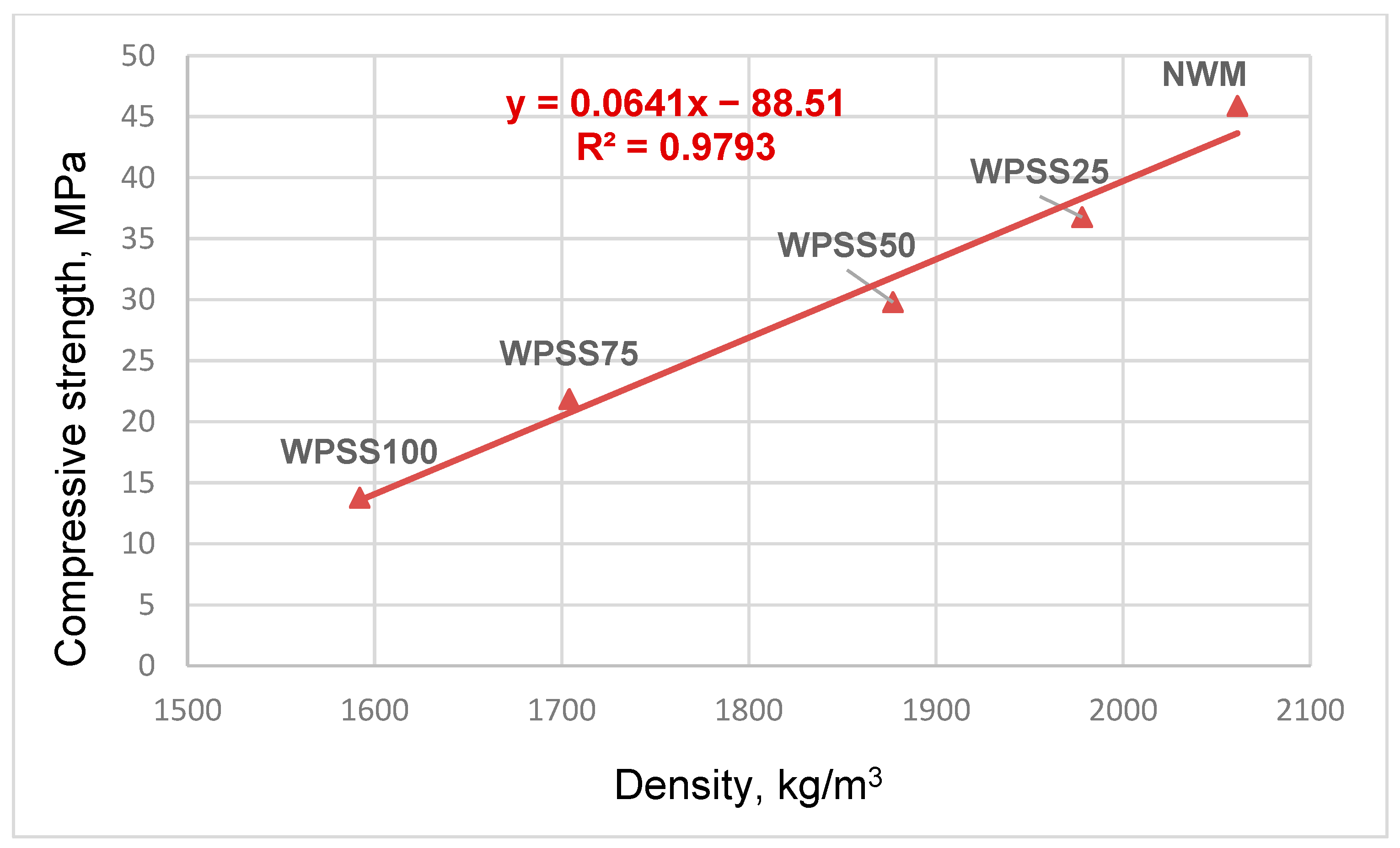

- The incorporation of 25, 50, 75 and 100% of LSS reduced the compressive strength of WPSS25, WPSS50, WPSS75 and WPSS100 mortars by 20, 35, 52 and 70%, respectively, compared with that of the NWM control mortar. This could be useful when these eco-composites are used in applications requiring low strengths, such as paving stones or sidewalk borders.

