A Review of the Performance Properties of Geopolymer Pavement-Quality Concrete

Abstract

1. Introduction

- (a)

- Precursor materials used in geopolymer concrete.

- (b)

- Alkaline activators used in geopolymer concrete.

- (c)

- Material properties relevant to the performance of geopolymer pavement-quality concrete.

- (d)

- Performance studies on geopolymer pavement-quality concrete.

2. Precursor Materials Used in Geopolymer Concrete

2.1. Natural Pozzolans

2.2. Artificial Pozzolans

2.2.1. Fly Ash

2.2.2. Ground Granulated Blast Furnace Slag

2.2.3. Silica Fume

2.2.4. Red Mud

2.2.5. Calcined Clay

2.2.6. Iron-Rich Clay

2.2.7. Nonferrous Slag

2.2.8. Clay-Rich Sludge

2.2.9. Glass Powder

2.2.10. Rice Husk Ash

2.2.11. Sugarcane Bagasse Ash

2.2.12. Corncob Ash

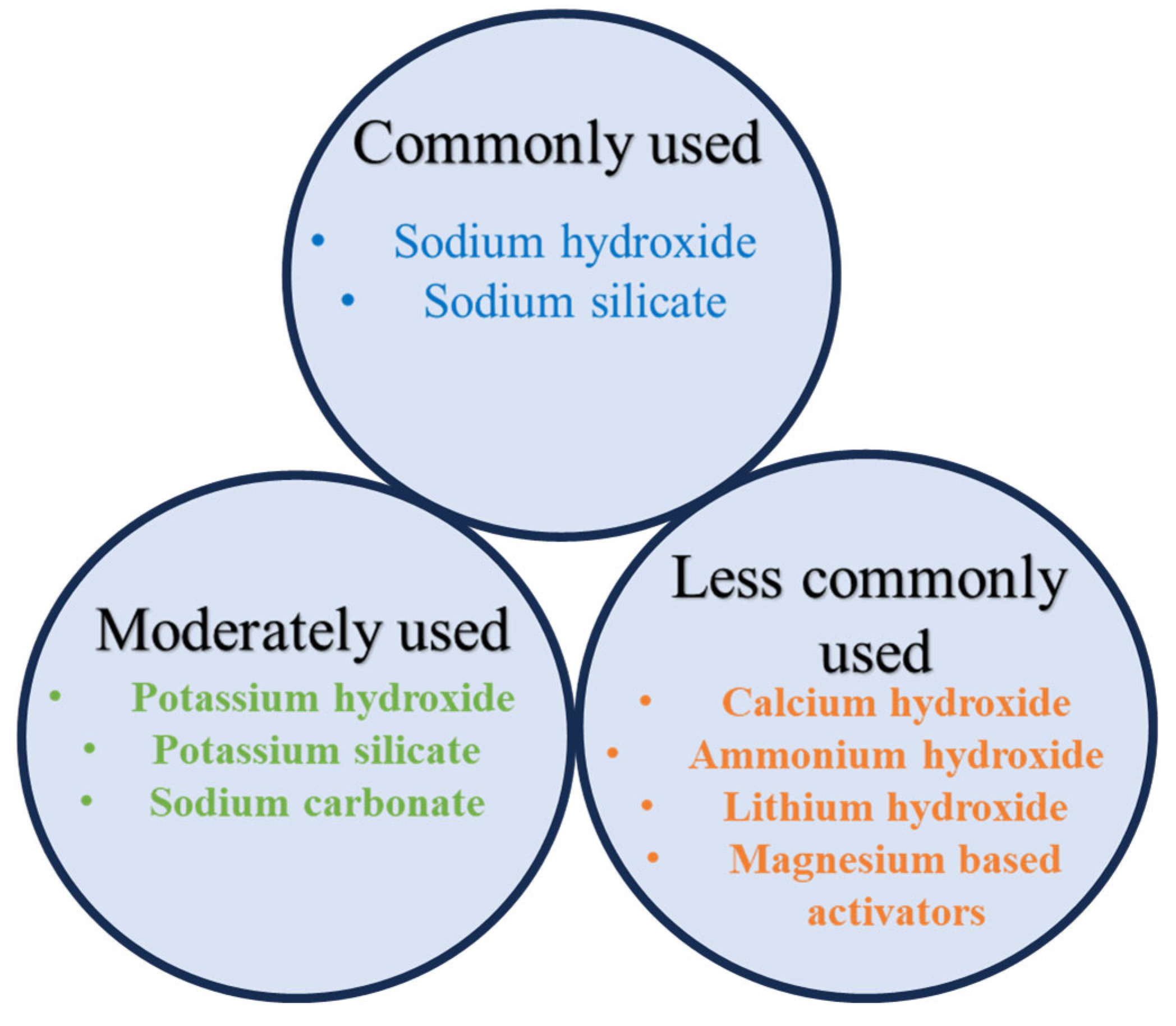

3. Alkaline Activators Used in Geopolymer Concrete

4. Material Properties Relevant to the Performance of Geopolymer Pavement-Quality Concrete

4.1. Flow Properties

4.2. Compressive Strength

4.3. Split Tensile Strength

4.4. Flexural Strength

4.5. Modulus of Elasticity

4.6. Resistance to Abrasion

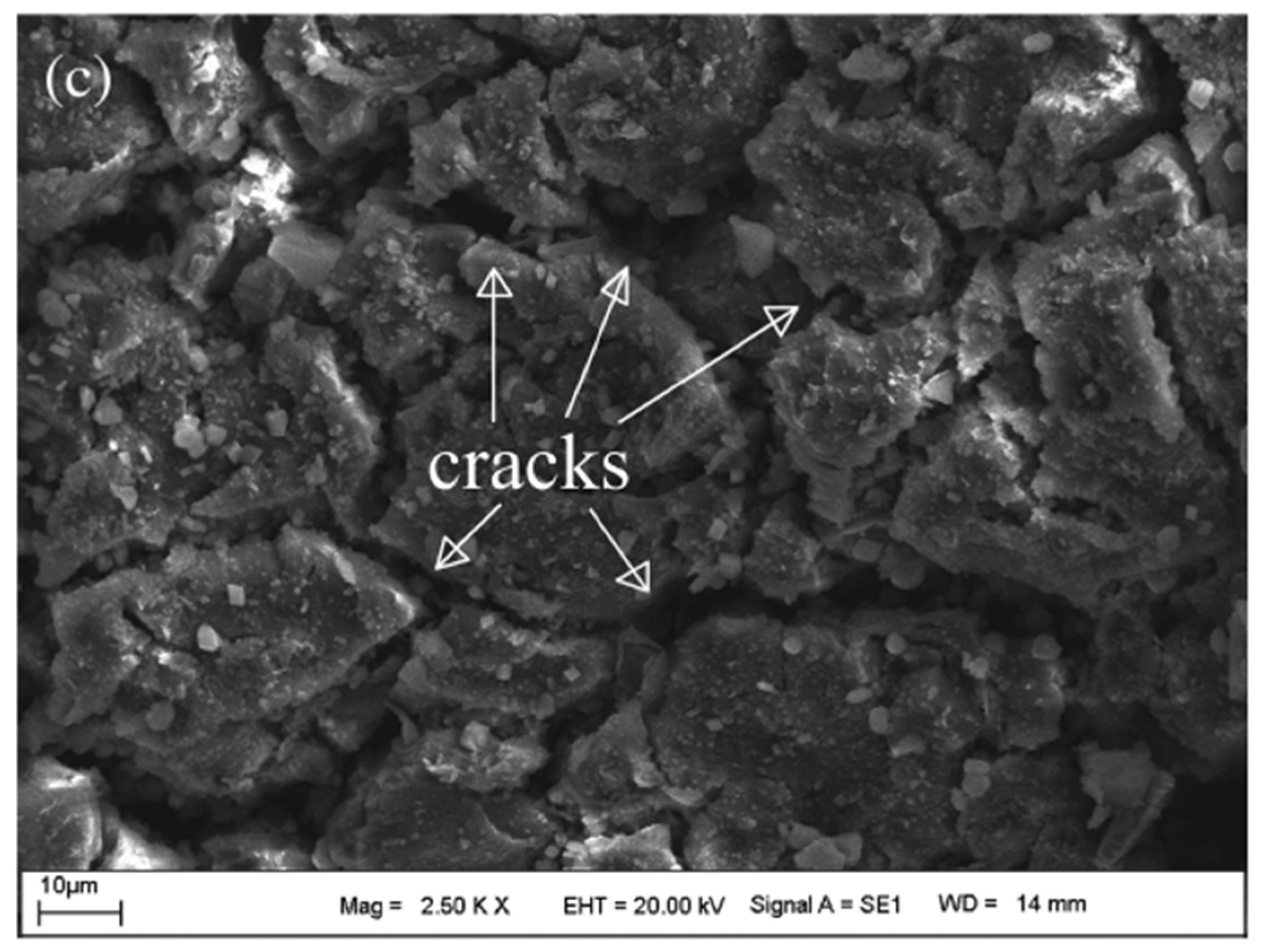

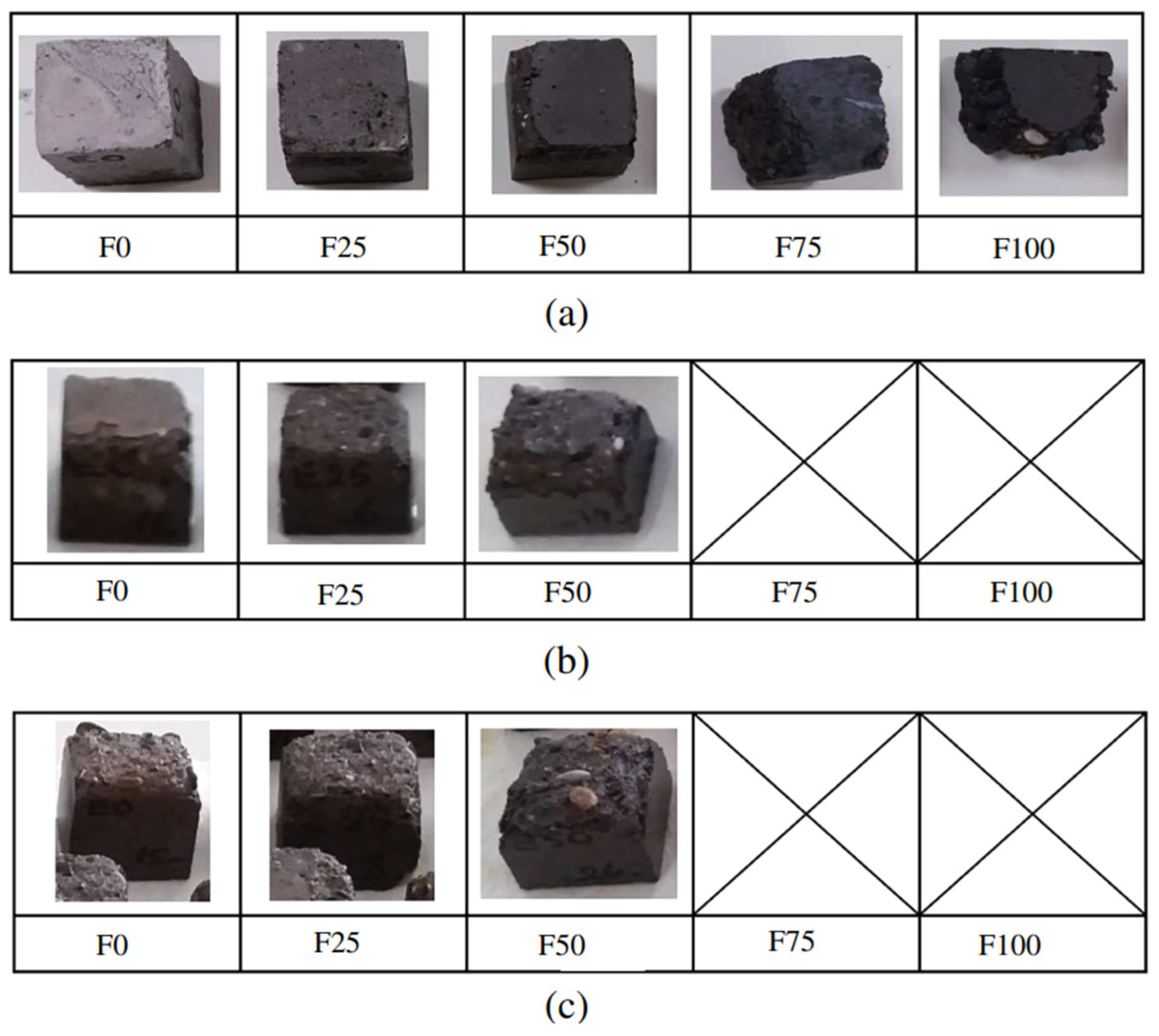

4.7. Resistance to Freeze–Thaw and Wet–Dry Cycles

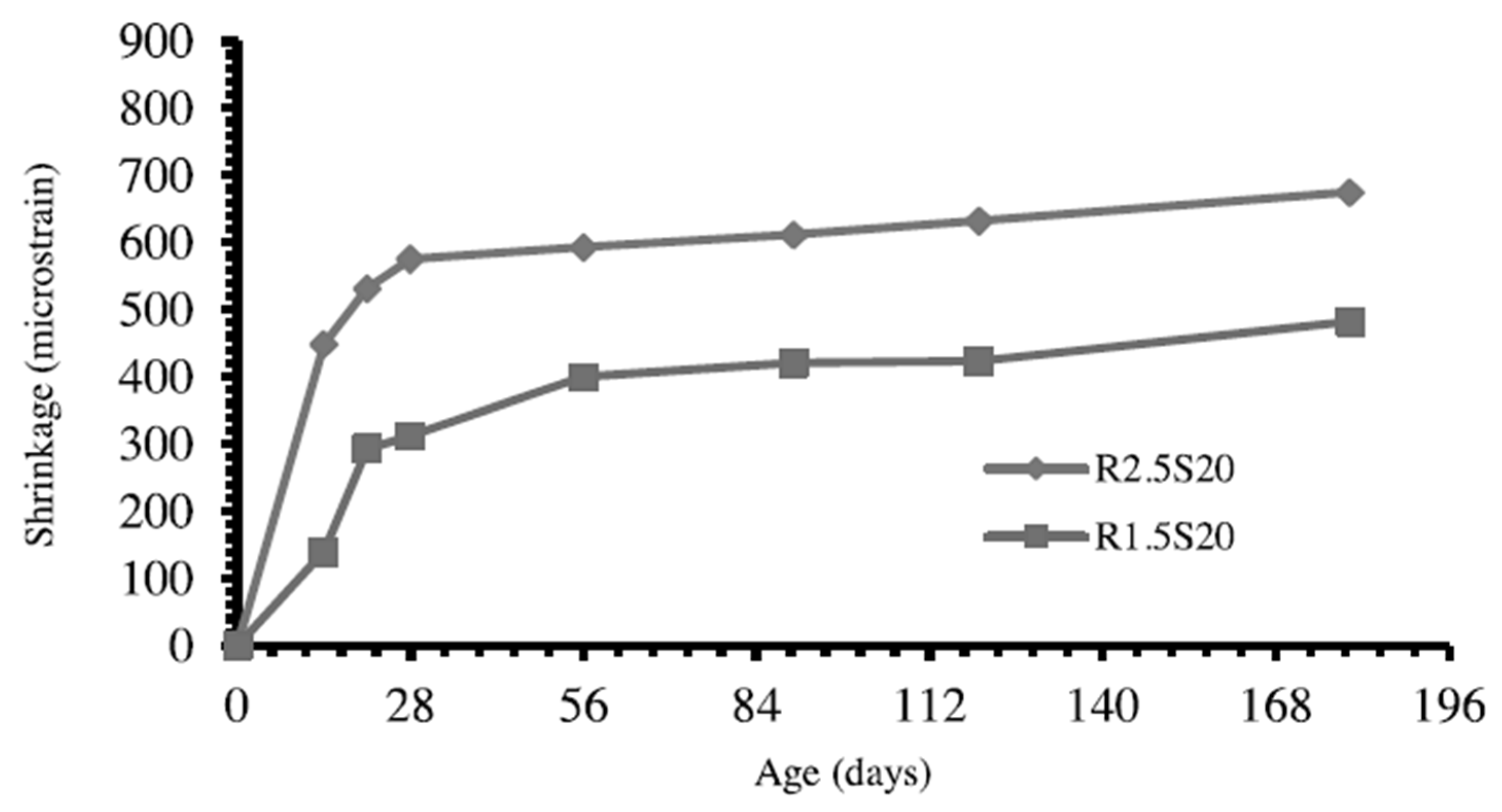

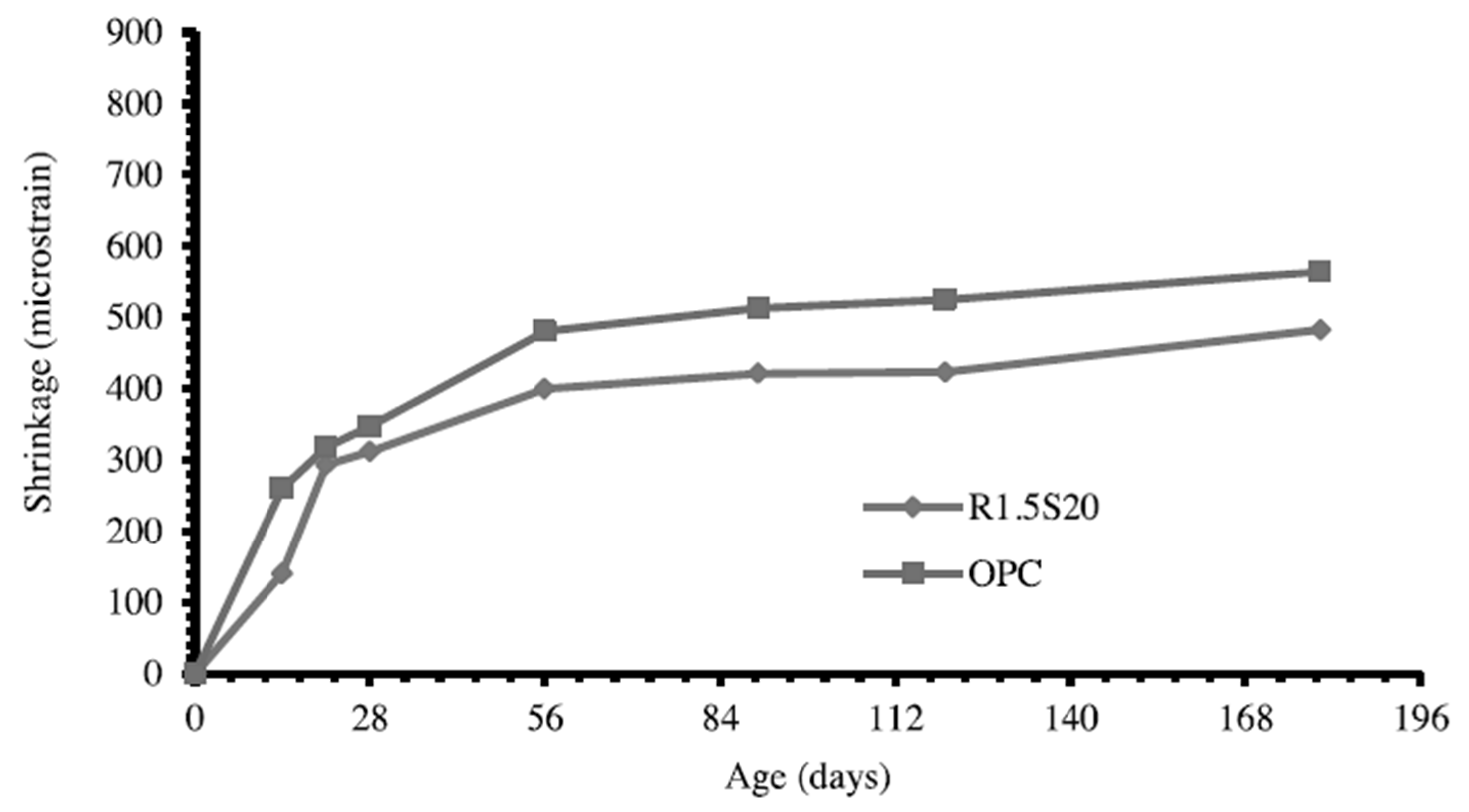

4.8. Drying Shrinkage

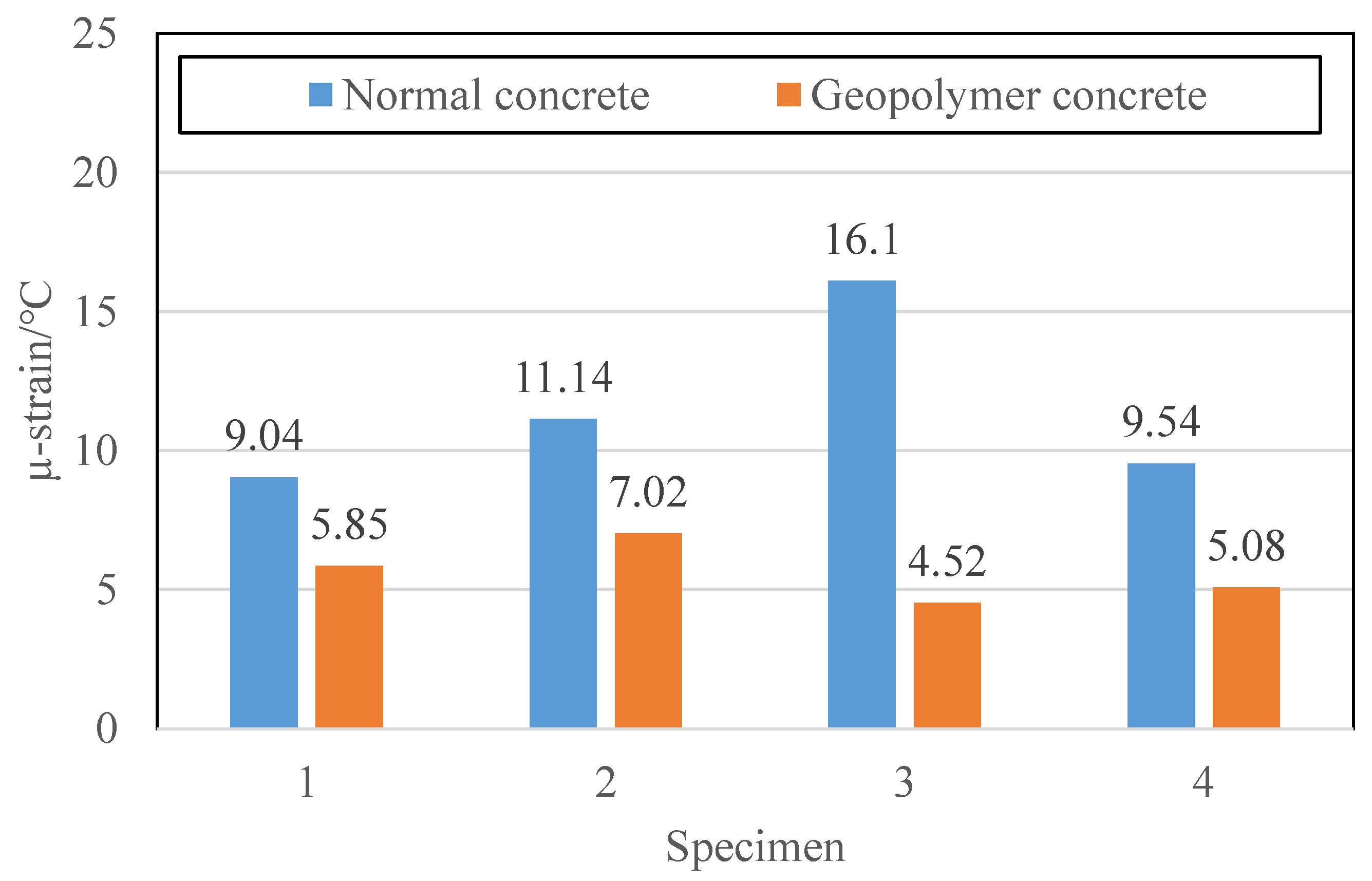

4.9. Coefficient of Thermal Expansion

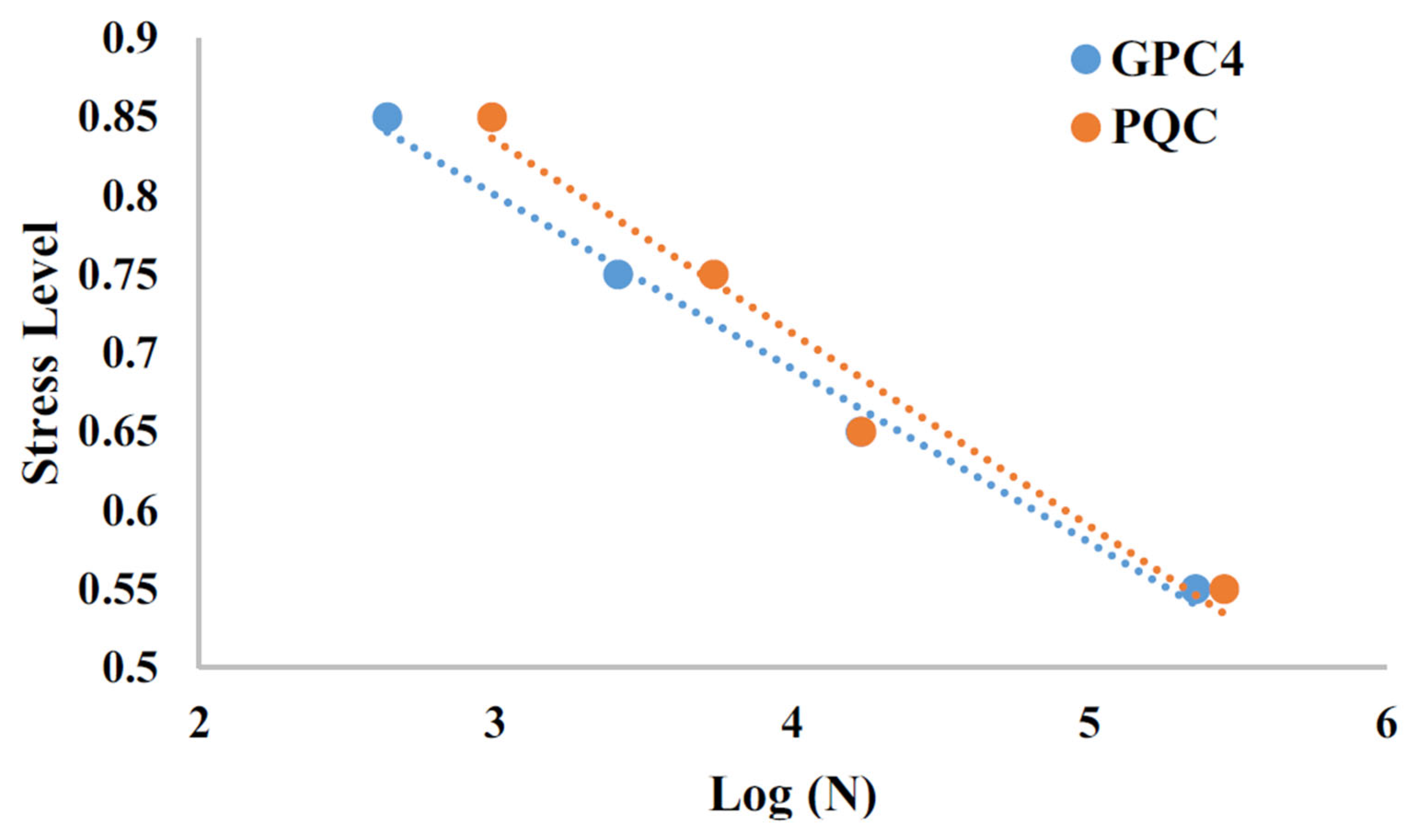

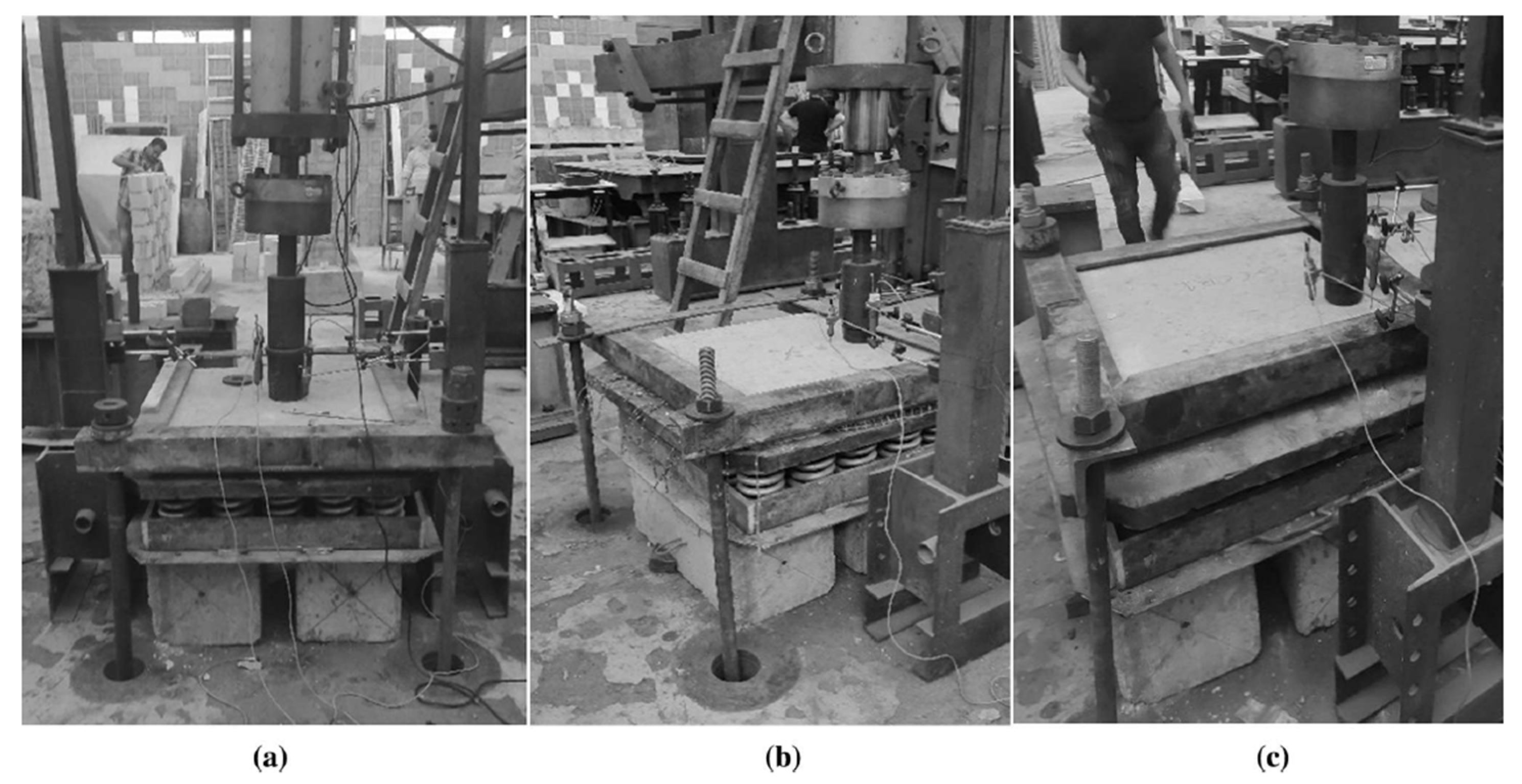

5. Performance Studies on Geopolymer Pavement-Quality Concrete

6. Summary of Geopolymer Mixes for Pavement Application

