1. Introduction

With the rising need for environmentally sustainable construction, it is increasingly important to feature sustainable materials such as fly ash, blast-furnace slag, recycled aggregates, and seawater in concrete mixes. These materials not only reduce the environmental impact of concrete production but also improve its mechanical properties when properly optimized. However, traditional experimental methods for determining the compressive strength of these mixes are time-consuming and resource-intensive. While Artificial Neural Networks (ANNs) have been widely applied in predicting concrete mixture strength, no studies have utilized ANNs to analyze the impact of seawater in concrete mixes. This study aims to develop an ANN model to predict the compressive strength of sustainable concrete, incorporating seawater and other sustainable materials. It utilizes a database of 768 records; the first 749 records are a subset of a larger dataset created in Ref. [

1], each representing a unique concrete mix design with varying proportions of sustainable materials. The subset was selected to include only concrete specimens aged 28 days or less. The last 19 records (representing a limited number of samples) correspond to seawater-based mixtures derived from the experimental data in Ref. [

2]. While we acknowledge that this is a small sample size, it is nonetheless interesting to examine whether the ANN model can extract meaningful patterns from it during the learning process. All of the specimen sizes and shapes were normalized to cylinders having a 15 cm diameter.

The input variables for the model included concrete age as well as key mix parameters such as cement, fresh- and seawater, coarse and fine aggregates, fly ash, blast-furnace slag, and superplasticizer contents. The output variable is the compressive strength of the concrete mixture. By leveraging the ability of ANNs to capture non-linear relationships between these variables, this study aims to provide a more efficient and accurate approach to predicting compressive strength, reducing reliance on time-consuming and resource-intensive experimental methods.

Traditional methods for estimating concrete compressive strength, such as empirical equations and regression-based models, often fall short in capturing the non-linear and multivariate interactions present in sustainable concrete mix designs. These approaches typically rely on extensive experimental testing and fixed assumptions, which can limit their adaptability to mixes involving alternative materials like seawater, fly ash, or blast-furnace slag. In contrast, machine learning methods, particularly ANNs, offer a powerful alternative capable of modeling complex relationships without predefined assumptions.

In addition, laboratory compressive strength testing is not only time-consuming and costly but is also limited in its scalability, making it less practical for evaluating numerous sustainable mix designs in a timely manner.

This paper starts by providing the context and defining the significance of the research in

Section 2. Then, a literature overview of recent applications of machine learning in the field of concrete research is presented in

Section 3 and

Section 4, followed by a detailed explanation of the dataset and methodology used to build the predictive ANN model in

Section 5. The development process, model architecture, and training approach are then described in

Section 6. Useful information on the dataset utilized in this work is provided in

Section 7, while a comparison of ANN results to traditional regression methods and to a Random Forest algorithm is provided in

Section 8. Finally, the paper provides key findings and recommendations for future studies in sustainable concrete modeling.

2. Research Significance

Cement serves as the primary binding material in concrete mixtures, initiating the hydration process when combined with water. Water not only activates the cement but also improves the workability of the mix. While fine aggregates fill the voids between larger particles and improve the general cohesiveness of the mix, coarse aggregates provide structural strength and dimensional stability. The growing emphasis on sustainable construction practices has driven interest in alternative materials Refs. [

3,

4,

5]. Supplementary cementitious materials like blast-furnace slag and fly ash are incorporated to enhance long-term strength, reduce permeability, and improve resistance to chemical attacks, while also contributing to sustainability by recycling industrial by-products. Blast-furnace slag is a non-metallic residue of the iron-making process formed during iron melting. Cement slag is made from iron blast-furnace slag and is composed mainly of silicates and aluminosilicates of calcium, providing hydraulic properties that contribute to the strength gain of concrete Ref. [

6]. Fly ash, on the other hand, is a residue of the combustion of pulverized coal in electric power plants, consisting of silica, iron, and calcium Ref. [

6].