- At lower replacement levels (≤25% WPSS), the composite maintains approximately 80% of reference mechanical strength while achieving modest thermal improvements, making it particularly suitable for structural applications where load-bearing capacity remains critical.

- Adding LSS significantly decreases UPV, with reductions from 8% to 39% as its content increases from 25% to 100%. Notably, the WPSS25 composite mortar meets the UPV criteria for structural applications.

- LSS aggregates incorporated into WPSS100 composite mortars slightly increased the ductility but reduced the dynamic modulus of elasticity (Ed) by 18%, 36%, 58% and 69% for the mixtures containing 25%, 50%, 75% and 100% LSS, respectively, compared with that of NWM. These mortars can therefore be used to produce more flexible and more resistant eco-cementitious materials.

- The thermal performance of WPSS composites was improved. Indeed, the thermal conductivity of WPSS25, WPSS50, WPSS75, and WPSS100 mixtures was improved by 4%, 8%, 14%, and 18%, respectively, compared with that of NWM. This result encourages us to apply this type of synthesized aggregate LSS in thermal insulation materials due to its energy performance.

- The measured sorptivity coefficient decreased progressively with increasing WPSS content. Compared with NWM, the sorptivity was reduced by approximately 22%, 38%, 43%, and 46% for WPSS 50, WPSS 75, and WPSS 100, respectively. Therefore, the incorporation of LSS can be considered more durable, with enhanced resistance to water penetration, making it suitable for use in eco-efficient cement-based materials.

- The eco-friendly composite mortars are not susceptible to alkali–silica reaction, which confirms their potential to improve the durability of structures. This feature offers a promising solution to prevent problems related to the reactivity of aggregates.

- This study represents an important contribution to the field of recycling plastic waste as aggregates to be used in mortar and concrete. It has provided valuable information on various potential applications of the composite aggregates in clean green buildings.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hees, T.; Zhong, F.; Stürzel, M.; Mülhaupt, R. Tailoring hydrocarbon polymers and all-hydrocarbon composites for circular economy. Macromol. Rapid Commun. 2019, 40, 1800608. [Google Scholar] [CrossRef] [PubMed]

- Hachemi, H.; Seladji, C.; Negadi, L.; Bhandari, R.; Aryal, S.; Sacko, B.D.D. Improving municipal solid waste management in Algeria and exploring energy recovery options. Renew. Energy 2024, 230, 120861. [Google Scholar] [CrossRef]

- A.N.D. Available online: https://and.dz/caracterisation-des-dechets-menagers-et-assimiles-campagne-nationale-2018-2019/ (accessed on 1 June 2025).

- Pacheco-Torgal, F.; Khatib, J.; Colangelo, F.; Tuladhar, R. Use of Recycled Plastics in Eco-Efficient Concrete; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M.; Alaskar, A. Use of recycled plastic as fine aggregate in cementitious composites: A review. Constr. Build. Mater. 2020, 253, 119146. [Google Scholar] [CrossRef]

- Abeysinghe, S.; Gunasekara, C.; Bandara, C.; Nguyen, K.; Dissanayake, R.; Mendis, P. Engineering performance of concrete incorporated with recycled high-density polyethylene (HDPE)—A systematic review. Polymers 2021, 13, 1885. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Šavija, B.; Paul, S.C.; Anggraini, V. Engineering properties of concrete with waste recycled plastic: A review. Sustainability 2018, 10, 3875. [Google Scholar] [CrossRef]

- ACI 213R, Guide for Structural Lightweight Aggregate Concrete; American Concrete Institute Committee 213R: Farmington Hills, MI, USA, 2014.

