Investigation into the Properties of Alkali-Activated Fiber-Reinforced Slabs, Produced with Marginal By-Products and Recycled Plastic Aggregates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

2.2.1. Production of Mortars

2.2.2. Production of Slabs

3. Results

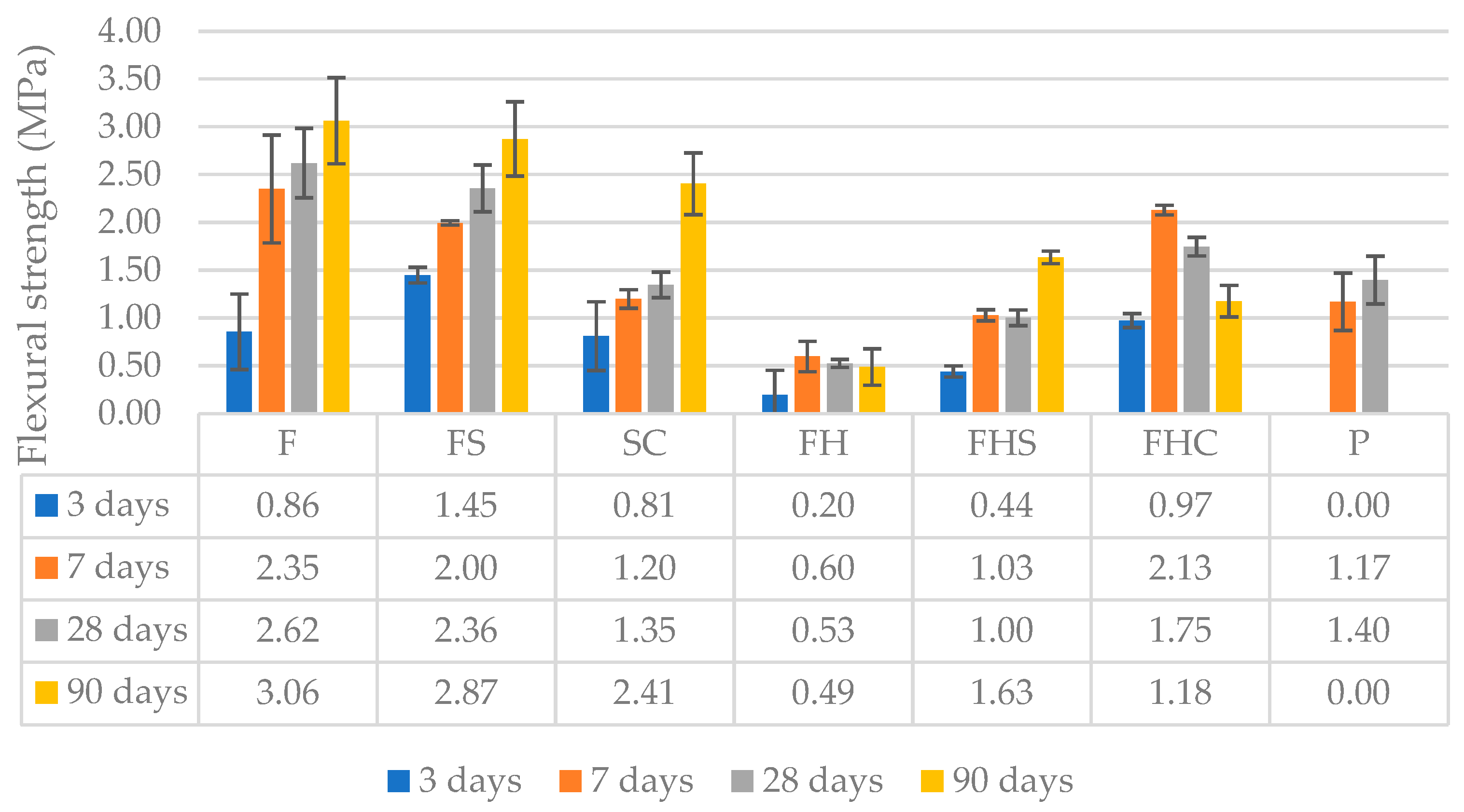

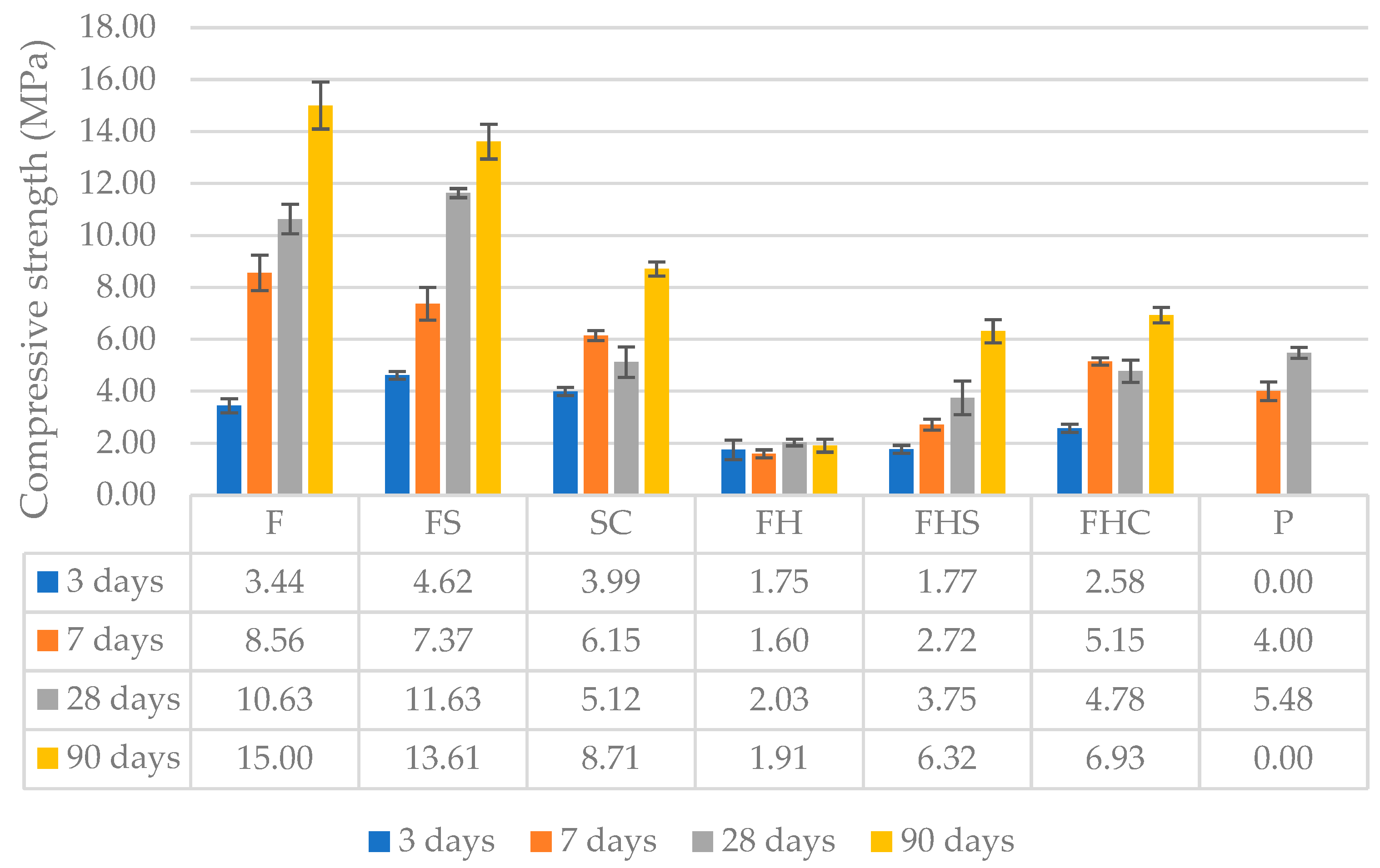