Moreover, seawater can be used as a partial substitute for freshwater in regions facing water shortages. However, its application requires careful assessment due to the risk of chloride-induced corrosion that leads to durability issues and structural degradation in reinforced concrete structures Ref. [

7], a drawback that is not present when using freshwater. In fact, seawater contains high concentrations of dissolved salts (e.g., sodium chloride and magnesium sulfate), which can lead to cracking, spalling, and structural deterioration over time Ref. [

8]. Studying and modelling the inclusion of seawater in concrete mixtures is relevant due to its sustainability benefits as well as the need to understand and mitigate its potential risks.

Finally, superplasticizers are added to increase the workability of the mix without increasing the water content, allowing for high-performance concrete Ref. [

6].

Although ANNs have been widely applied for concrete strength prediction, their application to a seawater-integrated concrete mixture remains underexplored in the literature. This study distinguishes itself by applying ML and ANN modeling to a dataset of concrete mixes containing seawater, fly ash, and slag, a novel approach in sustainable construction research, addressing a key gap in the literature regarding an area that is still underexplored.

By leveraging a dataset of 768 proven experimental records, the proposed model advances the current state of the art by eliminating the need to wait up to 28 days for standard concrete testing, thus enabling immediate strength estimation. It also reduces reliance on costly, time-consuming, and labor-intensive lab experiments. Furthermore, the model provides a fast, efficient, and eco-friendly alternative for evaluating concrete performance. These findings contribute to the broader field of material and structural engineering by enhancing data-driven approaches to material optimization, ultimately supporting the development of more environmentally responsible construction solutions.

3. Literature Review

In recent years, the use of machine learning techniques has gained significant traction in civil engineering, offering innovative solutions to complex challenges related to material behavior, structural performance, and construction processes. A formative paper Ref. [

9] introduced a novel approach to material modeling by employing neural networks to capture complex behaviors directly from experimental data. This method enabled neural networks to “learn” the intricate relationships between stresses and strains, providing a unified framework for representing material behavior beyond the limitations of traditional mathematical models. More recently, a comprehensive review Ref. [

10] synthesized recent advancements in AI for civil engineering applications, including strength modeling, optimization, and real-time decision-making. In parallel, other studies Ref. [

11] have applied advanced ensemble deep convolutional neural networks for structural damage identification, paving the way for similar models in concrete property prediction. The work of Ref. [

12], which developed an AI-powered graphical user interface (GUI) to predict the axial capacity of concrete-filled steel tube columns, further illustrates the growing trend toward integrating user-friendly machine learning tools in structural engineering practice. Finally, Ref. [

13] confirmed the effectiveness of ANNs in predicting the elastic modulus of recycled aggregate concrete mixes.

Over the years, extensive research has focused on improving methods to predict the compressive strength of concrete mixtures in particular, which is a critical factor in construction engineering Ref. [

14]. While traditional techniques have been widely used, they often fall short in capturing the intricate interactions among variables. Recent advancements in Machine Learning (ML), particularly Artificial Neural Networks (ANNs), have introduced a promising alternative.

Refs. [

15,

16] demonstrated the effectiveness of ML models in predicting the 28-day compressive strength of concrete mixes, while Ref. [

17] utilized computer-generated mix design data to train an ANN model for predicting 28-day compressive strength. Other studies have demonstrated the capability of Artificial Neural Networks (ANNs) to accurately predict the compressive strength of different concrete types, such as self-compacting concrete Refs. [

18,

19], high-performance concrete (HPC) Refs. [

20,

21], and recycled aggregate concrete Ref. [

13].

In addition, Ref. [

22] confirmed the effectiveness of ANNs in predicting the mechanical properties of concrete incorporating waste foundry sand, offering valuable insights for advancing sustainable construction practices. Furthermore, the ability of ANNs to capture non-linear relationships in complex mix designs was demonstrated by Refs. [

22,

23]. Moreover, Ref. [

24] demonstrated the effectiveness of ANNs in predicting the compressive strength of fly ash concrete, while Ref. [

25] applied ANNs to model the strength of concrete containing ground granulated blast-furnace slag (GGBFS).