- Most of the geopolymer mixes utilize fly ash and GGBFS in varying ratios, with NaOH molarity ranging from 10 to 16, and sodium silicate to sodium hydroxide ratio ranging from 1.5 to 2.5.

- Geopolymer mixes with a 50:50 or 40:60 proportion of GGBFS to fly ash showed good strength development under ambient curing conditions, making them suitable for high-volume roads as per IRC:58-2015, IRC:44-2017, and MoRTH specifications.

- Higher molarity (14–16 M) was used in mixes with a desired early strength or dense microstructure, such as the metakaolin-based mix. Mixes with higher GGBFS content also achieved the required strength using either ambient or oven curing.

- The total binder content was consistently around 400–450 kg/m3, indicating a consensus on binder quantity for geopolymer pavement-quality concrete.

- Notably, oven curing was applied where faster geopolymerization was needed, while most studies preferred ambient curing, aligning with site practices.

- Overall, it confirms that well-optimized geopolymer mixes with proper activator ratios and precursor blends can effectively meet PQC standards for high- and low-volume roads.

7. Challenges of Geopolymer Concrete

8. Conclusions

- The quality of precursor materials is crucial in achieving the desired properties for geopolymer pavement-quality concrete. Most studies in the past focused on the use of fly ash and GGBFS as precursor materials, and very few studies have explored other industrial and agricultural wastes. It shows that other precursors have potential in the application of geopolymer pavement-quality concrete. It is important to carefully assess the physical and chemical characteristics of precursor