- Abduallah, R.; Burris, L.; Castro, J.; Sezen, H. Utilization of Different Types of Plastics in Concrete Mixtures. Constr. Mater. 2025, 5, 39. [Google Scholar] [CrossRef]

- Alkhrissat, T. Impact of adding waste polyethylene (PE) and silica fume (SF) on the engineering properties of cement mortar. Case Stud. Chem. Environ. Eng. 2024, 9, 100731. [Google Scholar] [CrossRef]

- Benosman, A.S.; Taibi, H.; Mouli, M.; Senhadji, Y.; Belbachir, M.; Bahlouli, I.; Houivet, D. Effect of addition of PET on the mechanical performance of PET-Mortar Composite materials. J. Mater. Environ. Sci. 2015, 6, 559–571. [Google Scholar]

- Caniato, M.; Cozzarini, L.; Schmid, C.; Gasparella, A. Acoustic and thermal characterization of a novel sustainable material incorporating recycled microplastic waste. Sustain. Mater. Technol. 2021, 28, e00274. [Google Scholar] [CrossRef]

- Hacini, M.; Benosman, A.S.; Tani, N.K.; Mouli, M.; Senhadji, Y.; Badache, A.; Latroch, N. Utilization and assessment of recycled polyethylene terephthalate strapping bands as lightweight aggregates in Eco-efficient composite mortars. Constr. Build. Mater. 2021, 270, 121427. [Google Scholar] [CrossRef]

- Kaur, G.; Pavia, S. Physical properties and microstructure of plastic aggregate mortars made with acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), polyoxymethylene (POM) and ABS/PC blend waste. J. Build. Eng. 2020, 31, 101341. [Google Scholar] [CrossRef]

- Latroch, N.; Benosman, A.S.; Bouhamou, N.; Senhadji, Y.; Mouli, M.; Badache, A. Effect of High Temperature on Composite Mortars Containing Hazardous Expanded Polyvinyl Chloride Waste. J. Hazard. Toxic Radioact. Waste 2021, 25, 04021011. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R.J. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Mouzoun, K.; Bouyahyaoui, A.; Abdelali, H.M.; Cherradi, T.; Baba, K.; Masrour, I.; Zemed, N. Comparative assessment of PVC waste and natural sand in concrete and mortar: Structural, environmental, and economic implications. Eur. J. Environ. Civ. Eng. 2025, 1–29. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Sambucci, M.; Chougan, M.; El-Seidy, E.; Biblioteca, I.; Valente, M.; Tirillò, J.; Al-Kheetan, M.J.; Ghaffar, S.H. Sustainable repurposing of polyvinyl chloride waste as aggregates in limestone-calcined clay cement. J. Clean. Prod. 2025, 491, 144862. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Study of the suitability of unfired clay bricks with polymeric HDPE & PET wastes additives as a construction material. J. Build. Eng. 2020, 27, 100956. [Google Scholar] [CrossRef]

- Del Rey Castillo, E.; Almesfer, N.; Saggi, O.; Ingham, J.M. Light-weight concrete with artificial aggregate manufactured from plastic waste. Constr. Build. Mater. 2020, 265, 120199. [Google Scholar] [CrossRef]

- Ikechukwu, A.F.; Shabangu, C. Strength and durability performance of masonry bricks produced with crushed glass and melted PET plastics. Case Stud. Constr. Mater. 2021, 14, e00542. [Google Scholar] [CrossRef]

- Aneke, F.I.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar] [CrossRef]

- Webo, W.; Khoathane, M.C.; Mhike, W.; Mohlamonyane, R.S. Enhancing sustainability: Composite materials from recycled HDPE and denim fillers. Polym. Eng. Sci. 2025, 65, 2395–2404. [Google Scholar] [CrossRef]

- Alahmad, F.; Al Abdallah, H.; El Maaddawy, T.; Abu-Jdayil, B. Development of Unsaturated Polyester Mortar Made with Dune Sand as a Sustainable Alternative in Construction. Results Eng. 2025, 25, 104335. [Google Scholar] [CrossRef]

- Babatunde, Y.; Mwero, J.; Mutuku, R.; Jimoh, Y.; Oguntayo, D. Influence of material composition on the morphology and engineering properties of waste plastic binder composite for construction purposes. Heliyon 2022, 8, e11207. [Google Scholar] [CrossRef] [PubMed]

- Nuruzzaman, M.; Shathi, A.S.; Yousuf, A.; Islam, J.; Rana, S.; Alam, S.; Biswas, P.K.; Rahman, A.; Mondal, I.H. Composite materials from waste plastics: A sustainable approach for waste management and resource utilization. Polym. Polym. Compos. 2025, 33, 09673911251318542. [Google Scholar] [CrossRef]