Similarly, Ref. [

26] explored ANN-based predictive modeling using a diverse dataset gathered from literature, historical records, and industry sources. The authors further compared ML techniques, noting that while linear and ridge regression provided accurate predictions, lasso regression simplified the model at the cost of slight performance degradation. The study highlighted how machine learning, particularly ANNs, can enhance concrete mix design, optimize material use, and reduce reliance on conventional testing methods.

Recent developments in soft computing and deep learning have further advanced the strength prediction of special concrete mixes. For example, Ref. [

27] applied deep learning to predict the compressive strength of CFRP-confined concrete, achieving high accuracy and outperforming conventional models. Similarly, Ref. [

28] utilized knowledge-aided machine learning techniques to map the strength of agro-ecological lightweight concrete made from oil palm by-products, illustrating how localized materials can be accurately modeled using several AI-driven methods.

Alternatively, hybrid models combining ANNs with Genetic Algorithms and optimization algorithms have also shown significant promise in handling complex, non-linear relationships Refs. [

23,

29]. For example, Ref. [

23] developed a hybrid ANN model combined with multi-objective grey wolf optimization to predict the compressive strength of silica fume concrete, achieving high accuracy. Similarly, Ref. [

30] compared the performance of ANNs with other predictive models, such as regression and an adaptive neuro-fuzzy inference system (ANFIS), in predicting the compressive strength of no-slump concrete, further demonstrating the versatility of ANNs in handling diverse concrete mix designs.

While numerous studies have applied Artificial Neural Networks (ANNs) to predict concrete properties, only a few have examined concrete mixes in which seawater is used as a replacement for freshwater. This study contributes to filling that gap by analyzing a dataset that includes seawater-mixed concrete, thus offering new insights into the performance of sustainable mixes under such conditions.

4. Comparative Overview of Soft Computing Techniques in Concrete Strength Prediction

The previous section has demonstrated the growing role of soft computing techniques in predicting concrete mixtures’ compressive strength, including ANNs, Support Vector Machines (SVM), Genetic Programming (GP), and Ensemble Learning.

Table 1 provides a summary of previous studies outlining the model type, number of records, input parameters, and the range of compressive strength predicted. This overview highlights the breadth of current machine learning applications in civil engineering and positions the present study.

Among the various soft computing methods explored in the literature, ANNs were selected for this work due to their proven effectiveness and suitability for extensive customization (number of layers, number of neurons, and various activation functions), making them ideal for modeling the complex interactions of variables such as seawater, fly ash, and blast-furnace slag in concrete. Their superior performance in prior concrete strength studies further reinforced their suitability for this application.

5. Methodology of This Work

5.1. Dataset

Each one of the 768 records forming this dataset represents a concrete mix with specific proportions of coarse aggregate, fine aggregate, seawater, water, blast-furnace slag, fly ash, superplasticizer, and cement contents. The data were collected from multiple sources, based on experimental tests. The range of input variables and the output are listed in

Table 2.

5.2. Data Preprocessing and Justification for ANN Use

To ensure model reliability and reproducibility, several preprocessing steps were applied to the dataset prior to training. The data were first inspected for missing values, and any incomplete records were excluded to maintain consistency across all input variables.

All input features were then normalized using Min–Max scaling to a [0, 1] range to improve model convergence and stability. This step is essential in ANN training as it prevents features with large numerical ranges from dominating the learning process.

Additionally, the dataset was shuffled randomly and split into training, validation, and testing sets (70%, 15%, and 15%) using stratified sampling to maintain distribution across compressive strength ranges.

Unlike linear models that assume additive and independent effects, ANNs use layered network structures to extract high-level patterns and interactions between multiple input variables. Prior studies Refs. [

14,

20] have demonstrated that ANNs outperform traditional models in predicting concrete strength, particularly when multiple supplementary materials are involved. Given the heterogeneous nature of sustainable concrete mixes in this work, including the use of seawater, fly ash, and slag, ANNs provide a robust and flexible modeling framework for accurate strength prediction.