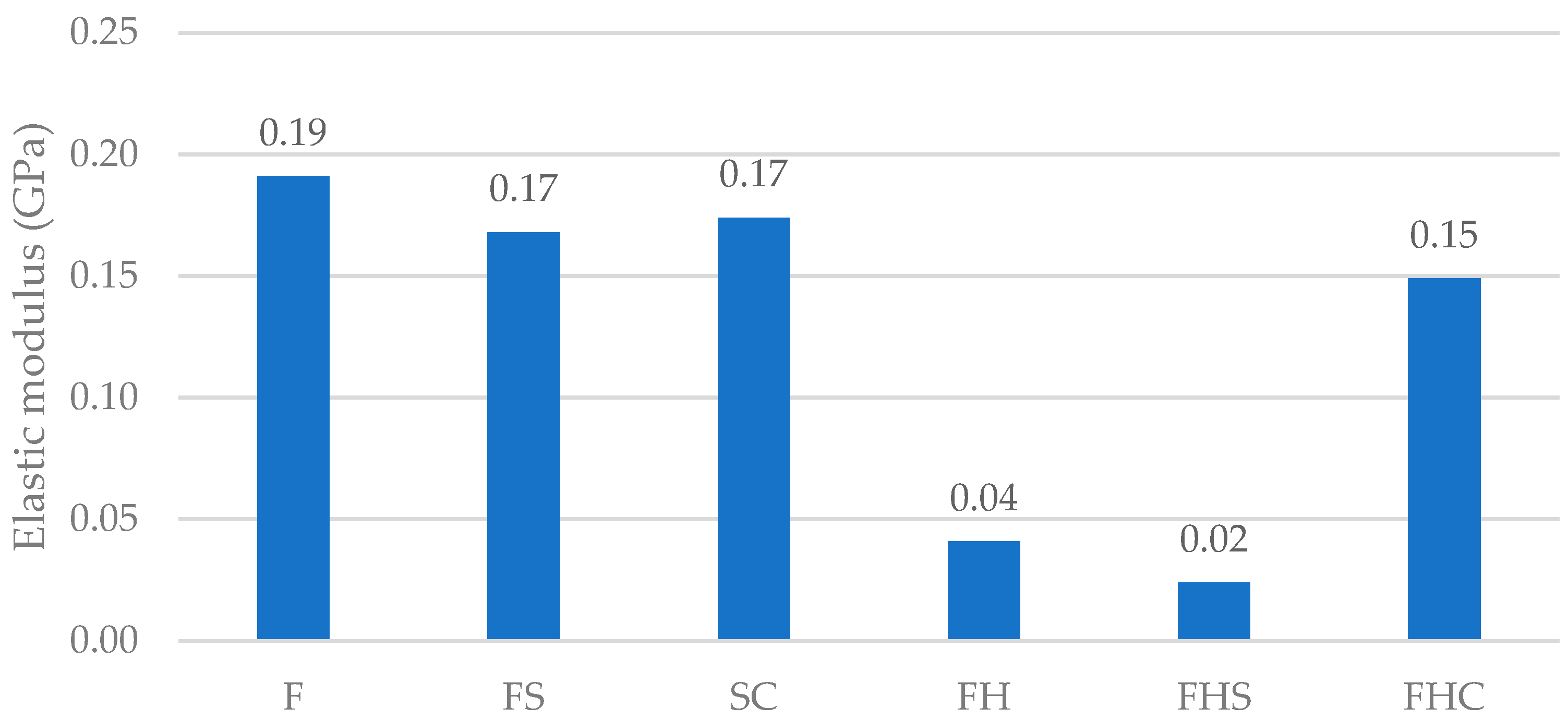

3.1. Testing of Mortars

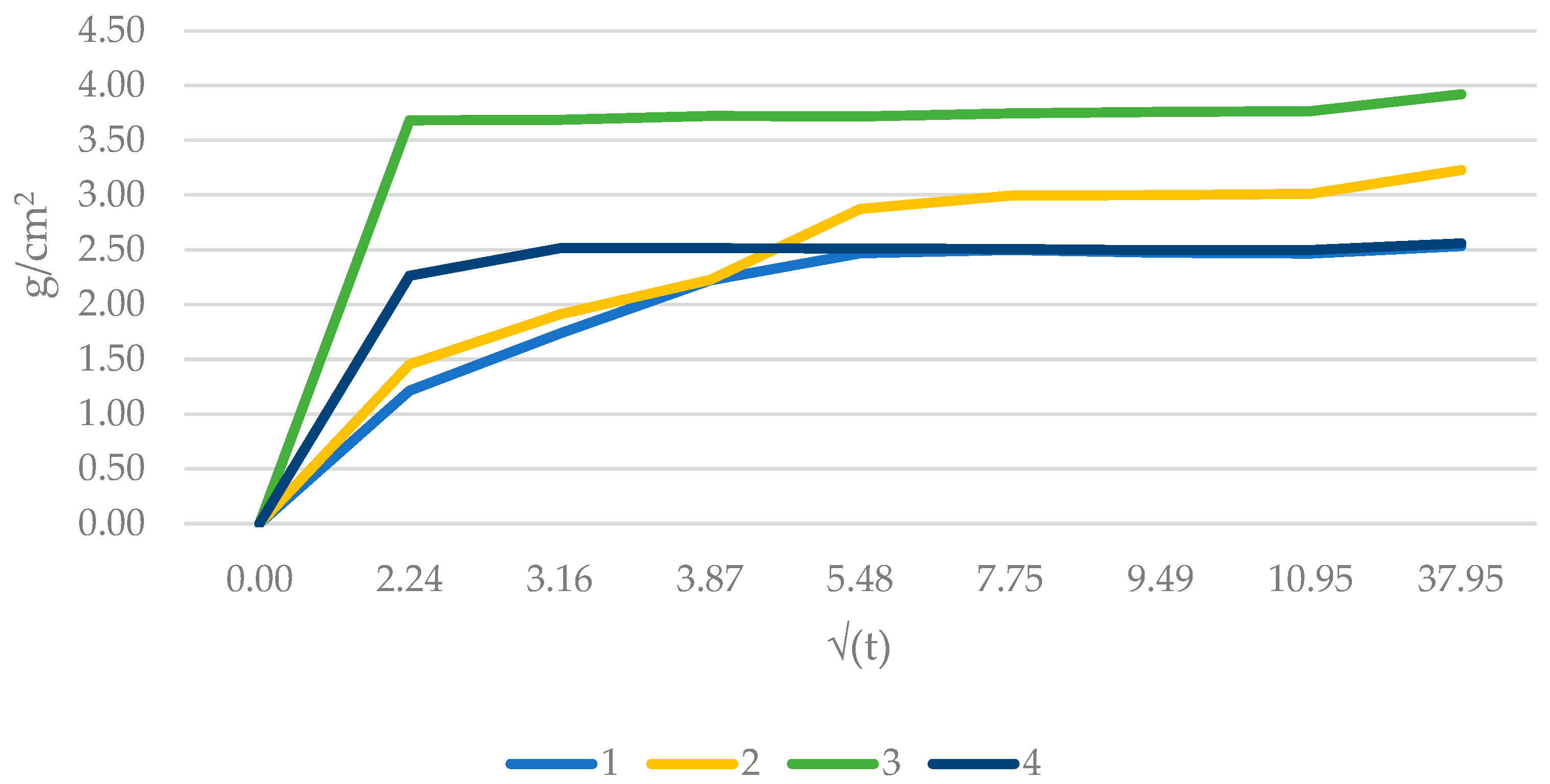

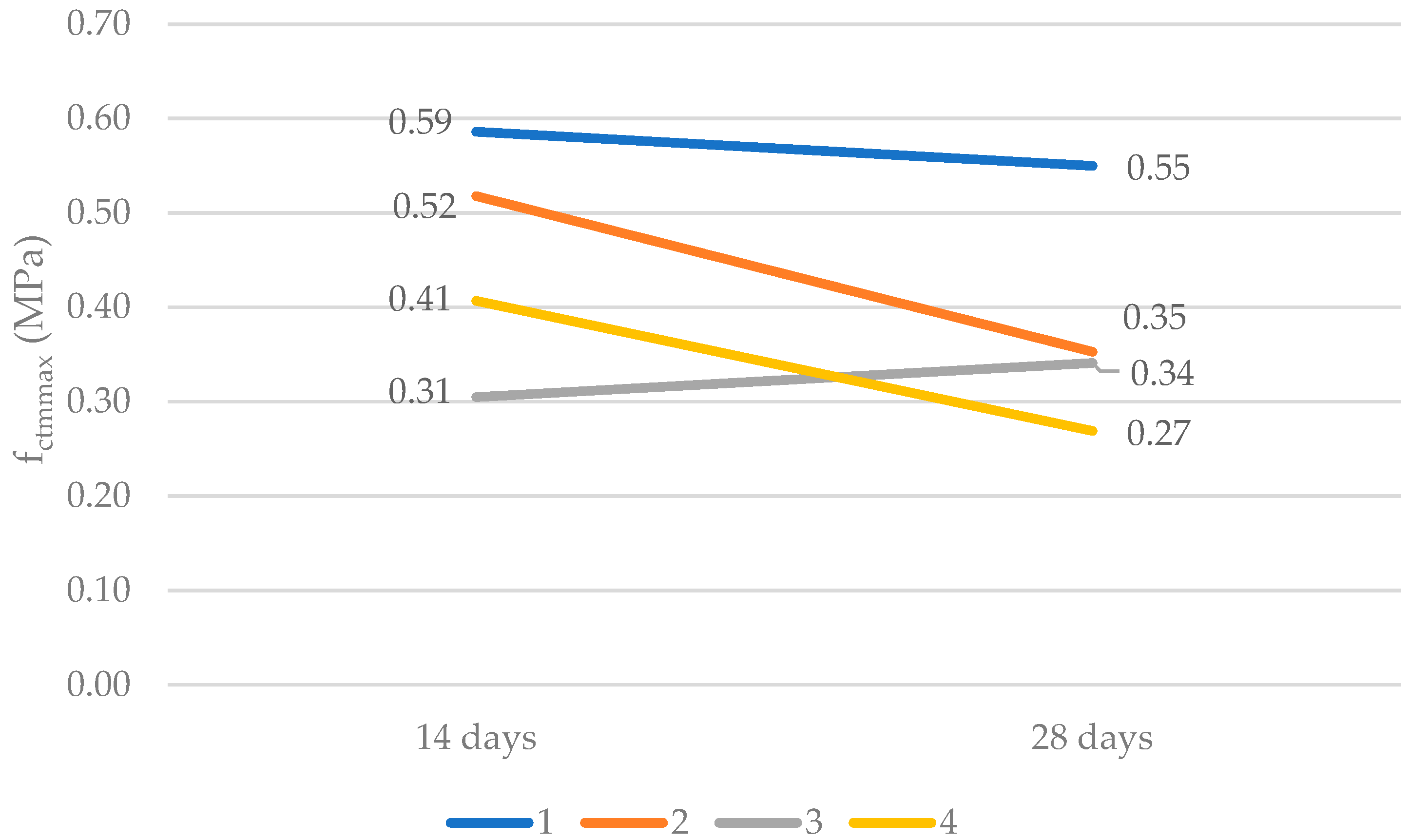

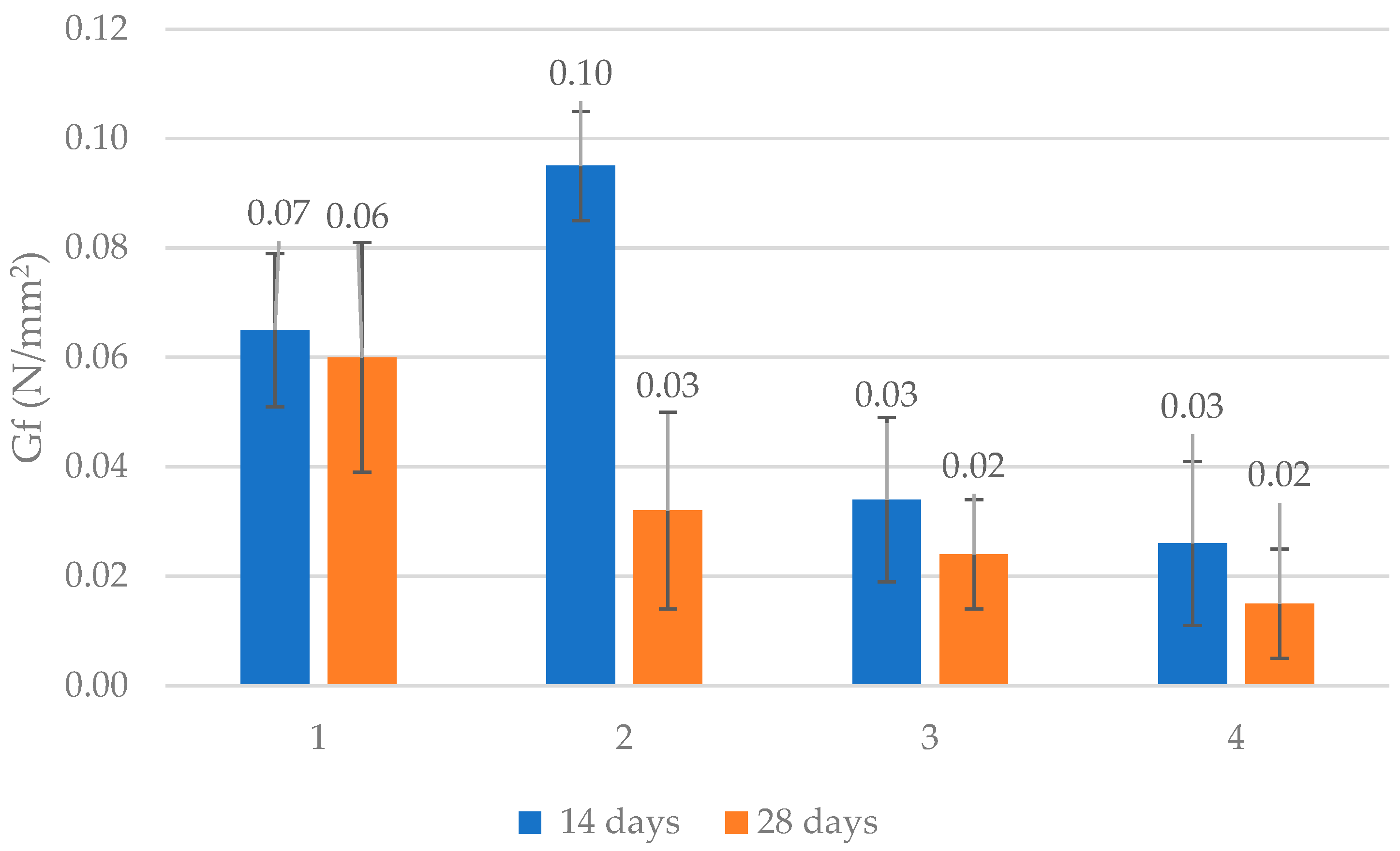

3.2. Testing of Slabs

4. Discussion

4.1. Testing of Mortars

4.2. Testing of Slabs

5. Conclusions

- Alkali-activation of mortars containing Greek by-products such as fly ash and ladle furnace slag can result in mortars with a compressive strength of around 10 MPa at 28 days.

- Hydrated fly ash mortars and ladle furnace slag mortars did not produce the same strength results; however, the addition of 10% of cement could enhance their mechanical properties.

- Alkali-activated mortars have brittle behavior (low static modulus of elasticity). However, the addition of cement, even in low amounts (10%), can improve the results.

- pH values are extremely high in all cases. Although high pH is needed to start the reaction process, it does not guarantee high-level strengths. Moreover, high pH seems to hinder the role of admixtures in the mixtures, decrease the setting time, and increase the viscosity of the mortars.