- Vinod Kumar, R.; Kumar, D.R. Innovative Utilization of HDPE-Plastic Aggregates in Concrete: Fresh and Mechanical Properties. In Proceedings of the ICCESP, Trivandrum, India, 6–8 December 2024; pp. 13–22. [Google Scholar] [CrossRef]

- Vinod Kumar, R.; Kumar, D.R. Durability Properties of Concrete with HDPE-Plastic Aggregate. In Proceedings of the ICCESP, Trivandrum, India, 6–8 December 2024; pp. 1–12. [Google Scholar] [CrossRef]

- Kashi, M.; Swan, C.W.; Holmstrom, O.; Malloy, R.A. Innovative lightweight synthetic aggregates developed from coal Flyash. In Proceedings of the 13th International Symposium on Use and Management of Coal Combustion Products (CCPs), Orlando, FL, USA, 11–15 January 1999. [Google Scholar]

- Jansen, D.C.; Kiggins, M.L.; Swan, C.W.; Malloy, R.A.; Kashi, M.G.; Chan, R.A.; Javdekar, C.; Siegal, C.; Weingram, J. Lightweight fly ash-plastic aggregates in concrete. Transp. Res. Rec. 2001, 1775, 44–52. [Google Scholar] [CrossRef]

- Binici, H.; Gemci, R.; Kaplan, H. Physical and mechanical properties of mortars without cement. Constr. Build. Mater. 2012, 28, 357–361. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.J.; Chung, J.S.; Cho, S.K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Kim, Y.J.; Lachemi, M. Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles. Constr. Build. Mater. 2009, 23, 2829–2835. [Google Scholar] [CrossRef]

- Mohandesi, J.A.; Refahi, A.; Sadeghi Meresht, E.; Berenji, S. Effect of temperature and particle weight fraction on mechanical and micromechanical properties of sand-polyethylene terephthalate composites: A laboratory and discrete element method study. Compos. Part B Eng. 2011, 42, 1461–1467. [Google Scholar] [CrossRef]

- Gouasmi, M.T.; Benosman, A.S.; Hamed, T. Development of materials based on PET-siliceous sand composite aggregates. J. Build. Mater. Struct. 2018, 4, 58–67. [Google Scholar] [CrossRef]

- Bouaziz, S.; Tahar, K.A. Behavior of the Composite Lightweight Concrete. Appl. Mech. Mater. 2012, 146, 39–50. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Ghataora, G.; Khan, M.I.; Dirar, S. Novel lightweight concrete containing manufactured plastic aggregate. Constr. Build. Mater. 2017, 148, 386–397. [Google Scholar] [CrossRef]

- Liu, P.; Farzana, R.; Rajarao, R.; Sahajwalla, V. Lightweight expanded aggregates from the mixture of waste automotive plastics and clay. Constr. Build. Mater. 2017, 145, 283–291. [Google Scholar] [CrossRef]

- Ennahal, I.; Maherzi, W.; Benzerzour, M.; Mamindy, Y.; Abriak, N.-E. Performance of Lightweight Aggregates Comprised of Sediments and Thermoplastic Waste. Waste Biomass Valorization 2021, 12, 515–530. [Google Scholar] [CrossRef]

- Górak, P.; Postawa, P.; Trusilewicz, L.N.; Łagosz, A. Lightweight PET based composite aggregates in Portland cement materials-Microstructure and physicochemical performance. J. Build. Eng. 2021, 34, 101882. [Google Scholar] [CrossRef]

- Erdogmus, E.; Sutcu, M.; Gencel, O.; Kazmi, S.M.S.; Munir, M.J.; Velasco, P.M.; Ozbakkaloglu, T. Enhancing thermal efficiency and durability of sintered clay bricks through incorporation of polymeric waste materials. J. Clean. Prod. 2023, 420, 138456. [Google Scholar] [CrossRef]

- Owen, M.M.; Wong, L.S.; Achukwu, E.O.; Saharudin, M.S.; Akil, H.M. Enhanced mechanical, thermal, and morphological properties of waste PET plastics reinforced with coated biodegradable kenaf fibers for infrastructure applications. Constr. Build. Mater. 2024, 442, 137659. [Google Scholar] [CrossRef]