materials to ascertain their application in geopolymer pavement-quality concrete. The exploration of locally available precursor materials can reduce the carbon footprint of geopolymer concrete pavements and thereby achieve the sustainable development goals in the pavement industry.

- The strength properties of geopolymer concrete were found to be superior and meet the requirements of geopolymer pavement-quality concrete. However, attention should be given to the optimum proportion of precursors and alkaline solution in the mix design process.

- The modulus of elasticity of geopolymer concrete shows variability when compared to conventional Portland cement concrete. Several factors, such as precursor materials, concentration of alkaline activators, and curing conditions, influence the elastic modulus of geopolymer concrete. Moreover, ambient curing can produce a desirable elastic modulus for geopolymer pavement-quality concrete and therefore show practical viability in construction.

- The drying shrinkage of geopolymer concrete was found to be lower than that of the conventional Portland cement concrete, and similar trends were observed for the coefficient of thermal expansion. The reduction in the coefficient of thermal expansion of the geopolymer concrete will positively contribute towards the long-term performance of concrete pavements.

- The durability of geopolymer concrete with respect to resistance to abrasion and freeze–thaw resistance was found to be excellent and was attributed to the formation of dense binding phases such as sodium alumina silicate hydrate and calcium alumina silicate hydrate in the hardened geopolymer concrete.