6. Model Development and Hyperparameter Tuning

The ANN model was developed, trained, validated, and tested using the PyTorch 2.2.1 library developed in Python 3.10.11. The network is based on a fully-connected architecture including an input of multiple layers corresponding to the input variables, variable numbers of neurons in each, and an output layer with one neuron representing the predicted compressive strength. The model was trained using the mean absolute error (mae) loss function. To identify the optimal architecture for the ANN model, we have studied the performance of various configurations by varying the number of layers, the number of neurons per layer, and several epochs of training. Finally, two network structures, flat and horn were implemented. The flat architecture is straightforward with an equal number of neurons in each layer, while for the horn architecture, this number is divided by two for the subsequent layer until reaching the number of outputs.

Table 3 summarizes the ranges that were tested for different configurations. The model’s performance was validated using a 5-fold cross-validation approach for each ANN architecture, as shown in

Table 3.

We first started by doing ANN training in a progressive process for different values of epochs to achieve model convergence. Training and validation losses have stabilized after 100 epochs of training for all network configurations.

Figure 1 shows an example of training results for the case of a flat network having three layers and 100 neurons per layer. It is clear that losses have reached a plateau and that no more learning can be achieved.

Losses have decreased to around 15% of the starting values, which proves the ANN model has updated its weights and captured the data’s underlying patterns to predict the output equation.

The model performance depends on several key factors, mainly the number of layers and neurons. Similarly, the number of layers plays a crucial role in its ability to model complex, hierarchical, and non-linear relationships. A model with a high number of layers allows the model to learn more complex and abstract features in a step-by-step process, though careful optimization is necessary to avoid learning flaws such as over-fitting. The number of neurons in each layer further influences the ANN’s performance by expanding its feature space and allowing each layer to learn more features at the same level of abstraction. Furthermore, deeper networks (i.e., more layers) usually require more data and careful tuning to avoid overfitting issues (lack of generalization), while wider layers (i.e., more neurons) may lead to learning redundancy. Balancing the depth and width is essential for building effective and efficient ANN solutions. Increasing the number of neurons (n = 20, 40, 60, 80, 100, and 200) improves the model’s accuracy.

Among the numerous tested configurations, the best-performing model corresponds to the lowest test loss computed on the 15% of data (test set) not seen by the model during training. This criterion is relevant to make sure that the model is able to generalize correctly.

Table 4 shows the obtained values for the tested configurations that correspond to the flat architecture. The best model is achieved with a network of 200 neurons and four layers. These results highlight the importance of fine-tuning these parameters to achieve optimal ANN performance in terms of learning efficiency and accuracy.

Hyperparameter tuning plays a crucial role in optimizing the ANN’s model performance. Moreover, the model’s performance was evaluated using 5-fold cross-validation to ensure robust generalization of the prediction for each of the 18 ANN architectures studied. No information from the test set was seen by the model during training or hyperparameter tuning. The data were first randomly shuffled and then divided into two sets: test and train-validation. Cross-validation was applied exclusively on the train-validation set.

7. Dataset Availability and Reproducibility

To ensure transparency and enable independent verification, the full dataset used in this work, consisting of 768 records, can be provided upon request. The dataset includes all input variables (concrete age, cement, water, fine and coarse aggregates, seawater, fly ash, blast-furnace slag, and superplasticizer contents) along with the corresponding compressive strength values. Each sample reflects experimental data sourced from published studies or laboratory results.

Prior to model training, the dataset was reviewed for missing values and inconsistencies. Records with incomplete entries were excluded, and outliers were retained only if verified as valid experimental results. As part of preprocessing, all numerical variables were normalized using Min–Max scaling to a [0, 1] range to ensure balanced input for ANN training. Although some records show a freshwater content of 0 kg/m3, these mixes include seawater as a full or partial replacement, ensuring that all mixes contain the necessary water component for concrete hydration.