- Sau, D.; Shiuly, A.; Hazra, T. Utilization of plastic waste as replacement of natural aggregates in sustainable concrete: Effects on mechanical and durability properties. Int. J. Environ. Sci. Technol. 2024, 21, 2085–2120. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Khan, M.I.; Ghataora, G.; Dirar, S. Production of recycled plastic aggregates and its utilization in concrete. J. Mater. Civ. Eng. 2017, 29, 04016248. [Google Scholar] [CrossRef]

- Gouasmi, M.; Benosman, A.; Taïbi, H. Improving the properties of waste plastic lightweight aggregates-based composite mortars in an experimental saline environment. Asian J. Civ. Eng. 2019, 20, 71–85. [Google Scholar] [CrossRef]

- EN 196-1:2005; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 459-2; Building Lime–Part 2: Test Methods. European Committee for Standardization: Brussels, Belgium, 2002.

- NF P18-459; Béton–Essai Pour Béton Durci–Essai De Porosité Et De Masse Volumique. Association Française de Normalisation: Paris, France, 2010.

- ASTM C597-09; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. J. Clean. Prod. 2016, 112, 702–711. [Google Scholar] [CrossRef]

- ASTM D5334; Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM C1260; Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method), ASTM Standards in Building Codes. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- C1585-13, A; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic—Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013.

- Senthil Kumar, K.; Baskar, K. Development of ecofriendly concrete incorporating recycled high-impact polystyrene from hazardous electronic waste. J. Hazard. Toxic Radioact. Waste 2015, 19, 04014042. [Google Scholar] [CrossRef]

- Ge, Z.; Huang, D.; Sun, R.; Gao, Z. Properties of plastic mortar made with recycled polyethylene terephthalate. Constr. Build. Mater. 2014, 73, 682–687. [Google Scholar] [CrossRef]

- Gouasmi, M.; Benosman, A.S.; Taïbi, H.; Kazi Tani, N.; Belbachir, M. Destructive and Non-destructive testing of an industrial screed mortar made with lightweight composite aggregates WPLA. Int. J. Eng. Res. Afr. 2017, 33, 140–158. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Jayasinghe, R.R.; Herath, G.P.; Abeyrathna, W.P.; Hendawitharana, M.P.; Liyanage, C.; Williams, K.; Halwatura, R.U. Strength Properties of Recycled Waste Plastic and Quarry Dust as Substitute to Coarse Aggregates: An Experimental Methodology. Mater. Circ. Econ. 2023, 5, 5. [Google Scholar] [CrossRef]

- Badache, A.; Benosman, A.S.; Senhadji, Y.; Mouli, M. Thermo-physical and mechanical characteristics of sand-based lightweight composite mortars with recycled high-density polyethylene (HDPE). Constr. Build. Mater. 2018, 163, 40–52. [Google Scholar] [CrossRef]

- Shariq, M.; Prasad, J.; Masood, A. Studies in ultrasonic pulse velocity of concrete containing GGBFS. Constr. Build. Mater. 2013, 40, 944–950. [Google Scholar] [CrossRef]

- Azhdarpour, A.M.; Nikoudel, M.R.; Taheri, M. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete; a laboratory evaluation. Constr. Build. Mater. 2016, 109, 55–62. [Google Scholar] [CrossRef]

- Senhadji, Y.; Escadeillas, G.; Benosman, A.S.; Mouli, M.; Khelafi, H.; Ould Kaci, S. Effect of incorporating PVC waste as aggregate on the physical, mechanical, and chloride ion penetration behavior of concrete. J. Adhes. Sci. Technol. 2015, 29, 625–640. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Akçaözoğlu, K.; Atiş, C.D. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. Part B Eng. 2013, 45, 721–726. [Google Scholar] [CrossRef]

- IS 13311-1; Indian Standard, Method of Non-Destructive Testing of Concrete–Methods of Test, Part 1: Ultrasonic Pulse Velocity [CED 2: Cement and Concrete]. Bureau of Indian Standards: New Delhi, India, 1992.