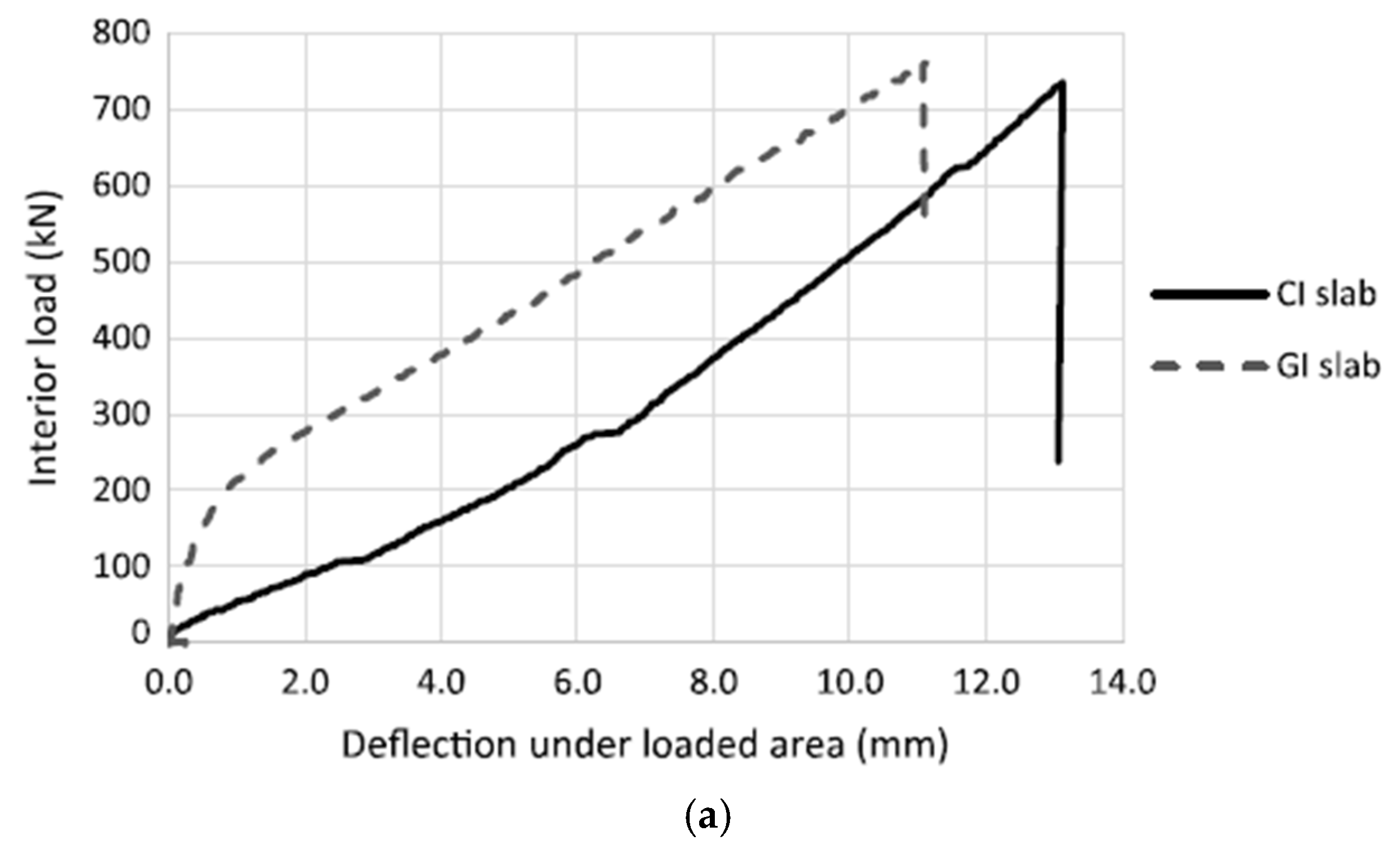

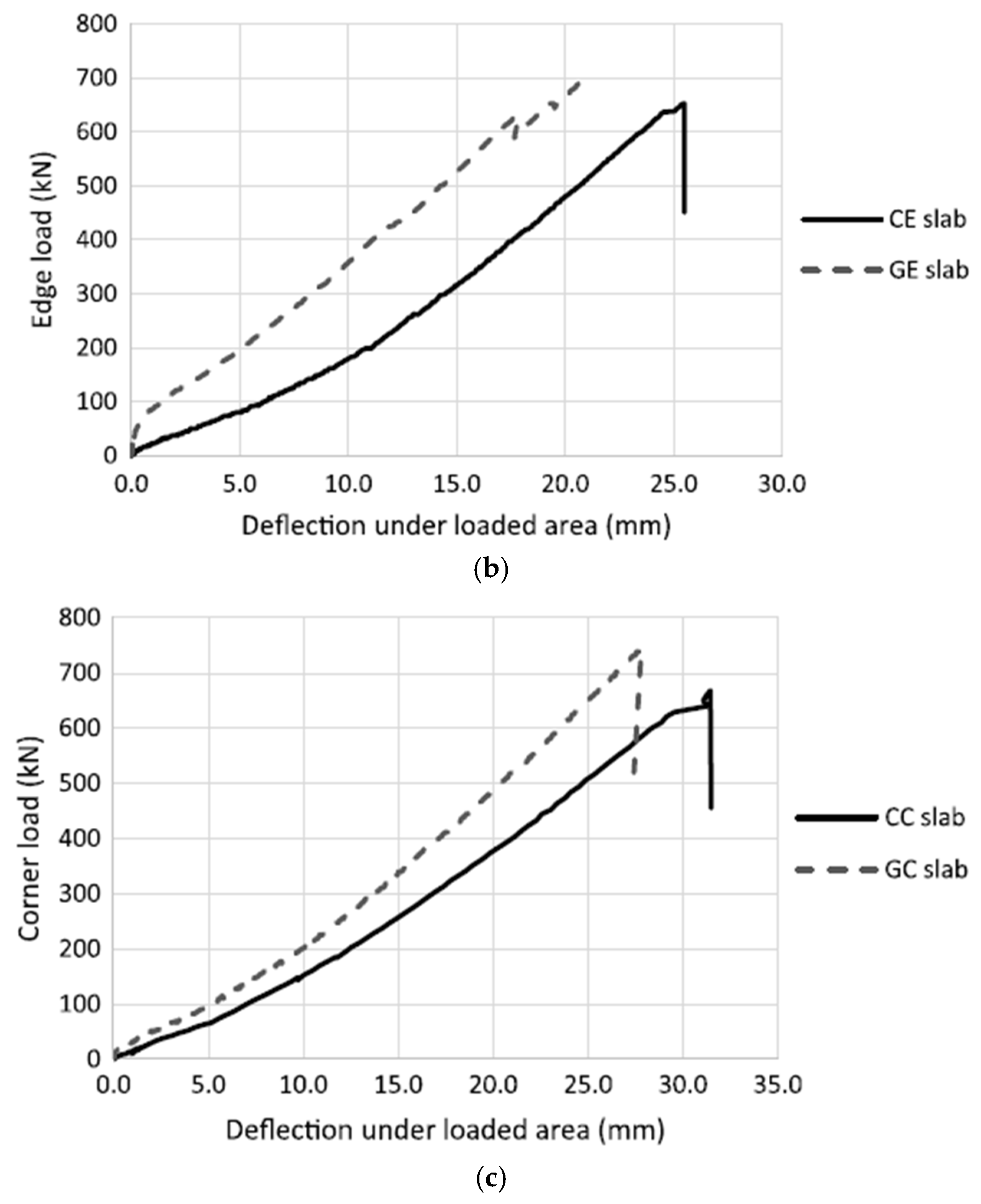

- The results of fatigue analysis for ambient-cured geopolymer concrete indicate that the fracture propagation in geopolymer pavement-quality concrete is similar to that of the conventional Portland cement concrete. Additionally, the mechanical loading test on geopolymer concrete slabs indicates a higher load-carrying capacity for geopolymer concrete slabs when compared to the conventional Portland cement concrete slabs.

9. Future Recommendations

- Future studies should focus on evaluating properties of geopolymer concrete relevant to the performance of concrete pavement. Pertinent properties such as elastic modulus, coefficient of thermal expansion, drying shrinkage, and thermal conductivity should be determined.

- The potential of locally available industrial and agricultural waste should be studied for its use as precursor material in geopolymer pavement-quality concrete.

- Emphasis should be given to developing alternative activators derived from waste materials to reduce cost and improve the energy efficiency of geopolymer pavement-quality concrete.

- There is significant scope to understand the effect of recycled aggregates in geopolymer concrete and further evaluate its pertinent properties for pavement application.

- Studies can also be carried out to evaluate the field performance of geopolymer pavement-quality concrete and ascertain its optimum design for resilient concrete pavement in the context of extreme global climate change.

- Research shows the environmental benefits of various precursors in construction materials [142,143], and there is great scope to explore their benefits in geopolymer pavement-quality concrete. A systematic approach, such as life cycle analysis (LCA) or life cycle cost analysis (LCCA), can provide valuable insights into the product’s life, environmental, and financial impacts. Additionally, it can assist in assessing the sustainability of a product by identifying the areas for improvement and minimizing environmental burdens.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rout, M.D.; Biswas, S.; Shubham, K.; Sinha, A.K. A Systematic Review on Performance of Reclaimed Asphalt Pavement (RAP) as Sustainable Material in Rigid Pavement Construction: Current Status to Future Perspective. J. Build. Eng. 2023, 76, 107253. [Google Scholar] [CrossRef]

- India Brand Equity Foundation. Road Infrastructure in India. Available online: https://www.ibef.org/industry/roads-india (accessed on 11 December 2024).

- Akintayo, B.D.; Babatunde, O.M.; Olanrewaju, O.A. Comparative Analysis of Cement Production Methods Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach. Sustainability 2024, 16, 484. [Google Scholar] [CrossRef]

- Dawoudian, J.; Bahamin, S.; Tantoh, H.B. Environmental impact assessment of cement industries using mathematical matrix method: Case of Ghayen cement, South Khorasan, Iran. Environ. Sci. Pollut. Res. Int. 2021, 28, 22348–22358. [Google Scholar] [CrossRef] [PubMed]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and Developments in Green Cement and Concrete Technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Sustainable Development. In The Poly(sialate) Terminology: A Very Useful and Simple Model for the Promotion and Understanding of Green-Chemistry; Geopolymer Institute: Saint-Quentin, France, 2005. [Google Scholar]

- Yu, J.; Ji, F.; Lv, Q.; Li, W.; Lin, Z.; Peng, Y. Mechanical property and microstructure of fly ash-based geopolymer by calcium activators. Case Stud. Constr. Mater. 2024, 21, e03811. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, B.; Zhou, H.; Ma, Y.; Jiang, X. A state-of-the-art review of crushed urban waste glass used in OPC and AAMs (geopolymer): Progress and challenges. Clean. Mater. 2022, 4, 100083. [Google Scholar] [CrossRef]

- Paiste, P.; Liira, M.; Heinmaa, I.; Vahur, S.; Kirsimäe, K. Alkali activated construction materials: Assessing the alternative use for oil shale processing solid wastes. Constr. Build. Mater. 2016, 122, 458–464. [Google Scholar] [CrossRef]