8. Model Performance Evaluation and Results

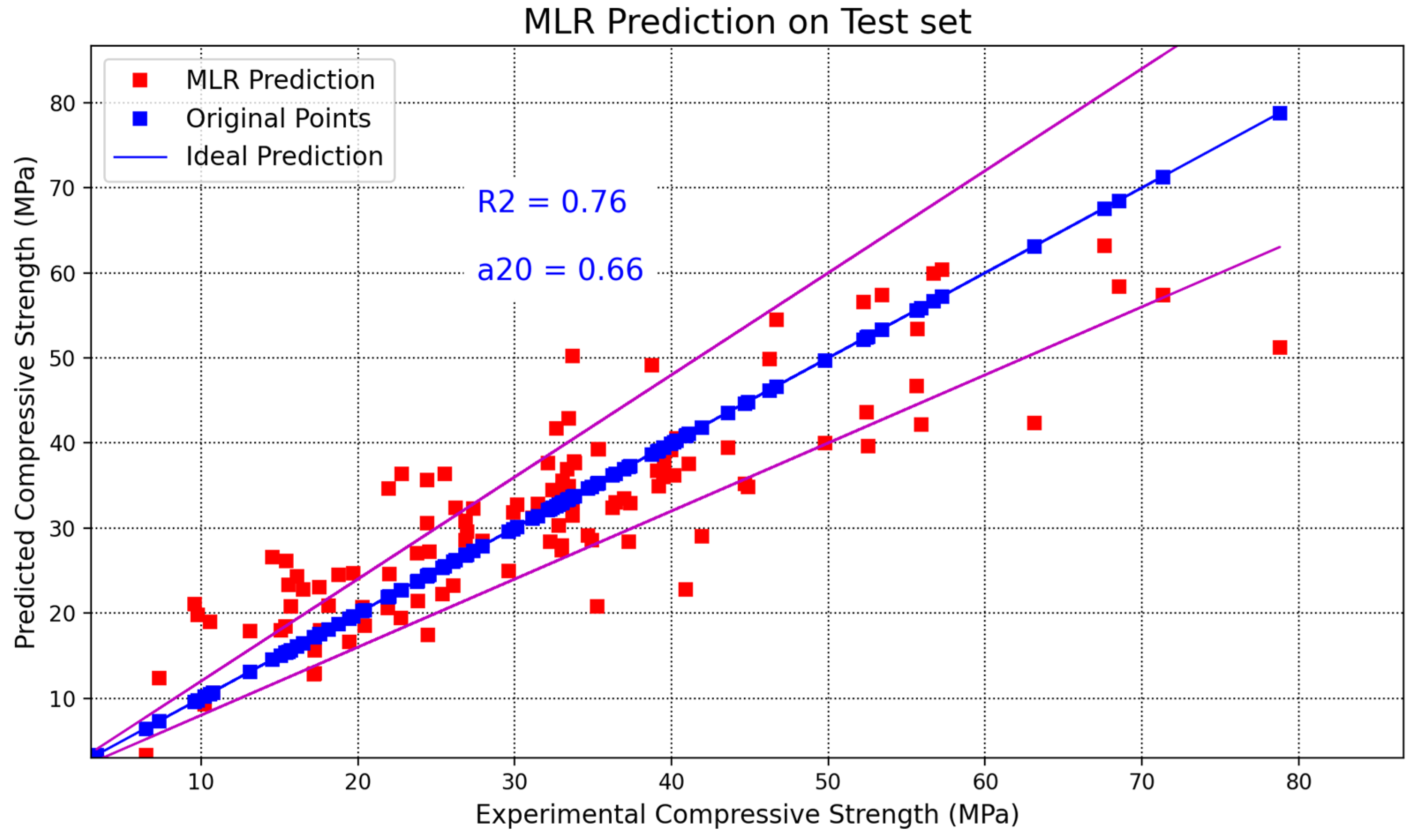

The model’s effectiveness was assessed on the data of the test set (15% of the original dataset) by comparing the true and predicted values using two key metrics: coefficient of determination (R2), and the a20 index. The a20 index quantifies the proportion of predictions that fall within ±20% of the actual values, providing an intuitive measure of model reliability in engineering applications.

To assess the effectiveness of using ML to predict the compressive strength of concrete mixtures with a trained ANN, the model’s performance is compared against existing methods. This comparison provides a well-rounded evaluation of its capabilities.