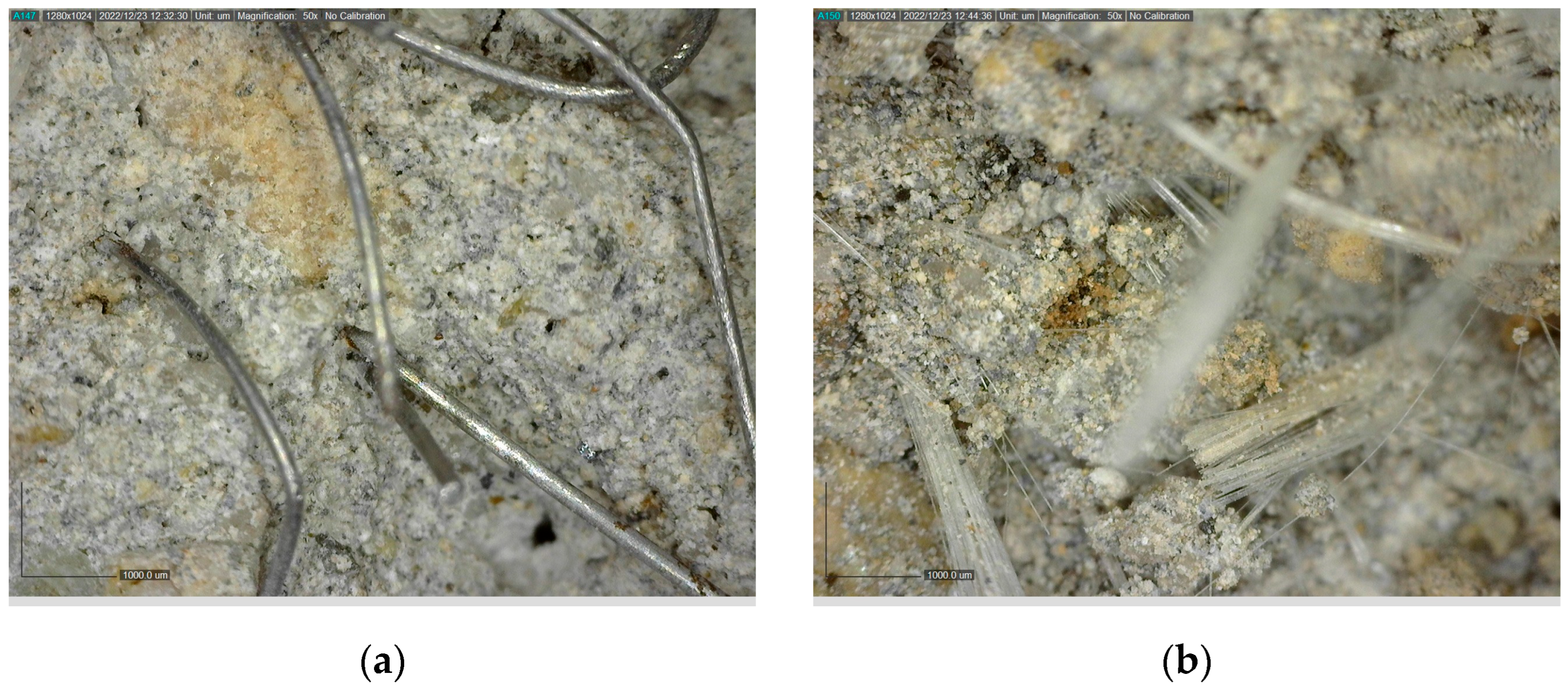

- The incorporation of steel and glass fibers seemed to decrease the flexural strength and first crack fracture energy of the produced slabs. This could be attributed to the poor interface between the fibers and the mixture, possibly due to the low workability and flash setting of the material.

- The addition of PET aggregates at 60% of the sand aggregates resulted in lightweight slabs (1320 kg/m3) with good physical properties (porosity and capillary) in relation to the reference mixture. Mechanical properties were reduced but at expected levels and presented comparable or even better behavior to the reinforced mixtures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The role of inorganic polymer technology in the development of “green concrete”. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Puertas, F.; González-Fonteboa, B.; González-Taboada, I.; Alonso, M.M.; Torres-Carrasco, M.; Rojo, G.; Martínez-Abella, F. Alkali-activated slag concrete: Fresh and hardened behaviour. Cem. Concr. Compos. 2018, 85, 22–31. [Google Scholar] [CrossRef]

- Thwe, K.S.; Ayawanna, J.; Mase, L.Z.; Chaiyaput, S. Utilization of ladle furnace slag and fly ash as partially replacement of cement. Clean. Eng. Technol. 2025, 25, 100910. [Google Scholar] [CrossRef]

- Criado, M.; Fernández-Jiménez, A.; Palomo, A.; Sobrados, I.; Sanz, J. Effect of the SiO2/Na2O ratio on the alkali activation of fly ash. Part II:29Si MAS-NMR Survey. Microporous Mesoporous Mater. 2008, 109, 525–534. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Komnitsas, K.; Soultana, A.; Bartzas, G. Marble waste valorization through alkali activation. Minerals 2021, 11, 46. [Google Scholar] [CrossRef]

- Kesikidou, F.; Konopisi, S.; Anastasiou, E.K. Influence of Concrete Sludge Addition in the Properties of Alkali-Activated and Non-Alkali-Activated Fly Ash-Based Mortars. Adv. Civ. Eng. 2021, 2021, 5534002. [Google Scholar] [CrossRef]

- Ke, X.; Bernal, S.A.; Ye, N.; Provis, J.L.; Yang, J. One-Part Geopolymers Based on Thermally Treated Red Mud/NaOH Blends. J. Am. Ceram. Soc. 2015, 98, 5–11. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Alkaline activation of different aluminosilicates as an alternative to Portland cement: Alkali activated cements or geopolymers La activación alcalina de diferentes aluminosilicatos como una alternativa al Cemento Portland: Cementos activados alcalinamente o geopolímeros. Rev. Ing. Constr. 2017, 32, 5–12. [Google Scholar] [CrossRef]

- Tsimas, S.; Moutsatsou-Tsima, A. High-calcium fly ash as the fourth constituent in concrete: Problems, solutions and perspectives. Cem. Concr. Compos. 2005, 27, 231–237. [Google Scholar] [CrossRef]

- Papayianni, I.; Anastasiou, E.; Papachristoforou, M.; Caplanidis, C.; Bairaklili, P. Performance of dry and moist calcareous fly ash in soil stabilization. In Proceedings of the EuroCoalAsh 2019 Conference, Dundee, UK, 10–12 June 2019. [Google Scholar]

- Gismera, S.; Alonso, M.D.M.; Palacios, M.; Puertas, F. Rheology of alkali-activated mortars: Influence of particle size and nature of aggregates. Minerals 2020, 10, 726. [Google Scholar] [CrossRef]

- Papayianni, I.; Konopisi, S.; Datsiou, K.; Kesikidou, F. Products of Alkali-Activated Calcareous Fly Ash and Glass Cullet. Int. J. Res. Eng. Technol. 2014, 3, 43–51. [Google Scholar] [CrossRef]

- Almohana, A.I.; Abdulwahid, M.Y.; Galobardes, I.; Mushtaq, J.; Almojil, S.F. Producing sustainable concrete with plastic waste: A review. Environ. Chall. 2022, 9, 100626. [Google Scholar] [CrossRef]

- Dawood, A.O.; AL-Khazraji, H.; Falih, R.S. Physical and mechanical properties of concrete containing PET wastes as a partial replacement for fine aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Kesikidou, F.; Georgilas, A.; Tsiakaloglou, G.; Anastasiou, E.K. Investigation on the use of PET and XLPE plastic wastes as aggregates in cement-based mortars. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: London, UK, 2023. [Google Scholar] [CrossRef]

- Almeida, F.; Cunha, V.M.C.F.; Miranda, T.; Cristelo, N. Indirect tensile behaviour of fibre reinforced alkali-activated composites. Fibers 2018, 6, 30. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Abdelgader, H.S.; Murali, G.; Ozbakkaloglu, T.; Lee, Y.H.; Lee, Y.Y. Fiber-reinforced alkali-activated concrete: A review. J. Build. Eng. 2022, 45, 103638. [Google Scholar] [CrossRef]

- Rashad, A.M. Effect of steel fibers on geopolymer properties—The best synopsis for civil engineer. Constr. Build. Mater. 2020, 246, 118534. [Google Scholar] [CrossRef]