- Xiao, R.; Jiang, X.I.; Zhang, M.; Polaczyk, P.; Huang, B. Analytical investigation of phase assemblages of alkali-activated materials in CaO-SiO2-Al2O3 systems: The management of reaction products and designing of precursors. Mater. Des. 2020, 194, 108975. [Google Scholar] [CrossRef]

- Plati, C. Sustainability Factors in Pavement Materials, Design, and Preservation Strategies: A Literature Review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Jiang, D.; Shi, C.; Zhang, Z. Recent progress in understanding setting and hardening of alkali-activated slag (AAS) materials. Cem. Concr. Compos. 2022, 134, 104795. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef] [PubMed]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Farooq, F.; Jin, X.; Faisal Javed, M.; Akbar, A.; Izhar Shah, M.; Aslam, F.; Alyousef, R. Geopolymer concrete as sustainable material: A state of the art review. Constr. Build. Mater. 2021, 306, 124762. [Google Scholar] [CrossRef]

- Zhao, J.; Tong, L.; Li, B.; Chen, T.; Wang, C.; Yang, G.; Zheng, Y. Eco-friendly geopolymer materials: A review of performance improvement, potential application and sustainability assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N.; Rahman, I.; Nigam, M.; Ahmed, M.; Mallick, J. Geopolymer Concrete: A Material for Sustainable Development in Indian Construction Industries. Crystals 2022, 12, 514. [Google Scholar] [CrossRef]

- Raza, A.; El Ouni, M.H.; Azab, M.; Ali, K.; Haider, H.; Rashedi, A. A scientometric review on mechanical and durability performance of geopolymer Paste: Effect of various raw materials. Constr. Build. Mater. 2022, 345, 128297. [Google Scholar] [CrossRef]

- Parathi, S.; Nagarajan, P.; Pallikkara, S.A. Ecofriendly geopolymer concrete: A comprehensive review. Clean Technol. Environ. Policy 2021, 23, 1701–1713. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. A state-of-the-art review on the durability of geopolymer concrete for sustainable structures and infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Matsimbe, J.; Dinka, M.; Olukanni, D.; Musonda, I. Geopolymer: A Systematic Review of Methodologies. Materials 2022, 15, 6852. [Google Scholar] [CrossRef] [PubMed]

- Jwaida, Z.; Dulaimi, A.; Mashaan, N.; Othuman Mydin, M.A. Geopolymers: The green alternative to traditional materials for engineering applications. Infrastructures 2023, 8, 98. [Google Scholar] [CrossRef]

- Ikotun, J.O.; Aderinto, G.E.; Madirisha, M.M.; Katte, V.Y. Geopolymer Cement in Pavement Applications: Bridging Sustainability and Performance. Sustainability 2024, 16, 5417. [Google Scholar] [CrossRef]

- Firdous, R.; Stephan, D.; Djobo, J.N.Y. Natural pozzolan based geopolymers: A review on mechanical, microstructural and durability characteristics. Constr. Build. Mater. 2018, 190, 1251–1263. [Google Scholar] [CrossRef]

- Siddique, R. Effect of volcanic ash on the properties of cement paste and mortar. Resour. Conserv. Recycl. 2011, 56, 66–70. [Google Scholar] [CrossRef]

- Villa, C.; Pecina, E.; Torres, R.; Gómez, L. Geopolymer synthesis using alkaline activation of natural zeolite. Constr. Build. Mater. 2010, 24, 2084–2090. [Google Scholar] [CrossRef]

- Obraniak, A.; Gluba, T.; Ławińska, K.; Derbiszewski, B. Minimisation of environmental effects related with storing fly ash from combustion of hard coal. Environ. Prot. Eng. 2018, 44, 177–189. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis. Materials 2022, 15, 7098. [Google Scholar] [CrossRef] [PubMed]

- Dwivedi, A.; Jain, M.K. Fly ash–waste management and overview: A Review. Recent Res. Sci. Technol. 2014, 6, 1. [Google Scholar]

- Mortar, N.A.M.; Kamarudin, H.; Rafiza, R.A.; Meor, T.; Rosnita, M. Compressive Strength of Fly Ash Geopolymer Concrete by Varying Sodium Hydroxide Molarity and Aggregate to Binder Ratio. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864, 012037. [Google Scholar]

- Ahmed, H.U.; Mahmood, L.J.; Muhammad, M.A.; Faraj, R.H.; Qaidi, S.M.; Sor, N.H.; Mohammed, A.S.; Mohammed, A.A. Geopolymer concrete as a cleaner construction material: An overview on materials and structural performances. Clean. Mater. 2022, 5, 100111. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Bohra, V.K.J.; Nerella, R.; Madduru, S.R.C. Material properties, processing & characterization of fly ash based geopolymer. Mater. Today Proc. 2019, 19, 2617–2621. [Google Scholar]