Multilinear regression is a statistical method used to model the relationship between a single dependent variable (the output) and two or more independent variables (the inputs). It assumes that the dependent variable can be expressed as a linear combination of the independent variables, each multiplied by a coefficient that represents its influence on the outcome. The coefficients are determined by minimizing the sum of the squared differences between the observed and predicted values (ordinary least squares or OLS) [

31]. A Multilinear Regression (MLR) model was fitted on the original dataset, as shown in Equation (1):

(CQ): Cement quantity, (FW): Freshwater content, (CA): Coarse aggregate content, (FA): Fine aggregate content, (SW): Seawater content, (BFS): Blast-Furnace Slag content, (FAS): Fly Ash content, (SP): Super Plasticizer content.

The standard errors of each input computed with the MLR are given below in

Table 5:

It is important to rank the input variables based on their impact on the output (compressive strength) and their statistical significance. According to the standard errors of each input in the MLR model, the curing age is the most influential factor, followed by cement quantity and blast-furnace slag content. Fly ash (FAS) also showed a meaningful effect, while freshwater (FW) and seawater (SW) had moderate but significant negative impacts, likely due to their influence on the water-to-cement ratio. Fine and coarse aggregates (FA and CA) had smaller contributions. On the other hand, superplasticizer (SP) showed a negligible effect in this model. It is worth noting that since MLR assumes a linear relationship and an additive influence of features, this feature importance analysis does not take into account the effect of non-linear feature interactions.

The Random Forest (RF) algorithm is an ensemble learning algorithm widely used for regression tasks due to its robustness, accuracy, and ability to model complex relationships. It operates by constructing a large number of decision trees during training, each built on a different random subset of the data using the technique of bootstrap aggregation. At each node of a tree, a random subset of features is considered for splitting, which introduces diversity among the trees. The final prediction is obtained by averaging the outputs of all trees. This approach reduces overfitting and enhances generalization performance. We implemented the RF algorithm using 50 different decision trees on the same dataset using the same split between training, validation, and testing used for the ANN model.

The coefficient of determination was then computed for all models on the test set (15%).

Compared to MLR, ANN demonstrates better performance with a higher coefficient of determination (R

2) and a higher a20 index as shown in

Table 6. Indeed, the limitations of MLR in capturing the data’s complexity stem from its inherent design, which is primarily suited for modeling linear relationships between variables. This restricts its effectiveness in representing more complex, non-linear patterns.

On the other hand, the RF algorithm achieves the highest R

2, while ANN demonstrates the best performance in terms of the a20 index (

Table 6).

It is important to highlight that the a20 index represents a stricter accuracy metric, as it assesses the proportion of predictions falling within a ±20% margin of the actual values (prediction measure). In contrast, the R2 score reflects how well a model captures the overall variance in the data (a statistical measure). Given that the objective of this study is to estimate the compressive strength of concrete mixtures with high precision, the most suitable model is ANN since it achieves the highest a20 index.

In practical applications, especially near design thresholds, a model with R2 = 0.76 may produce errors of several megapascals more than a model with R2 = 0.84. For instance, an error of even 3–5 MPa may lead to unsafe design or excessive overdesign, impacting both structural safety and material efficiency. Furthermore, an a20 index of 0.66 (MLR model) implies that over one-third of the predictions fall outside an acceptable ±20% range, which could lead to unsafe design or unnecessary overdesign. Improving this metric to 0.78 (RF algorithm) and more significantly to 0.82 (ANN model) reduces the risk of such deviations significantly (lowering the proportion of outliers from 34% to 22% then 18%). This improvement could translate into more consistent quality control, greater confidence in selecting optimal mix designs without extensive laboratory testing, reduced need for conservative safety margins, and potentially lower costs due to more accurate material specification. Therefore, the improvement is not only statistically meaningful but also practically relevant in real-world applications.

To visually illustrate the prediction deviation of the models on the data of the test set, we have plotted the predicted values and the true original values on the same curve as shown in

Figure 2 (MLR model),

Figure 3 (ANN model), and

Figure 4 (RF model). Ideally, the distribution of the predicted values should be close to a slope curve at 45 degrees from the origin. Moreover, the a20 index margin (purple lines) was added to the figure to evaluate how closely the predicted values are considered acceptably close to the experimental results. It also provides a quantitative benchmark for acceptable prediction error in practical or engineering contexts.