- Guo, Y.-C.; Li, X.-M.; Zhang, J.; Lin, J.-X. A review on the influence of recycled plastic aggregate on the engineering properties of concrete. J. Build. Eng. 2023, 79, 107787. [Google Scholar] [CrossRef]

- Wang, R.; Meyer, C. Performance of cement mortar made with recycled high impact polystyrene. Cem. Concr. Compos. 2012, 34, 975–981. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.; Allahyari, H.; Nikbin, I. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Benosman, A.S.; Taïbi, H.; Senhadji, Y.; Mouli, M.; Belbachir, M.; Bahlouli, M. Plastic waste particles in mortar composites: Sulfate resistance and thermal coefficients. Prog. Rubber Plast. Recycl. Technol. 2017, 33, 171–202. [Google Scholar] [CrossRef]

- Ahrens, J.T. Rock Physics & Phase Relation: A Handbook of Physical Constant; American Geophysical Union: Washington, DC, USA, 1995; p. 240. [Google Scholar]

- Hannawi, K.; Prince, W.; Kamali-Bernard, S. Effect of thermoplastic aggregates incorporation on physical, mechanical and transfer behaviour of cementitious materials. Waste Biomass Valorization 2010, 1, 251–259. [Google Scholar] [CrossRef]

- Boudenne, A. Etude Expérimentale et Théorique des Propriétés Thermophysiques de Matériaux Composites à Matrice Polymère. Ph.D. Thesis, Université de Paris 12, Paris, France, 2003. [Google Scholar]

- Gouasmi, M.; Benosman, A.; Taïbi, H.; Belbachir, M.; Senhadji, Y. Les Propriétés physico-thermiques des mortiers à base des agrégats composites «PET-sable siliceux». J. Mater. Environ. Sci. 2016, 7, 409–415. [Google Scholar]

- Alqahtani, F.K.; Zafar, I. Characterization of processed lightweight aggregate and its effect on physical properties of concrete. Constr. Build. Mater. 2020, 230, 116992. [Google Scholar] [CrossRef]

- Rilem, L. Functional classification of lightweight concrete. Mater. Struct. 1978, 11, e283. [Google Scholar]

- Mounanga, P.; Turcry, P.; Poullain, P. Effets thermique et mécanique de l’incorporation de déchets de mousse de polyuréthane dans un mortier. In Proceedings of the XXIVèmes Rencontres Universitaires de Génie Civil, Construire, Un Nouveau Défi, La Grande Motte, France, 1–2 June 2006. [Google Scholar]

- Aattache, A.; Mahi, A.; Soltani, R.; Mouli, M.; Benosman, A.S. Experimental study on thermo-mechanical properties of Polymer Modified Mortar. Mater. Des. 2013, 52, 459–469. [Google Scholar] [CrossRef]

- Latroch, N.; Benosman, A.S.; Bouhamou, N.-E.; Senhadji, Y.; Mouli, M. Physico-mechanical and thermal properties of composite mortars containing lightweight aggregates of expanded polyvinyl chloride. Constr. Build. Mater. 2018, 175, 77–87. [Google Scholar] [CrossRef]

- Swamy, R.N. The Alkali-Silica Reaction in Concrete; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar]

| Elements | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | SO3 | Na2O | PAF | Cl− | CaCO3 | CO2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 17.40 | 4.12 | 2.97 | 61.15 | 1.16 | 0.66 | 2.46 | 0.13 | 8.85 | 0.017 | - | - |