- Chandra, K.S.; Krishnaiah, S.; Reddy, N.G.; Hossiney, N.; Peng, L. Strength Development of Geopolymer Composites Made from Red Mud–Fly Ash as a Subgrade Material in Road Construction. J. Hazard. Toxic. Radioact. Waste 2021, 25, 04020068. [Google Scholar] [CrossRef]

- Li, L.-M.; Xie, J.-H.; Zhang, B.-F.; Feng, Y.; Yang, J. A state-of-the-art review on the setting behaviours of ground granulated blast furnace slag- and metakaolin-based alkali-activated materials. Constr. Build. Mater. 2023, 368, 130389. [Google Scholar] [CrossRef]

- Mishra, J.; Nanda, B.; Patro, S.K.; Krishna, R.S. A comprehensive review on compressive strength and microstructure properties of GGBS-based geopolymer binder systems. Constr. Build. Mater. 2024, 417, 135242. [Google Scholar] [CrossRef]

- Liu, B.; Zhuang, K.; Li, D.; Fang, Y.; Pan, G. Understanding the early reaction and structural evolution of alkali activated slag optimized using K-A-S-H nanoparticles with varying K2O/SiO2 ratios. Compos. B Eng. 2020, 200, 108311. [Google Scholar] [CrossRef]

- Thakur, G.; Singh, Y.; Singh, R.; Prakash, C.; Saxena, K.K.; Pramanik, A.; Basak, A.; Subramaniam, S. Development of GGBS-Based Geopolymer Concrete Incorporated with Polypropylene Fibers as Sustainable Materials. Sustainability 2022, 14, 10639. [Google Scholar] [CrossRef]

- Ravikumar, D.; Peethamparan, S.; Neithalath, N. Structure and strength of NaOH activated concretes containing fly ash or GGBFS as the sole binder. Cem. Concr. Compos. 2010, 32, 399–410. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.-L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef] [PubMed]

- Tanu, H.M.; Unnikrishnan, S. Mechanical Strength and Microstructure of GGBS-SCBA based Geopolymer Concrete. J. Mater. Res. Technol. 2023, 24, 7816–7831. [Google Scholar] [CrossRef]

- Grace, M.A.; Clifford, E.; Healy, M.G. The potential for the use of waste products from a variety of sectors in water treatment processes. J. Clean. Prod. 2016, 137, 788–802. [Google Scholar] [CrossRef]

- Türköz, M.; Umu, S.U.; Öztürk, O. Effect of Silica Fume as a Waste Material for Sustainable Environment on the Stabilization and Dynamic Behavior of Dispersive Soil. Sustainability 2021, 13, 4321. [Google Scholar] [CrossRef]

- Billong, N.; Oti, J.; Kinuthia, J. Using silica fume based activator in sustainable geopolymer binder for building application. Constr. Build. Mater. 2021, 275, 122177. [Google Scholar] [CrossRef]

- Vogt, O.; Ukrainczyk, N.; Koenders, E. Effect of Silica Fume on Metakaolin Geopolymers’ Sulfuric Acid Resistance. Materials 2021, 14, 5396. [Google Scholar] [CrossRef] [PubMed]

- Hasanzadeh, A.; Shooshpasha, I. A study on the combined effects of silica fume particles and polyethylene terephthalate fibres on the mechanical and microstructural characteristics of cemented sand. Int. J. Geosynth. Ground Eng. 2021, 7, 98. [Google Scholar] [CrossRef]

- Hasanzadeh, A.; Shooshpasha, I. PET fiber reinforcement efficiency in the mechanical and microstructural characteristics of cemented sand modified with silica fume. Constr. Build. Mater. 2023, 397, 132363. [Google Scholar] [CrossRef]

- Zhao, Q.; Ma, C.; Lu, X.; Huang, B.; Chen, Z.; Lian, C. Effect of silica fume on the efflorescence, strength, and micro-properties of one-part geopolymer incorporating sewage sludge ash. Constr. Build. Mater. 2024, 436, 136840. [Google Scholar] [CrossRef]

- Wang, M.; Liu, X. Applications of red mud as an environmental remediation material: A review. J. Hazard. Mater. 2021, 408, 124420. [Google Scholar] [CrossRef] [PubMed]

- Svobodova-Sedlackova, A.; Calderón, A.; Fernandez, A.I.; Chimenos, J.M.; Berlanga, C.; Yücel, O.; Barreneche, C.; Rodriguez, R. Mapping the research landscape of bauxite by-products (red mud): An evolutionary perspective from 1995 to 2022. Heliyon 2024, 10, e24943. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Ji, Y. Mechanical properties and permeability of red mud-blast furnace slag-based geopolymer concrete. SN Appl. Sci. 2021, 3, 23. [Google Scholar] [CrossRef]

- Zakira, U.; Zheng, K.; Xie, N.; Birgisson, B. Development of high-strength geopolymers from red mud and blast furnace slag. J. Clean. Prod. 2023, 383, 135439. [Google Scholar] [CrossRef]

- Bellum, R.R.; Venkatesh, C.; Madduru, S.R.C. Influence of Red Mud on Performance Enhancement of Fly Ash-Based Geopolymer Concrete. Innov. Infrastruct. Solut. 2021, 6, 1–9. [Google Scholar] [CrossRef]

- Liang, X.; Ji, Y. Experimental study on durability of red mud-blast furnace slag geopolymer mortar. Constr. Build. Mater. 2021, 267, 120942. [Google Scholar] [CrossRef]

- Kadhum, A.O.; Haider, M.O. Experimental Investigation of Self-Compacting High Performance Concrete Containing Calcined Kaolin Clay and Nano Lime. Civ. Eng. J. 2020, 6, 1798–1808. [Google Scholar] [CrossRef]

- Update on Calcined Clay, January 2025. Available online: https://www.globalcement.com/news/item/18361-update-on-calcined-clay-january-2025#:~:text=The%20work%20by%20Aumund%20and,cement%20manufacturers%20and%20equipment%20suppliers (accessed on 15 January 2025).

- Niyomukiza, J.B.; Eisazadeh, A.; Tangtermsirikul, S. Recent advances in slope stabilization using porous vegetation concrete in landslide-prone regions: A review. J. Build. Eng. 2023, 76, 107129. [Google Scholar] [CrossRef]

- Caselles, L.D.; Balsamo, B.; Benavent, V.; Trincal, V.; Lahalle, H.; Patapy, C.; Montouillout, V.; Cyr, M. Behavior of Calcined Clay Based Geopolymers under Sulfuric Acid Attack: Meta-Illite and Metakaolin. Constr. Build. Mater. 2023, 363, 129889. [Google Scholar] [CrossRef]

- Yamchelou, M.T.; Law, D.; Brkljac, R.; Gunasekara, C.; Li, J.; Patnaikuni, I. Geopolymer synthesis using low-grade clays. Constr. Build. Mater. 2021, 268, 121066. [Google Scholar] [CrossRef]

- Saikia, N.; Bharali, D.; Sengupta, P.; Bordoloi, D.; Goswamee, R.; Saikia, P.; Borthakur, P. Characterization, beneficiation and utilization of a kaolinite clay from Assam, India. Appl. Clay Sci. 2003, 24, 93–103. [Google Scholar] [CrossRef]

- Starý, J.; Jirásek, J.; Pticen, F.; Zahradník, J.; Sivek, M. Review of production, reserves, and processing of clays (including bentonite) in the Czech Republic. Appl. Clay Sci. 2021, 205, 106049. [Google Scholar] [CrossRef]

- Guillemin, F.; Lecomte-Nana, G.; El Hafiane, Y.; Peyratout, C.; Smith, A. Influence of the firing atmosphere onto the thermal transformation of iron-enriched kaolin. Appl. Clay Sci. 2024, 258, 107512. [Google Scholar] [CrossRef]

- Patrisia, Y.; Law, D.W.; Gunasekara, C.; Wardhono, A. Long-term durability of iron-rich geopolymer concrete in sulphate, acidic and peat environments. J. Build. Eng. 2024, 97, 110744. [Google Scholar] [CrossRef]

- Matalkah, F.; Aqel, R.; Ababneh, A. Enhancement of the Mechanical Properties of Kaolin Geopolymer Using Sodium Hydroxide and Calcium Oxide. Procedia Manuf. 2020, 44, 164–171. [Google Scholar] [CrossRef]

- Marsh, A.; Yang, T.; Adu-Amankwah, S.; Bernal, S. Utilization of metallurgical wastes as raw materials for manufacturing alkali-activated cements. In Waste and Byproducts in Cement-Based Materials; Woodhead Publishing: Cambridge, UK, 2021; pp. 335–383. [Google Scholar]

- Li, X.Y.; Liu, H.W.; Zhang, Y.S.; Mahlknecht, J.; Wang, C.Q. A review of metallurgical slags as catalysts in advanced oxidation processes for removal of refractory organic pollutants in wastewater. J. Environ. Manag. 2024, 352, 120051. [Google Scholar] [CrossRef] [PubMed]

- Kovacs, T.; Bator, G.; Schroeyers, W.; Labrincha, J.; Puertas, F.; Hegedus, M.; Doherty, R. From raw materials to NORM by-products. In Naturally Occurring Radioactive Materials in Construction; Woodhead Publishing: Thorston, UK, 2017; pp. 135–182. [Google Scholar]

- Rossi, L.; Patel, R.A.; Dehn, F. Compressive behaviour of alkali-activated slag-based concrete and Portland cement concrete incorporating novel multiple hooked-end steel fibres. Mater. Struct. 2023, 56, 96. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, R.; Hu, W.; Jiang, X.; Zhang, X.; Huang, B. Effect of granulated phosphorus slag on physical, mechanical and microstructural characteristics of Class F fly ash based geopolymer. Constr. Build. Mater. 2021, 291, 123287. [Google Scholar] [CrossRef]

- Detho, A.; Kadir, A.A.; Ahmad, S. Utilization of wastewater treatment sludge in the production of fired clay bricks: An approach towards sustainable development. Results Eng. 2024, 21, 101708. [Google Scholar] [CrossRef]

- Weng, C.H.; Lin, D.F.; Chiang, P.C. Utilization of sludge as brick materials. Adv. Environ. Res. 2003, 7, 679–685. [Google Scholar] [CrossRef]