- He, J.; Bi, Y.; Zhang, Y.; Lu, H.; Fan, L.; Zhao, K.; Wu, W. Analysis of Factors Influencing the Performance of Fiber Reinforced Concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2021. [Google Scholar] [CrossRef]

- Behbahani, H.P.; Nematollahi, B.; Farasatpour, M. Steel Fiber Reinforced Concrete: A Review. In Proceedings of the International Conference on Structural Engineering Construction and Management (ICSECM2011), Kandy, Sri Lanka, 16–18 December 2011. [Google Scholar]

- Ahmad, J.; González-Lezcano, R.A.; Majdi, A.; Ben Kahla, N.; Deifalla, A.F.; El-Shorbagy, M.A. Glass Fibers Reinforced Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Materials 2022, 15, 5111. [Google Scholar] [CrossRef]

- Koktsidis, K. Experimental Investigation of Mortars Produced by the Process of Alkaline Activation for the Production of Precast Boards. Diploma Thesis, Aristotle University of Thessaloniki, Thessaloniki, Greece, 2022. (In Greek). Available online: https://ikee.lib.auth.gr/record/345001/files/Koktsidis.pdf (accessed on 2 February 2025).

- ASTM C 593-19; Standard Specification for Fly Ash and Other Pozzolans for Use with Lime for Soil Stabilization. ASTM International: West Conshohocken, PA, USA, 2019.

- Kesikidou, F.; Konopisi, S.; Papayianni, I. Alkali-activated concrete products based on industrial by-products. In Proceedings of the EUROCOALASH 2021 Conference, Thessaloniki, Greece, 2–4 November 2021. [Google Scholar]

- ASTM C33; Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2011.

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- EN 1015-3:2003; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee: Brussels, Belgium, 2003.

- EN 1015-11:2006; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee: Brussels, Belgium, 2006.

- British Standard BS 1881-203:1986; Testing Concrete: Recommendations for Measurement of Velocity of Ultrasonic Pulses in Concrete. British Standards Institution: London, UK, 1986.

- British Standard BS 1881-121; Testing Concrete—Part 121: Method for Determination of Static Modulus of Elasticity in Compression. British Standards Institution: London, UK, 1983.

- RILEM TC: CPC 11.3; Absorption of Water by Concrete by Immersion Under Vacuum. RILEM Recommendations for the Testing and Use of Constructions Materials. E & FN SPON: London, UK, 1984; pp. 36–37. [CrossRef]

- EN 1015-10:1999; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 1999.

- EN 1015-18:2002; Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient due to Capillary Action of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 2002.

- EN 1339:2003; Concrete Paving Flags—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2003.

- JCI-S-002-2003; Method of Test for Chloride Ion Content in Hardened Concrete. Japan Concrete Institute: Tokyo, Japan, 2003.

- Kashani, A.; Provis, J.L.; Qiao, G.G.; Van Deventer, J.S.J. The interrelationship between surface chemistry and rheology in alkali activated slag paste. Constr. Build. Mater. 2014, 65, 583–591. [Google Scholar] [CrossRef]

- Shi, D.; Ye, J.; Zhang, W. Effects of activator content on properties, mineralogy, hydration and microstructure of alkali-activated materials synthesized from calcium silicate slag and ground granulated blast furnace slag. J. Build. Eng. 2020, 32, 101791. [Google Scholar] [CrossRef]

- Bencardino, F.; Rizzuti, L.; Spadea, G.; Swamy, R.N. Experimental evaluation of fiber reinforced concrete fracture properties. Compos. B Eng. 2010, 41, 17–24. [Google Scholar] [CrossRef]

- Roussel, N. Understanding the Rheology of Concrete; Woodhead Publishing: Cambridge, UK, 2012; ISBN 9780857095282. [Google Scholar]

- Chindaprasirt, P.; Phoo-ngernkham, T.; Hanjitsuwan, S.; Horpibulsuk, S.; Poowancum, A.; Injorhor, B. Effect of calcium-rich compounds on setting time and strength development of alkali-activated fly ash cured at ambient temperature. Case Stud. Constr. Mater. 2018, 9, e00198. [Google Scholar] [CrossRef]

- Oderji, S.Y.; Chen, B.; Shakya, C.; Ahmad, M.R.; Shah, S.F.A. Influence of superplasticizers and retarders on the workability and strength of one-part alkali-activated fly ash/slag binders cured at room temperature. Constr. Build. Mater. 2019, 229, 116891. [Google Scholar] [CrossRef]

- Enders, M. The CaO distribution to mineral phases in a high calcium fly ash from Eastern Germany. Cem. Concr. Res. 1996, 26, 243–251. [Google Scholar] [CrossRef]

- Risdanareni, P.; Puspitasari, P.; Januarti Jaya, E.J. Chemical and Physical Characterization of Fly Ash as Geopolymer Material. In Proceedings of the MATEC Web of Conferences ETIC, Ho Chi Minh City, Vietnam, 5–6 August 2016; Volume 97. [Google Scholar] [CrossRef]

- Yusslee, E.; Beskhyroun, S. Performance Evaluation of Hybrid One-Part Alkali Activated Materials (AAMs) for Concrete Structural Repair. Buildings 2022, 12, 2025. [Google Scholar] [CrossRef]

- Abubakar, L.; Yeasmin, N.; Bhattacharjee, A. Waste Polyethylene Terephthalate (PET) as a Partial Replacement of Aggregates in Sustainable Concrete. Constr. Mater. 2024, 4, 738–747. [Google Scholar] [CrossRef]

- Yadav, D.; Prashanth, M.H.; Kumar, N. Numerical study on the effect of steel fibers on fracture and size effect in concrete beams. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Praneedpolkrang, P.; Dokduea, W.; Mangkhang, K.; Jaturapitakkul, C.; Tangchirapat, W. Mechanical and compatibility properties of alkali-activated repair mortar reinforced with microfibers. Case Stud. Constr. Mater. 2025, 22, e04717. [Google Scholar] [CrossRef]