| Ss | 83.29 | 0.21 | 0.45 | 7.03 | 4.20 | - | - | - | - | - | 1.00 | |

| Sc | 11.76 | - | 0.91 | 44.35 | - | - | - | - | - | - | 59.09 | 26.00 |

| C3S | C2S | C3A | C4AF |

|---|---|---|---|

| 64.00 | 15.00 | 8.00 | 12.16 |

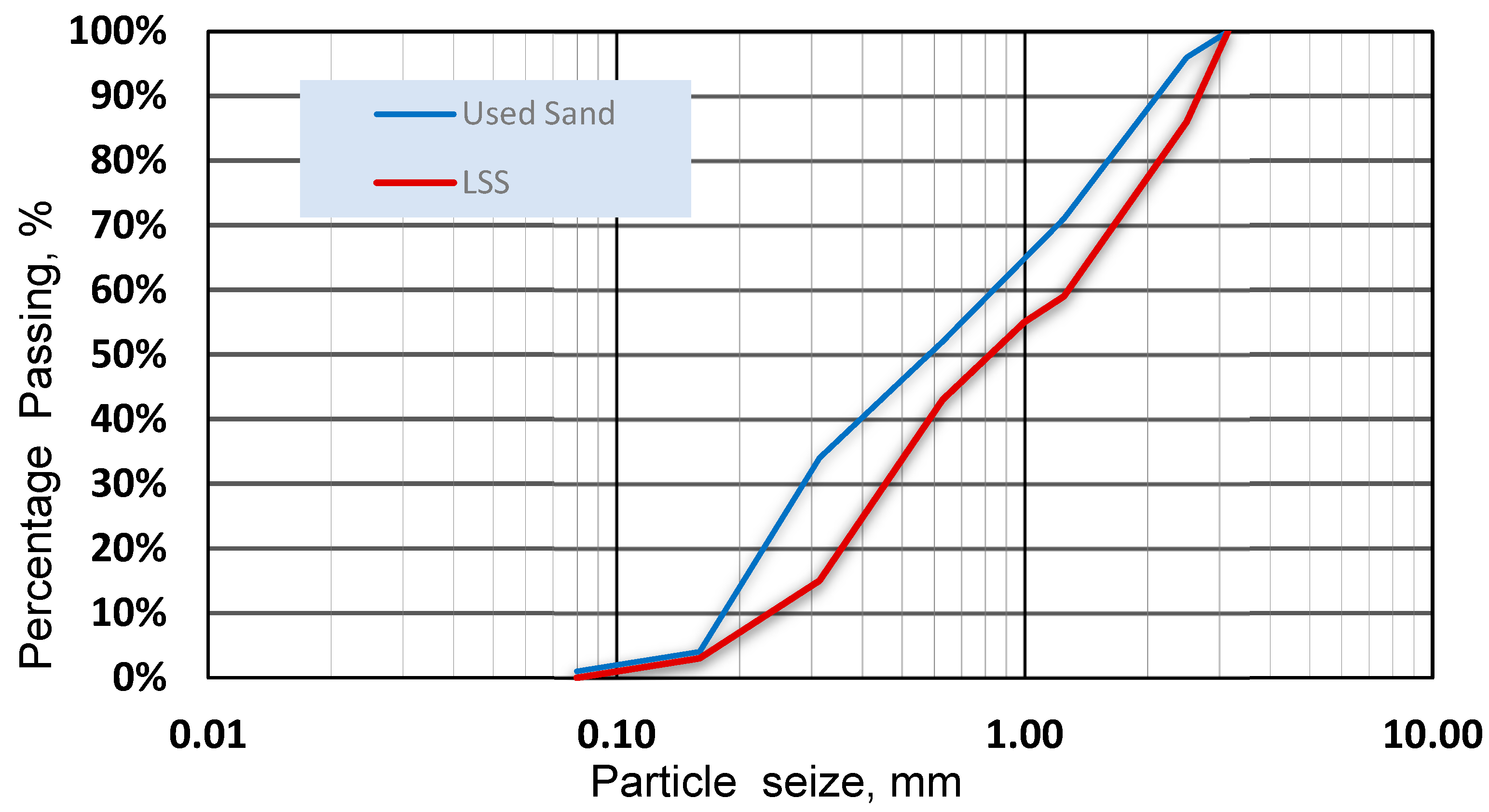

| Physical Properties | Natural Sand | LSS |

|---|---|---|

| Shape | Angular | Angular |

| Absolute density (g/cm3) | 2.630 | 1.68 |

| Apparent density (g/cm3) | 1.460 | 1.020 |

| Equivalent of sand «%» | 77.00 | - |

| Fineness modulus «FM» | 2.42 | 2.93 |

| Absorption coefficient (%) | 0.56 | 0.04 |

| Coefficient of curvature «Cc» | 0.55 | 0.60 |

| Coefficient of uniformity «Cu» | 4.72 | 5.83 |

| Thermal conductivity «k» (W/m·K) | - | 0.589 |

| Composites | LSS/S (%) * | Sand Mix(g) | Admixture (% Binder) ** | Cement (g) | Water | w/b *** | Spreading (%) | ||