- Detho, A.; Kadir, A.A.; Shayuti, A.; Rahim, B.A.; Ghazouani, N.; Mabrouk, A.; Elhag, A.B.; Rassem, H.H. Improvement of engineering properties and environmental impact of fired clay bricks utilizing industry sludge waste. Sci. Rep. 2025, 15, 4820. [Google Scholar] [CrossRef] [PubMed]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Mañosa, J.; Cerezo-Piñas, M.; Maldonado-Alameda, A.; Formosa, J.; Giro-Paloma, J.; Rosell, J.; Chimenos, J. Water treatment sludge as precursor in non-dehydroxylated kaolin-based alkali-activated cements. Appl. Clay Sci. 2021, 204, 106032. [Google Scholar] [CrossRef]

- Pourakbar, S.; Maneshmoaveni, A.; Moazami, D.; Moretti, L.; Yousefi, A.; Cristelo, N. Stabilization of clay soil using alkali-activated sewage sludge. J. Rock Mech. Geotech. Eng. 2025, 17, 3213–3224. [Google Scholar] [CrossRef]

- Selvakumar, M.; Geetha, S.; Rangan, S.K.; Sithrubi, T.; Sathyashriya, K. Effect of glass powder as partial fine aggregate replacement on properties of basalt fibre reinforced concrete. Mater. Today Proc. 2021, 43, 1460–1464. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of Glass Powder-Based Geopolymer Stabilized Road Bases Containing Recycled Waste Glass Aggregate. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Samarakoon, M.H.; Ranjith, P.G.; De Silva, V.R.S. Effect of soda-lime glass powder on alkali-activated binders: Rheology, strength and microstructure characterization. Constr. Build. Mater. 2020, 241, 118013. [Google Scholar] [CrossRef]

- Romero, A.R.; Toniolo, N.; Boccaccini, A.R.; Bernardo, E. Glass-Ceramic Foams from ‘Weak Alkali Activation’ and Gel-Casting of Waste Glass/Fly Ash Mixtures. Materials 2019, 12, 588. [Google Scholar] [CrossRef] [PubMed]

- Chelluri, S.; Hossiney, N. Performance evaluation of ternary blended geopolymer binders comprising of slag, fly ash and brick kiln rice husk ash. Case Stud. Constr. Mater. 2024, 20, e02918. [Google Scholar] [CrossRef]

- Rice Husk Ash Market—Forecast (2025–2031). Available online: https://www.industryarc.com/Report/16231/rice-husk-ash-rha-market.html (accessed on 28 January 2025).

- Hossain, S.S.; Roy, P.; Bae, C.-J. Utilization of waste rice husk ash for sustainable geopolymer: A review. Constr. Build. Mater. 2021, 310, 125218. [Google Scholar] [CrossRef]

- Mahdi, S.N.; Babu R, D.V.; Hossiney, N.; Abdullah, M.M.A.B. Strength and durability properties of geopolymer paver blocks made with fly ash and brick kiln rice husk ash. Case Stud. Constr. Mater. 2022, 16, e00800. [Google Scholar] [CrossRef]

- Marathe, S.; Martyna, N.; Gronostajska, B. Alkali-Activated Permeable Concretes with Agro-Industrial Wastes for a Sustainable Built Environment. Materials 2025, 18, 87. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.; Singh, J.; Kumar, S. A sustainable environmental study on corn cob ash subjected to elevated temperature. Curr. World Environ. 2018, 13, 144. [Google Scholar] [CrossRef]

- Lizotte, P.L.; Savoie, P.; De Champlain, A. Ash content and calorific energy of corn stover components in eastern Canada. Energies 2015, 8, 4827–4838. [Google Scholar] [CrossRef]

- Xiong, G.; Cundy, A.; Guo, X. Utilization of Corn Cob Ash (CCA) to Prepare Geopolymer Grout: Reaction Mechanism, Crack Repair Effectiveness and Life Cycle Assessment. J. Clean. Prod. 2024, 476, 143741. [Google Scholar] [CrossRef]

- Sodium Hydroxide Market Size and Share Analysis-Growth Trends and Forecasts (2025–2032). Available online: https://www.coherentmarketinsights.com/industry-reports/sodium-hydroxide-market (accessed on 2 May 2025).

- Sodium Silicate Market Size, Share & Trends Analysis Report by Application, by Region, and Segment Forecasts (2023–2030). Available online: https://www.grandviewresearch.com/industry-analysis/sodium-silicate-market#:~:text=The%20global%20sodium%20silicate%20market,%25%20from%202023%20to%202030 (accessed on 2 May 2025).

- Potassium Hydroxide Market Analysis, Size, and Forecast (2025–2029). Available online: https://www.technavio.com/report/potassium-hydroxide-market-analysis (accessed on 2 May 2025).

- Potassium Silicate Market Analysis, by Form, by End-Use, and Region, GLOBAL MARKET INSIGHTS (2023–2033). Available online: https://www.factmr.com/report/potassium-silicate-market (accessed on 2 May 2025).

- Alsalman, A.; Assi, L.N.; Kareem, R.S.; Carter, K.; Ziehl, P. Energy and CO2 Emission Assessments of Alkali-Activated Concrete and Ordinary Portland Cement Concrete: A Comparative Analysis of Different Grades of Concrete. Clean. Environ. Syst. 2021, 3, 100047. [Google Scholar] [CrossRef]

- Bouzón, N.; Payá, J.; Borrachero, M.V.; Soriano, L.; Tashima, M.M.; Monzó, J. Refluxed Rice Husk Ash/NaOH Suspension for Preparing Alkali Activated Binders. Mater. Lett. 2014, 115, 72–74. [Google Scholar] [CrossRef]

- Tong, K.T.; Vinai, R.; Soutsos, M.N. Use of Vietnamese rice husk ash for the production of sodium silicate as the activator for alkali-activated binders. J. Clean. Prod. 2018, 201, 272–286. [Google Scholar] [CrossRef]

- Nimwinya, E.; Arjharn, W.; Horpibulsuk, S.; Phoo-Ngernkham, T.; Poowancum, A. A Sustainable Calcined Water Treatment Sludge and Rice Husk Ash Geopolymer. J. Clean. Prod. 2016, 119, 128–134. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterization. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Vinai, R.; Soutsos, M.J.C.; Research, C. Production of sodium silicate powder from waste glass cullet for alkali activation of alternative binders. Cem. Concr. Res. 2019, 116, 45–56. [Google Scholar] [CrossRef]

- Melges, J.L.P.; Monzó, J.; Tashima, M.M.; Moraes, J.C.B.; Borrachero, M.V.; Soriano, L.; Akasaki, J.L.; Payá, J. Increasing the sustainability of alkali-activated binders: The use of sugar cane straw ash (SCSA). Constr. Build. Mater. 2016, 124, 148–154. [Google Scholar] [CrossRef]

- Alonso, M.M.; Gascó, C.; Morales, M.M.; Suárez-Navarro, J.A.; Zamorano, M.; Puertas, F. Olive Biomass Ash as an Alternative Activator in Geopolymer Formation: A Study of Strength, Durability, Radiology and Leaching Behaviour. Cem. Concr. Compos. 2019, 104, 103384. [Google Scholar] [CrossRef]

- De Moraes Pinheiro, S.M.; Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Olive-stone biomass ash (OBA): An alternative alkaline source for the blast furnace slag activation. Constr. Build. Mater. 2018, 178, 327–338. [Google Scholar] [CrossRef]

- Waqas, R.M.; Butt, F.; Zhu, X.; Jiang, T.; Tufail, R.F. A Comprehensive Study on the Factors Affecting the Workability and Mechanical Properties of Ambient Cured Fly Ash and Slag Based Geopolymer Concrete. Appl. Sci. 2021, 11, 8722. [Google Scholar] [CrossRef]

- Hossiney, N.; Sepuri, H.K.; Mohan, M.K.; Arjun, H.R.; Govindaraju, S.; Chyne, J. Alkali-Activated Concrete Paver Blocks Made with Recycled Asphalt Pavement (RAP) Aggregates. Case Stud. Constr. Mater. 2020, 12, e00322. [Google Scholar] [CrossRef]

- Hossiney, N.; Sepuri, H.K.; Mohan, M.K.; Chandra, K.S.; Kumar, S.L.; Thejas, H.K. Geopolymer concrete paving blocks made with Recycled Asphalt Pavement (RAP) aggregates towards sustainable urban mobility development. Cogent Eng. 2020, 7, 1824572. [Google Scholar] [CrossRef]

- Skariah Thomas, B.; Yang, J.; Bahurudeen, A.; Chinnu, S.N.; Abdalla, J.A.; Hawileh, R.A.; Siddika, A.; Hamada, H.M. Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Clean. Mater. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Badkul, A.; Paswan, R.; Singh, S.K.; Tegar, J.P. A comprehensive study on the performance of alkali activated fly ash/GGBFS geopolymer concrete pavement. Road Mater. Pavement Des. 2022, 23, 1815–1835. [Google Scholar]

- Mehta, P.K.; Aitcin, P.C. Microstructural basis of selection of materials and mix proportions for high-strength concrete. Spec. Publ. 1990, 121, 265–286. [Google Scholar]

- Ministry of Road Transport & Highways. Specifications for Road and Bridge Works; Ministry of Road Transport & Highways: New Delhi, India, 2013.