- Bhutta, A.; Farooq, M.; Zanotti, C.; Banthia, N. Pull-out behavior of different fibers in geopolymer mortars: Effects of alkaline solution concentration and curing. Mater. Struct./Mater. Constr. 2017, 50, 80. [Google Scholar] [CrossRef]

| Raw Material | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | SO3 | Na2O | K2O | L.o.I | CaOf |

|---|---|---|---|---|---|---|---|---|---|---|

| Fly ash | 35.70 | 11.08 | 36.78 | 5.07 | 3.21 | 5.08 | 0.44 | 0.91 | 0.59 | 9.41 |

| Hydrated fly ash | 45.88 | 11.56 | 24.49 | 5.46 | 1.79 | 2.40 | 0.54 | 1.16 | 1.01 | 4.50 |

| Ladle furnace slag | 38.78 | 1.74 | 39.18 | 2.19 | 3.33 | 0.12 | 0.63 | 0.04 | 11.4 | 1.59 |

| CEM I42.5 | 25.84 | 5.67 | 59.19 | 3.23 | 1.53 | 1.24 | 0.84 | 0.89 | 2.81 | 2.52 |

| Type of Binder | Compressive Strength (MPa) | |

|---|---|---|

| 7 Days | 28 Days | |

| Fly ash | 6.83 | 7.66 |

| Hydrated fly ash | 3.88 | 4.70 |

| Ladle furnace slag | 1.03 | 1.49 |

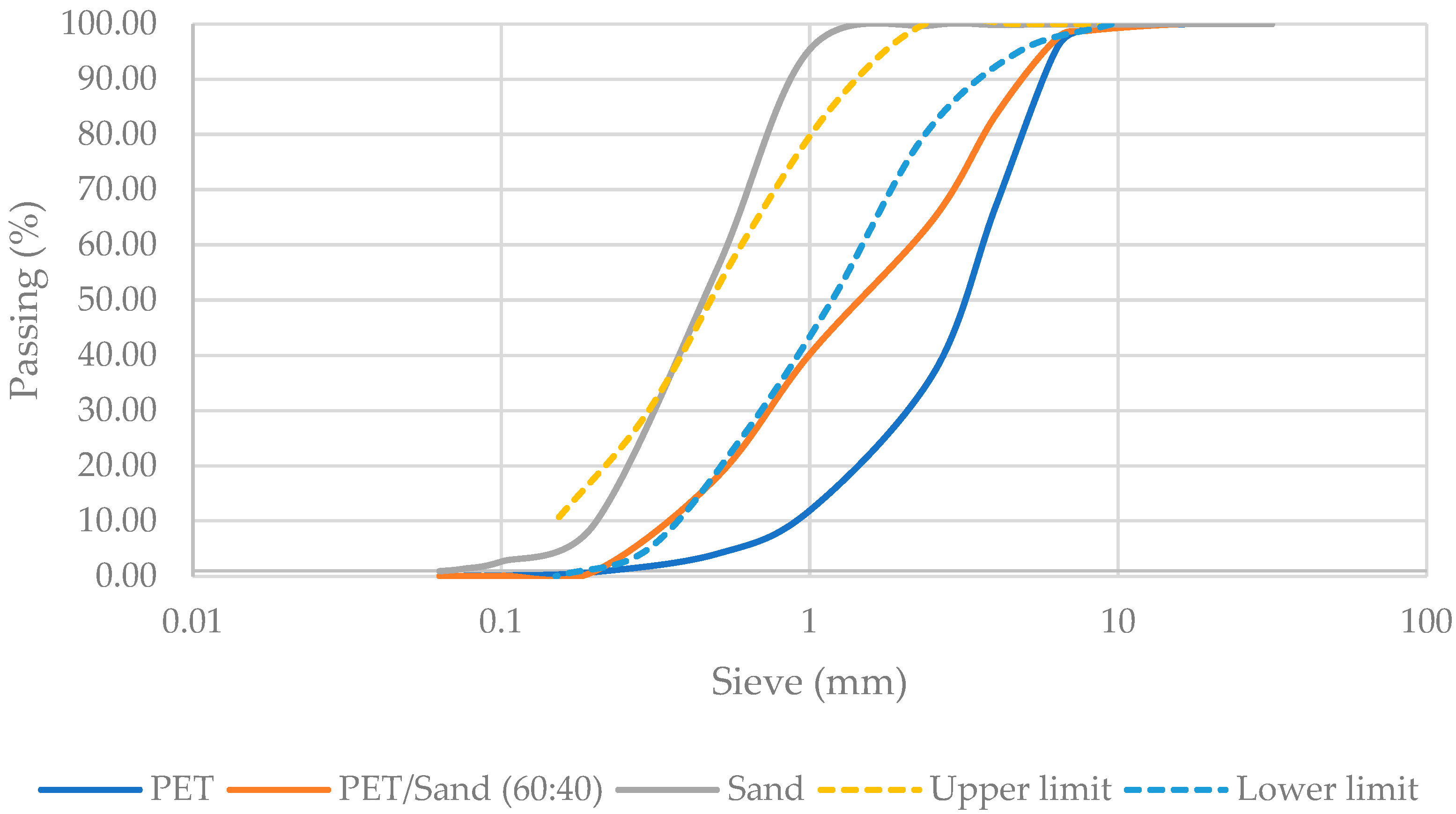

| Type of Aggregates | Specific Gravity (kg/m3) | Size (mm) |

|---|---|---|

| Siliceous sand | 2670 | 0–2 |

| Recycled plastic aggregates (PET) | 920–950 | 0–4 |

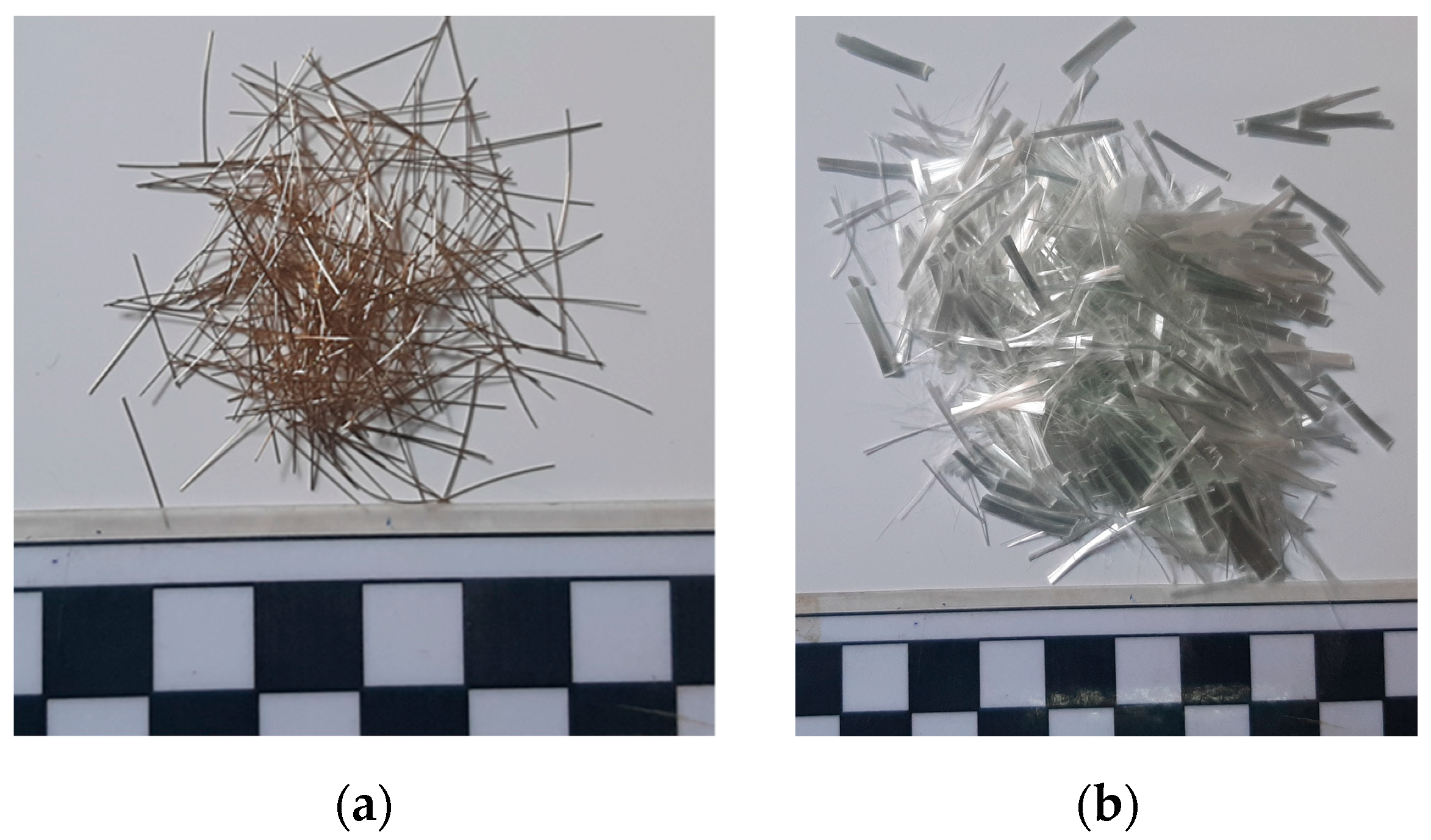

| Steel fibers | 7850 | 13 |

| Glass fibers | 2850 | 13 |

| No | Mixture | Fly Ash | Hydrated Fly Ash | LFS | Cement | River Sand (0–2) mm | PET Aggregates (0–4) mm | L/B | Average Workability (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | F | 1 | - | - | - | 2 | - | 0.80 | 115 |

| 2 | FS | 0.5 | - | 0.5 | - | 2 | - | 0.80 | 125 |

| 3 | SC | - | - | 0.9 | 0.1 | 2 | - | 0.80 | 135 |

| 4 | FH | - | 1 | - | - | 2 | - | 0.80 | 135 |

| 5 | FHS | - | 0.5 | 0.5 | - | 2 | - | 0.80 | 110 |

| 6 | FHC | - | 0.9 | - | 0.1 | 2 | - | 0.80 | 120 |

| 7 | P | 1 | - | - | - | 0.85 | 0.65 | 0.80 | 155 |

| Mixture | Fly Ash | Sand (0–2) mm | PET (0–4) mm | Liquid/ Binder | Steel Fibers | Glass Fibers |

|---|---|---|---|---|---|---|

| 1 | 1 | 2 | - | 0.5 | - | - |

| 2 | 1 | 2 | - | 0.5 | 1% | - |

| 3 | 1 | 2 | - | 0.5 | - | 1% |

| 4 | 1 | 0.8 | 1.2 | 0.5 | - | - |