As shown in

Figure 3, the concentration of ANN predictions within this margin demonstrates the ANN model’s strong generalization capability and robustness across a wide range of concrete mix designs, in contrast with the results obtained in

Figure 2 with the MLR model.

Figure 3 (ANN model) exhibits the highest concentration of predicted points within the boundary lines, followed by

Figure 4 (RF model), while

Figure 2 (MLR model) shows the lowest concentration. This distribution further proves that the ANN model has enhanced the prediction accuracy of the concrete mixture compressive strength for the 116 records of the test set (15%).

To understand the complexity of the equation linking the concrete mixture compressive strength to the materials contents, we have computed the R2 coefficient and a20 index for several network architectures, by varying the number of layers for the optimal number of neurons (200) first, then by varying the number of neurons for the optimal number of layers (4).

Table 7 indicates that increasing the depth of the ANN architecture above four layers cannot further increase the two performance metrics. On the other hand,

Table 8 shows that below 100 neurons achieves a low performance, and that at 200 neurons, a wide architecture is required to capture enough non-linear relationships linking the concrete mixture compressive strength and the input variables.

This work proves that machine learning, particularly ANN, offers a powerful alternative to conventional experimental methods for predicting the compressive strength of sustainable concrete mixes.

Compared to traditional experimental approaches, which require the preparation, curing, and destructive testing of numerous concrete specimens, machine learning significantly reduces the time, cost, and material consumption associated with strength prediction. Once trained, the ANN model can provide rapid and accurate estimates of compressive strength, eliminating the need for repeated physical testing for every new mix design. This not only streamlines the concrete development process but also contributes to more sustainable practices by minimizing raw material usage and laboratory waste. Moreover, the ability of the model to generalize across a wide range of mixture designs allows for efficient exploration and optimization of sustainable concrete formulations that may not be feasible to test exhaustively in the lab. As such, machine learning serves as a valuable tool in accelerating innovation in concrete technology while supporting environmental and economic goals.

9. Conclusions

This study investigated the application of machine learning techniques, particularly ANN, to predict the compressive strength of sustainable concrete mixes. The research involved an overview of existing approaches, followed by the development of a transparent and reproducible methodology that includes model tuning and performance evaluation.

The focus on sustainable concrete is especially relevant given the increasing use of alternative materials such as fly ash, natural pozzolans, and seawater, which introduce greater variability in concrete properties. Traditional empirical models often struggle to account for these variations and for the non-linear interactions between the concrete components, making data-driven approaches like ANN a powerful alternative. This paper successfully developed an ANN model to predict the compressive strength of sustainable concrete mixture using a dataset of 768 samples. The model achieved a test loss of 5.1% demonstrating its effectiveness and potential for practical applications. In addition, a comparison with other models, i.e., MLR and RF, demonstrated further the ANN model’s validity. Furthermore, the results of this work show that ANN models can effectively learn complex patterns within heterogeneous data and deliver high-accuracy predictions across a range of sustainable concrete compositions.

By reducing the dependence on exhaustive laboratory testing, the proposed approach supports faster, more cost-effective assessments of innovative and environmentally conscious mix designs. It also promotes a shift toward performance-based design, which is particularly valuable in regions where sustainable construction practices and alternative materials are becoming the norm.

These results align with previous research that has shown the effectiveness of ANNs in predicting the compressive strength of various concrete types, including self-compacting concrete and recycled aggregate concrete. It also contributes to the growing body of knowledge on the use of machine learning techniques in civil engineering and paves the way for more efficient and accurate methods of material testing.

Future research should consider incorporating additional environmental and durability factors and exploring hybrid techniques to further improve the adaptability of predictive models for sustainable construction applications. Moreover, given the interpretability of machine learning models, an important direction for future research is to conduct feature importance analysis to determine which input variables most strongly influence model predictions. This approach helps pinpoint the key factors driving the outcomes, enabling researchers and engineers to prioritize and optimize these variables for improved performance and decision-making. In more complex models, it also uncovers non-linear relationships and interactions that may not be immediately apparent.