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical Fundamentals of Geopolymers in Sustainable Construction. Mater. Today Sustain. 2024, 82, 100842. [Google Scholar] [CrossRef]

- Eisa, M.S.; Basiouny, M.E.; Fahmy, E.A. Effect of metakaolin-based geopolymer concrete on the length of rigid pavement slabs. Innov. Infrastruct. Solut. 2021, 6, 91. [Google Scholar] [CrossRef]

- Alanazi, H.; Yang, M.; Zhang, D.; Gao, Z. Early strength and durability of metakaolin-based geopolymer concrete. Mag. Concr. Res. 2016, 69, 46–54. [Google Scholar] [CrossRef]

- Rambabu, D.; Sharma, S.K.; Akbar, M.A. Fatigue analysis of ambient-cured geopolymer concrete for high-traffic pavements. Environ. Sci. Pollut. Res. 2024. [Google Scholar] [CrossRef] [PubMed]

- Tahir, M.F.M.; Abdullah, M.M.A.B.; Rahim, S.Z.A.; Mohd Hasan, M.R.; Sandu, A.V.; Vizureanu, P.; Ghazali, C.M.R.; Kadir, A.A. Mechanical and Durability Analysis of Fly Ash Based Geopolymer with Various Compositions for Rigid Pavement Applications. Materials 2022, 15, 3458. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Sharma, S.K.; Akbar, M.A. A Detailed Investigation on Assessing the Introduction of Hybrid Fibres in Geopolymer Composites for Pavement Application. Int. J. Pavement Eng. 2024, 25, 2403681. [Google Scholar] [CrossRef]

- Ravi Kumar, N.S.M.; Venkateswara Rao, S. Experimental studies on pavement quality geopolymer-based concrete (PQGPC) for high-volume roads: A sustainable infrastructure. Int. J. Pavement Eng. 2024, 25, 2337917. [Google Scholar] [CrossRef]

- Marathe, S.; Shetty, T.S.; Mithun, B.; Ranjith, A. Strength and durability studies on air cured alkali activated pavement quality concrete mixes incorporating recycled aggregates. Case Stud. Constr. Mater. 2021, 15, e00732. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- IRC 58: 2002; Guidelines for the Design of Plain Jointed Rigid Pavements for Highways. The Indian Roads Congress: New Delhi, India, 2002.

- IS 456: 2000; Indian Standard Plain and Reinforced Concrete Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- Abbass, M.; Singh, G. Fatigue analysis of rice husk ash and basalt fibre-based sustainable geopolymer concrete in rigid pavements. Mater. Today Proc. 2021, 45, 5014–5022. [Google Scholar] [CrossRef]

- Rambabu, D.; Sharma, S.K.; Akbar, M.A. A review on suitability of using geopolymer concrete for rigid pavement. Innov. Infrastruct. Solut. 2022, 7, 286. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.; Sumajouw, D.; Rangan, B. On the development of fly ash-based geopolymer concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar] [CrossRef] [PubMed]

- Hardjito, D.; Wallah, S.; Sumajouw, D.; Rangan, B. The stress-strain behaviour of fly ash-based geopolymer concrete. Dev. Mech. Struct. Mater. 2004, 35, 831–834. [Google Scholar]

- Guerrieri, M.; Sanjayan, J.G. Behavior of combined fly ash/slag-based geopolymers when exposed to high temperatures. Fire Mater. 2010, 34, 163–175. [Google Scholar] [CrossRef]

- Puertas, F.; Amat, T.; Fernandez-Jimenez, A.; Vazquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- Bondar, D.; Lynsdale, C.J. Engineering Properties of Alkali-Activated Natural Pozzolan Concrete. ACI Mater. J. 2011, 108, 64–72. [Google Scholar] [CrossRef]

- Migunthanna, J.; Rajeev, P.; Sanjayan, J. Waste Clay Brick as a Part Binder for Pavement Grade Geopolymer Concrete. Int. J. Pavement Res. Technol. 2024, 17, 1450–1467. [Google Scholar] [CrossRef]

- Özdal, M.; Karakoç, M.B.; Özcan, A. Investigation of the properties of two different slag-based geopolymer concretes exposed to freeze–thaw cycles. Struct. Concr. 2019, 22, E332–E340. [Google Scholar] [CrossRef]

- Yang, M.; Paudel, S.R.; Gao, Z.J. Snow-proof roadways using steel fiber–reinforced fly ash geopolymer mortar–concrete. J. Mater. Civil. Eng. 2021, 33, 04020444. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, J.; Wang, J.; Wang, C.; Huang, P.; Fang, C. Sulfate resistance of recycled aggregate concrete with GGBS and fly ash–based geopolymer. Materials 2019, 12, 1247. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Xiong, G. Resistance of fiber-reinforced fly ash-steel slag based geopolymer mortar to sulfate attack and drying-wetting cycles. Constr. Build. Mater. 2021, 269, 121326. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. Drying shrinkage of slag blended fly ash geopolymer concrete cured at room temperature. Procedia Eng. 2015, 125, 594–600. [Google Scholar] [CrossRef]

- Asayesh, S.; Shirzadi Javid, A.A.; Ziari, H.; Mehri, B. Evaluating Fresh State, Hardened State, Thermal Expansion and Bond Properties of Geopolymers for the Repairing of Concrete Pavements under Restrained Conditions. Constr. Build. Mater. 2021, 292, 123398. [Google Scholar] [CrossRef]

- Eisa, M.S.; Fahmy, E.A.; Basiouny, M.E. Using metakaolin-based geopolymer concrete in concrete pavement slabs. Innov. Infrastruct. Solut. 2022, 7, 1. [Google Scholar] [CrossRef]

- Upadhyay, H.; Mungule, M.; Iyer, K.K.R. Issues and challenges for development of geopolymer concrete. Mater. Today Proc. 2022, 65, 1567–1574. [Google Scholar] [CrossRef]

- Sindhunata; van Deventer, J.S.J.; Lukey, G.C.; Xu, H. Effect of Curing Temperature and Silicate Concentration on Fly-Ash-Based Geopolymerization. Ind. Eng. Chem. Res. 2006, 45, 3559–3568. [Google Scholar] [CrossRef]

- Danish, A.; Ozbakkaloglu, T.; Ali Mosaberpanah, M.; Salim, M.U.; Bayram, M.; Yeon, J.H.; Jafar, K. Sustainability benefits and commercialization challenges and strategies of geopolymer concrete: A review. J. Build. Eng. 2022, 58, 105005. [Google Scholar] [CrossRef]

- Ajay, A.; Ramaswamy, K.P.; Thomas, A.V. A Critical Review on the Durability of Geopolymer Composites in Acidic Environment. IOP Conf. Ser. Earth Environ. Sci. 2020, 491, 012044. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Hajibabaei, M.; Thives, L.P.; Haritonovs, V.; Buttgereit, A.; Queiroz, C.; Gschösser, F. Environmental potentials of asphalt mixtures fabricated with red mud and fly ash. Road Mater. Pavement Des. 2021, 22, S690–S701. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. A comparative study of the mechanical and life cycle assessment of high content fly ash and recycled aggregate concrete. J. Build. Eng. 2020, 29, 101173. [Google Scholar] [CrossRef]

| SI. No. | Precursors Used | NaOH Molarity | Compressive Strength (MPa) | Split Tensile Strength (MPa) | Reference | |

|---|---|---|---|---|---|---|

| 1 | GGBFS, fly ash | 10, 12, 14 | 2.5 | 35 to 53 | 3.96 to 4.82 | Badkul et al. [108] |

| 2 | Metakaolin | 16 | 2.5 | 32 | 3.80 | Eisa et al. [112] |

| 3 | GGBFS, fly ash | 8 | 1.5 | 50 | 3.65 | Rambabu et al. [114] |

| 4 | Fly ash | 10 | 2 | 47 | - | Tahir et al. [115] |

| 5 | GGBFS, fly ash | 12 | 2 | 48 | - | Singh et al. [116] |

| 6 | GGBFS, fly ash | 14 | 2.5 | 55 | 3.56 | Kumar et al. [117] |

| 7 | GGBFS, fly ash | 12 | 3 | 62 | 4.20 | Marathe et al. [118] |

| SI. No. | Precursors Used | NaOH Molarity | Flexural Strength (MPa) | Reference | |

|---|---|---|---|---|---|

| 1 | GGBS, fly ash | 10, 12, 14 | 2.5 | 5 to 6 | Badkul et al. [108] |

| 2 | Metakaolin | 16 | 2.5 | 8.6 | Eisa et al. [112] |

| 3 | GGBS, fly ash | 8 | 1.5 | 5.6 | Rambabu et al. [114] |

| 4 | GGBS, fly ash | 12 | 2 | 4.5 | Singh et al. [116] |

| 5 | GGBS, fly ash | 14 | 2.5 | 4.7 | Kumar et al. [117] |

| 6 | GGBS, fly ash | 12 | 3 | 5.8 | Marathe et al. [118] |

| 7 | Rice husk ash | 14 | 2 | 5.4 | Abbass et al. [122] |

| SI. No. | Precursors | NaOH Molarity | Binder Content (kg/m3) | Curing Type | Curing Duration | Reference | |

|---|---|---|---|---|---|---|---|

| 1 | Fly ash, GGBFS | 14 | 2.5 | 450 | Ambient | 28 | Kumar et al. [117] |

| 2 | Fly ash, GGBFS | 12 | 1.5 | 400 | Ambient | 28 | Rambabu et al. [114] |

| 3 | Fly ash, GGBFS | 12 | 2.5 | 400 | Ambient | 28 | Badkul et al. [108] |

| 4 | Metakaolin | 16 | 2.5 | 320 | Ambient | 7 | Eisa et al. [112] |

| 5 | Fly ash, GGBFS | 12 | 2.0 | 400 | Ambient | 28 | Singh et al. [116] |

| 6 | Fly ash, GGBFS | 12 | 2.5 | 440 | Ambient | 28 | Marathe et al. [118] |

| 7 | Fly ash | 10 | 2.0 | 400 | Ambient | 28 | Tahir et al. [115] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chelluri, S.; Hossiney, N.; Chandra, S.; Bekoe, P.; Tia, M. A Review of the Performance Properties of Geopolymer Pavement-Quality Concrete. Constr. Mater. 2025, 5, 49. https://doi.org/10.3390/constrmater5030049

Chelluri S, Hossiney N, Chandra S, Bekoe P, Tia M. A Review of the Performance Properties of Geopolymer Pavement-Quality Concrete. Construction Materials. 2025; 5(3):49. https://doi.org/10.3390/constrmater5030049

Chicago/Turabian StyleChelluri, Saikrishna, Nabil Hossiney, Sarath Chandra, Patrick Bekoe, and Mang Tia. 2025. "A Review of the Performance Properties of Geopolymer Pavement-Quality Concrete" Construction Materials 5, no. 3: 49. https://doi.org/10.3390/constrmater5030049

APA StyleChelluri, S., Hossiney, N., Chandra, S., Bekoe, P., & Tia, M. (2025). A Review of the Performance Properties of Geopolymer Pavement-Quality Concrete. Construction Materials, 5(3), 49. https://doi.org/10.3390/constrmater5030049