| Mixture | F | FS | SC | FH | FHS | FHC | P |

|---|---|---|---|---|---|---|---|

| Porosity (%) | 13.31 | 15.06 | 19.85 | 24.37 | 22.40 | 16.66 | 21.22 |

| Mixture | pH | ||

|---|---|---|---|

| 3 Days | 7 Days | 60 Days | |

| F | 14.3 | 14.4 | 13.8 |

| FS | 14.4 | 14.5 | 13.6 |

| SC | 14.6 | 14.7 | 13.9 |

| FH | 14.5 | 14.5 | 13.6 |

| FHS | 14.6 | 14.7 | 13.9 |

| FHC | 14.7 | 14.8 | 13.9 |

| Mixture | Age (days) | Average UPV (km/s) | Standard Deviation (km/s) | Porosity (%) | Density (kg/m3) |

|---|---|---|---|---|---|

| 1 | 14 | 1.694 | 0.083 | 19.9 | 1520 |

| 1 | 28 | 1.706 | 0.059 | 21.7 | 1460 |

| 2 | 14 | 1.694 | 0.083 | 21.9 | 1590 |

| 2 | 28 | 1.706 | 0.059 | 23.4 | 1490 |

| 3 | 14 | 1.694 | 0.083 | 28.4 | 1520 |

| 3 | 28 | 1.706 | 0.059 | 29.2 | 1470 |

| 4 | 14 | 1.694 | 0.083 | 20.6 | 1400 |

| 4 | 28 | 1.706 | 0.059 | 21.9 | 1320 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kesikidou, F.; Koktsidis, K.; Anastasiou, E.K. Investigation into the Properties of Alkali-Activated Fiber-Reinforced Slabs, Produced with Marginal By-Products and Recycled Plastic Aggregates. Constr. Mater. 2025, 5, 48. https://doi.org/10.3390/constrmater5030048

Kesikidou F, Koktsidis K, Anastasiou EK. Investigation into the Properties of Alkali-Activated Fiber-Reinforced Slabs, Produced with Marginal By-Products and Recycled Plastic Aggregates. Construction Materials. 2025; 5(3):48. https://doi.org/10.3390/constrmater5030048

Chicago/Turabian StyleKesikidou, Fotini, Kyriakos Koktsidis, and Eleftherios K. Anastasiou. 2025. "Investigation into the Properties of Alkali-Activated Fiber-Reinforced Slabs, Produced with Marginal By-Products and Recycled Plastic Aggregates" Construction Materials 5, no. 3: 48. https://doi.org/10.3390/constrmater5030048

APA StyleKesikidou, F., Koktsidis, K., & Anastasiou, E. K. (2025). Investigation into the Properties of Alkali-Activated Fiber-Reinforced Slabs, Produced with Marginal By-Products and Recycled Plastic Aggregates. Construction Materials, 5(3), 48. https://doi.org/10.3390/constrmater5030048