|---|---|---|---|---|---|---|---|---|---|

| LSS (g) | Sand (g) | Total Aggregate (g) | |||||||

| NWM | 0 | 0.0 | 1350.0 | 1350.0 | 0.90 | 450 | 225 | 0.5 | 70 |

| WPSS25 | 25 | 235.8 | 1012.5 | 1248.3 | 0.50 | 450 | 225 | 0.5 | 74 |

| WPSS50 | 50 | 471.6 | 675.0 | 1146.6 | 0.40 | 450 | 225 | 0.5 | 73 |

| WPSS75 | 75 | 707.4 | 337.5 | 1044.9 | 0.35 | 450 | 225 | 0.5 | 80 |

| WPSS100 | 100 | 943.2 | 0.0 | 943.2 | 0.30 | 450 | 225 | 0.5 | 69 |

| Properties | Correlation Equation | Correlation Coeff. |

|---|---|---|

| Cs (MPa)–UPV (m/s) | Y = 0.0522x + 1.7967 | R2 = 0.9878 |

| UPV (m/s)–density (g/cm3) | Y = 0.2935x + 0.8611 | R2 = 0.9978 |

| Ed (GPa)–Cs (MPa) | Y = 11.954x + 2.9406 | R2 = 0.9897 |

| λ (W/m·K)–density (g/cm3) | Y = 0.6153 + 1.2119 | R2 = 0.9953 |

| λ (W/m·K)–UPV (m/s) | Y = 2.0971 + 1.1941 | R2 = 0.9984 |

| Fs (MPa)–Cs (MPa) | Y = 19.408 + 4.2017 | R2 = 0.9612 |

| Cs (MPa)–density (g/cm3) | Y = 0.0153 + 1.3899 | R2 = 0.9793 |

| λ (W/m·K)–porosity (%) | Y = 29.056x2 − 68.331x + 57.257 | R2 = 0.9434 |

| Cs (MPa)–porosity (%) | Y = 0.167x2 − 1.2285x + 39.65 | R2 = 0.9697 |

| Porosity (%)–sorptivity (cm/s−0.5) | Y = 0.0885x−3.5695x + 52.63 | R2 = 0.7523 |

| Density (g/cm3)–porosity% | Y = 7.6061x2−379.97 + 6322.2 | R2 = 0.7738 |

| Sorptivity (cm/s−0.5)–density (g/cm3) | Y = 1 × 10−9X3.0826 | R2 = 0.8868 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badache, A.; Latroch, N.; Hacini, M.; Benosman, A.S.; Mouli, M.; Senhadji, Y.; Maherzi, W. Innovative Composite Aggregates from Thermoplastic Waste for Circular Economy Mortars. Constr. Mater. 2025, 5, 58. https://doi.org/10.3390/constrmater5030058

Badache A, Latroch N, Hacini M, Benosman AS, Mouli M, Senhadji Y, Maherzi W. Innovative Composite Aggregates from Thermoplastic Waste for Circular Economy Mortars. Construction Materials. 2025; 5(3):58. https://doi.org/10.3390/constrmater5030058

Chicago/Turabian StyleBadache, Abdelhak, Noureddine Latroch, Mostefa Hacini, Ahmed Soufiane Benosman, Mohamed Mouli, Yassine Senhadji, and Walid Maherzi. 2025. "Innovative Composite Aggregates from Thermoplastic Waste for Circular Economy Mortars" Construction Materials 5, no. 3: 58. https://doi.org/10.3390/constrmater5030058

APA StyleBadache, A., Latroch, N., Hacini, M., Benosman, A. S., Mouli, M., Senhadji, Y., & Maherzi, W. (2025). Innovative Composite Aggregates from Thermoplastic Waste for Circular Economy Mortars. Construction Materials, 5(3), 58. https://doi.org/10.3390/constrmater5030058